Patents

Literature

574 results about "High pitch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

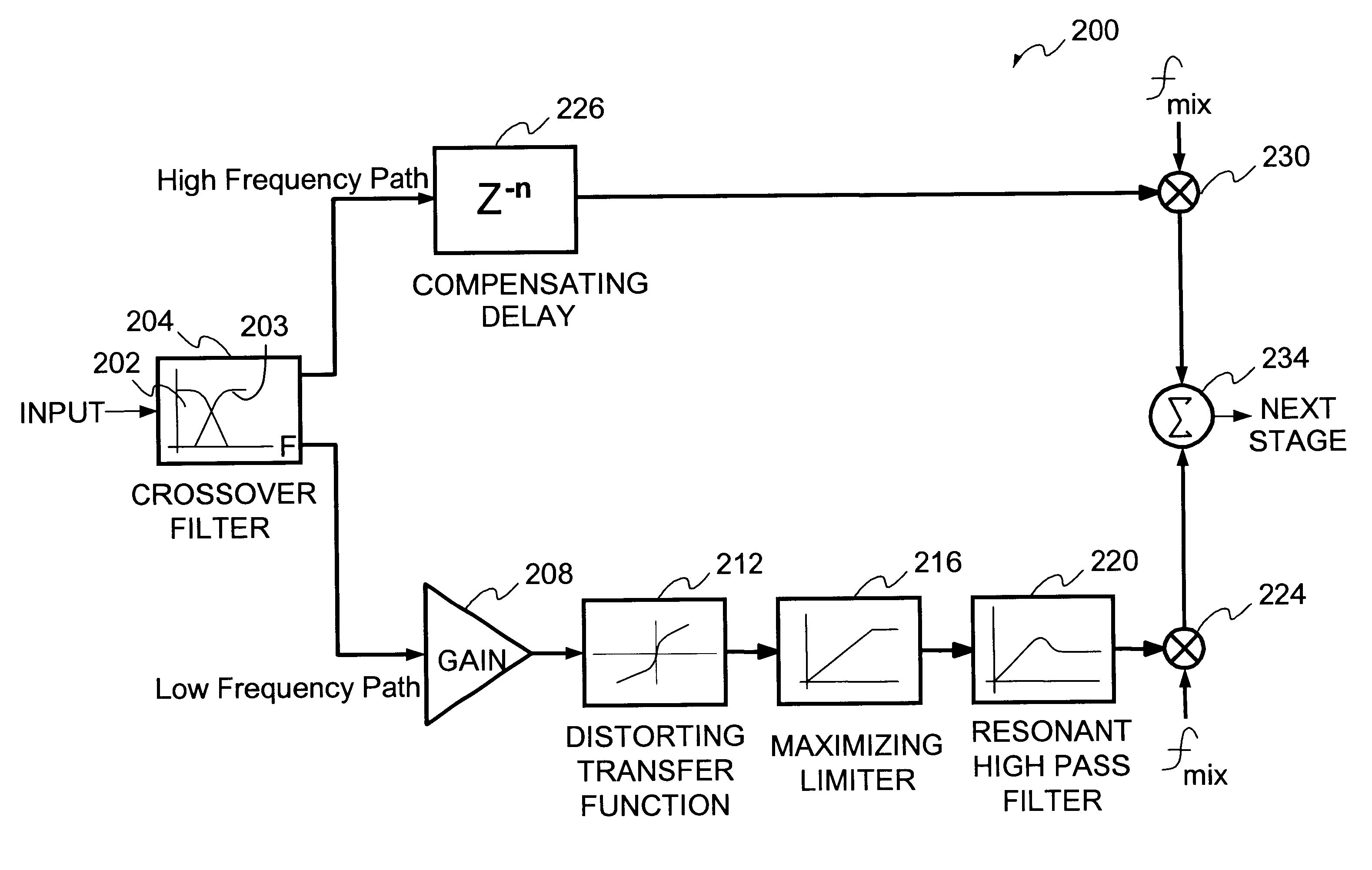

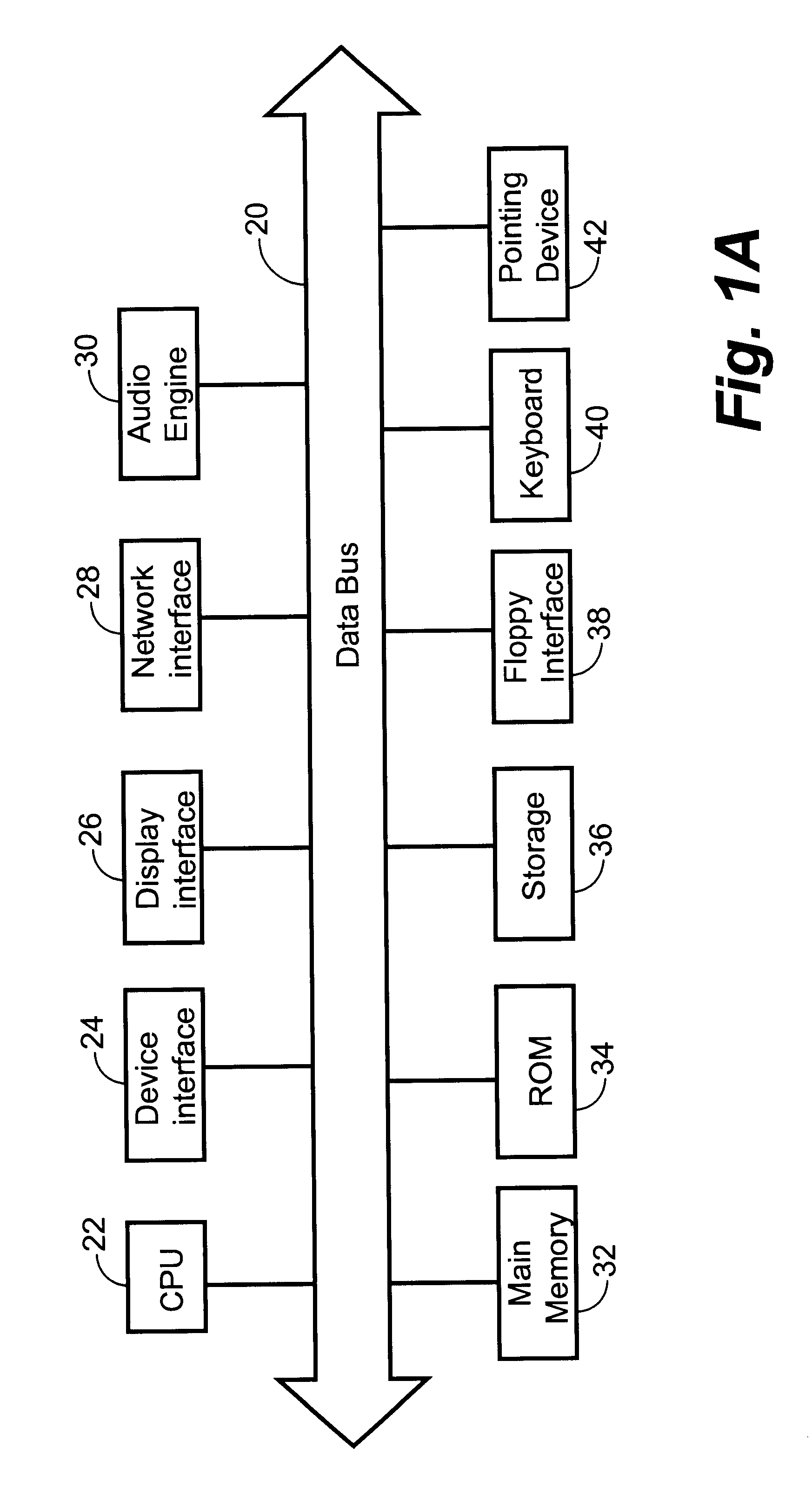

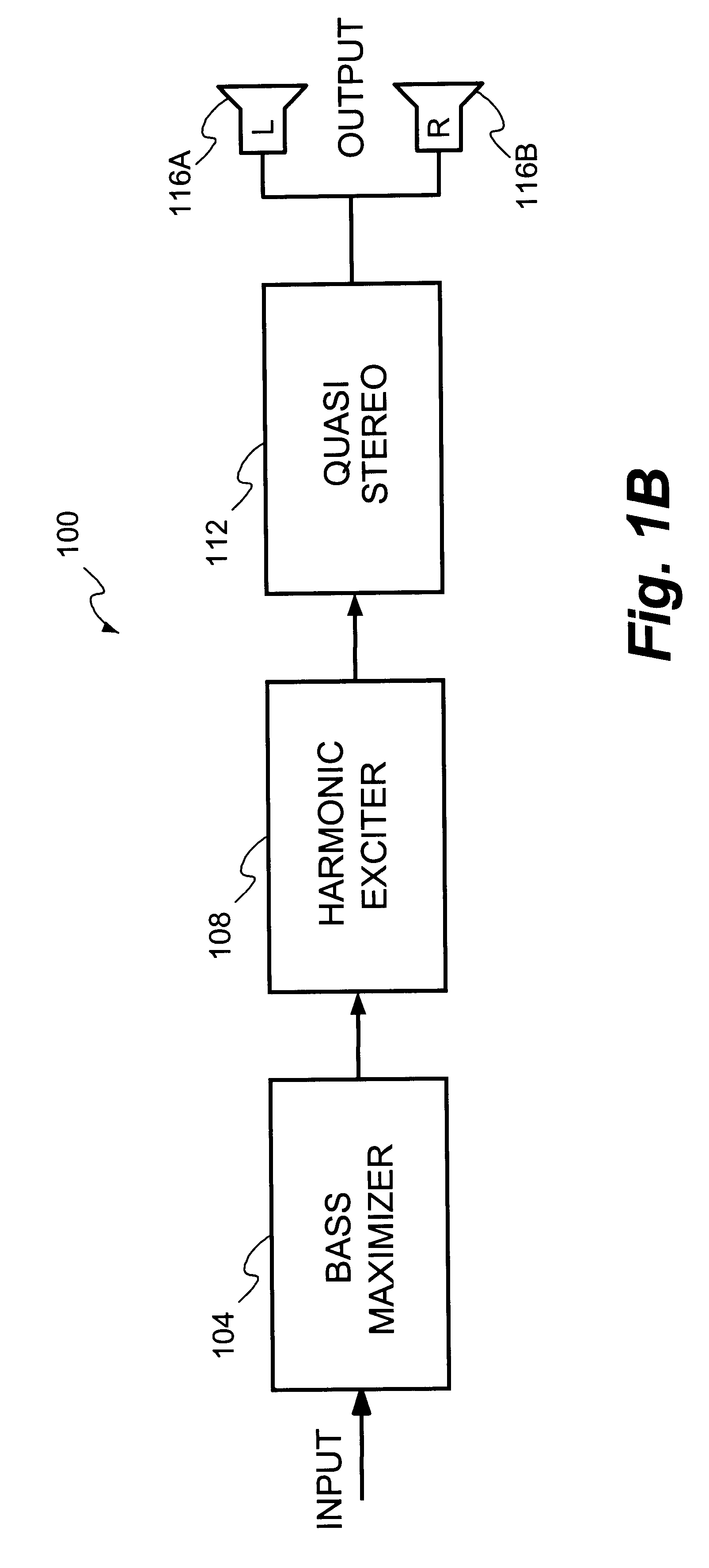

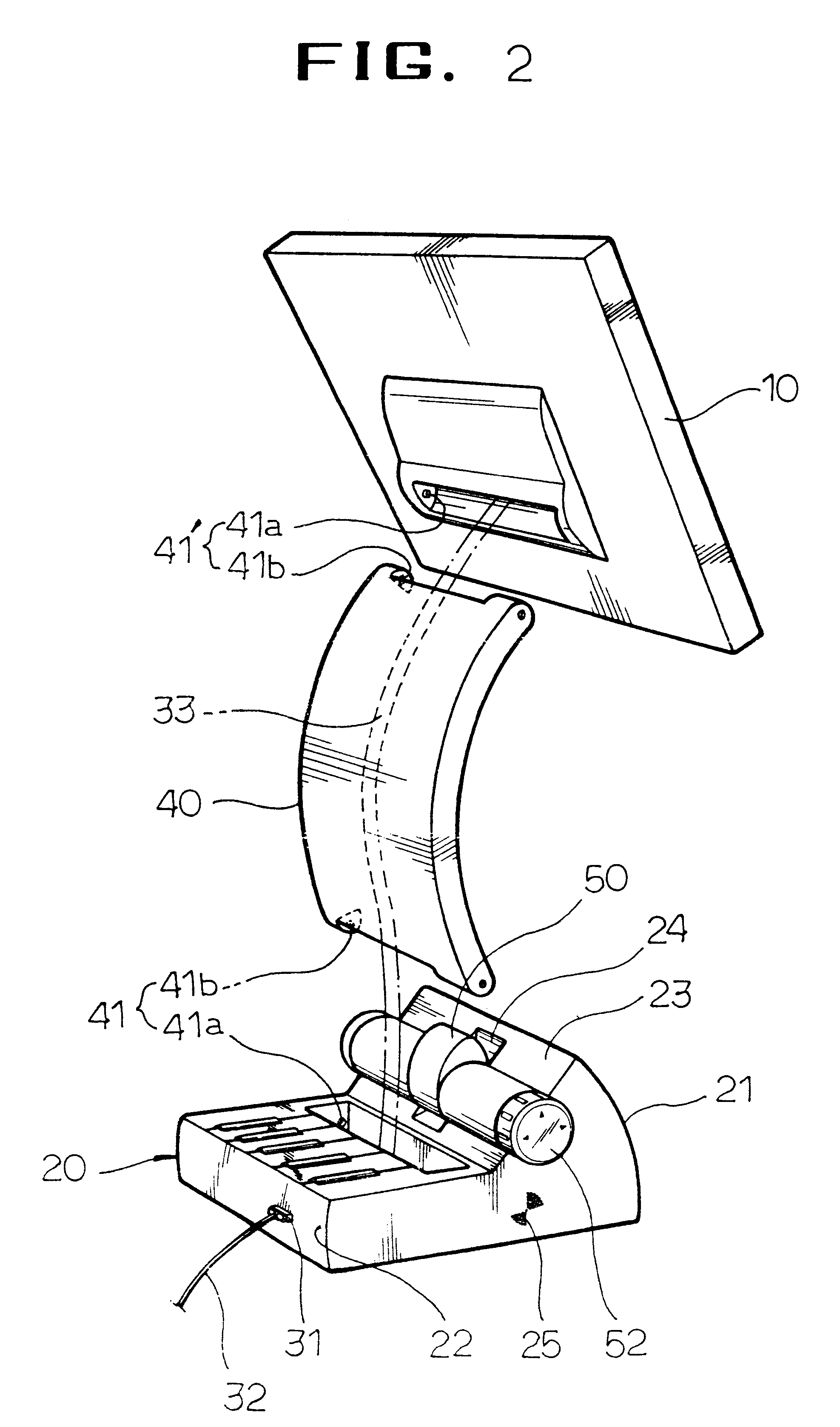

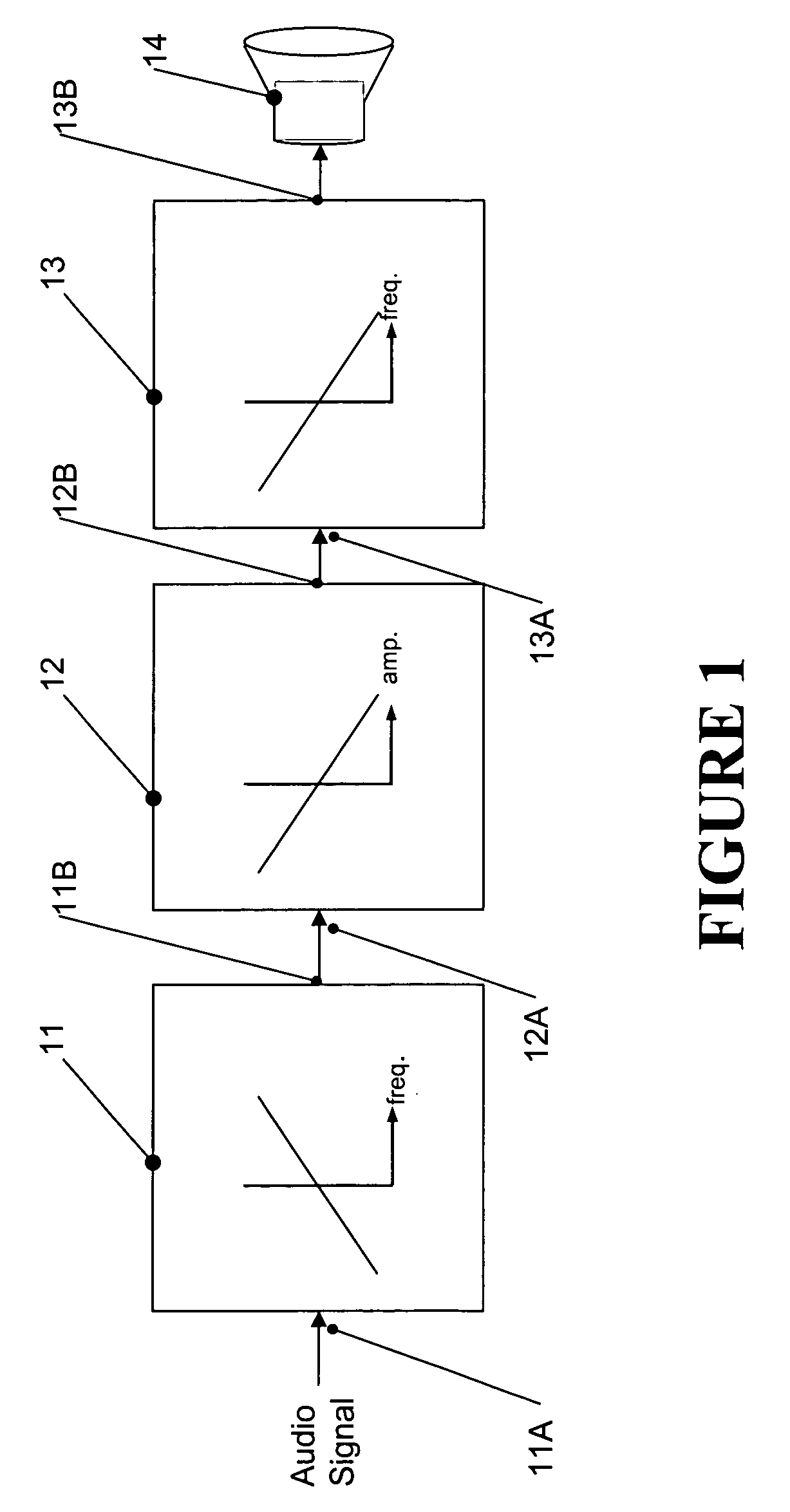

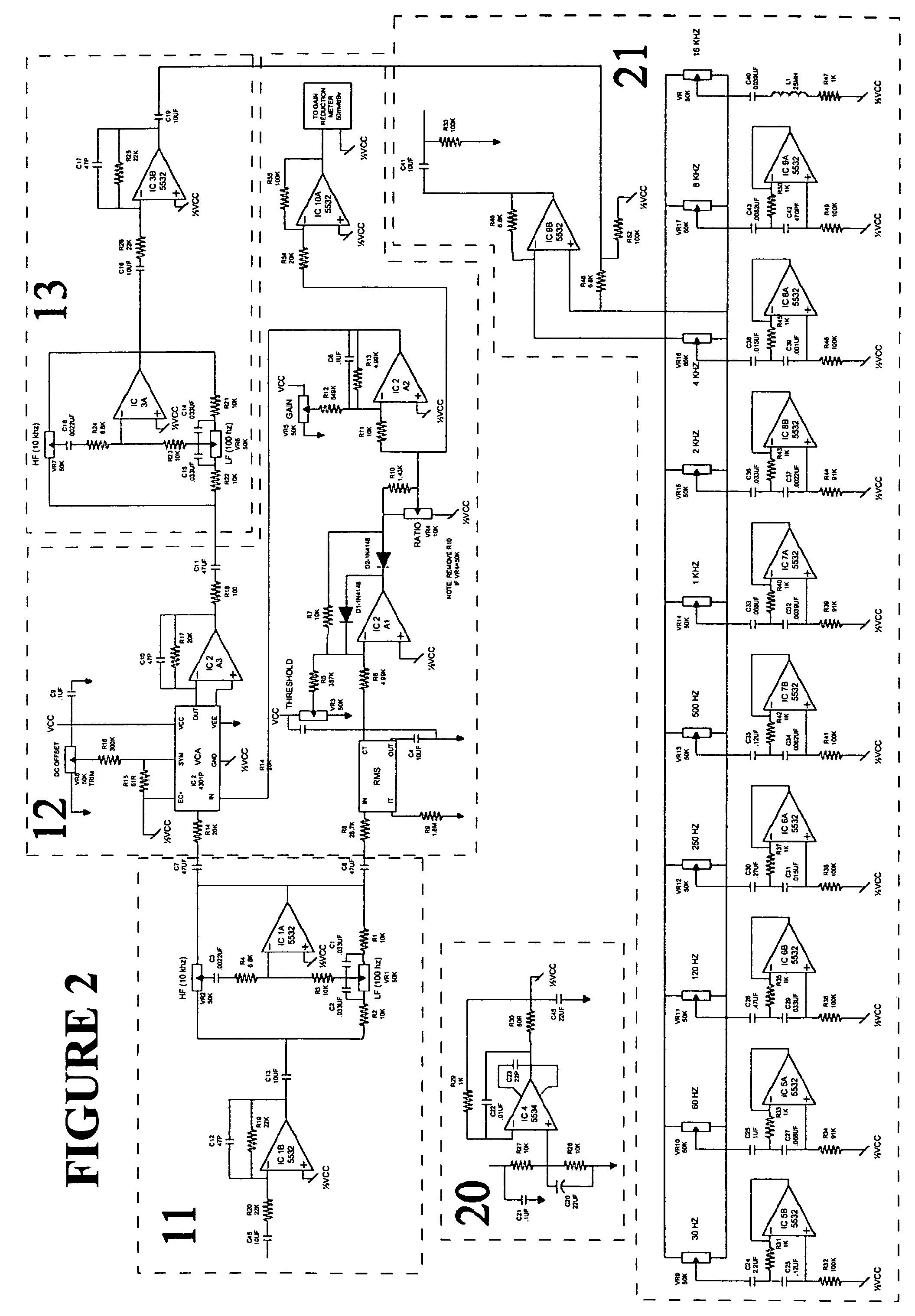

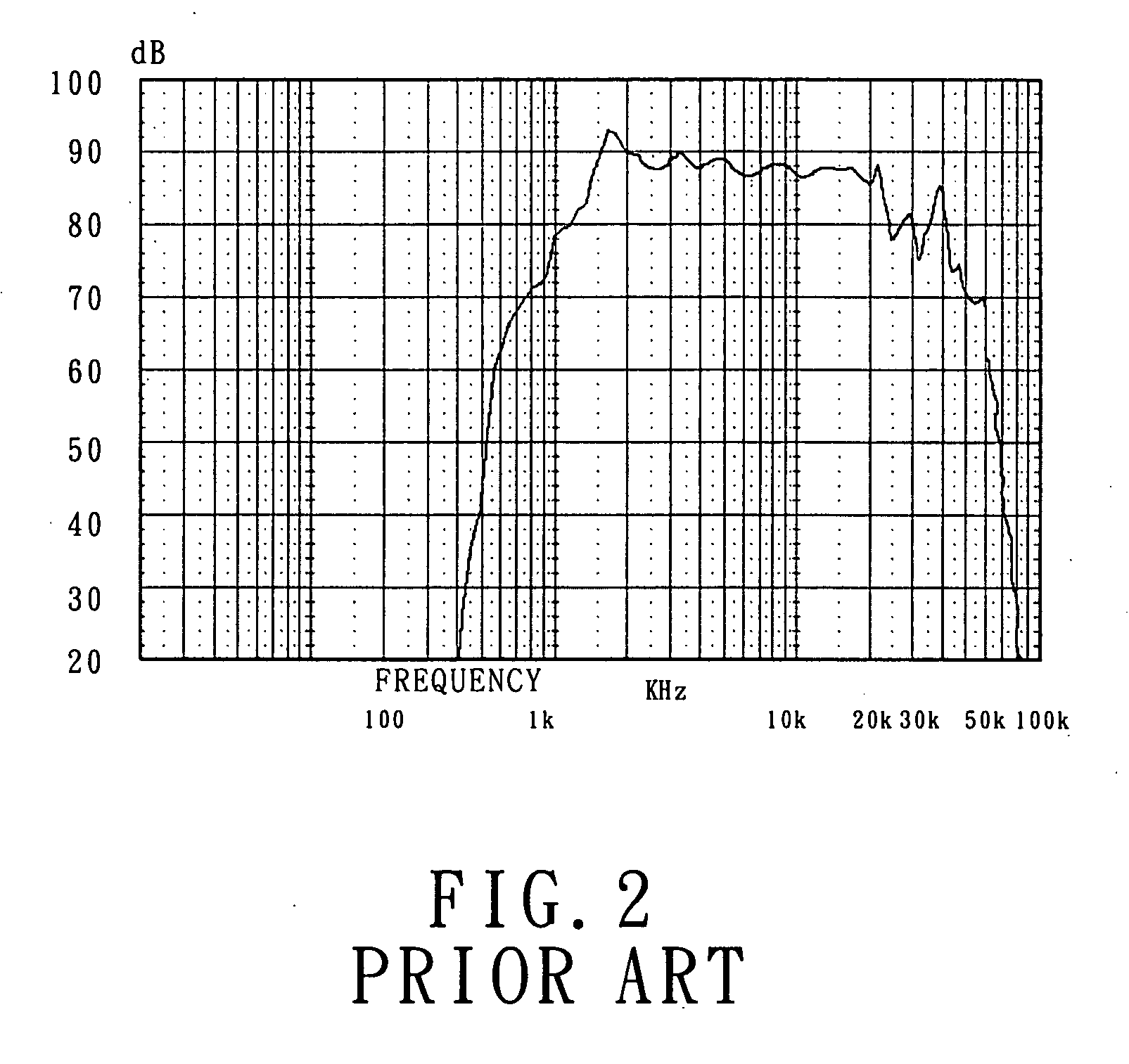

Method and system for enhancing audio signals

InactiveUS6606388B1Facilitates separate modificationFacilitates enhancementElectrophonic musical instrumentsGain controlHarmonicComputer module

A technique for enhancing audio signals generated from compressed digital audio files is described. The technique uses a Bass Maximizer module, a Harmonic Exciter module and a Quasi Stereo module. The Bass Exciter module enhances the intensity, depth and punch of the bass audio content by creating harmonic sequences from low frequency components contained in the original input signal. The Harmonic Exciter module adds to the treble audio content of the original input signal by generating harmonic series from the high frequency components contained in the input signal. The Quasi Stereo Module creates a stereo image of the enhanced input signal by adding and subtracting delayed and filtered versions of the enhanced input signal with itself to create left and right channeled stereo-like outputs. The technique provides a useful tool to regenerate from an audio signal more pleasant and joyful sounds.

Owner:ARBORETUM SYST

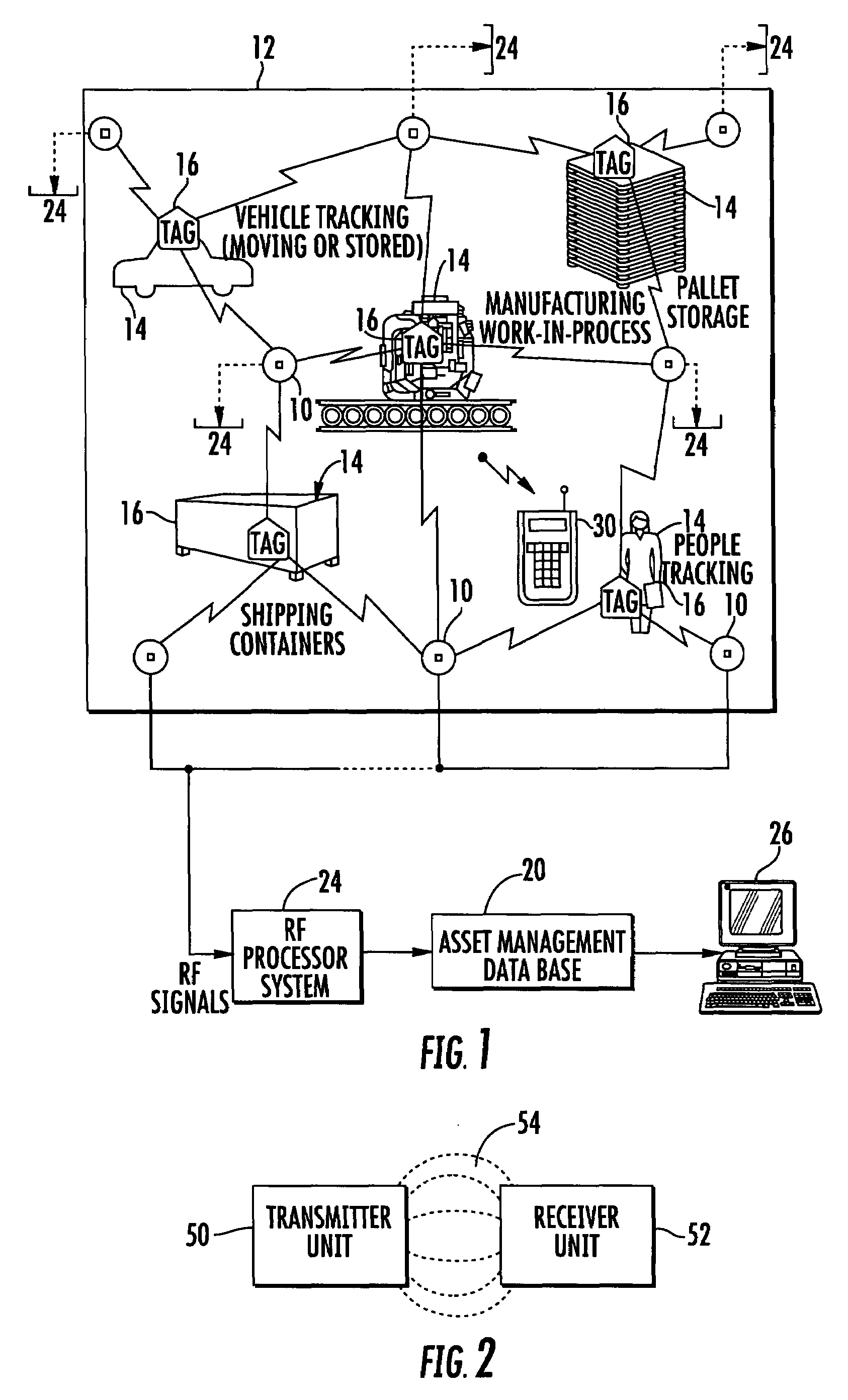

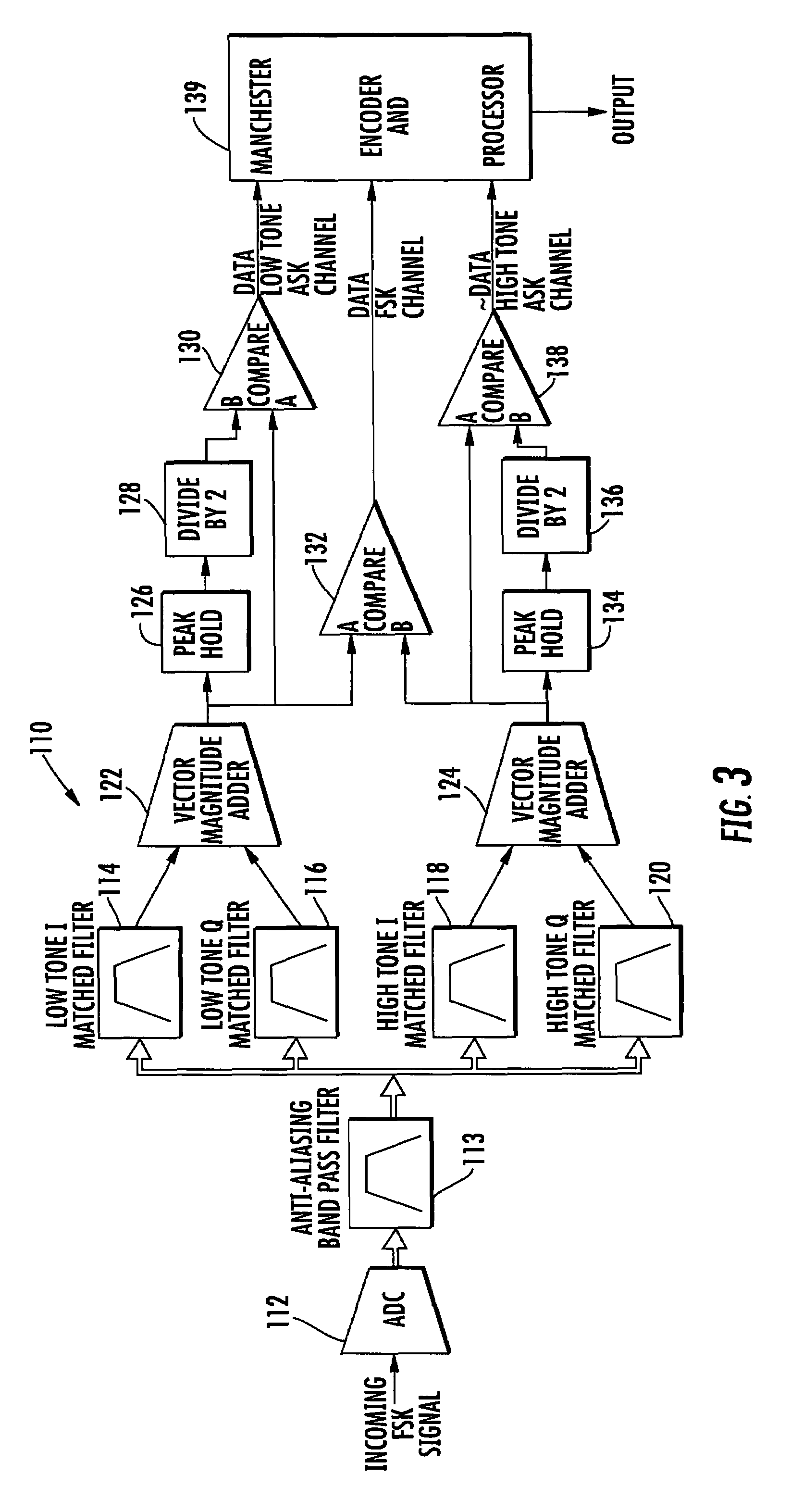

Receiver for object locating and tracking systems and related methods

Owner:ZEBRA TECH CORP

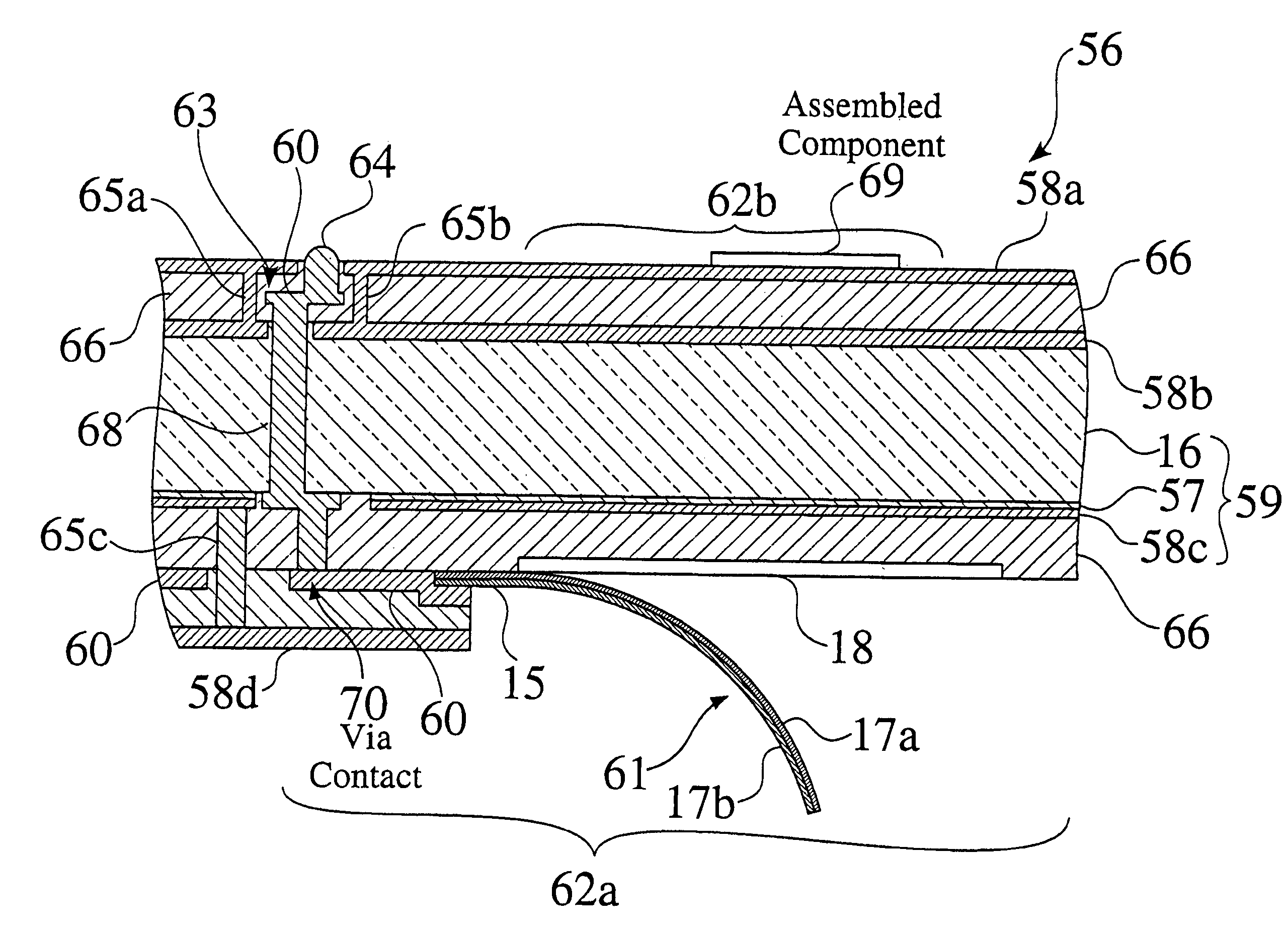

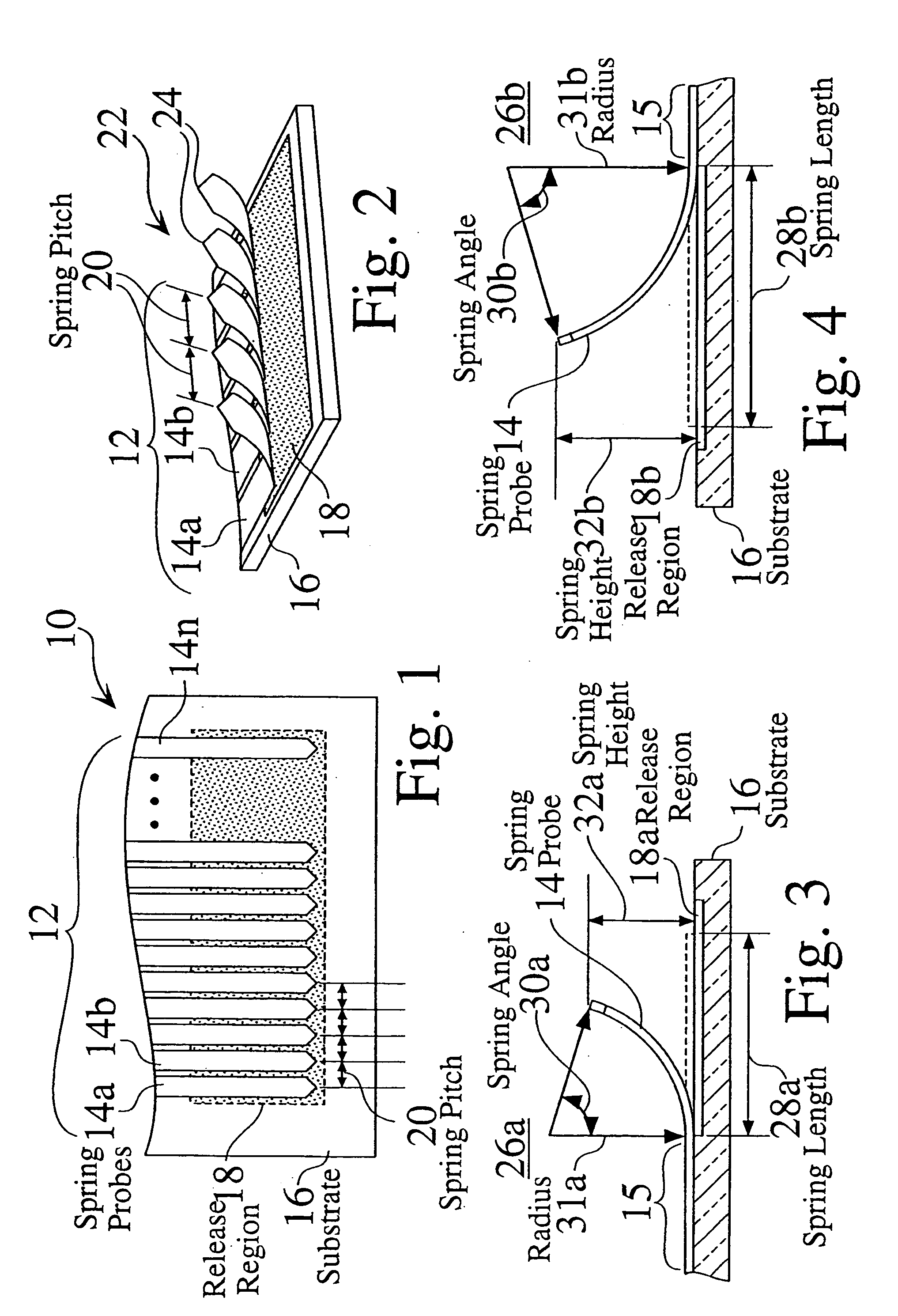

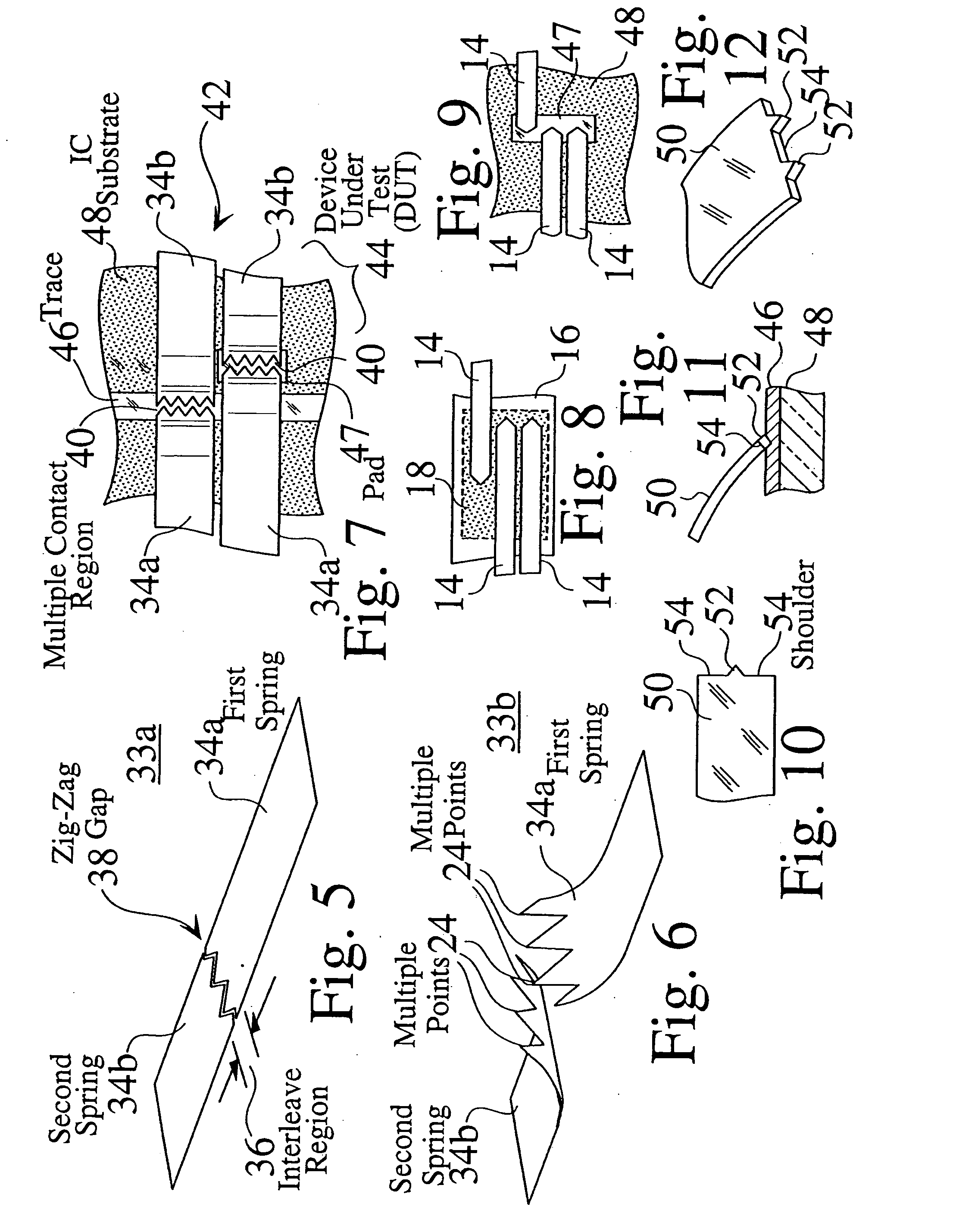

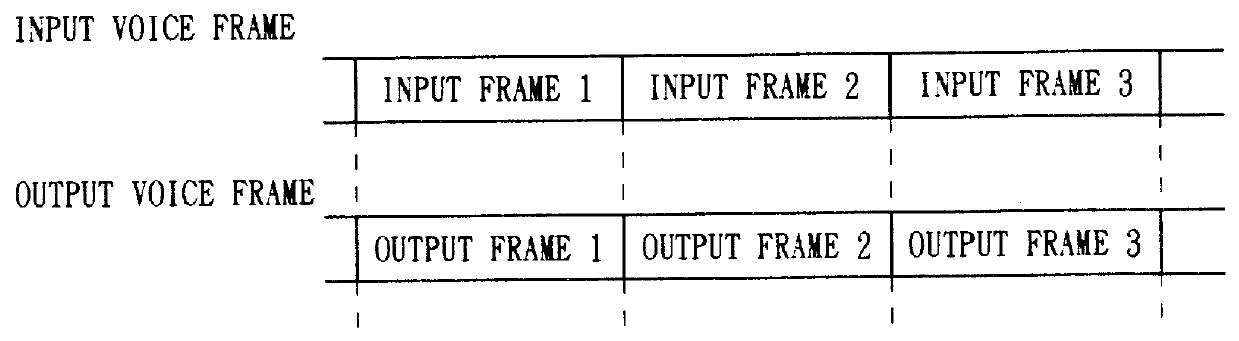

Systems for testing and packaging integrated circuits

InactiveUS20050026476A1Electrical measurement instrument detailsSolid-state devicesHigh densitySemiconductor package

Several embodiments of stress metal springs are disclosed, which typically comprise a plurality of stress metal layers that are established on a substrate, which are then controllably patterned and partially released from the substrate. An effective rotation angle is typically created in the formed stress metal springs, defining a looped spring structure. The formed springs provide high pitch compliant electrical contacts for a wide variety of interconnection systems, including chip scale semiconductor packages, high density interposer connectors, and probe contactors. Several embodiments of massively parallel interface integrated circuit test assemblies are also disclosed, comprising one or more substrates having stress metal spring contacts, to establish connections between one or more separated integrated circuits on a compliant wafer carrier.

Owner:ADVANTEST CORP

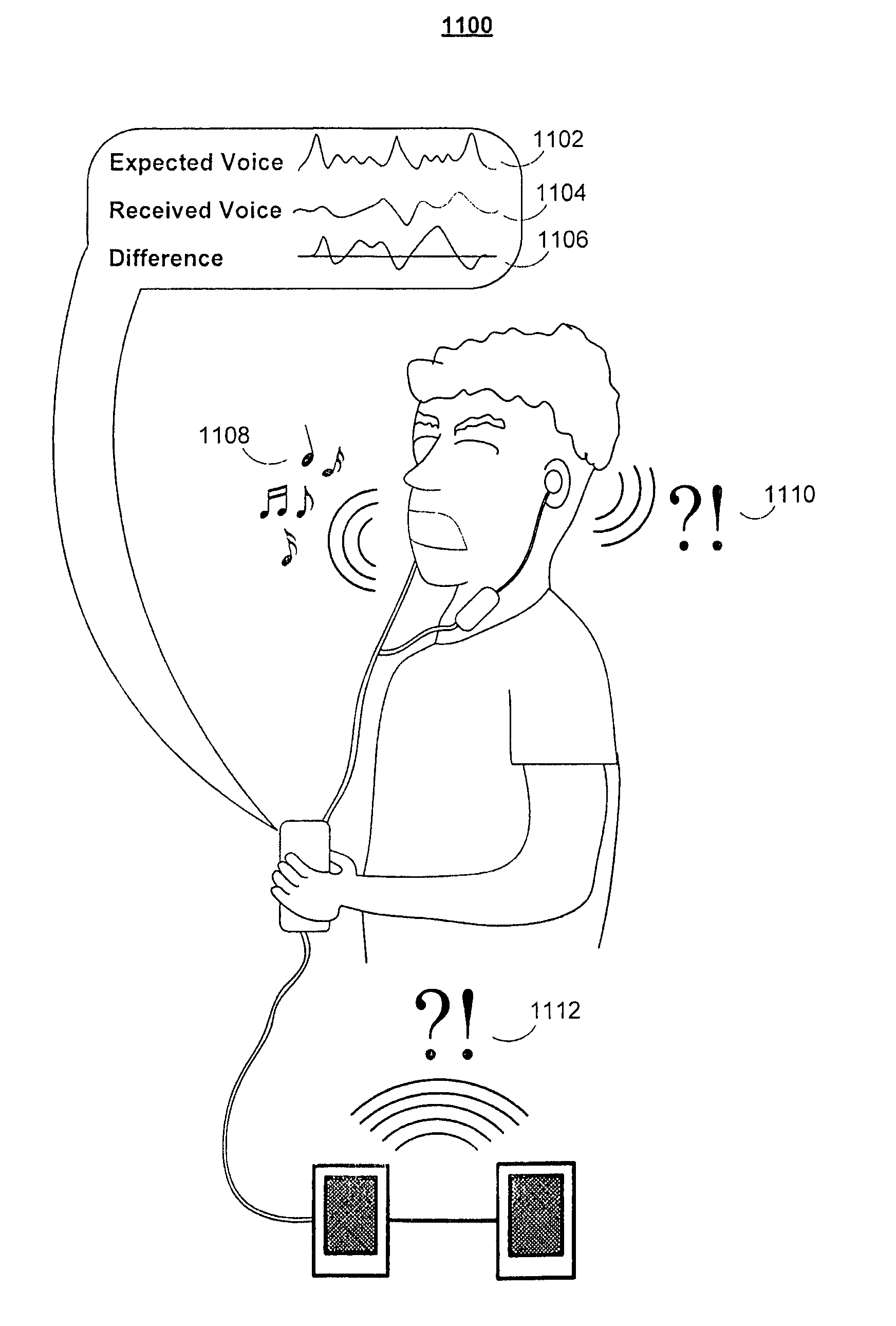

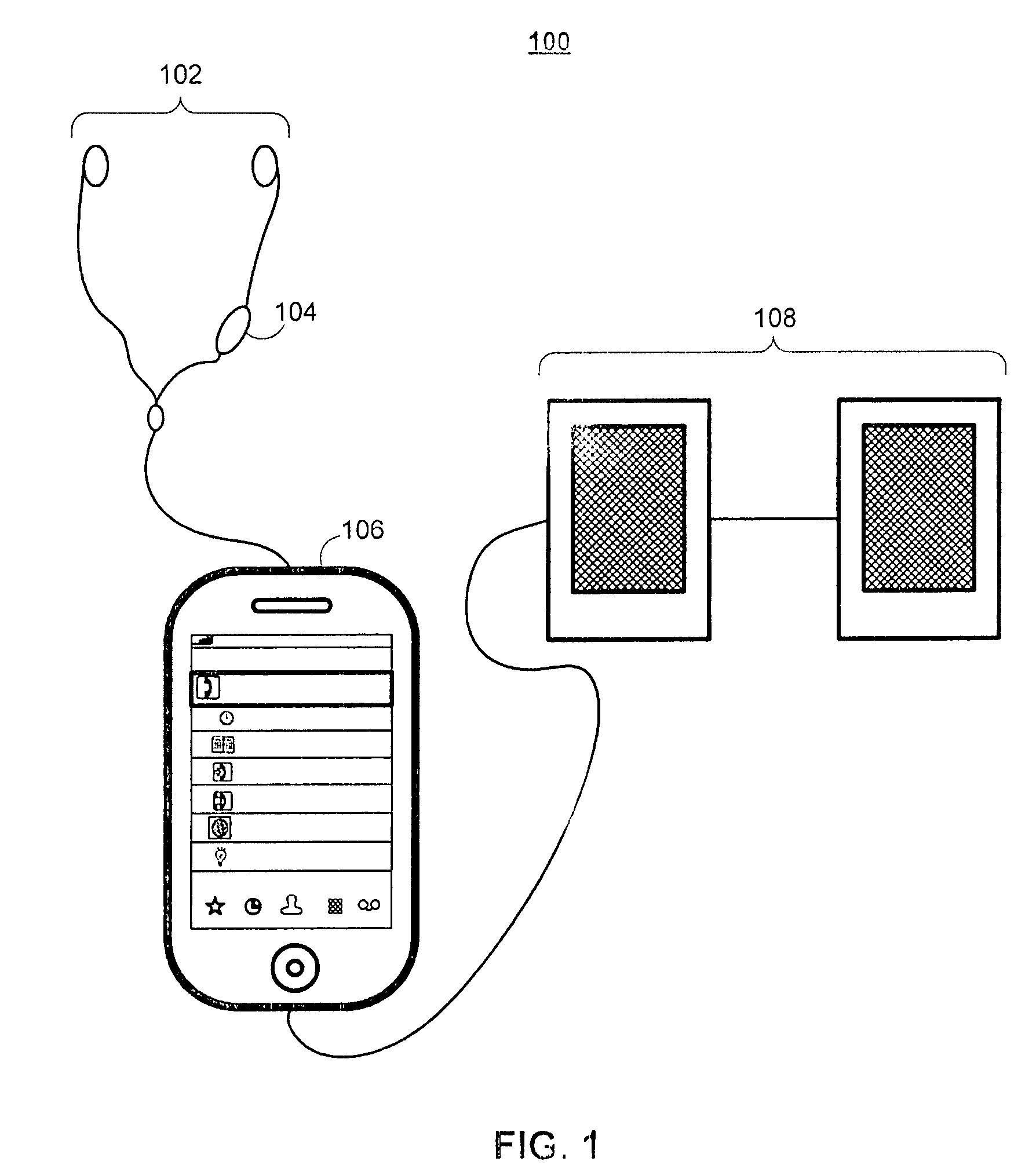

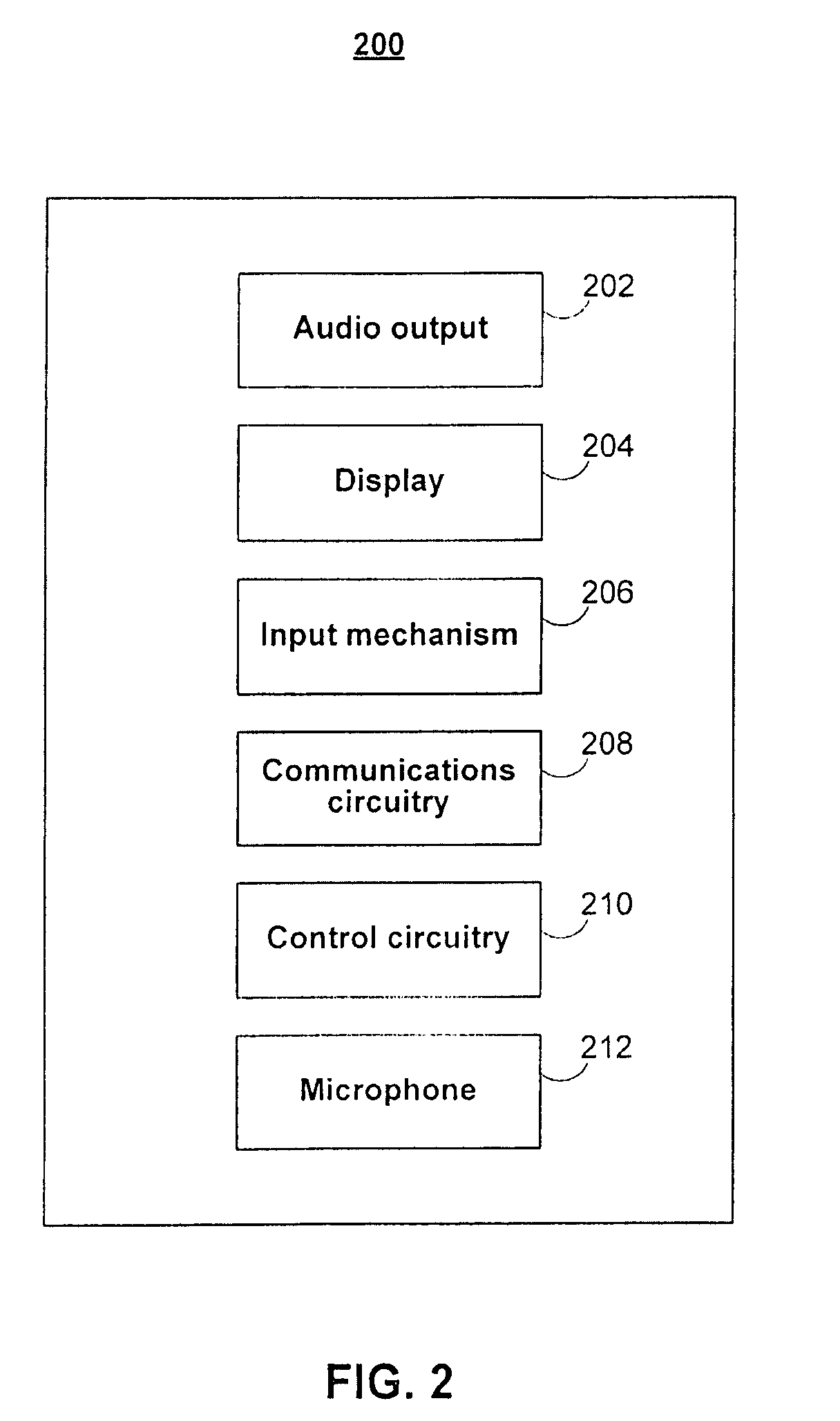

Methods and systems for providing real-time feedback for karaoke

Systems and methods for providing real-time feedback to karaoke users are provided. The systems and methods for providing users with real-time feedback while they are singing karaoke generally relate to receiving the user's vocals, determining whether the user is singing on key / pitch and providing real-time feedback to the user while the karaoke song is being sung. The feedback will be positive feedback if user is on key / pitch and it will be negative feedback if user is off key / pitch. For example, the feedback signal if the user is singing too low can be an exaggerated low signal of the user's own voice. This will encourage the user to sing at a higher pitch.

Owner:APPLE INC

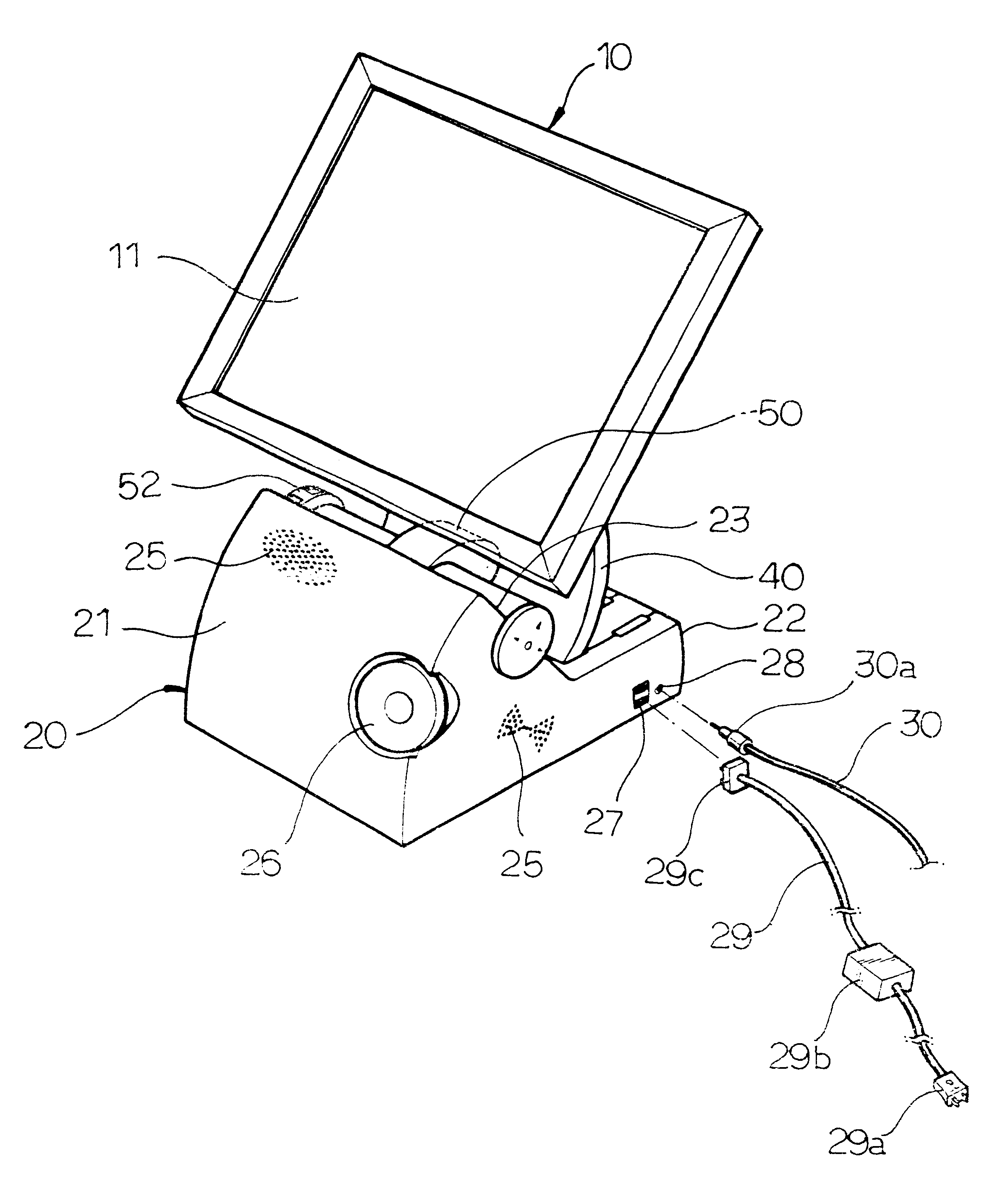

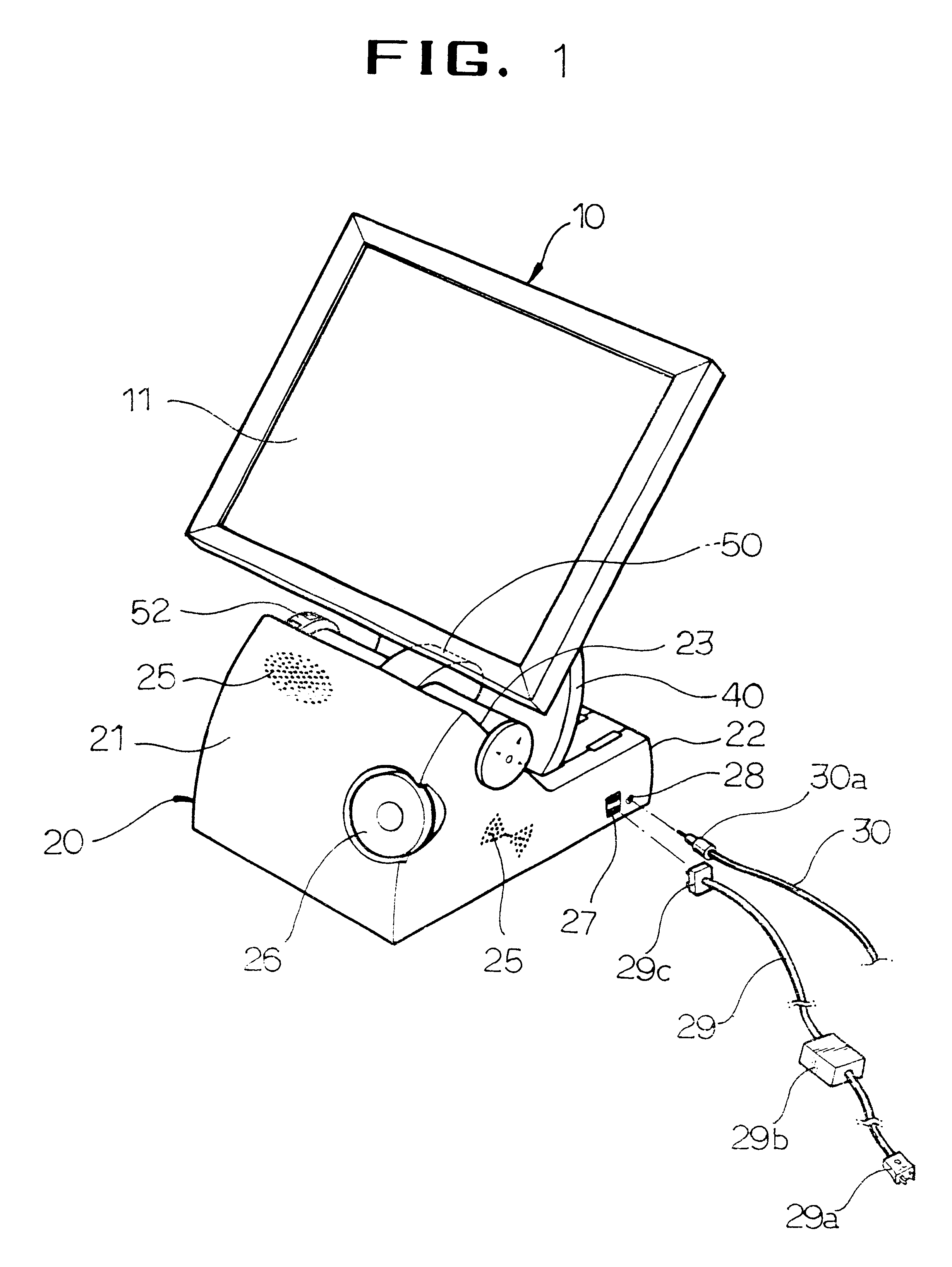

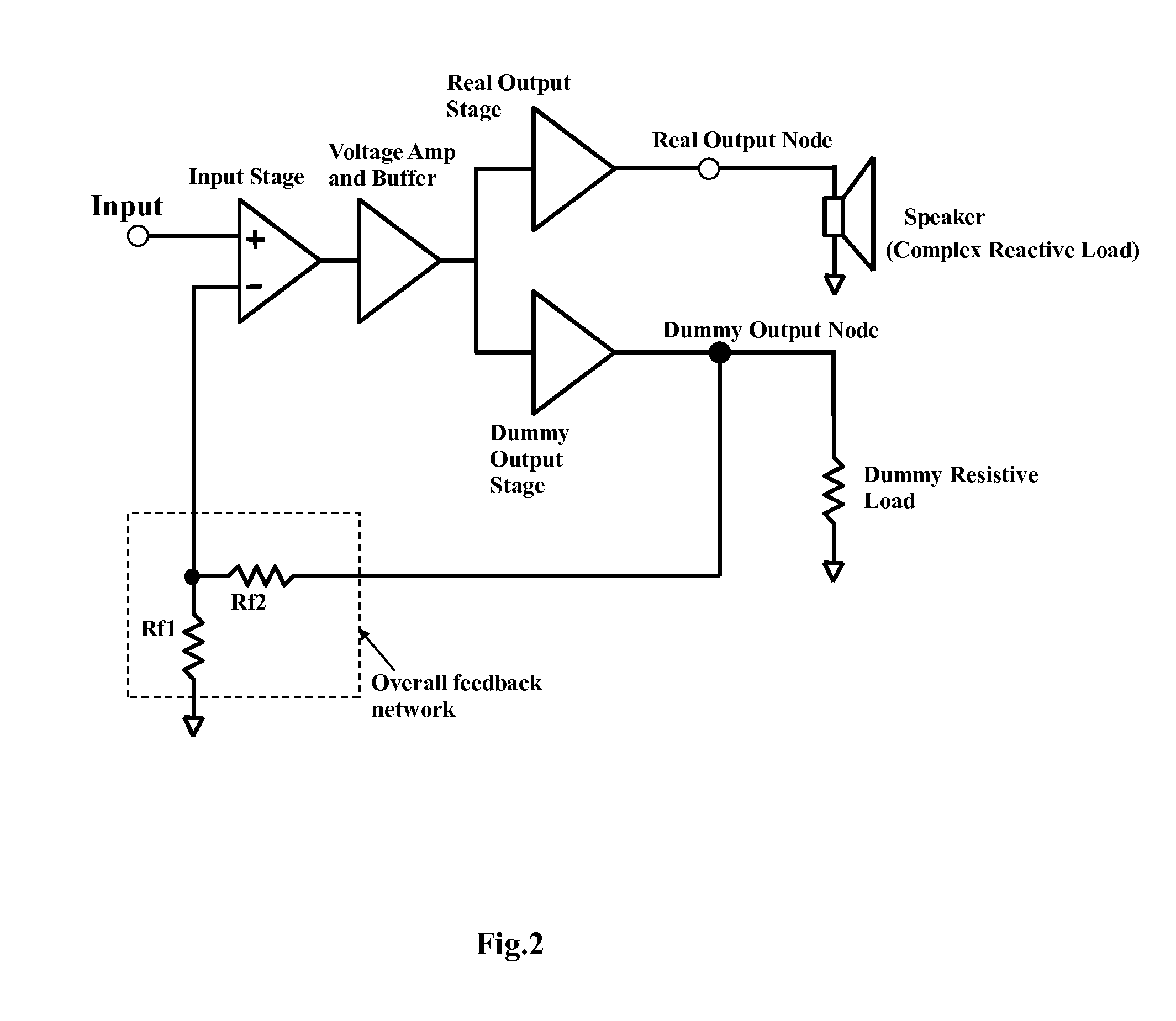

Liquid crystal display

InactiveUS6411271B1Less expensiveEasy to adjust the angleStatic indicating devicesDigital data processing detailsLiquid-crystal displayEngineering

A liquid crystal display including many speakers within a stand and having a display unit, a display angle of which can be adjusted by a cam in order that a user can conveniently see it. The stand supports the display unit through a support and has an inclined part between a front part and a rear part. In addition, a speaker for outputting a high-pitched sound is installed within the front part of the stand and speakers for outputting a middle-low pitched sound are installed within the both sides of the stand. The support is rotatably connected to the display unit and the stand by a driving of the cam and contacted with the cam provided to toe inclined part of the stand and the angle of the support is adjusted by a rotation of the cam and so an angle of the display unit is adjusted.

Owner:SAMSUNG ELECTRONICS CO LTD

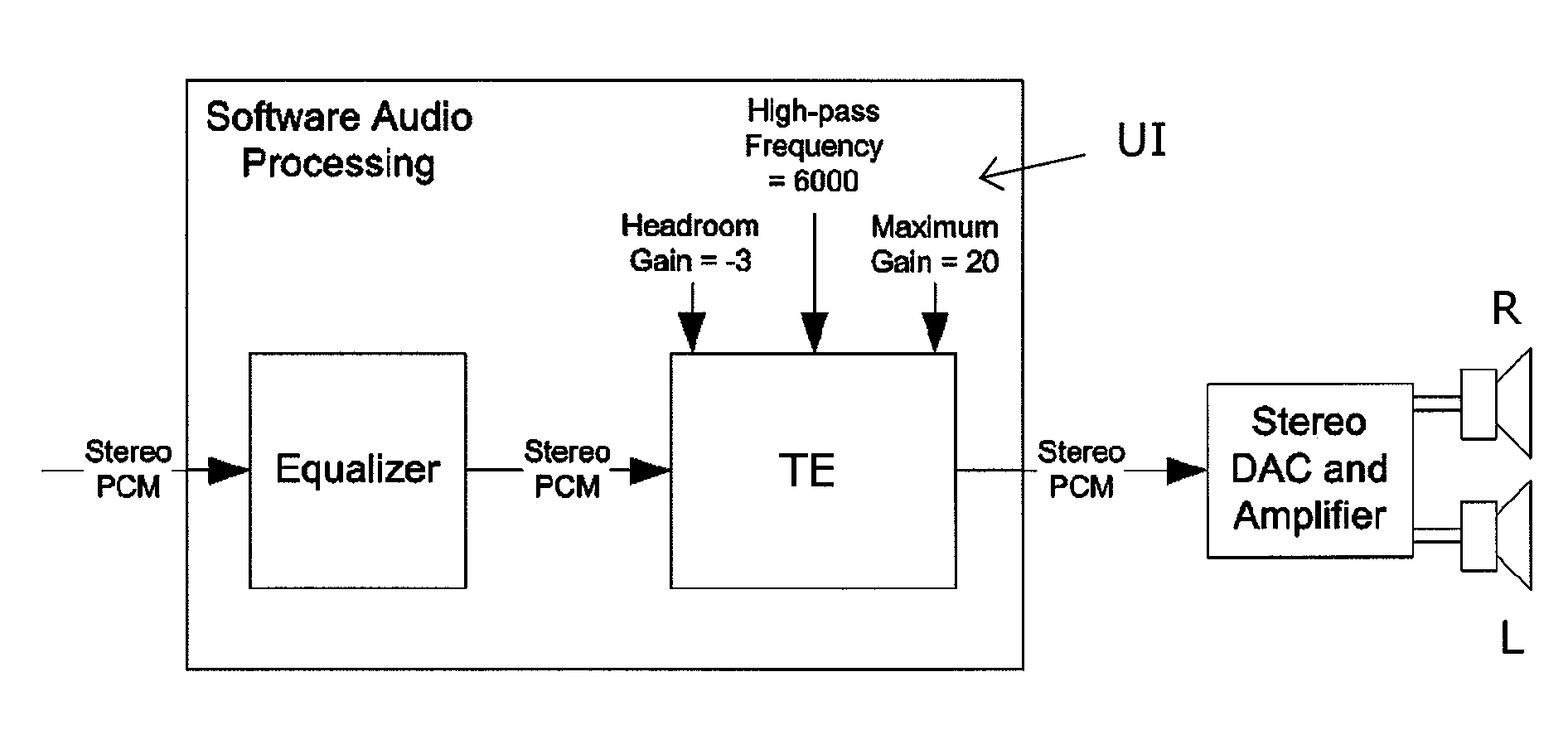

Processing of an audio signal for presentation in a high noise environment

ActiveUS7254243B2Weakening rangeIncreases magnitudeGain controlVolume compression/expansionEngineeringEqualization

Owner:BONGIOVI ACOUSTICS LLC

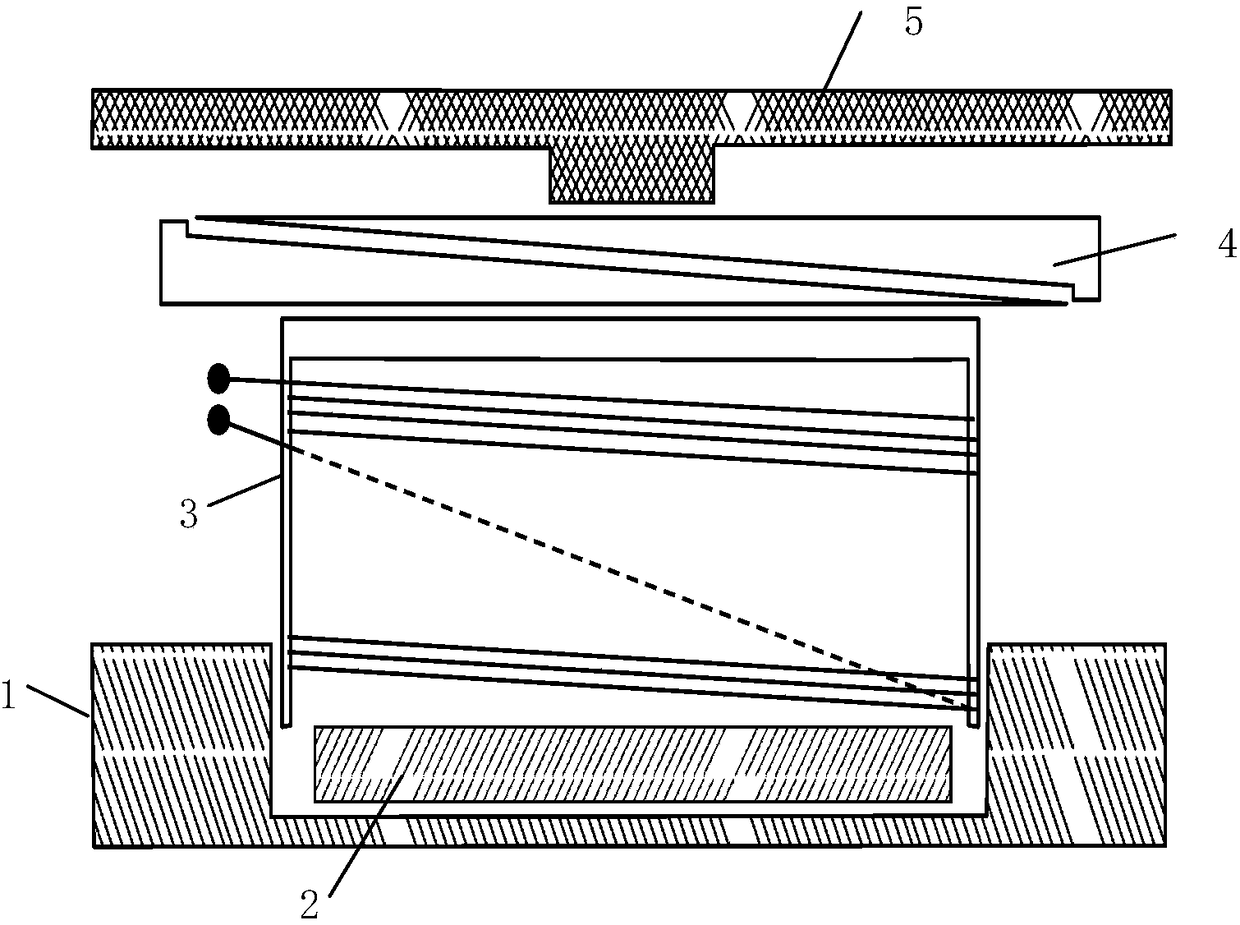

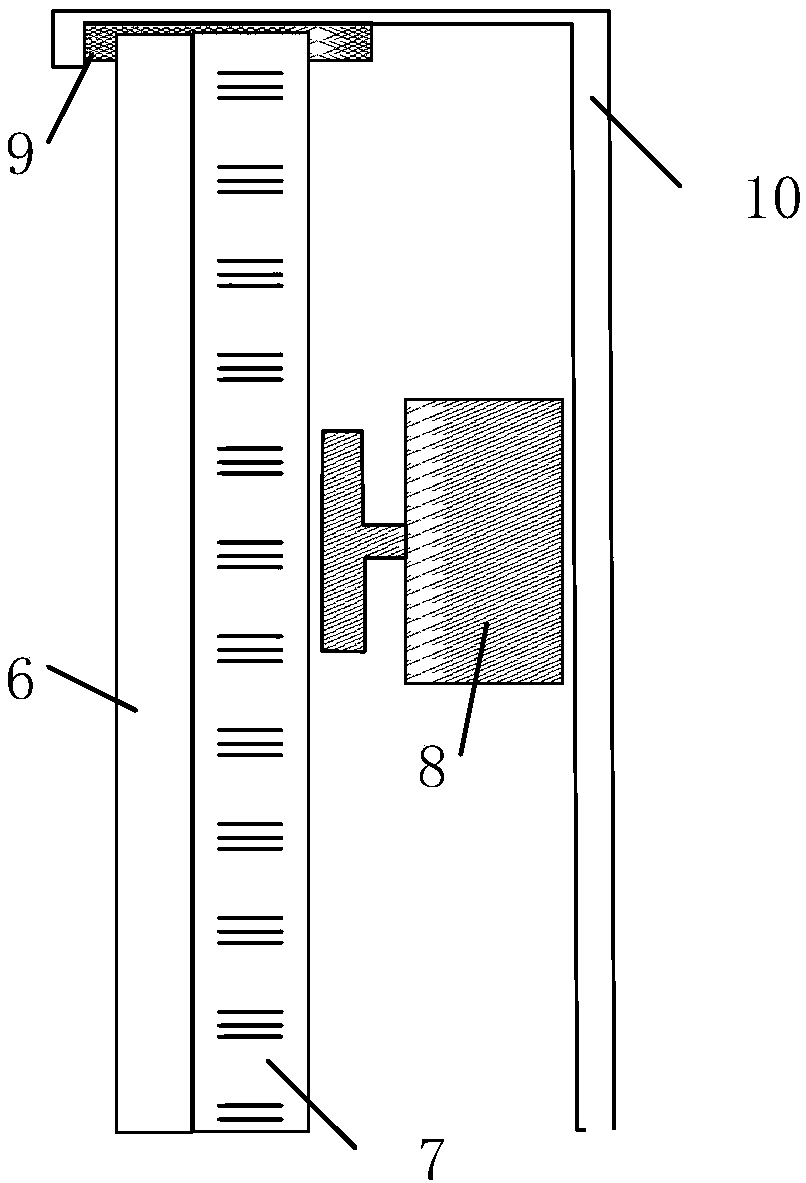

Electromagnetic excitation energy converter, laser projection optical sound screen, and synchronous display method thereof

ActiveCN108462917ASolve the pain points of useMeet audio-visual experience needsProjectorsFrequency/directions obtaining arrangementsVibration amplitudeHigh-pitched

The invention discloses an electromagnetic excitation energy converter, a laser projection optical sound screen, and a synchronous display method thereof, and relates to the technical field of the image display and the acoustics. A hard or flexible laser projection optical screen is used as display and sound production of a sound production component, the electromagnetic excitation energy converter is used for pushing the screen or an auxiliary sound production board to vibrate the same, thereby forming an acoustic output; a low pitch enhancing unit, a middle pitch enhancing unit and high pitch enhancing unit are further provided, and the graceful tone quality capable of covering the full frequency bands can be played through the processing of a power amplifier and a frequency divider; andthe sound-picture synchronization technology can be achieved through a specific algorithm and software processing. Through the scheme disclosed by the invention, the vibration amplitude of the screencan be controlled to be imperceptible by the human eye while the screen is vibrated to excite the sound production, thereby guaranteeing that the display picture cannot be interfered, and a laser projection optical sound screen system scheme capable of displaying excellent picture and playing the beautiful sound is formed, the problem that the traditional box type sound group is large in volume,inconvenient for use, and separated in picture display and sound is solved, and the audio visual experience demand of the user is satisfied.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

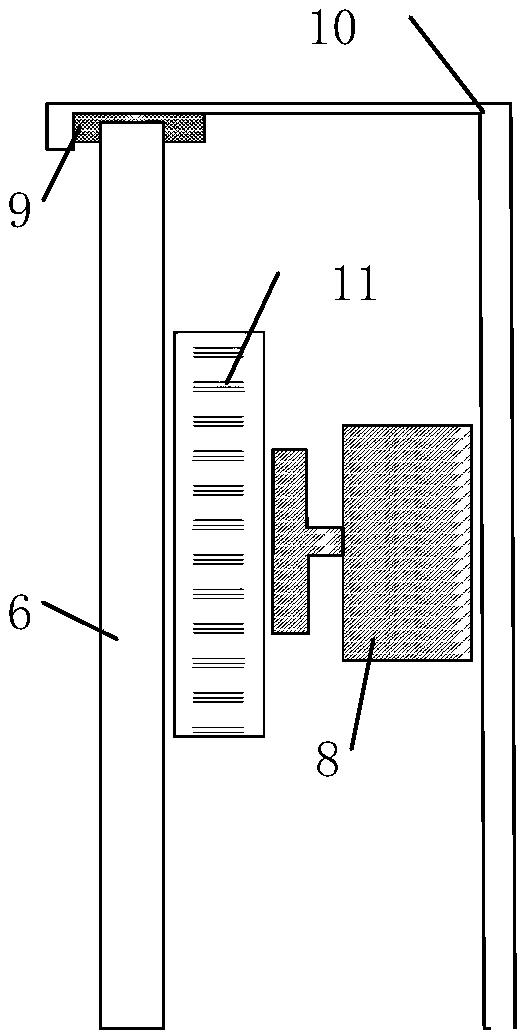

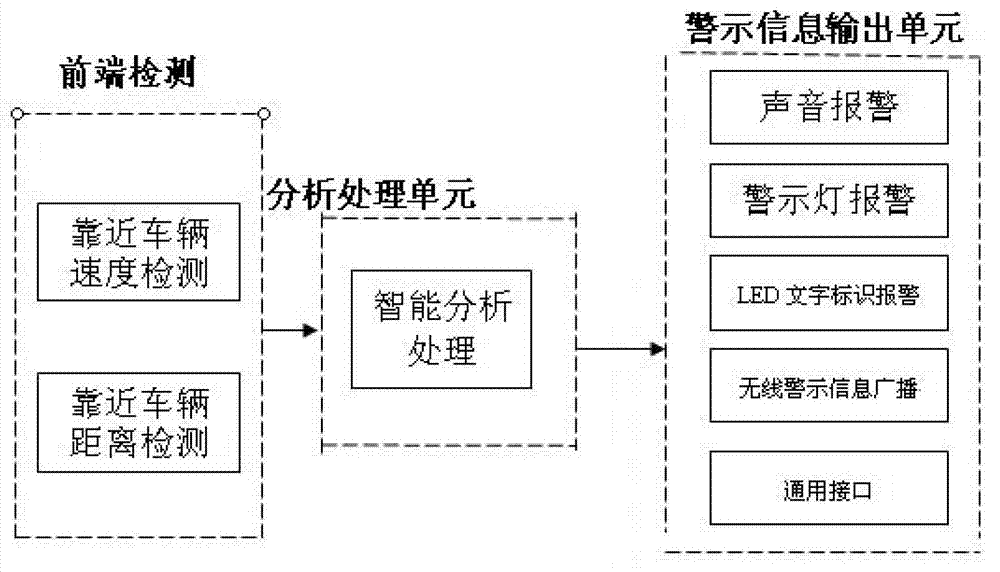

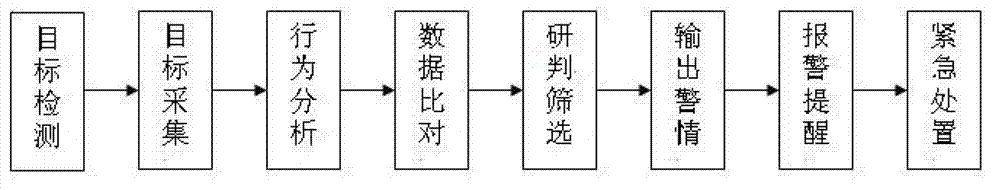

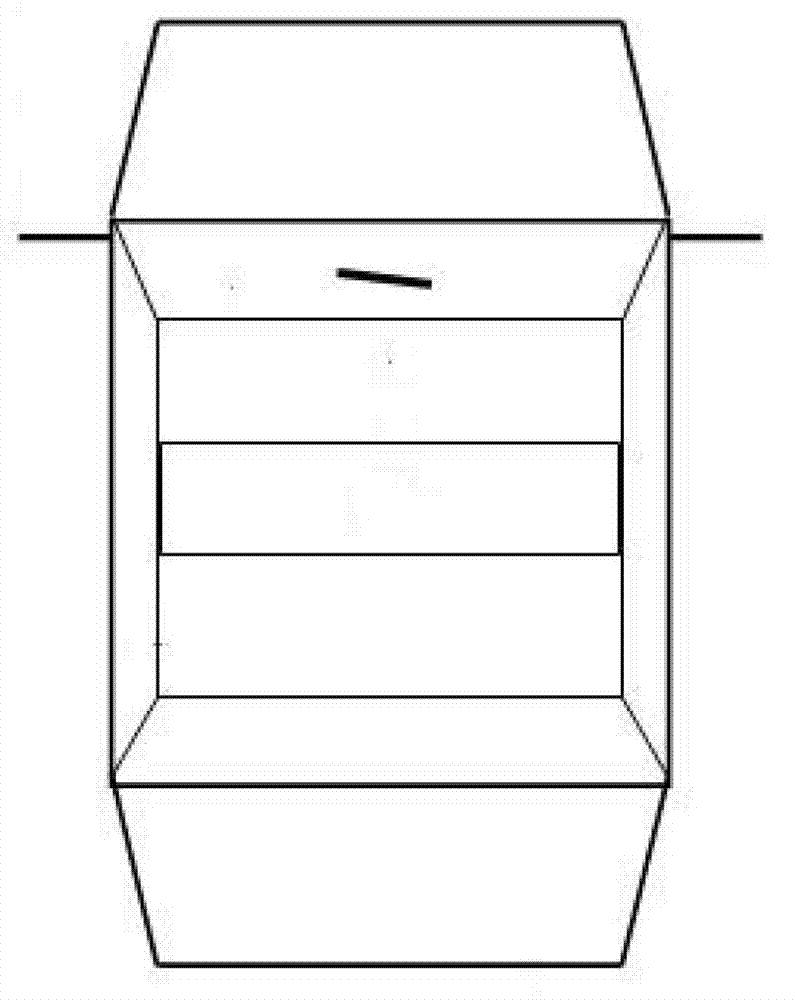

Early warning protection method for danger and intelligent early warning protector for dangerous events for road workers

InactiveCN103208166ATimely warning of dangerTimely danger warningAlarmsDistance detectionInteraction interface

The invention belongs to an intelligent early warning protector for dangerous events. The protector is formed by modular integration design of front detection apparatuses (a distance sensor, a speed sensor and the like), an analysis processing unit and a warning message output unit (a large-decibel high pitch warning horn, a high-lighting danger warning lamp and a light-emitting diode (LED) changeable message warning sign, a wireless signal emitter, a message general interaction interface and the like). By means of an early warning protection method for danger and the intelligent early warning protector for dangerous events for road workers, high-frequency distance detection sampling and speed detection sampling can be performed on a plurality of vehicles in a detection range in vehicle coming directions; approaching objects or persons around sentries are detected in real time, and by means of functions of intelligent analysis, automatic screening and warning to vehicles in the coming directions and events approaching the sentries, the output unit can send warning messages or signals to protected persons by employing different methods according to pre-settings of the protector when the protector detects that dangerous events approach. Time is gained for road work and sentry danger processing, the reaction and processing time is increased, traffic accidents and criminal cases are reduced, and positive significances are provided for guaranteeing lives and properties of people.

Owner:宝鸡市公安局交通警察支队

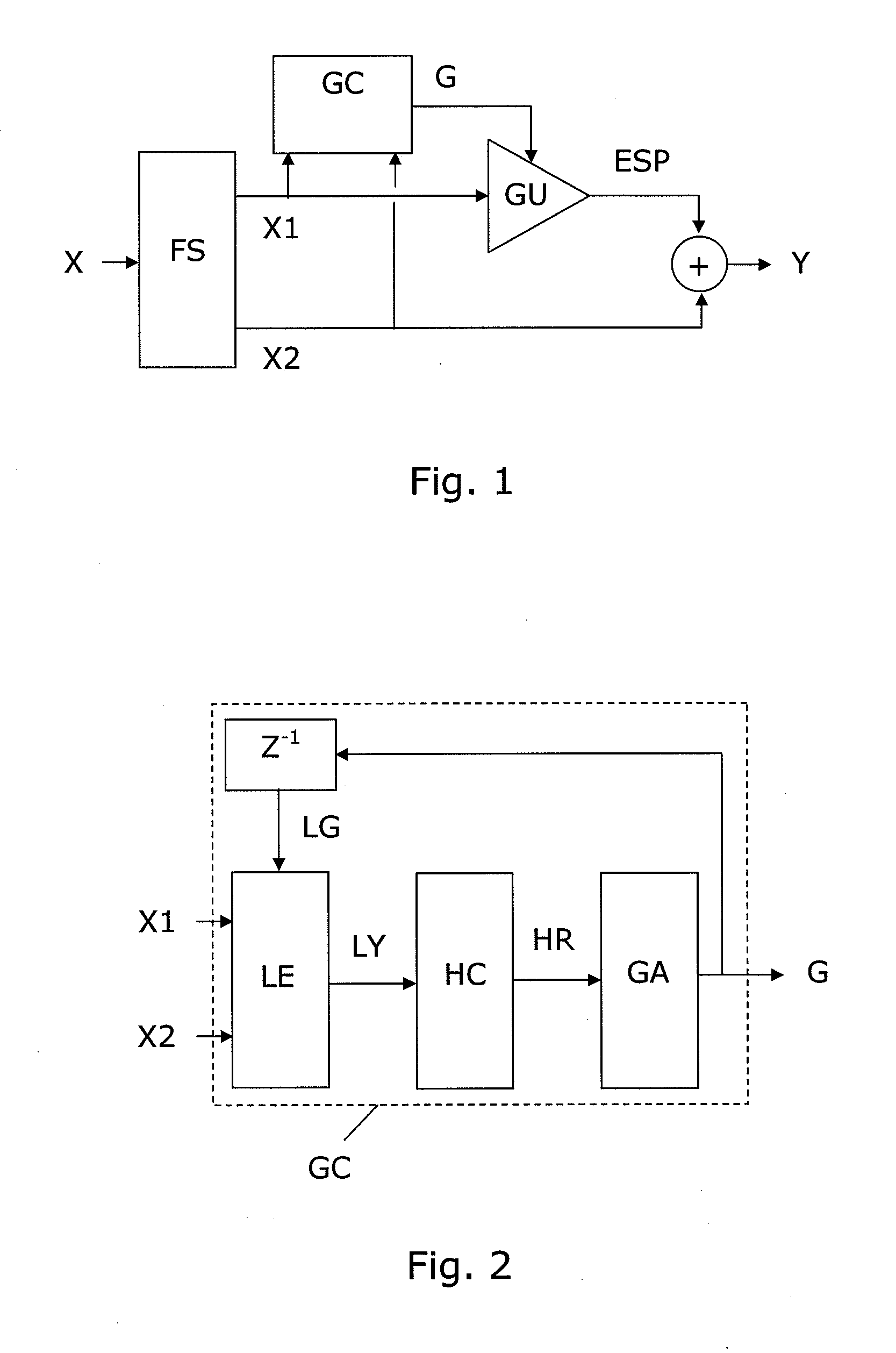

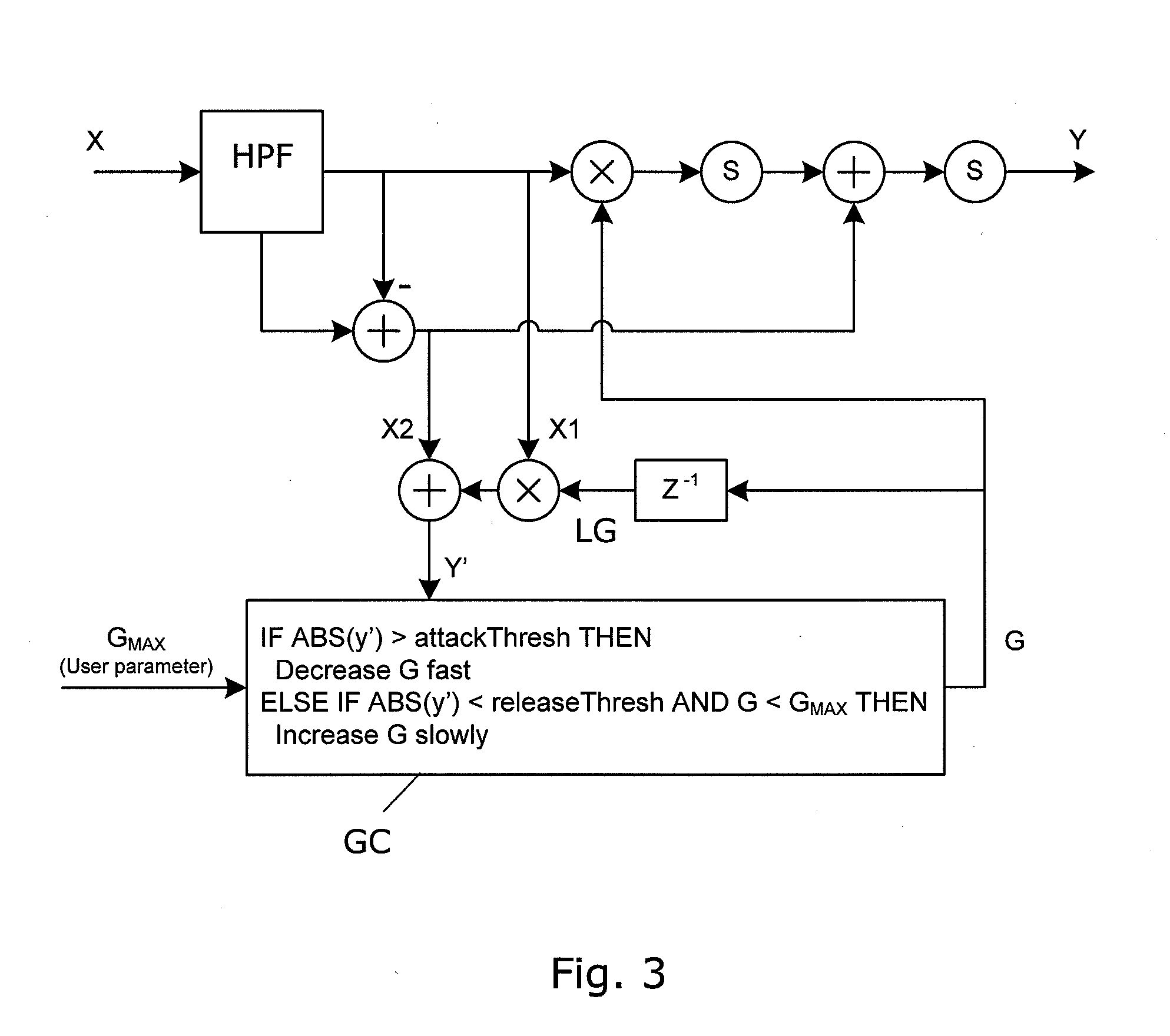

Dynamic enhancement of audio signals

InactiveUS20110002467A1Limited dynamic capabilitySeverely sound qualityDigital/coded signal combination controlTransducer casings/cabinets/supportsFrequency spectrumComputer science

An audio processor for generating an audio output signal (Y) with an enhanced spectral component compared to an audio input signal (X). The processor comprises a frequency splitter (FS) for splitting the input (X) into first and second parts (X1, X2) representing different frequency bands. A gain calculator (GC) estimates a level (LY) of the enhanced audio output signal (Y) for a case where the first signal part (X1) is gained by a previous enhancement gain value (LG). A dynamic headroom (HR) available is calculated based on the estimated level (LY). An enhancement gain (G) is then calculated based on the available dynamic headroom (HR), and this enhancement gain G is applied to the first signal part (X1), and finally the enhanced output signal (Y) is generate by combining the enhanced signal part (ESP) and the second signal part (X2). Preferably, the enhancement gain G calculation is updated for each signal sample, thus allowing fast adjustments of the gain G to avoid clipping distortion. The audio processor is suited to provide bass and / or treble enhancement and it provides a high utilization of the dynamic range available without audible artefacts. Still, the algorithm is simple to implement and is thus suited for enhancing audio performance of compact low cost devices.

Owner:AM3D

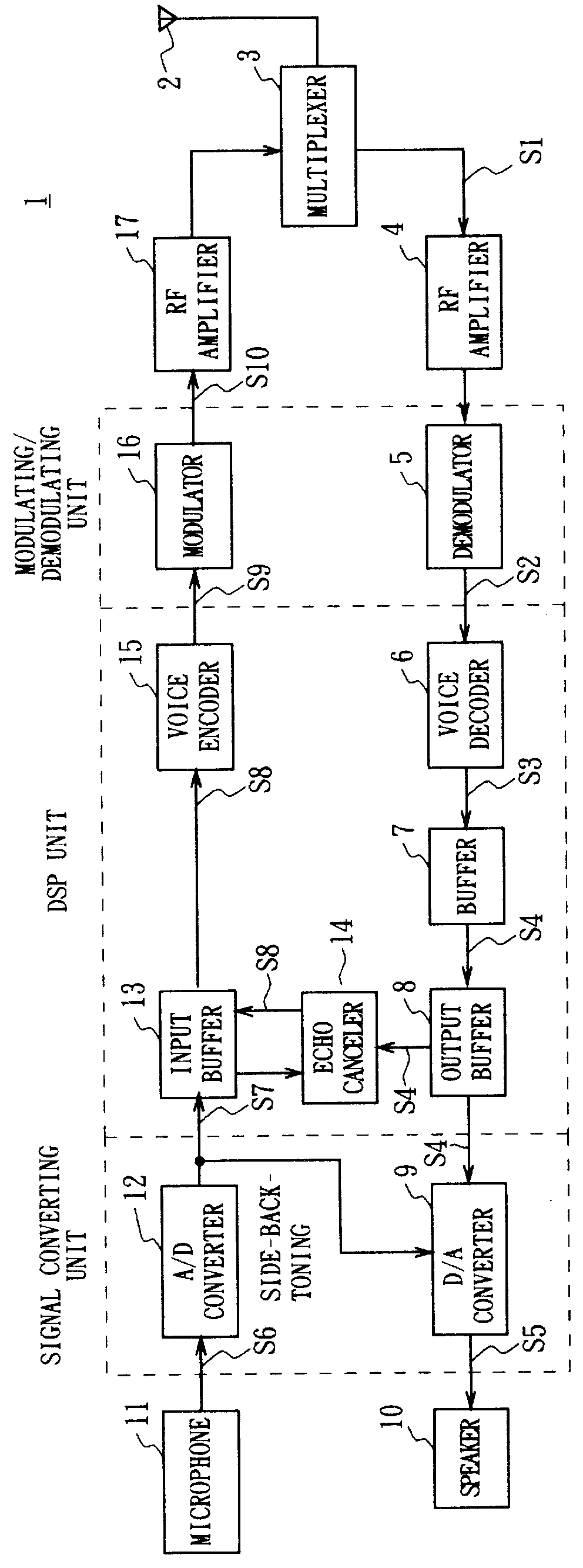

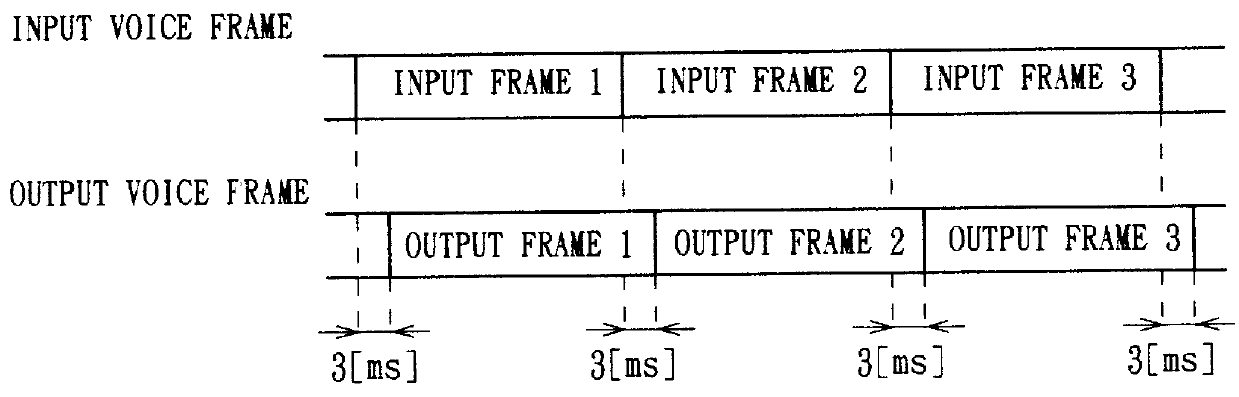

Telephone system and voice encoding/decoding method

InactiveUS6085072ATwo-way loud-speaking telephone systemsSubstation speech amplifiersDecoding methodsFrame based

A telephone system and a voice encoding / decoding method capable of reducing the consumed power by reducing the memory capacity of buffer and generating high-tone-quality voice. The system writes an input voice frame to an input buffer and eliminates the delayed disturbance in a voice signal from the input voice frame based on the output voice frame to execute echo-canceling, and decodes the received voice packet data, so that the boundary of input voice frames can be set before the boundary of output voice frames, at least, for the time necessary for the echo-canceling and decoding. Thereby, the output voice frame can always be written at the same time as the input voice frame written to the input buffer and the delayed disturbance in the voice signal can be eliminated from the input voice frame based on the output voice frame and, thus the high-tone-quality voice can be generated.

Owner:SONY CORP

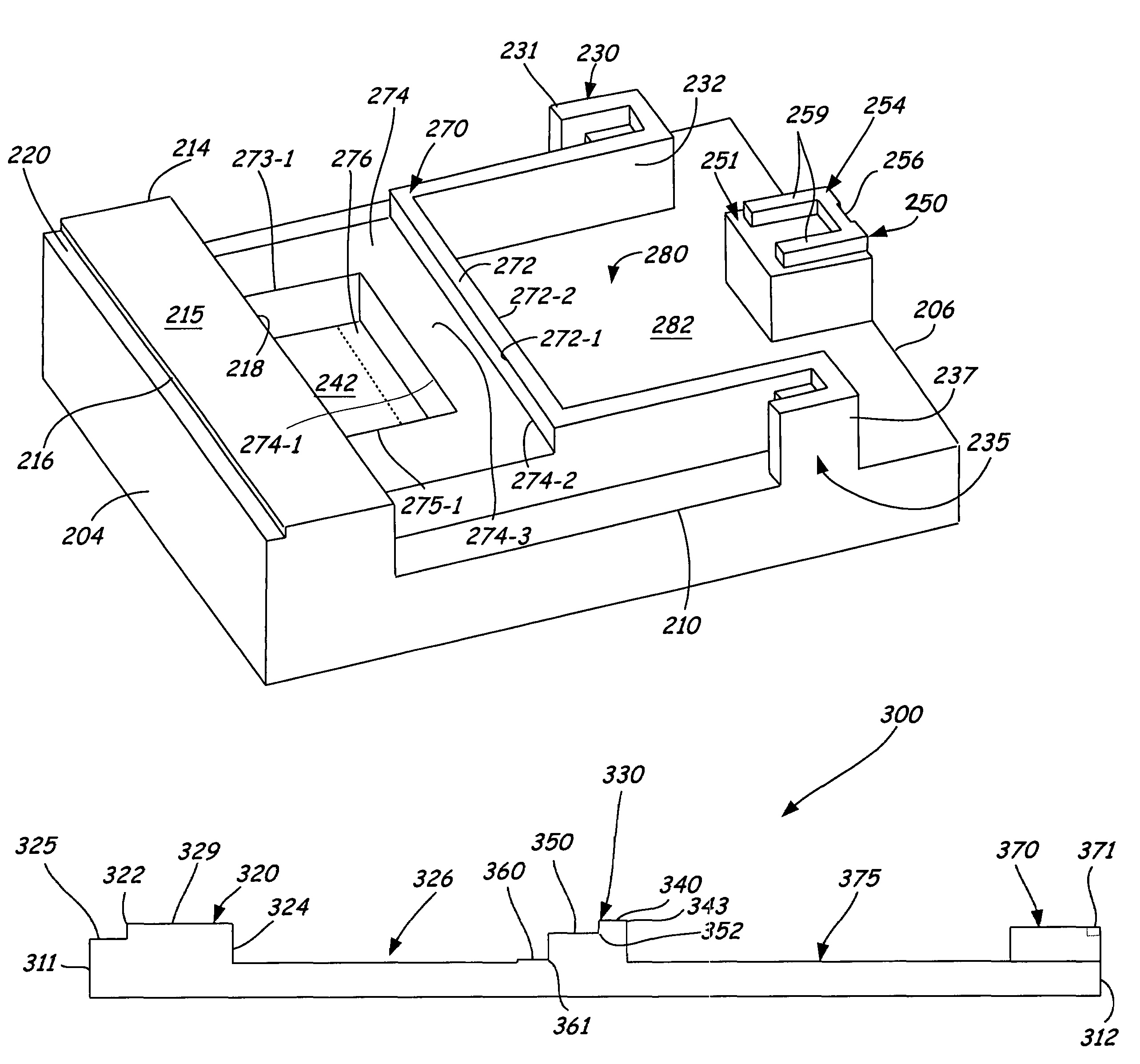

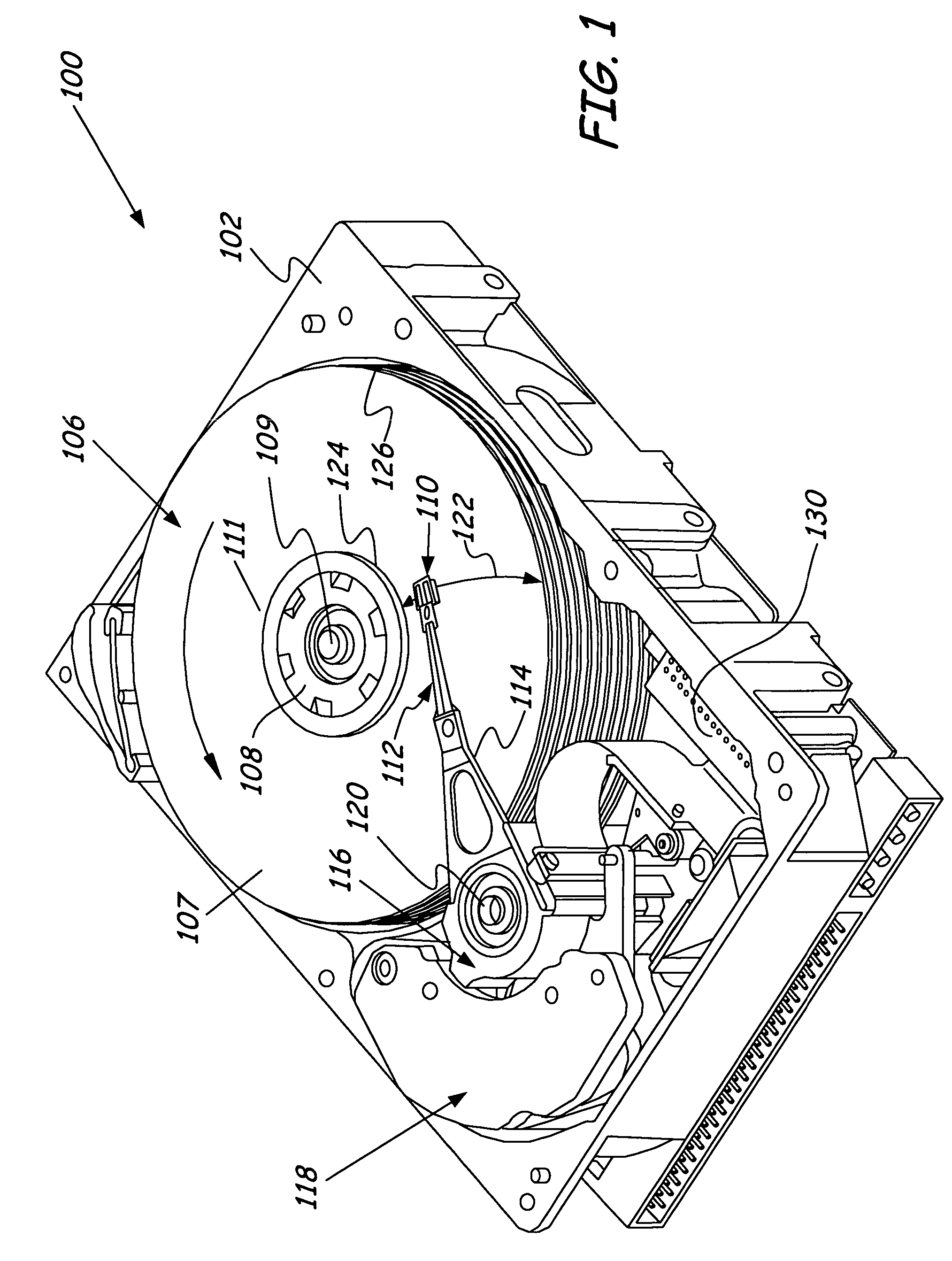

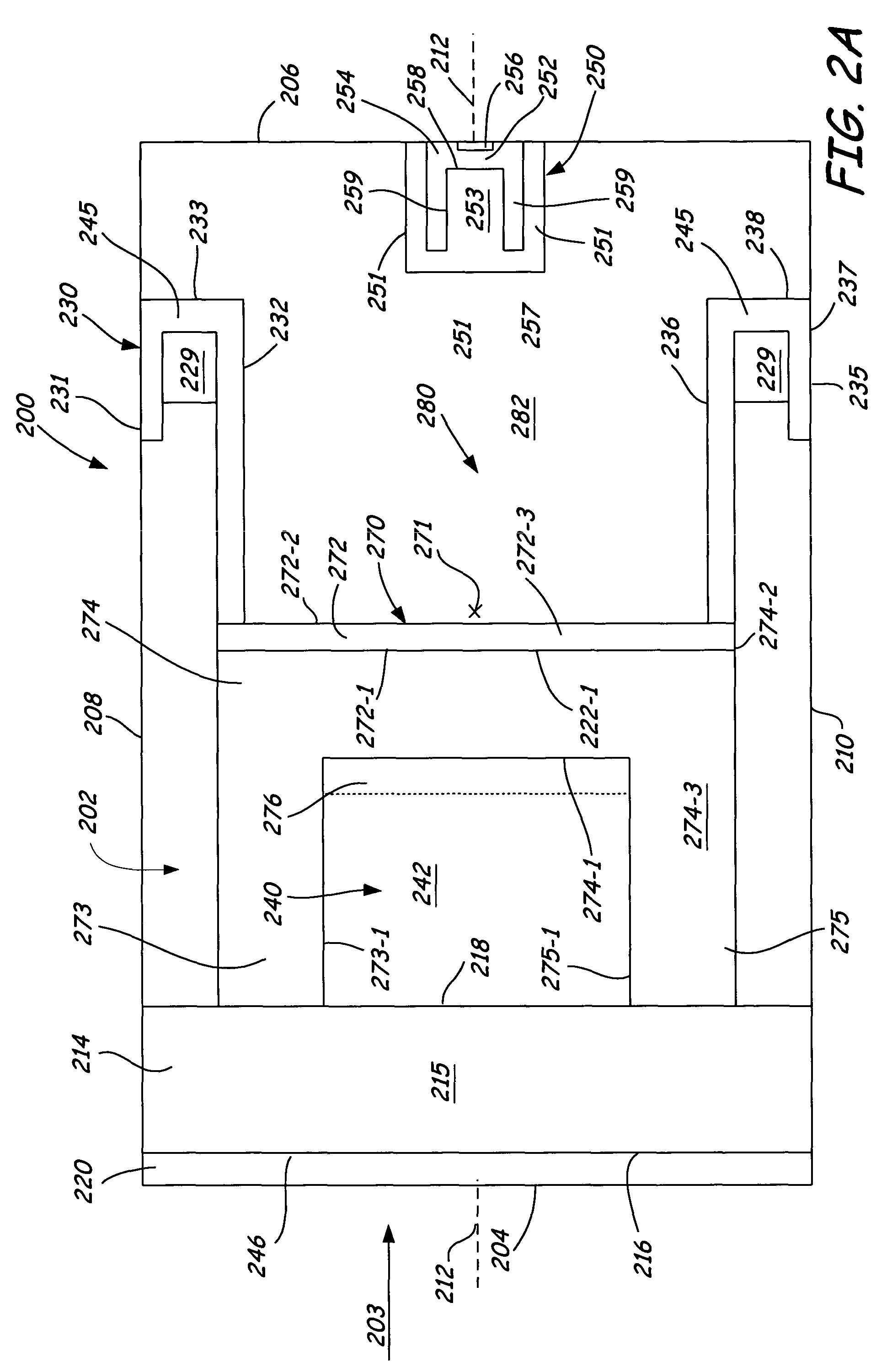

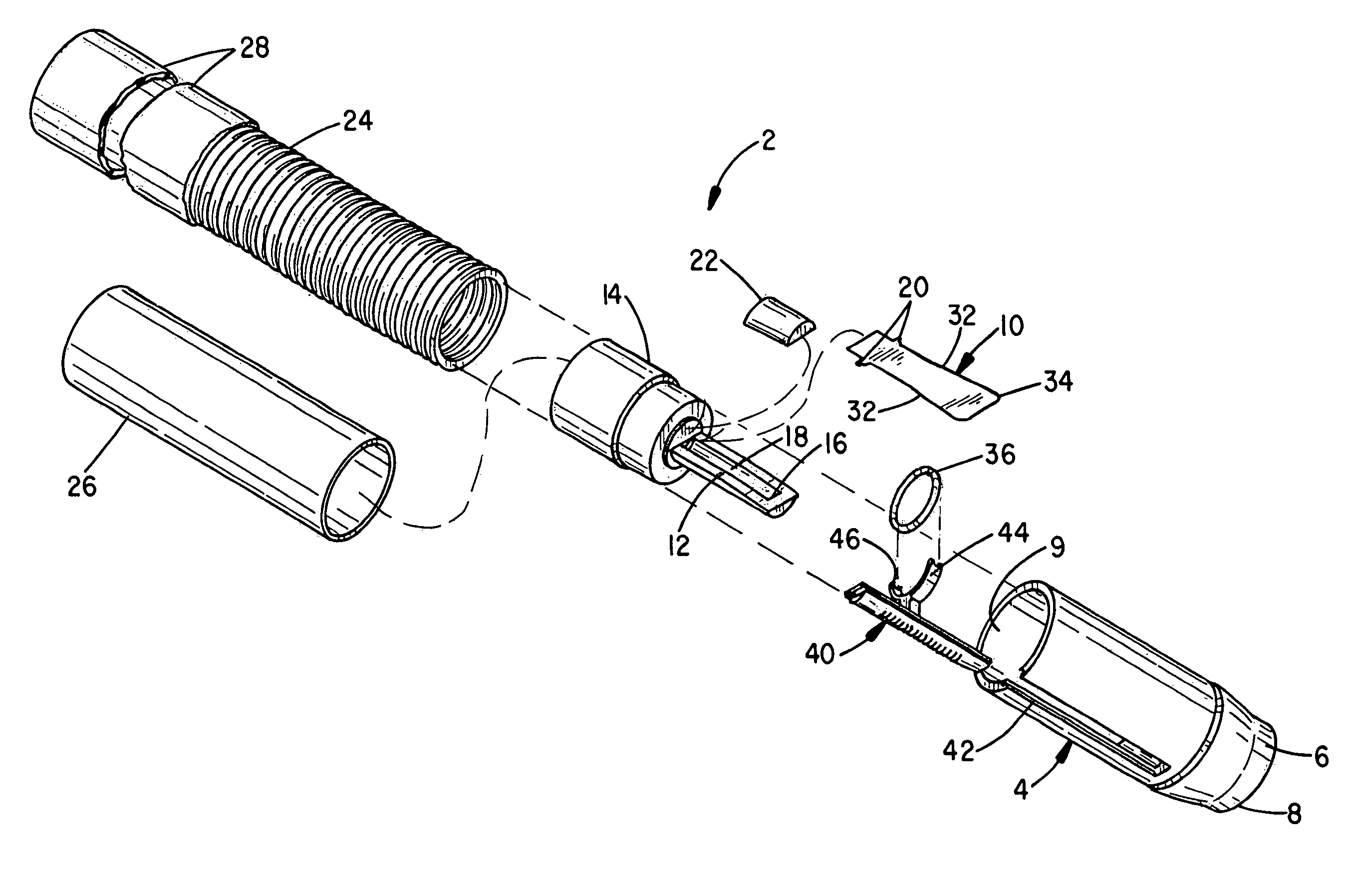

Center split feature and pressurization for altitude insensitivity, high pitch torque and high preload sensitivity air bearing slider

InactiveUS7245455B2Change effectChange pressureFluid-dynamic spacing of headsRecord information storageThree levelAir bearing

The present invention is directed to a bearing surface on a slider having a center split pressurization feature which minimizes the effects of altitude or change in ambient air pressure on the flying characteristics of the slider. After a cavity dam and a subambient pressurization cavity is the center split feature. The center split feature is located proximate the centroid of the slider body and the bearing surface. The center split feature has, at least, three levels including a first center split level a second center split level and a third center split level. The first center split level is at the same level as the bearing surface level and is located closest to the centroid. The second center split level is located forward of, in the direction of air flow, the first center split level. The second center split level is also recessed from the first center split level to the same level as the first recessed level. The third center split level is located forward of the second center split level and is recessed from the second center split level.

Owner:SEAGATE TECH LLC

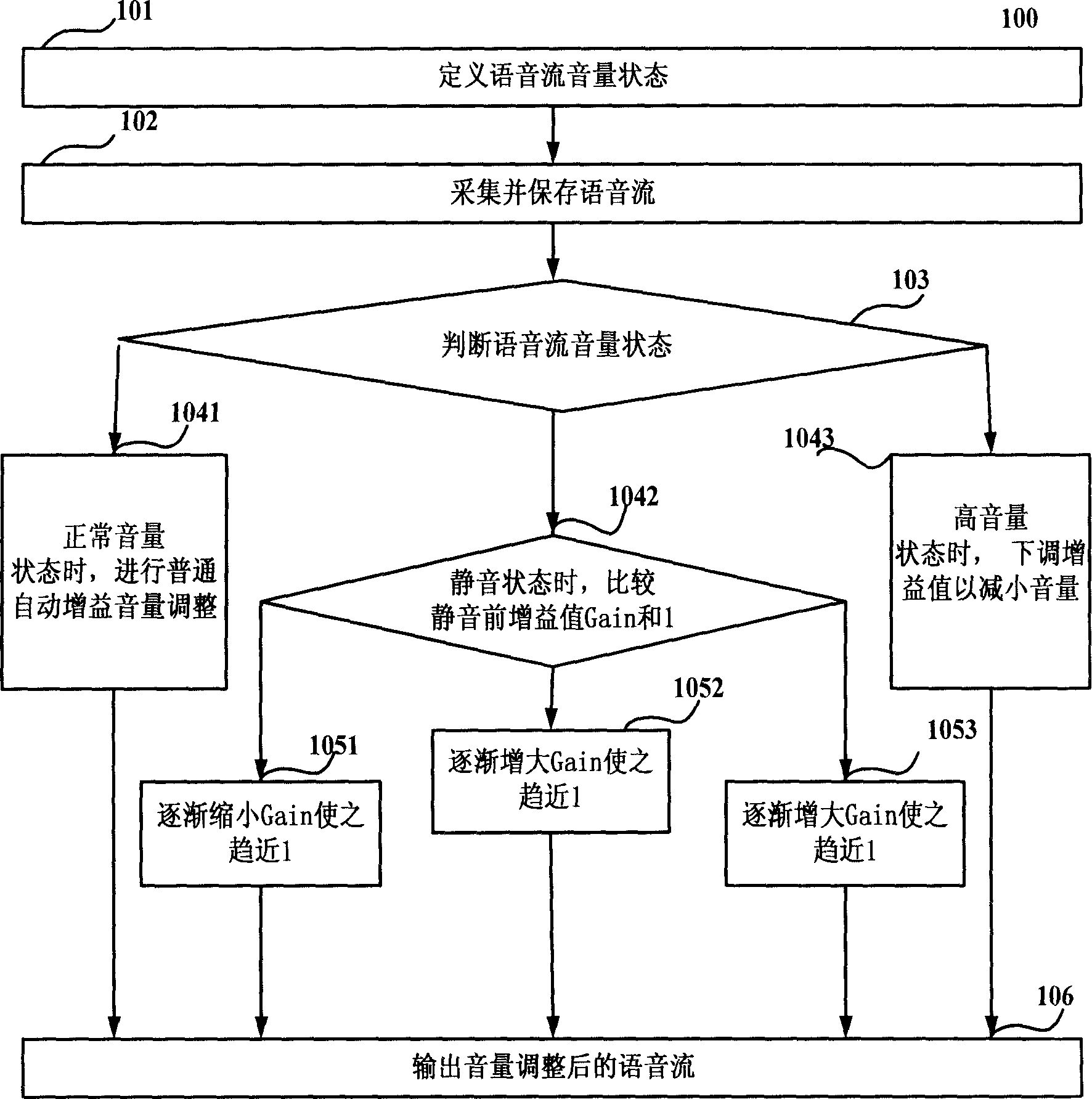

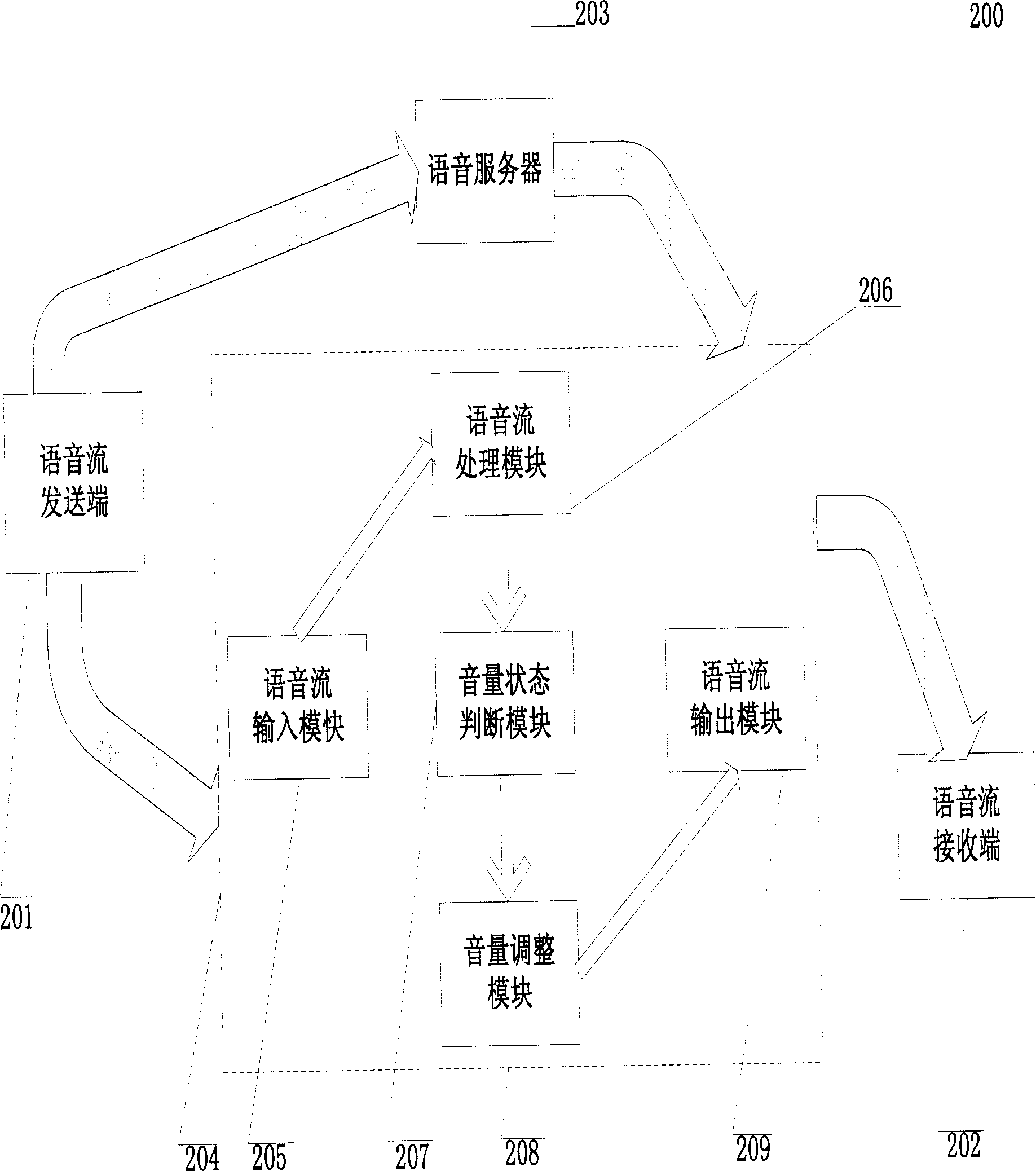

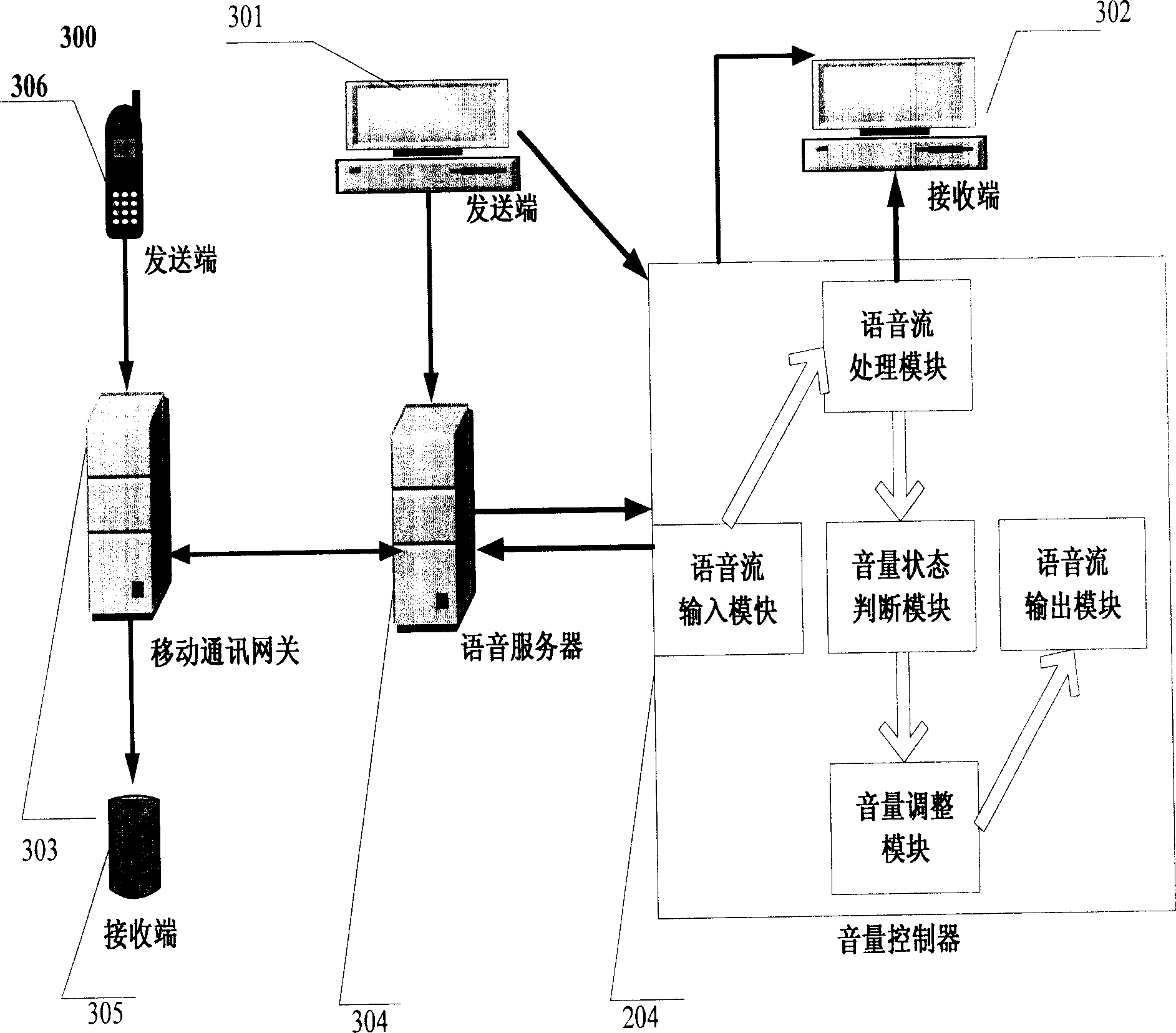

Volume control method and system

ActiveCN1885711AImplement volume limitAchieve multi-channel balanceTwo-way loud-speaking telephone systemsTelevision conference systemsVocal tractHigh-pitched

The disclosed auto gain volume control method for communication comprises: pre-defining voice flow state to decide in transmission for AGC and smooth transition from high pitch to silence. This invention overcomes defects of volume and voice discontinuity, and fit for video conference.

Owner:TENCENT TECH (SHENZHEN) CO LTD

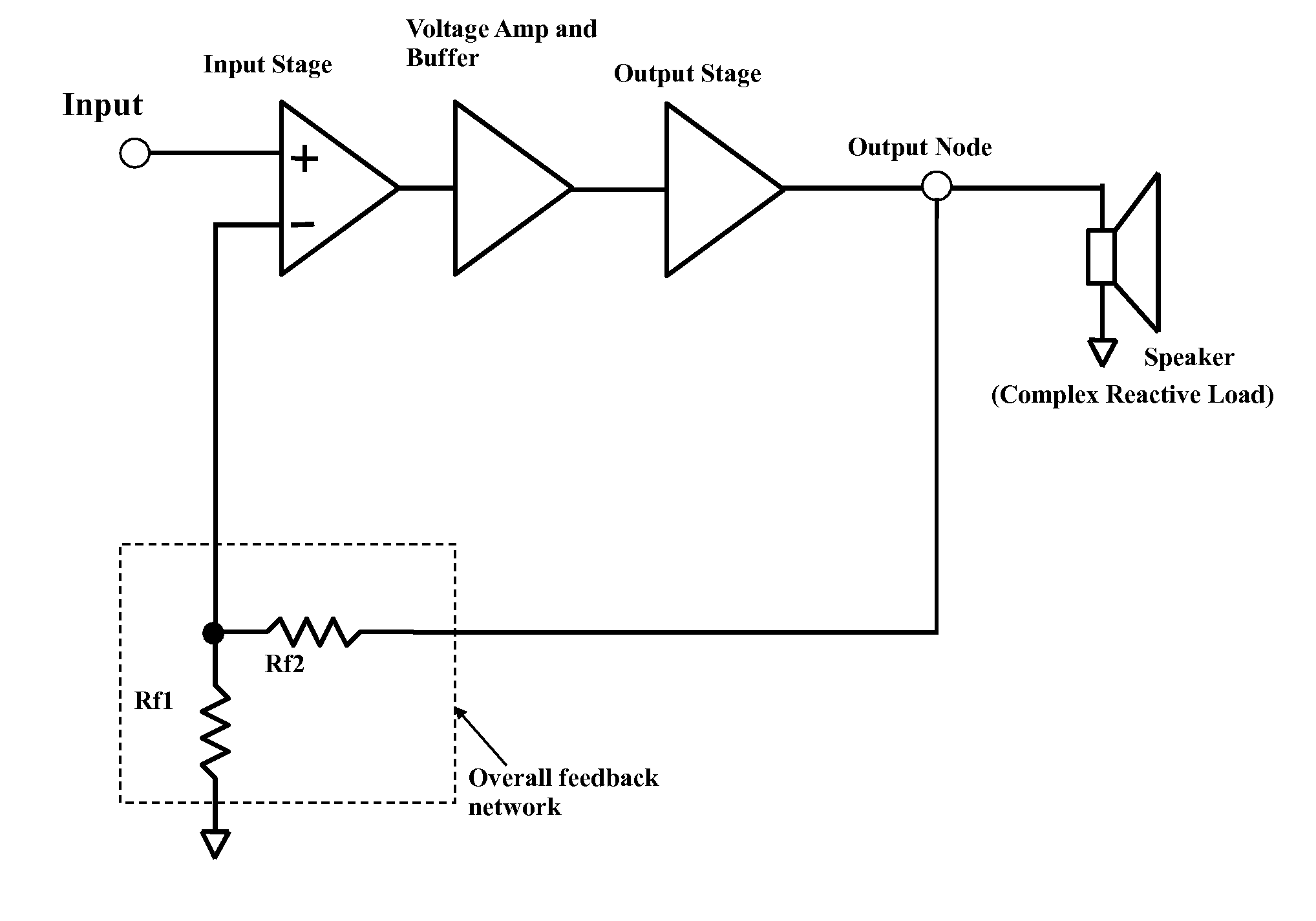

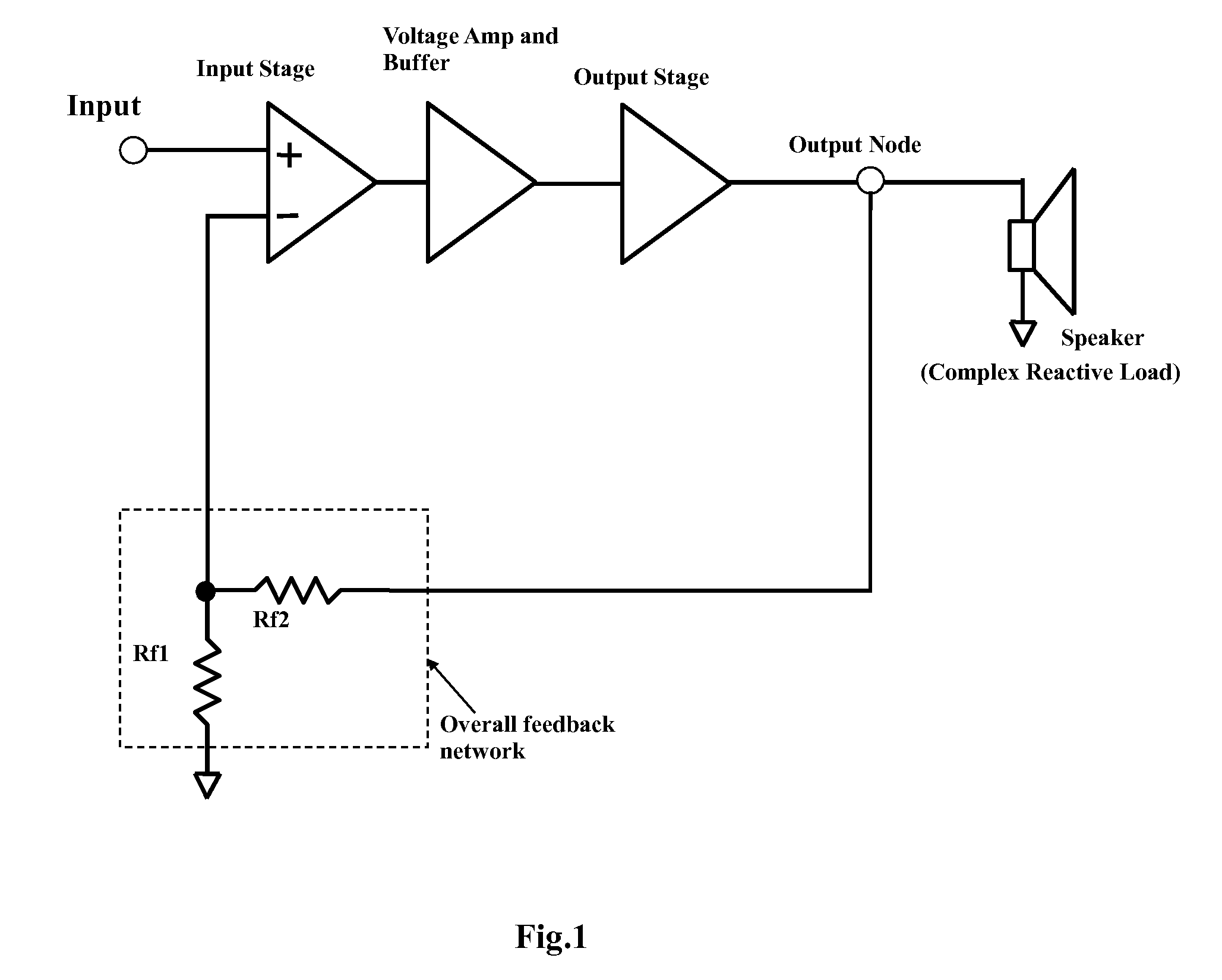

Audio Power Amplifier with Feedback-Shifting Technology

InactiveUS20090245541A1Low costImprove performanceNegative-feedback-circuit arrangementsLow frequency amplifiersAudio power amplifierIntermediate frequency

A solid stage audio power amplifier comprises of two output stages with one generating the real output signal that drives the real loud speaker load and the other mimicking the real output stage and generating a dummy output signal that drives a dummy resistor load. A frequency dependent feedback selection network, denoted as Feedback-Shifting network hereafter, is implemented between the two outputs and the input of the amplifier to fulfill a unique global feedback loop. In a particular embodiment, the Feedback-Shifting network can be constructed so that it receives more feedback information from the real output node than from the dummy output node at low frequencies, but less feedback information from the real output node than from the dummy output node at mid to high frequency bands. Such a power amplifier performs as a traditional solid state feedback amplifier at low frequencies by generating a clear and tight bass, but it sounds similar to an open loop tube amplifier at higher frequencies by reproducing natural mid-band and treble with less listening fatigue.

Owner:WANG ZHENWU

Rear projector and producing method thereof

InactiveUS6851810B2Display imageHigh quality imagingTelevision system detailsBuilt-on/built-in screen projectorsEngineeringWoofer

Owner:SEIKO EPSON CORP

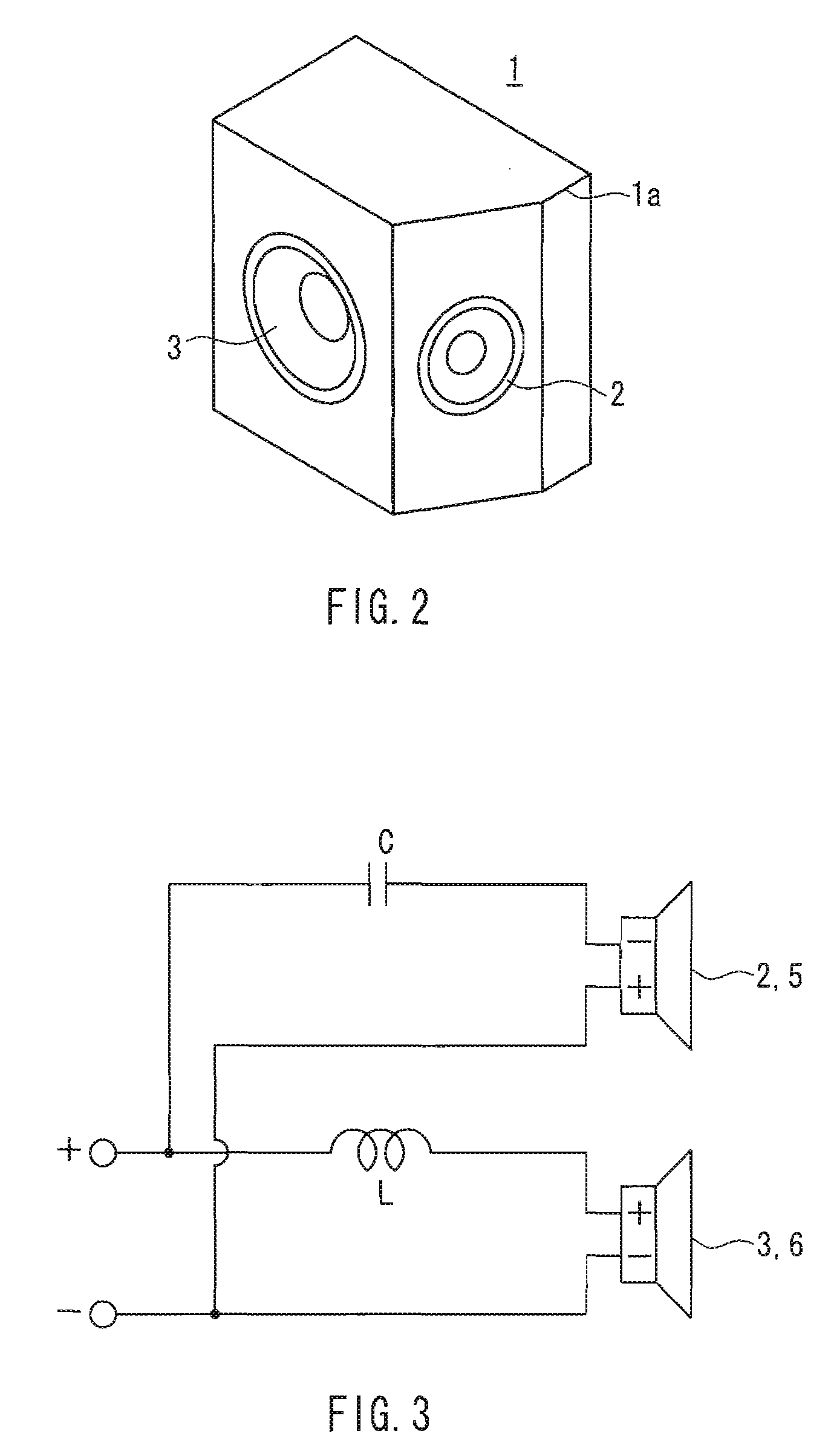

Speaker device

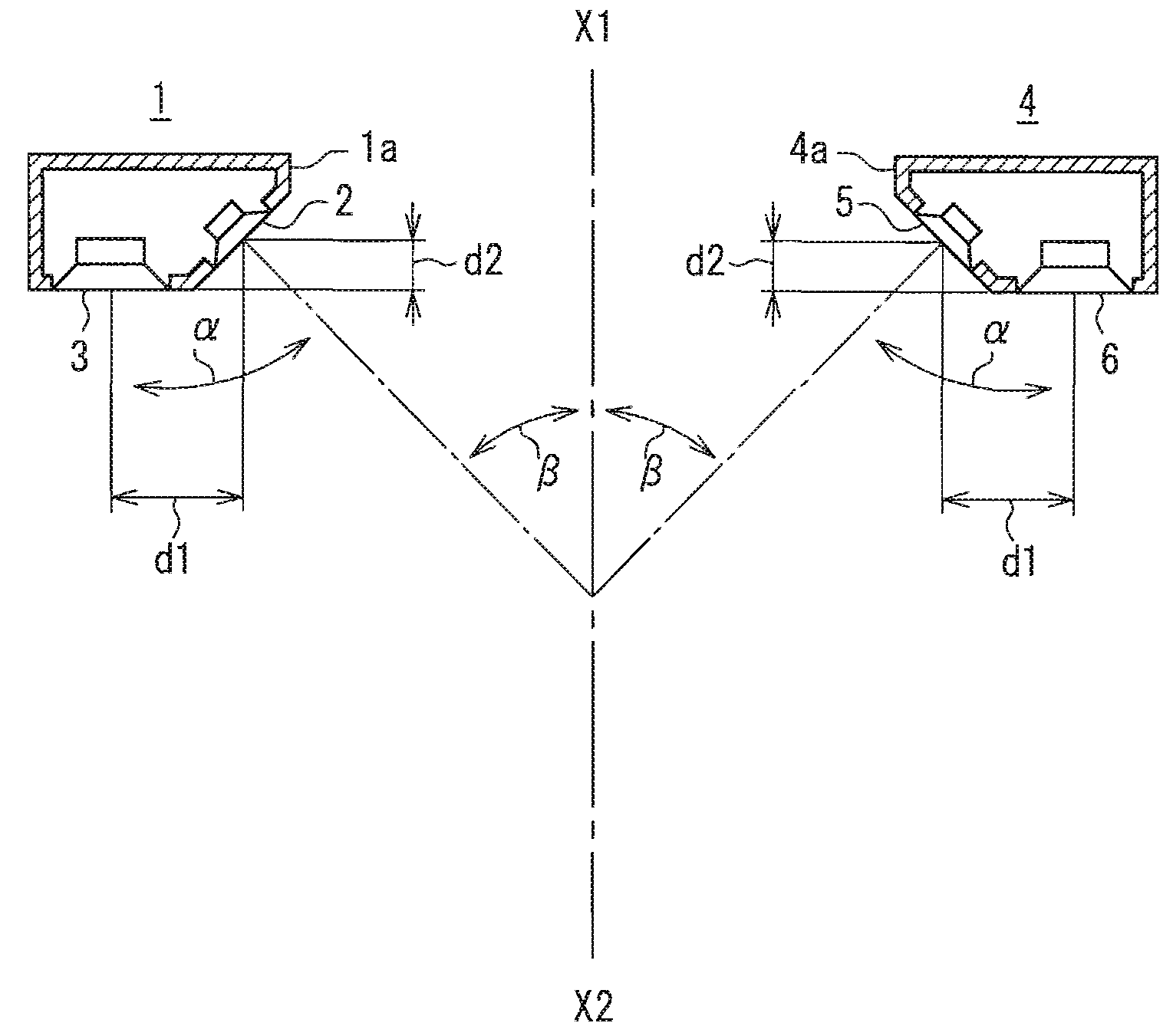

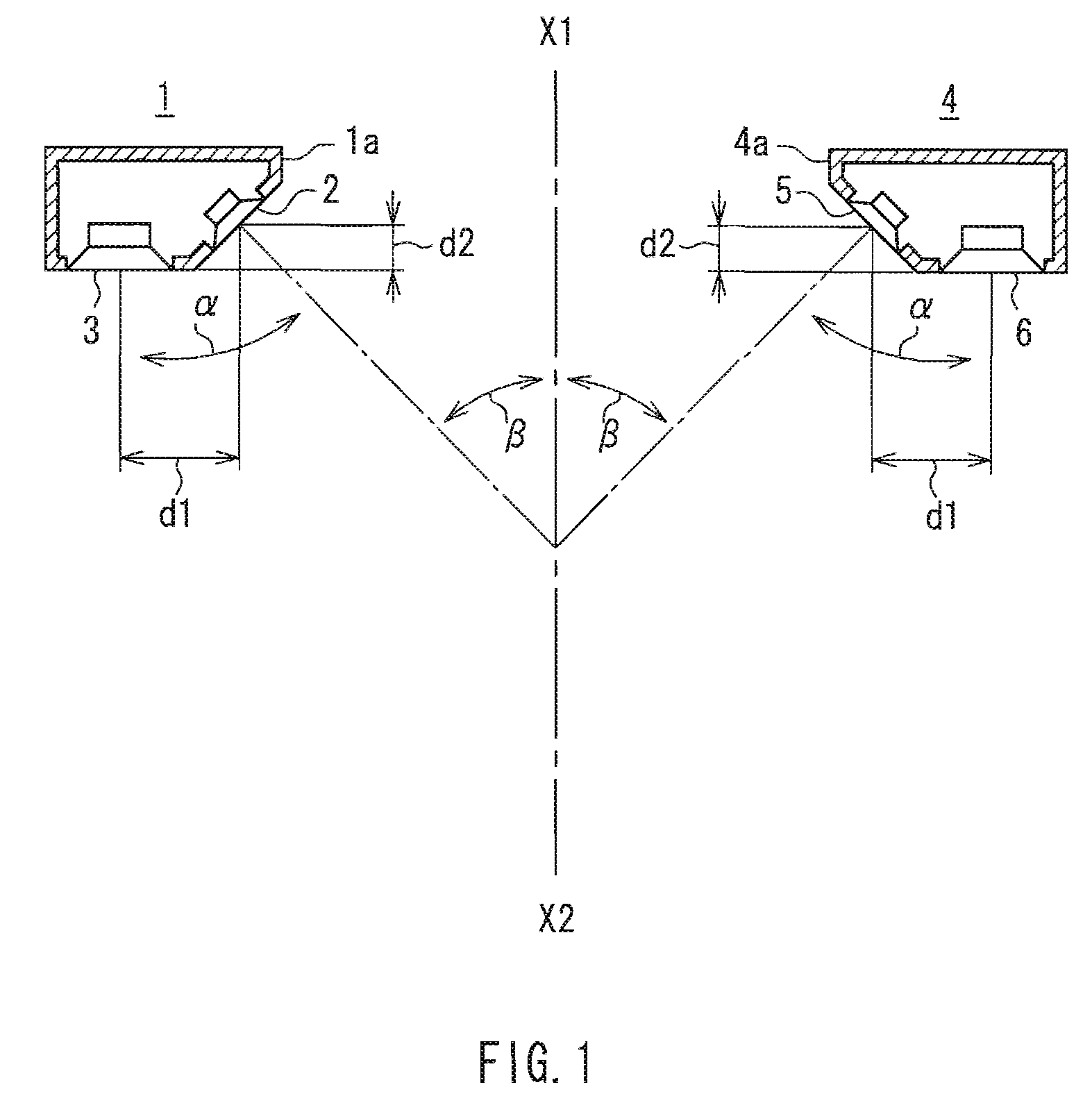

InactiveUS20090279721A1Good effectReduce sound pressureLoudspeaker spatial/constructional arrangementsTransducer casings/cabinets/supportsSound imagePhase difference

A speaker device includes first speaker units 2 and 5 and second speaker units 3 and 6 that are arranged symmetrically as viewed from a listening center axis X1-X2. The first speaker units 2 and 5 emit sounds in inward directions and reproduces at least the mid-range and above, and the second speaker units 3 and 6 emit sounds in a front direction and attenuates the treble range. With respect to a listening position in a front direction of one of the speaker systems 1 and 4, a sound arriving to the listening position from the first speaker unit of the speaker system located closer to the listening position, and a sound arriving thereto from the second speaker unit of the same speaker system, are destructive to each other in the mid-range due to a phase difference, whereby a sound pressure in the mid-range arriving from the speaker system located closer to the listening position is attenuated more, as compared with a sound pressure in the mid-range arriving from the speaker system located farther from the listening position. It is possible to achieve an excellent effect of expanding a listening position range for obtaining the center sound image localization, the natural sound quality without sense of discomfort, the large sound pressure reproduction, and the downsizing.

Owner:PANASONIC CORP

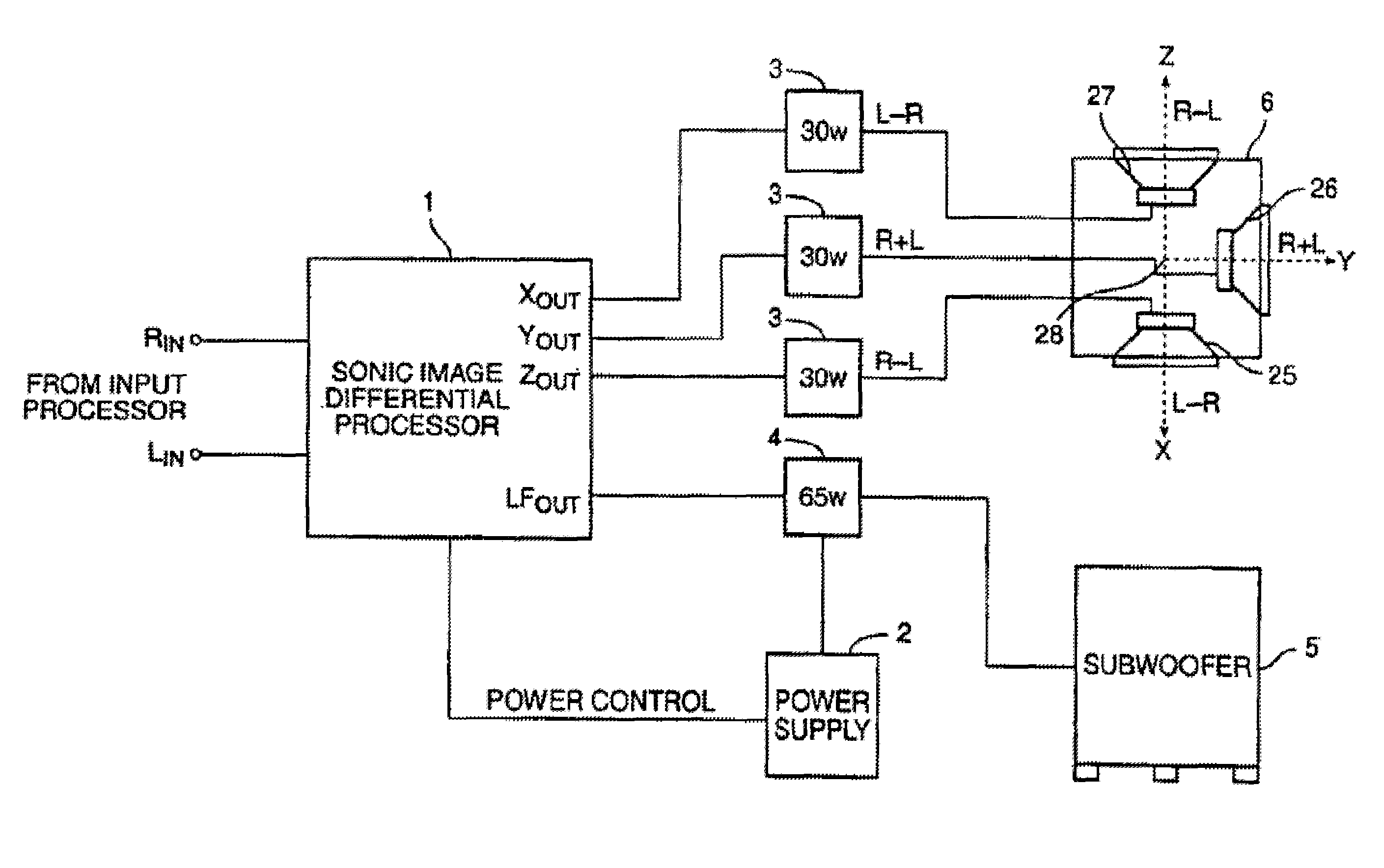

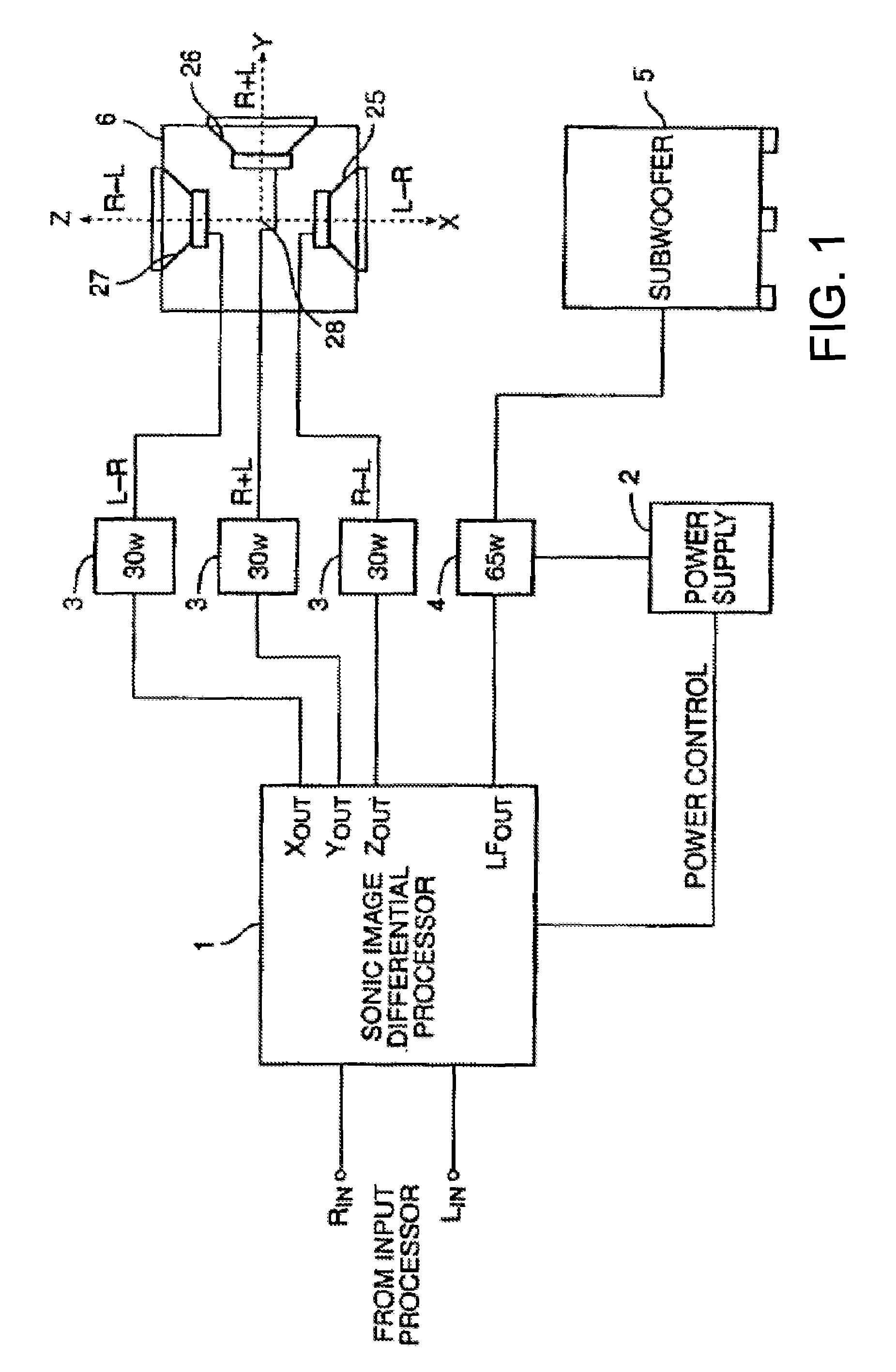

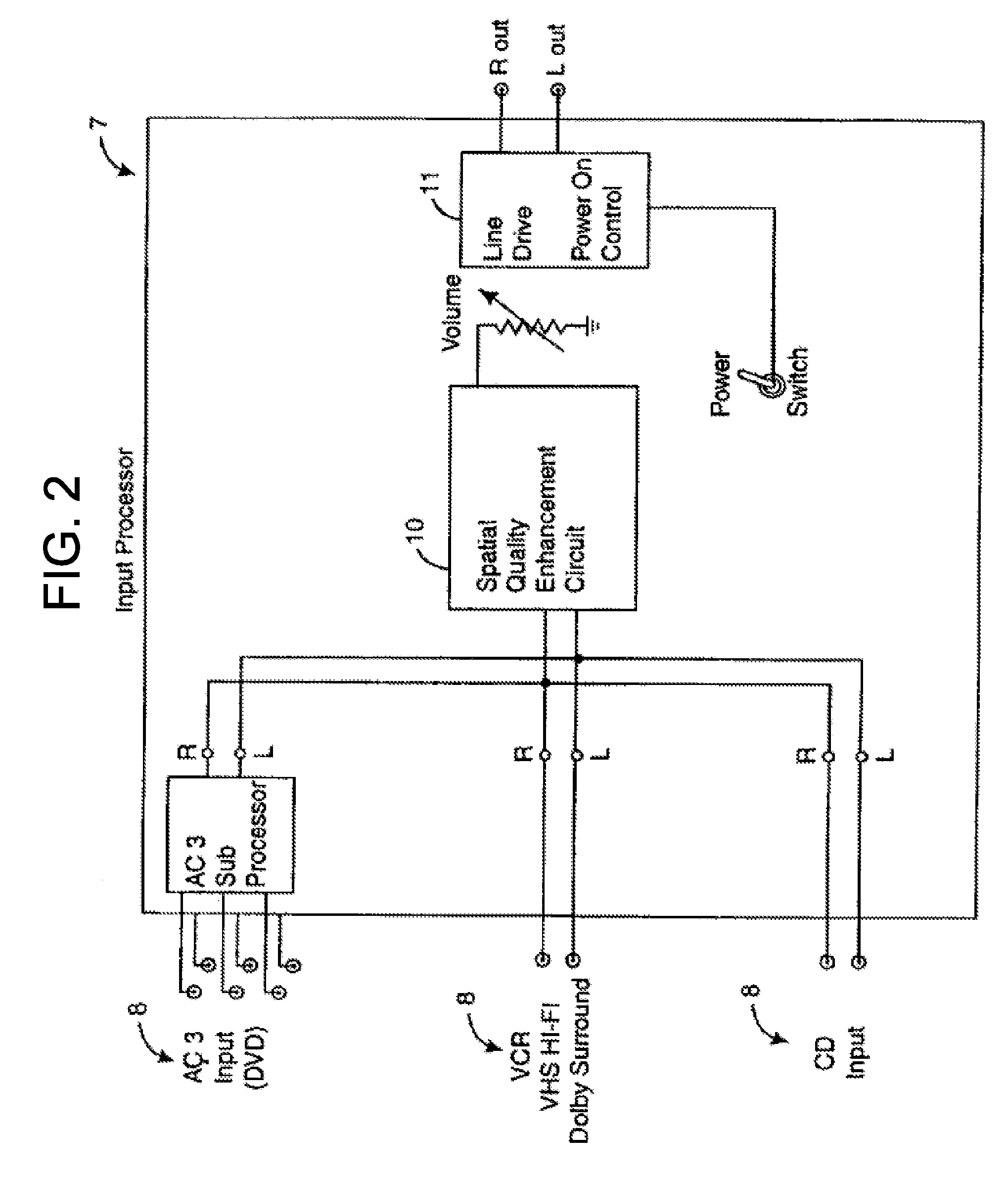

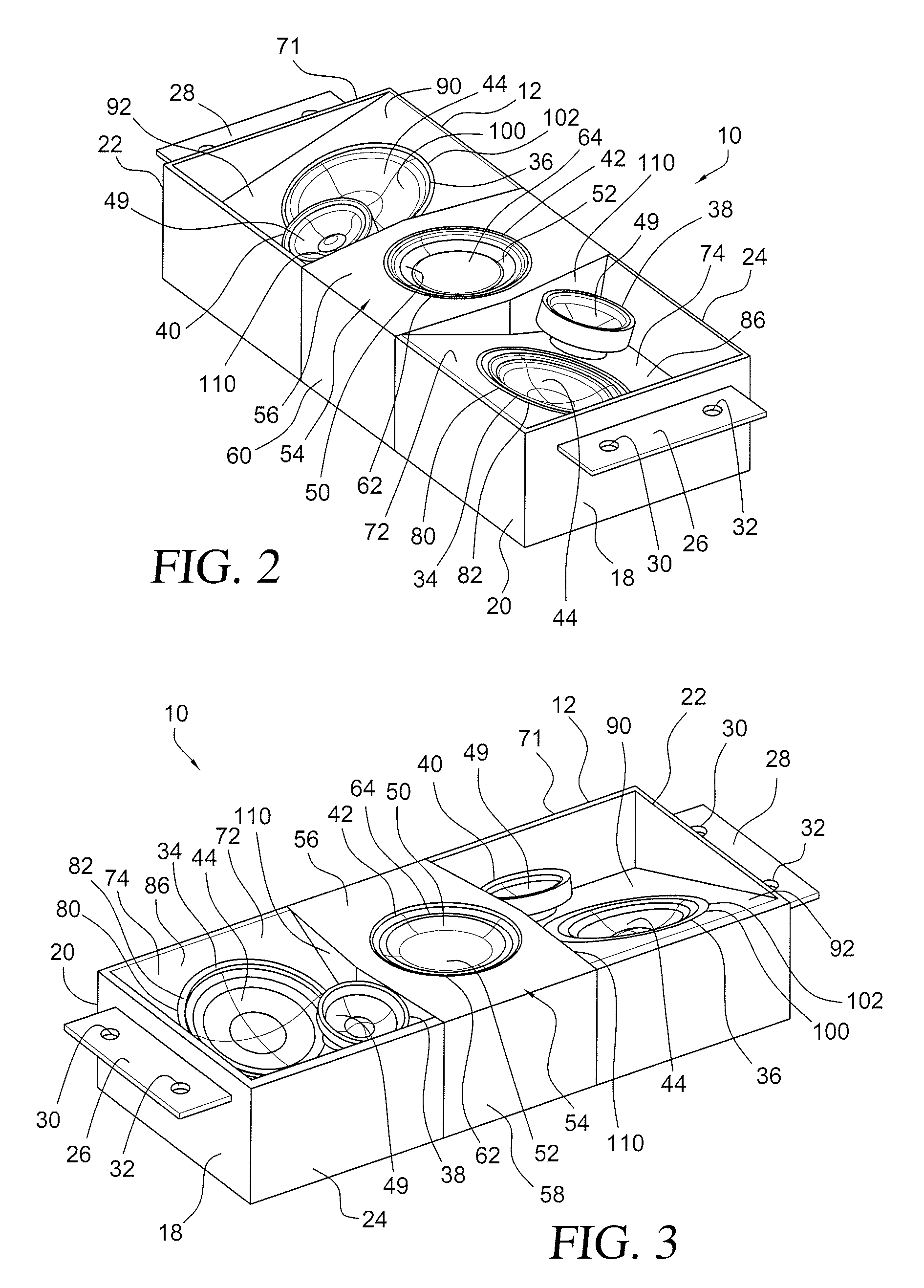

Point source speaker systems

InactiveUS20080285762A1Removal costEliminate spaceDocking-station type assembliesTransducers for sound channels pluralitySound waveEngineering

Point source speaker systems are provided. The point source speaker system receives audio input from a device. The system comprises a mountable enclosure, which contains a speaker array. The array includes a substantially forward facing left speaker, a substantially forward facing center speaker, a substantially forward facing right speaker and a horizontally mounted woofer speaker. A woofer tunnel is located behind the left, center and right speakers. The woofer tunnel accelerates woofer sound waves and terminuses at a woofer baffle which leads to a woofer port. The left speaker, center speaker and right speaker may include more than one speaker. One or more of these left speakers and right speakers may be a tweeter. The left speakers receive a left minus right input, the center speakers receive a right plus left input, and the right speakers receive right minus left input.

Owner:KENTECH LABS

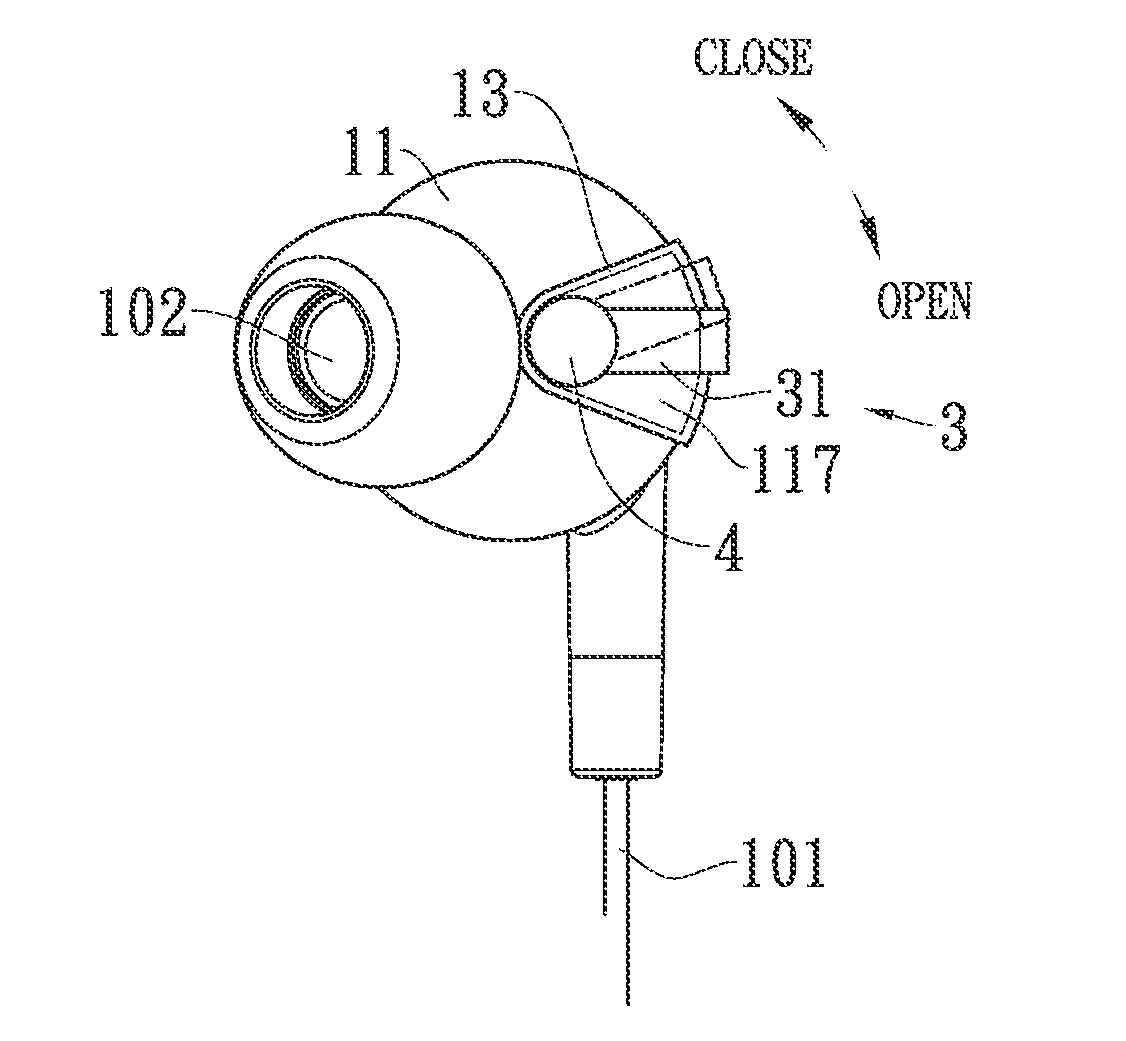

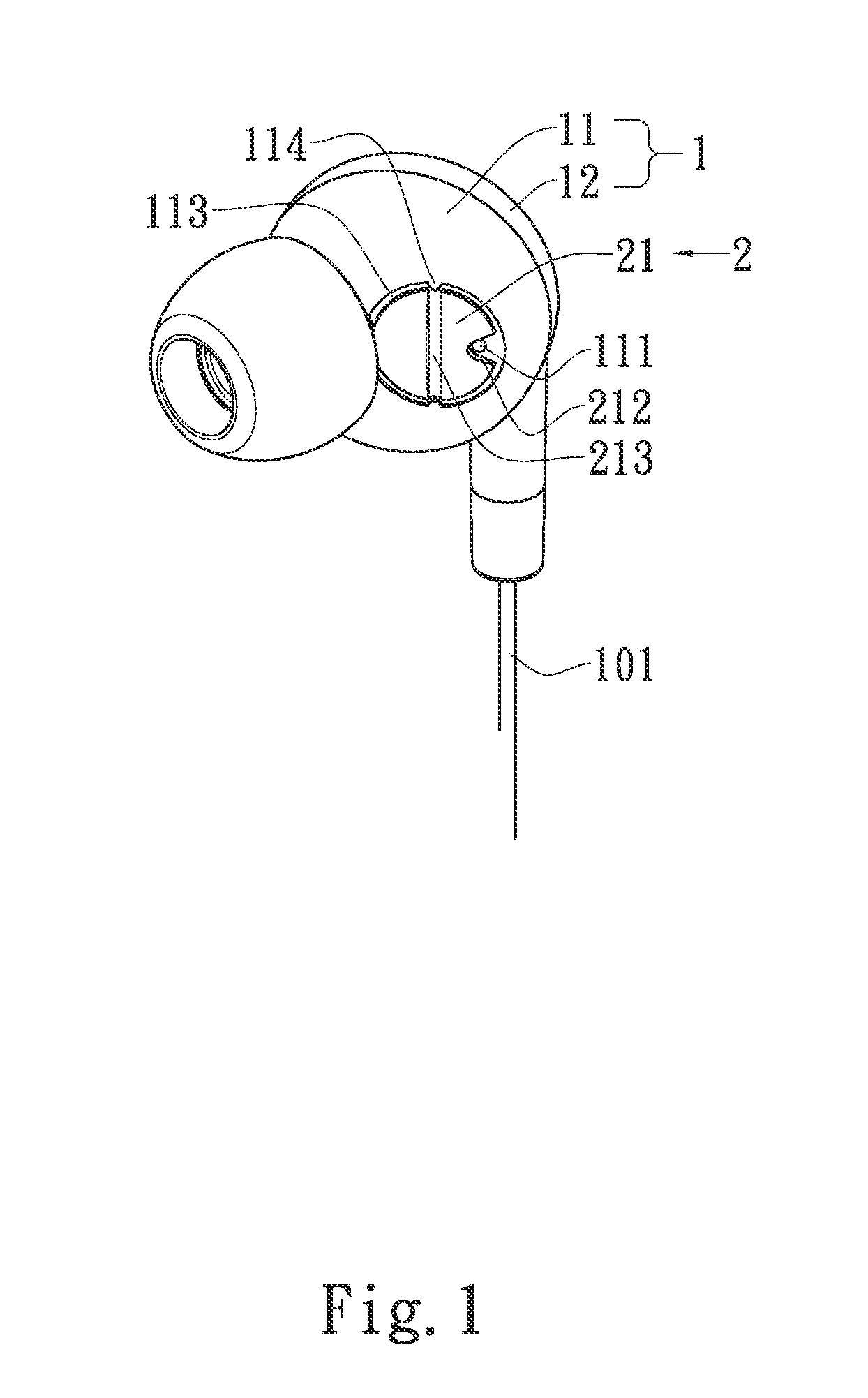

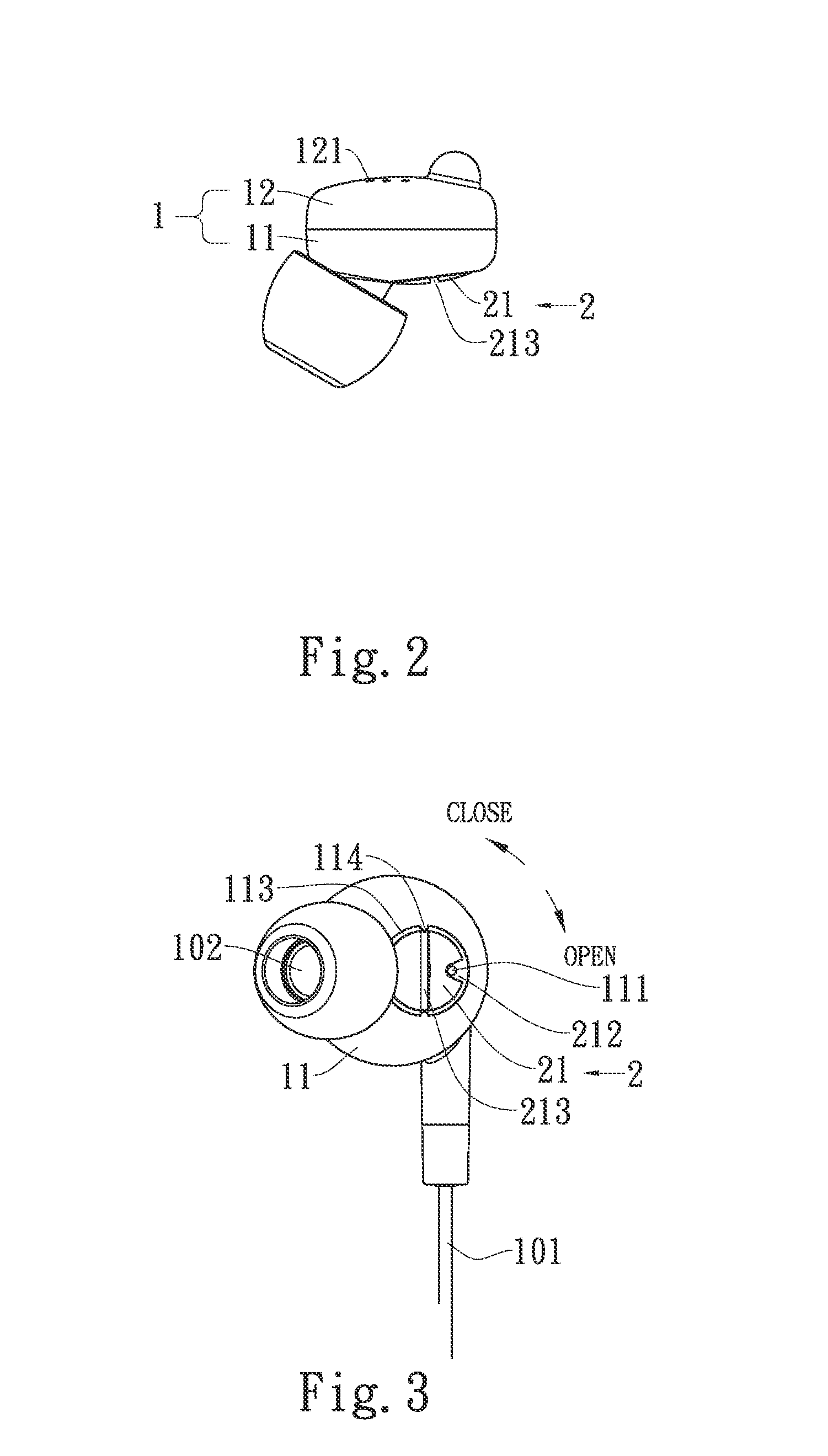

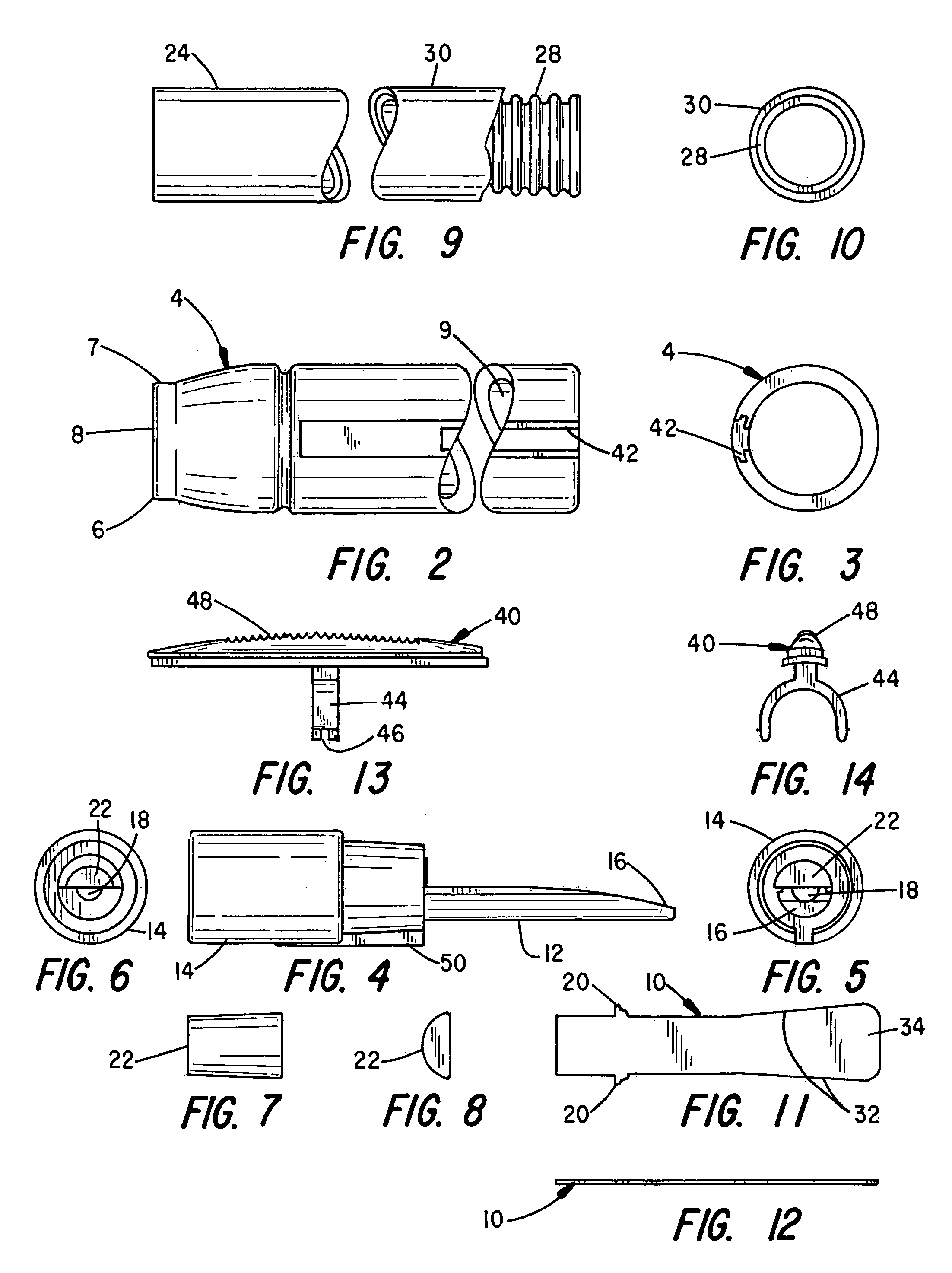

Earphone with tunable low pitch

InactiveUS20130136290A1Good effectIntra aural earpiecesFrequency/directions obtaining arrangementsEngineeringHeadphones

An earphone with tunable low pitch comprises a main member and a stirring member, wherein the main member has a chamber inside receiving a loud speaker, a low pitch room formed between the main member and the loud speaker, at least a fixing air hole provided at the rear side of the main member, a high pitch room formed between the front side of the main member and the loud speaker, at least a regulative air hole is provided at the high pitch room; the stirring member, which is pivotally joined to the pivot hole, is designed as a disk to close the regulative air hole or as airflow baffles to close corresponding airflow passages gradually such that the regulative air hole or the airflow passages can be partly or fully blocked by the stirring member to change the speed of the air entering or leaving the high pitch room and result in good low frequency resonant effect.

Owner:REXTEC INT

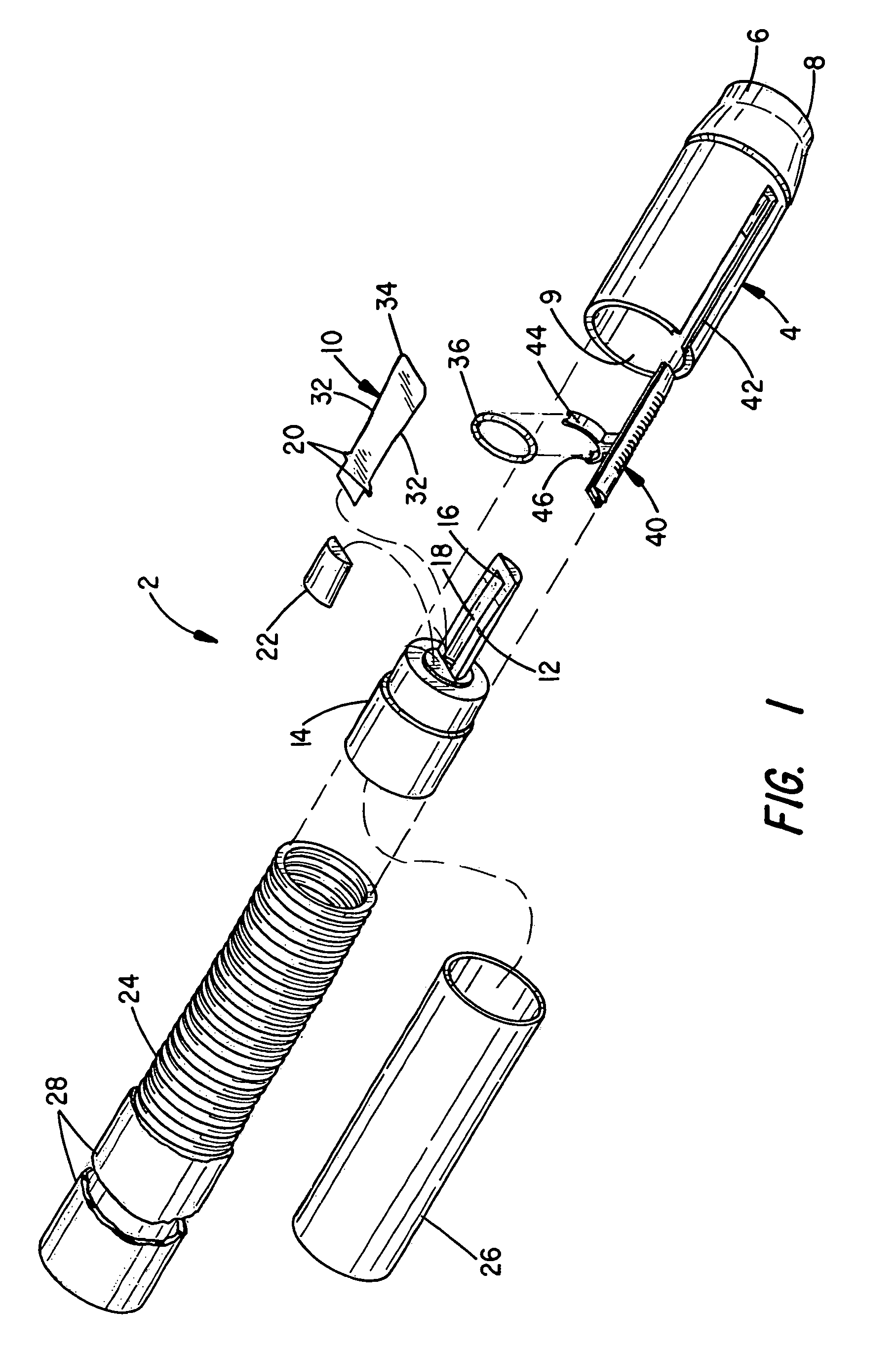

Slide actuated animal call

ActiveUS7637795B1Enhances high and low endReduces possible freeze-upMusical toysAnimal huntingEngineeringActuator

A deer call assembly that mimics sounds ranging from the high pitched sounds of fawns and does to the low-pitched grunts of bucks. The pitch is infinitely adjustable over a range with a slide actuator that manipulates a band restraint that captures a reed to a longitudinally grooved tone board. An arcuate, grooved collar depends to capture the O'ring. The reed is rigidly secured to the tone board at one end with a peg. A preferred reed exhibits peripheral edges that taper outward as the reed extends to a wide billed end where the edges project beyond the longitudinal sides of the tone board.

Owner:ILLUSION OUTDOORS LLC

Helmholtz resonator type marine signal

ActiveUS7360499B1Easy to transportReduce power consumptionTransducer detailsWhistlesElectricityPower efficient

A power efficient, acoustical Helmholtz resonator foghorn including a plurality of electrical emitters, some of which are redundant, arrayed at one end of a blocked tube with a plurality of exhaust ports located therein surrounded by a standoff tubular member. The foghorn tuned to provide a high pitch thus providing a compact horn having an acoustical path capable of producing an exceptional wavelength in a generally concentric horizontal sound propagation the horn configurable for use as either a one-half mile or two mile marine navigational aid for offshore structures, buoys, and the like.

Owner:ESSI CORP

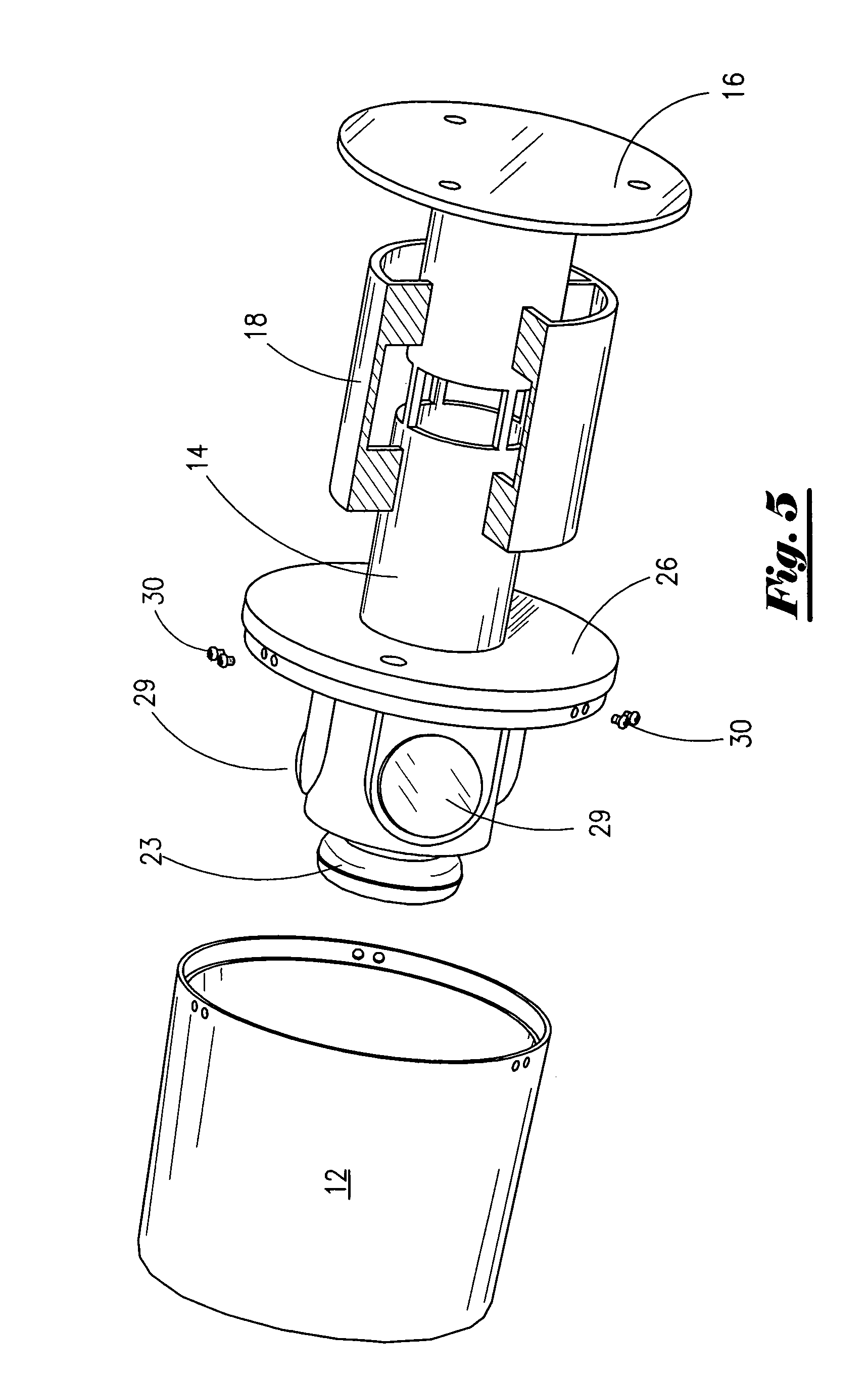

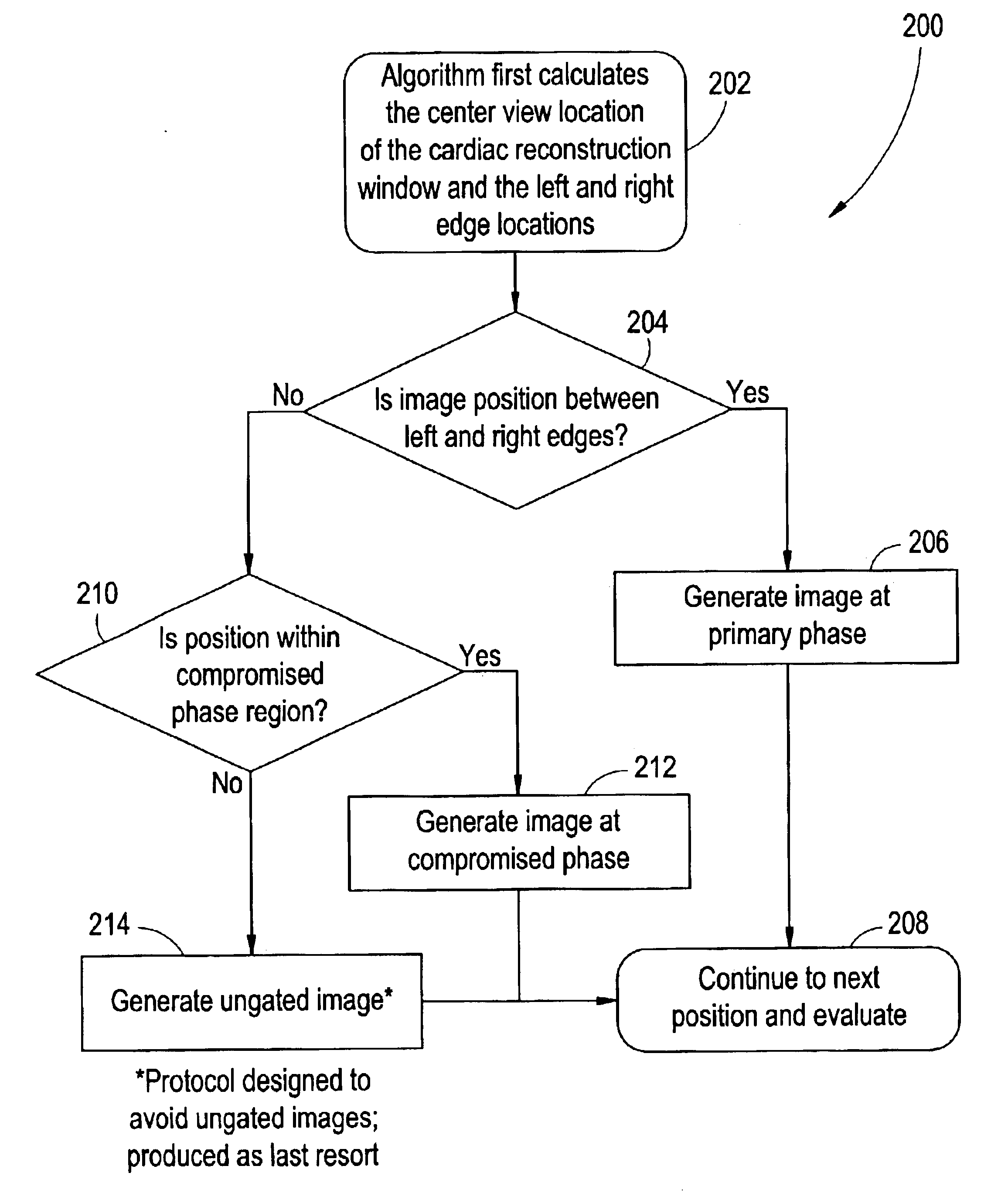

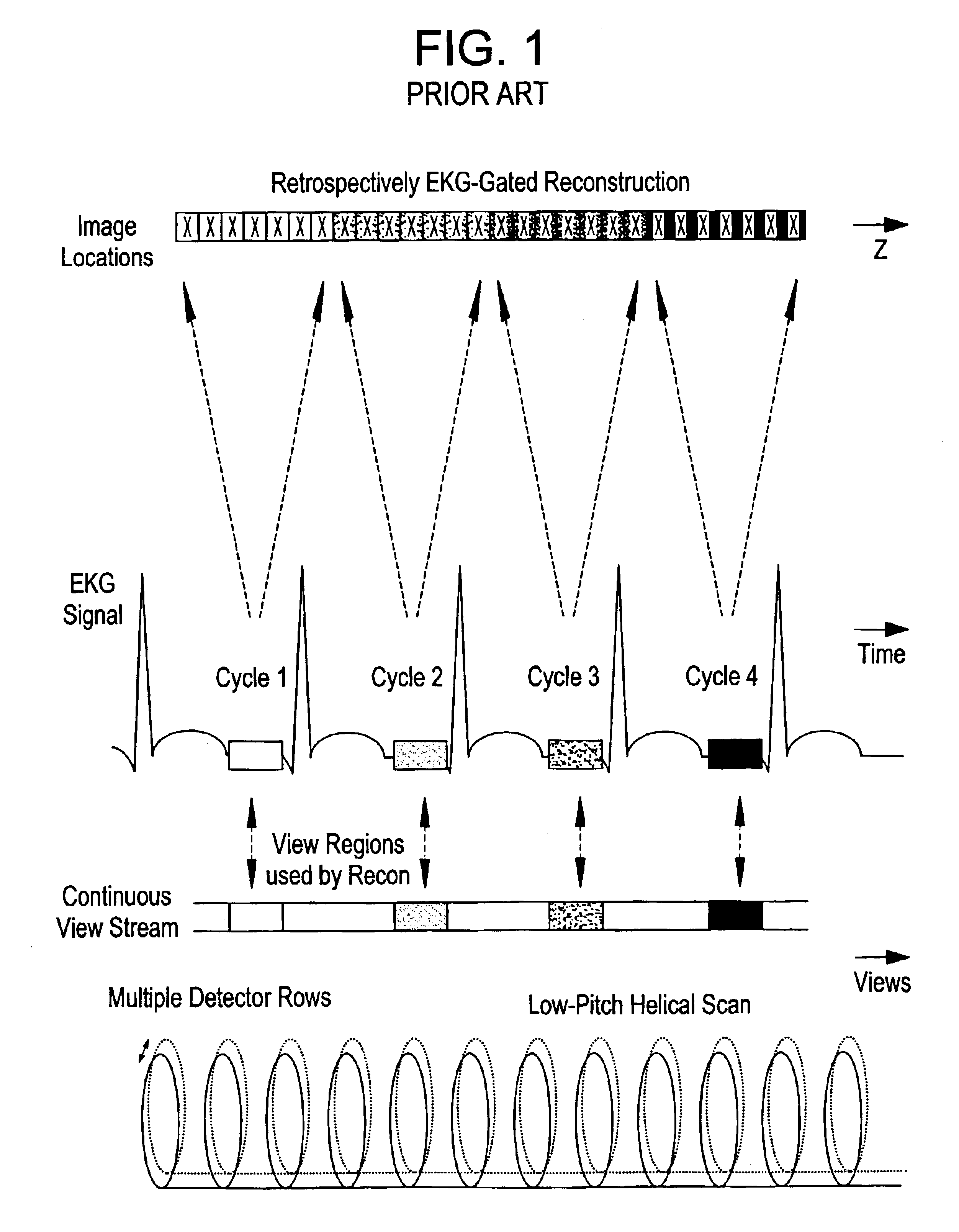

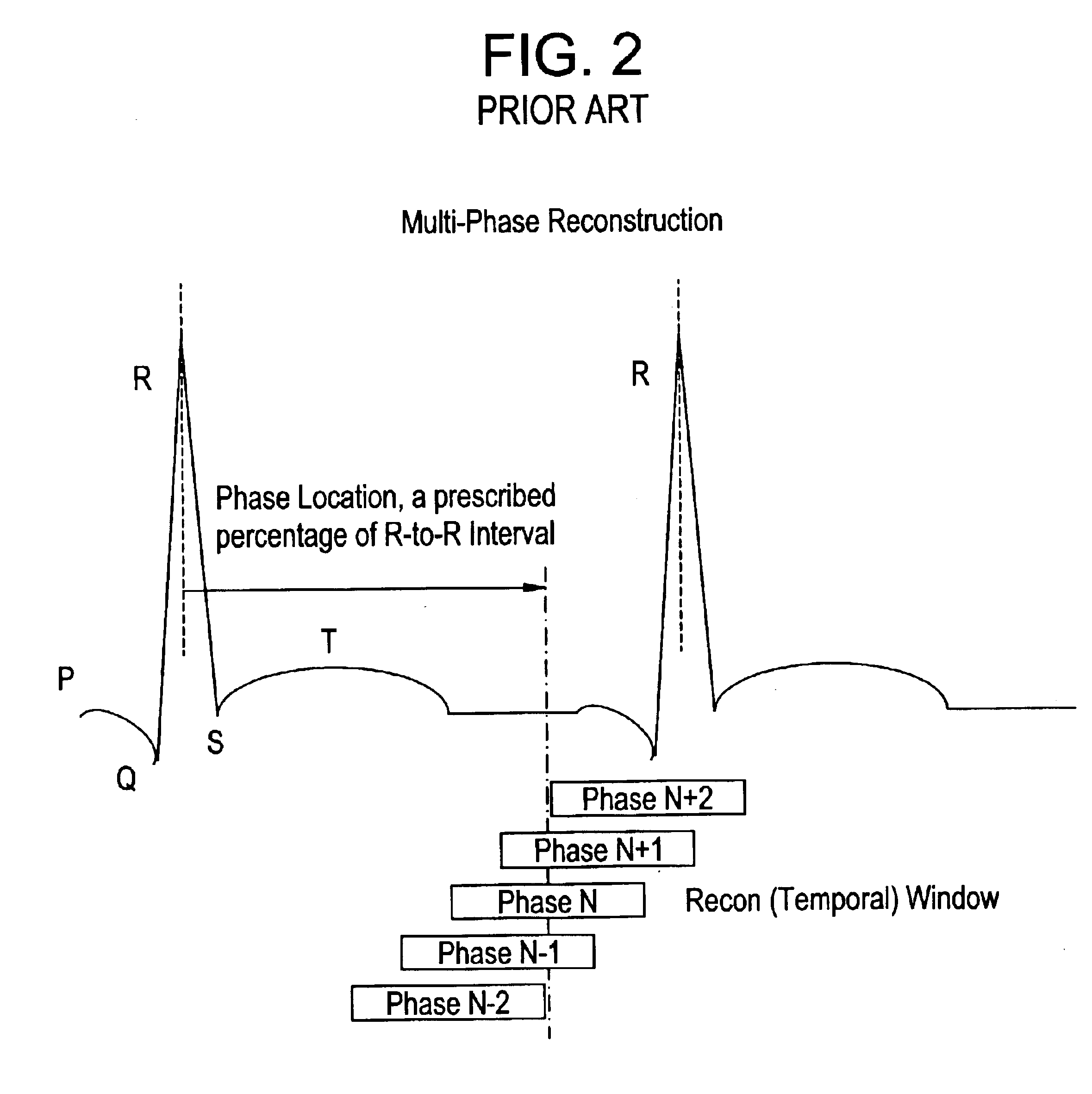

High pitch cardiac helical scan with extended reconstruction windows

InactiveUS6865250B2Reduce radiation doseIncreasing a helical scanning pitchReconstruction from projectionRadiation/particle handlingHelical scanCardiac cycle

A method for image reconstruction and reducing patient dose, and an imaging system for accomplishing these methods, includes selecting a primary phase of a cardiac cycle and calculating compromised phase regions based on a selected compromised phase value. If the image position is located within the primary phase, then an image is generated at the primary phase. If the image position is not located within the primary phase, but is located within a compromised phase region, then an image is generated at the compromised phase region.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

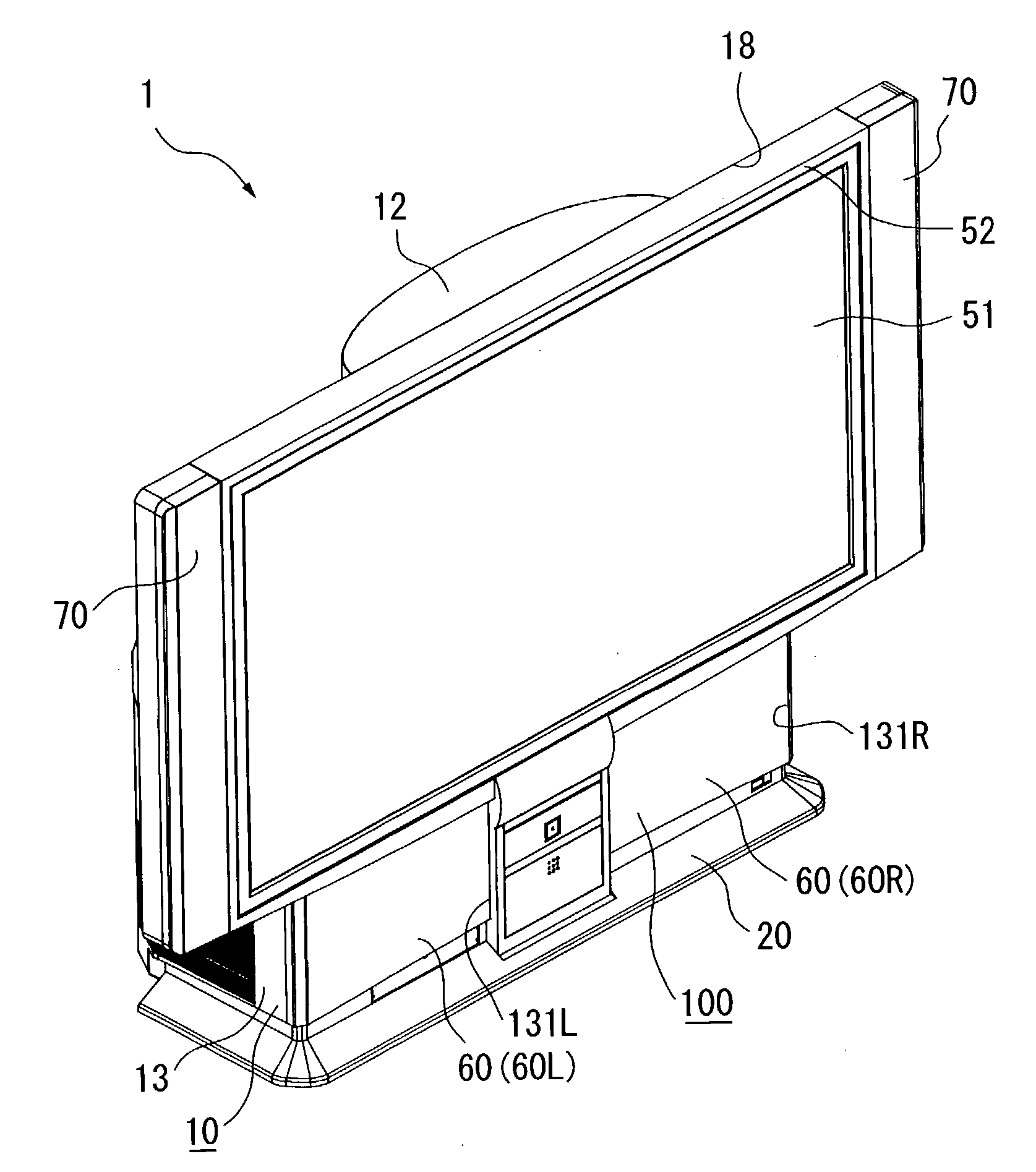

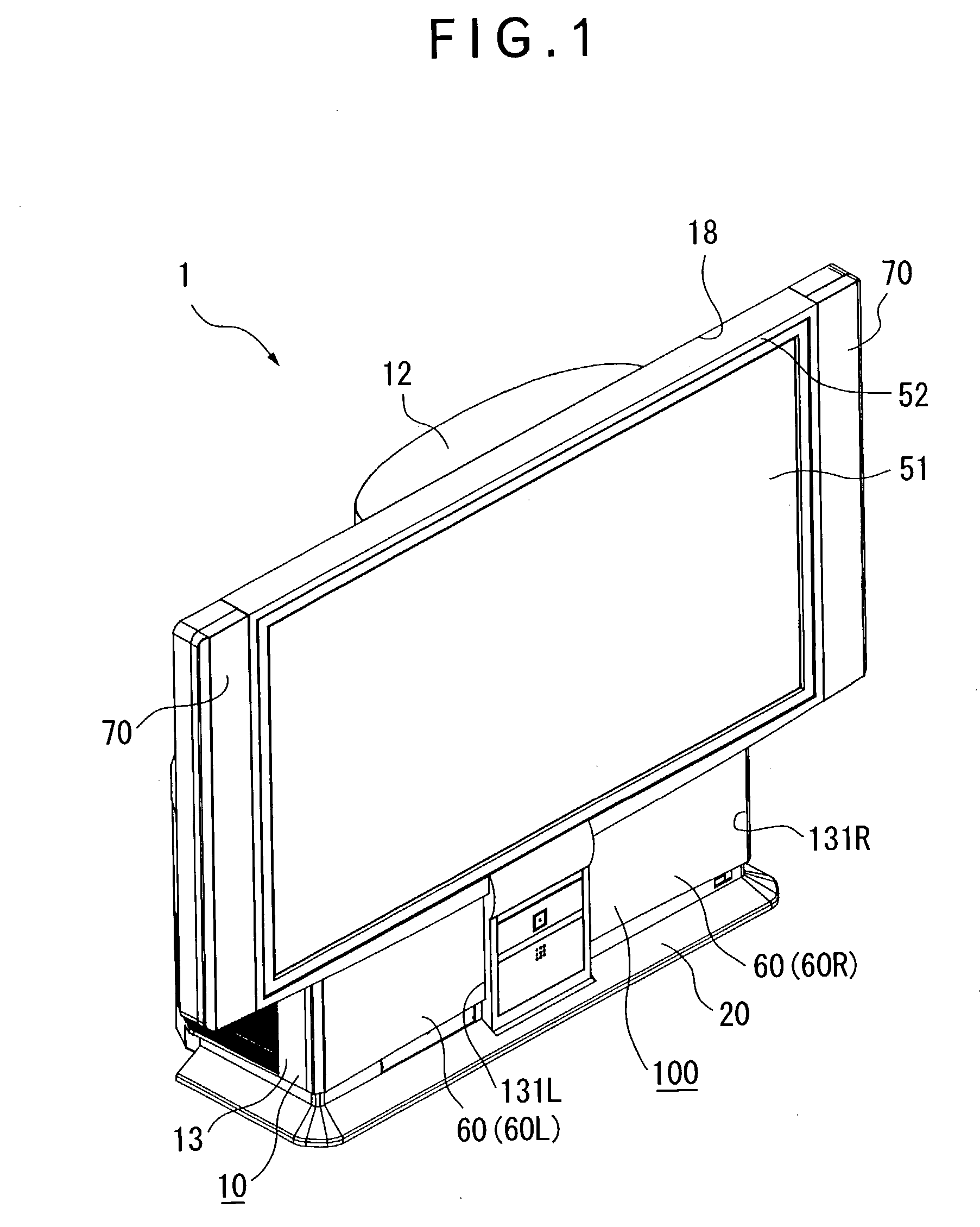

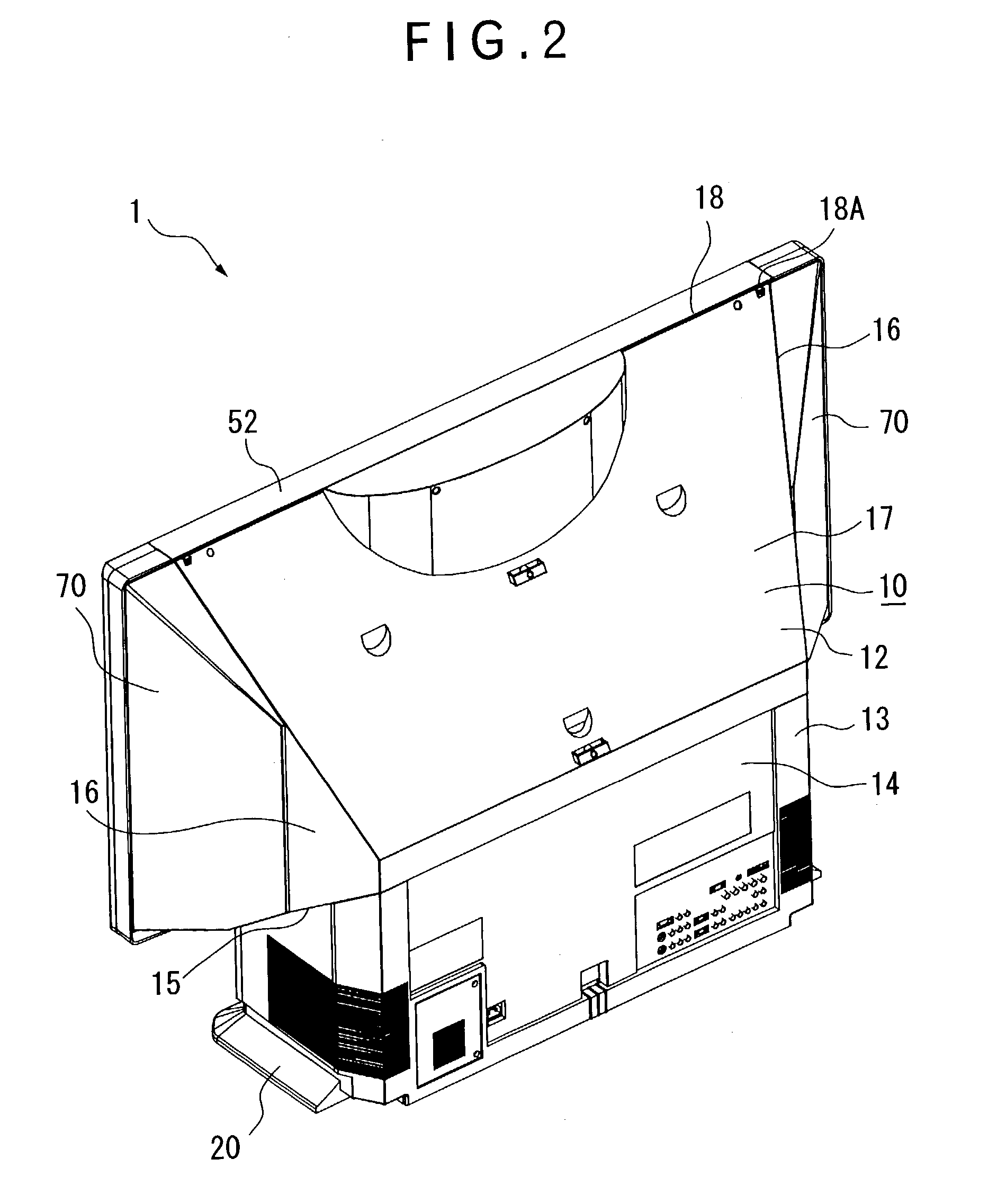

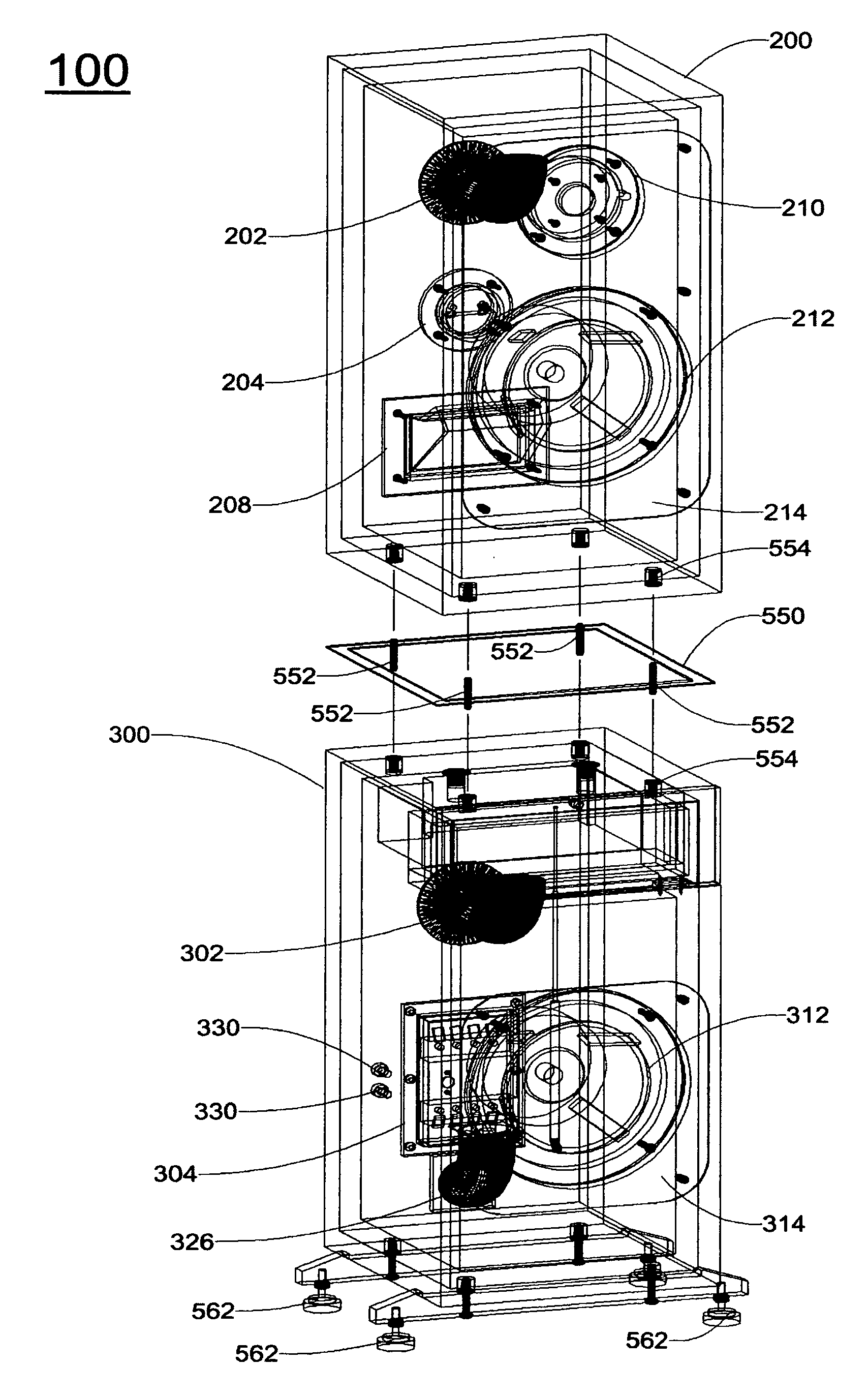

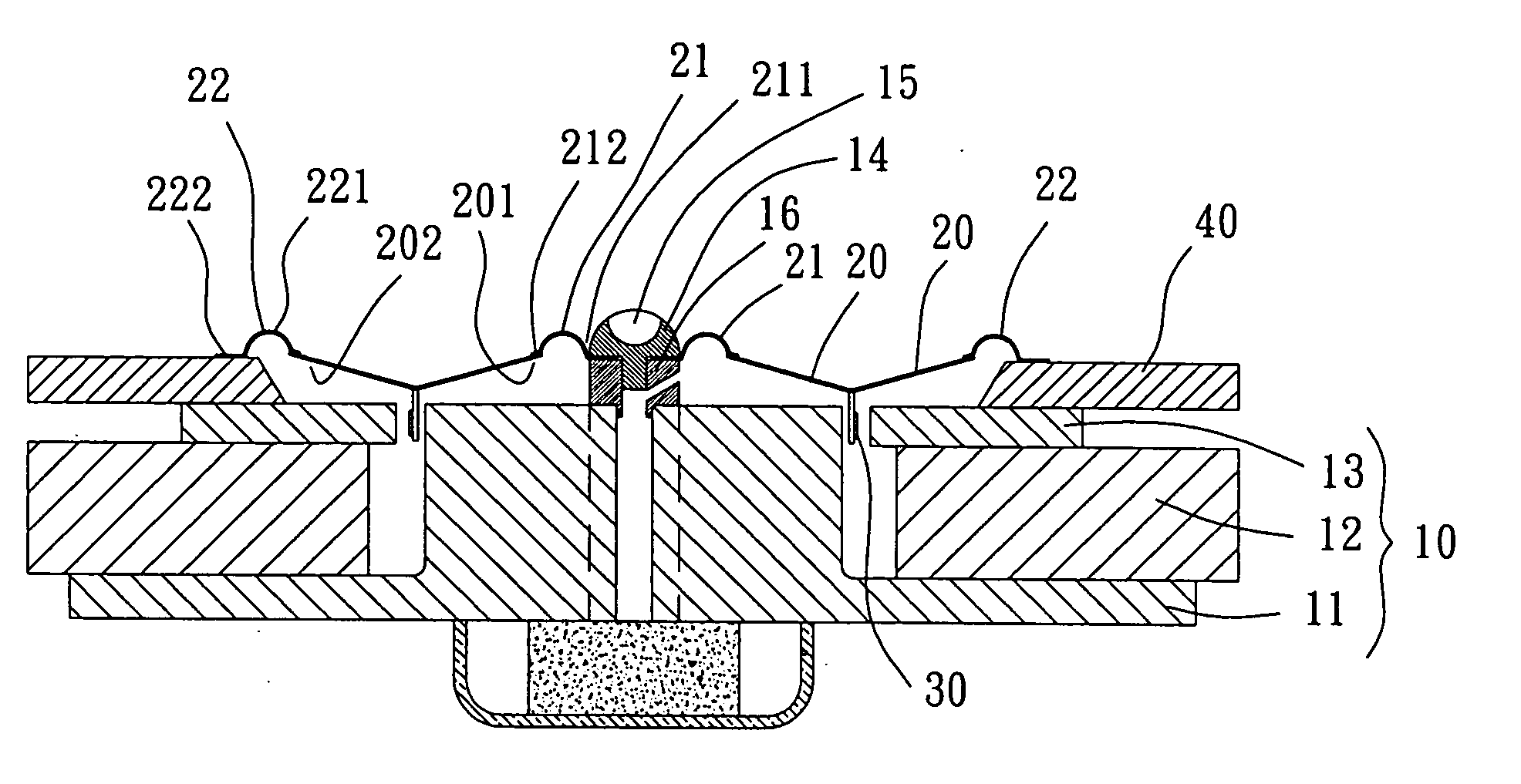

Rear projector and producing method thereof

InactiveUS20030202162A1High quality imagingLow costTelevision system detailsBuilt-on/built-in screen projectorsEngineeringWoofer

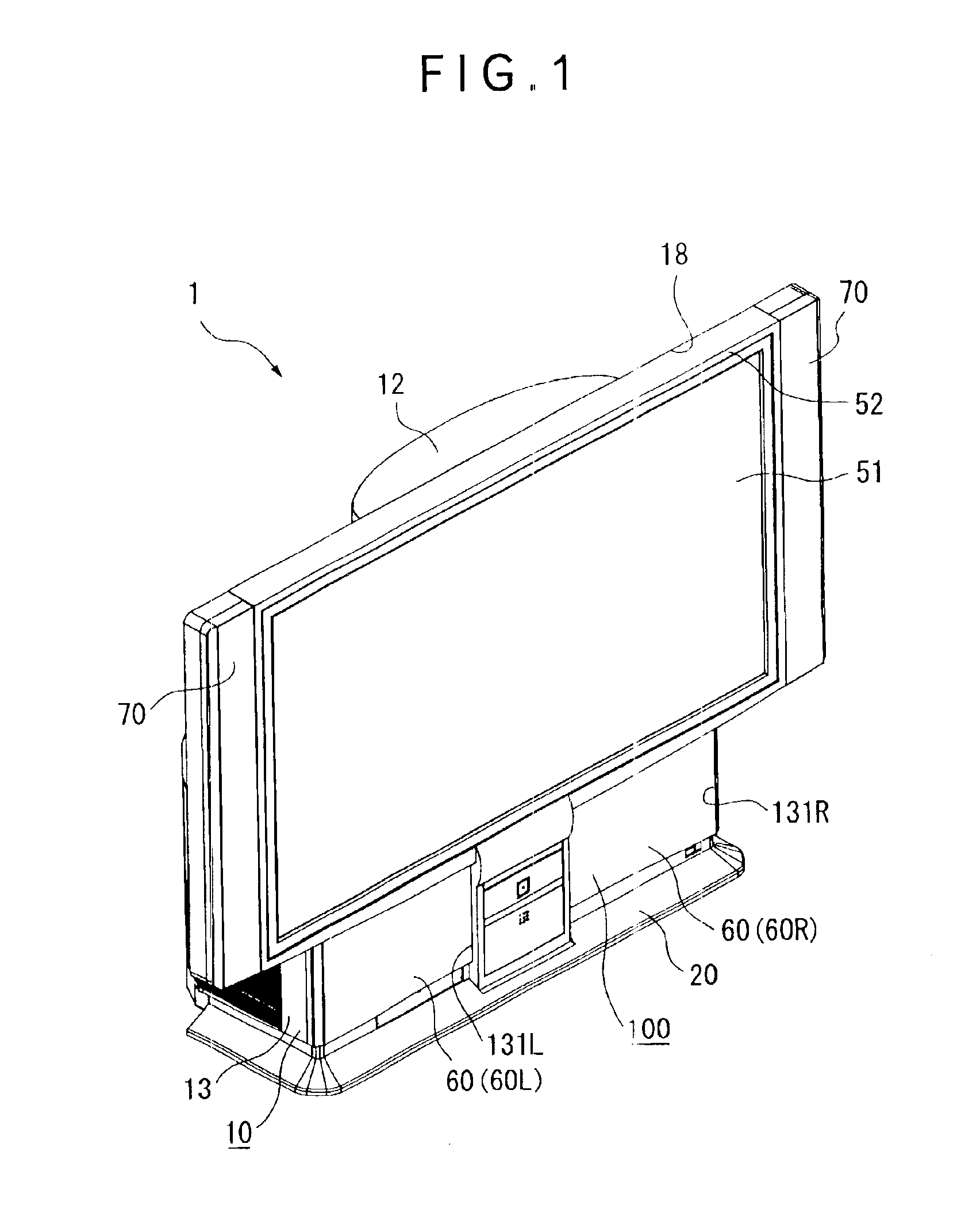

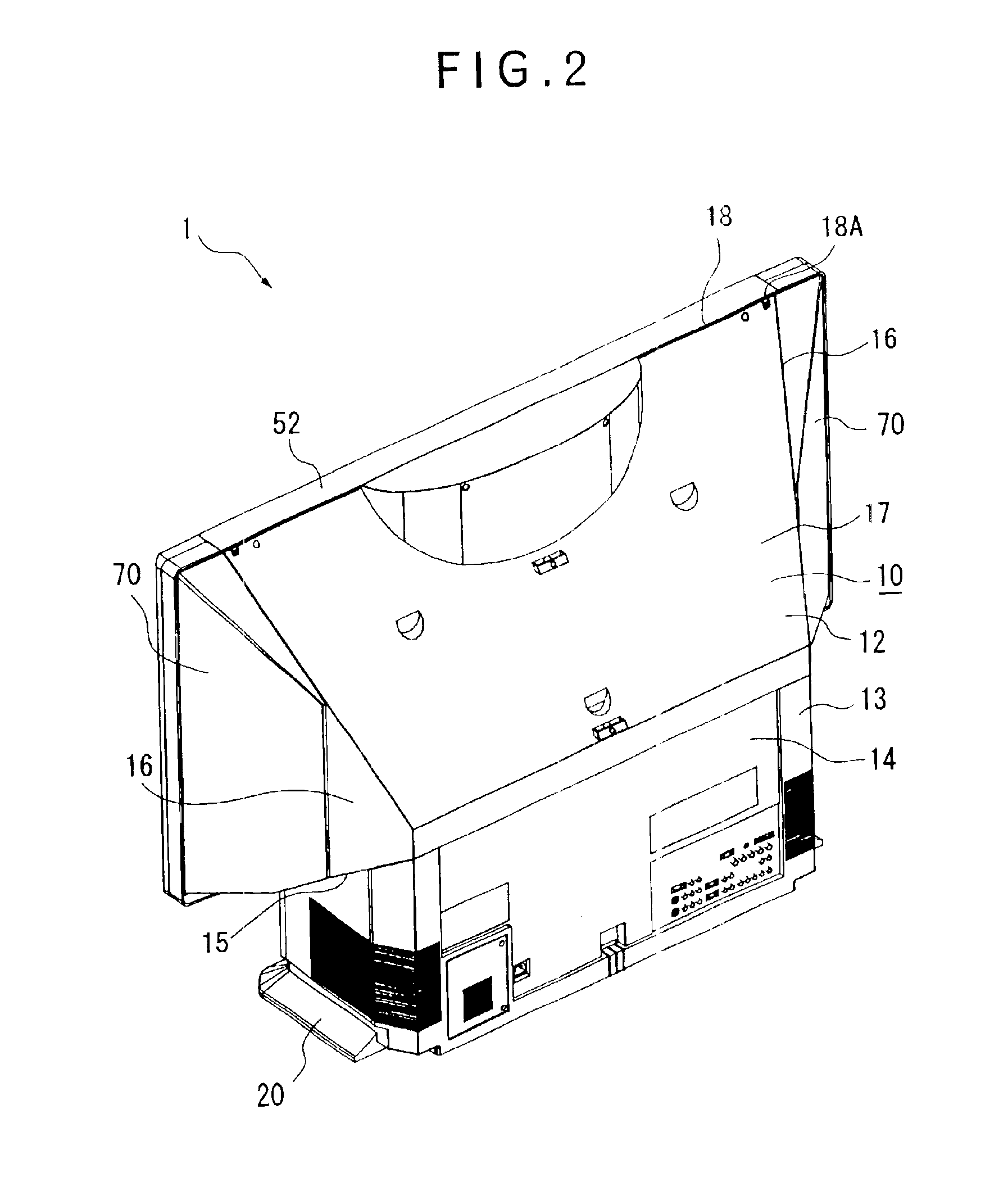

A rear projector (1) has a lower cabinet (13) disposing an image generator and an upper cabinet (12) for a screen body (51) to be mounted, two woofer boxes (60) being mounted on the front side of the lower cabinet (13) and high-pitched sound speaker boxes (70) being respectively mounted on the right and left lateral sides of the upper cabinet (12), so that, since the woofer box (60) is disposed in the lower cabinet (13), vibration is not easily transferred to a screen body (51) on the upper cabinet (12) and a reflection mirror inside the upper cabinet (12), thus avoiding flicker of the image on the screen body (51) even when great volume of sound is outputted by the woofer box (60).

Owner:SEIKO EPSON CORP

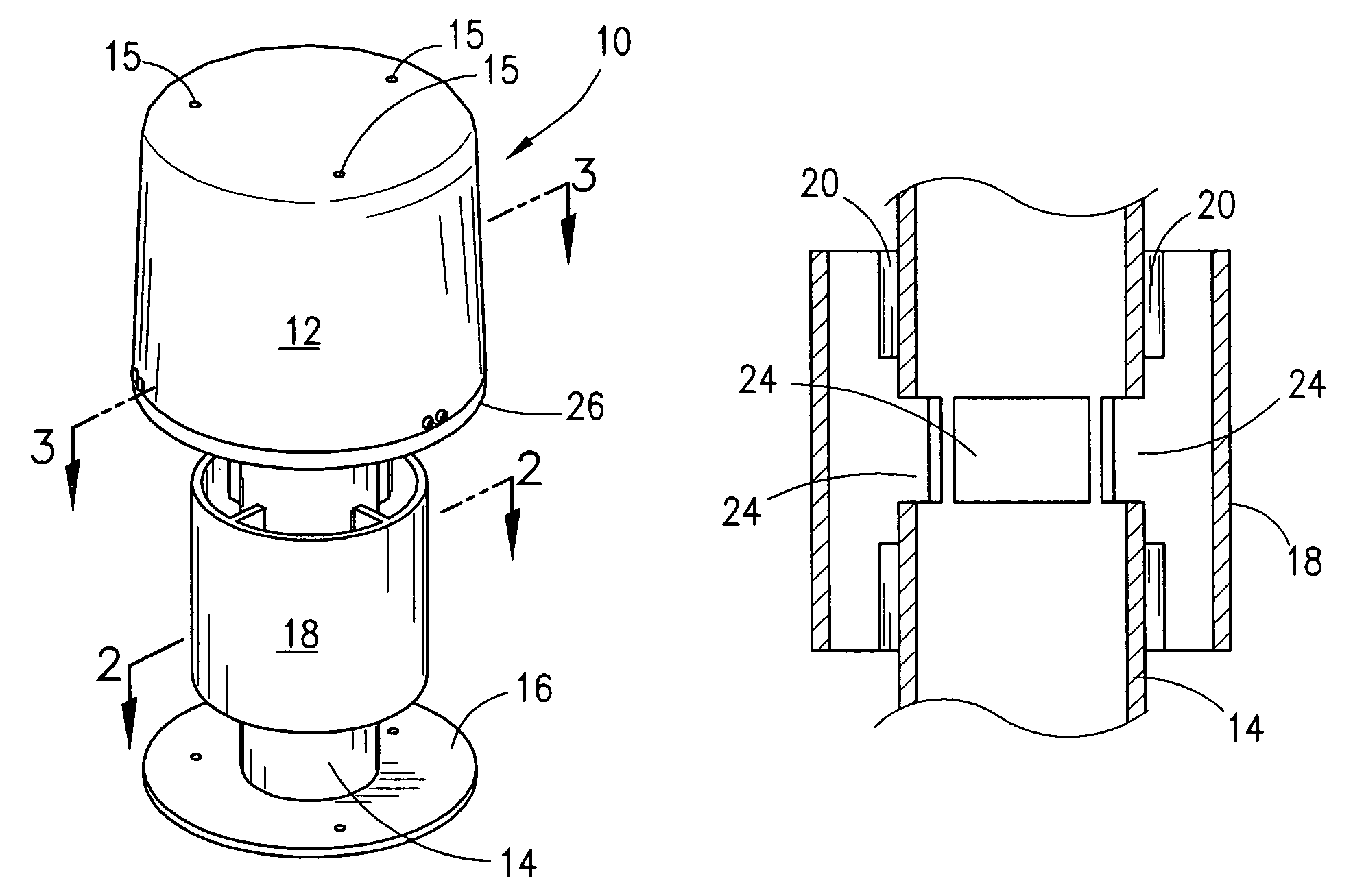

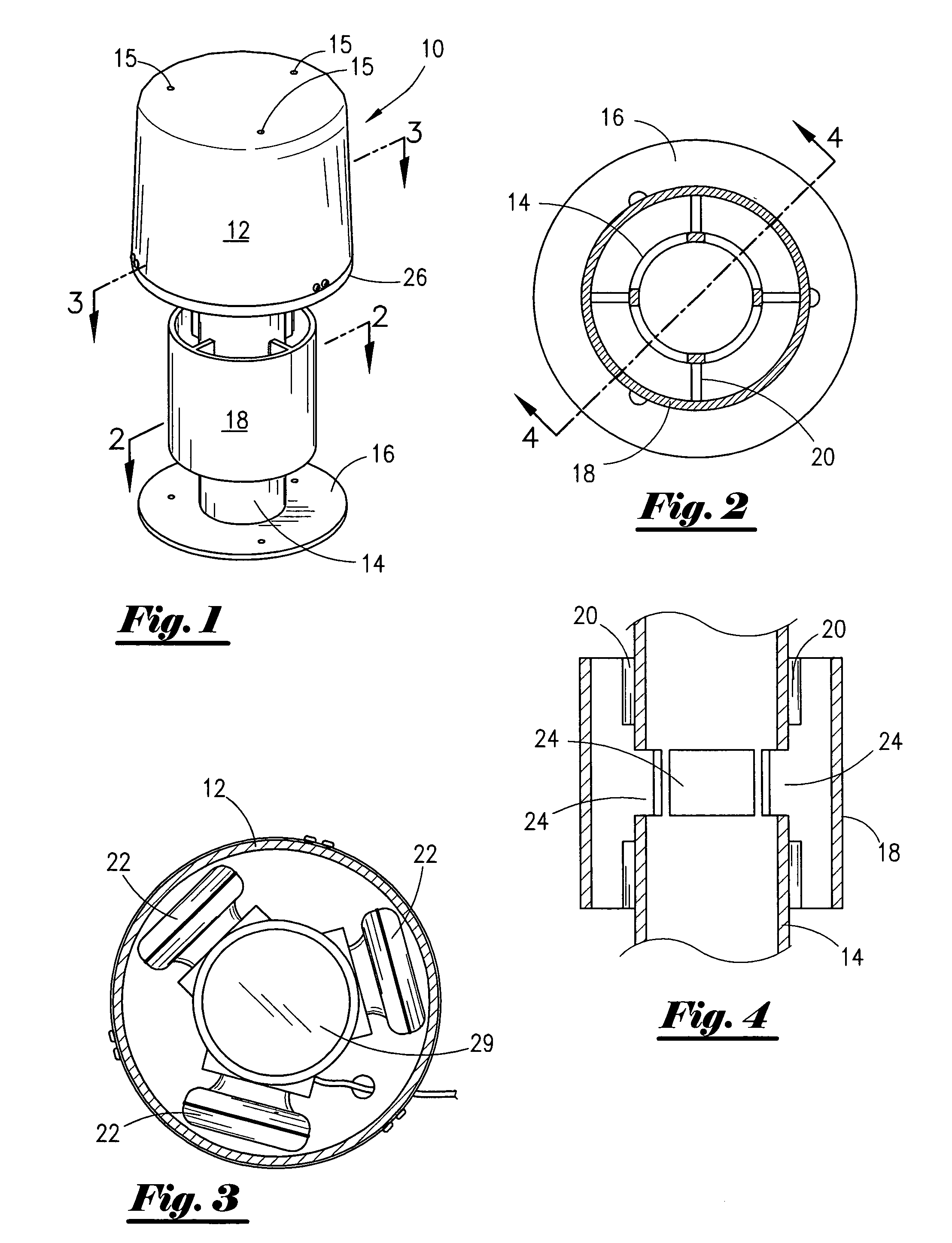

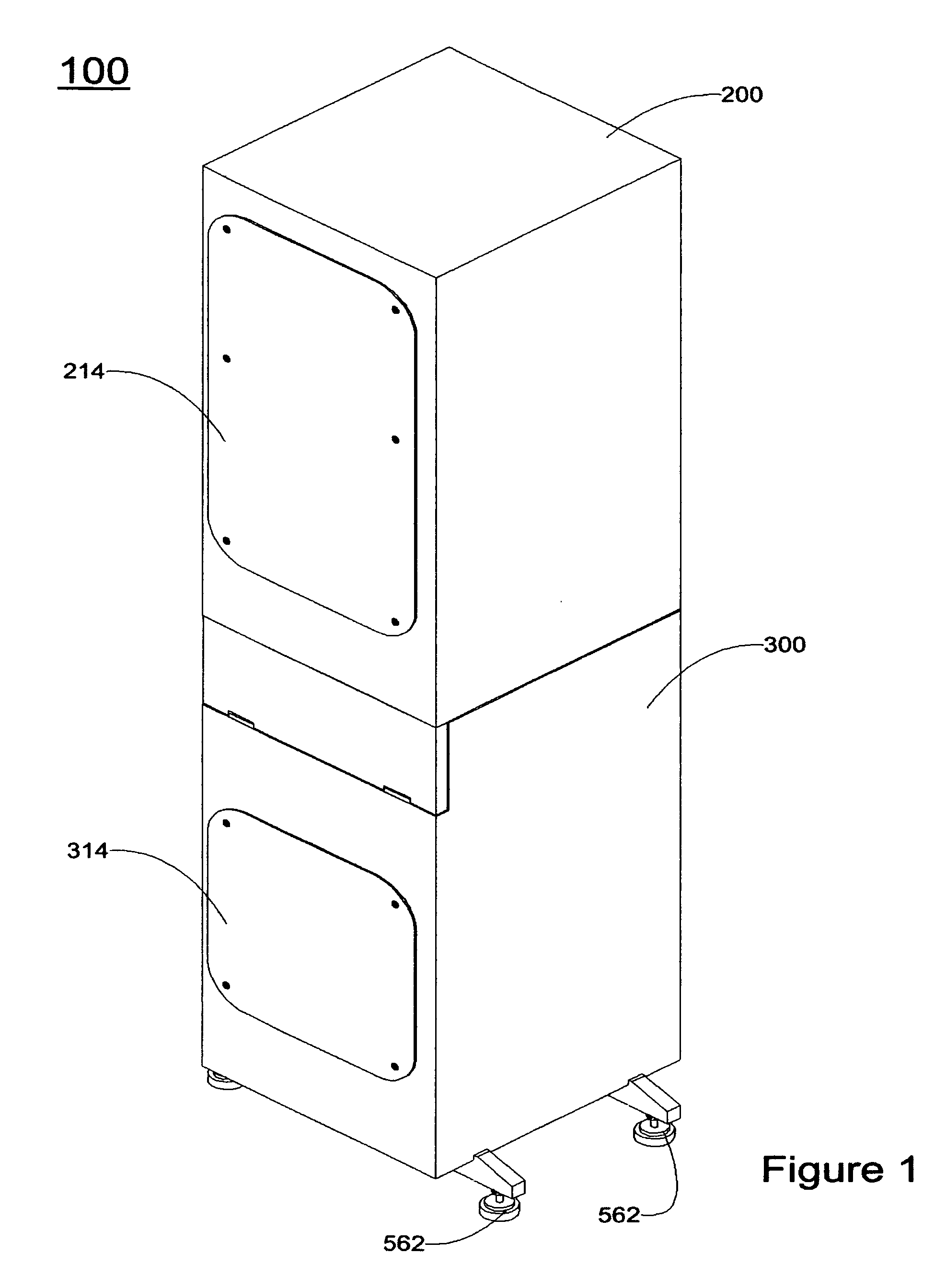

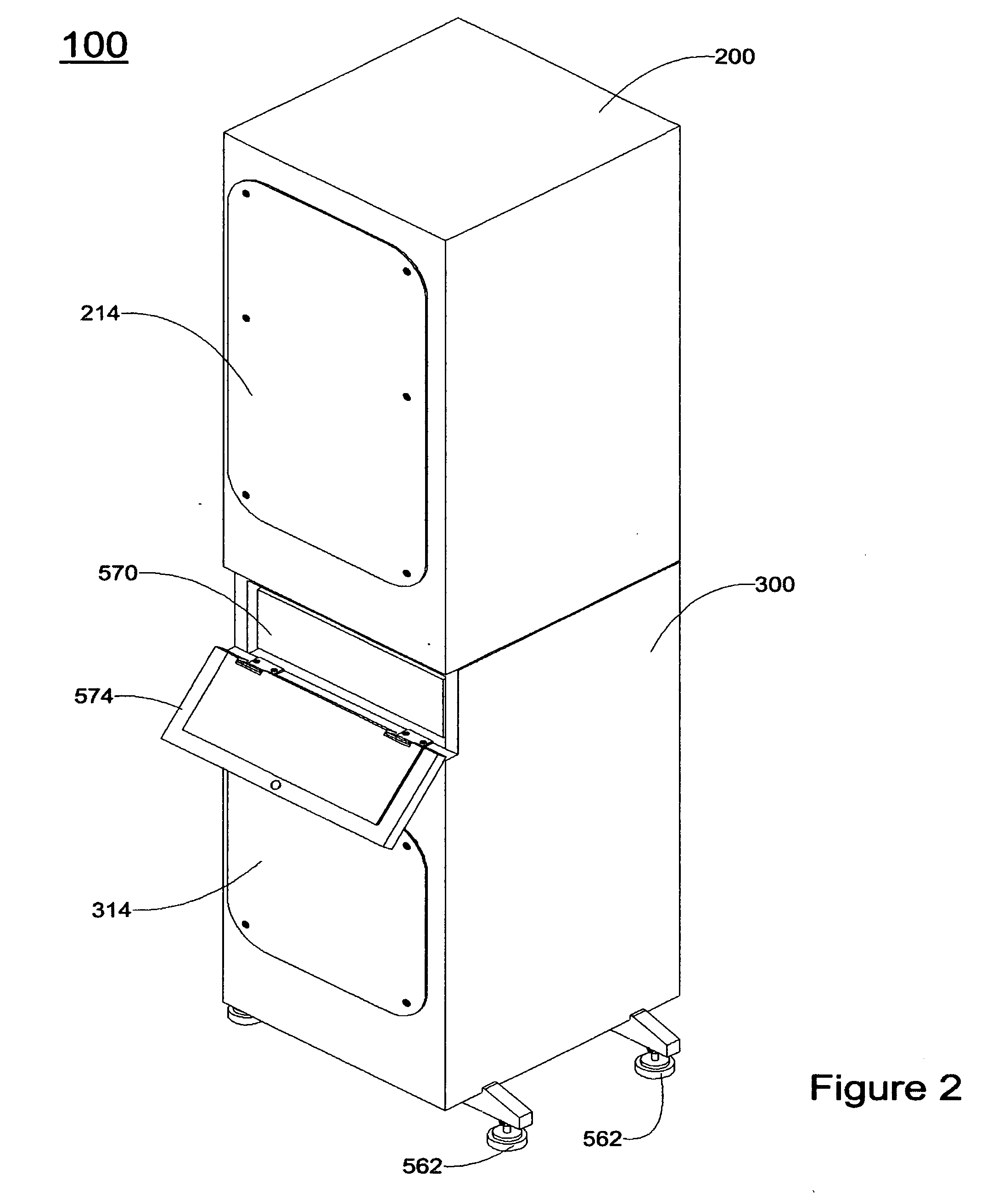

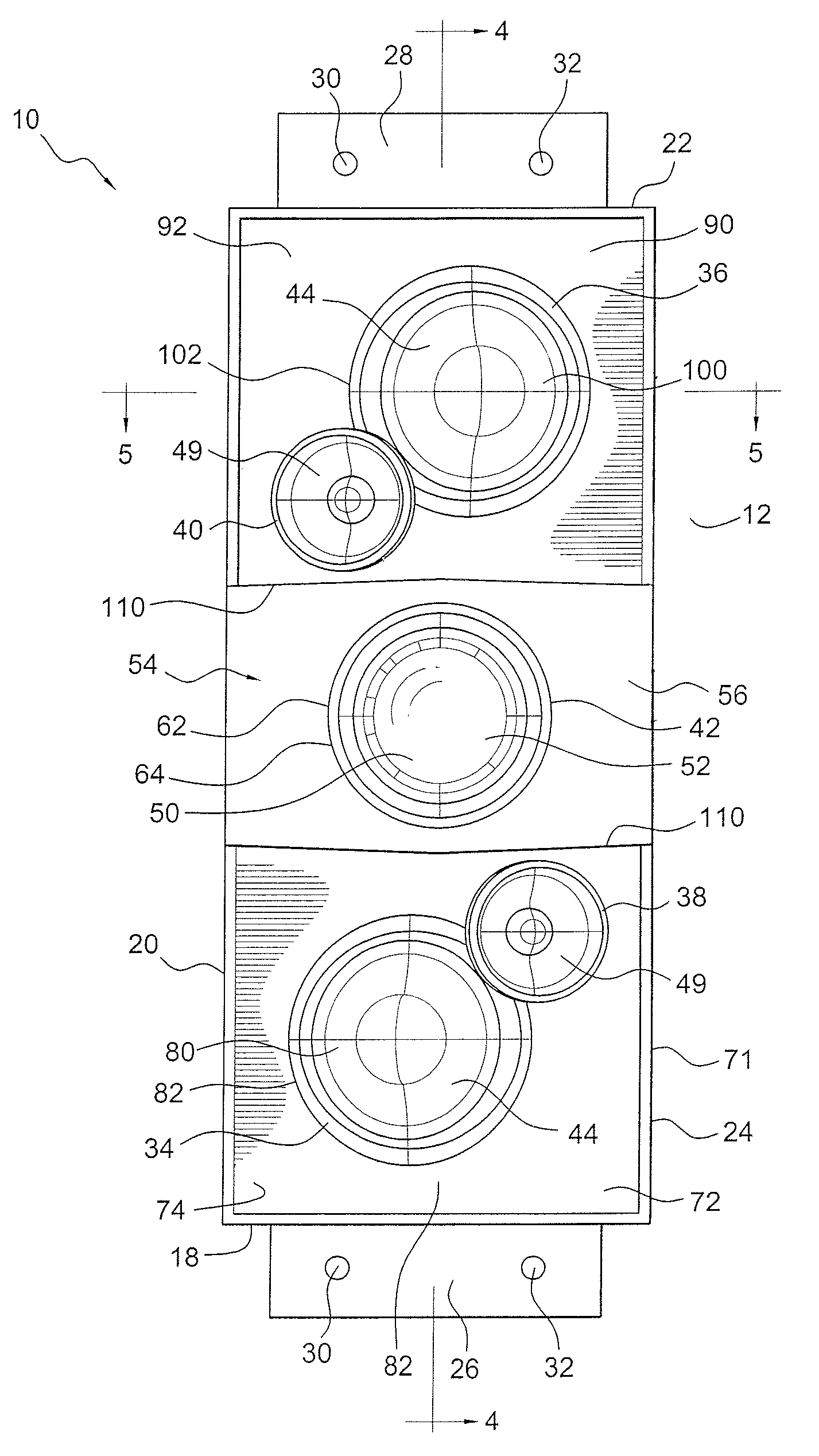

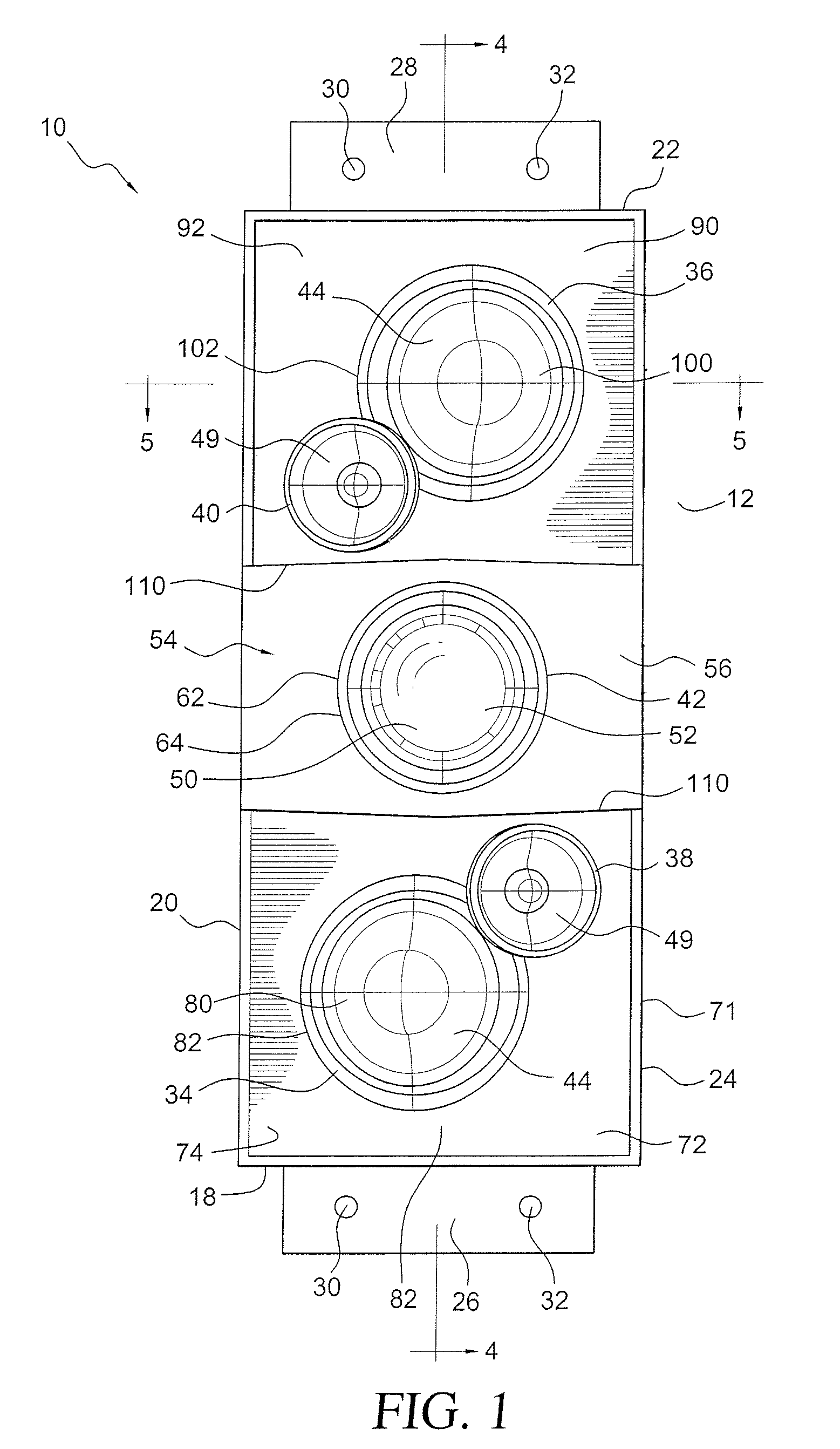

Outdoor High-Fidelity/High Power Audio & Speaker System

A water-resistant and weatherproof high-fidelity / high power audio and speaker system adapted for outside use includes a top speaker member including a first speaker, a bottom speaker member including a second speaker, an audio component member and high current low voltage dc power supply for being mounted under the top speaker member, a spacer member for spacing the top speaker member with the bottom speaker member, and a guide member for cooperating with the spacer member to align the top speaker member and the bottom speaker member. The guide member may be a dowel pin, and the top speaker member may include a speaker terminal member to connect to the first speaker. The top speaker member may include a cabinet handle member to aid in lifting the top speaker member, and the top speaker member may include a tweeter speaker member. The top speaker member may include a woofer speaker member, and the top speaker member may include a base port member for passage of base level sounds.

Owner:HUGHES JERRY

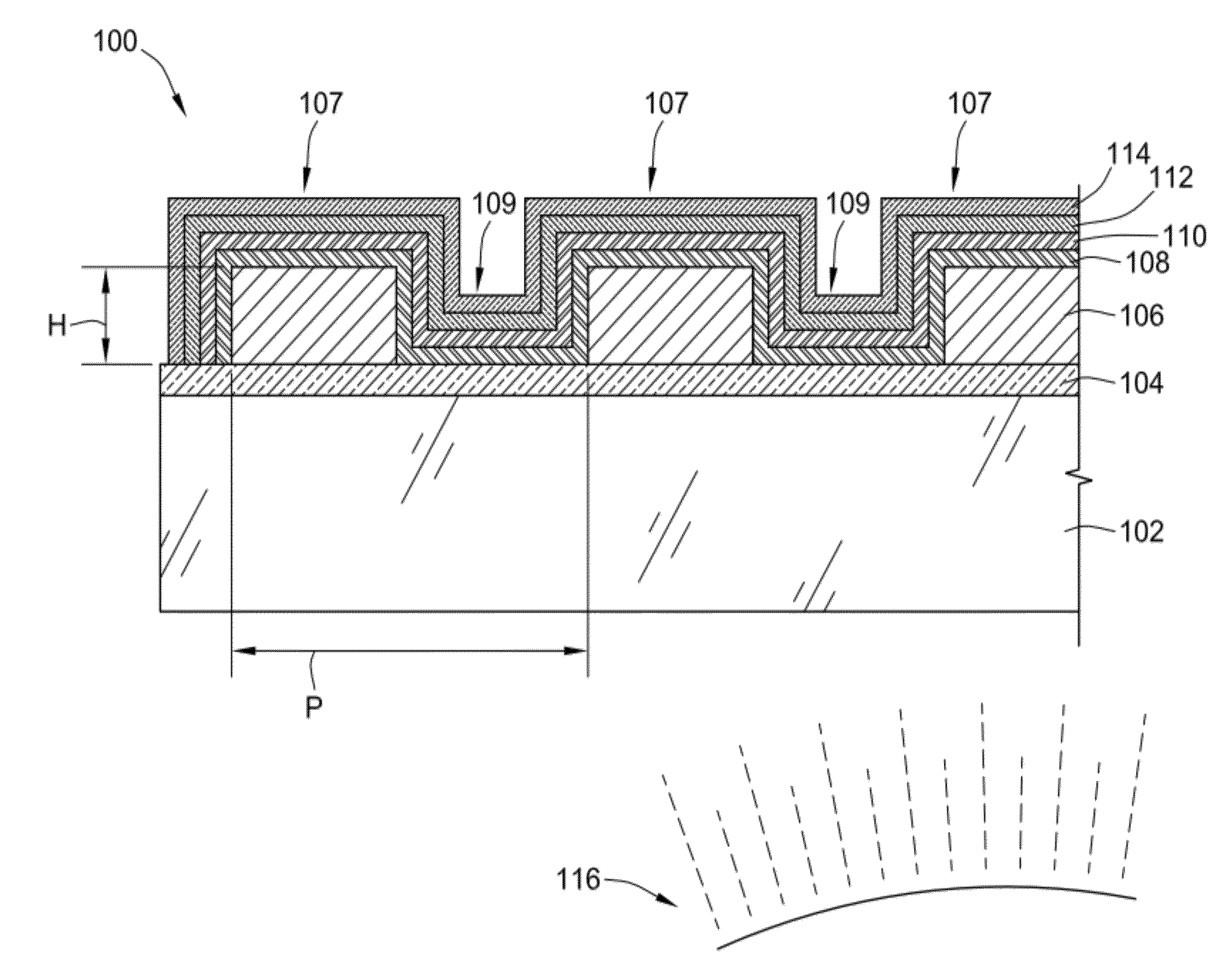

Speaker Assembly

ActiveUS20100119089A1Transducers for sound channels pluralityLoudspeaker casing supportsEngineeringMirror image

A speaker assembly includes a speaker housing with a closed top wall, an opposed open end and first, second, third and fourth sidewalls extending downwardly from the closed top wall. The closed top wall is substantially planar and forms a support surface. First and second midrange drivers and first and second high frequency drivers are mounted within the housing, wherein the first midrange driver and the first tweeter are mirror images of second midrange driver and the second tweeter. A first support bracket supports the first midrange driver and first tweeter along a first side of the closed top wall adjacent the first sidewall of the speaker housing. The first support bracket includes a planar support surface which is obliquely oriented relative to a plane in which the closed top wall lies. A second support bracket supports the second midrange driver and the second tweeter along a second side of the closed top wall adjacent the third sidewall of the speaker housing. The first support bracket includes a planar support surface which is obliquely oriented relative to the plane in which the closed top wall lies.

Owner:TRACY DENNIS A

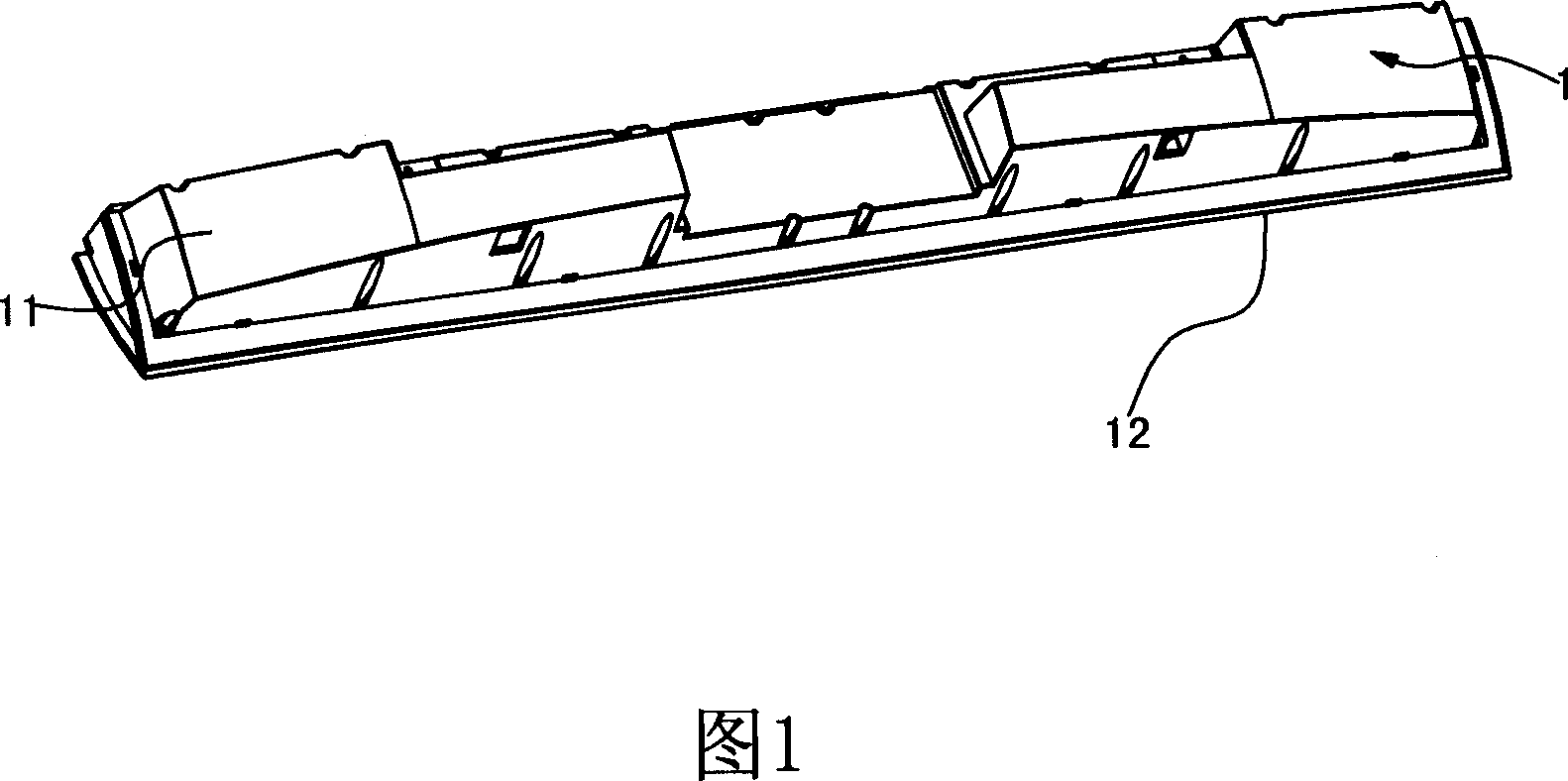

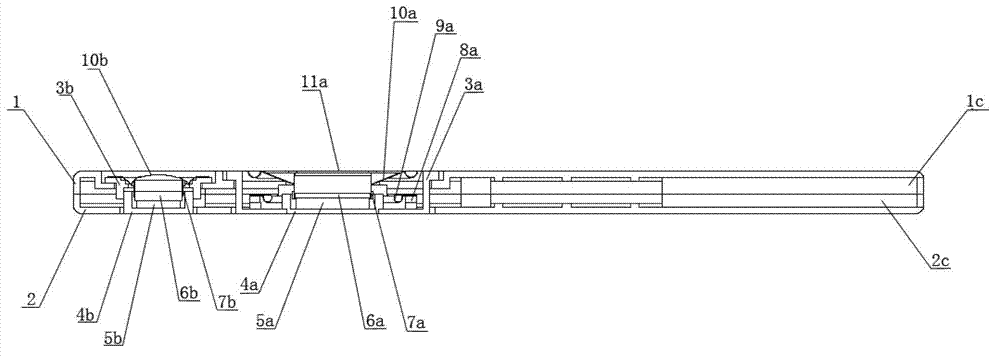

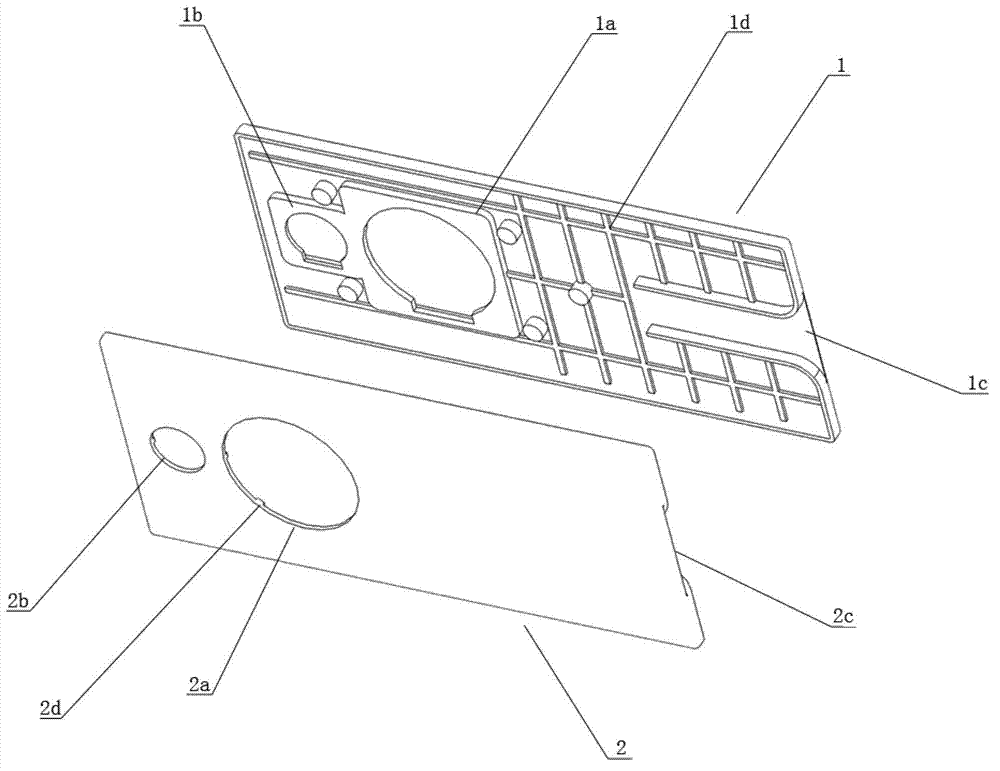

Built in sound system of thin audio frequency device

InactiveCN1988731AStrong and magnificentShocking bass effectFrequency/directions obtaining arrangementsEngineeringVideo equipment

The invention discloses a built-in sound system for thin video equipment, which uses two-fractional frequency labyrinth inverter speaker, and includes the loudspeaker, frequency divider, pilot pipe, box, althorn and sackbut. The structure of box is produced based on the internal space of video equipment and capacity requirement, and the labyrinth pilot pipe is installed on the wall of box cavity. In this invention, maze pilot pipe forms a longer bass channel in the box, to make the bass reflex in the channel for many times and double the strength, then after the collision reflection of the wall and desk, the air audio pressure is enhanced greatly, to achieve a HI-FI sound.

Owner:AMOI TECH

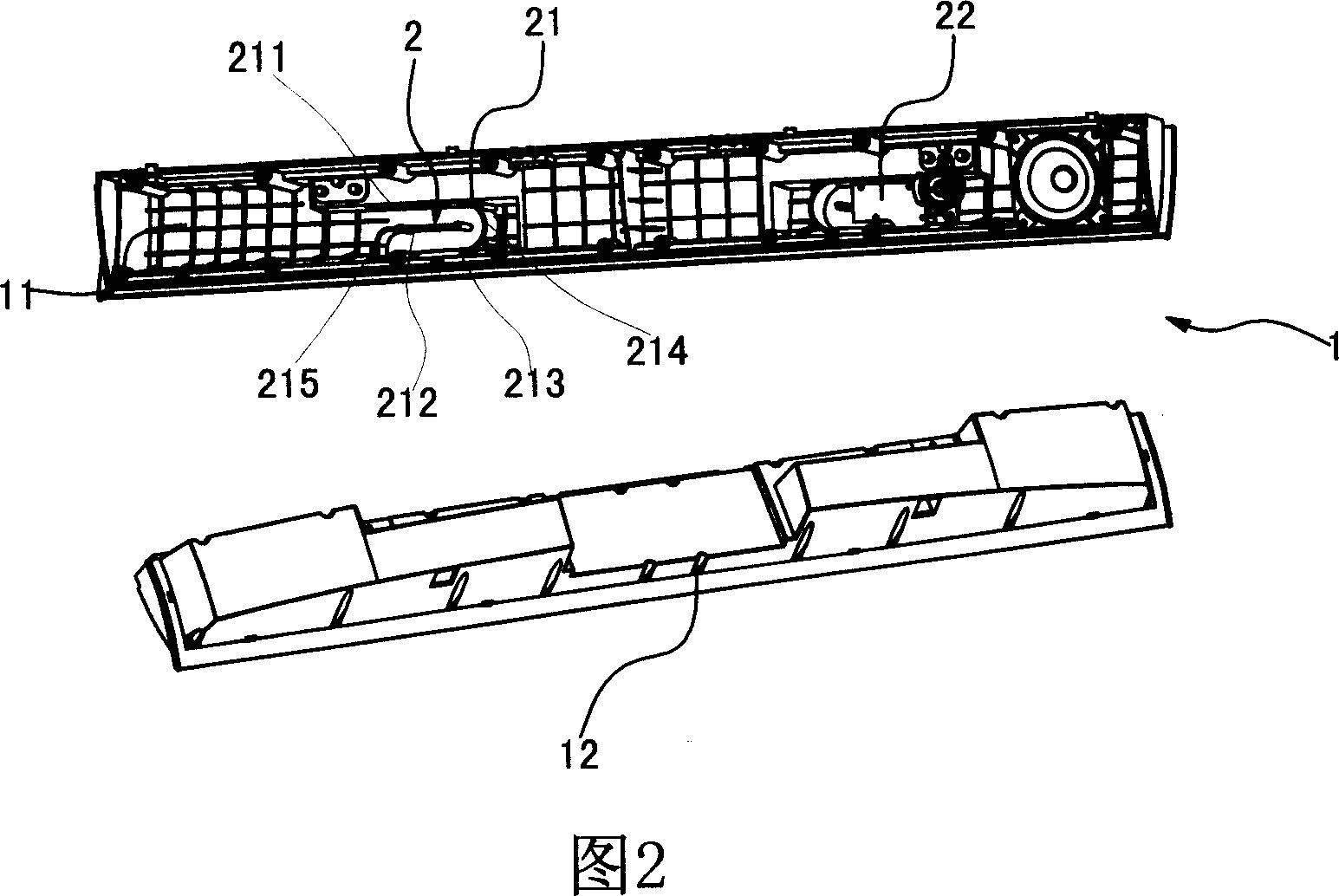

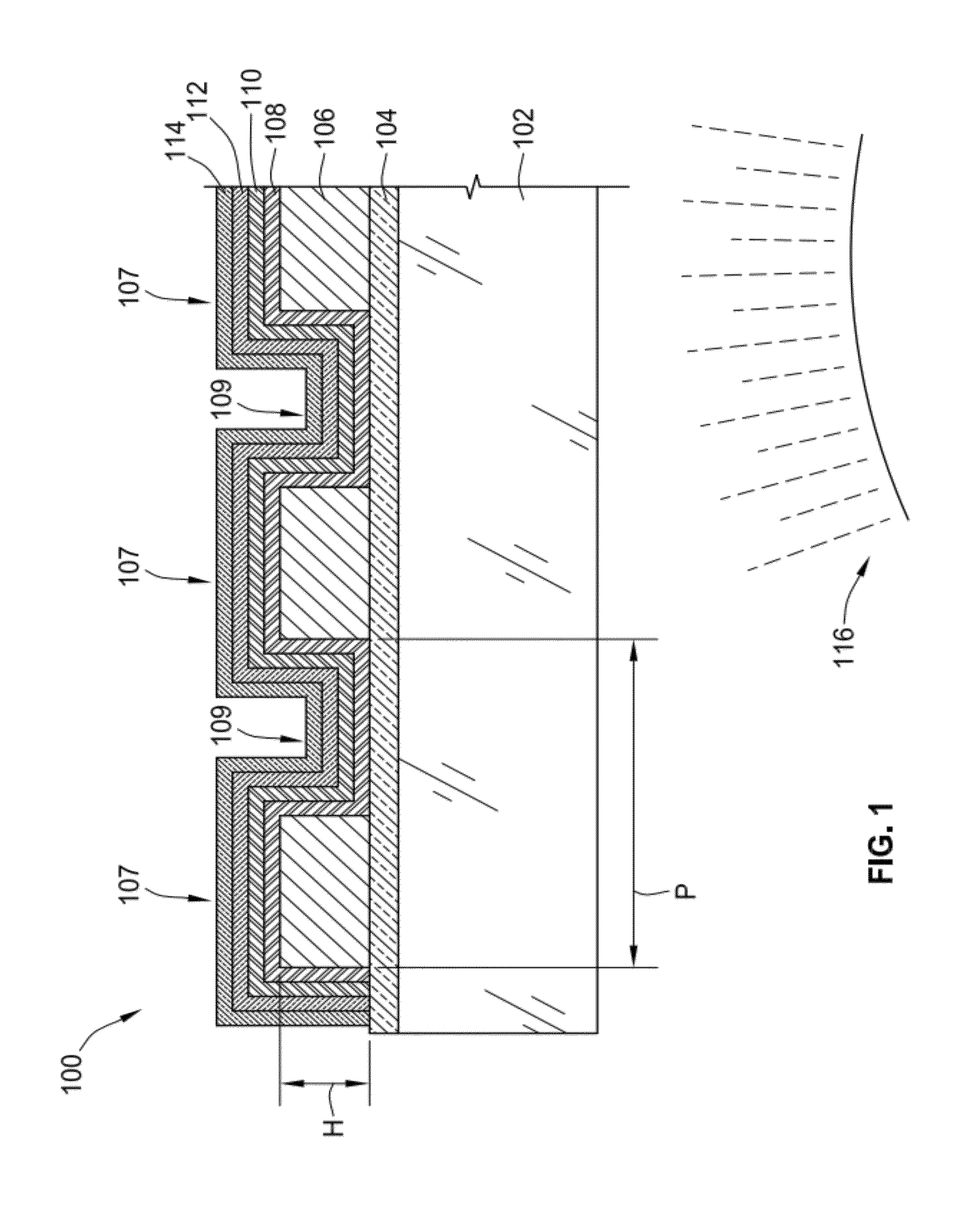

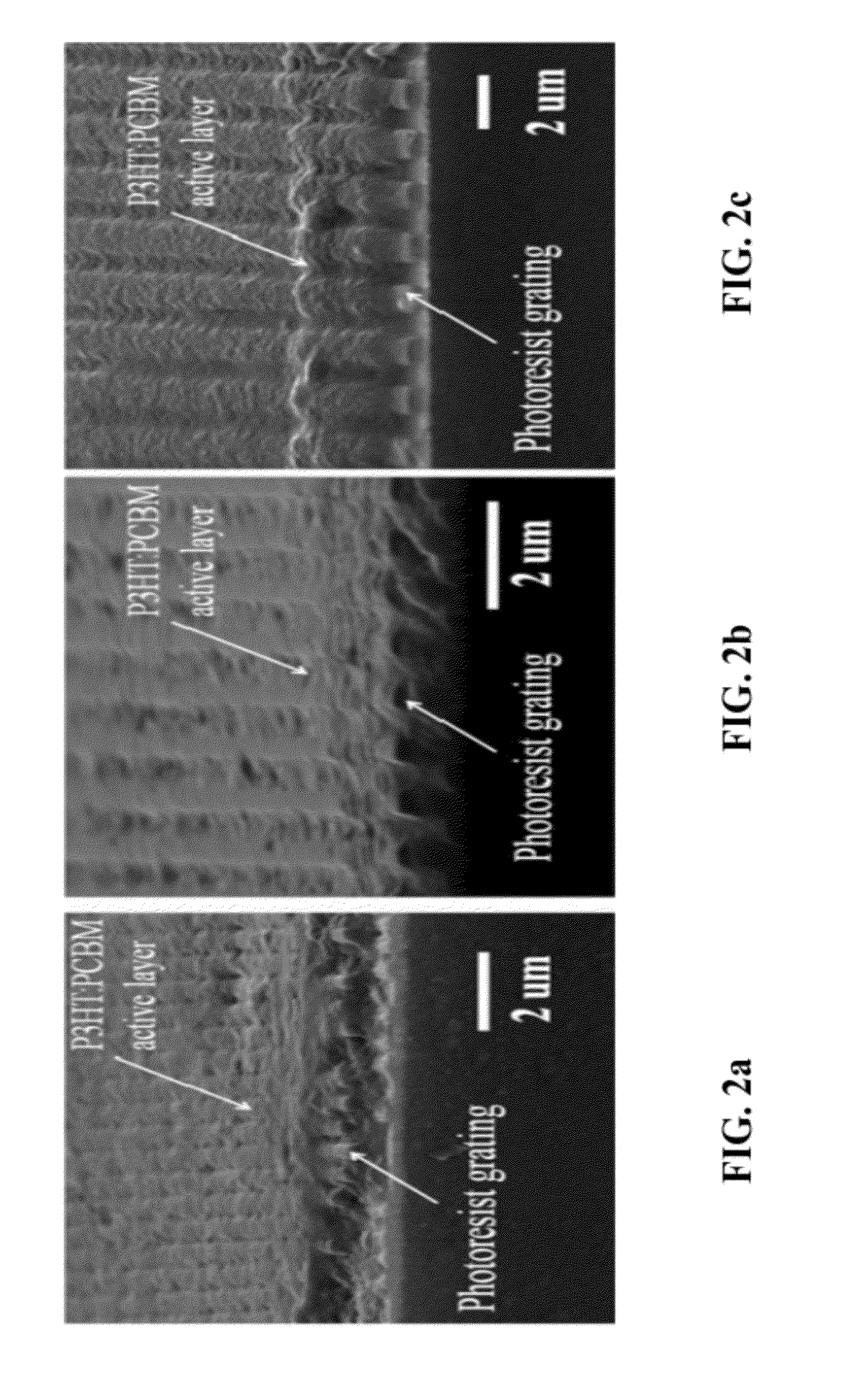

Textured Micrometer Scale Templates as Light Managing Fabrication Platform for Organic Solar Cells

InactiveUS20120048368A1Promote absorptionImprove battery efficiencyNanoinformaticsSolid-state devicesOrganic solar cellGrating

A three-dimensional, microscale-textured, grating-shaped organic solar cell geometry. The solar cells are fabricated on gratings to give them a three-dimensional texture that provides enhanced light absorption. Introduction of microscale texturing has a positive effect on the overall power conversion efficiency of the devices. This grating-based solar cell having a grating of pre-determined pitch and height has shown improved power-conversion efficiency over a conventional flat solar cell. The improvement in efficiency is accomplished by homogeneous coverage of the grating with uniform thickness of the active layer, which is attributed to a sufficiently high pitch and low height of the underlying gratings. Also the microscale texturing leads to suppressed reflection of incident light due to the efficient coupling of the incident light into modes that are guided in the active layer.

Owner:IOWA STATE UNIV RES FOUND

Super tweeter

ActiveUS20050238197A1Improve sound qualityNon-planar diaphragms/conesFrequency/directions obtaining arrangementsAcoustic waveMechanical engineering

A super tweeter includes a magnetic base, a voice coil, a frame annularly mounted to the magnetic base, a central supporting member mounted on a central portion of the magnetic base, a diaphragm, an annular inner supporting member, and an annular outer supporting member. The diaphragm is connected between an annular outer side of the annular inner supporting member and an annular inner side of the annular outer supporting member. An annular inner side of the annular inner supporting member is engaged with the central supporting member. An annular outer side of the annular outer supporting member is engaged with the frame. The annular inner supporting member and the annular outer supporting member cause the diaphragm to vibrate in a balanced manner, generating super high frequency range of sound waves.

Owner:SUN TECHN ELECTRIC

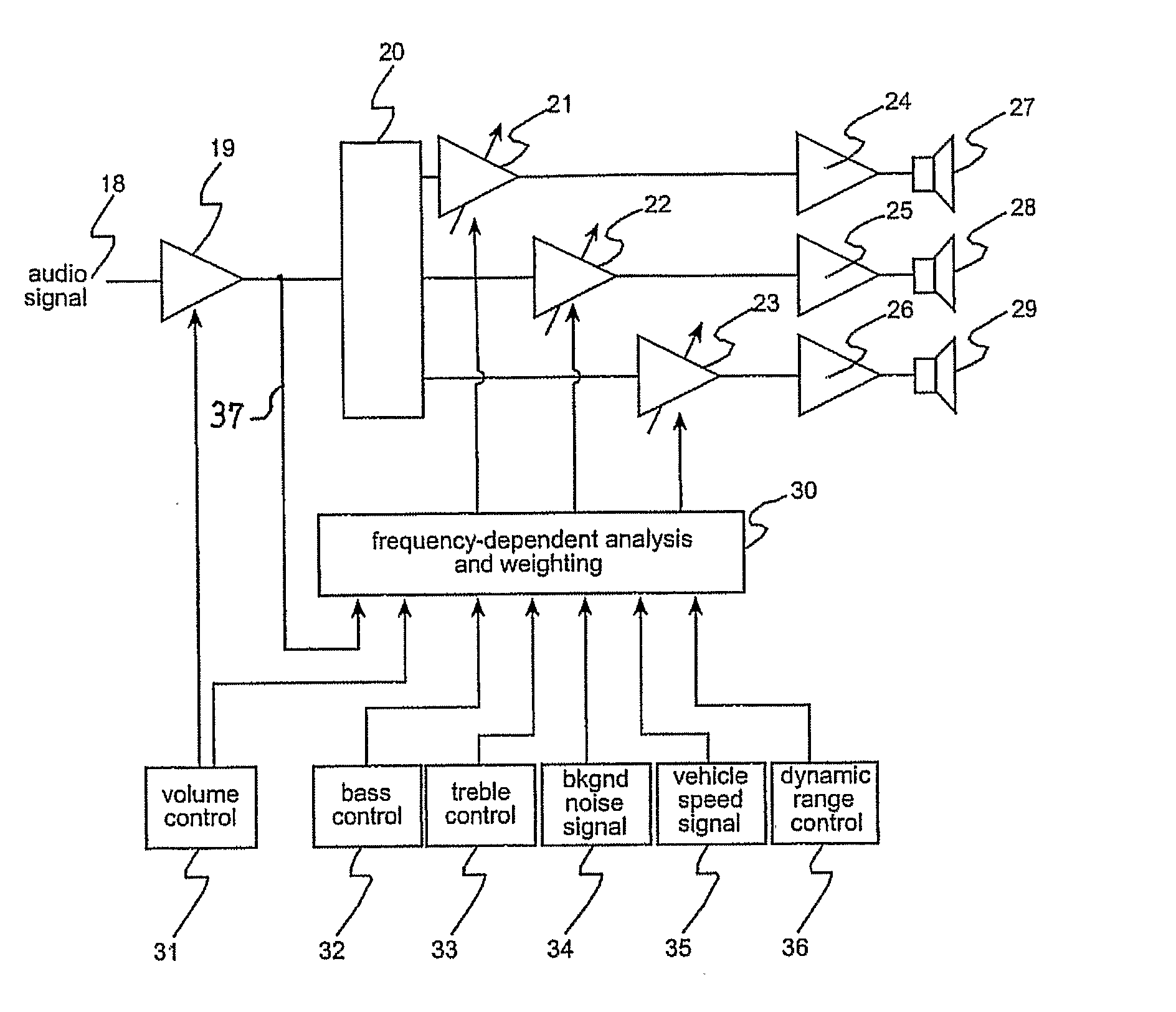

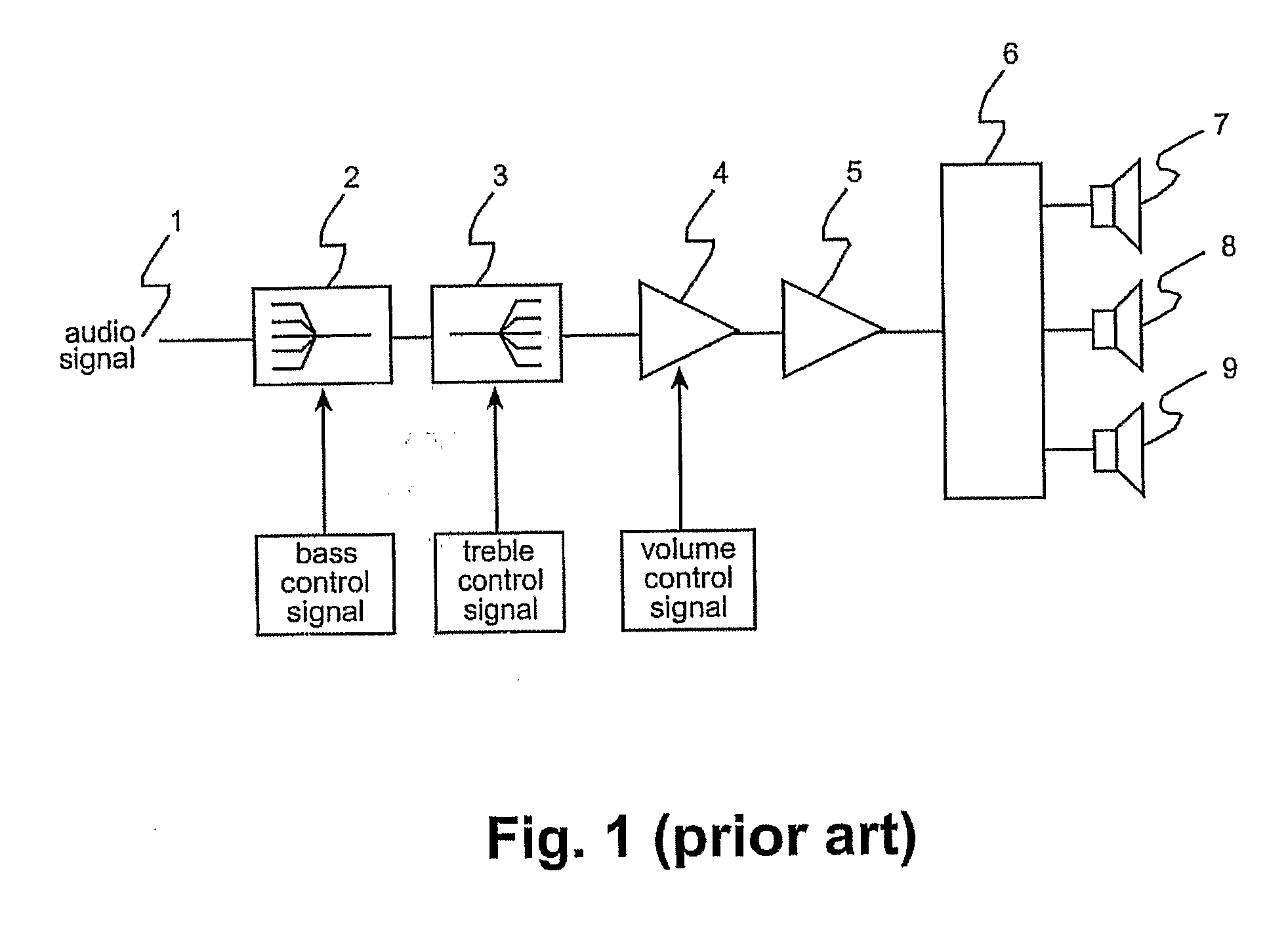

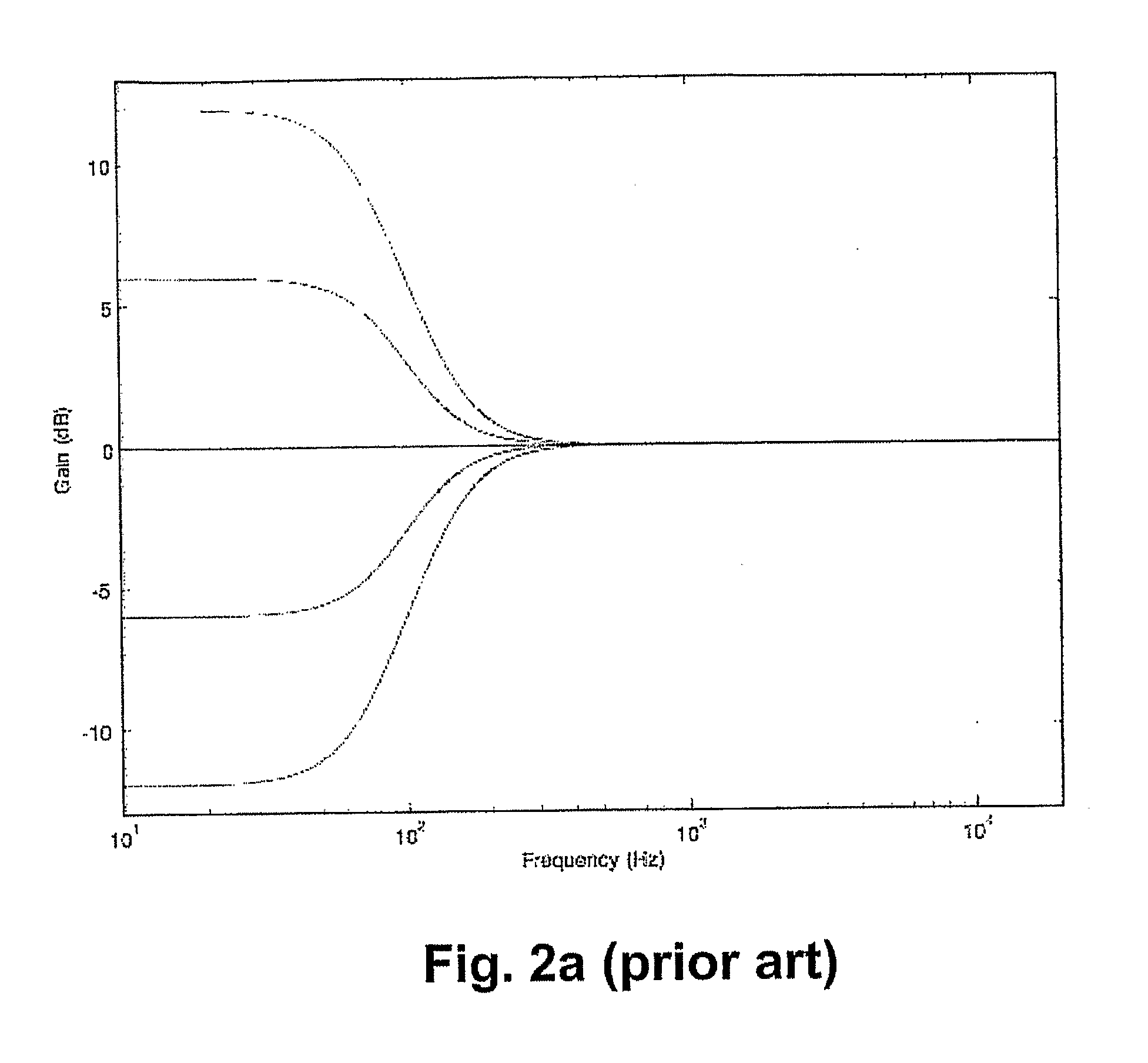

Speed- and User-Dependent Timbre and Dynamic Range Control Method, Apparatus and System for Automotive Audio Reproduction Systems

InactiveUS20070242837A1Avoiding undesirable phase effectEasy to implementStereophonic circuit arrangementsDigital/coded signal combination controlAutomotive systemsPeak value

Typically, changes in timbre in an audio reproduction system use analogue or digital filters, either shelving filters (as in the case of bass, treble and loudness controllers) and / or peaking filters (as in the case of speed-and noise-compensation in automotive systems). A problem associated with this implementation lies in the audibility of the phase shift caused by these filters. According to the invention, this and further problems are solved by utilising the crossover network of the system itself—with level adjustable output signals—to attain desired timbre and / or dynamic range adjustments and hence avoiding undesirable phase effects of the traditional bass and treble control filters. An input signal (18) is according to an embodiment of the invention divided by a cross over network (20) into a number of frequency bands and applied via level control means (21, 22, 23) and separate power amplifiers (24, 25, 26) to loudspeaker drivers (27, 28, 29). In this manner, the mentioned phase shifts can be avoided and by proper control of the level adjustment means by a frequency-dependent analysis and weighting network (30), desired adjustment of timbre and dynamic range of the audio reproduction can be achieved. Also control dependent on vehicle speed and / or background noise can be incorporated into the system..

Owner:BANG & OLUFSEN

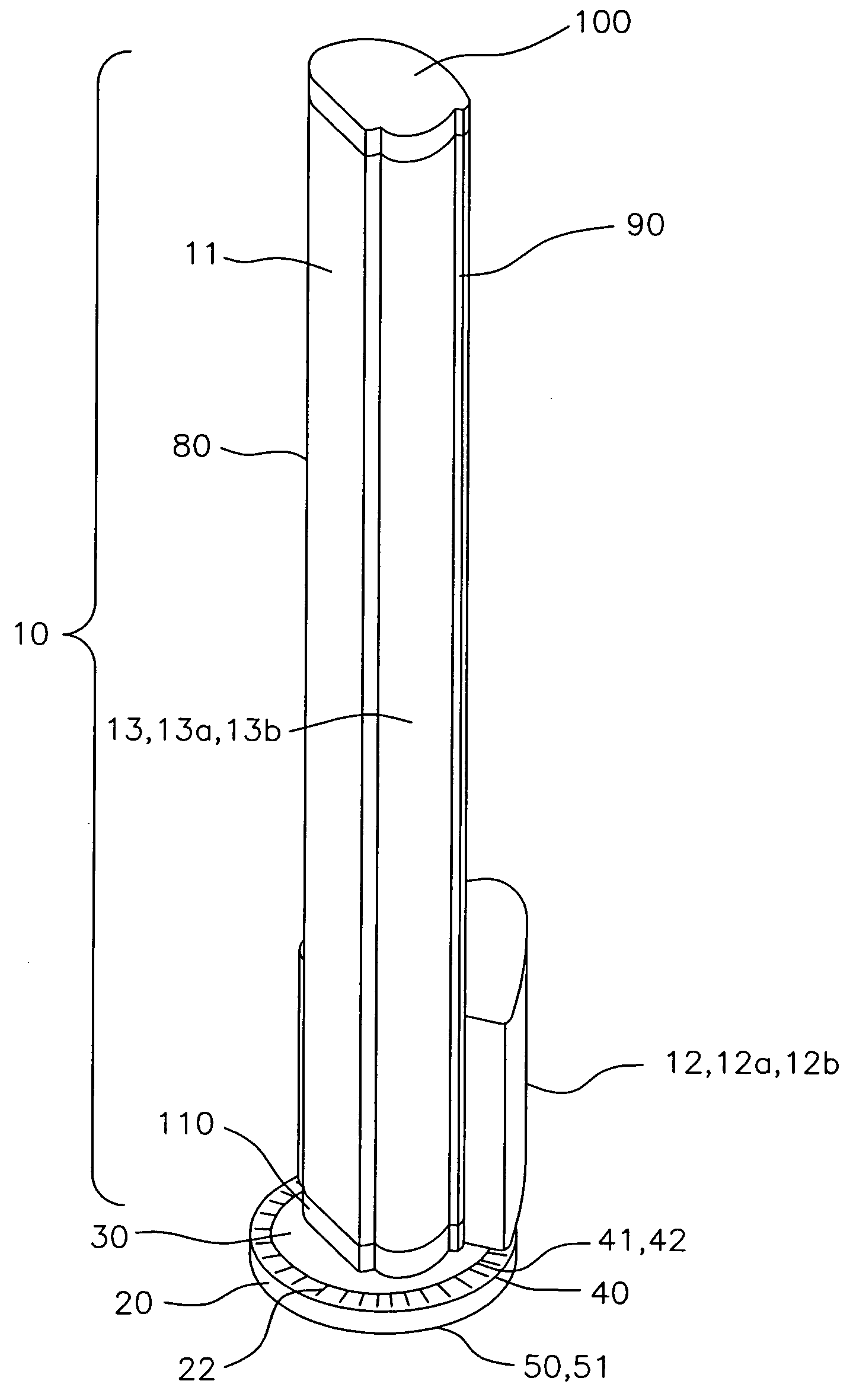

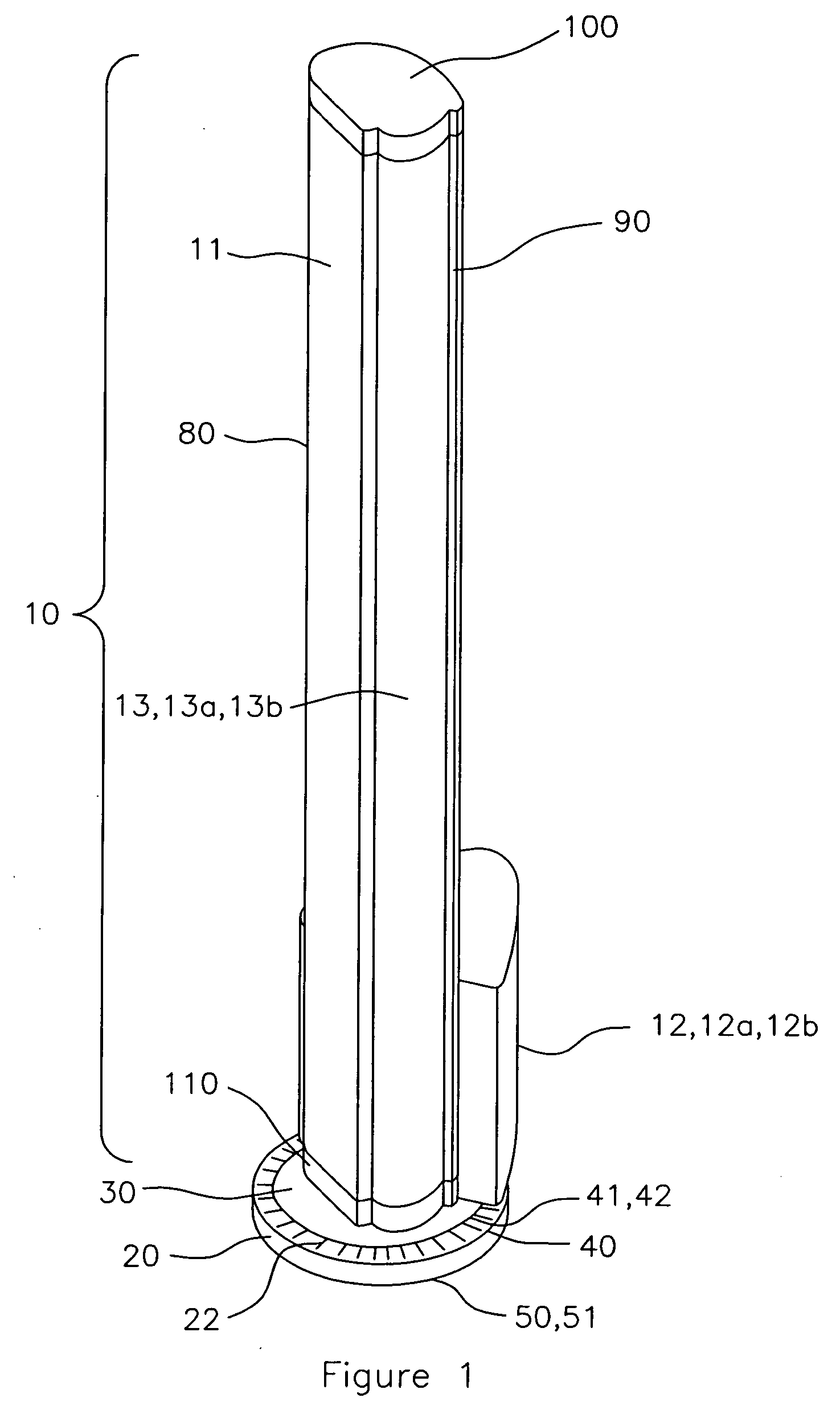

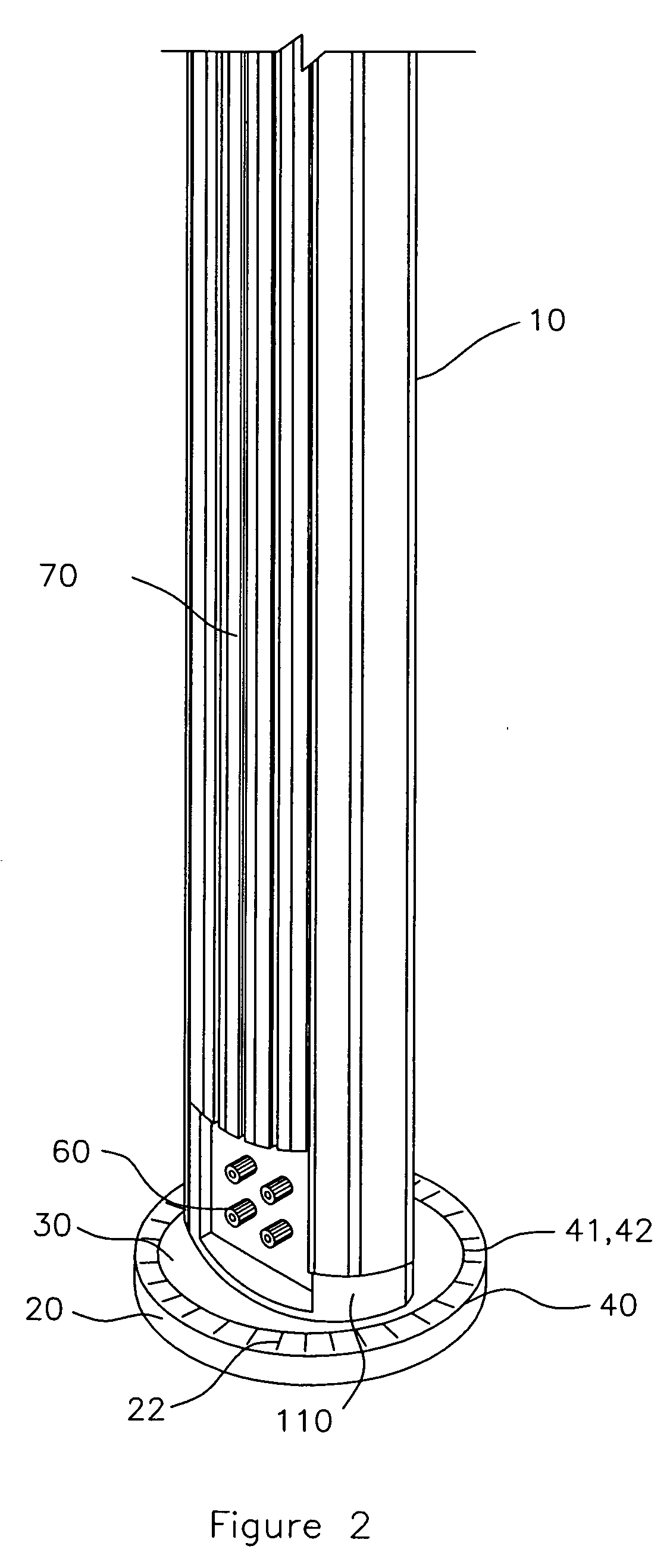

Surround sound positioning tower system and method

InactiveUS20050058314A1Easy to customizeProper disposalLoudspeaker casing supportsCabinetsEngineeringAngular rotation

A surround sound system and method involving a surround sound tower (10) having planar speakers (11b); a base plate (20); and a structure for positioning (30) the surround sound tower on the base plate (20), the surround sound tower (10) being mounted on, and normal to, the positioning structure (30) for customizing sound direction and constructive interference patterns by interactively positioning the sound tower (10) and by modular usage of both sub-woofers (12a) and tweeters (13a), economizing floor space, especially in a home theater environment, the positioning structure (30) having a structure for indicating an angular rotation (40) of the surround sound tower (10) relative to the base plate (20) and a structure for facilitating rotation (50) of the angular rotation indicating structure (40).

Owner:MONSTER

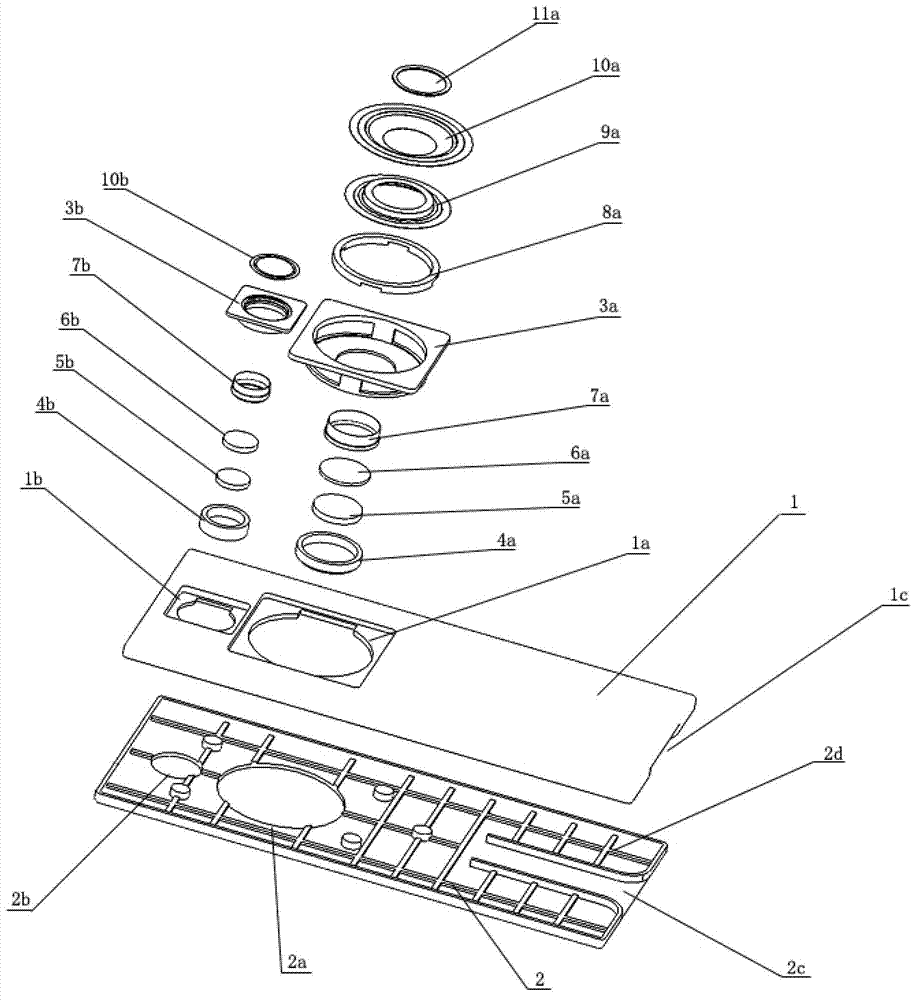

Thin double-cone phase inversion type loudspeaker box

ActiveCN103037283AAvoid \"acoustic short circuit\"Avoid interferenceFrequency/directions obtaining arrangementsInverterSound quality

The invention relates to a thin double-cone phase inversion type loudspeaker box. A box body is mainly composed of a lower shell and an upper shell, wherein a high pitch unit installing hole, a low pitch unit installing hole and a lower shell phase inversion hole are formed in the lower shell, the high pitch unit installing hole and the low pitch unit installing hole are distributed along the long axis direction and are located in the left half portion of the lower shell, the high pitch unit installing hole is close to the left end of the lower shell, the lower shell phase inversion hole is arranged along the long axis direction and is located in the right half portion of the lower shell, and an opening of the lower shell phase inversion hole is located in the right end of the lower shell. A high pitch unit positioning groove, a low pitch unit positioning groove and an upper shell phase inversion hole are formed in the upper shell, wherein the lower shell and the upper shell constitute the box body. A high pitch loudspeaker unit is arranged in the high pitch unit installing hole and the high pitch unit positioning groove, and a subwoofer unit is arranged in the low pitch unit installing hole and the low pitch unit positioning groove. An inverter tube is formed by corresponding combination of the lower shell phase inversion hole and the upper shell phase inversion hole. The thin double-cone phase inversion type loudspeaker box is ingenious and reasonable in structure, and pretty good low frequency tone quality is achieved under the condition that the thin structure of the loudspeaker box is guaranteed.

Owner:WUXI JIEFU ELECTROACOUSTIC

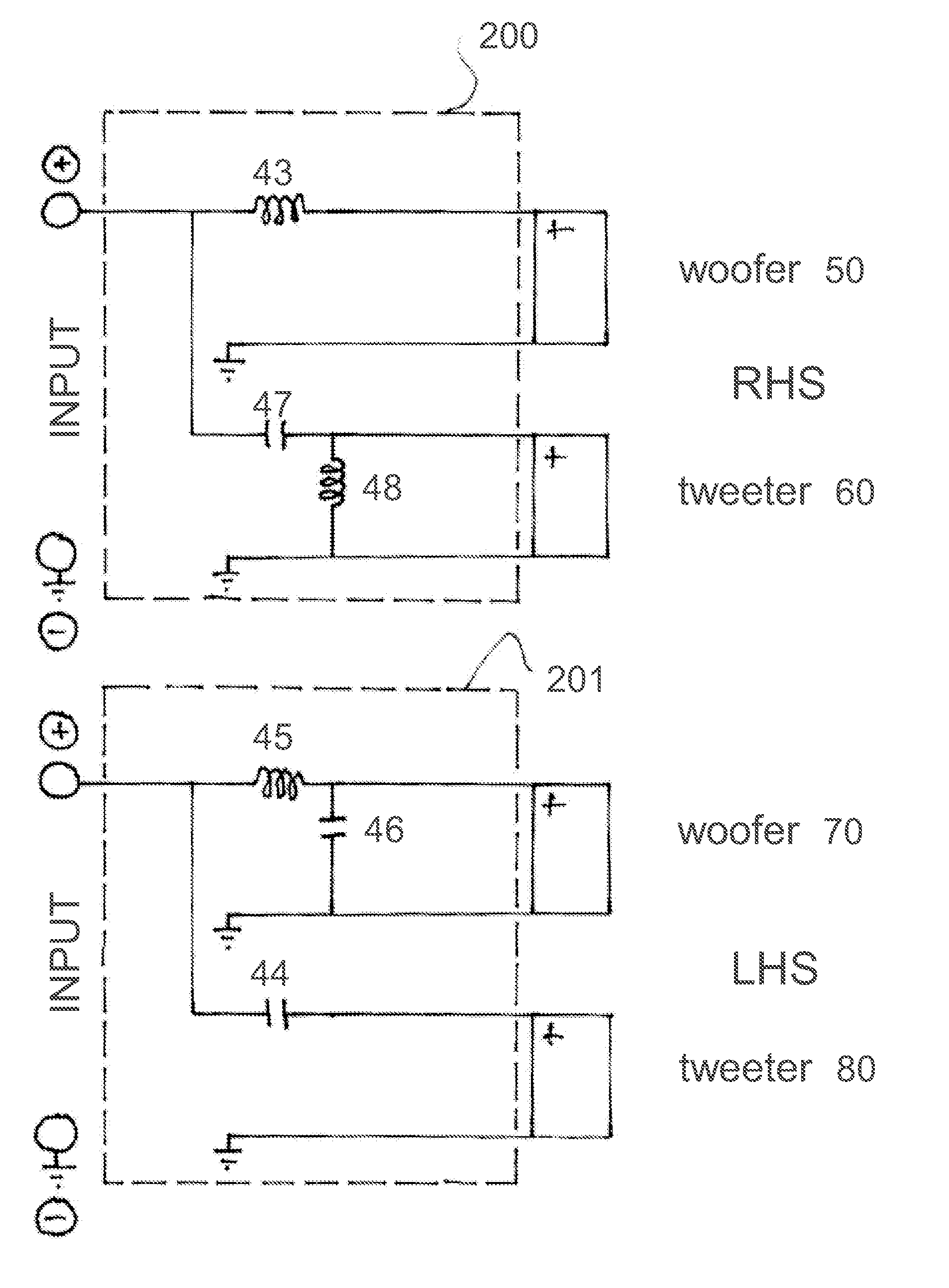

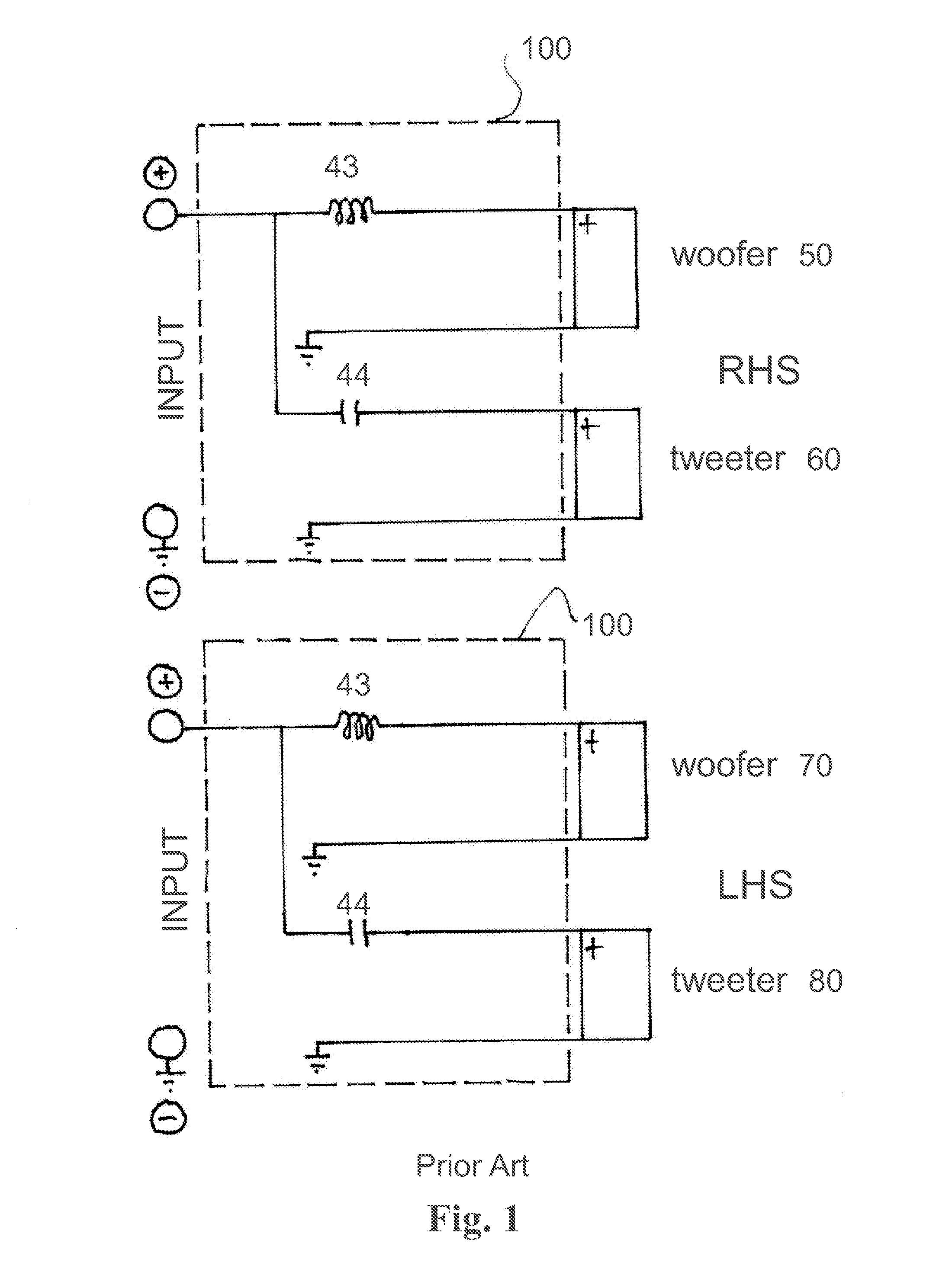

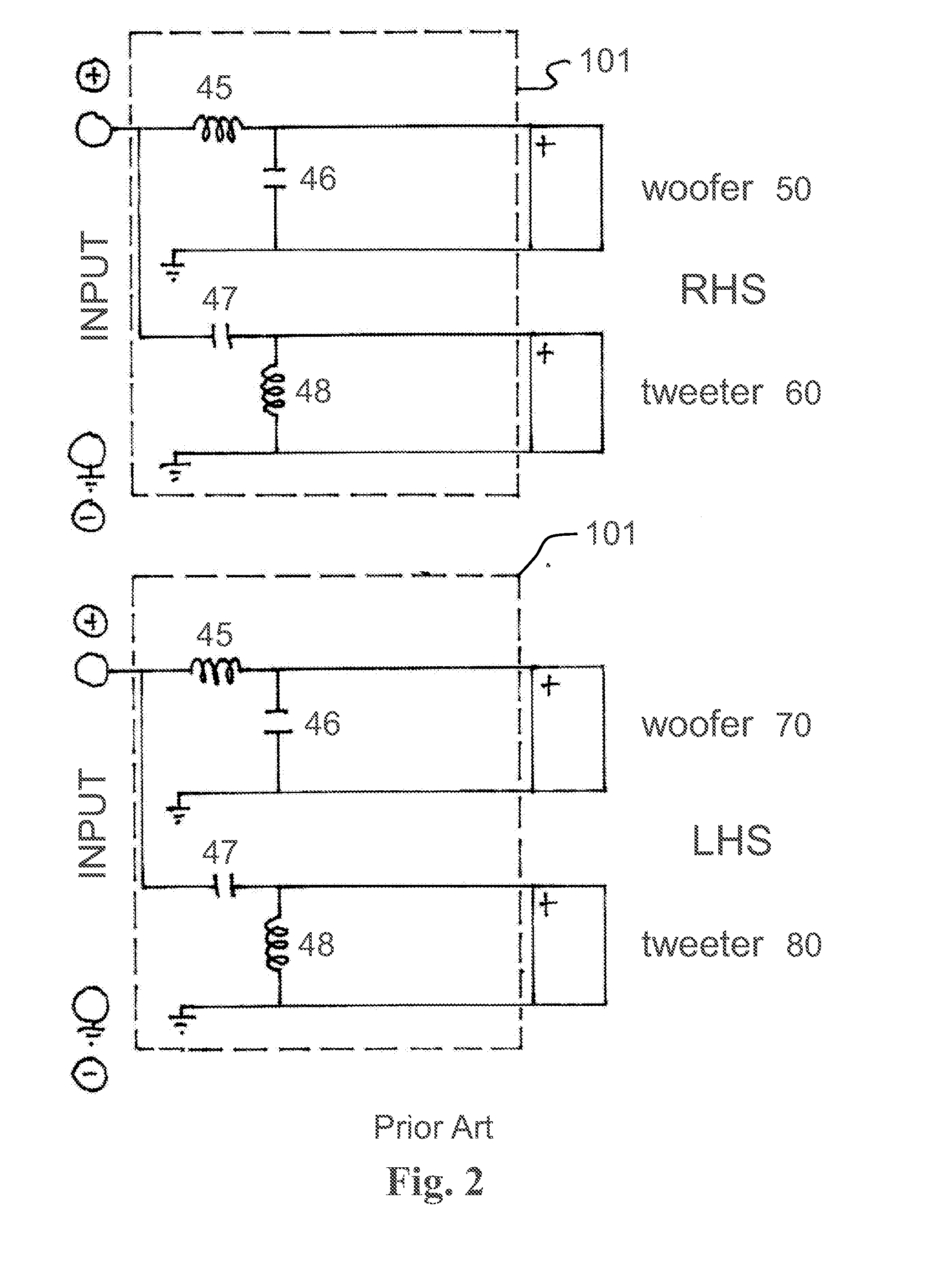

Phase-Unified Loudspeakers: Parallel Crossovers

ActiveUS20140219480A1Promote reproductionPossible interferenceStereophonic circuit arrangementsLoudspeaker signals distributionPhase distortionEngineering

Complimentary crossovers that reduce phase distortion in loudspeaker systems, typically pairs, are described. In the fundamental embodiment, each loudspeaker possesses two drivers, a woofer and a tweeter. The “effective third-order” crossover on the right-hand loudspeaker remains “symmetric,” but the “effective third-order” crossover on the left-hand loudspeaker is rendered “asymmetric,” as described. Other embodiments apply this principle to higher crossover orders and greater numbers of drivers. This technology can be combined with other circuits like a Zobel, typically used for impedance correction. Some configurations of “phase-unified” loudspeakers require that a Zobel is applied to all drivers except the tweeter. Accordingly a rule combining effective crossover order and handedness is established.

Owner:COLLINS WILLIAM E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com