Method for preparing KA oil and derivatives of KA oil by electrocatalytic hydrogenation of lignin-based phenolic compounds

A technology of electrocatalytic hydrogenation and compound electricity, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high cost of raw materials and catalysts, environmental pollution, Complicated production process and other issues, to achieve the effects of large-scale industrial production, cost reduction, and high conversion rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

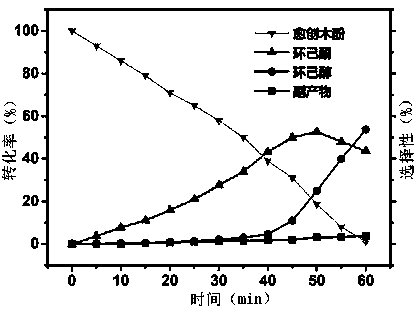

Method used

Image

Examples

Embodiment A

[0040] Example A The preparation method of the loading capacity of 0.5% platinum and 1% nickel supported mesoporous carbon catalyst Pt-NiB / MC is as follows:

[0041] 1) Take 100 g of mesoporous carbon (MC) as the carbon carrier, according to the loading amount of platinum element loaded on the mesoporous carbon carrier The amount is based on the mass of the mesoporous carbon carrier as 1wt%, and the theoretical amount of platinum chloride and nickel sulfate hexahydrate corresponding to the required platinum element is calculated, and 0.87 grams of platinum chloride and 4.49 grams of nickel sulfate hexahydrate are dissolved in 400 mL In water, the corresponding solution of platinum salt and nickel salt is prepared, the mesoporous carbon is immersed in the salt solution, and stirred at room temperature for 12 hours, so that the platinum salt and nickel salt solution are evenly dispersed on the surface of the mesoporous carbon carrier, which is called A solution;

[0042] 2) Dis...

Embodiment B

[0046] Embodiment B load is 2% palladium, the preparation method of 4% iron supported activated carbon catalyst Pd-FeB / AC is as follows:

[0047] 1) Take 100 grams of activated carbon (AC) as the carbon carrier, according to the loading amount of palladium element loaded on the activated carbon carbon carrier, the mass of the carbon carrier is 2 wt%, and according to the loading amount of the iron element loaded on the activated carbon carrier The mass of carrier is 4wt%, and the theoretical dosage of 3.33 grams of palladium chloride and 17.28 grams of ferric nitrate corresponding to the required palladium element is calculated, and the palladium chloride and ferric nitrate of theoretical dosage are dissolved in 500 mL of water to form corresponding palladium salts and iron salt solution, activated carbon is soaked in the salt solution, stirred at room temperature for 10 hours, so that the palladium salt and iron salt solution are evenly dispersed on the surface of the activate...

Embodiment C

[0052] Example C The loading capacity is 5% ruthenium, the preparation method of 10% cobalt supported carbon nanotube catalyst Ru-CoB / CNTs is as follows:

[0053] 1) Take 50 grams of carbon nanotubes (CNTs) as the carbon carrier. According to the loading amount of ruthenium element loaded on the carbon nanotube carrier, the mass of the carbon nanotube carrier is 5 wt%. According to the cobalt element loaded on the carbon nanotube carrier The loading capacity is 10 wt% with the mass of carbon nanotube carrier, calculate the theoretical dosage of 5.14 grams of ruthenium trichloride and 24.70 grams of cobalt nitrate corresponding to the required ruthenium element, dissolve the gram of ruthenium chloride of theoretical dosage and the gram of cobalt nitrate Prepare the corresponding ruthenium salt and cobalt salt solution in 300 mL water, impregnate the carbon nanotubes in the salt solution, and stir at room temperature for 8 hours, so that the ruthenium salt and cobalt salt solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com