Preparation method for rutile phase vanadium dioxide superfine nano powder

A technology of vanadium dioxide and ultrafine nanometers, which is applied in the field of preparation of rutile phase vanadium dioxide ultrafine nanometer powders, can solve the problems of organic solvent toxicity and safety, difficult water recycling, large particle uniformity, etc., and achieve relative The effect of low value, high production speed and high particle purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of rutile phase vanadium dioxide ultrafine nano-powder, comprising the following steps:

[0035] S1. Add ammonia water to the tetravalent vanadium solution A, and stir to obtain a suspension B; wherein, the concentration of vanadium ions in the tetravalent vanadium solution A is 0.1-2mol / L, which is dissolved in water by tetravalent vanadium salt, And it is obtained by stirring at a rotating speed of 50-2500r / min for 1-60min, preferably 25min. Wherein the tetravalent vanadium salt can be one or more of vanadyl sulfate, vanadyl oxalate, vanadyl chloride, vanadyl ascorbate, vanadyl citrate or vanadyl tartrate, and can also be through other vanadium compounds, such as penta Vanadium oxide, ammonium metavanadate or sodium vanadate is reduced by a reducing agent to form a tetravalent vanadium salt; the water here is pure water, distilled water or deionized water;

[0036] S2. Carry out sealing, heat preservation and stirring treatment on the suspension ...

Embodiment 1

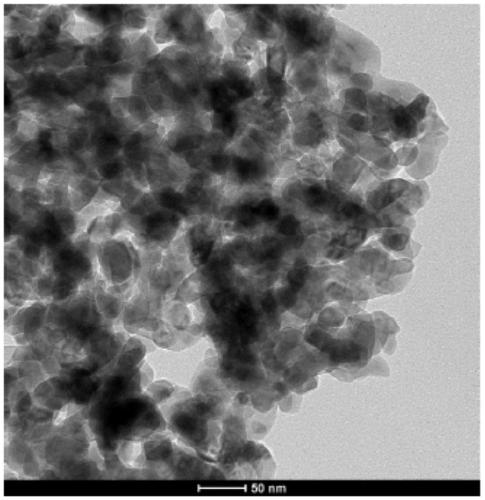

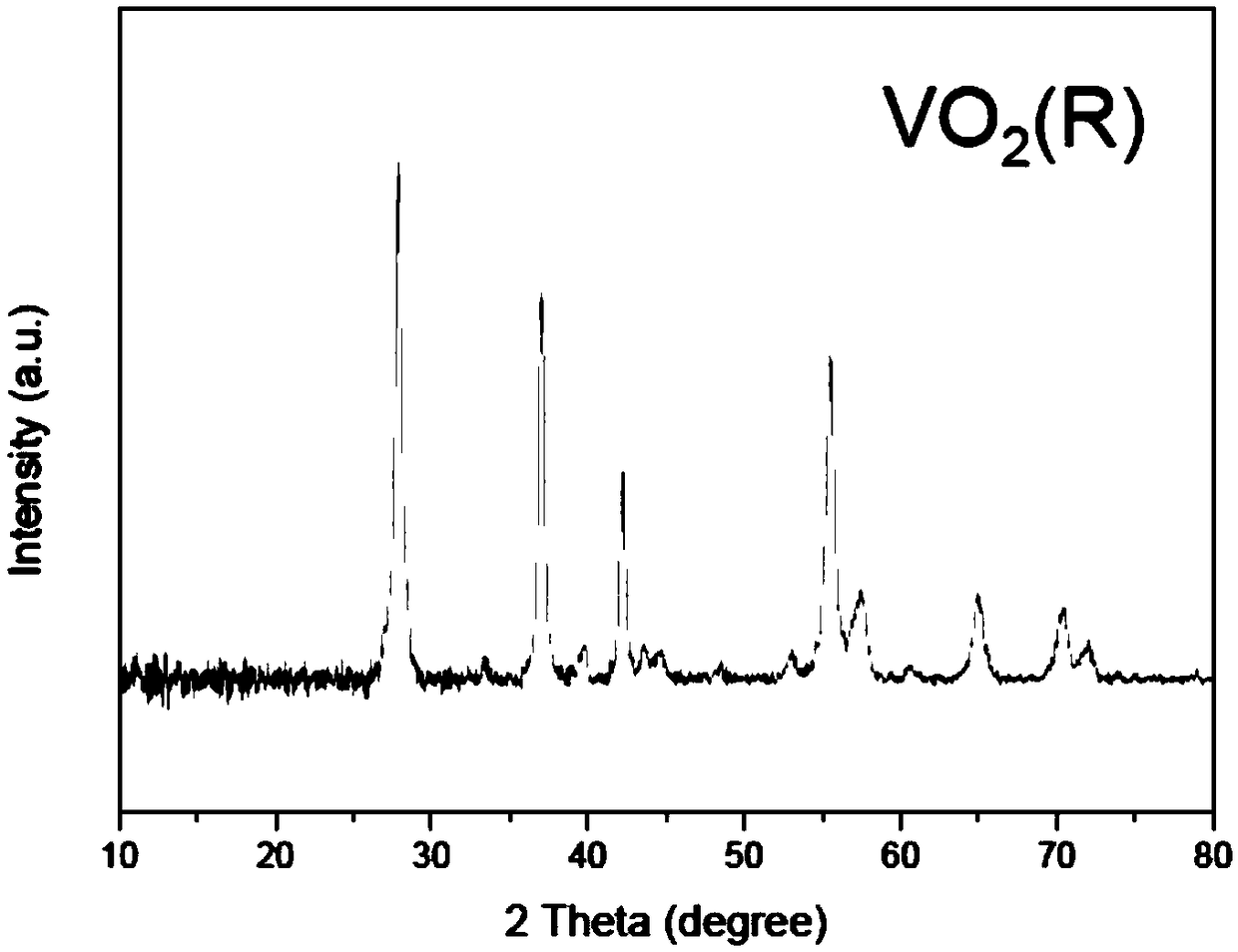

[0049] Preparation of non-doped rutile phase vanadium dioxide ultrafine nanopowder

[0050] 1) Colloidal suspension preparation:

[0051] Take 4g of vanadyl sulfate, add the powder into a 200ml flask, add 60ml of deionized water and keep stirring for 10 minutes. Add 10 ml of 25% ammonia water and continue stirring for 10 minutes to obtain a cloudy precursor solution. Seal the flask containing the turbid precursor solution, heat it to 80° C. and keep it warm for 2 hours to obtain a colloidal suspension.

[0052] 2) Colloid treatment:

[0053] Transfer the colloidal suspension obtained in step 1) to a plastic centrifuge tube, put it into a centrifuge, keep centrifuging at a speed of 6000r / min for 10 minutes, take it out, remove the supernatant, add deionized water, and remove the precipitate Mix well in water and put it into an ultrasonic cleaning machine for ultrasonic treatment for 5 minutes, put it into a centrifuge for centrifugation, repeat the operation three times, tak...

Embodiment 2

[0059] Preparation of 1% tungsten-doped vanadium dioxide ultrafine nano-powder in rutile phase

[0060] 1) Colloidal suspension preparation:

[0061] Take 4g of vanadyl sulfate, put the powder into a 200ml flask, add 60ml of deionized water and keep stirring for 10 minutes, then add 0.07g of ammonium metatungstate. After continuing to stir for 10 minutes, add 10 ml of 25% ammonia water, and continue stirring for 10 minutes to obtain a cloudy precursor solution. Seal the flask containing the turbid precursor solution, heat it to 80° C. and keep it warm for 2 hours to obtain a colloidal suspension.

[0062] 2) Colloid treatment:

[0063] Transfer the colloidal suspension obtained in step 1) to a plastic centrifuge tube, put it into a centrifuge, keep centrifuging at a speed of 6000r / min for 10 minutes, take it out, remove the supernatant, add deionized water, and remove the precipitate Mix well in water and put it into an ultrasonic cleaning machine for ultrasonic treatment f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com