Preparation method of nano lanthanum oxide/graphene/sulfur composite material

A technology of nano-lanthanum oxide and composite materials, which is applied in the field of preparation of nano-lanthanum oxide/graphene/sulfur composite materials, can solve the problems of low utilization rate of positive electrode active materials, complicated preparation process, short cycle life, etc., and achieve easy diffusion and The effect of ion transport, simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Graphene oxide was prepared by the Hummers method: first, 1 g of graphite (325 mesh), 0.5 g of NaNO 3 Pour 23mL of concentrated sulfuric acid into a 250mL beaker, add 3g KMnO4 into the above beaker in an ice bath, then stir for 30min, then add 30mL of deionized water while stirring, and continue stirring for 15min. Then add 50 mL of deionized water again, and finally add 30 mL of H to the mixed solution 2 o 2 , to obtain a graphite oxide solution (containing a large amount of H + ). Add deionized water to the prepared graphite oxide solution, place it in a centrifuge tube for centrifugation (6000 rpm / min), remove the supernatant in the centrifuge tube after centrifugation, add deionized water again, and centrifuge (6000 rpm / min ), repeat this operation until the solution pH=7, and finally obtain the neutral graphite oxide solution. The prepared graphite oxide solution was ultrasonically dispersed at room temperature using an ultrasonic disperser at 50 kHz for 2 ...

Embodiment 2

[0040] (1) utilize Hummers method to prepare graphene oxide (same as embodiment 1);

[0041] (2) Weigh a certain amount of lanthanum chloride to make a 0.2 mol / L solution, and add NaOH dropwise until pH=10. After standing for 4 hours, the precipitate was filtered, washed 4 times with distilled water, and then dried in an oven at 60°C for 10 hours; the molar concentration of NaOH was 0.6moL / L.

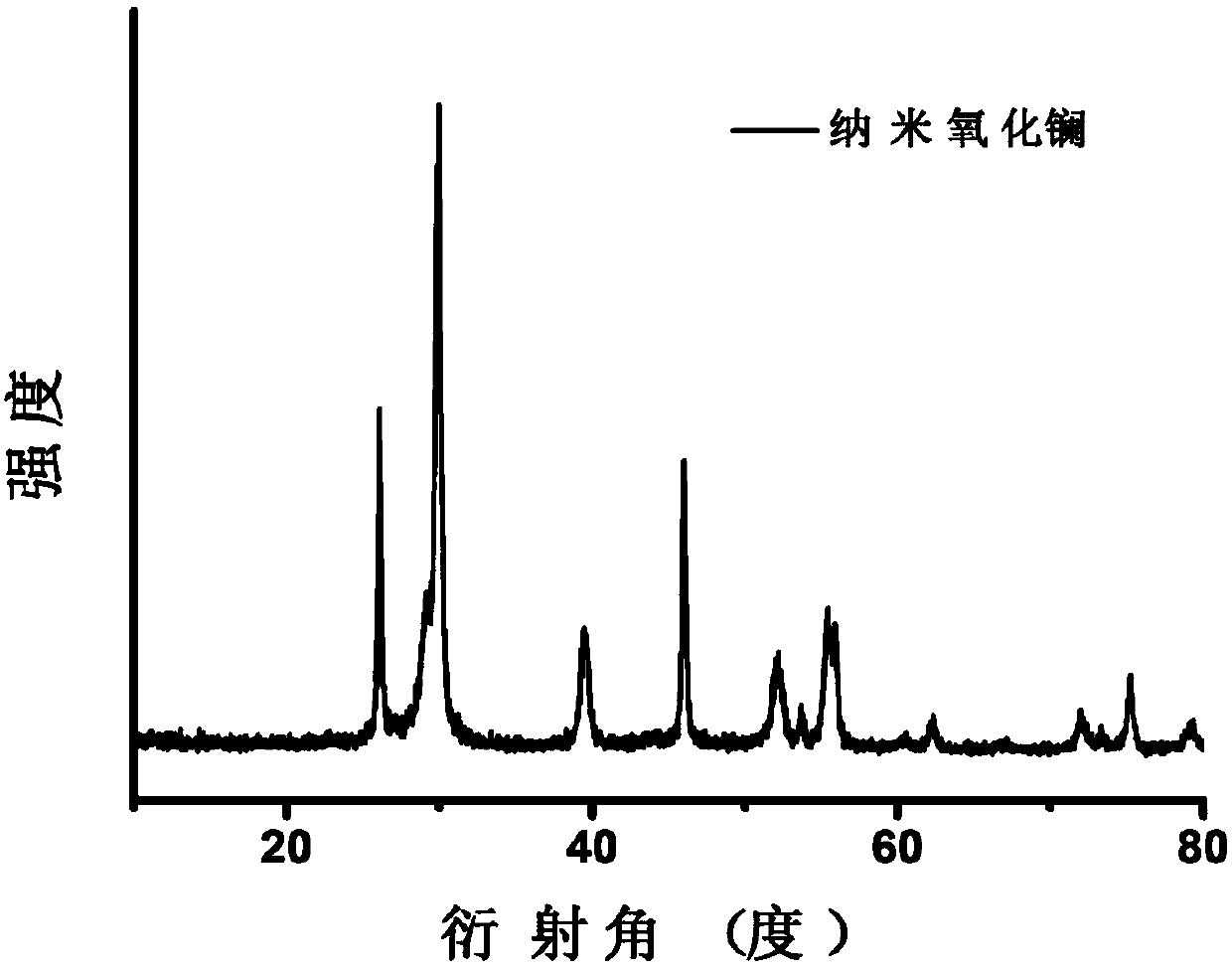

[0042] (3) Grind the dried precipitate slightly, or directly put it into a mortar, put it into a tube furnace, and calcinate it at 450° C. for 3 hours under a nitrogen atmosphere to obtain nano-lanthanum oxide;

[0043] (4) Take a certain amount of nano-sulfur powder (purity is 99.99%) and dissolve it in carbon disulfide (purity is 99.5%) to form a solution of 30 mg / mL;

[0044] (5) Take the graphene oxide and nano-lanthanum oxide prepared in the first step according to the ratio of mass ratio 1:15, according to the ratio of mixture and deionized water mass ratio of 0.01:1, the mixture...

Embodiment 3

[0048] (1) utilize Hummers method to prepare graphene oxide (same as embodiment 1);

[0049] (2) Weigh a certain amount of lanthanum chloride to make a 2mol / L solution, and add NaOH dropwise until pH=10. After standing for 4 hours, the precipitate was filtered, washed 6 times with distilled water, and then dried in an oven at 100°C for 12 hours; the molar concentration of NaOH was 0.6moL / L.

[0050] (3) The dried precipitate is slightly ground, or directly put into a mortar, put into a tube furnace, and calcined at 900° C. for 6 hours under a nitrogen atmosphere to obtain nano-lanthanum oxide;

[0051] (4) Take a certain amount of nano-sulfur powder (purity is 99.99%) and dissolve it in carbon disulfide (purity is 99.5%) to form a solution of 30 mg / mL;

[0052] (5) Take the graphene oxide and nano-lanthanum oxide prepared in the first step according to the ratio of 1:20 in mass ratio, and add the mixture into deionized water according to the ratio of 0.01:1 in the mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com