Fluorescent powder capable of promoting plant growth, preparation thereof and light conversion film prepared from fluorescent powder

A technology that promotes plant growth and phosphor, applied in the field of light-transfer film, can solve the problems of increasing planting costs and energy consumption, complicated LED chip technology, and difficulty in large-scale application, and achieves improved light energy conversion efficiency, cheap source channels, The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

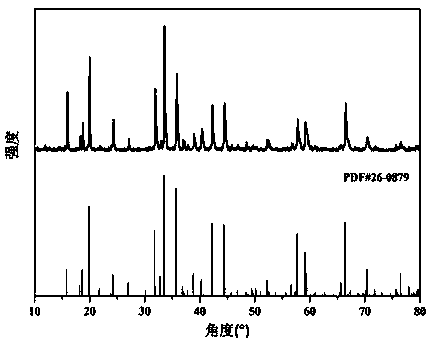

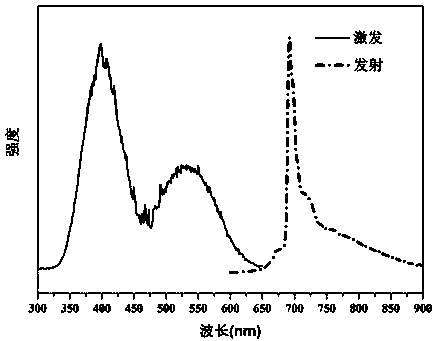

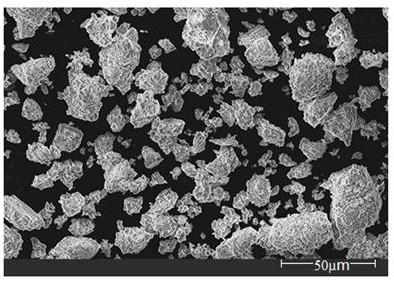

Embodiment 1

[0035] According to SrMgAl 9.95 o 17 :0.05Cr 3+ The stoichiometric ratio of the molecular formula, respectively weighed SrCO 3 , MgO, Al 2 o 3 and Cr 2 o 3 , mixed to get the material, then add H with a quality of 2% of the material quality 3 BO 3 , mix well to form a mixture, after fully grinding evenly, put it into an alumina crucible, place it in a tube furnace with a temperature of 1450°C and calcinate for 6 hours under a nitrogen atmosphere, cool to room temperature with the furnace, and grind to obtain SrMgAl 9.95 o 17 :0.05Cr 3+ powder.

[0036] According to the mass ratio of 100:15, the obtained SrMgAl 9.95 o 17 :0.05Cr 3+ Powder and Commercial Yellow Phosphor Y (3-y) Al 5 o 12 :yCe 3+ , mixed in an agate mortar, and fully ground until the powder color is uniform, to obtain a mixed fluorescent powder.

[0037]According to the mass ratio of 1:1, take the two components in the epoxy resin AB glue and mix them to get the mixed glue, then add the mixed fl...

Embodiment 2

[0053] According to SrMgAl 9.95 o 17 :0.05Cr 3+ The stoichiometric ratio of the molecular formula, respectively weighed Sr(NO 3 ) 2 , MgSO 4 , Al(NO 3 ) 3 and Cr 2 o 3 , mixed to get the material, and then add H with a mass of 1% of the mass of the material 3 BO 3 , mix well to form a mixture, after fully grinding evenly, put it into an alumina crucible, place it in a tube furnace with a temperature of 1400°C and calcinate it under a nitrogen atmosphere for 8 hours, cool to room temperature with the furnace, and grind to obtain SrMgAl 9.95 o 17 :0.05Cr 3+ powder.

[0054] According to the mass ratio of 100:10, the obtained SrMgAl 9.95 o 17 :0.05Cr 3+ Powder and Commercial Yellow Phosphor Y (3-y) al 5 o 12 :yCe 3+ , mixed in an agate mortar, and fully ground until the powder color is uniform, to obtain a mixed fluorescent powder.

[0055] According to the mass ratio of 1:0.8, take the two components in the epoxy resin AB glue and mix them to obtain the mixed...

Embodiment 3

[0057] According to SrMgAl 9.95 o 17 :0.05Cr 3+ The stoichiometric ratio of the molecular formula, respectively weighed Sr(NO 3 ) 2 , MgCO 3 , Al(NO 3 ) 3 and Cr 2 (SO 4 ) 3 , mixed to obtain the material, and then adding H with a quality of 1.5% of the material 3 BO 3 , mix well to form a mixture, after fully grinding evenly, put it into an alumina crucible, place it in a tube furnace at a temperature of 1500°C, and calcinate it under a nitrogen atmosphere for 4 hours, cool to room temperature with the furnace, and grind to obtain SrMgAl 9.95 o 17 :0.05Cr 3+ powder.

[0058] According to the mass ratio of 100:20, the obtained SrMgAl 9.95 o 17 :0.05Cr 3+ Powder and Commercial Yellow Phosphor Y (3-y) al5 o 12 :yCe 3+ , mixed in an agate mortar, and fully ground until the powder color is uniform, to obtain a mixed fluorescent powder.

[0059] According to the mass ratio of 1:1.2, take the two components in the epoxy resin AB glue and mix them to get the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com