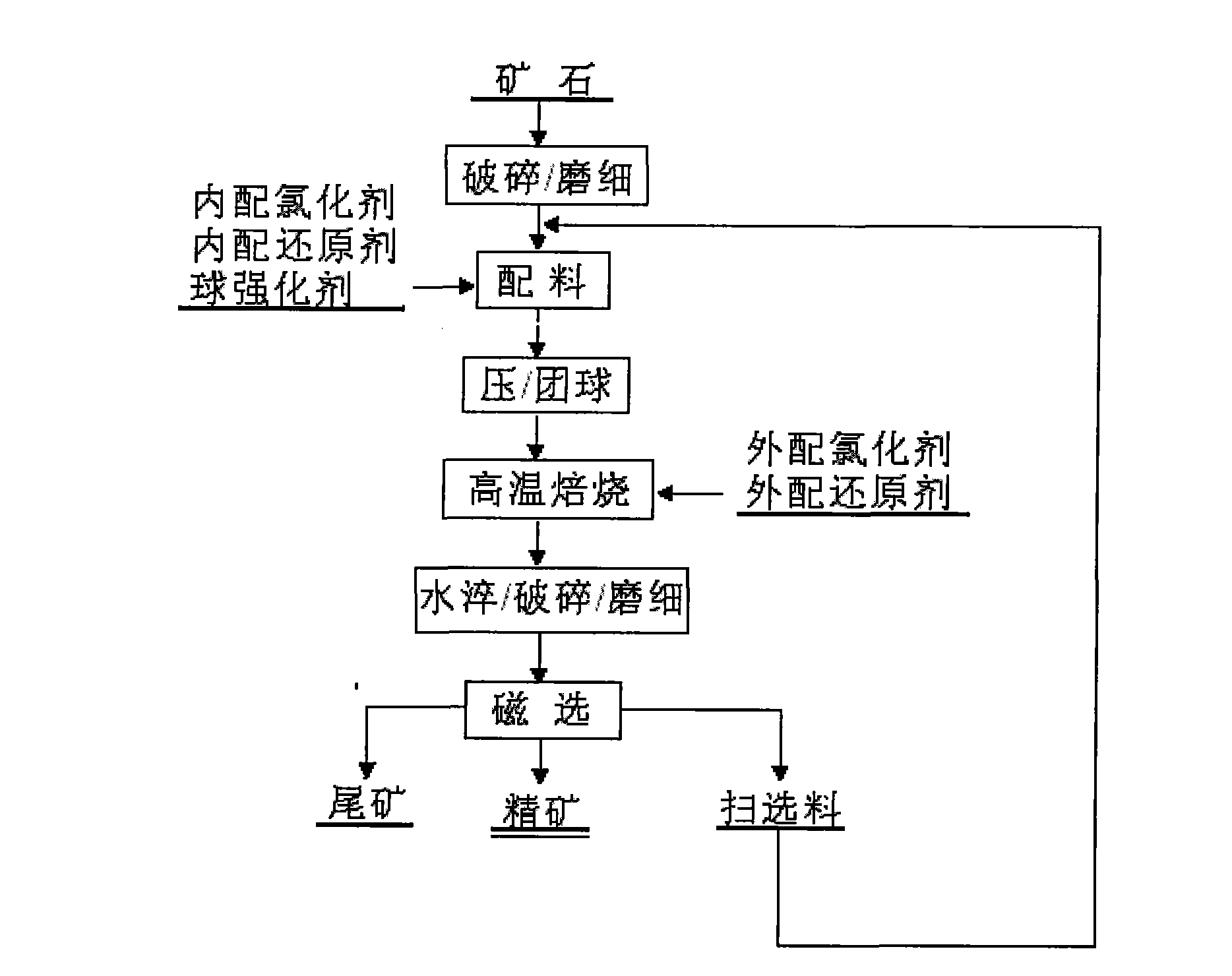

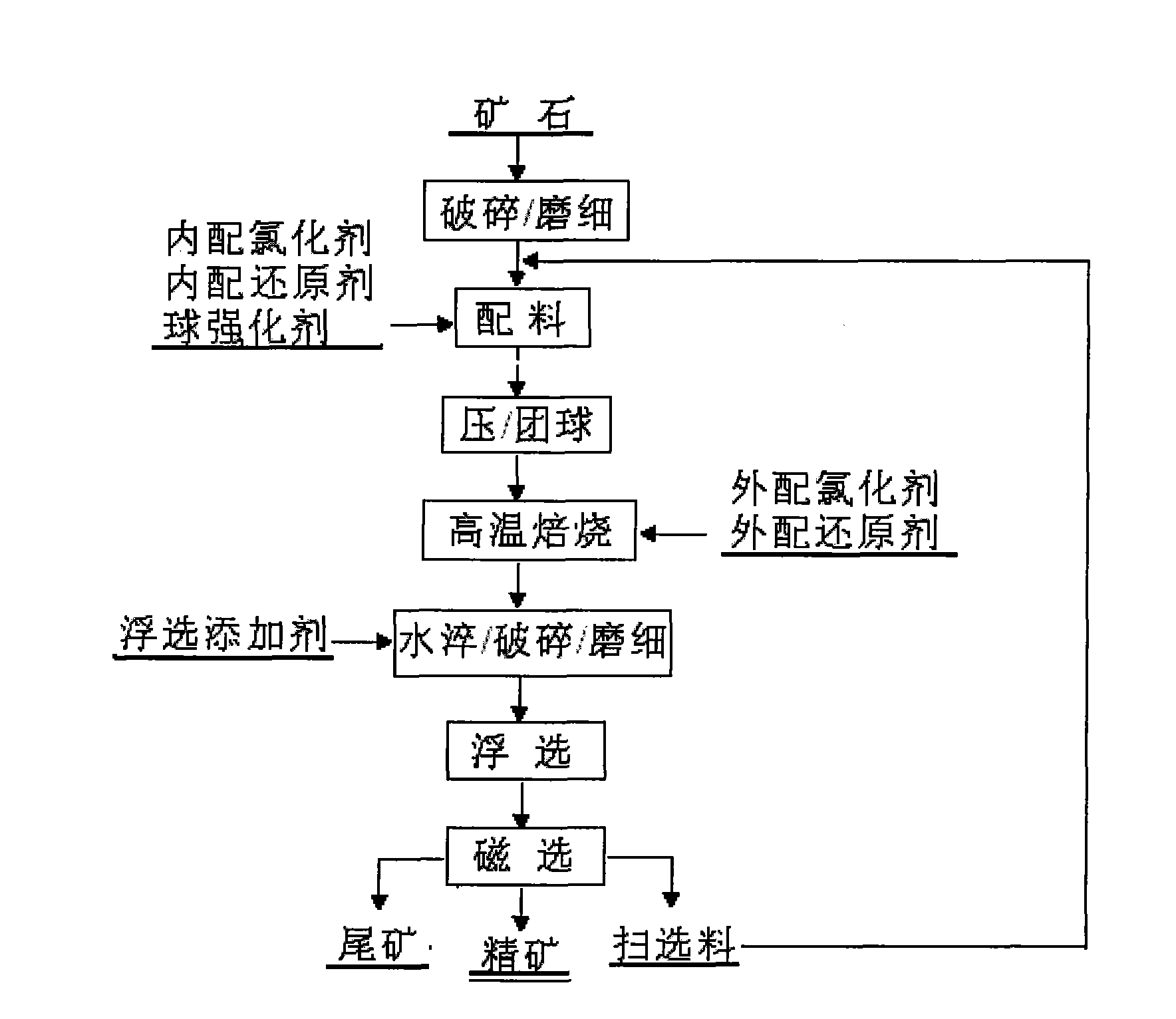

Method for efficiently concentrating cobalt and nickel from low-grade nickeliferous laterite ore

A laterite nickel ore and low-grade technology, applied in chemical instruments and methods, wet separation, magnetic separation, etc., can solve the problems of high operating cost and large investment, and achieve high reaction efficiency, short investment cycle, and quick results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A. Control the moisture content of the mineral material to be less than 15%, crush it, grind it finely, and pass it through a 100-mesh sieve;

[0036] B. Add 80kg of calcium chloride, 60kg of coal powder, and 30kg of sodium chloride per 1 ton of dry mineral powder, mix well, add appropriate amount of water to moisten, and press into balls with a diameter of 18mm; air cool to remove part of the water;

[0037] C. Add 80kg of magnesium chloride and 80kg of anthracite for every 1 ton of ore balls, and mix them into the roaster;

[0038] D. Control the roasting temperature to 980°C and the roasting time to 40 minutes to roast the material;

[0039] E. Crushing the roasted material, wet grinding, and passing through a 200-mesh sieve; wet magnetic separation, the selected magnetic field strength is 2200 Gauss, and the sweeping magnetic field strength is 3200 Gauss;

[0040] F. Roasting flue gas purification and absorption treatment.

[0041] Through the control of the above...

Embodiment 2

[0043] A. Control the moisture content of the mineral material to be less than 15%, crush it, grind it finely, and pass it through a 100-mesh sieve;

[0044] B. Add 20kg of sodium chloride, 85kg of magnesium chloride, 50kg of coal powder, and 25kg of calcium oxide per 1 ton of dry mineral powder, mix well, add appropriate amount of water to moisten, and granulate into balls with a diameter of 25mm; remove the part by air cooling moisture;

[0045] C. Add 180kg of ferric chloride and 100kg of anthracite for every 1 ton of ore balls, and mix them into the roaster;

[0046] D. Control the roasting temperature to 920°C and the roasting time to 80 minutes to roast the material;

[0047] E. Crushing the roasted material, wet grinding, and passing through a 200-mesh sieve; wet magnetic separation, the selected magnetic field strength is 2400 Gauss, and the sweeping magnetic field strength is 3350 Gauss;

[0048] F. Roasting flue gas purification and absorption treatment.

[0049] ...

Embodiment 3

[0051] A. Control the moisture content of the mineral material to be less than 15%, crush it, grind it finely, and pass it through a 100-mesh sieve;

[0052] B. Add 30kg of sodium chloride, 60kg of magnesium chloride, 50kg of coal powder, and 30kg of calcium oxide per 1 ton of dry mineral powder, mix evenly, add appropriate amount of water to moisten, and pelletize into balls with a diameter of 28mm; remove the part by air cooling moisture;

[0053] C. Add 50kg of magnesium chloride, 120kg of ferric chloride, and 85kg of anthracite for every 1 ton of ore balls, and mix them into the roaster;

[0054] D. Control the roasting temperature to 880°C and the roasting time to 90 minutes to roast the material;

[0055] E. Break the roasted material, add 1860 grams of copper nitrate per ton of material, add water to wet grind and activate the material; control the liquid-solid ratio 4:1, add water and milk of lime, and adjust the pH to 10.2; press "one rough one Flotation is carried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com