Nano-enhanced leadless solder and preparation method thereof

A lead-free solder, nano-enhanced technology, used in welding equipment, welding/cutting media/materials, welding media, etc., can solve problems such as low yield strength, poor wettability of welded joints, and low tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

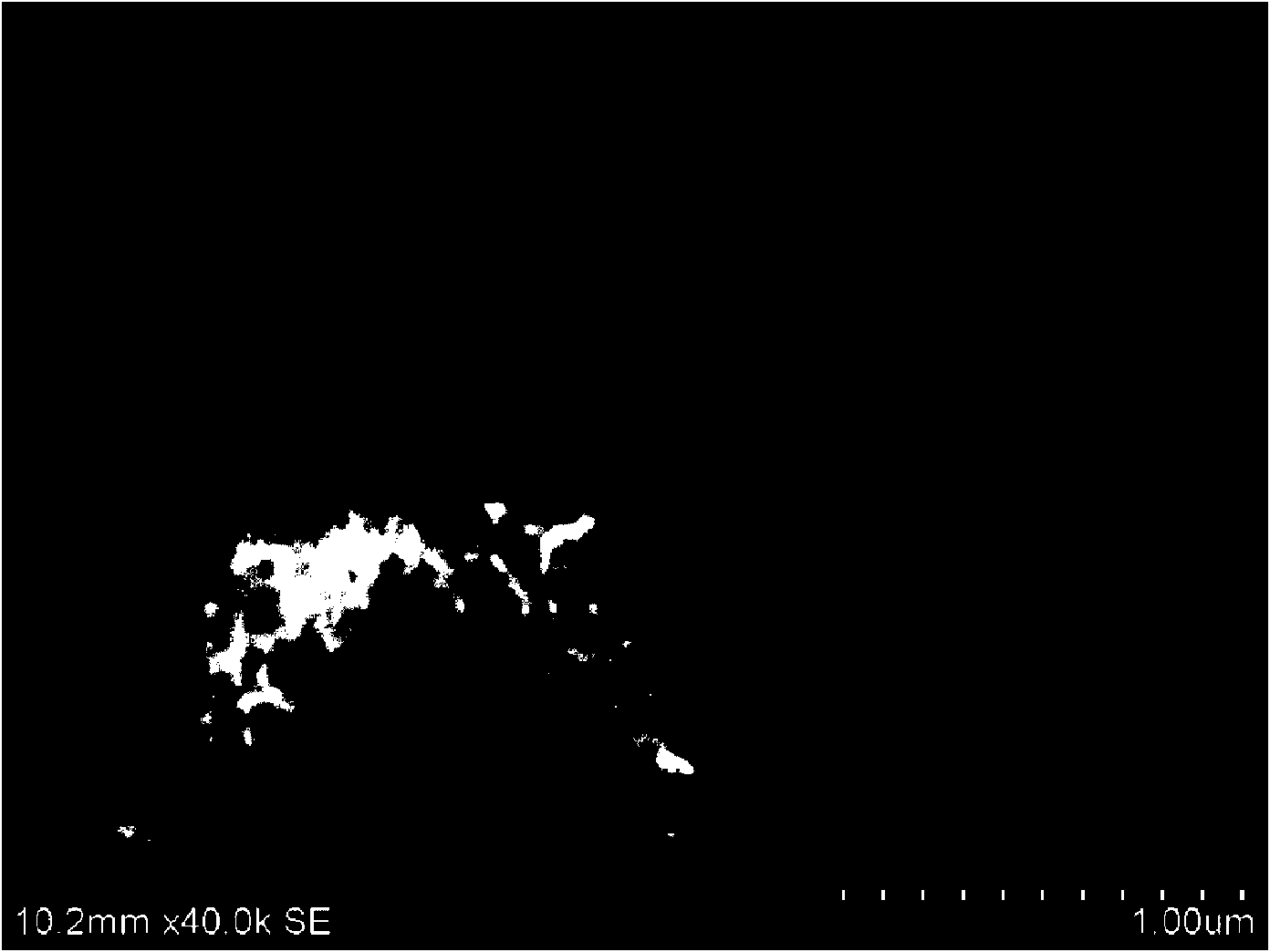

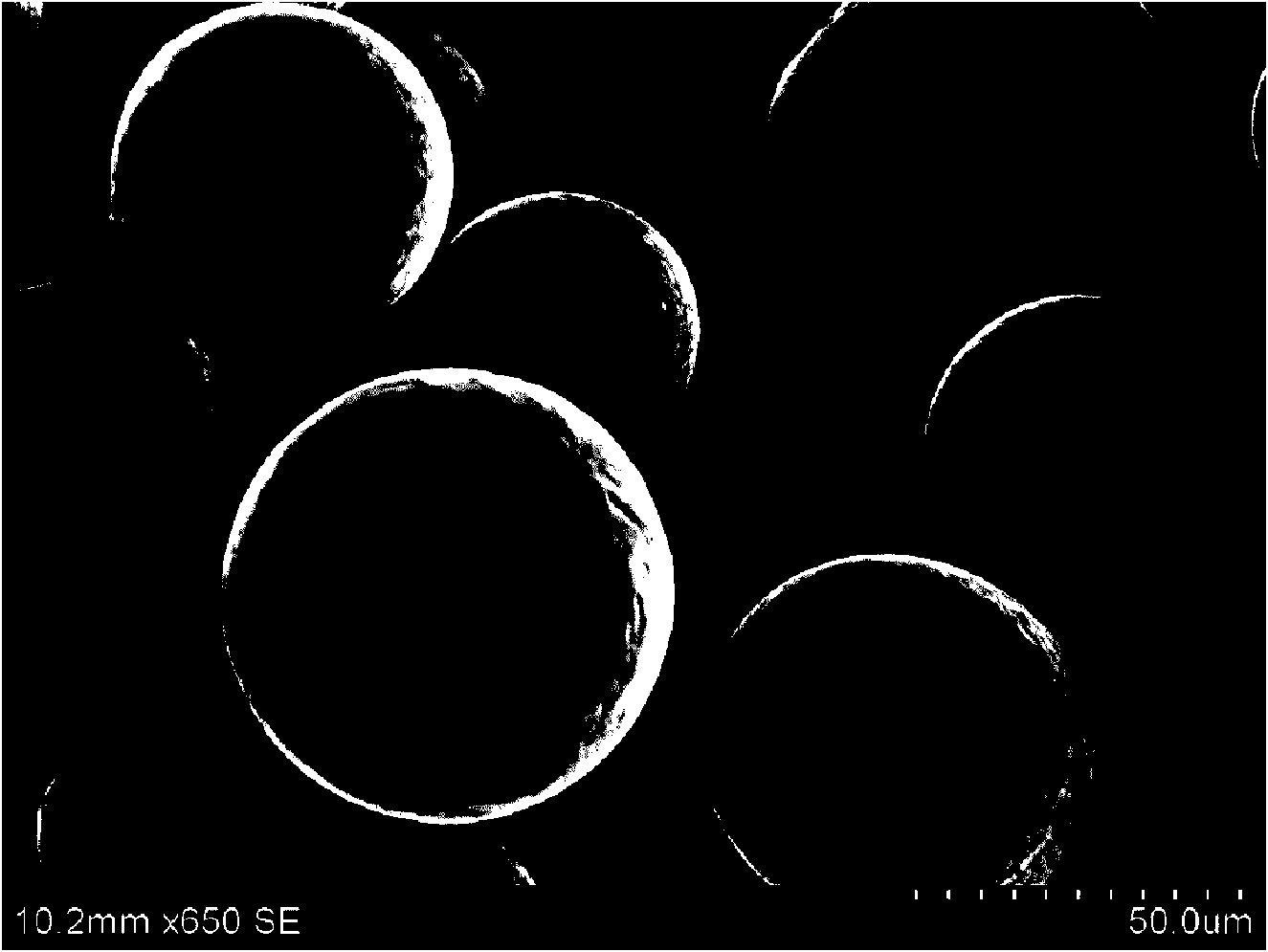

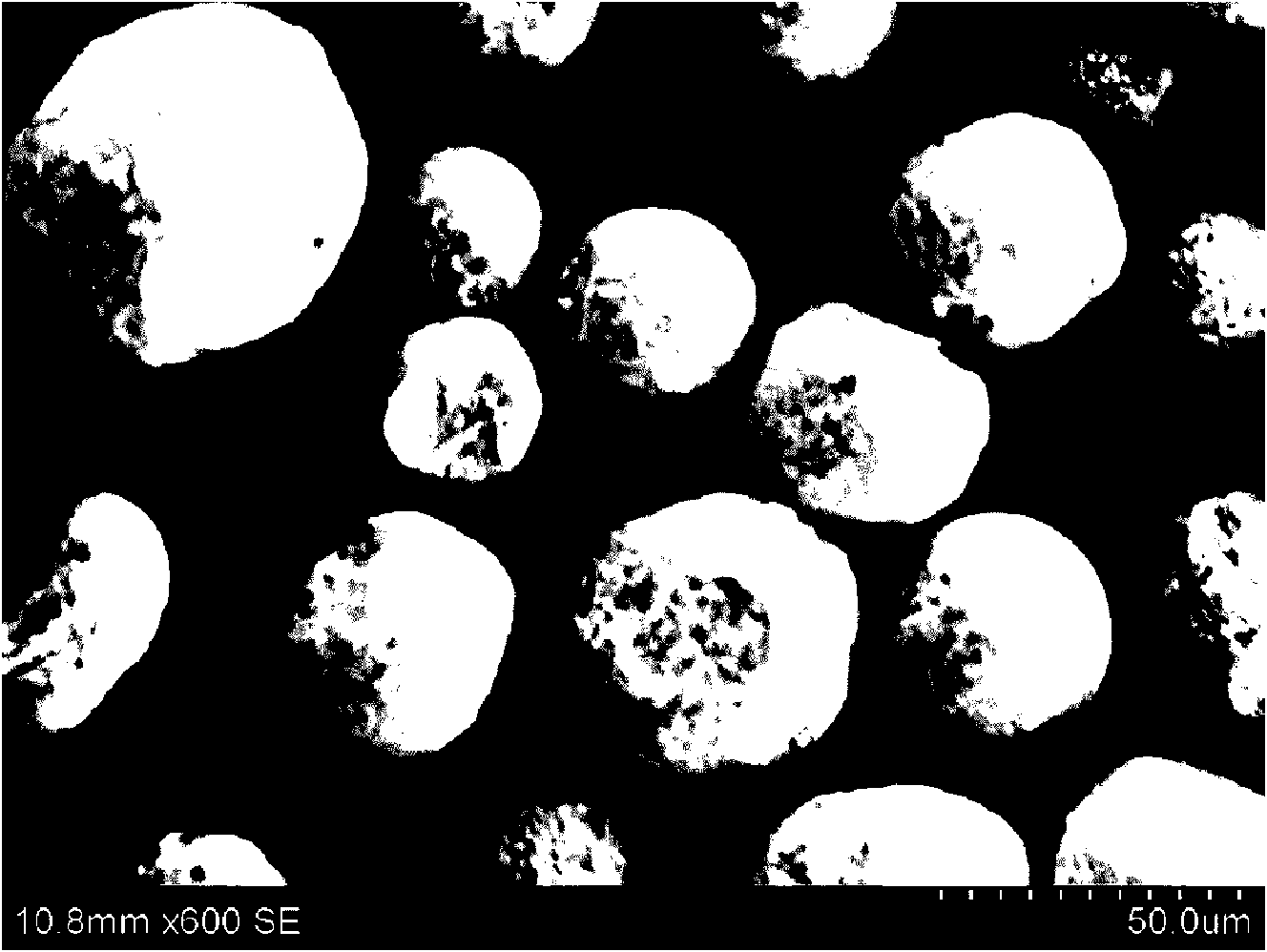

[0010] Embodiment 1: In this embodiment, the nano-reinforced lead-free solder is made of carbon nanotubes and Sn-58Bi solder; wherein the mass content of carbon nanotubes in the mixture of carbon nanotubes and Sn-58Bi solder is 0.03% to 0.07%.

specific Embodiment approach 2

[0011] Specific embodiment two: the preparation method of the nano-reinforced lead-free solder in the specific embodiment one is as follows: 1. Add carbon nanotubes in the mixed acid solution, sonicate for 1.5h under the condition of ultrasonic power of 100W, and then Stir for 2 hours under conditions, then naturally cool to room temperature, and then centrifuge at a speed of 800 rpm for 30 minutes; 2. Wash the carbon nanotubes treated in step 1 with deionized water until the pH of the washing solution is 7, filter, and pour into the filter residue Add absolute ethanol to the mixture, wherein the volume ratio of filter residue to absolute ethanol is 1:10, then dry in a quartz tube filled with argon at a temperature of 60°C for 2.5 hours, and then dry in a drying room with an air pressure of less than 30Pa and a temperature of Dry at 80°C for 2.5 hours, and then ball mill for 7 hours at a speed of 260r / min; 3. Mix the carbon nanotubes treated in step 2 with Sn-58Bi solder, and t...

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 2 in that the mass ratio of the grinding balls to the filter residue in step 2 is 40:1. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com