Patents

Literature

90results about How to "Helps control production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formula of culture medium for industrial production of sparasis crispa and production process

ActiveCN101955392AWide range of sources and cheapFast growthHorticultureFertilizer mixturesBiotechnologySparassis crispa

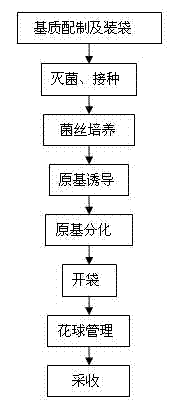

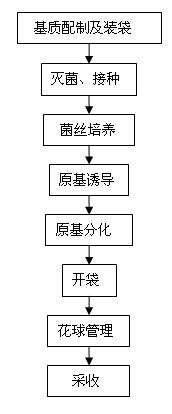

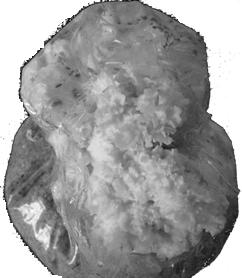

The invention provides a formula of a culture medium for industrial production of sparasis crispa and a production process. The formula of the culture medium comprises the following components in percentage by dry weight: 65 to 75 percent of pine sawdust, 10 to 20 percent of husk, 5 to 10 percent of potato powder, 5 to 10 percent of flour, 0.1 to 0.5 percent of peptone, 0.1 percent of ammonium sulfate and 1.2 to 1.8 percent of brown sugar. The production process comprises the following steps of: preparing and bagging the culture medium; sterilizing and inoculating; culturing hypha; inducing a primodium; differentiating the primodium; opening the bag; managing balls; and harvesting. The invention provides a formula of a culture medium for industrial production of sparasis crispa, which has the advantages of rich nutrition, balanced proportion, good ventilation, and capacity of meeting the requirement of industrial production. The production process has the advantages of short hypha culturing time, uniform fruiting at bag openings, good fruiting consistency, convenience of management, contribution to industrial culture, white mushroom body, high yield, and high biological transformation rate of over 43 percent.

Owner:FUQING CITY FIRE KIRIN EDIBLE FUNGUS TECH DEV +1

Aluminium foil material for tableware and manufacturing method of aluminium foil for tableware

InactiveCN101812616AHigh strengthReduce supersaturationMetal rolling arrangementsAluminum foilGrain growth

The invention relates to an aluminium foil material for tableware and a manufacturing method of aluminium foils for the tableware, belonging to the technical field of manufacture of aluminium alloy materials and the aluminium foils. The aluminium foil material comprises the following components in percentage by weight: 0.2-0.30% of Si, 1.40-1.50% of Fe, 0.05% of Cu, 0.50-0.60% of Mn, 0.05% of Mg, 0.01% of Cr, 0.05% of Zn, 0.05% of Ti, and the balance of Al, wherein the components are smelted into an alloy. The manufacturing method of the aluminium foils for the tableware comprises the following steps of: a, smelting; b, casting; c, uniform annealing; d, cold rolling; e, foil rolling; and f, finished product annealing. The invention can prevent an aluminium coil from generating grain growth during the uniform annealing and also has better machining property and easy rolling.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

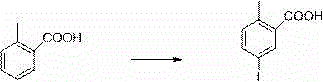

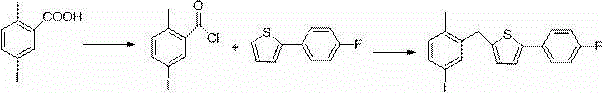

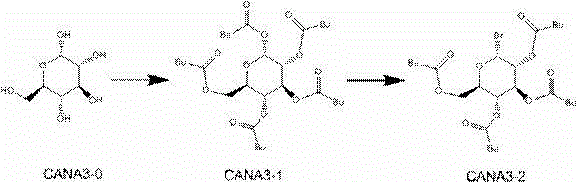

New synthesis process of canagliflozin

The present invention discloses a new synthesis process of canagliflozin. The new synthesis process comprises: adopting 2-methyl benzoic acid as a starting raw material, and adopting a self-made catalyst, iodic acid and iodine to carry out a reaction to produce an intermediate 1, or adopting 2-methyl benzoic acid as a starting raw material, and adding liquid bromine under effects of a metal reagent and a catalyst to synthesize an intermediate 2; optionally selecting the intermediate 1 or 2 to carry out an acylation reaction with thionyl chloride, and then carrying out a Friedel-Crafts reaction to produce an intermediate 3; adopting ALPHA-D-glucose as a raw material, carrying out a reaction with pivaloyl chloride to protect all hydroxyl, and carrying out a reaction with zinc bromide and bromotrimethylsilane to produce an intermediate 4; linking the intermediate 3 and the intermediate 4 to produce an intermediate 5; and finally under an acid condition, removing the pivaloyl to produce the target compound. The new synthesis process has characteristics of high yield, mild condition, safety, reliability, cheap and easily available raw material, and easy production cost control, and is suitable for industrial production.

Owner:HAIMEN RUIYI MEDICAL TECH

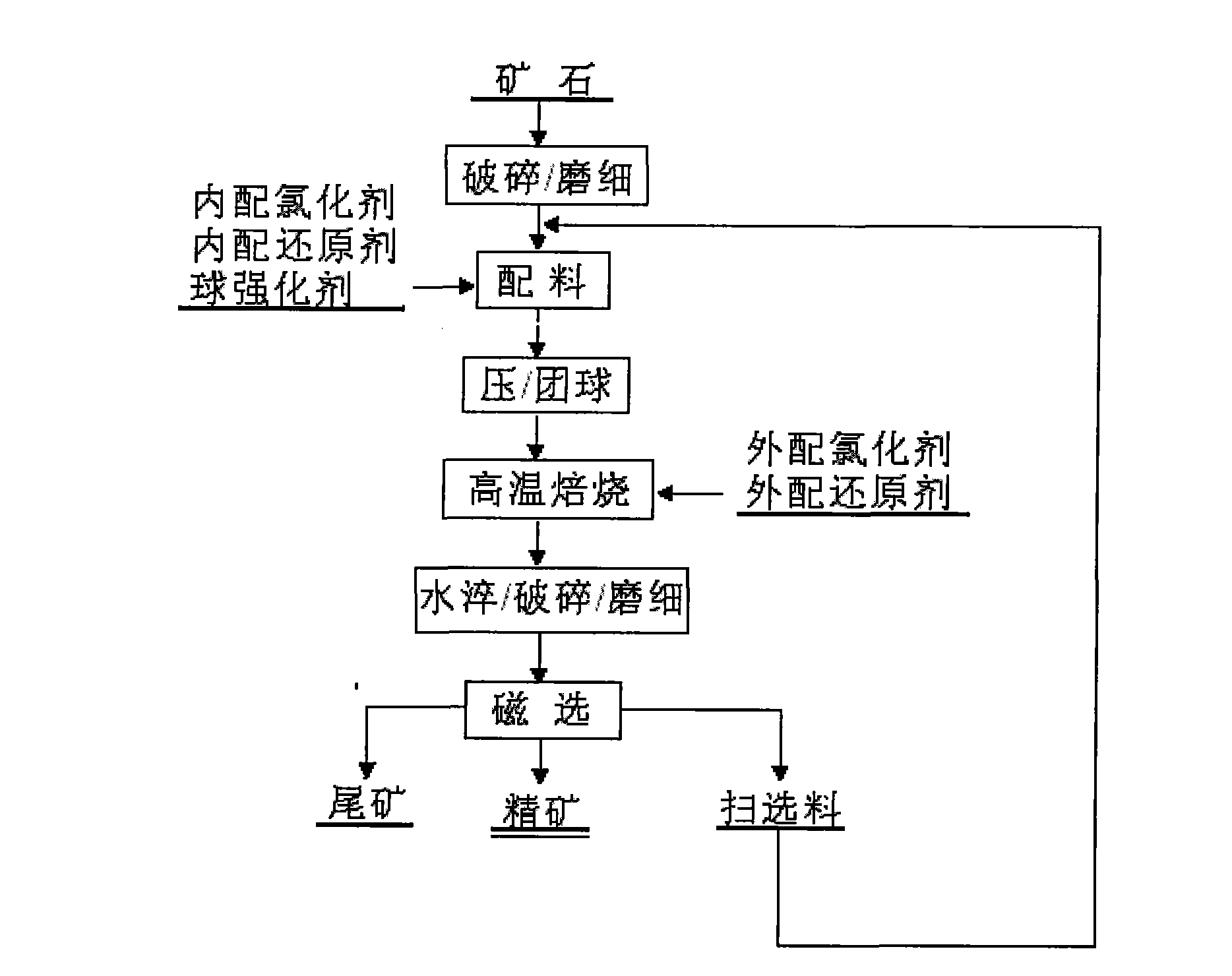

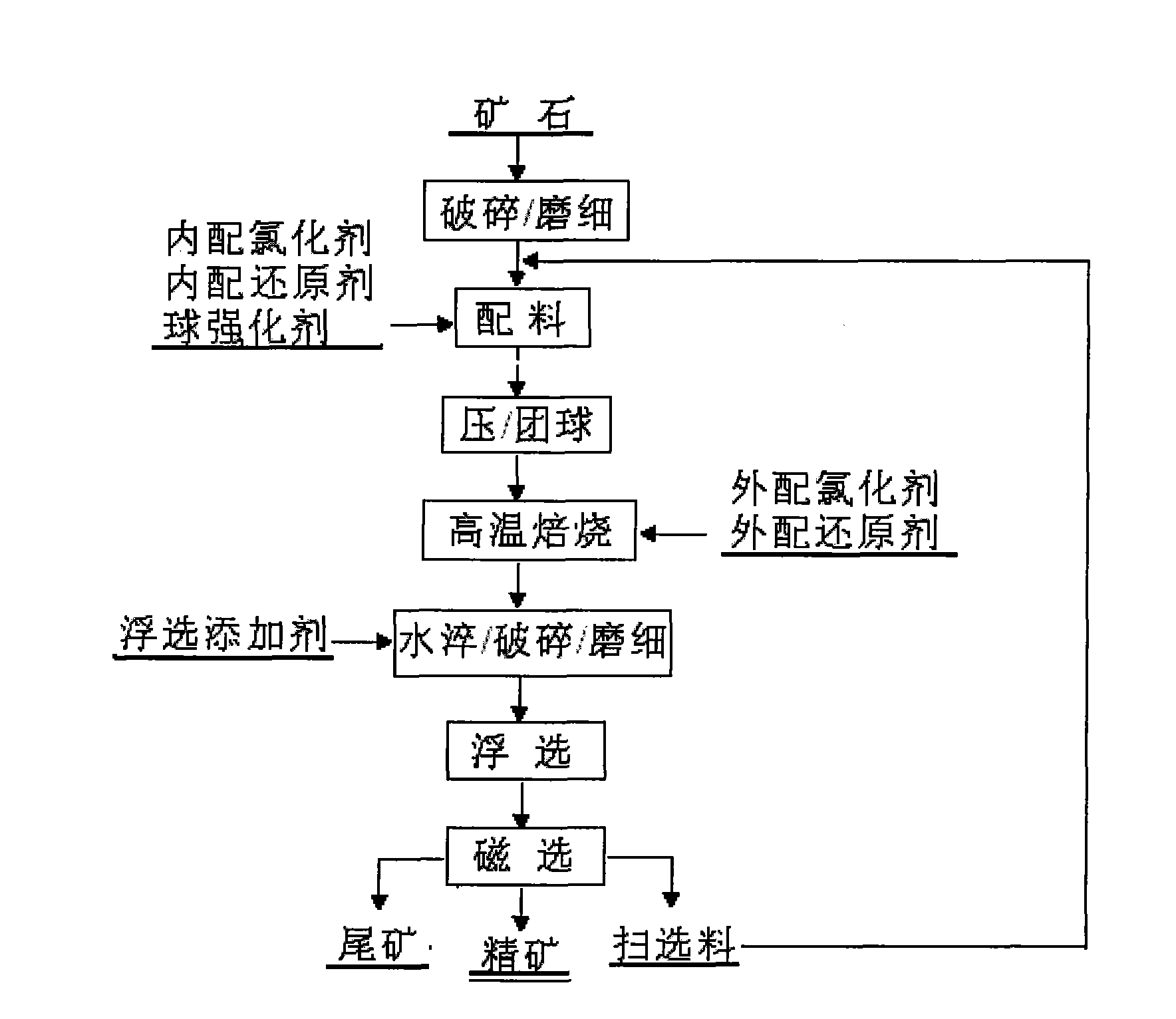

Method for efficiently concentrating cobalt and nickel from low-grade nickeliferous laterite ore

InactiveCN101514401ASimple processPractical processMagnetic separationWet separationLower gradeAlloy

The invention provides a method for efficiently concentrating cobalt and nickel from a low-grade nickeliferous laterite ore. The method is based on mine-phase reconstruction, and the ore is subject to physical treatment, high temperature chlorination and reduction roasting to convert the nickel and the cobalt in the ore from oxide or composite oxide (silicate and ferrite) mineral into magnetic metal or alloy, magnetic separation method or combined floatation-magnetic separation method is used for separation to concentrate the cobalt and the nickel. The method is used for treating the low-grade nickeliferous laterite ore (Ni is 0.2-2.0%), contents of the nickel ore concentrate is more than ten times of that of the crude nickel ore; and the nickel recovery is more than 80%.

Owner:CENT SOUTH UNIV

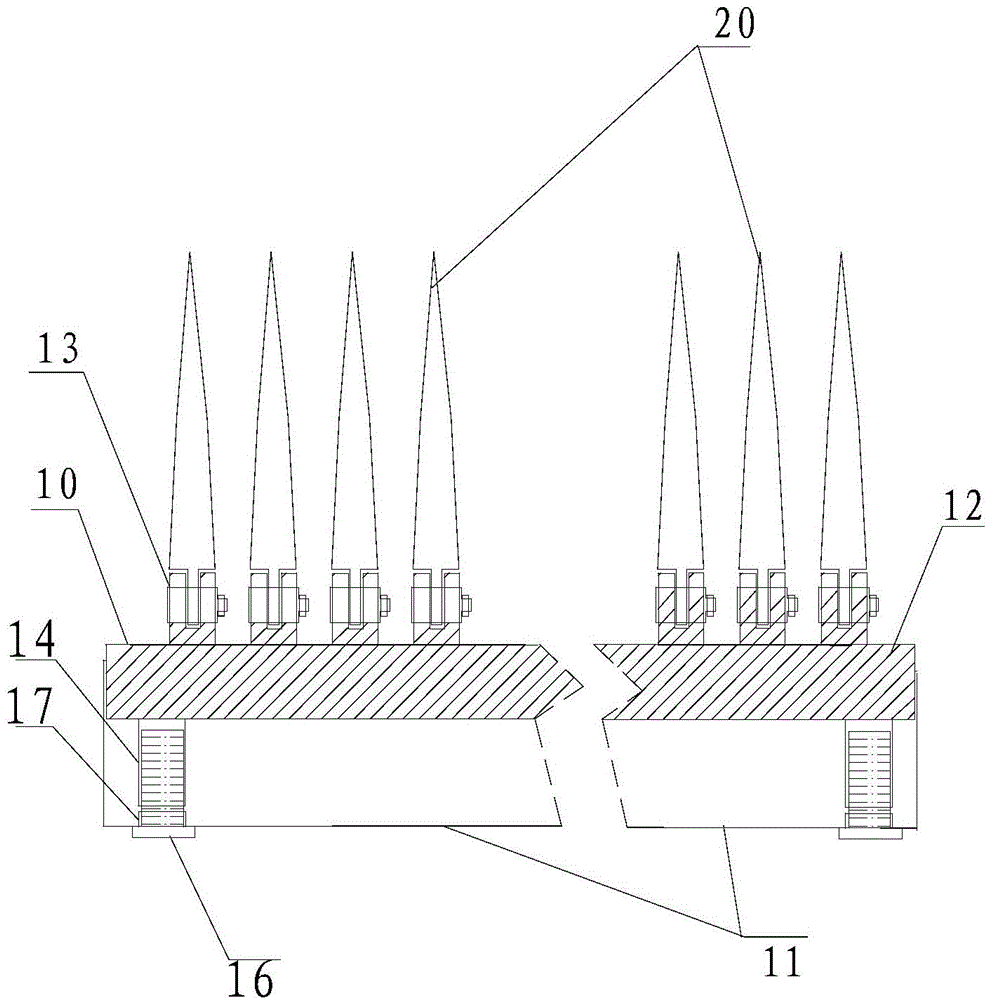

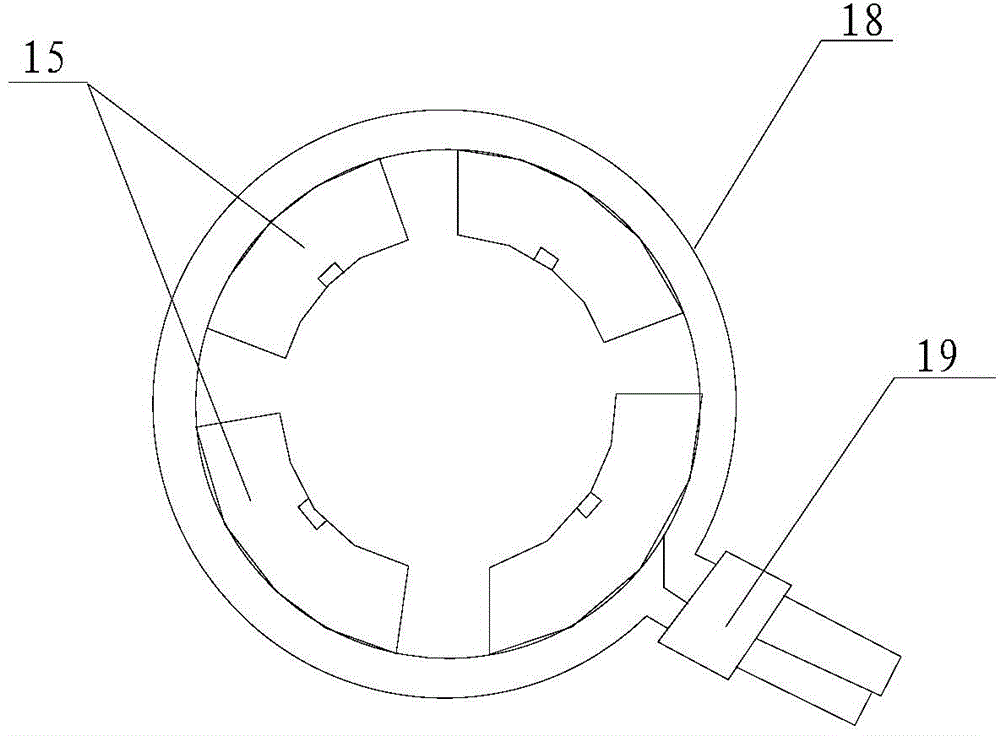

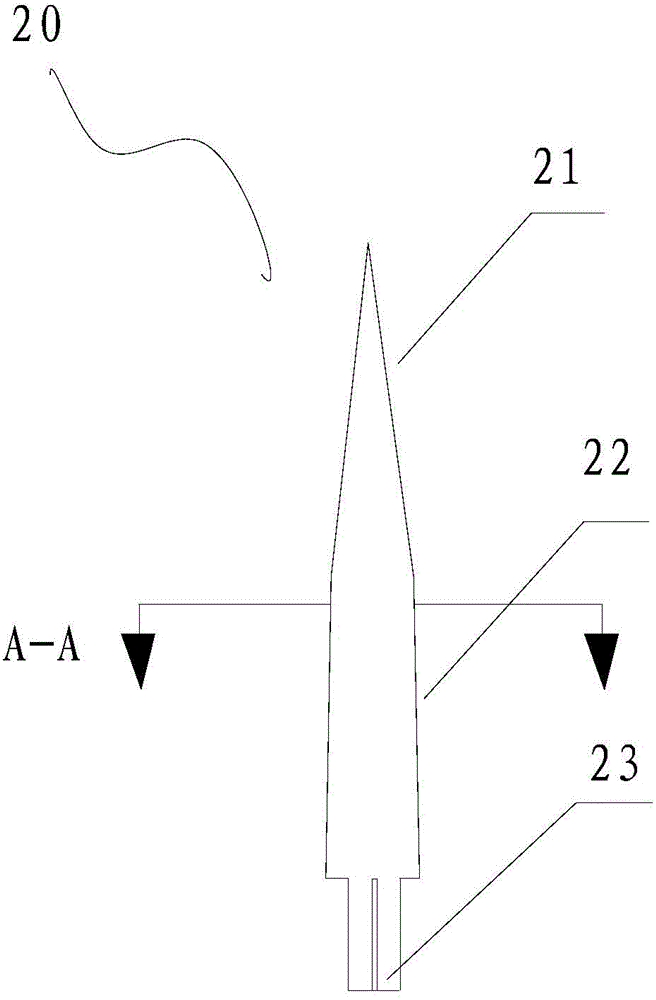

Needle base structure convenient for replacing needles

Owner:WUXI GUOSONG ENVIRONMENTAL PROTECTION MACHINERY

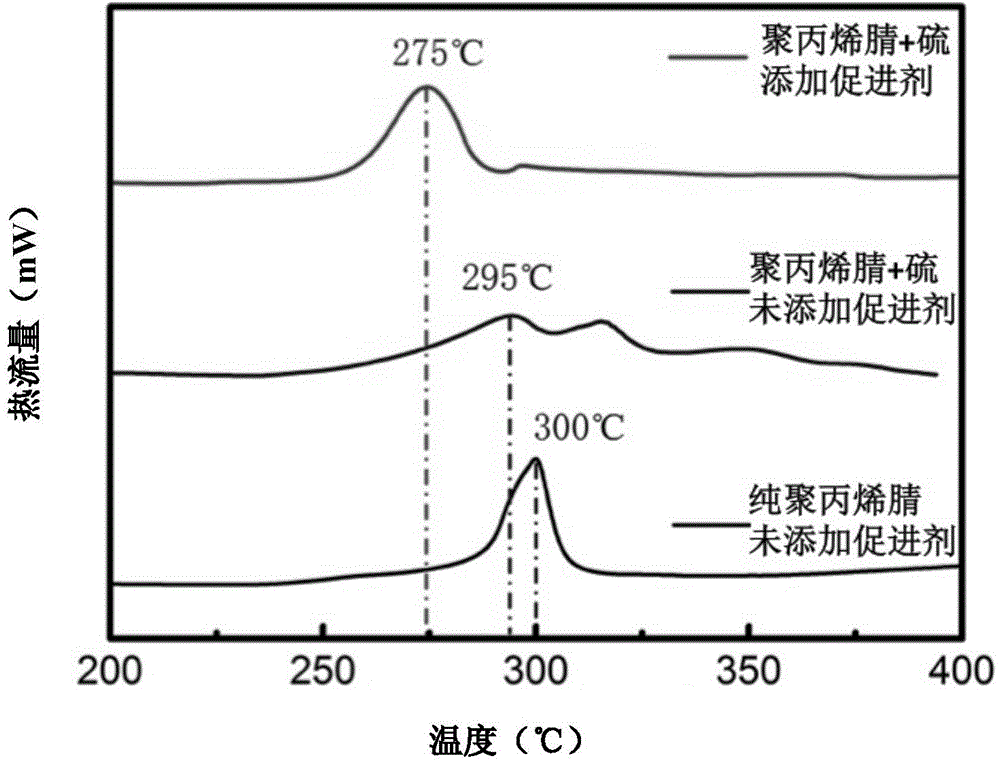

Method for increasing sulfur content of sulfur-carbon composite through vulcanization accelerator

InactiveCN105633351AHigh sulfur contentImprove discharge capacityCell electrodesCarbon compositesLithium–sulfur battery

The invention discloses a method for increasing a sulfur content of a sulfur-carbon composite through a vulcanization accelerator. The method comprises the steps of enabling a carbon source, a sulfur source and the vulcanization accelerator to be mixed and ball milled to obtain a uniform mixture; and putting the uniform mixture into a sealed container, and pumping protective gas to enable the mixture to be fully reacted at a vulcanizing temperature of 100-700 DEG C to obtain the sulfur-carbon composite. The method provided by the invention is simple and effective, and capable of greatly increasing the sulfur content of the sulfur-carbon composite; therefore, the electrochemical performance of a lithium-sulfur battery taking the sulfur-carbon composite as the positive electrode material can be improved; for example, the discharge capacity and the cycling stability of the battery can be dramatically improved while other impurities affecting the operation of the battery are not introduced either.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Preparation method of polymer-inorganic composite electrolyte

InactiveCN110600797AContinuous preparationFast preparationSolid electrolytesFinal product manufactureComposite electrolyteSlurry

The invention belongs to the field of lithium batteries, and particularly relates to a preparation method of a polymer-inorganic composite electrolyte and a preparation method of a lithium battery. The preparation method of the polymer-inorganic composite electrolyte comprises the following steps: 1, adding a polymer, inorganic nanoparticles and an inorganic oxide electrolyte into a solvent, and performing stirring to form uniform slurry; 2, coating an electrode or a diaphragm matrix with the slurry, and performing drying to form a polymer-inorganic composite membrane; 3, soaking the polymer-inorganic composite membrane in a lithium salt solution to make the polymer-inorganic composite membrane fully contact a lithium salt, and carrying out vacuum drying to obtain the polymer-inorganic composite electrolyte. The invention provides the preparation method of the polymer-inorganic composite electrolyte for the lithium ion / lithium battery and the preparation method of the lithium battery,and the preparation methods can realize rapid, low-cost and large-scale production.

Owner:TIANJIN SPACE POWER TECH CO LTD

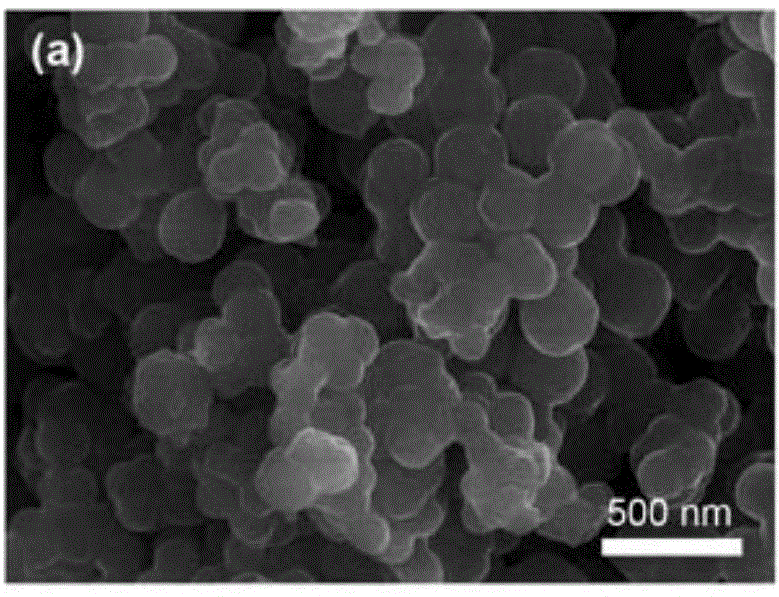

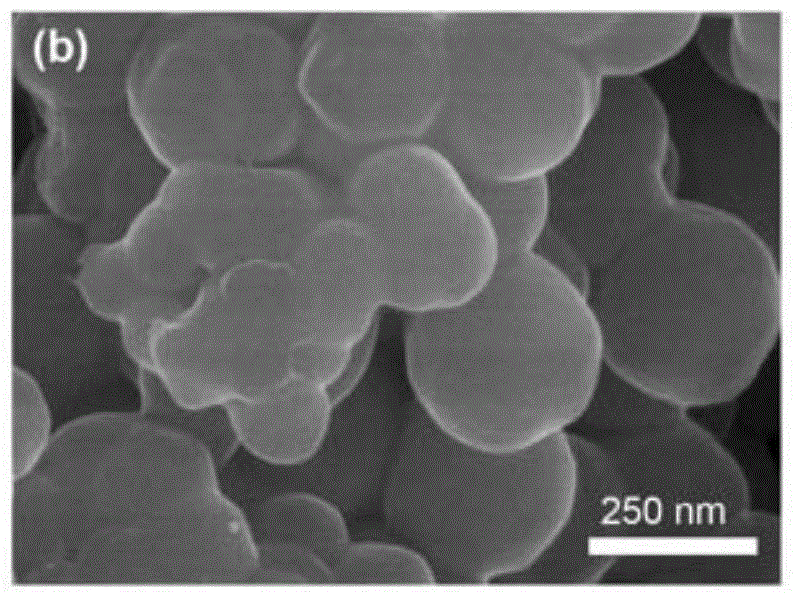

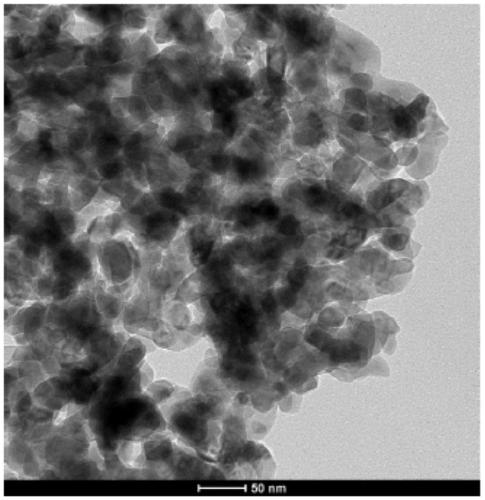

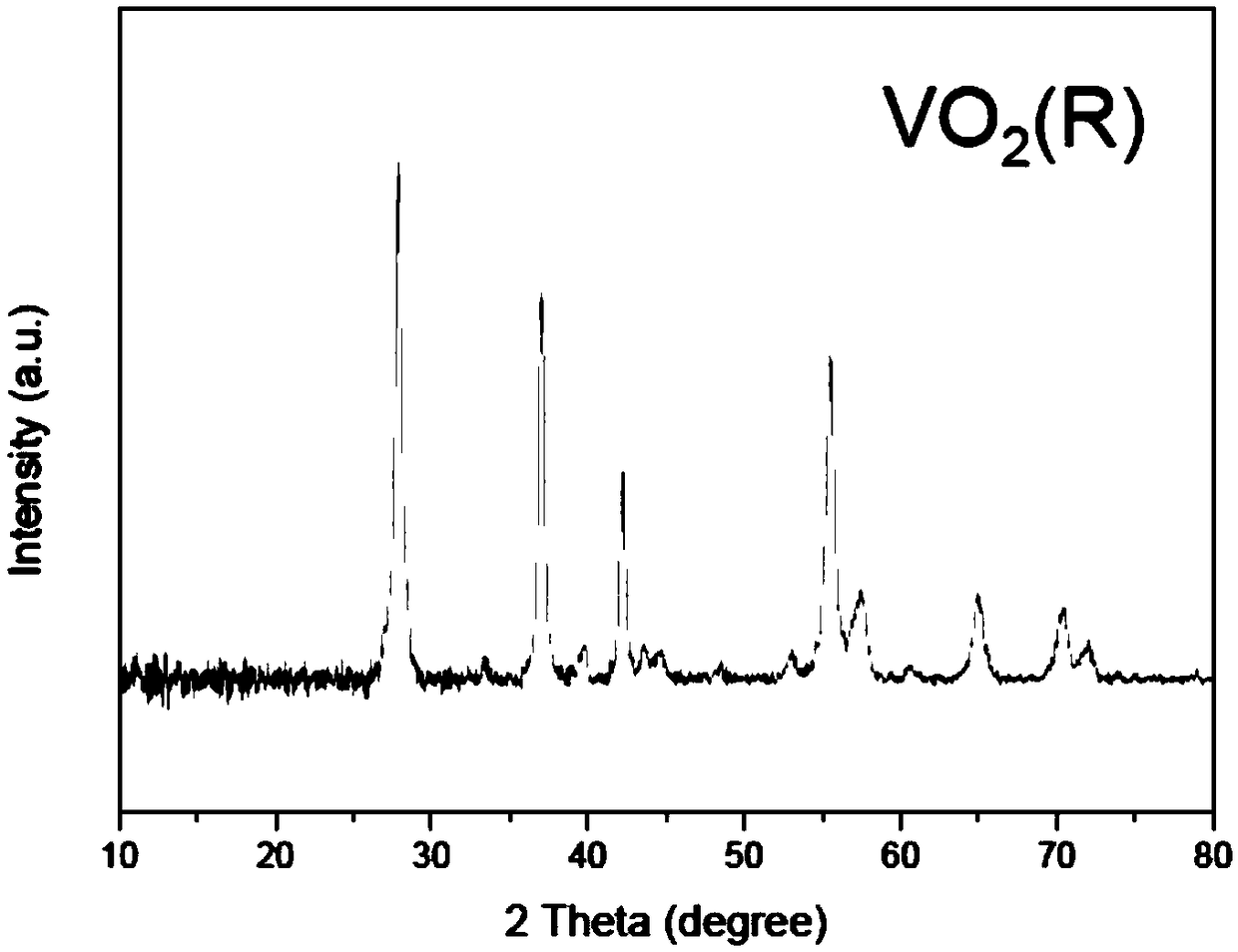

Preparation method for rutile phase vanadium dioxide superfine nano powder

InactiveCN109319838ARaw materials are cheapFast productionNanotechnologyVanadium oxidesSolventAmmonium hydroxide

The invention discloses a preparation method for rutile phase vanadium dioxide superfine nano powder, which comprises the following steps: S1, enabling ammonium hydroxide to quickly react with an acidic tetravalent vanadium solution to obtain turbid liquid B; S2, performing sealing, heat preservation and stirring treatment on the turbid liquid B to obtain a colloidal suspension C, wherein the temperature for heat preservation is not higher than the boiling point of a solvent in the tetravalent vanadium solution; S3, performing solid-liquid separation and cleaning on the colloidal suspension Cto obtain hydrated vanadium hydroxide colloid D; S4, drying the hydrated vanadium hydroxide colloid D and sintering in the protection atmosphere to obtain the rutile phase vanadium dioxide superfine nano powder. The rutile phase vanadium dioxide particles prepared by the process method disclosed by the invention have the advantages of high purity, smaller and even size and good dispersion and canserve as an excellent raw material for high-quality vanadium dioxide intelligent temperature-control coated windows.

Owner:INST FOR PROCESS MODELING & OPTIMIZATION JITRI

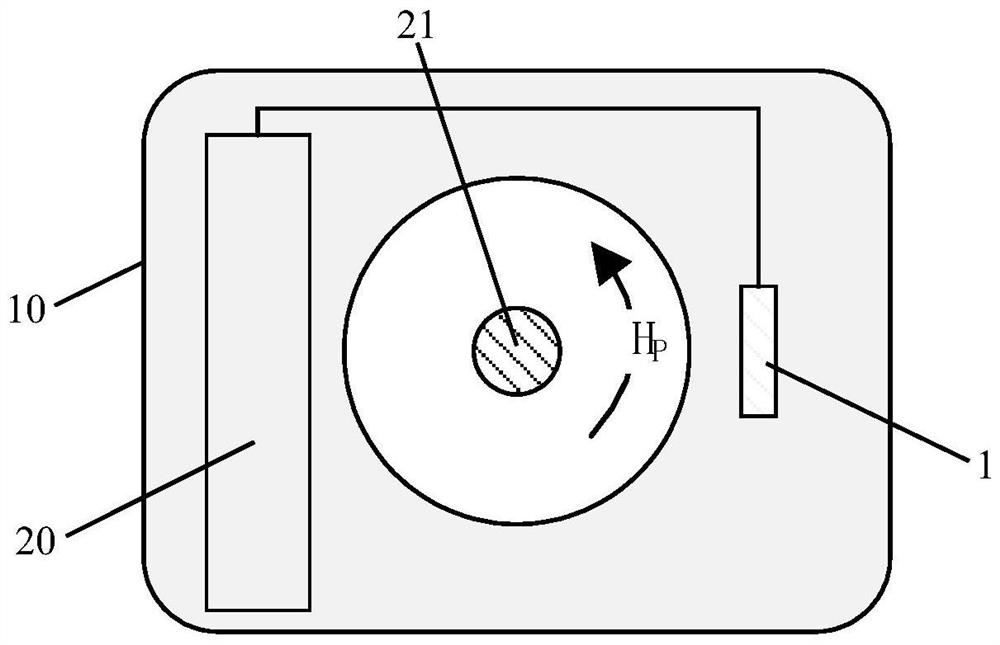

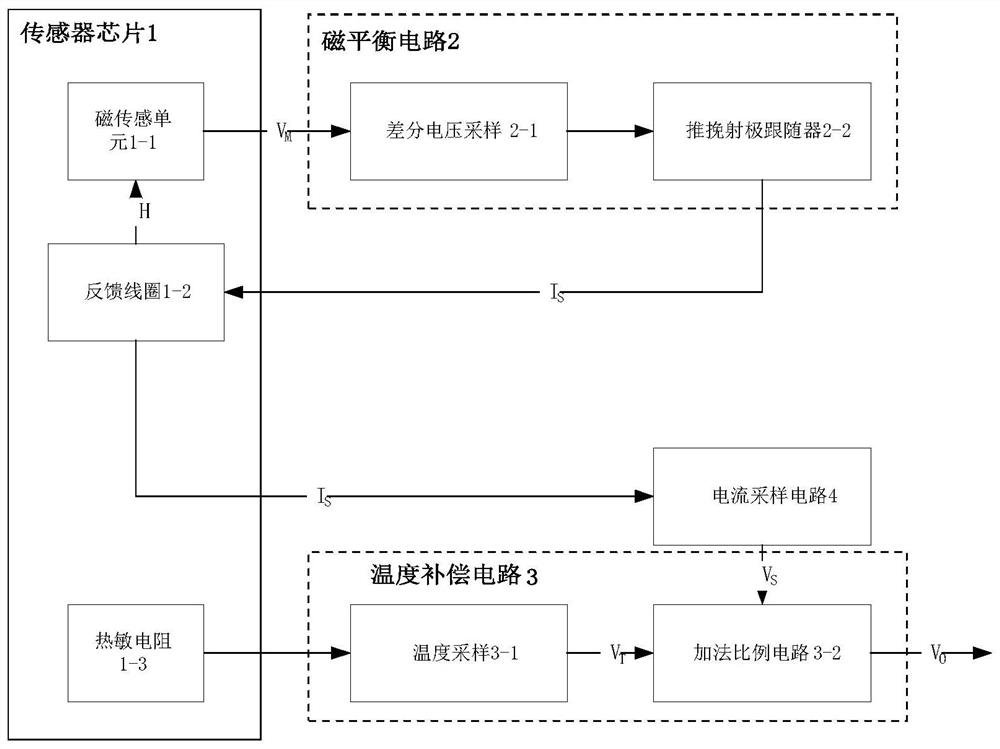

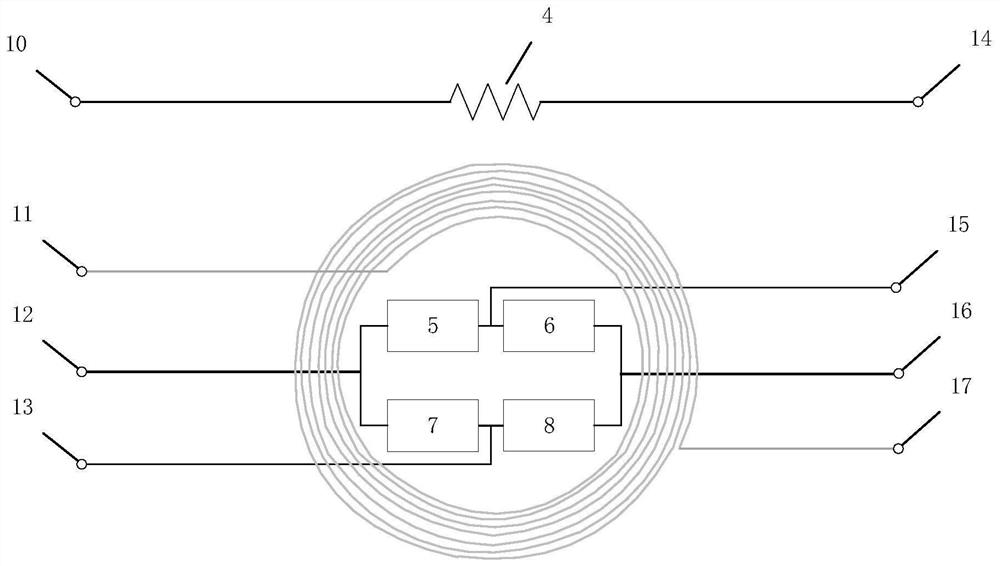

Magnetic sensing chip, closed-loop feedback current sensor and preparation method of closed-loop feedback current sensor

PendingCN111650428AReduce volumeReduce weightCurrent/voltage measurementVoltage/current isolationSignal processing circuitsClosed loop feedback

The invention discloses a magnetic sensing chip, a closed-loop feedback current sensor and a preparation method of the closed-loop feedback current sensor. The closed-loop feedback current sensor includes a shell; the magnetic sensing chip and the signal processing circuit are arranged in the shell, the magnetic sensing chip comprises a magnetic sensing unit composed of magneto-resistor elements and a feedback coil arranged above the magnetic sensing unit, the feedback coil is of a planar spiral line structure formed by etching a conductive material, and the spiral line plane is perpendicularto the sensitive direction of the magnetic sensing unit; the signal processing circuit comprises a magnetic balance circuit and a current sampling circuit, and the magnetic sensing chip is connected with a power supply through an input terminal and connected with the magnetic balance circuit through an output terminal; the magnetic balance circuit is connected with the feedback coil and provides current for the feedback coil, so that the feedback coil generates a feedback magnetic field; the current sampling circuit is connected with the feedback coil and collects and outputs a current signalof the feedback coil. According to the closed-loop feedback current sensor, the magneto-resistor elements and the feedback coil are integrated in the magnetic sensing chip, so that the size and the weight of the closed-loop feedback current sensor are reduced.

Owner:珠海多创科技有限公司

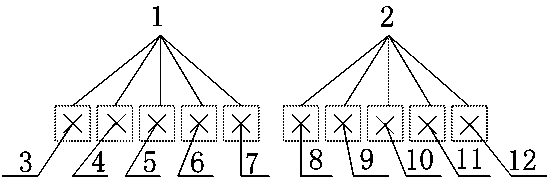

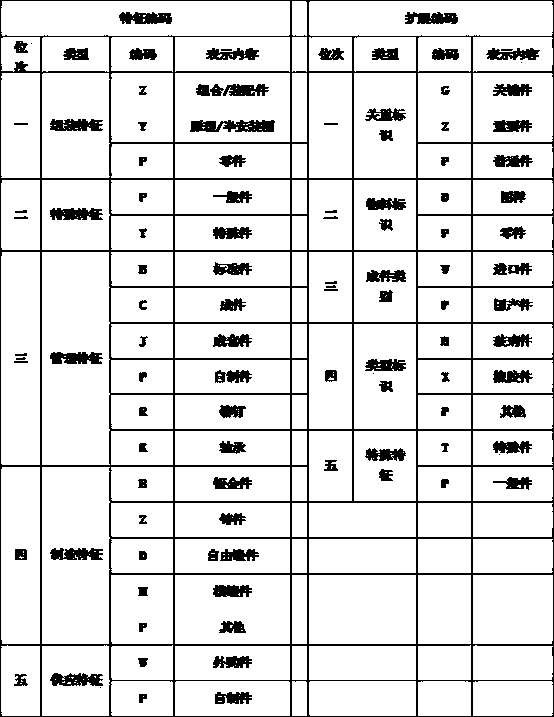

Code management method for product classification and identification

InactiveCN103955800AEasy to identifyImprove manufacturing efficiencyResourcesProgramming languageManagement efficiency

The invention discloses a code management method for product classification and identification. According to the code management method, ten bits of codes are included, wherein the first five bits of codes are feature codes, and the last five bits of codes are extended codes; according to the feature codes, the first-bit code is an assembly feature code, the second-bit code is a special feature code, the third-bit code is a management feature code, the fourth-bit code is a manufacturing feature code, and the fifth-bit code is a supply feature code; according to the extended codes, the first-bit code is a key identification code, the second-bit code is a material identification code, the third-bit code is a unit goods category code, the fourth-bit code is a type identification code, and the fifth-bit code is a special feature code. According to the code management method for product classification and identification, relevant features of products are presented visually, so that identification of an information-based system is facilitated, production and management efficiency of an enterprise can be improved, product loss caused by unclear classification is reduced, and production cost can be easily controlled.

Owner:JIANGXI HONGDU AVIATION IND GRP

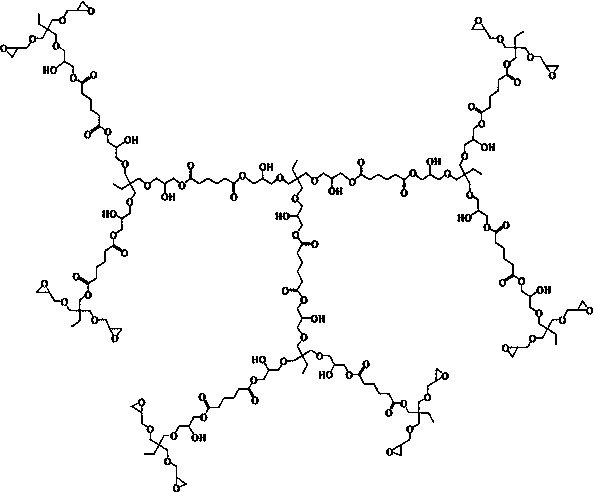

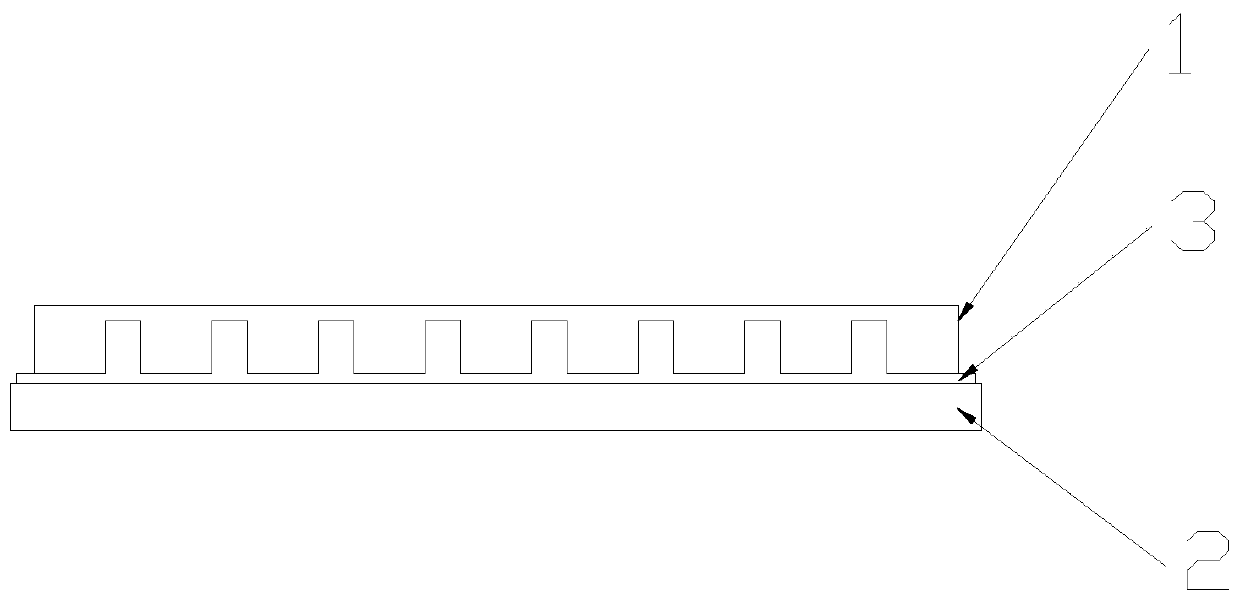

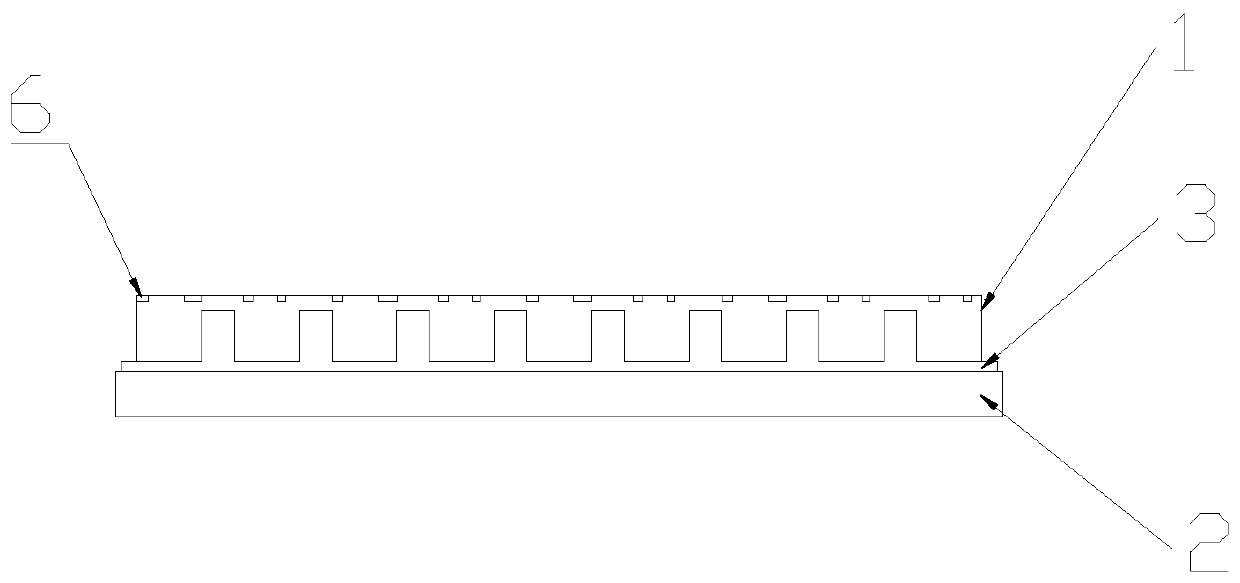

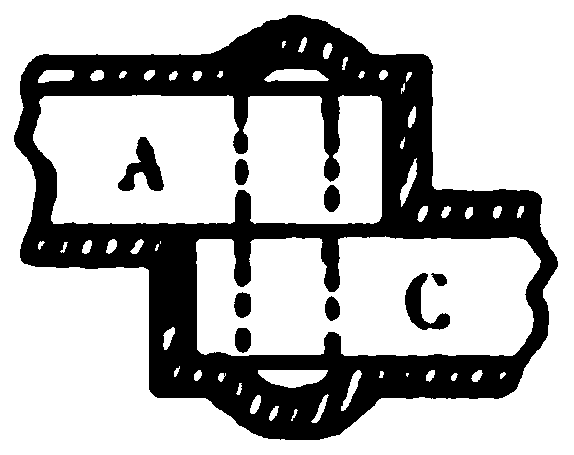

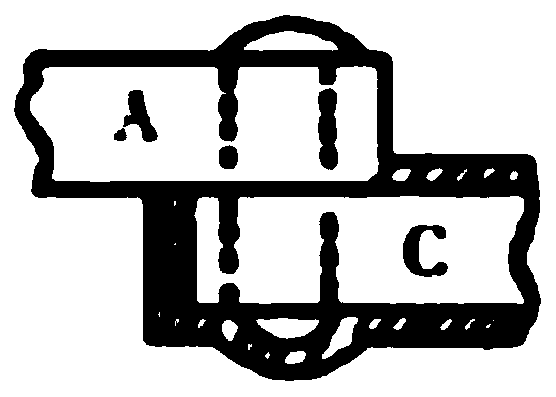

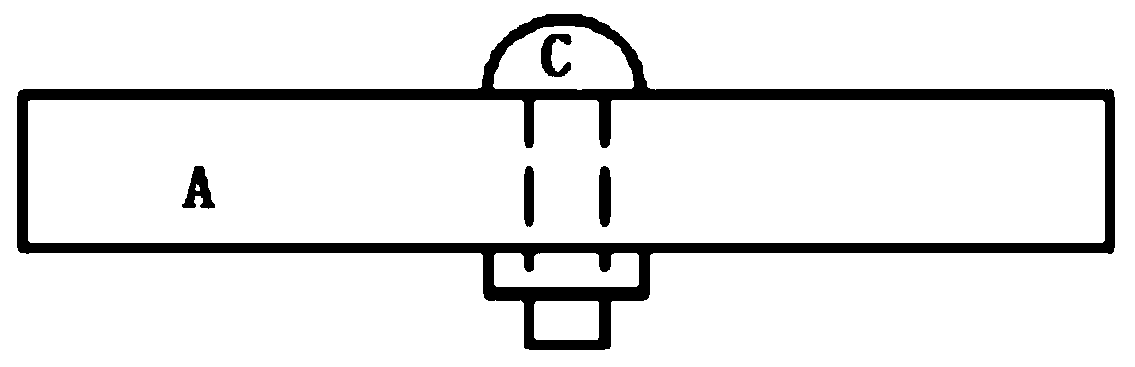

Synthesis process of 1-(beta-D-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene

ActiveCN104557895AHigh yieldMild conditionsOrganic chemistryBulk chemical productionBenzeneMethyl group

The invention discloses a preparation method of 1-(beta-D-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene. The method has the advantages of short route, no requirement on low temperature, solid starting raw materials and intermediate, convenience in purification, good stereoselectivity and the like.

Owner:JIANGSU SINOBIOPHARMA

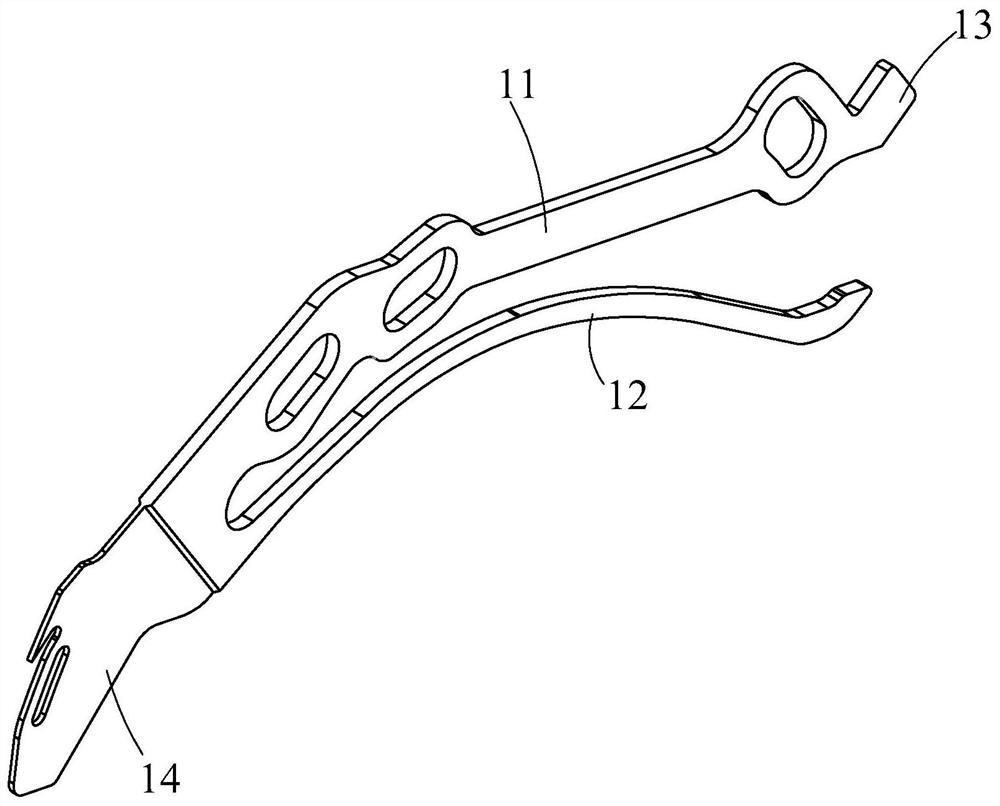

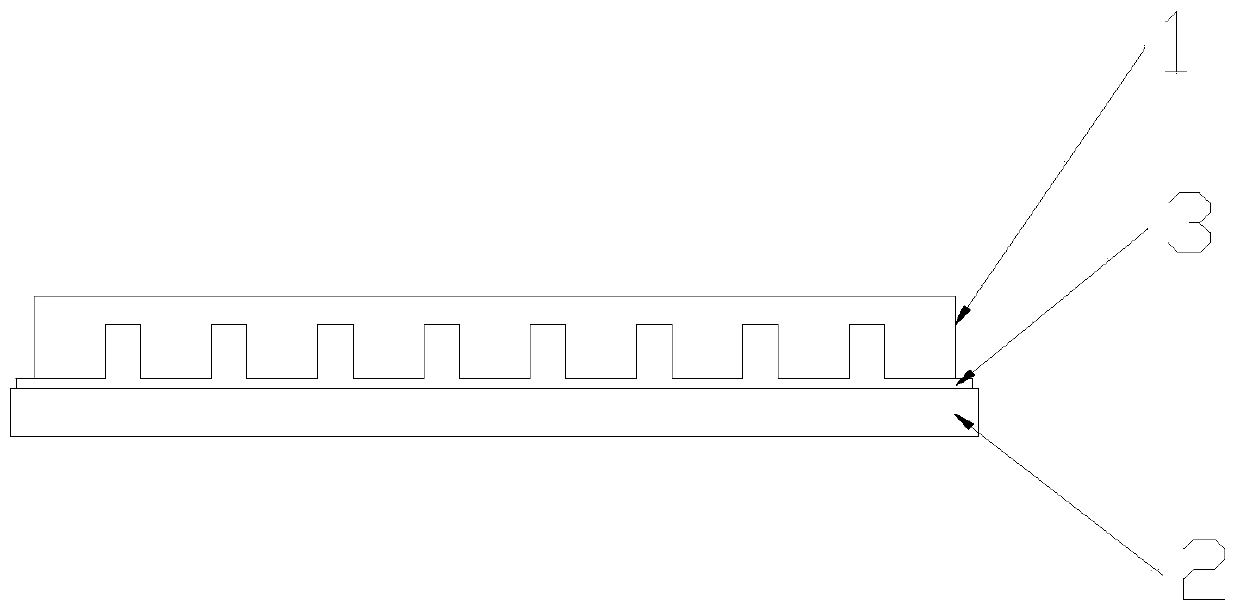

Yarn pressing device of flat knitting machine and working method of yarn pressing device

The invention relates to a yarn pressing device of a flat knitting machine and a working method of the yarn pressing device. A sinker is installed in a sinker containing groove; the sinker comprises a sinker body, an elastic presser foot part, a power piece heel part and a yarn pressing part; three rotary positioning holes are formed in the sinker body; a through hole for limiting is formed in the yarn pressing part; three through grooves are formed in a sinker needle plate; a first positioning steel wire is installed in each through groove, and the three first positioning steel wires penetrate through three rotary positioning holes respectively; three intersection points generated by the axial leads of the three first positioning steel wires and the same cross section are not on the same straight line, a virtual circle is determined by the three intersection points, and the circle centers of all the virtual circles form a virtual axial lead; and the power piece heel part enables the sinker to rotate back and forth around the virtual axial lead under the action of power. According to the yarn pressing device, the use requirements on rollers, presser feet and other flat knitting machine mechanisms during knitting are reduced, the structural design optimization of an integrated garment making machine is facilitated, and the overall production cost is favorably controlled.

Owner:桐乡市强隆机械有限公司

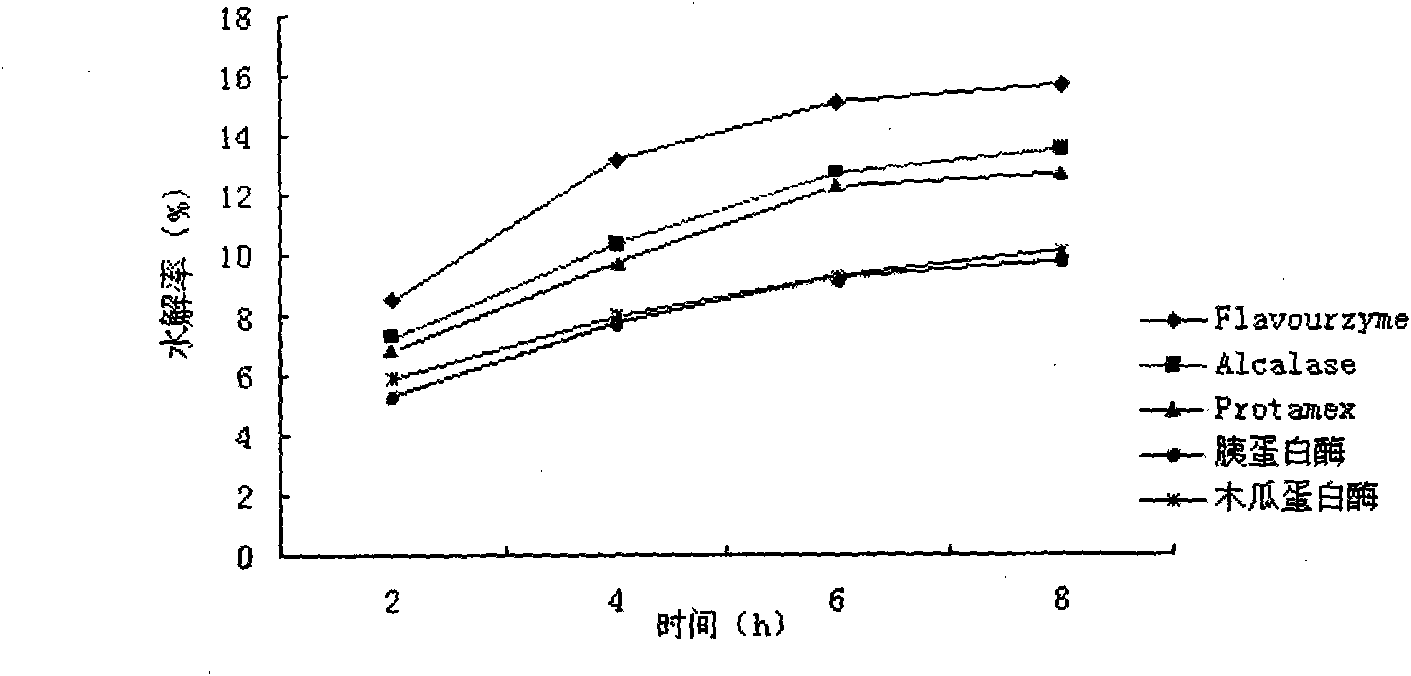

Pig bone extract, preparation method and application thereof

InactiveCN102579494AEnhance immune functionHelps control production costsUnknown materialsImmunological disordersFood industryProteolysis

The invention relates to a pig bone extract, a preparation method and an application thereof. The pig bone extract is a mixture chelated by protein enzymolyzed amino acid, micromolecule polypeptide, and inorganic elements, wherein the protein enzymolyzed amino acid and micromolecule polypeptide are extracted from pig bone raw materials, and the inorganic elements includes at least calcium. The pig bone extract comprises, by content of N, protein, polypeptide and amino acid with a total content not lower than 13w%, and calcium with a content not lower than 2w%, wherein the proteolysis rate>=18%, chelation rate of calcium >=75%. The preparation method includes subjecting the smashed extract of the pig bone raw materials to a solid-liquid separation, subjecting aqueous protein in the liquid to an enzymolysis, subjecting bone residues to an acidolysis, and subjecting the enzymolysis liquid and the acidolysis liquid to a chelation reaction so as to obtain the extract. The pig bone extract can be processed into drugs or health-care food which are capable of improving the immunologic function combined with acceptable auxiliary elements in pharmacy or food industry.

Owner:SICHUAN ACAD OF CHINESE MEDICINE SCI

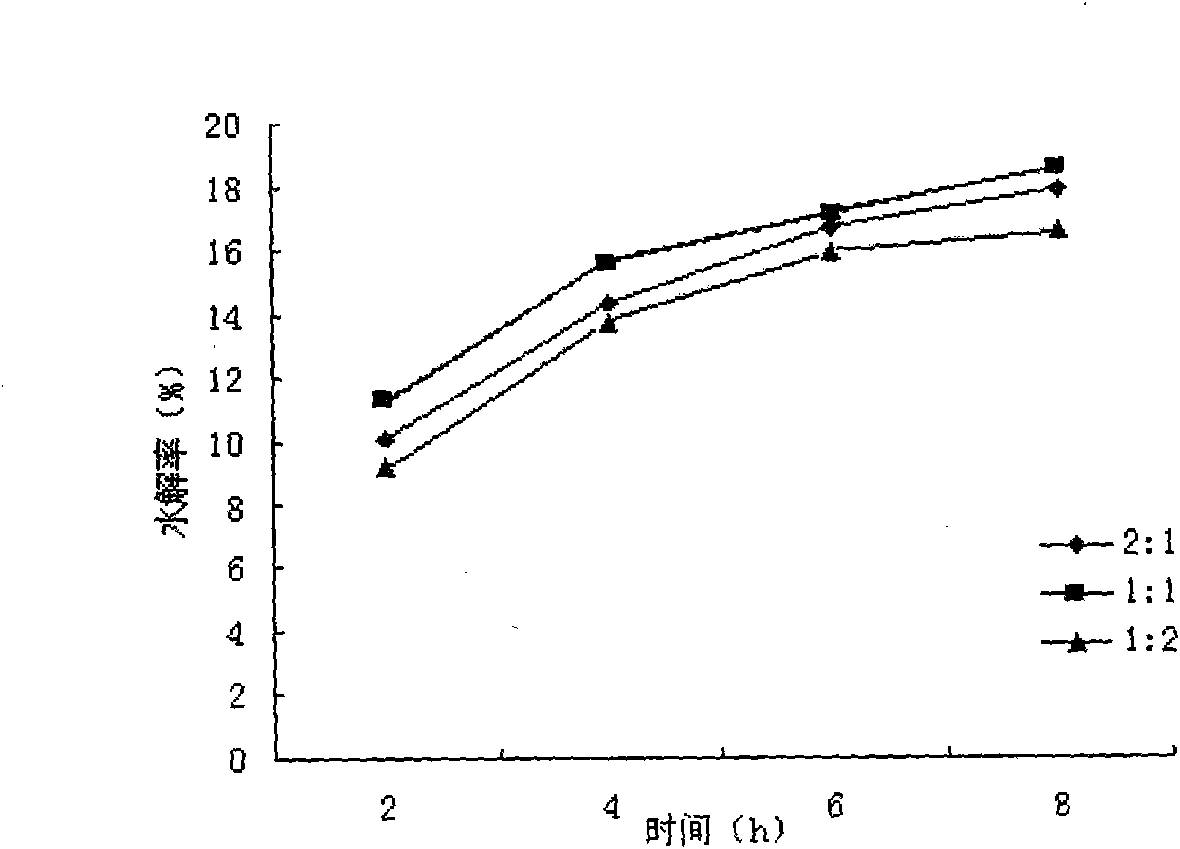

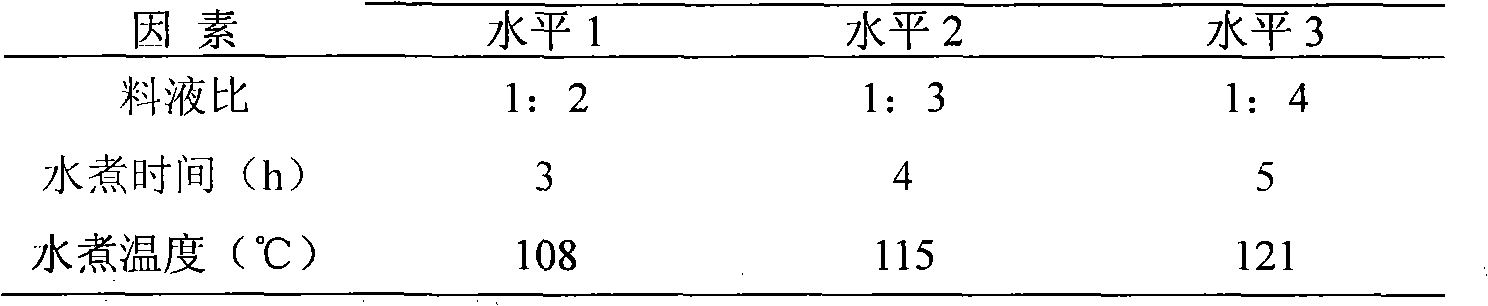

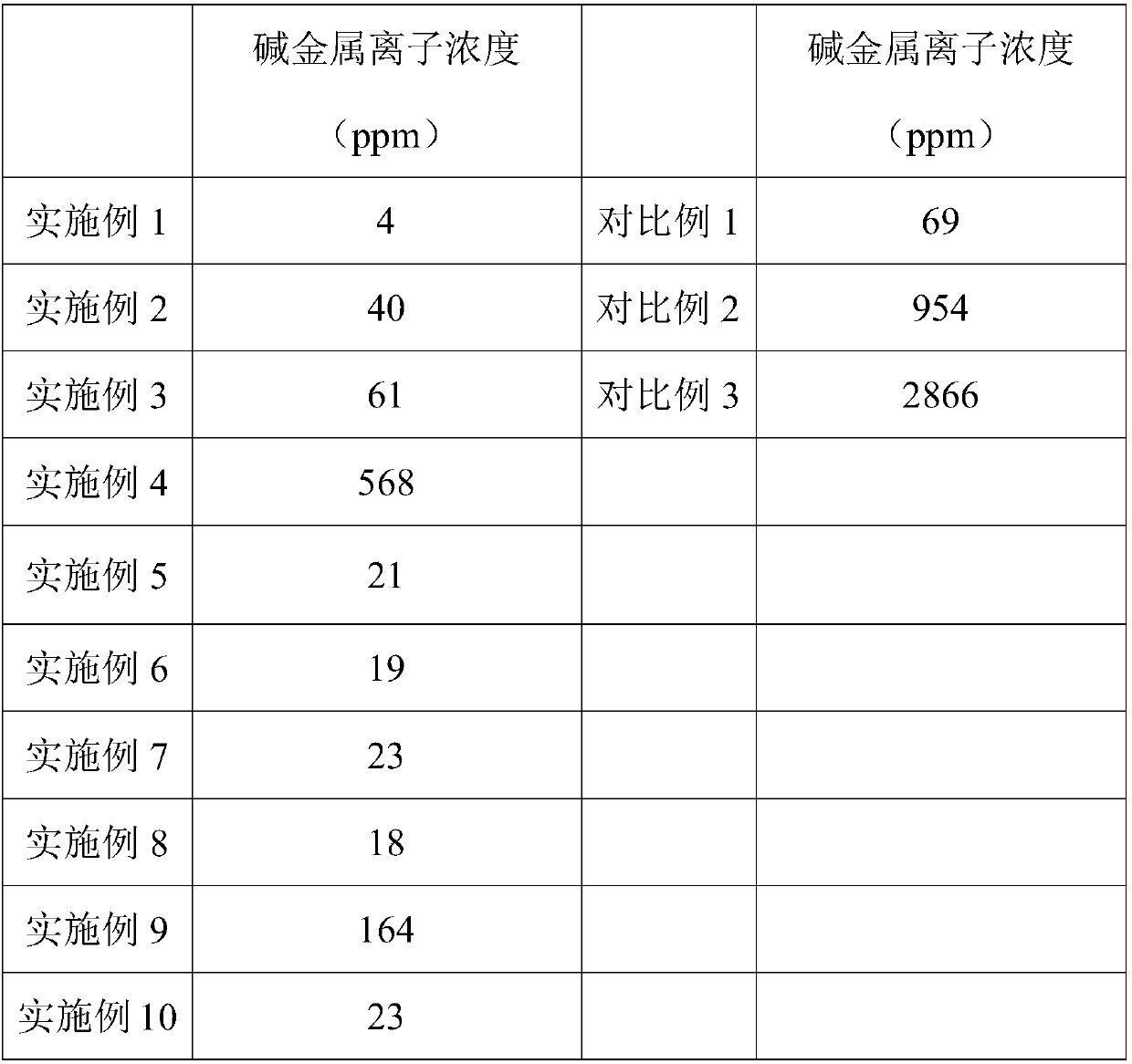

Catalyst and method for synthesizing polyethylene oxide polymer

ActiveCN107674195AQuality improvementImprove the environmentCatalystsHydrocarbon preparation catalystsPolyethylene oxidePhosphonium salt

The invention provides a catalyst for synthesizing a polyethylene oxide polymer. The catalyst comprises a component 1, a component 2 and a component 3. The component 1 is a crown ether. The component2 is a quaternary phosphonium salt. The component 3 is an alkali metal and / or an alkali metal compound. The catalyst can reduce an alkali metal ionic concentration of the product, improve product quality and is suitable for the high standard industrial field. The invention also provides a method for synthesizing the polyethylene oxide polymer. The method comprises mixing an active hydrogen-containing compound and the catalyst, adding ethylene oxide into the mixture in an oxygen-free environment or in a vacuum environment, controlling a temperature in a range of 100-180 DEG C and pressure lessthan or equal to 1.0MPa, keeping the conditions for 1-8h to obtain the reaction product containing the polyethylene oxide-containing polymer and adding an acidic compound for neutralization into the reaction product. The method is easy to operate, is environmentally friendly, improves product quality and is suitable for high-standard industrial production.

Owner:JIAHUA CHEM MAOMING

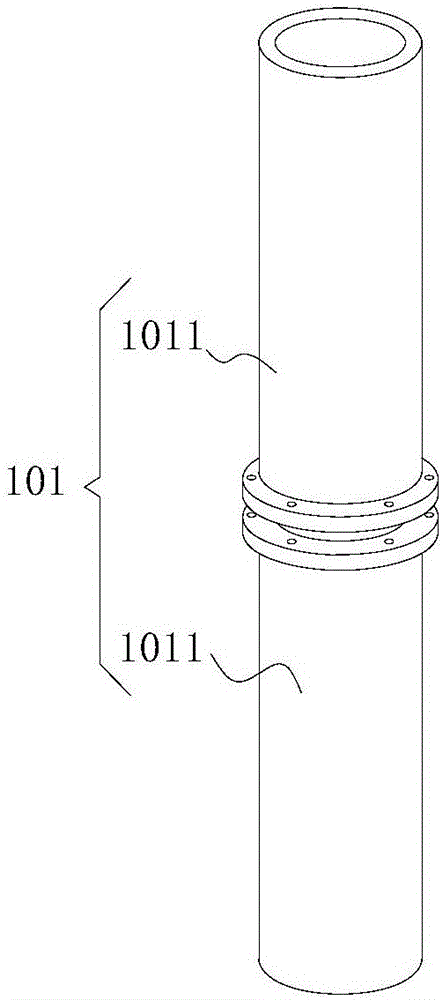

Height-adjustable needle seat structure

InactiveCN105316807AExtended service lifeWide range of applicationsCarding machinesBiomedical engineering

Owner:WUXI GUOSONG ENVIRONMENTAL PROTECTION MACHINERY

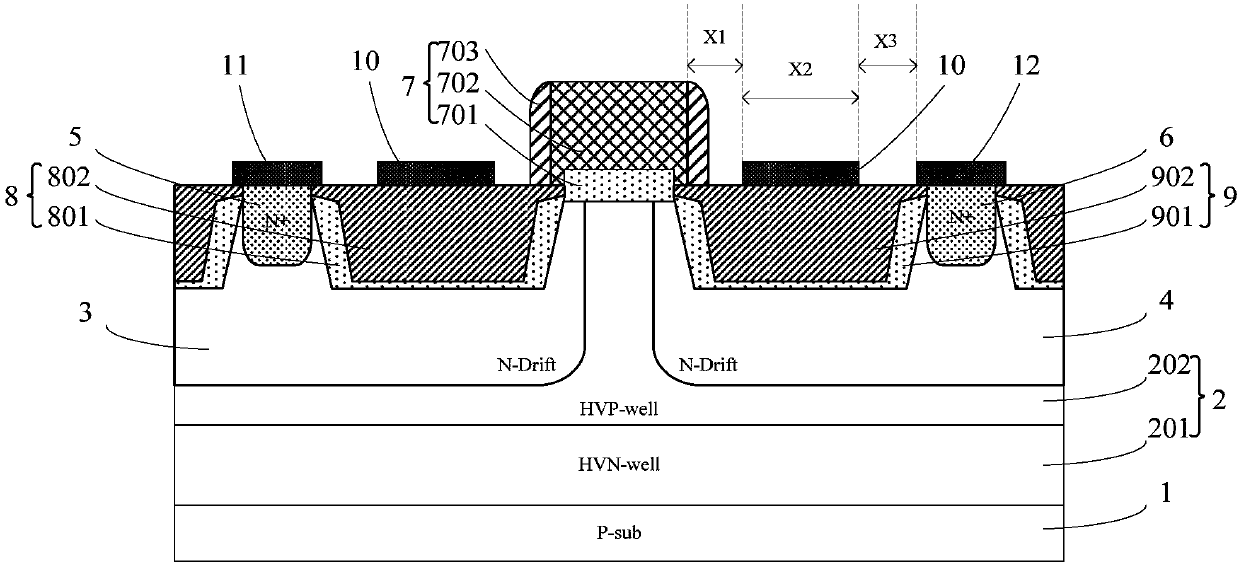

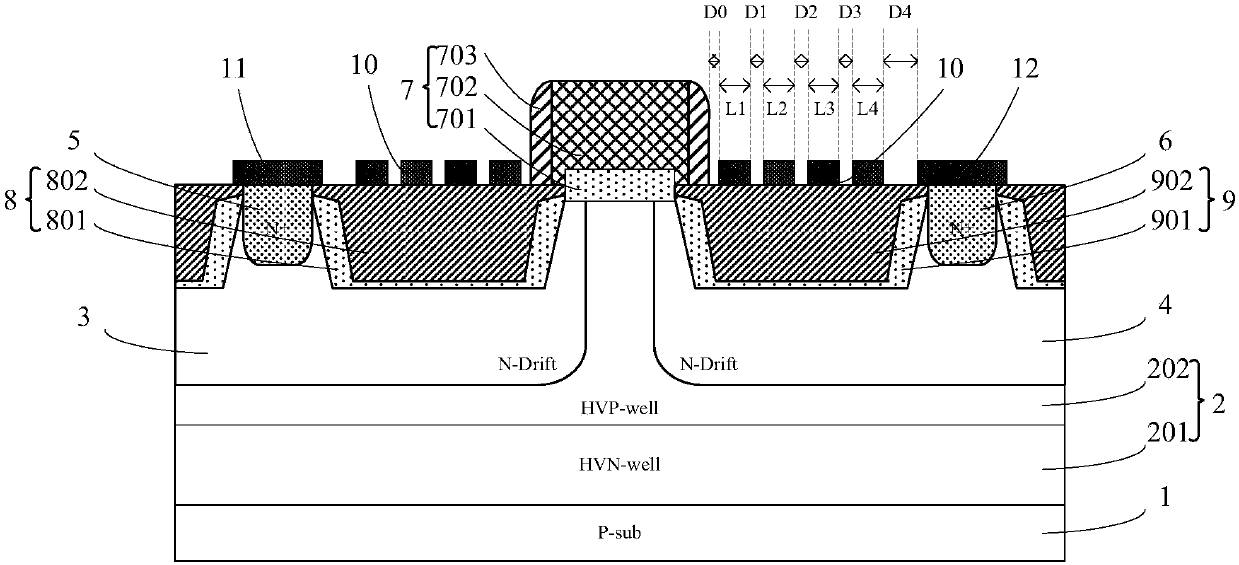

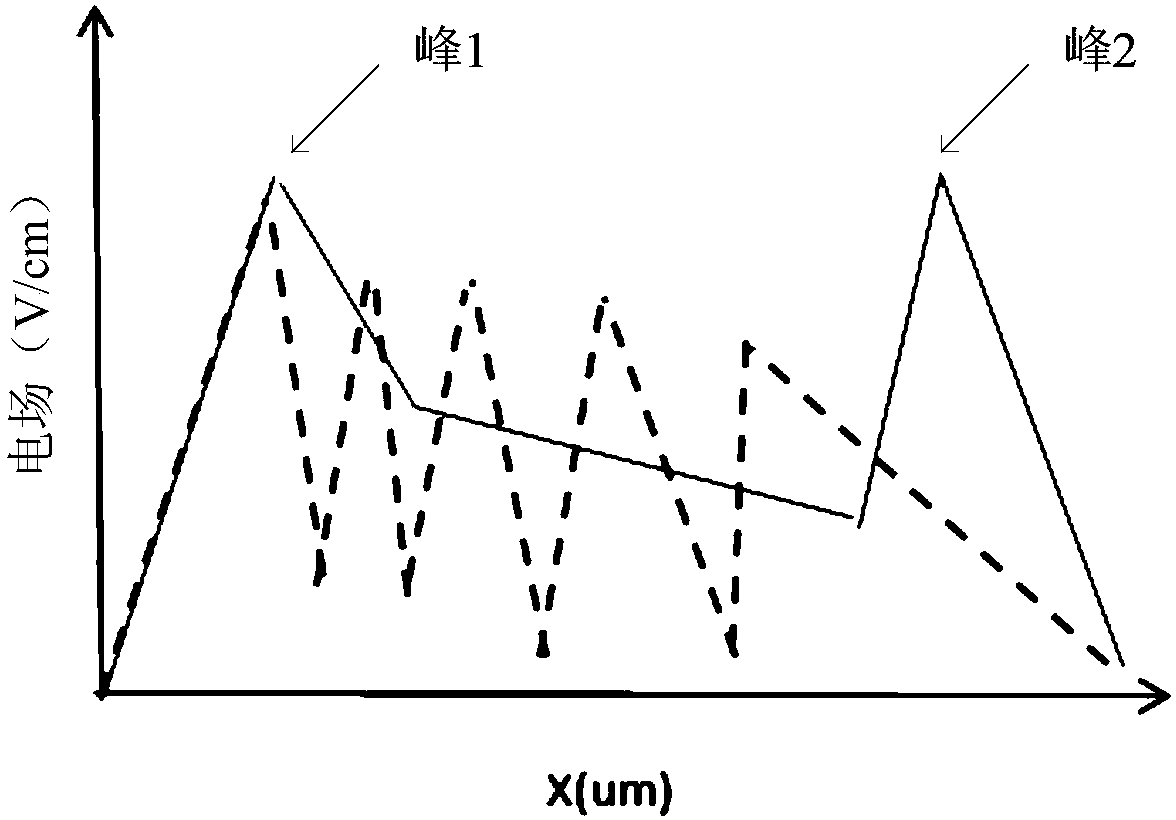

LDMOS (Lateral Diffusion MOS) structure

ActiveCN107785423AWill not increase the quantityIncrease the area of the depleted regionSemiconductor devicesLDMOSGate source capacitance

The invention provides a LDMOS (Lateral Diffusion MOS) structure. The LDMOS structure comprises a semiconductor substrate, a first drift area and a second drift area which are located in the semiconductor substrate and are arranged separately, a source which is located in the first drift area, a drain which is located in the second drift area, a gate structure which is located on the semiconductorsubstrate and whose two sides are contacted with the first drift area and the second drift area respectively, a first isolation structure which is located in the first drift area and isolates the source and the gate structure, and a second isolation structure which is located in the second drift area and isolates the drain and the gate structure, wherein both the first isolation structure and thesecond isolation structure are provided with floating field plates. One or more floating field plates is arranged on the isolation structures between the source-gate and the drain-gate, the area of adepleted area can be increased, collision ionization can be reduced, higher breakdown voltage and saturation leakage current Idsat can thus be acquired, and the gate-drain capacitance Cgd and the gate-source capacitance Cgs of the device are not deteriorated.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

Formula of culture medium for industrial production of sparasis crispa and production process

ActiveCN101955392BWide range of sources and cheapFast growthHorticultureBiotechnologySparassis crispa

The invention provides a formula of a culture medium for industrial production of sparasis crispa and a production process. The formula of the culture medium comprises the following components in percentage by dry weight: 65 to 75 percent of pine sawdust, 10 to 20 percent of husk, 5 to 10 percent of potato powder, 5 to 10 percent of flour, 0.1 to 0.5 percent of peptone, 0.1 percent of ammonium sulfate and 1.2 to 1.8 percent of brown sugar. The production process comprises the following steps of: preparing and bagging the culture medium; sterilizing and inoculating; culturing hypha; inducing aprimodium; differentiating the primodium; opening the bag; managing balls; and harvesting. The invention provides a formula of a culture medium for industrial production of sparasis crispa, which hasthe advantages of rich nutrition, balanced proportion, good ventilation, and capacity of meeting the requirement of industrial production. The production process has the advantages of short hypha culturing time, uniform fruiting at bag openings, good fruiting consistency, convenience of management, contribution to industrial culture, white mushroom body, high yield, and high biological transformation rate of over 43 percent.

Owner:FUQING CITY FIRE KIRIN EDIBLE FUNGUS TECH DEV +1

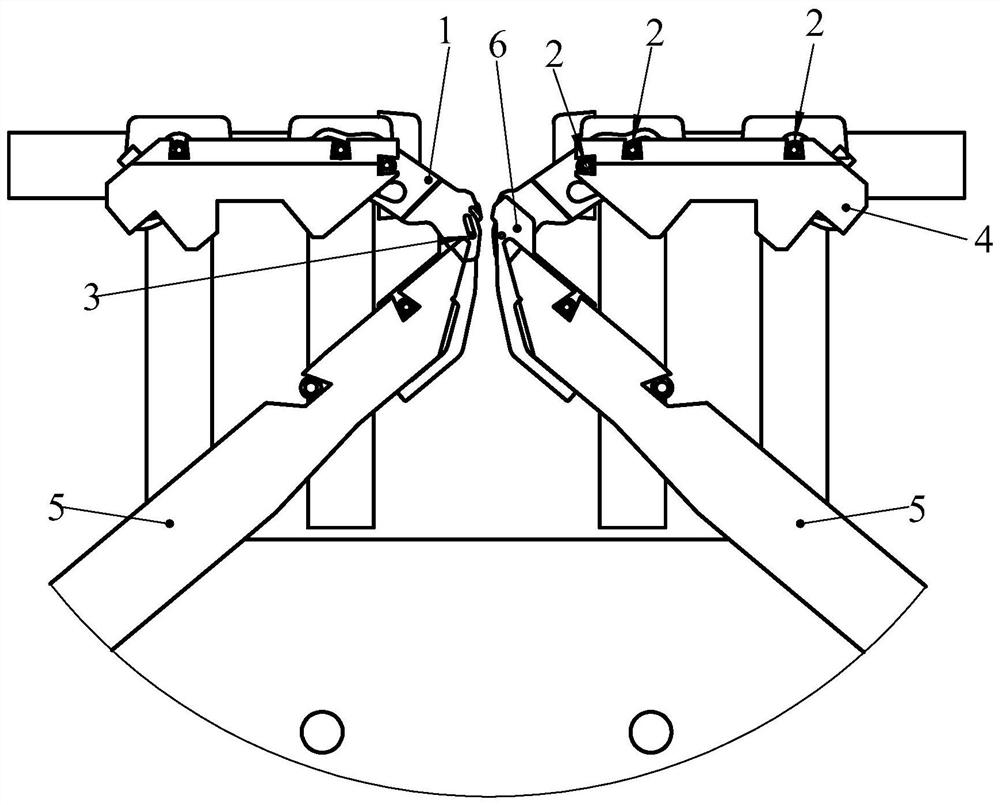

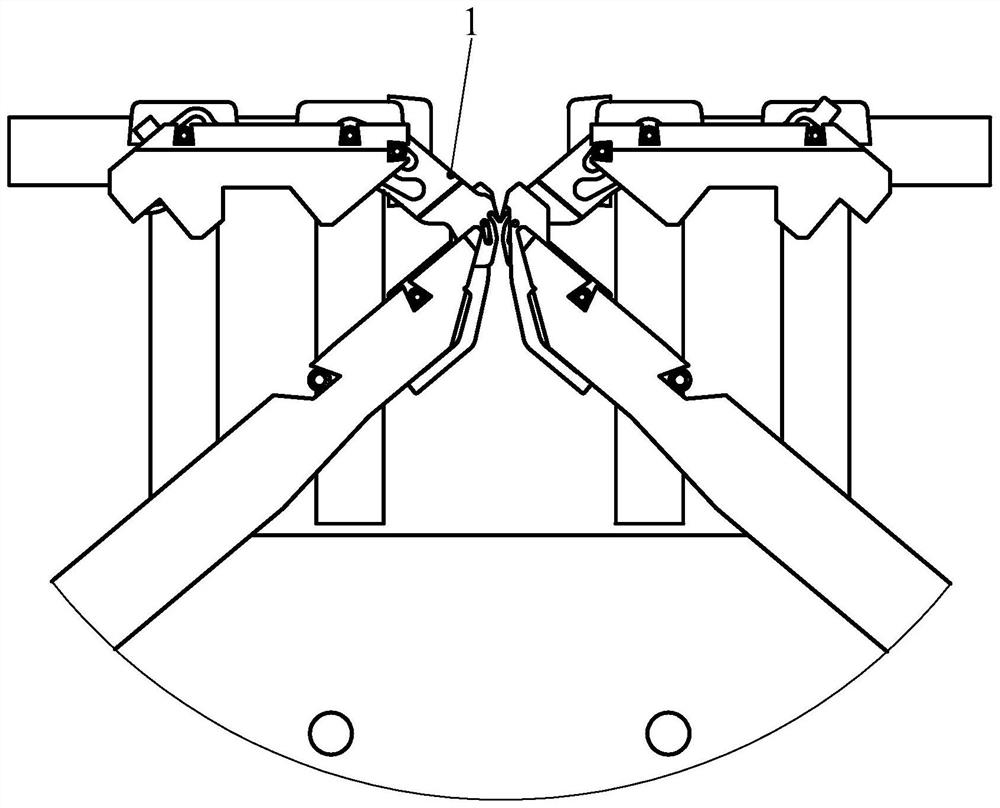

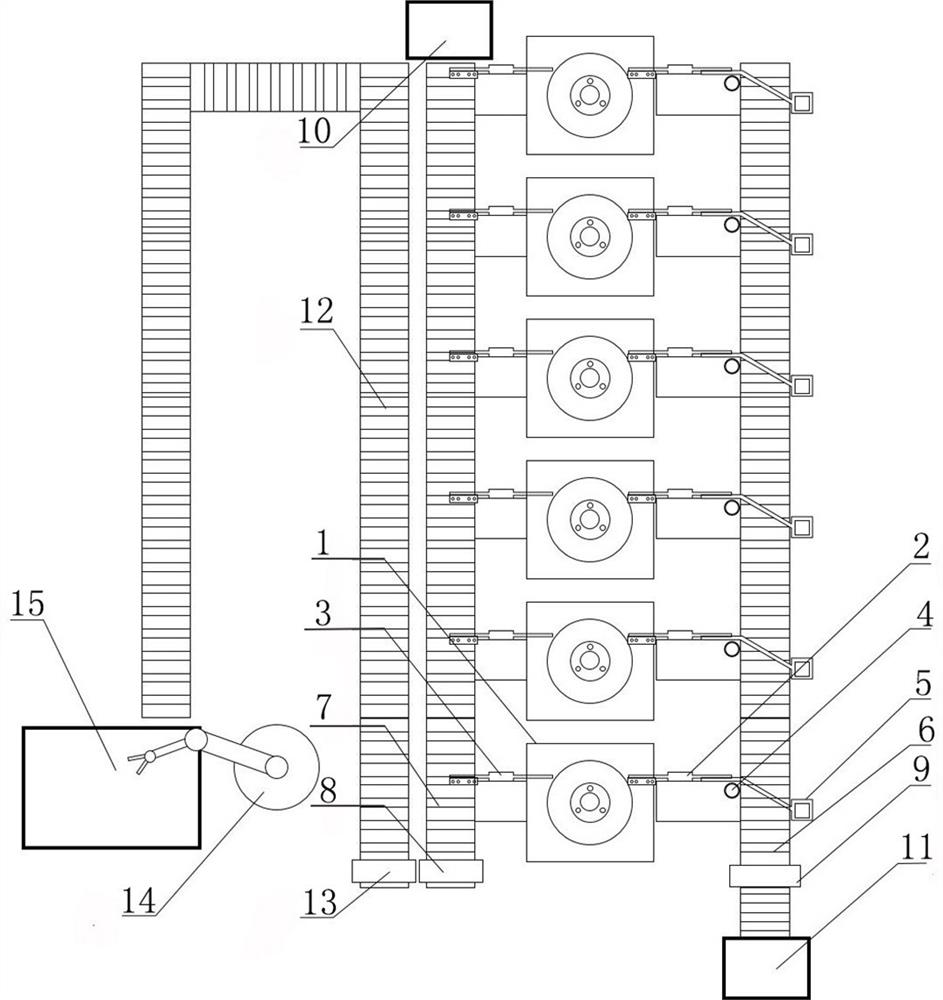

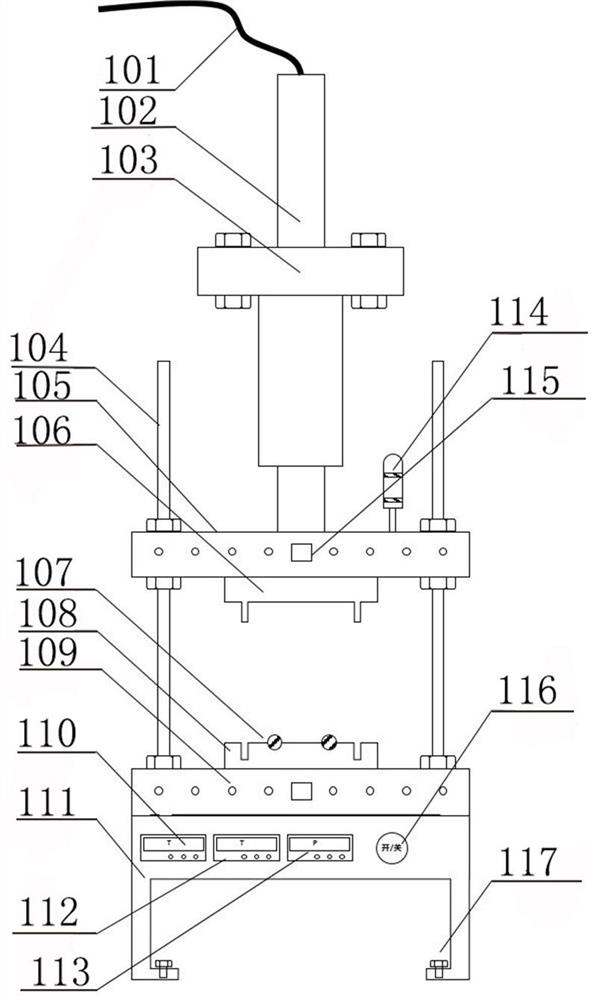

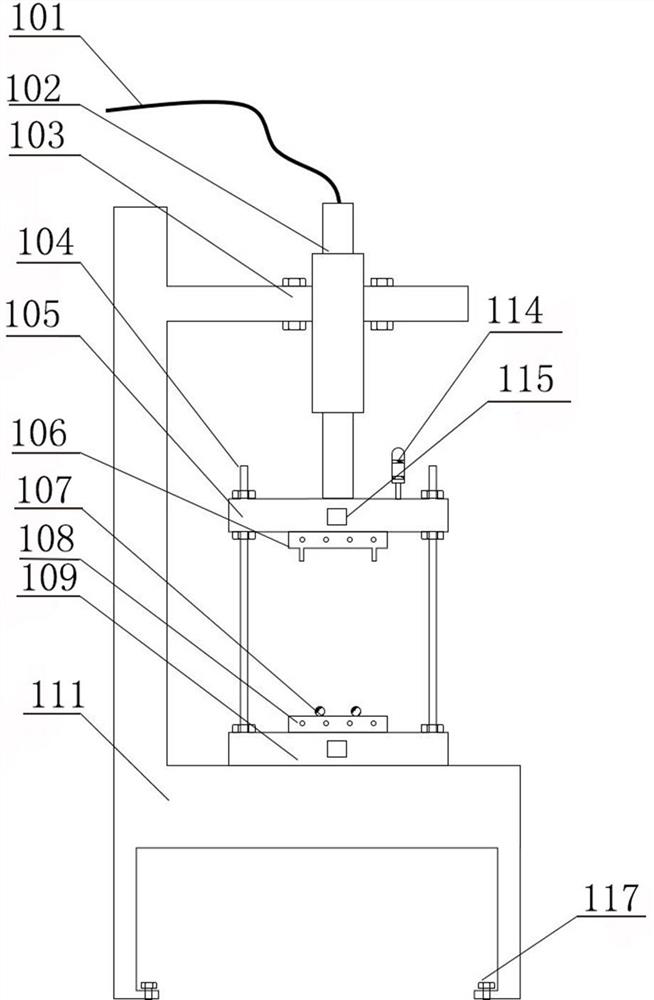

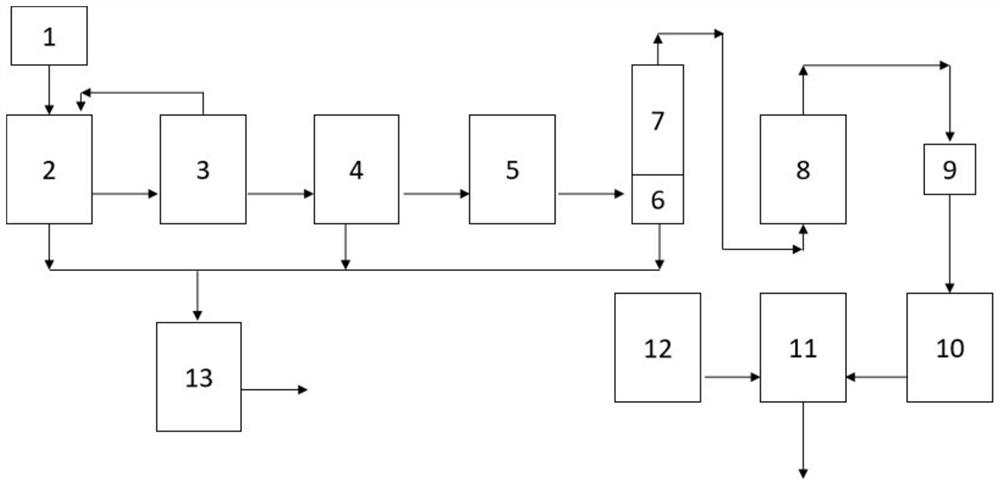

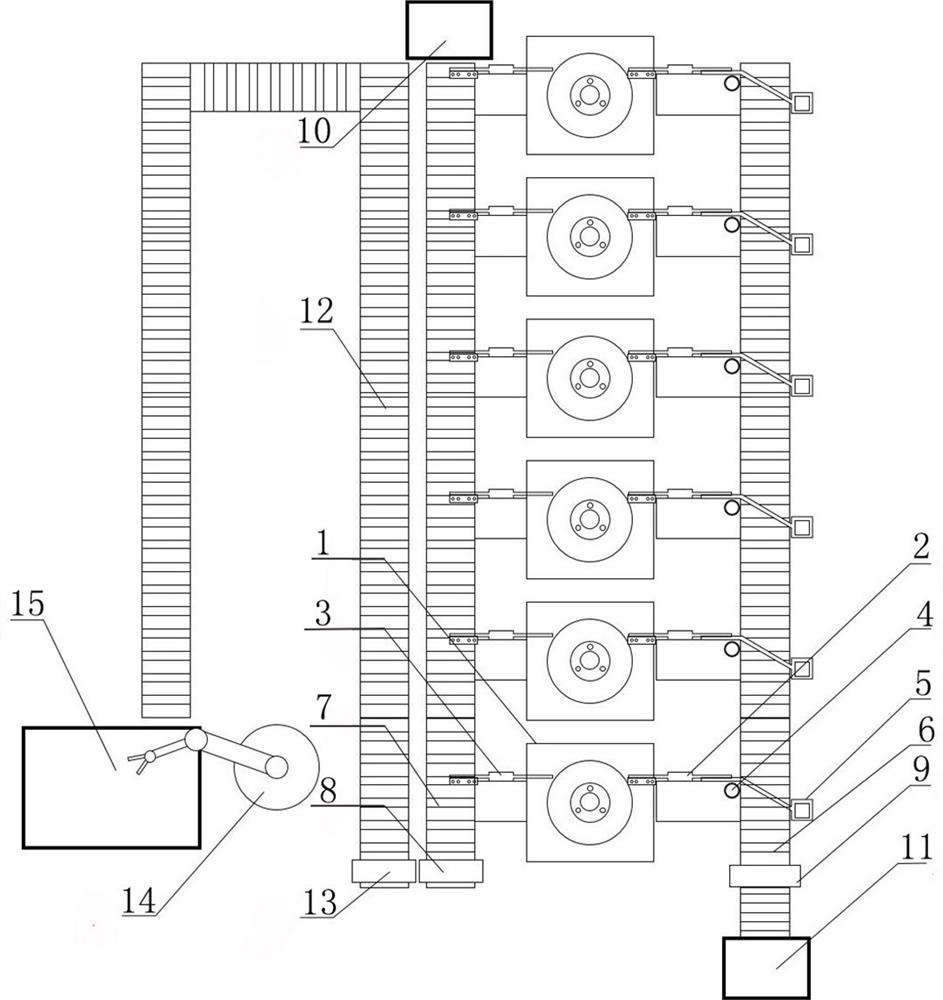

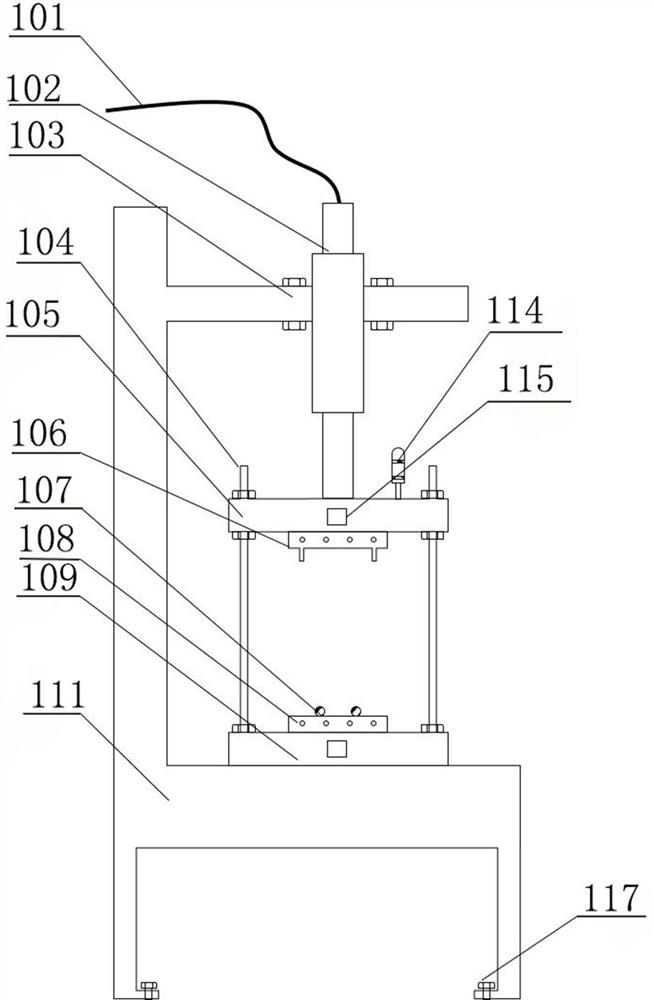

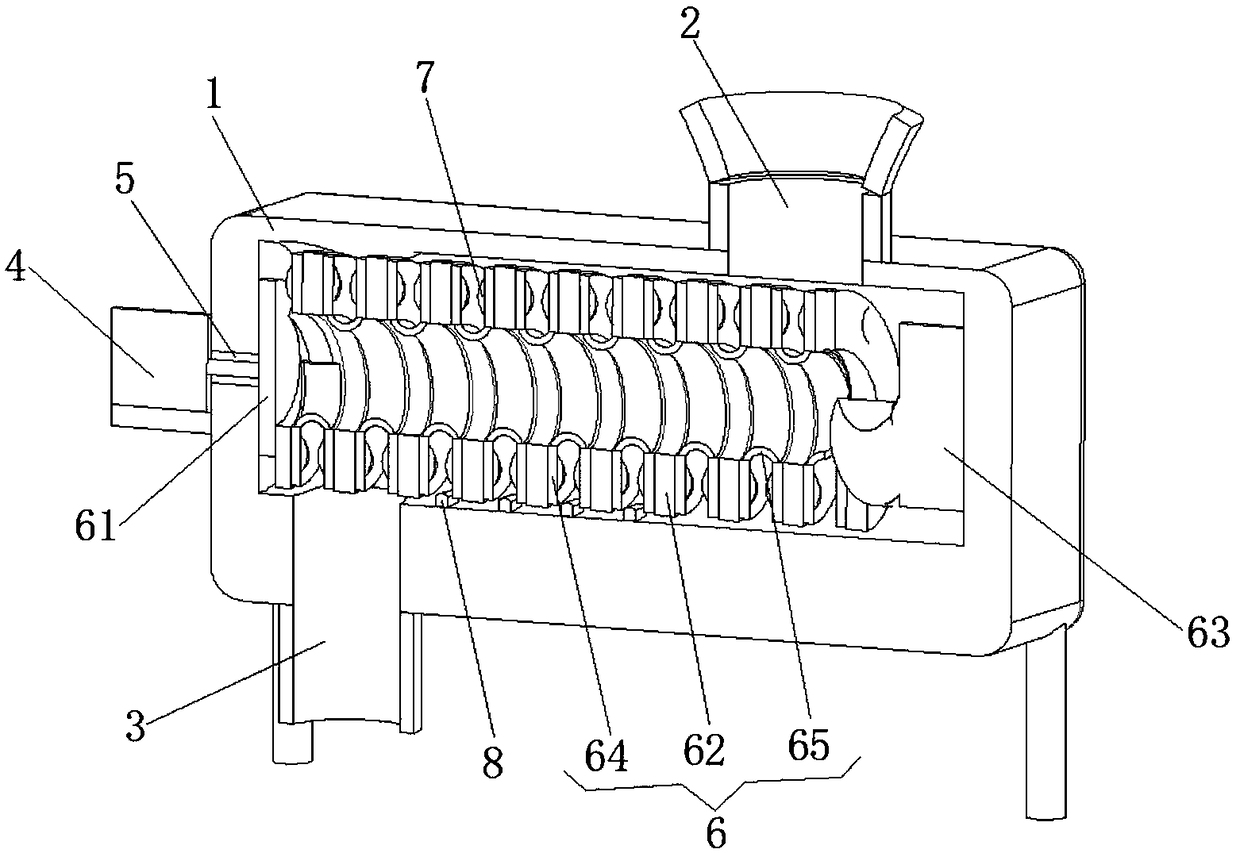

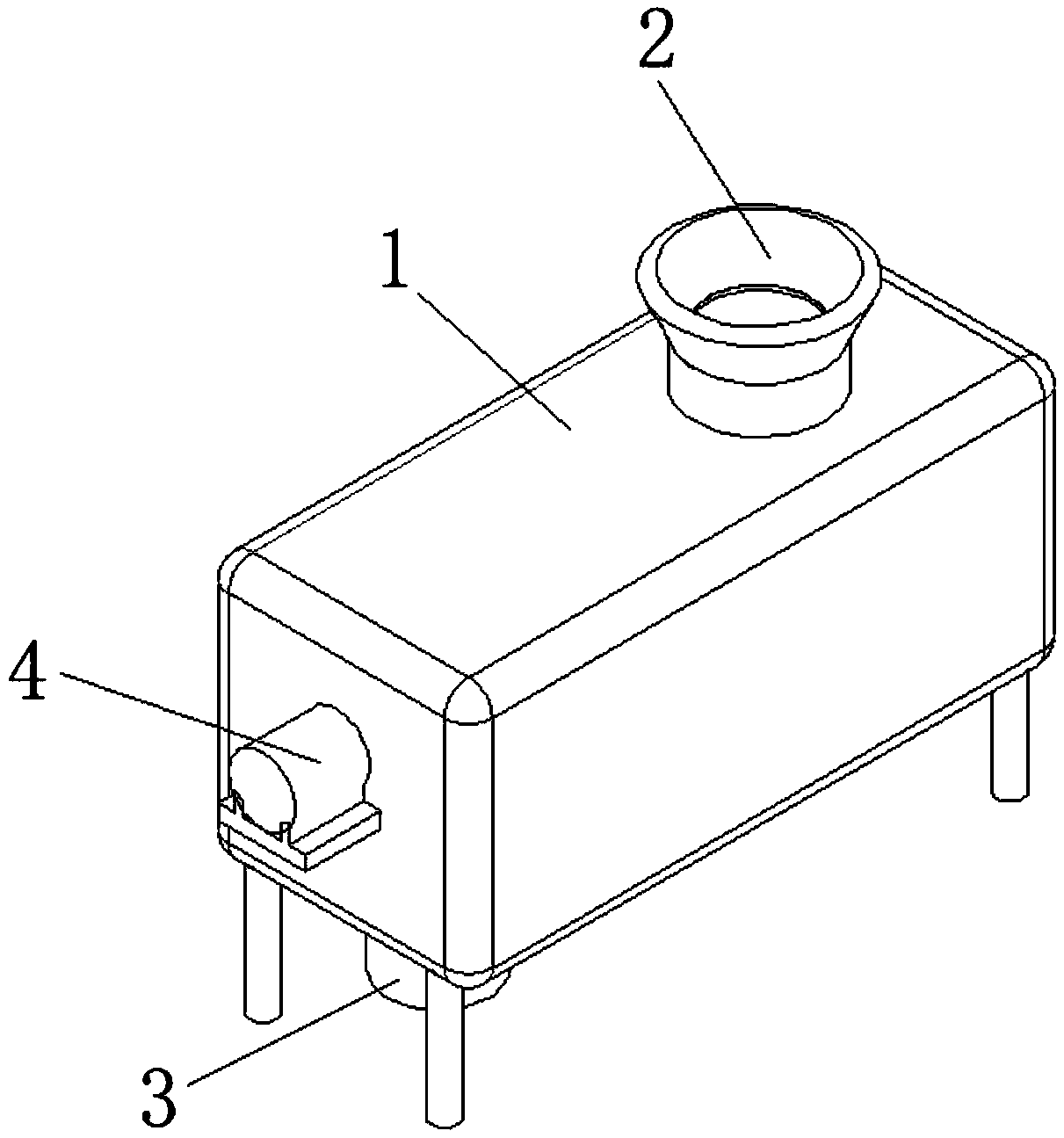

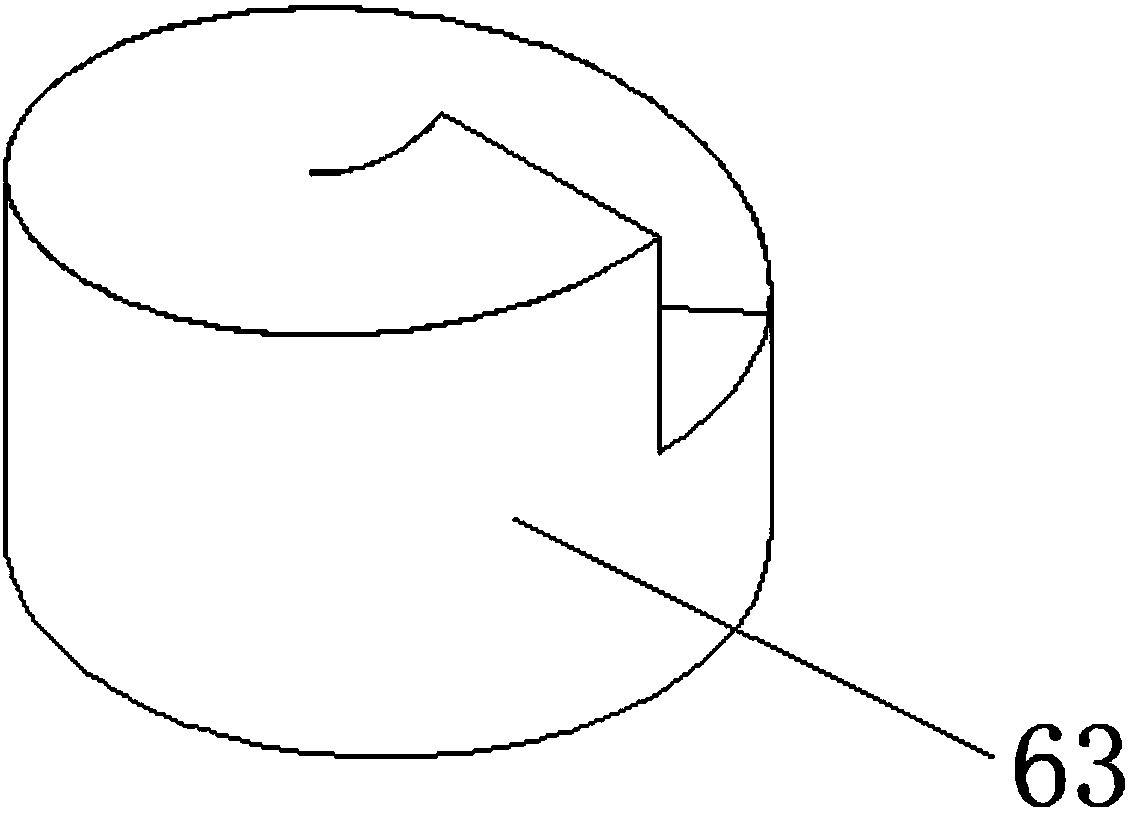

A system and method for automatic molding and vulcanization of rubber products

ActiveCN112959568BRealize automatic matchingRealize automatic mold vulcanizationCoatingsVulcanizationLogistics management

The invention discloses an automatic molding vulcanization system and method for rubber products. The system includes a logistics system and a plurality of molding vulcanization units with the same structure; the logistics system is arranged at both ends of each molding vulcanization unit; the molding vulcanization unit includes a vulcanizer (1), feeding mechanism (2), feeding auxiliary mechanism (5) and unloading mechanism (3); the logistics system includes feeding conveyor belt (6), unloading conveyor belt (7), motor A (8), motor B (9), finished product collection box (10), vibrating screen (11), mold conveyor belt (12), motor C (13), grabbing robot (14) and mold storage warehouse (15). The mold cavity of the present invention is small, the size is small, and the tonnage of the vulcanizing machine is small, so the vulcanization cost is low, and the mold can be automatically matched and the billet can be automatically molded and vulcanized. After the production task is completed, the mold can be automatically replaced to carry out the production task of the next drawing number, which is especially suitable Molded and vulcanized for military special rubber products.

Owner:CHENGDU HOLY AVIATION SCI & TECH CO LTD

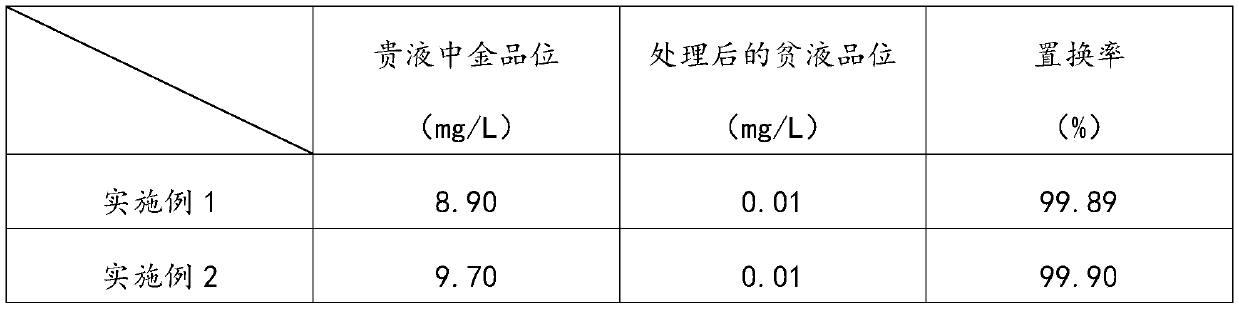

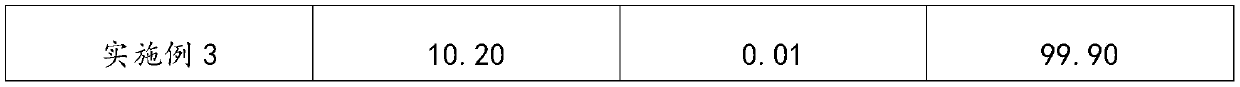

Method for recycling gold from gold-containing pregnant solution

InactiveCN111270071AEfficient removalReduce the impactProcess efficiency improvementPhysical chemistryProcess engineering

The invention relates to a method for recycling gold from a gold-containing pregnant solution, and belongs to the technical field of metallurgy. The method comprises the following steps of S1, preparing the pregnant solution; S2, purifying the pregnant solution; S3, conducting deoxidation on the pregnant solution; S4, pretreating the pregnant solution, wherein the pregnant solution which is obtained after deoxidation treatment in S3, sodium hydroxide, sodium sulfide and ammonium bicarbonate are mixed to prepare a solution, the solution is adjusted to be alkaline, and then uniform stirring is conducted to obtain a pretreated pregnant solution; and S5, conducting replacement on the pregnant solution, wherein the pretreated pregnant solution obtained in S4 and zinc powder are added into a replacer for a replacement rection, and then solid-liquid separation is conducted to obtain a solid, namely the product. According to the method, by adding the agents sodium hydroxide, sodium sulfide andammonium bicarbonate into the pregnant solution, impurity ions in the pregnant solution can be effectively removed, the possible influence on the zinc powder is lowered, the replacement efficiency ofthe zinc powder is improved, the production quality of gold mud is improved, and the production efficiency of the process is improved.

Owner:ZHAOJIN MINING

Synthesis of hyperbranched epoxy resin and application in waterproof rolls

The invention relates to the field of high polymer materials, and more particularly to the synthesis of hyperbranched epoxy resin and its application to asphalt waterproof rolls. Firstly, a hyperbranched epoxy resin is synthesized by using trimethylolpropane triglycidyl ether and dicarboxylic acid, and then the hyperbranched epoxy resin is applied to asphalt-based waterproof rolls. The product caneffectively improve the bonding performance of asphalt-based waterproof rolls.

Owner:UNIV OF JINAN

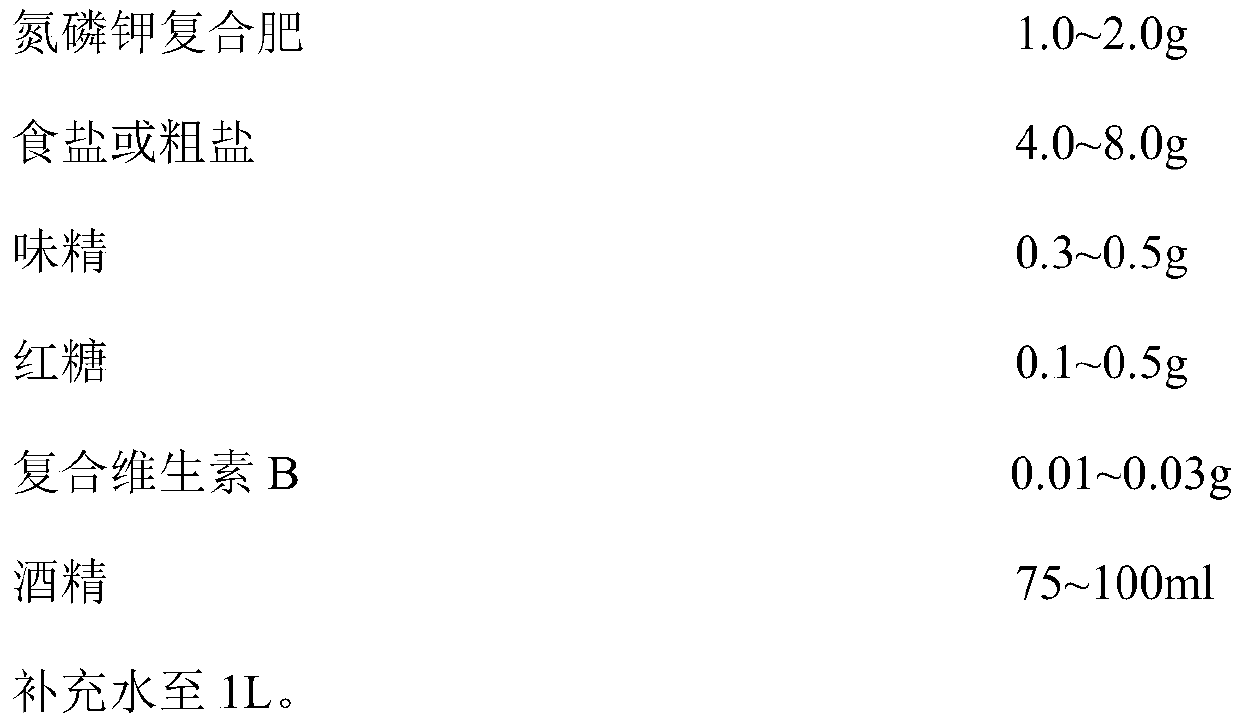

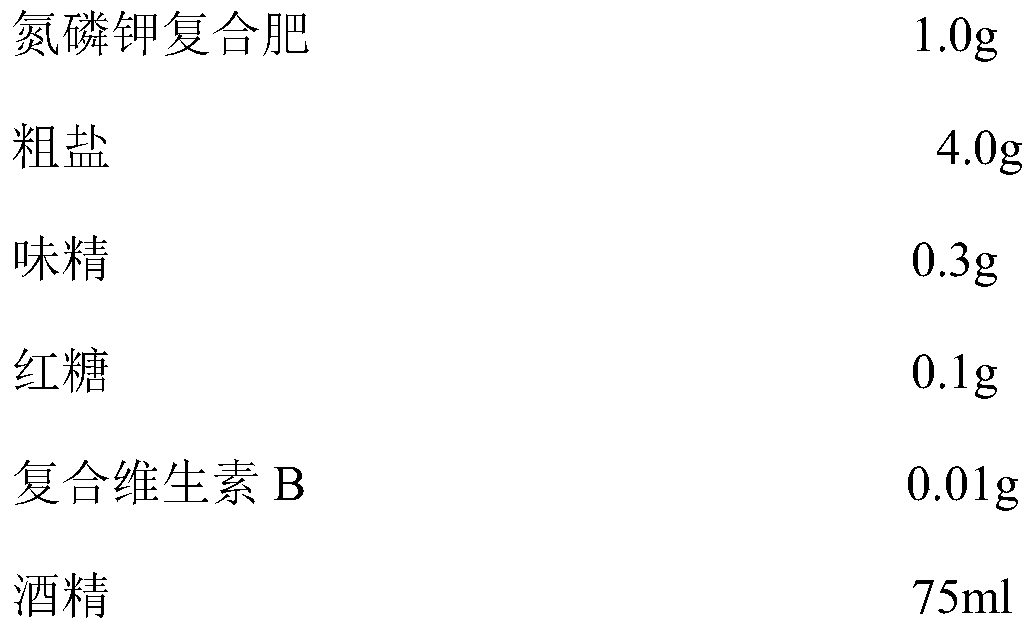

Simple and easy-to-prepare photosynthetic bacterium culture medium and preparation method thereof

ActiveCN110468087AFull of nutritionThe composition and preparation method are simpleBacteriaMicroorganism based processesFertilizerNutrition

The invention discloses a simple and easy-to-prepare photosynthetic bacteria culture medium and a preparation method thereof. Each liter of the culture medium is prepared from the following componentsby weight: 1.0-2.0 g of nitrogen, phosphorus and potassium compound fertilizer, 4.0-8.0 g of table salt or crude salt, 0.3-0.5 g of monosodium glutamate, 0.1-0.5 g of brown sugar, 0.01-0.03 g of complex vitamins B, 75-100 ml of alcohol, and water added to be 1 L. The photosynthetic bacteria culture medium comprises suitable carbon sources, nitrogen sources, microelements and growth factors, has comprehensive nutrition, and can guarantee the normal growth demand of photosynthetic bacteria, and the components and the preparation method are simple, raw materials are easy to obtain and cheap, sources are stable, and the simple and easy-to-prepare photosynthetic bacteria culture medium is especially suitable for farmers to independently activate and expand cultivation of the photosynthetic bacteria.

Owner:INST OF TROPICAL BIOSCI & BIOTECH CHINESE ACADEMY OF TROPICAL AGRI SCI

Grain production method for twice thinning by front cutting

ActiveCN111446162AReduce damageImprove the qualified rate of finished productsSemiconductor/solid-state device manufacturingCrystalliteDeposition process

The invention discloses a crystal grain production method for twice thinning through front cutting. The production method comprises the steps of front cutting, primary fixing, primary thinning, an intermediate process, secondary thinning, adhesive removal, a metal deposition process, secondary fixing, separation from a glass carrier plate and solvent cleaning. According to the invention, through cutting, primary fixing, primary thinning, the intermediate process, secondary thinning, adhesive removal, the metal deposition process, secondary fixing, separation from the glass carrier plate and solvent cleaning, a wafer is subjected to front cutting and twice thinning to obtain crystal grains; a traditional one-time cutting mode is replaced; damage to crystal grains caused by cutting is reduced; the finished product percent of pass of the crystal grains is increased; the cutting time of a single qualified crystal grain is shortened; a traditional process of completing back yellow light, ion implantation and metal deposition before cutting is replaced; and the production cost of the crystal grains is easily controlled.

Owner:绍兴同芯成集成电路有限公司

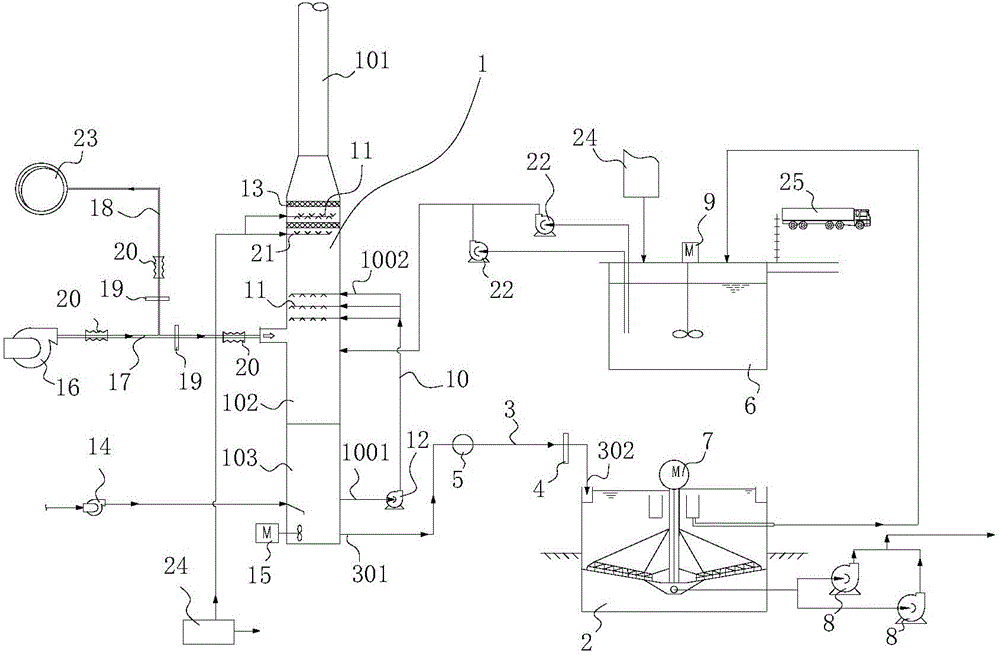

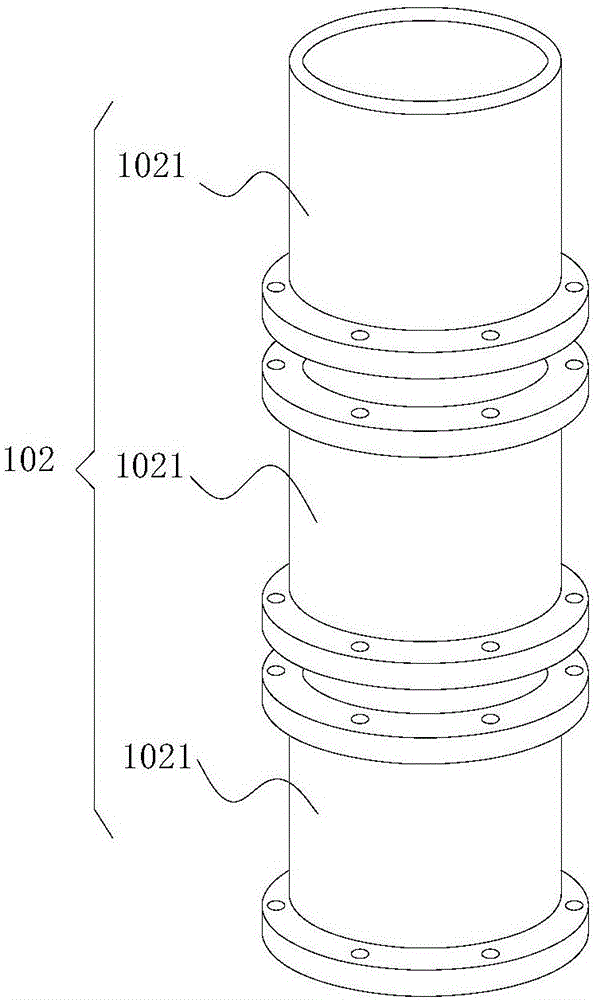

Complete desulfurization system of small boiler

The invention relates to a complete desulfurization system structure and layout of a small boiler. The invention aims at providing a complete desulfurization system of a small boiler, which prevents congestion during the discharge of slurry in an absorption tower, reduces the power consumption and reduces the occupied space. The system comprises an absorbent preparation system and an SO2 absorption system, wherein the SO2 absorption system comprises an absorption tower, a demister is arranged in the absorption tower, the SO2 absorption system comprises a sedimentation tank, the sedimentation tank is connected with the absorption tower by a siphon pipeline of which middle segment is bent upward, a siphon inlet end of the siphon pipeline is connected to a lower part of the absorption tower, and a siphon outlet end of the siphon pipeline is located above the sedimentation tank. According to the complete desulfurization system provided by the invention, the slurry in the absorption tower is discharged by a pipeline via the principle of pressure difference and siphon without consuming power, the blockage of the pipeline is also prevented in the process, and as the siphon pipeline is bent upward, the occupied space is reduced as well.

Owner:成都清源天成环保工程有限公司

Preparation method and application of composite heat-dissipating material

The invention discloses a preparation method of a composite heat-dissipating material. The preparation method includes stirring and dispersing all raw materials for 1-2 hours, and putting the raw materials into a ball mill for ball-milling treatment to enable the sieving residue per ten thousands of holes of an obtained material is not larger than 0.05%; melting and extruding the obtained evenly-mixed material by a screw extruder, and pulling, cooling and dicing the evenly-mixed material to obtain the composite heat-dissipating material. The preparation method has the advantages that branched chains PA6 with high melt fluidity and substantial active end groups are introduced, excellent melt fluidity and easiness in processing are achieved, dispersion of the heat-dissipating material in a base body is promoted effectively, dipping property and compatibility of fire retardants are improved, and the raw materials are completely wrapped and dispersed in the base body; heat conductivity of the heat-dissipating material is improved and swelling coefficient of the heat-dissipating material is reduced through addition of nano-diamonds, and accordingly, product service life is prolonged; the heat-dissipating material is particularly applicable to production of lampshades, support bases, substrates, low-voltage appliance covers and members of LED illumination products, electronic packaging members, IC (integrated circuit) chips, high-power electromechanical device members and the like.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

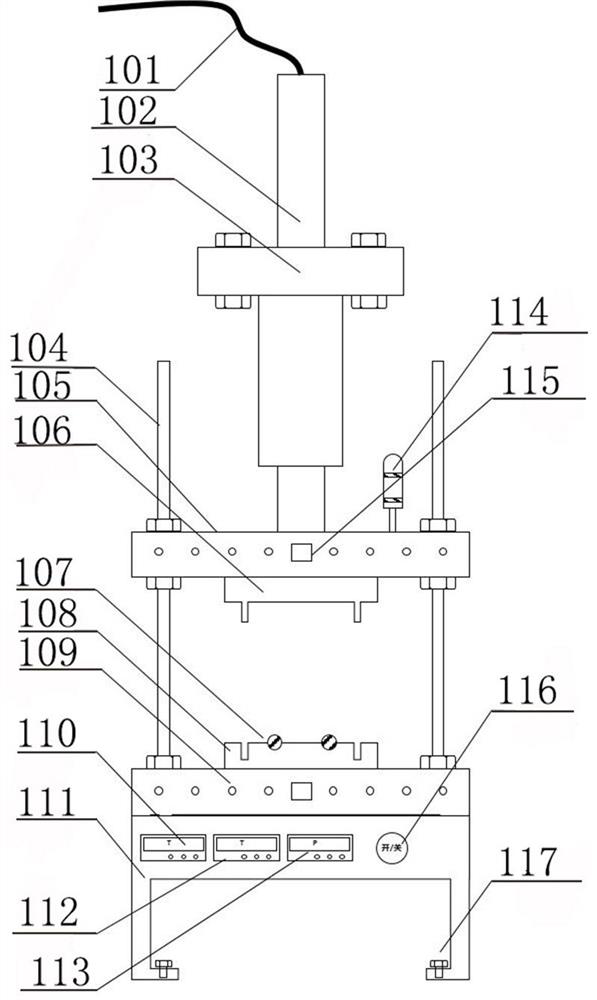

Waste photoresist stripping liquid recycling system

PendingCN113009794AAvoid influenceHelps control production costsPhotosensitive material processingProcess engineeringEnvironmental engineering

The invention relates to the technical field of waste liquid recycling treatment, in particular to a waste photoresist stripping liquid recycling system which comprises a pretreatment unit, an evaporation unit and a modulating and recycling unit. The pretreatment unit is used for removing photoresist and metal ions in waste liquid and comprises a nanofiltration membrane filtering device and an electrodialysis device which are communicated in sequence. Waste liquid sequentially passes through the nanofiltration membrane filtering device and the electrodialysis device and enters the evaporation unit; the evaporation unit is used for removing moisture in the waste liquid and comprises a rectifying tower, a dehydrating tower and a rectifying collecting tank which are communicated in sequence, and the rectifying tower is communicated with the electrodialysis device. The modulating and recycling unit comprises a recycling tank and a stock solution tank, and the recycling tank and the stock solution tank are both communicated with the rectification collecting tank. According to the present invention, the waste stripping liquid can be treated, the pollution to the environment is reduced, meanwhile, recycling and cyclic utilization are achieved, and the production cost of an enterprise is controlled.

Owner:SUZHOU KZONE EQUIP TECH

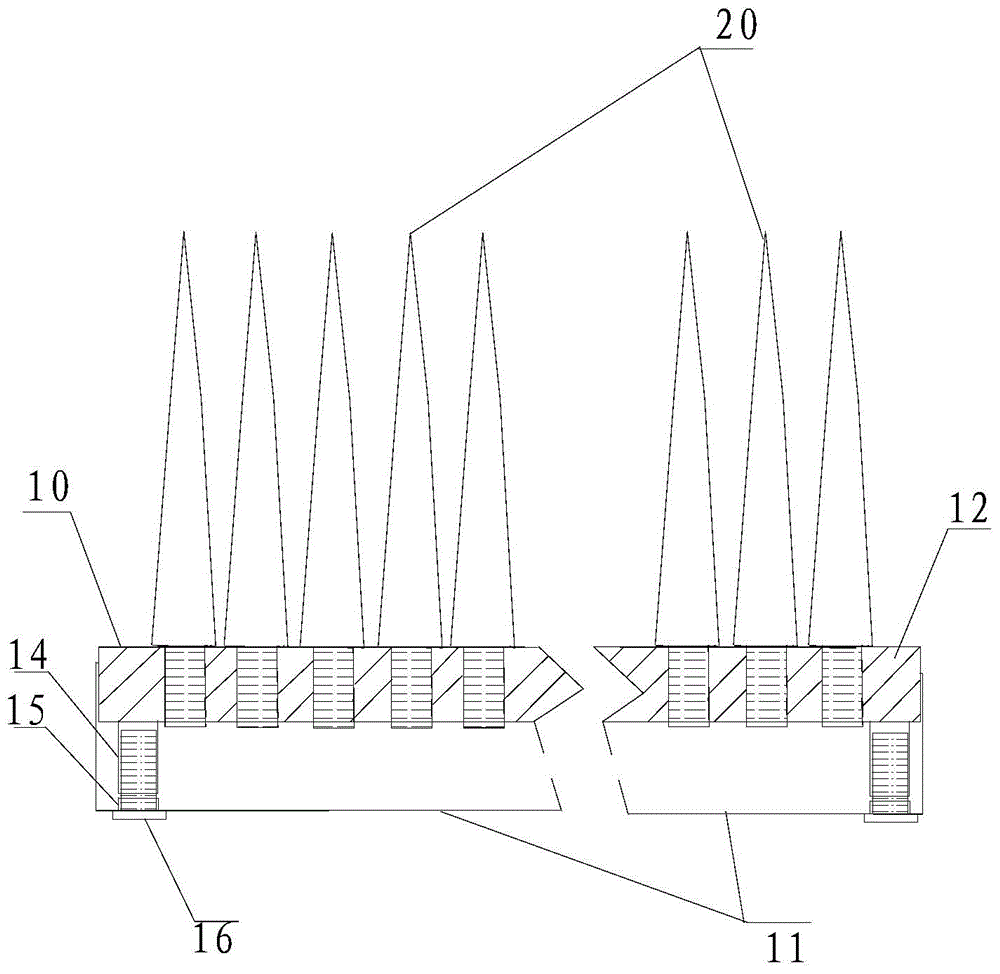

Automatic mold pressing vulcanization system and method for rubber product

ActiveCN112959568ARealize automatic matchingRealize automatic mold vulcanizationCoatingsVulcanizationLogistics management

The invention discloses an automatic mold pressing vulcanization system and method for a rubber product. The system comprises logistics systems and a plurality of mold pressing vulcanization units of the same structure. The logistics systems are arranged at the two ends of each mold pressing vulcanization unit; Each mold pressing vulcanization unit comprises a vulcanizing machine (1), a feeding mechanism (2), a feeding auxiliary mechanism (5) and a discharging mechanism (3). Each logistics system comprises a feeding conveyor belt (6), a discharging conveyor belt (7), a motor A (8), a motor B (9), a finished product collecting box (10), a vibrating screen (11), a mold conveyor belt (12), a motor C (13), a grabbing robot (14) and a mold storage tank (15). The automatic mold pressing vulcanization system has the advantages of less mold cavities, small size and small tonnage of the vulcanizing machine, so that the vulcanizing cost is lower, and automatic matching of the mold and automatic mold pressing vulcanization of blanks can be realized; the mold is automatically replaced after completion of a production task, and a production task with a next drawing number is implemented; and the automatic mold pressing vulcanization system is particularly suitable for mold pressing vulcanization of military special rubber products.

Owner:CHENGDU HOLY AVIATION SCI & TECH

Galvanic corrosion evaluation method for dissimilar metal plate mechanical connection structure in automobile

PendingCN111141661AReflect the actual corrosion situationEasy to operateWeighing by removing componentWeather/light/corrosion resistanceSalt spray testStructural engineering

The invention provides a galvanic corrosion evaluation method for a dissimilar metal plate mechanical connection structure in an automobile, which comprises the following steps of: (1) manufacturing aconnection test part consisting of an anode plate with a hole, a bolt and a nut according to two plate materials of the automobile dissimilar metal plate mechanical connection structure to be evaluated; (2) carrying out an artificial accelerated salt spray test on the connection test part, removing a corrosion product, and measuring the corrosion loss weight and the maximum corrosion depth of thecontact surface area of the surface of the anode plate and the bolt; calculating the maximum corrosion depth ratio and the equivalent uniform corrosion depth of the contact area of the surface of theanode plate and the bolt in the connection test part; and (3) evaluating galvanic corrosion of the dissimilar metal plate mechanical connection structure in the automobile through the maximum corrosion depth ratio and the equivalent uniform corrosion depth, and distinguishing risk levels. The method can well reflect the actual corrosion condition of the contact surface area between the dissimilarmetals, and is simple and easy to operate.

Owner:CHINA NAT ELECTRIC APP RES INST

Spiral conveying type peanut shell breaking device

The present invention belongs to the technical field of peanut processing and discloses a spiral conveying type peanut shell breaking device. The spiral conveying type peanut shell breaking device comprises a box body; the right end of the top wall of the box body fixedly communicates with a material feeding hopper; the right end of the bottom wall of the box body fixedly communicates with a material discharging pipe; the middle portion of the left side surface of the box body is fixedly provide with a gear motor; a support bearing is fixed in a hole formed in the middle portion of the left side wall of the box body; an output shaft of the gear motor is fixedly sleeved in the support bearing; and the inside of the box body is provided with a shelling and transporting mechanism. The spiralconveying type peanut shell breaking device can extrude and crush peanut shells through the arranging of the shelling and transporting mechanism. A spiral type structure can form raw material conveying. The spiral conveying type peanut shell breaking device is simple in structure, convenient for device maintenance and low in production cost.

Owner:徐州恭乐橡塑机械有限公司

Breeding method of temperature-resistant glutamic acid production strains

InactiveCN105219761AStable genetic traitsSignificant positive mutationBacteriaMutant preparationBiotechnologyPolyethylene glycol

The invention discloses a breeding method of temperature-resistant glutamic acid production strains. The method includes the steps of firstly, using the traditional strain breeding technology to perform mutagenesis on original strains, screening to obtain positive mutant strains with enhanced temperature resistance and increased glutamic acid production capacity; secondly; using lysozyme with the concentration of 1-2 g / L to perform enzymolysis on the strains for 3-5 hours to obtain glutamic acid production strain protoplasts; thirdly, irradiating with UV for 25-30 minutes, and heating to 55-60 DEG C for inactivation; fourthly, using polyethylene glycol for induced fusion; fifthly, performing progressive fusion on original strain multi-female parent protoplasts, and combining with multi-batch fermentation stability tests to breed the temperature-resistant glutamic acid production strains. The breeding method has the advantages that the method is high in temperature-resistant glutamic acid production strain screening efficiency; the temperature-resistant glutamic acid production strains bred by the method are high in acid production capacity, stable in genetic character and suitable for large-scale continuous production, continuous production and fermentation can be performed under high temperature, interference of high-temperature climate is overcome, and production cost can be controlled favorably.

Owner:SHANGHAI GUANSHENGYUAN TIANCHU FLAVORING

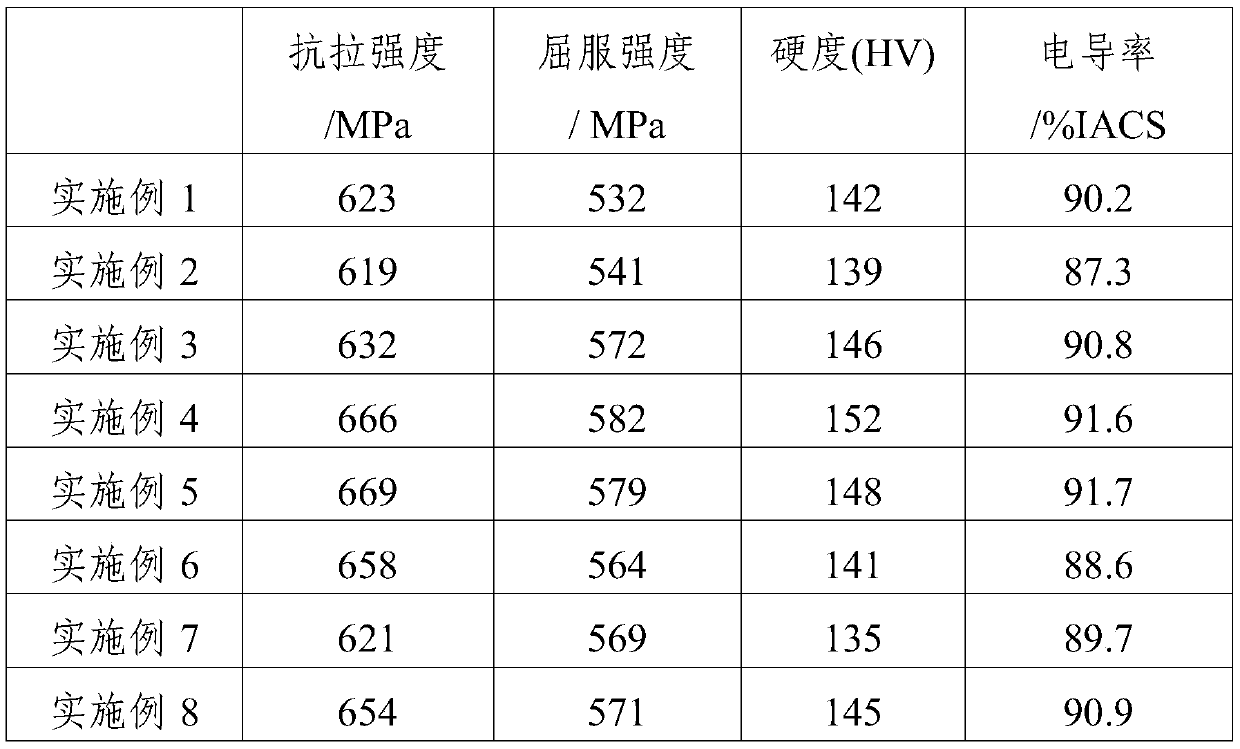

Graphene/silicon carbide reinforced copper-based composite material and preparation method thereof

InactiveCN111057899AAvoid reunionEnhancement effect is goodTransportation and packagingMetal-working apparatusStearic acidUltrasonic dispersion

The invention provides a graphene / silicon carbide reinforced copper-based composite material and a preparation method thereof, and relates to the technical field of copper-based composite materials. The graphene / silicon carbide reinforced copper-based composite material contains the following components of, in percentage by weight, 0.3wt%-0.8wt% of graphene, 0. 2wt%-0.6wt% of SiC, 0. 02wt%-0.2wt%of Ni, and the balance copper; the preparation method comprises the following steps that (1) mixing is carried out; (2) ultrasonic dispersion on graphene is carried out, mixed powder and stearic acidare added, ultrasonic dispersion is carried out, and then mixing and stirring are carried out; (3) ball milling is carried out; (4) drying is carried out; the stearic acid is removed; (5) pre-pressingforming is carried out, and a pressed shape is loaded into a graphite mold; and (6) vacuum hot pressing is carried out, wherein the hot pressing temperature is 840-860 DEG C, the hot pressing pressure is 40-50 MPa, the hot pressing time is 100-130 min; and (7) hot rolling is carried out; the temperature is heated to 360-400 DEG C, heat preservation is carried out, then the temperature is reducedto 160-180 DEG C, and then air cooling is carried out. According to the preparation method, the raw material selection and the raw material proportion are reasonable, and an optimized preparation process is combined, so that the prepared composite material has the advantages of being good in conductive performance, high in strength, high in hardness, good in toughness and excellent in wear resistance.

Owner:湖南碳材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis process of 1-(beta-D-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene Synthesis process of 1-(beta-D-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene](https://images-eureka.patsnap.com/patent_img/f1b46495-62a6-4276-a2dd-8ba4310273d9/HDA0000662232430000011.PNG)

![Synthesis process of 1-(beta-D-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene Synthesis process of 1-(beta-D-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene](https://images-eureka.patsnap.com/patent_img/f1b46495-62a6-4276-a2dd-8ba4310273d9/HDA0000662232430000021.PNG)

![Synthesis process of 1-(beta-D-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene Synthesis process of 1-(beta-D-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene](https://images-eureka.patsnap.com/patent_img/f1b46495-62a6-4276-a2dd-8ba4310273d9/HDA0000662232430000031.PNG)