Cr-doped near-infrared long-afterglow luminescent material with perovskite structure and preparation method thereof

A perovskite structure and luminescent material technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of limiting the application of long afterglow materials and slow development of long afterglow materials, so as to improve long afterglow luminescence and facilitate large-scale promotion , the effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The single doped Cr of this embodiment 3+ CaTiO 3 The preparation method of the near-infrared long afterglow luminescent material is as follows:

[0036] According to the following composition: the matrix is CaTiO 3 ;Cr 3+ The doping amount is 0.001mol%; Weigh titanium oxide, calcium carbonate, chromium oxide (Cr 2 o 3 ), after grinding and mixing in a reducing atmosphere (5% (volume percentage) H 2 +95% (volume percentage) N 2 ) at 900°C for 3 hours, then take it out, grind it again, and burn it at 1450°C for 2 hours.

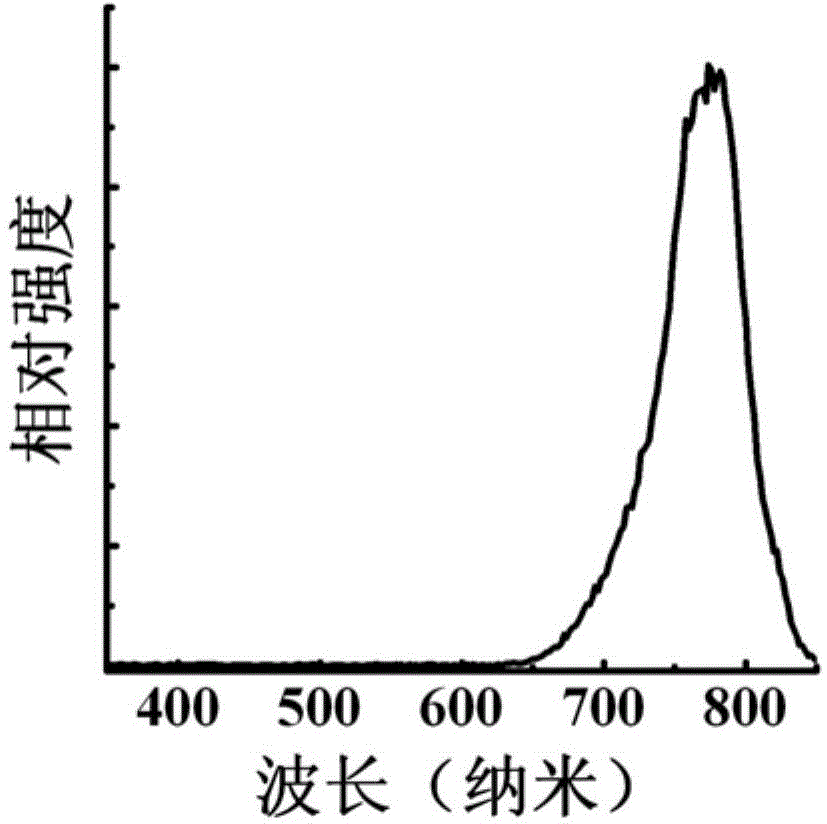

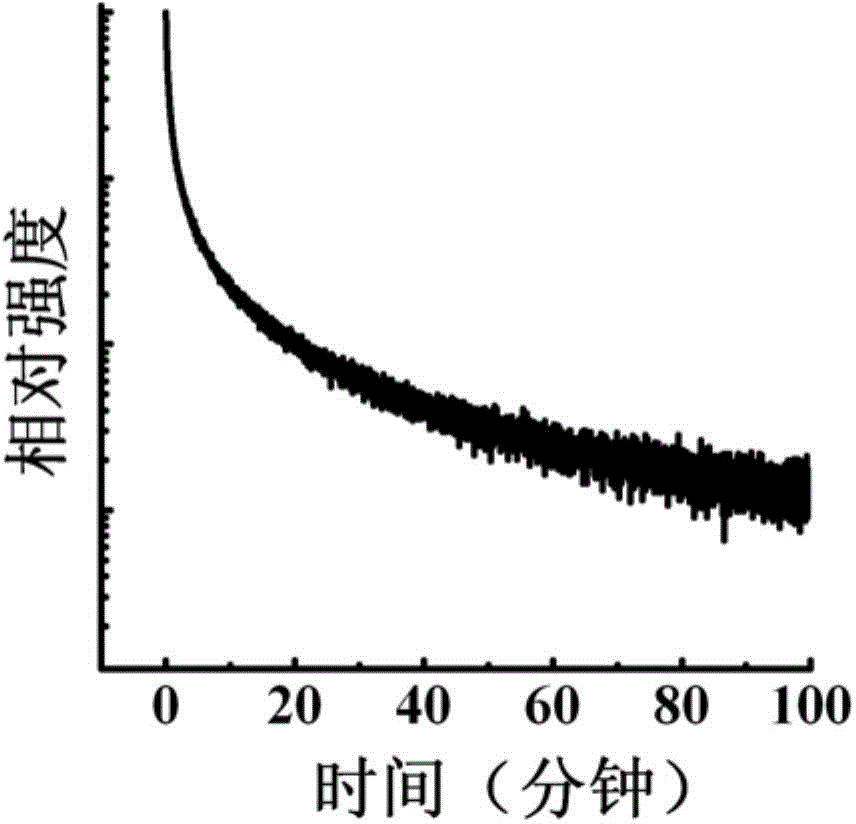

[0037] The long afterglow spectrum of the near-infrared long-afterglow luminescent material prepared in this embodiment is shown in Figure 1 (a). After irradiating with 254 nm ultraviolet light for 10 minutes, the test was performed after an interval of 30 seconds, and the near-infrared long-afterglow luminescence was obtained. The luminescence peak is located at 766,780 nm. As shown in Figure 1(b), the near-infrared long afterglow luminescenc...

Embodiment 2

[0039] Cr in this example 3+ and Bi 3+ Co-doped SrTiO 3 The preparation method of the near-infrared long afterglow luminescent material is as follows:

[0040] According to the following composition: the matrix is SrTiO 3 ;Cr 3+ The doping amount is 5mol%, Bi 3+ The doping amount is 20mol%; Weigh titanium oxide, strontium carbonate, chromium oxide (Cr 2 o 3 ), bismuth oxide (Bi 2 O), after grinding and mixing, pre-fire at 600°C for 1 hour in the air, take it out, grind again, and burn at 1300°C for 5 hours.

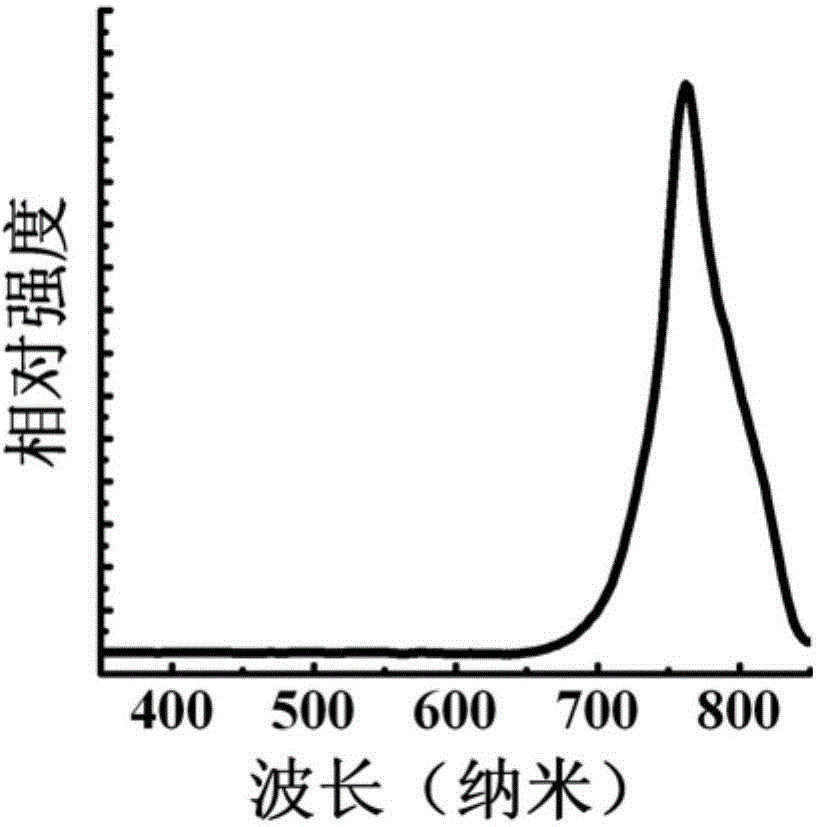

[0041] The long afterglow spectrum of the near-infrared long-lasting luminescent material prepared in this embodiment is shown in Figure 2(a). After irradiating with 254 nm ultraviolet light for 10 minutes, the test was performed after an interval of 30 seconds, and the near-infrared long-lasting luminescence was obtained. The luminescence peak is located at 766 nm. As shown in Figure 2(b), the near-infrared long afterglow luminescence at 766 nm was monitored, ...

Embodiment 3

[0043] The single doped Cr of this embodiment 3+ BaSnO 3 The preparation method of the near-infrared long afterglow luminescent material is as follows:

[0044] According to the following composition: the matrix is BaSnO 3 ;Cr 3+The doping amount is 5mol%; Weigh tin oxide, barium carbonate, chromium oxide respectively, grind and mix them in reducing atmosphere (5% H 2 +95%N 2 ) at 600°C for 1 hour, take it out, grind it again, and then fire it at 1350°C for 5 hours.

[0045] The long afterglow spectrum of the near-infrared long-afterglow luminescent material prepared in this embodiment is shown in Figure 3(a). After being irradiated with 254 nm ultraviolet light for 10 minutes and tested after an interval of 30 seconds, the near-infrared long afterglow luminescence was obtained. The luminescence peak is located at 800 nm. As shown in Figure 3(b), the near-infrared long afterglow luminescence at 800 nm was monitored, and the discovery time was as long as 100 minutes. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com