Direct liquefaction process of coal by replacing circling solvent with petroleum or petroleum refining byproduct

A technology for direct coal liquefaction and petroleum refining, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures. It can solve the problems of deposition and coking, and increase the severity of petroleum processing, so as to improve the yield, prevent lightening, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

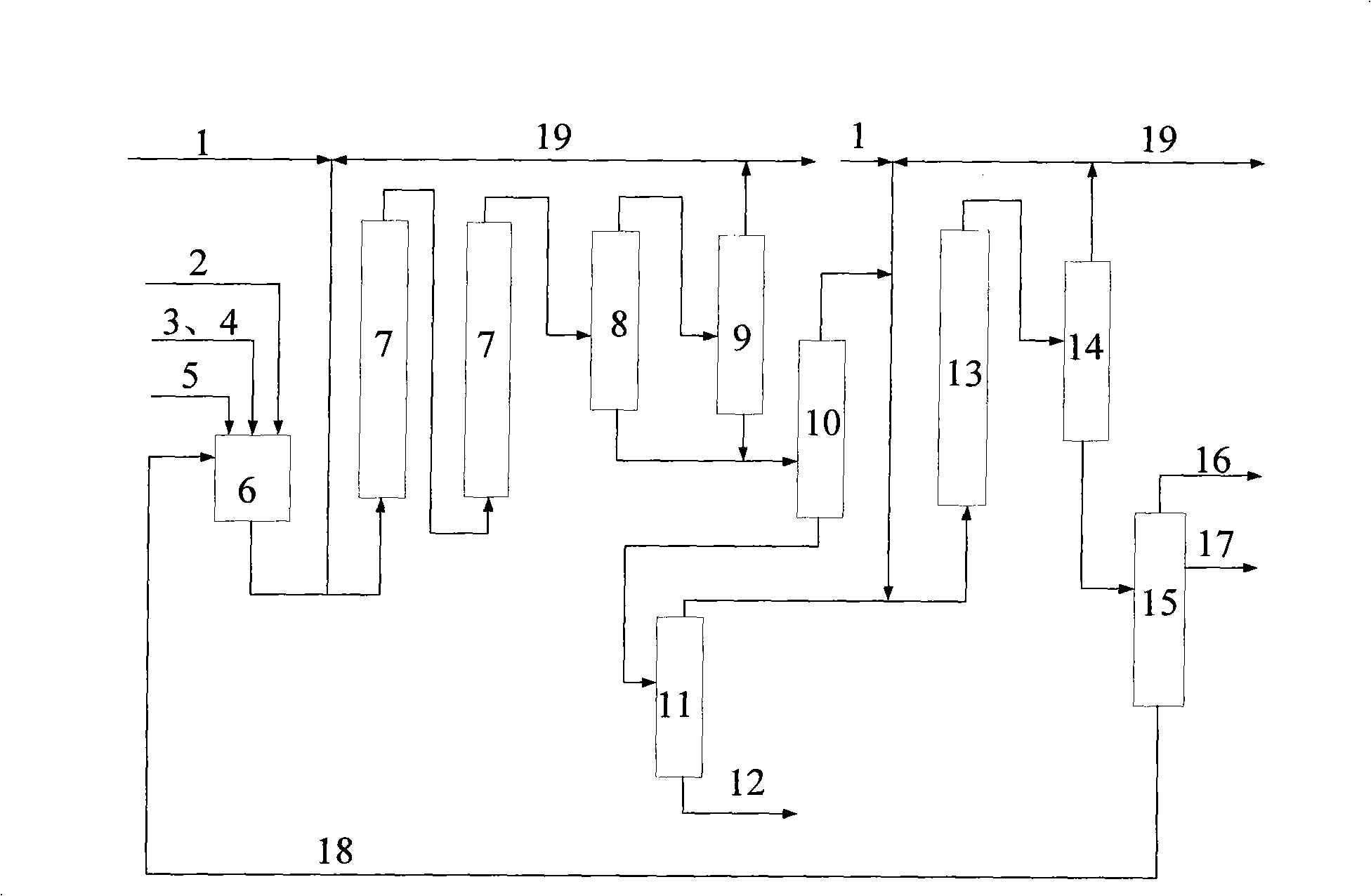

Method used

Image

Examples

Embodiment 1、2 and comparative example 1

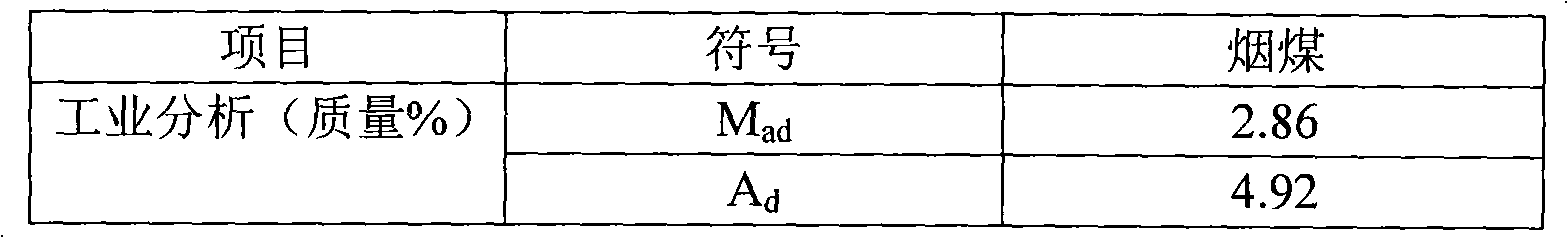

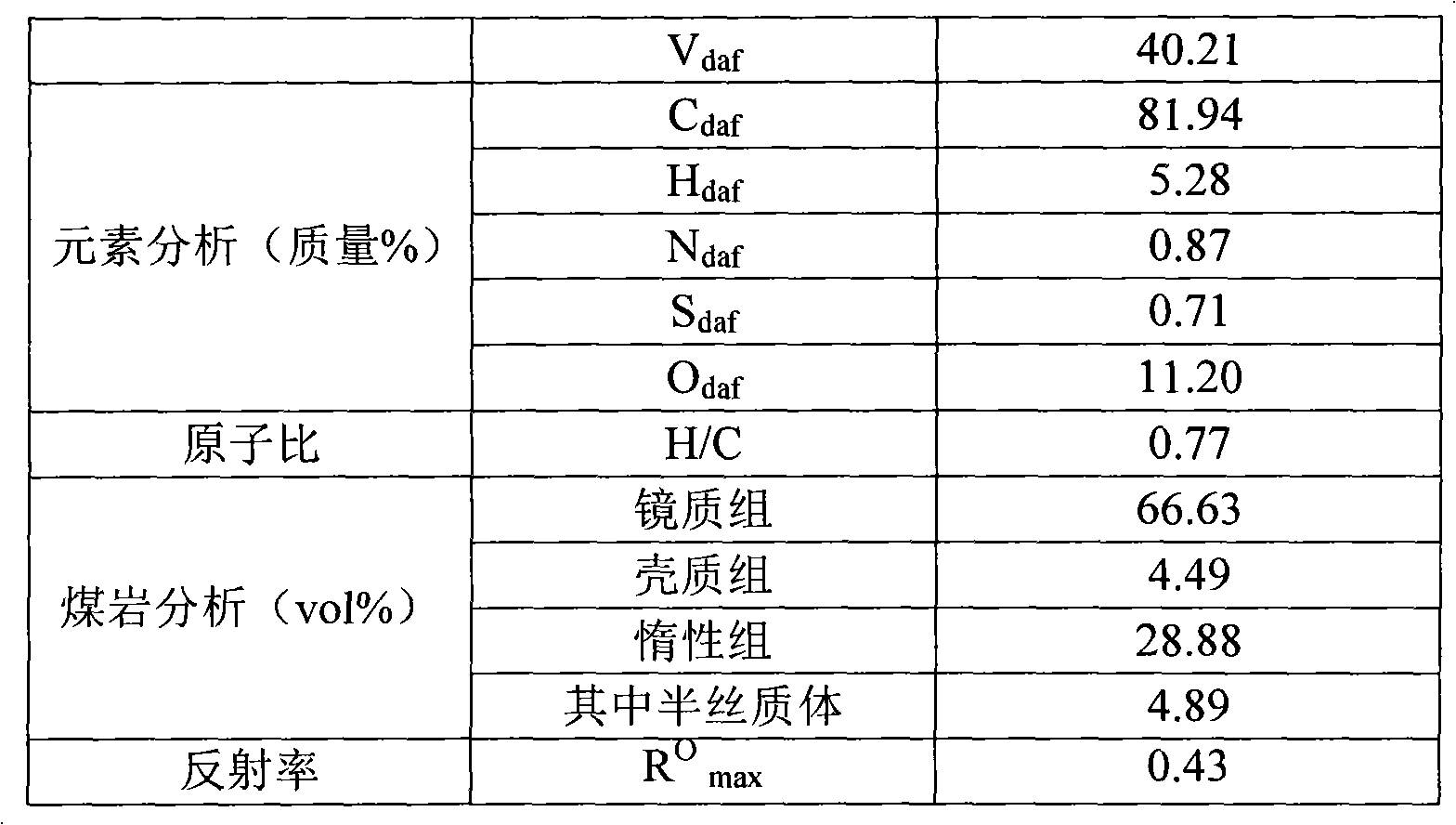

[0032] In this embodiment, bituminous coal is used as raw coal for coal liquefaction, and the properties of this kind of bituminous coal are shown in Table 1. In Table 1, daf refers to anhydrous ash free (daf, dry and ash free), the same below. The oil slurry dumped from the catalytic cracking unit of a petrochemical refinery is used as an additional solvent to replace the circulating solvent for direct coal liquefaction. The properties of the dumped oil slurry are shown in Table 2. The catalyst synthesized and prepared according to the method in the patent ZL03153377.9 "A Highly Dispersed Iron-Based Coal Direct Liquefaction Catalyst and Its Preparation Method" was selected, and its properties are shown in Table 3. A commercially available Ni-Mo based hydrotreating catalyst was used as the primary hydrogenation catalyst for liquefied product oil (IBP-530°C).

[0033] Table 1 Analysis data of bituminous coal quality

[0034]

[0035]

[0036] Table 2 Properties of FCC S...

Embodiment 3

[0058] The coal type, high-activity catalyst for direct coal liquefaction, co-catalyst, hydrogenation catalyst, and process used in this example are the same as those in Example 1, except that the used alternative direct coal liquefaction circulating solvent is high metal content, high pitch A heavy oil with a low quality content. The properties of the heavy oil used are shown in Table 8.

[0059] Table 9 shows the test results of the bituminous coal direct liquefaction continuous plant when adopting the method of the present invention and adding 10% of this heavy oil to replace the circulating solvent. The yield data in the table is calculated based on daf base coal + heavy oil.

[0060] Table 8 Properties of a heavy oil

[0061] project

[0062] Density (20℃), kg / m 3

[0063] Table 9

[0064] Process conditions

[0065] The data of table 9 is compared with the data of table 7, as can be known: when the ratio of heavy oil substitute solvent...

Embodiment 4

[0067] The coal type, high-activity catalyst for direct coal liquefaction, co-catalyst, hydrogenation catalyst and process used in this embodiment are the same as those in Example 1, except that the petroleum or petroleum refining process used instead of the circulating solvent for direct coal liquefaction The low value-added by-product is a kind of extracted aromatics after hydrotreatment, and its properties are shown in Table 10.

[0068] Table 11 shows the test results of the bituminous coal direct liquefaction continuous plant when the method of the present invention is adopted and 55% of the extracted aromatics after hydrotreating are used to replace the circulating solvent. The yield data in the table is calculated based on daf coal + extracted aromatics.

[0069] Table 10

[0070]

[0071] Table 11

[0072] Process conditions

[0073] Comparing the data in Table 11 with the data in Table 7, it can be seen that: when the ratio of the extracted aromatics su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com