Method for increasing sulfur content of sulfur-carbon composite through vulcanization accelerator

A technology of vulcanization accelerator and sulfur-carbon compound, which is applied in the field of electrochemical power supply, can solve the problem that it is difficult to efficiently increase the sulfur content of the sulfur-carbon compound, and achieves the effects of lowering temperature, simple equipment and increasing sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

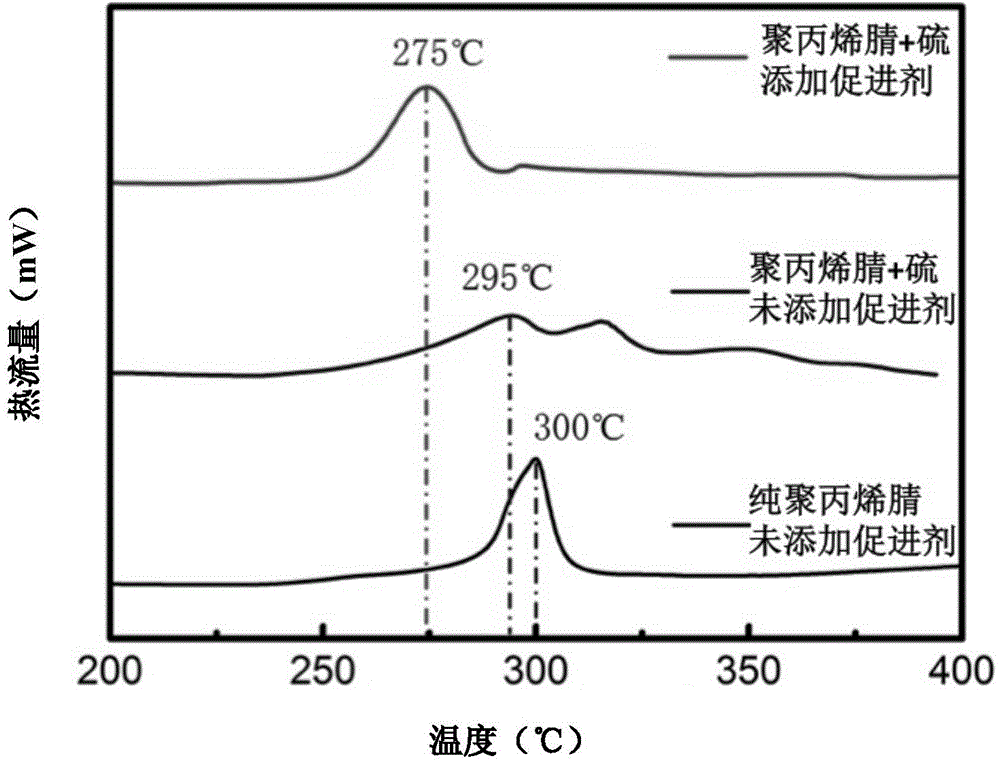

[0036] (1) Mix polyacrylonitrile, elemental sulfur, and 2-mercaptobenzothiazole in a mass ratio of 1:1:0.1, and put them into a ball mill tank for ball milling at a speed of 400 rpm for 3 hours to obtain Mix the reaction mixture homogeneously;

[0037] (2) Put the reaction mixture into an airtight container, place it in a vacuum tube furnace, pass in argon gas, raise the temperature to 185°C, keep it warm for 1 hour, then continue to raise the temperature to 280°C, and keep it warm for 6 hours. The heating rate is 10°C / hour. After the reaction was completed, it was naturally cooled to room temperature.

Embodiment 2

[0045] (1) Mix polyacrylonitrile, elemental sulfur, and 2-mercaptobenzothiazole in a mass ratio of 1:3:0.1, and put them into a ball mill tank for ball milling at a speed of 400 rpm for 3 hours to obtain Mix the reaction mixture homogeneously;

[0046] (2) Put the reaction mixture into an airtight container, place it in a vacuum tube furnace, pass in argon gas, raise the temperature to 185°C, keep it warm for 1 hour, then continue to raise the temperature to 320°C, and keep it warm for 6 hours. The heating rate is 10°C / hour. After the reaction was completed, it was naturally cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com