Preparation method of silk fibroin/graphene composite nano fiber support material

A technology of graphene composite and silk fibroin, which is applied in the field of preparation of silk fibroin/graphene composite nanofiber scaffold materials, can solve the problems of low conductivity, small dosage, weak electrochemical signal, etc., and achieve a simple and easy preparation method The effect of high efficiency, abundant raw material resources, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a kind of preparation method of silk fibroin / graphene composite nanofiber support material, described method comprises the following steps:

[0034] First add 30g silkworm cocoons to 1L 0.5% Nɑ 2 CO 3 In an aqueous solution, boil for 40 minutes and keep the temperature at a constant temperature for 2 hours, repeat the treatment three times, fully wash with deionized water, and place it in a drying oven at 50° C. to dry at a constant temperature after washing to obtain degummed silk. Add the dried silk to a 70°C ternary mixed solution of calcium chloride, absolute ethanol and water with a molar ratio of 1:8:2, dissolve it into a silk fibroin solution, and dialyze it with deionized water for 72 hours to remove the Ethanol and calcium chloride were used to prepare an aqueous silk fibroin solution, which was then freeze-dried at -80°C to obtain a pure silk fibroin sample.

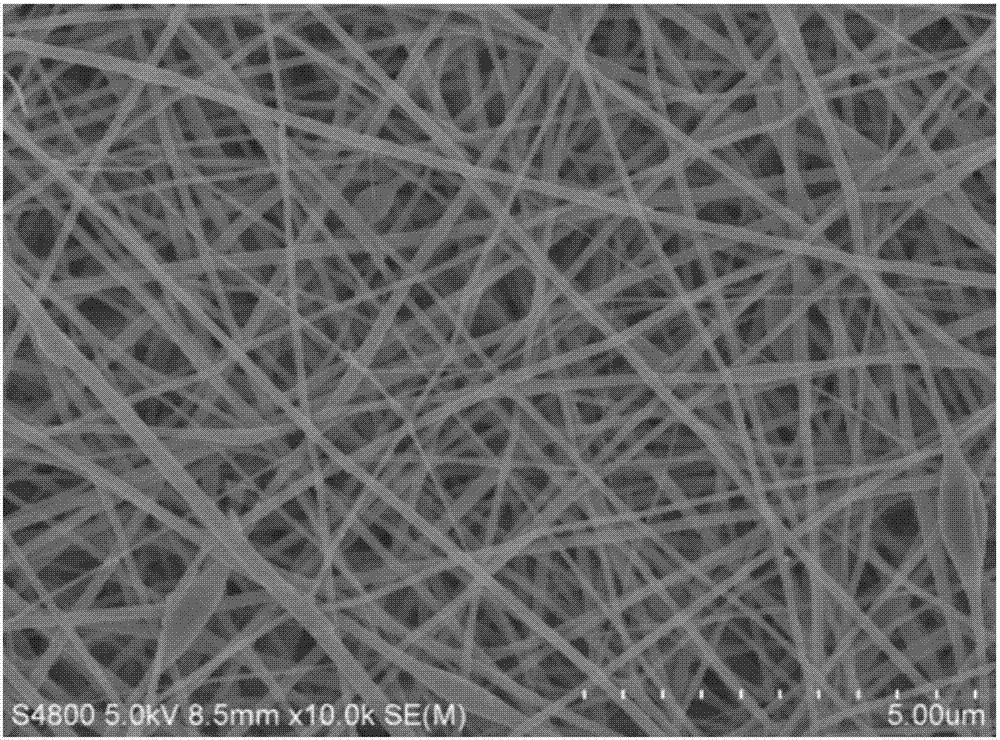

[0035] Dissolve 0.32g silk fibroin in 4mL hexafluoroisopropanol, st...

Embodiment 2

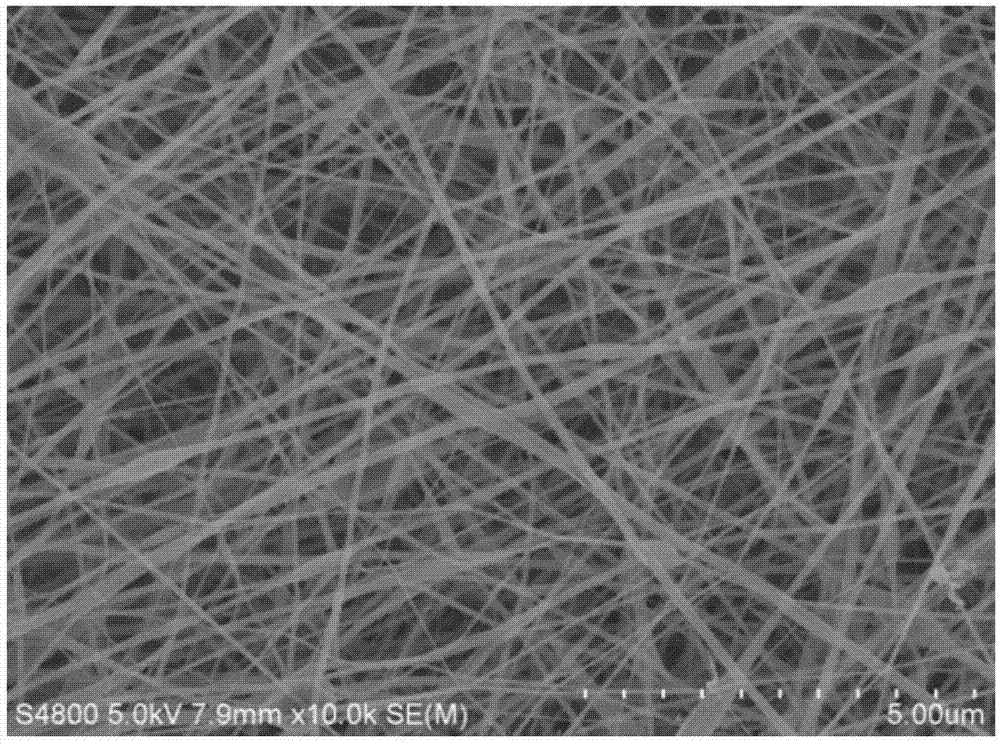

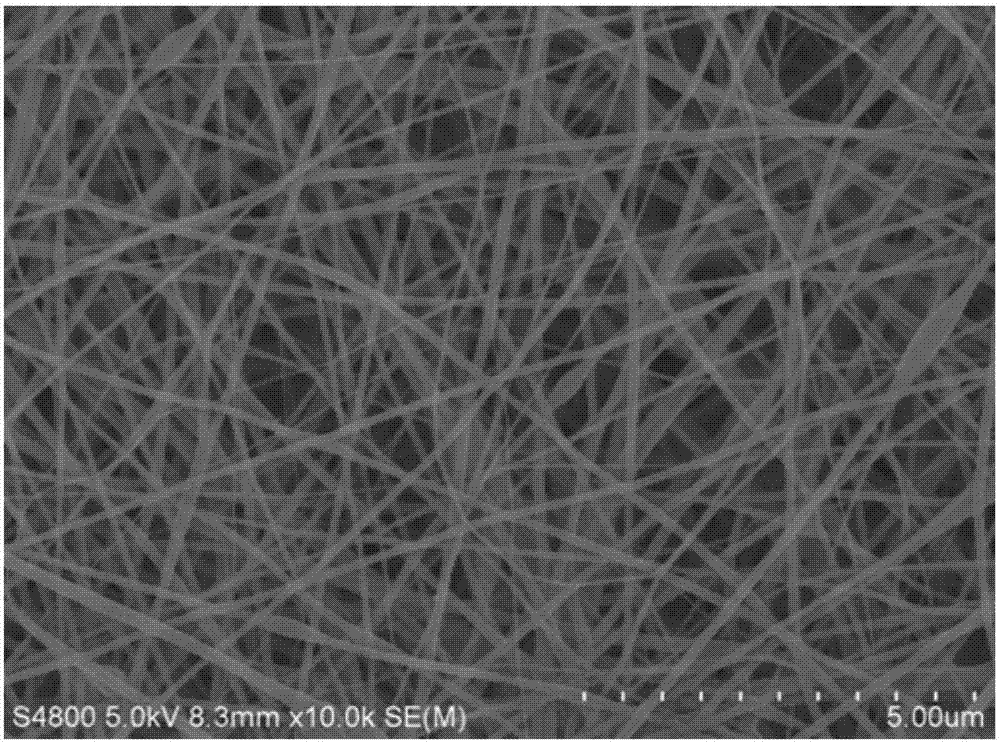

[0039] Weigh 0.32 g of silk fibroin prepared in Example 1 and dissolve it in 4 mL of hexafluoroisopropanol, stir until completely dissolved to obtain 0.08 g / mL silk fibroin liquid A, and take 1.6 mL of graphene with a pipette gun Centrifuge the ethanol dispersion at high speed, suck out the ethanol, transfer the graphene in the centrifuge tube to the silk fibroin solution with hexafluoroisopropanol, add a certain amount of hexafluoroisopropanol to make the silk fibroin solution reach 6mL, and ultrasonicate for 60min. Finally, the 0.06g / mL silk fibroin spinning solution B whose mass ratio of graphene and silk fibroin is 1:200 is obtained, and the spinning solution is injected into a 10mL syringe for electrospinning, and the process conditions are: spinning voltage 16kv, pushing speed 0.05mm / min, receiving distance 12cm, roller speed 100r / min. The obtained electrospun membrane was treated with absolute ethanol for 4 hours, and then dried in a vacuum oven at 50° C. for 24 hours t...

Embodiment 3

[0042]Weigh 0.32 g of silk fibroin prepared in Example 1 and dissolve it in 4 mL of hexafluoroisopropanol, stir until completely dissolved to obtain 0.08 g / mL silk fibroin liquid A, and take 3.2 mL of graphene with a pipette gun Centrifuge the ethanol dispersion at high speed, suck out the ethanol, transfer the graphene in the centrifuge tube to the silk fibroin solution with hexafluoroisopropanol, add a certain amount of hexafluoroisopropanol to make the silk fibroin solution reach 6mL, and ultrasonicate for 60min. Finally, the 0.06g / mL silk fibroin spinning solution B whose mass ratio of graphene and silk fibroin is 1:100 is obtained, and the spinning solution is injected into a 10mL syringe for electrospinning, and the process conditions are: spinning voltage 16kv, pushing speed 0.05mm / min, receiving distance 12cm, roller speed 100r / min. The obtained electrospun membrane was treated with absolute ethanol for 4 hours, and then dried in a vacuum oven at 50° C. for 24 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com