Technology for preparing 2-chromium picolinate through one-step method

A technology of chromium picolinate and preparation process, applied in the field of one-step preparation of chromium 2-picolinate, can solve problems such as increased production cost, environmental pollution, multiple by-products, etc., and achieves the effects of reduced damage, low price and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

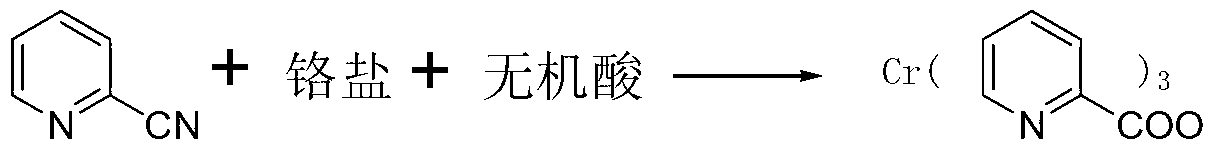

Method used

Image

Examples

Embodiment 1 1

[0015] Example 1 One-step preparation of chromium 2-picolinate

[0016] Under stirring conditions, add 40 kg of 30% by mass hydrochloric acid, 32.1 kg of 2-cyanopyridine and 26.6 kg of chromium trichloride hexahydrate into the reaction kettle. The temperature is raised to 70°C and reacted for 1.5 hours. After the reaction, the temperature is lowered. To room temperature, centrifuge the material to obtain a rose-red chromium 2-picolinate solid, dried at 80°C for 2 hours, weighed 41.2 kg, and the yield was 98.6%.

Embodiment 2 1

[0017] Example 2 One-step preparation of chromium 2-picolinate

[0018] Under stirring conditions, add 21.5kg of 98% sulfuric acid, 42.9kg of 2-cyanopyridine and 26.1kg of chromium sulfate to the reaction kettle in sequence. The temperature is raised to 50°C for 1.5 hours, and the temperature is lowered to room temperature. After the reaction, The material was centrifuged to obtain a rose-red chromium 2-picolinate solid, which was dried at 80° C. for 2 hours, weighed 55.2 kg, and the yield was 99.1%.

Embodiment 3 1

[0019] Example 3 One-step preparation of chromium 2-picolinate

[0020] Under stirring conditions, add 40 kg of 30% by mass hydrochloric acid, 32.7 kg of 2-cyanopyridine and 26.6 kg of chromium trichloride hexahydrate into the reaction kettle. The temperature is raised to 75°C and reacted for 1.5 hours. After the reaction, the temperature is lowered. After reaching room temperature, the material was centrifuged to obtain a rose-red chromium 2-picolinate solid, which was dried at 80°C for 2 hours, weighed 41.5 kg, and the yield was 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com