Method for separating and extracting peroxidase in sweet potato peels

A technology of peroxidase and sweet potato peel, applied in biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of increased cost investment and restriction of raw material sources, and achieves reduction of activity decline, cheap raw material sources, and easy industrial scale-up. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

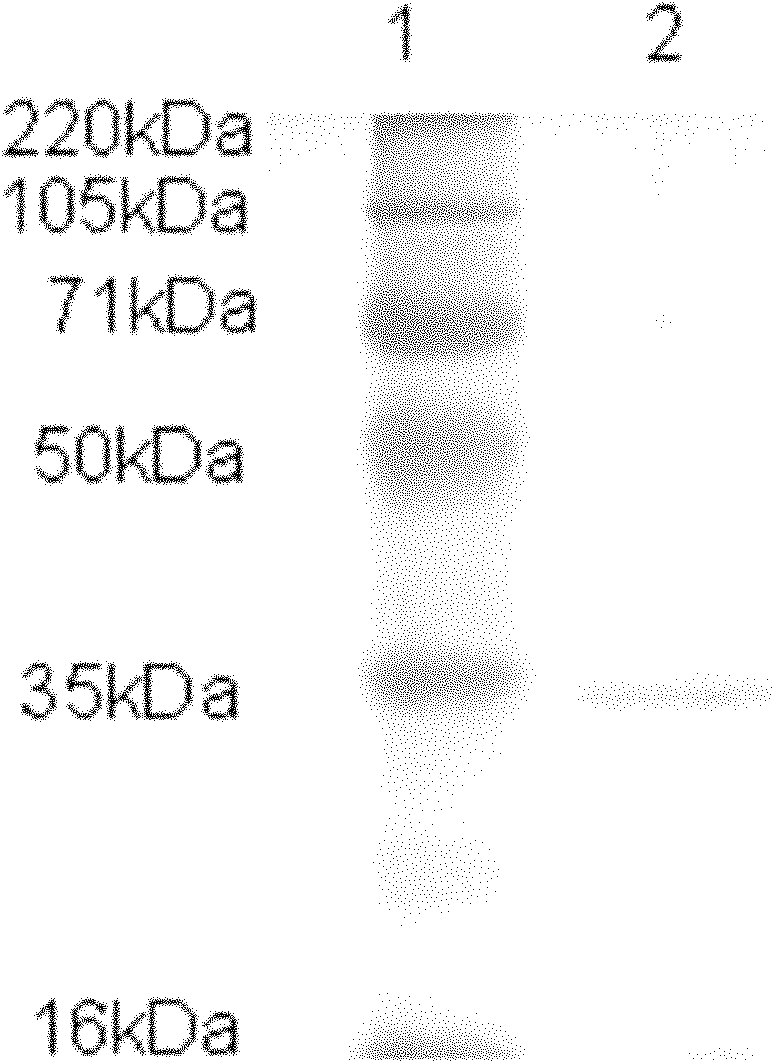

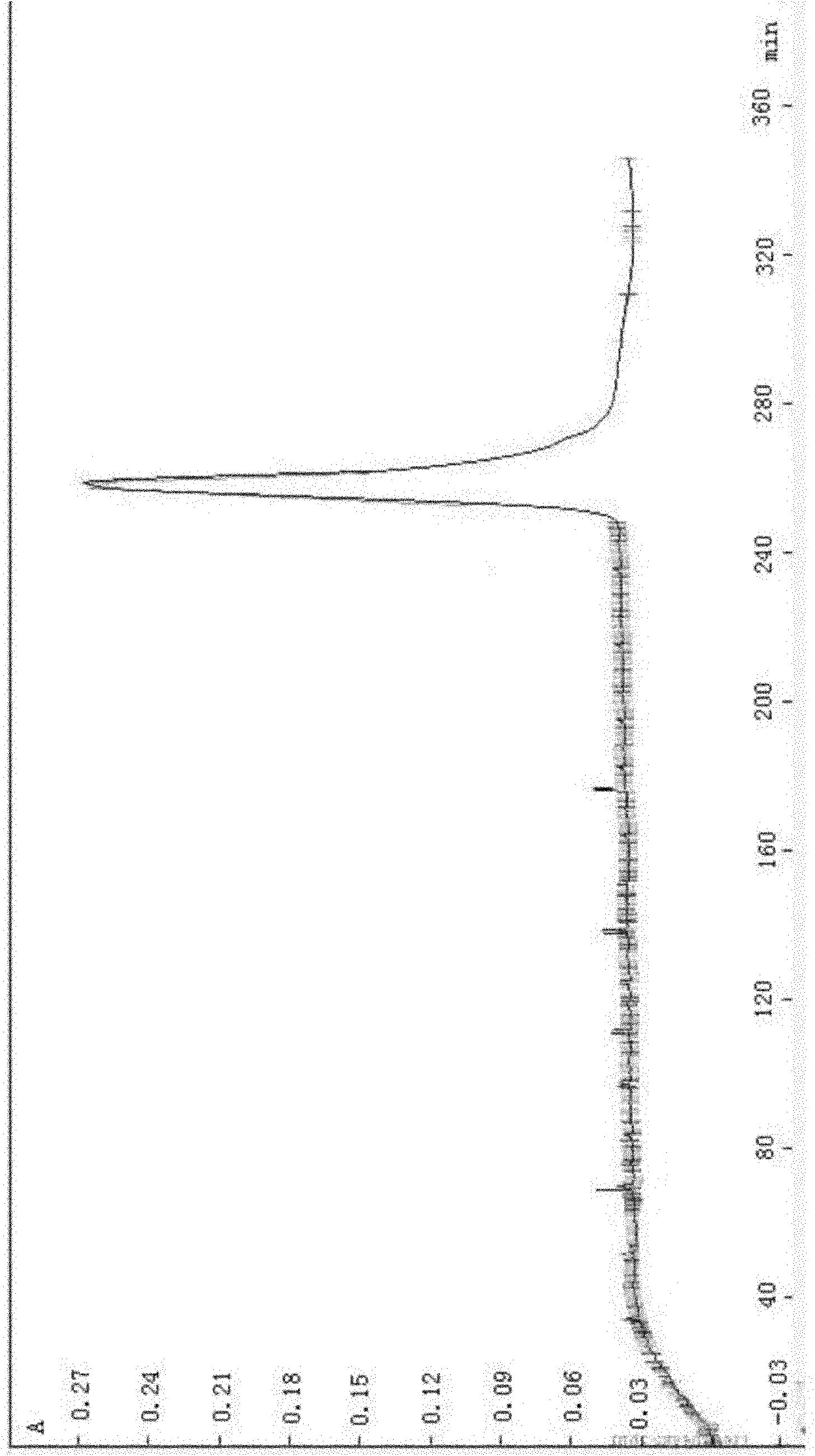

[0034] (1) Preparation and purification of sweet potato peroxidase

[0035] Take sweet potatoes, wash them, collect 500g of sweet potato skins, first add 0.5L of 10mM pH 8.0 phosphate buffer solution and mince, keep the temperature at 4°C during the mincer process, then add 2L of 10mM pH 8.0 phosphate buffer solution, stir well Then, put it in a refrigerator at 4°C and extract overnight. The filtrate was collected by filtration, the residue was extracted once more, and the filtrates were combined. Centrifuge the filtrate at 4°C and 5000rpm for 30min to remove starch and small tissue particles, collect the supernatant, add solid ammonium sulfate and PEG6000 while stirring, so that the mass percentage concentration of ammonium sulfate is 30%, and the mass percentage concentration of PEG6000 is 8%. , the addition was completed within about 1 hour, and transferred to a separatory funnel to stand still, keeping the temperature at 4°C. After standing and stratifying, the upper phas...

Embodiment 2

[0045] (1) Preparation and purification of sweet potato peroxidase

[0046] Take sweet potatoes, wash them, collect 500g of sweet potato skins, first add 0.5L of 10mM pH 8.0 phosphate buffer saline to grind, keep the temperature at 4°C during the grinding process, then add 2L of 10mM pH 8.0 phosphate buffer, stir well , placed in a refrigerator at 4°C, and leached overnight. The filtrate was collected by filtration, the residue was extracted twice, and the filtrate was combined. Centrifuge the filtrate at 4°C and 5000rpm for 30min to remove starch and small tissue particles, collect the supernatant, add solid ammonium sulfate and PEG6000 while stirring, so that the mass percentage concentration of ammonium sulfate is 30%, and the mass percentage concentration of PEG6000 is 8%. , the addition was completed within about 1 hour, and transferred to a separatory funnel to stand still, keeping the temperature at 4°C. After standing and stratifying, the upper phase solution was main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com