Automatic mold pressing vulcanization system and method for rubber product

A technology of molding vulcanization and vulcanization system, applied in the direction of coating, etc., can solve the problems of inability to realize continuous product vulcanization, limited degree of automation, different process routes, etc., and achieve the effect of simple structure, low cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

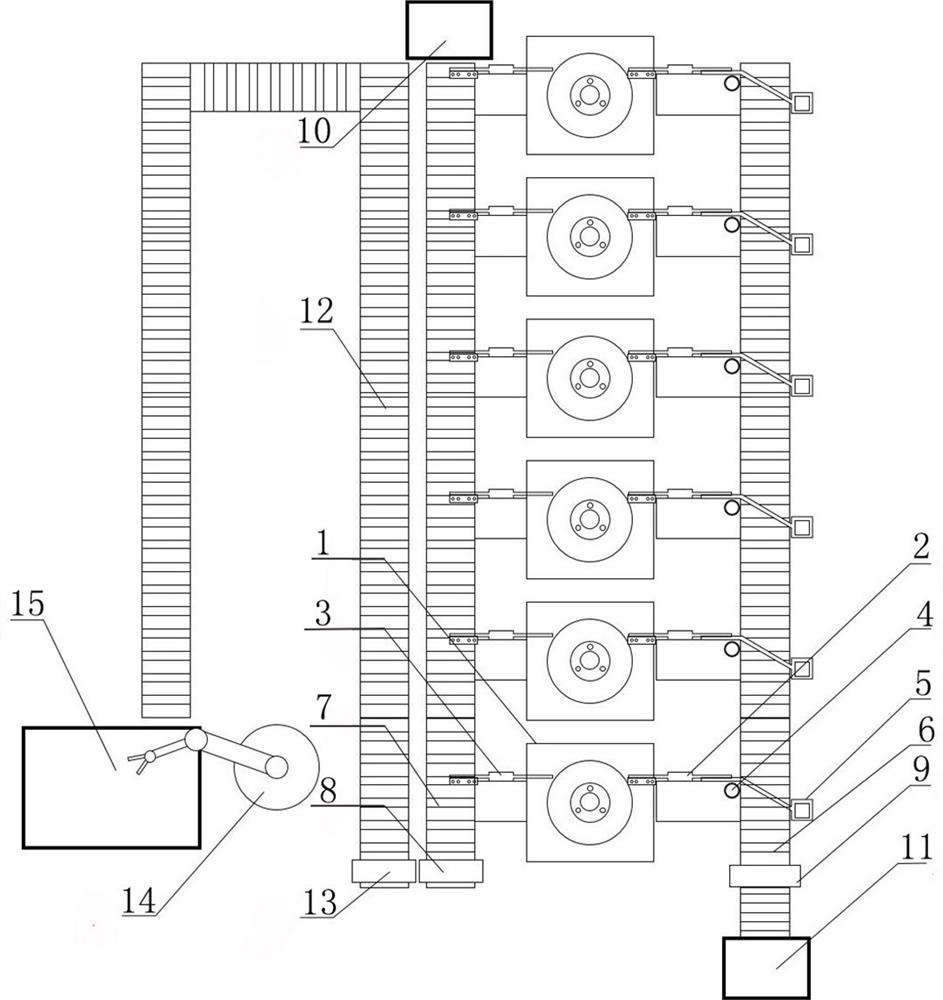

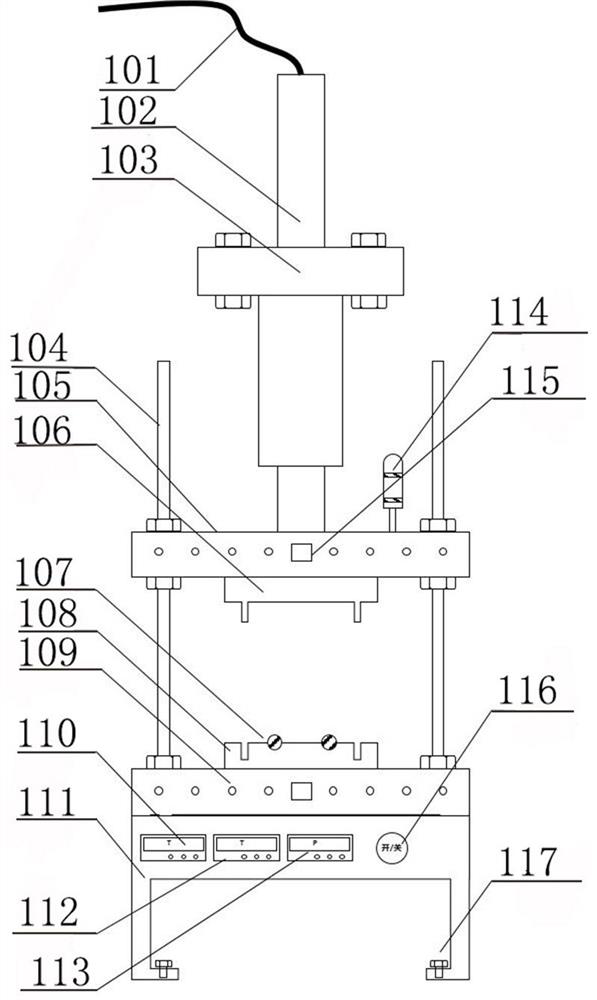

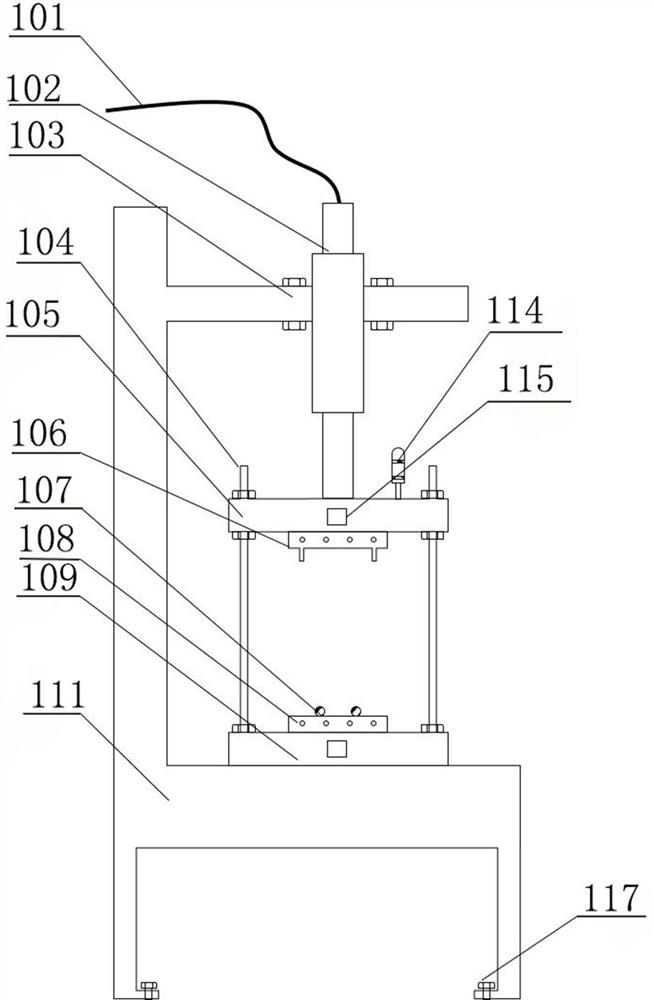

[0046] In this example, if Figure 1-5 As shown, an automatic molding vulcanization system for rubber products includes a logistics system and a plurality of molding vulcanization units with the same structure; the logistics system is arranged at both ends of each molding vulcanization unit;

[0047] The molded vulcanization unit includes a vulcanizer 1, a feeding mechanism 2, a feeding auxiliary mechanism 5 and an unloading mechanism 3. One end of the feeding mechanism 2 is connected to the feeding end of the vulcanizing machine 1, and the other end of the feeding mechanism 2 is One end of the feeding auxiliary mechanism 5 is connected, the other end of the feeding auxiliary mechanism 5 is connected to the logistics system, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com