Methods for preparing L-type zeolite guiding agent and zeolite

A zeolite directing agent and the technology of the directing agent, which are applied in the directions of L-type crystalline aluminosilicate zeolite and crystalline aluminosilicate zeolite, etc., can solve the problems of easily associated W heterocrystals or amorphous impurities, difficult crystallization conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

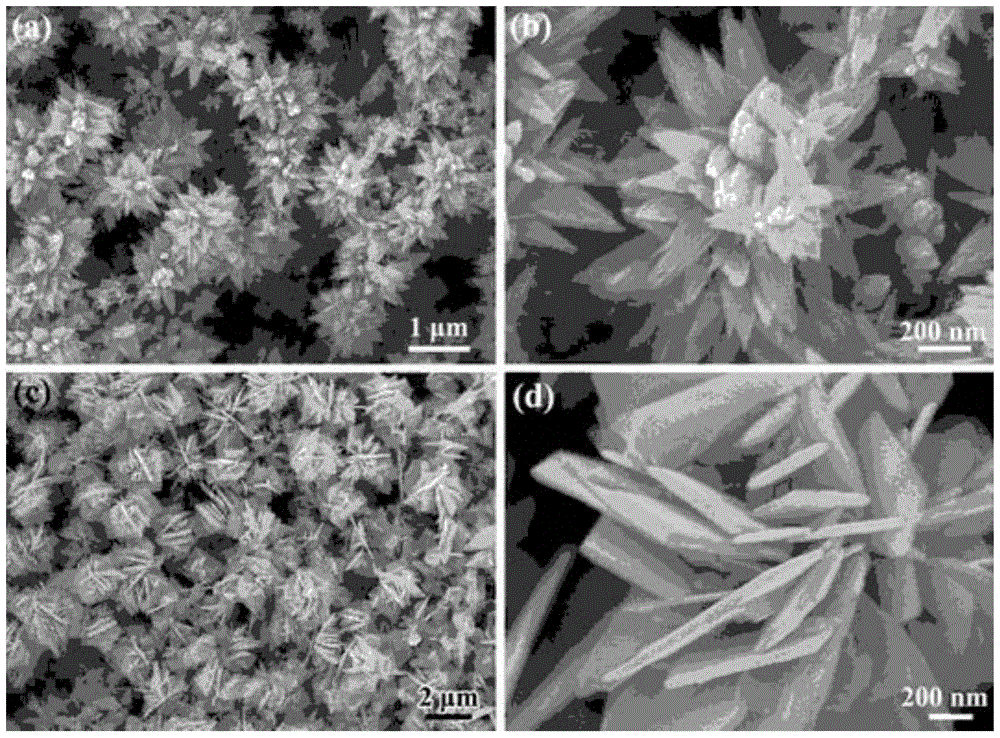

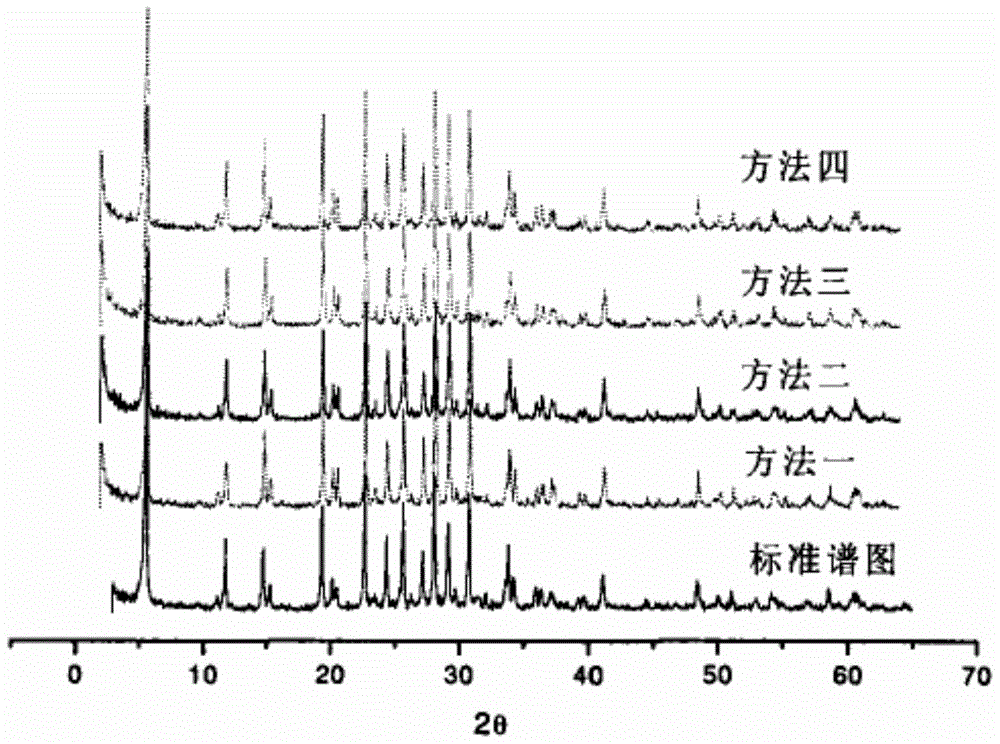

[0080] Example 1. Synthesis of L-type zeolite

[0081] The formula is: 0.35K 2 O:0.003Al 2 o 3 : SiO 2 :0.01M:35(H 2 O+C 2 h 5 Oh)

[0082] Raw materials: (A) silica sol (same as example A)

[0083] (B) Potassium hydroxide (purity 80.00%) was dissolved in distilled water and absolute ethanol.

[0084] (C) Aluminum sulfate.

[0085] Weigh 0.003mol (C) and add it to the corresponding stoichiometric (B), heat to dissolve, then add it to the corresponding (A), stir while adding, and stir for 15 minutes after the addition, to obtain a uniform gel ( D).

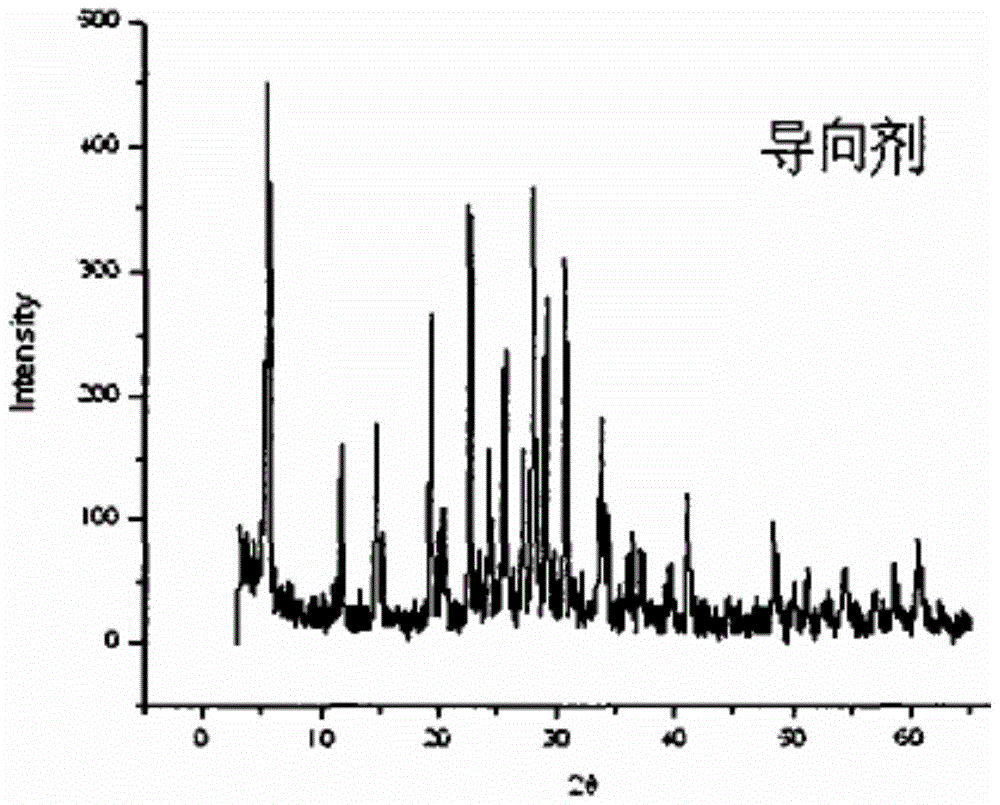

[0086] Add the stoichiometric directing agent prepared in Example A and aged for 72 hours to the gel (D), stir evenly, add the corresponding template agent M, namely glycine, stir for 10 minutes, heat to 150°C for crystallization by microwave, and crystallize for 24 Hours later, the colloidal suspension of zeolite L was obtained, and the resulting mixture was centrifuged with a high-speed centrifuge, the supernatant was ...

example 2

[0088] Example 2. Synthesis of L-type zeolite

[0089] The formula is: 0.5K 2 O:0.005Al 2 o 3 : SiO 2 :0.02M:500(H 2 O+C 2 h 5 Oh)

[0090] Raw materials: (A) silica sol (same as example A)

[0091] (B) Potassium hydroxide (purity 80.00%) was dissolved in distilled water and absolute ethanol.

[0092] (C) Aluminum sulfate.

[0093] Weigh 0.003mol (C) and add it to the corresponding stoichiometric (B), heat to dissolve, then add it to the corresponding (A), stir while adding, and stir for 15 minutes after the addition, to obtain a uniform gel ( D).

[0094] Add the stoichiometric directing agent prepared in Example A and aged for 72 hours to the gel (D), stir evenly, add the corresponding template agent M, namely glycine, stir for 10 minutes, heat to 150°C for crystallization by microwave, and crystallize for 24 Hours later, the colloidal suspension of zeolite L was obtained, and the resulting mixture was centrifuged with a high-speed centrifuge, the supernatant was ...

example 3

[0096] Example 3. Synthesis of L-type zeolite

[0097] The formula is: 0.25K 2 O:0.15Na 2 O:0.004Al 2 o 3 : SiO 2 :0.015M:50(H 2 O+C 2 h 5 Oh)

[0098] Raw material: (A) silica sol (same as example 1 (A))

[0099] (B) Potassium hydroxide (purity 80.00%) was dissolved in distilled water and absolute ethanol.

[0101] Weigh 0.004mol (C) and add it to the corresponding stoichiometric (B), heat to dissolve, then add it to the corresponding (A), stir while adding, and then stir for 15 minutes after the addition to obtain a uniform gel ( D).

[0102] Add the stoichiometric directing agent prepared in Example A and aged for 72 hours to the gel (D), stir evenly, add the corresponding template agent M, namely glycine, stir for 10 minutes, heat to 150°C for crystallization by microwave, and crystallize for 24 Hours later, the colloidal suspension of zeolite L was obtained, and the resulting mixture was centrifuged with a high-speed centrifuge, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com