Preparation method of carbon-silicon composite adsorbent

A composite adsorption and mixture technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve problems that have not yet been seen, and achieve the effects of reducing time consumption, cheap sources, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

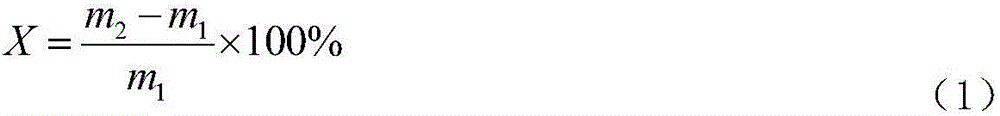

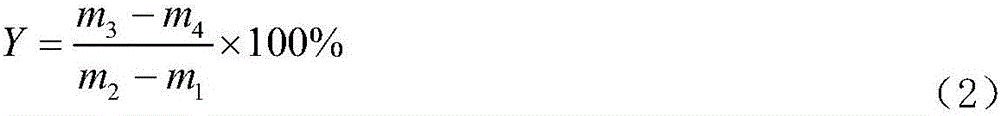

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of the gel mixture: First add deionized water to 10mL of water glass to dilute, the volume ratio of water glass to deionized water is 1:4, then add the ion exchange resin AmberliteIR120H + And stir until the solution pH=2, continue to stir for 10h, filter to obtain the filtrate, then add an appropriate amount of 200 mesh powdered activated carbon, so that the mass percentage of activated carbon in the solution is 0.5wt%, stir for 1min and ultrasonically oscillate for 3min, then add ammonia water dropwise The solution was allowed to stand for 12 h until the pH of the solution was 7 to obtain a gel mixture.

[0022] (2) Solvent replacement and hydrophobic modification: the obtained gel mixture was aged in isopropanol / n-hexane solution with a volume ratio of 1:1 at 60°C for 10 h, and then immersed in a volume ratio of 1:4: 5 in TMCS / isopropanol / n-hexane solution at 60°C for 24 hours to obtain a hydrophobic gel mixture.

[0023] (3) Drying treatment: the ob...

Embodiment 2

[0025] (1) Preparation of the gel mixture: First add deionized water to 10mL of water glass to dilute, the volume ratio of water glass to deionized water is 1:4, then add the ion exchange resin AmberliteIR120H + And stir until the solution pH=2, continue to stir for 10h, filter to obtain the filtrate, then add an appropriate amount of 200 mesh powdered activated carbon, so that the mass percentage of activated carbon in the solution is 2wt%, stir for 1min and ultrasonically oscillate for 3min, then add ammonia water dropwise until The pH of the solution was 7, and it was allowed to stand for 12 hours to obtain a gel mixture.

[0026] (2) Solvent replacement and hydrophobic modification: the obtained gel mixture was aged in isopropanol / n-hexane solution with a volume ratio of 1:1 at 60°C for 10 h, and then immersed in a volume ratio of 1:4: 5 in TMCS / isopropanol / n-hexane solution at 60°C for 24 hours to obtain a hydrophobic gel mixture.

[0027] (3) Drying treatment: the obtai...

Embodiment 3

[0029] (1) Preparation of the gel mixture: First add deionized water to 10mL of water glass to dilute, the volume ratio of water glass to deionized water is 1:4, then add the ion exchange resin AmberliteIR120H + And stir until the solution pH = 2, continue to stir for 10 h, filter to obtain the filtrate, stir for 1 min and ultrasonically shake for 3 min, then add ammonia water dropwise until the solution pH = 7, and stand for 12 h to obtain a gel mixture.

[0030] (2) Solvent replacement and hydrophobic modification: the obtained gel mixture was aged in isopropanol / n-hexane solution with a volume ratio of 1:1 at 60°C for 10 h, and then immersed in a volume ratio of 1:4: 5 in TMCS / isopropanol / n-hexane solution at 60°C for 24 hours to obtain a hydrophobic gel mixture.

[0031] (3) Drying treatment: the obtained hydrophobic gel mixture was placed in n-hexane solution for 12 hours, filtered, then the hydrophobic gel mixture was dried at normal temperature and pressure for 24 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com