Patents

Literature

30results about How to "Overcome the disadvantage of low yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

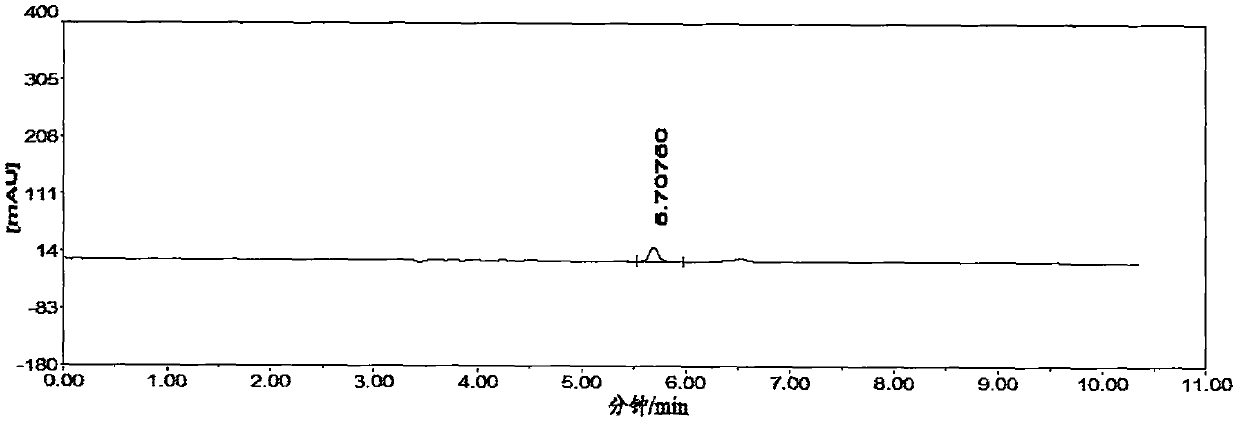

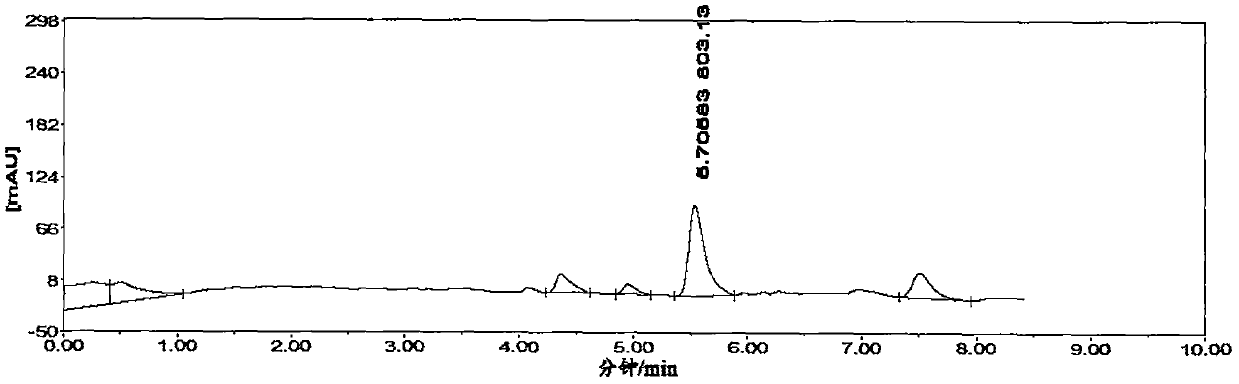

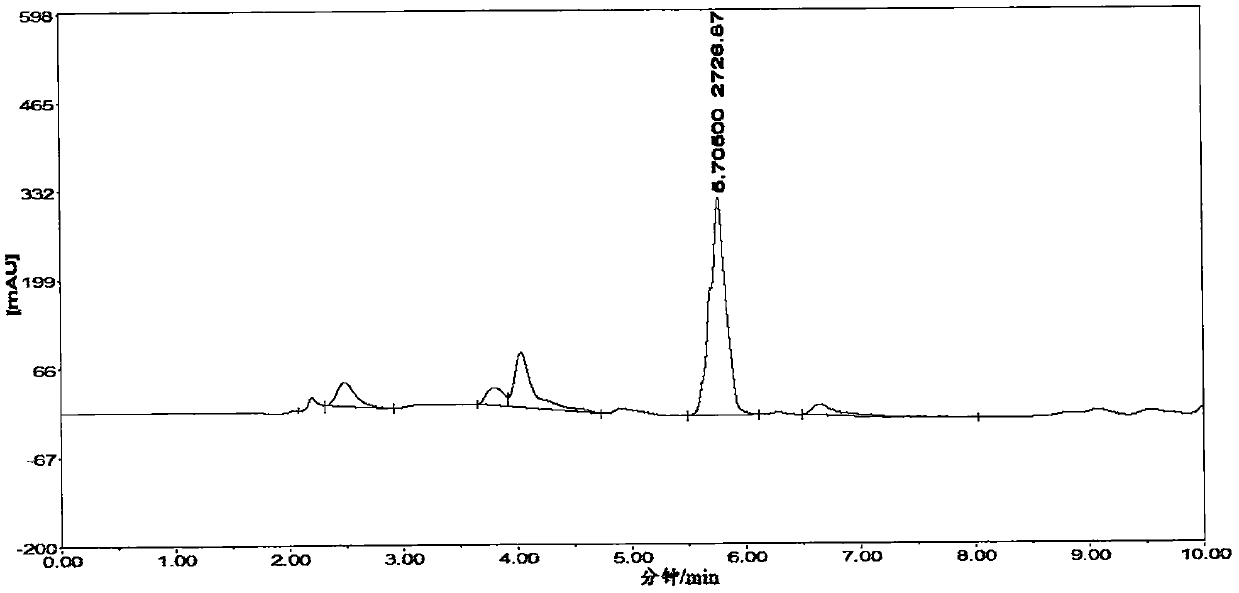

Nitrogen-doped activated carbon supported noble metal catalyst and application thereof

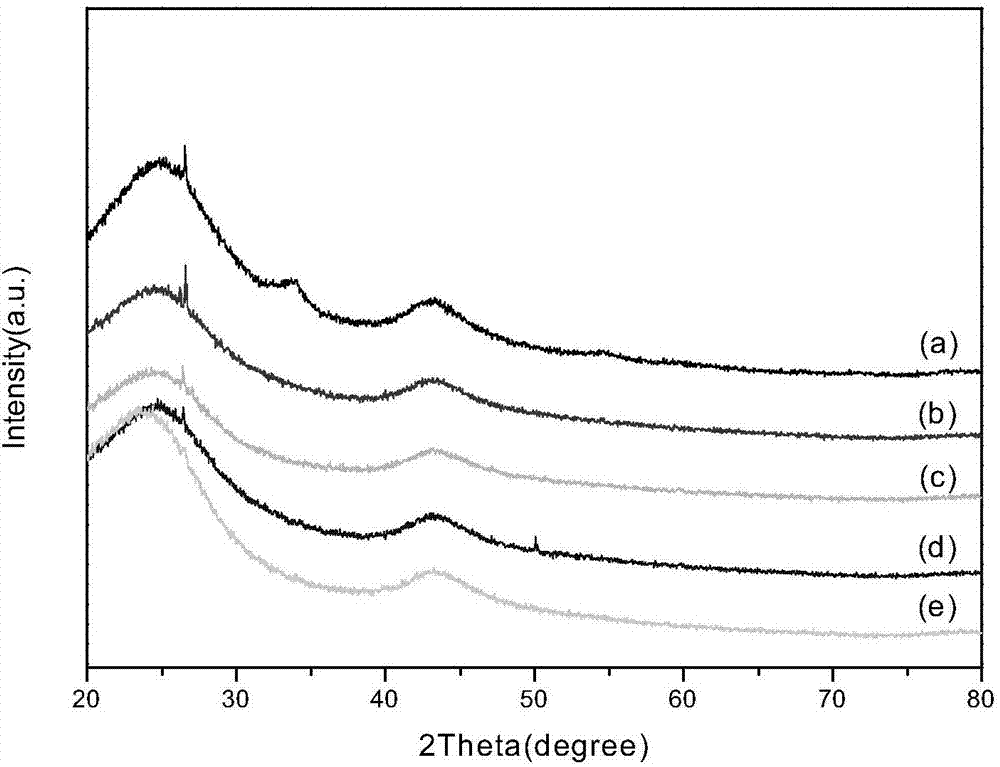

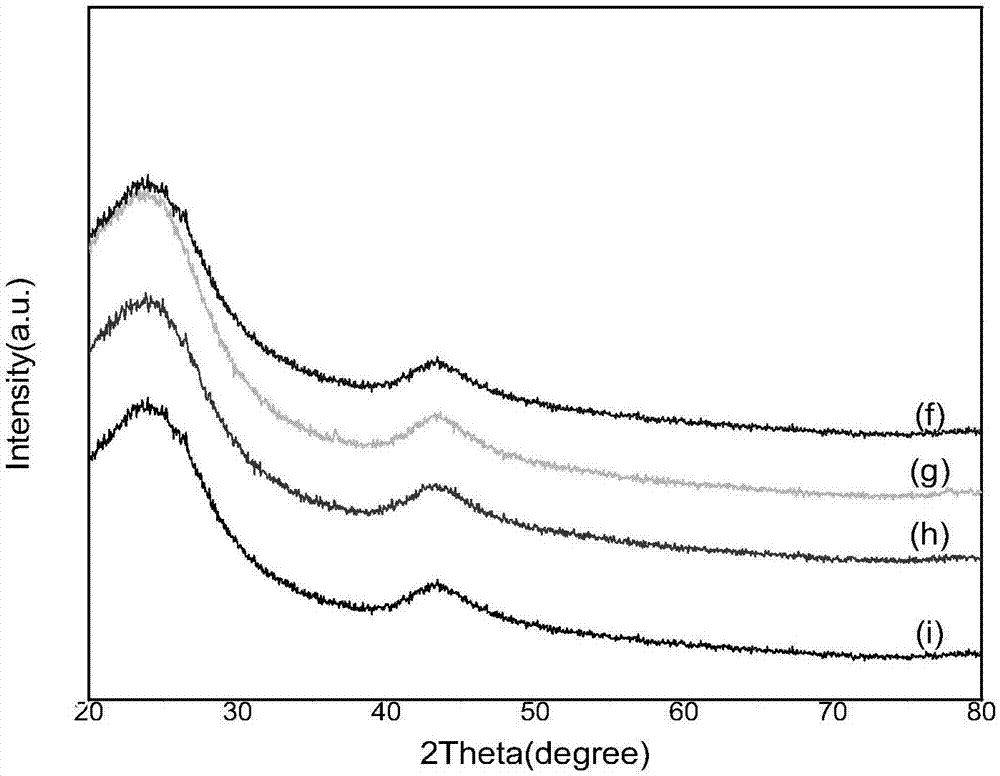

ActiveCN107413331AEnhanced electron transfer capabilityRedistribution of electronsOrganic compound preparationAmino compound preparationActivated carbonIridium

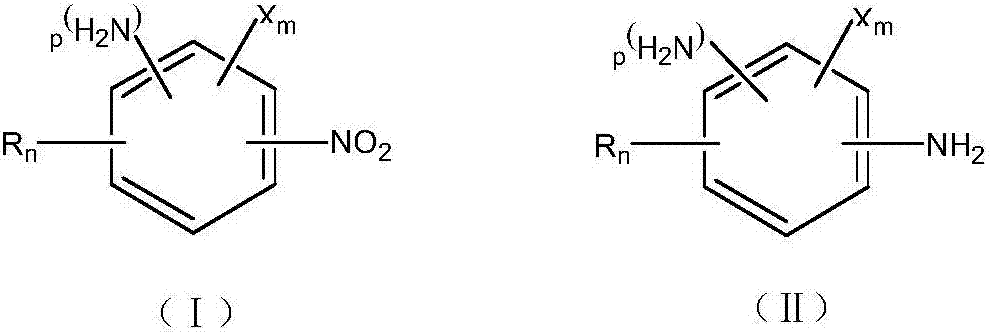

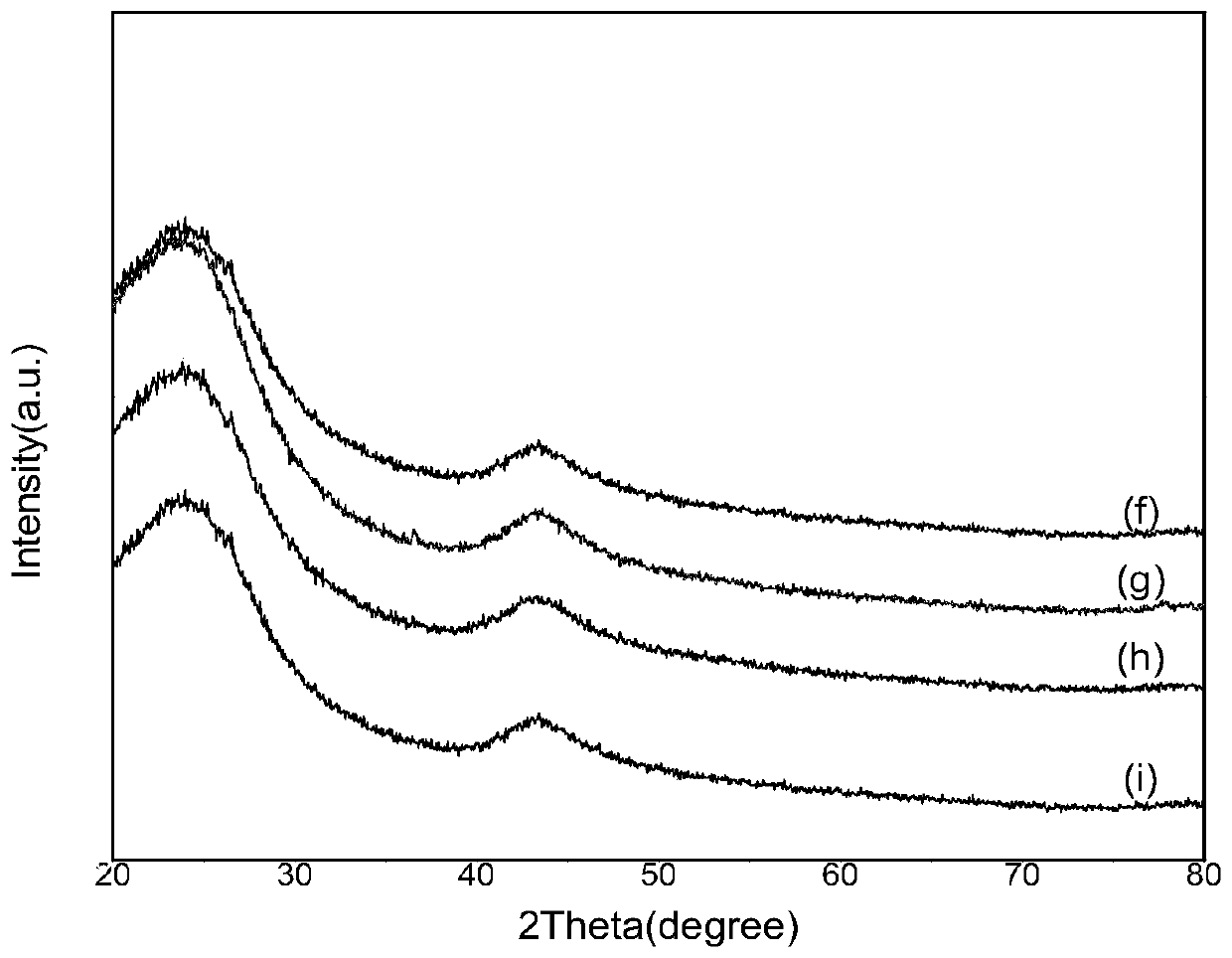

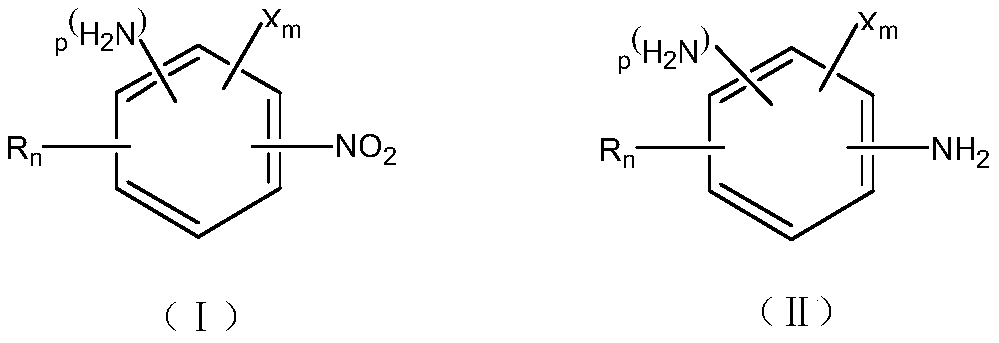

The invention discloses a nitrogen-doped activated carbon supported noble metal catalyst and an application thereof. The catalyst is composed of a carrier and an active component; the carrier is nitrogen-doped activated carbon; the active component is one of palladium, platinum, rhodium, ruthenium and iridium; and the load of the active component is not higher than 15wt% based on the mass of the carrier. The invention provides the application of the nitrogen-doped activated carbon supported noble metal catalyst to reaction for preparing an alkyl-containing halogenated aromatic aminocompound shown as a formula (II) by carrying out catalytic hydrogenation reduction on an alkyl-containing halogenated aromatic nitrocompound shown as a formula (I) to show that the nitrogen-doped activated carbon supported noble metal catalyst has the characteristics of high hydrogenation reaction rate, high catalytic activity, high selectivity and high stability.

Owner:ZHEJIANG UNIV OF TECH

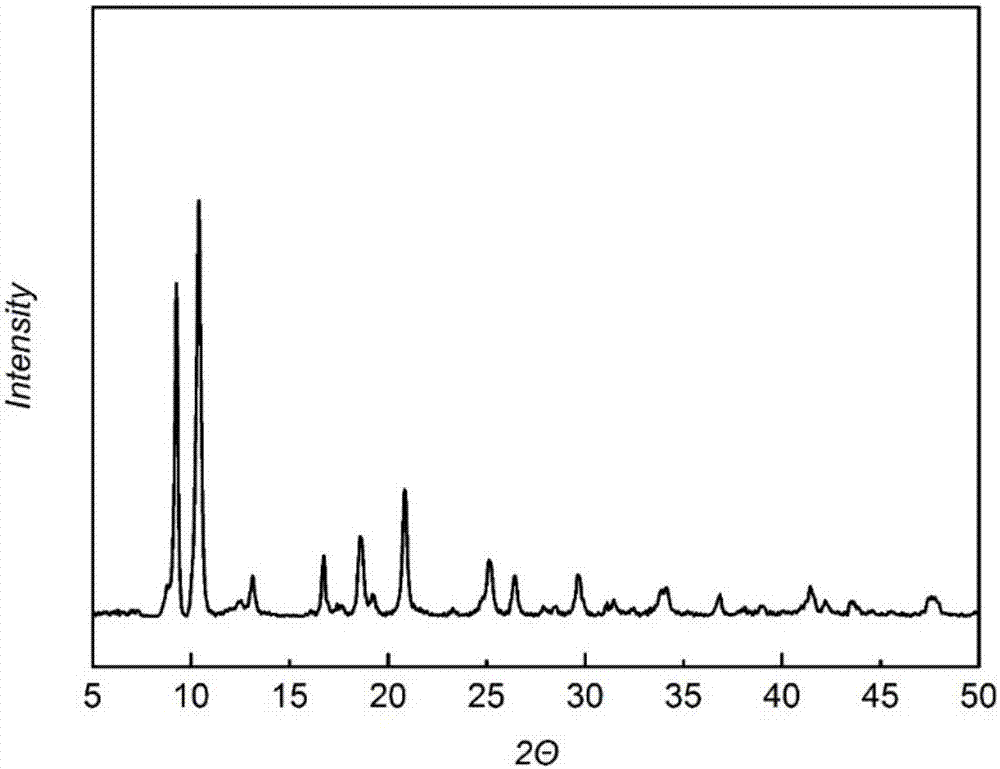

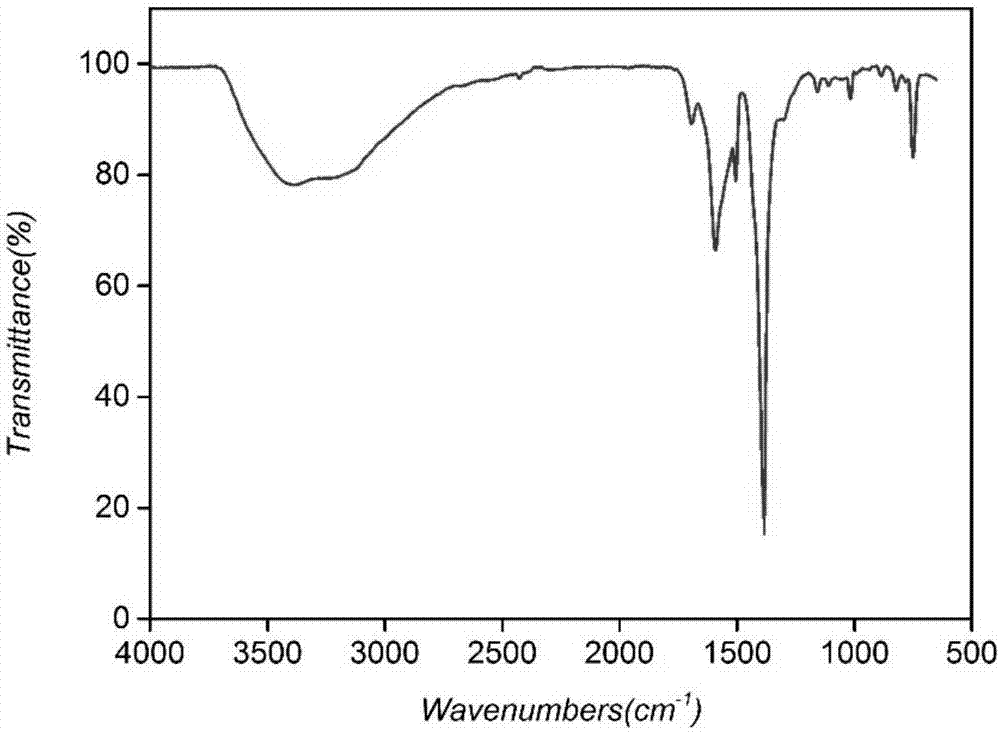

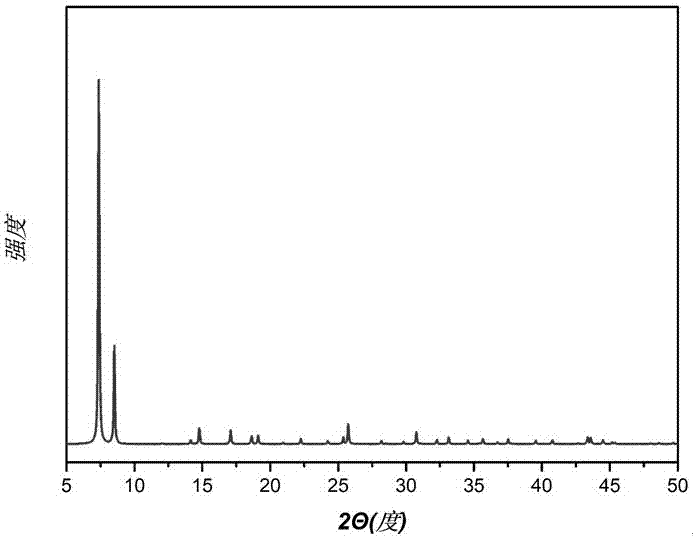

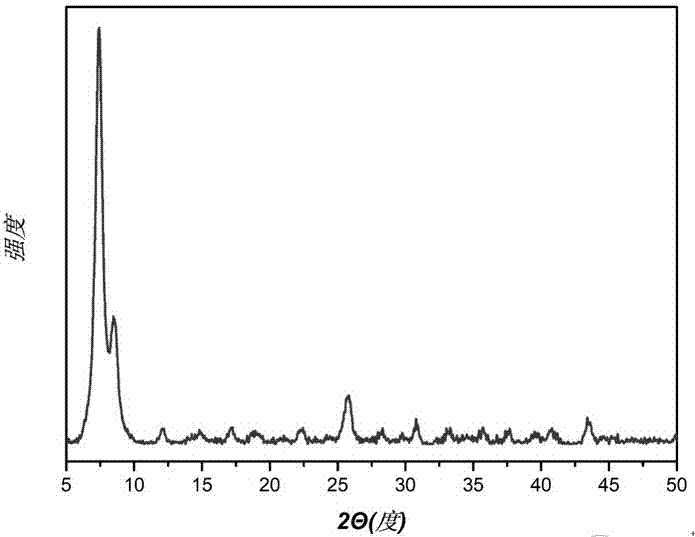

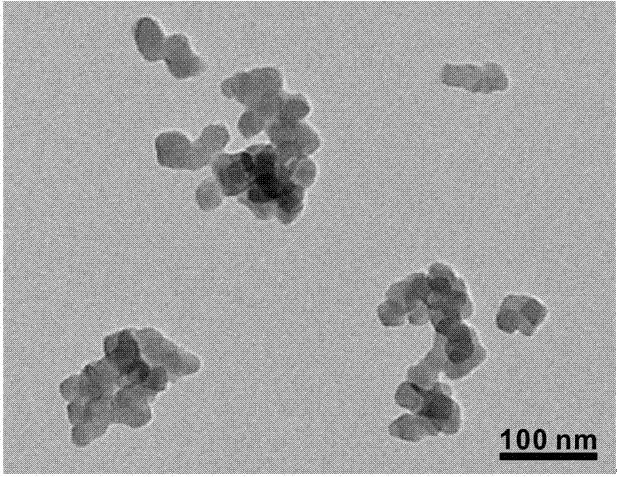

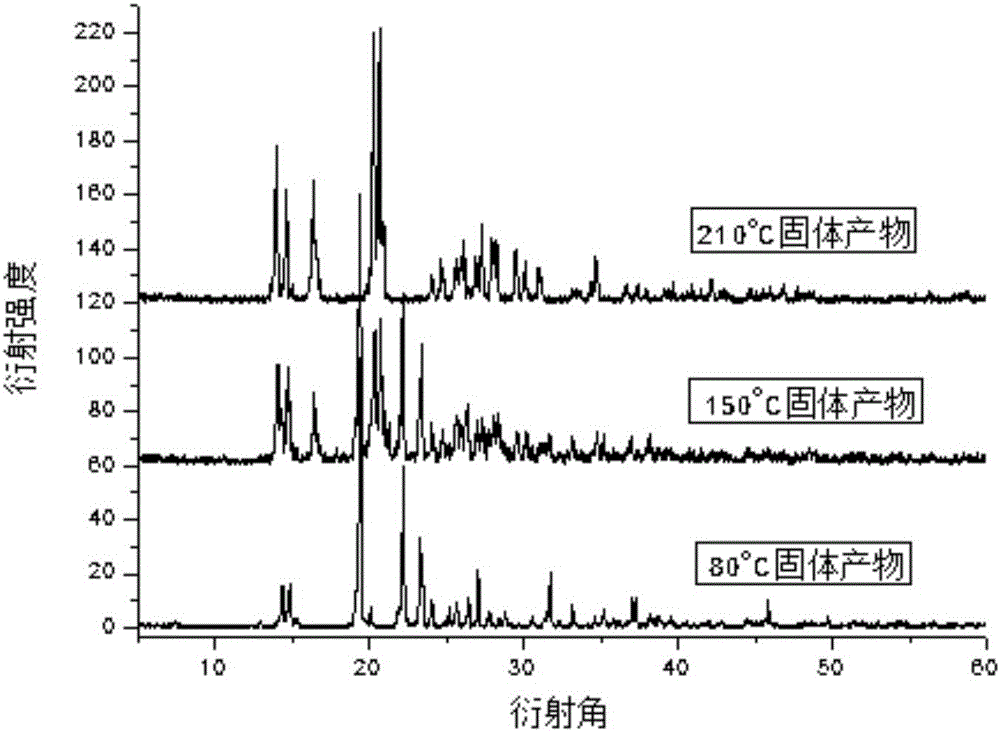

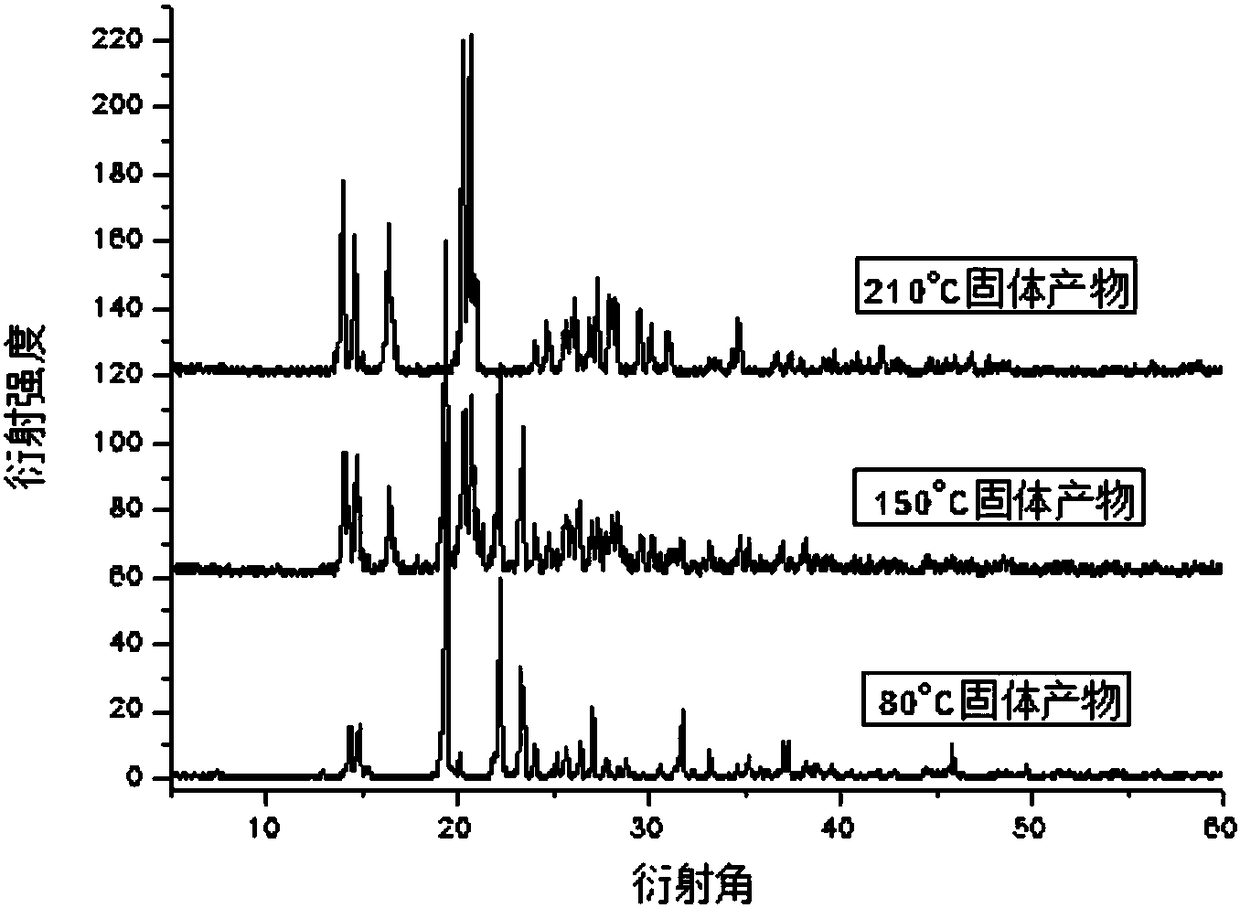

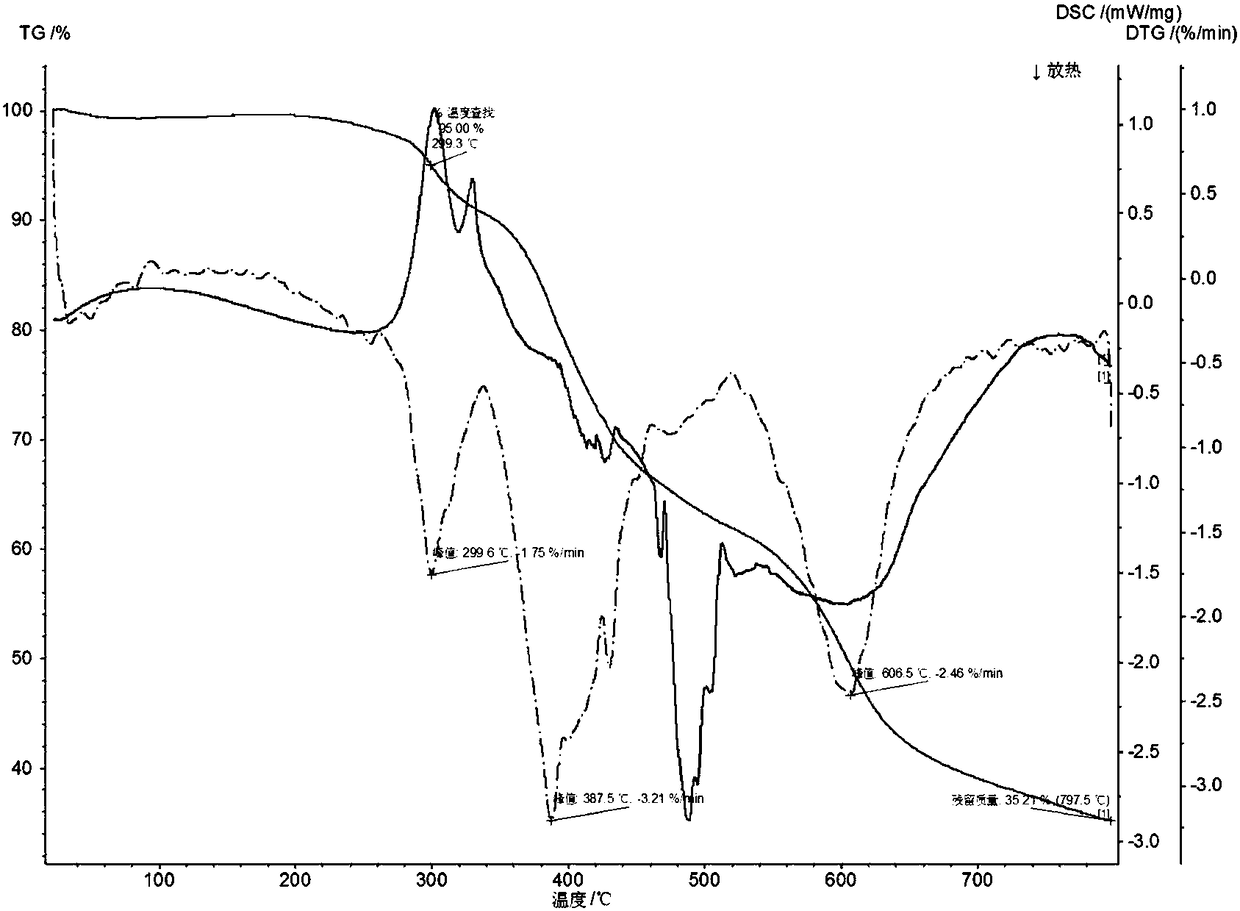

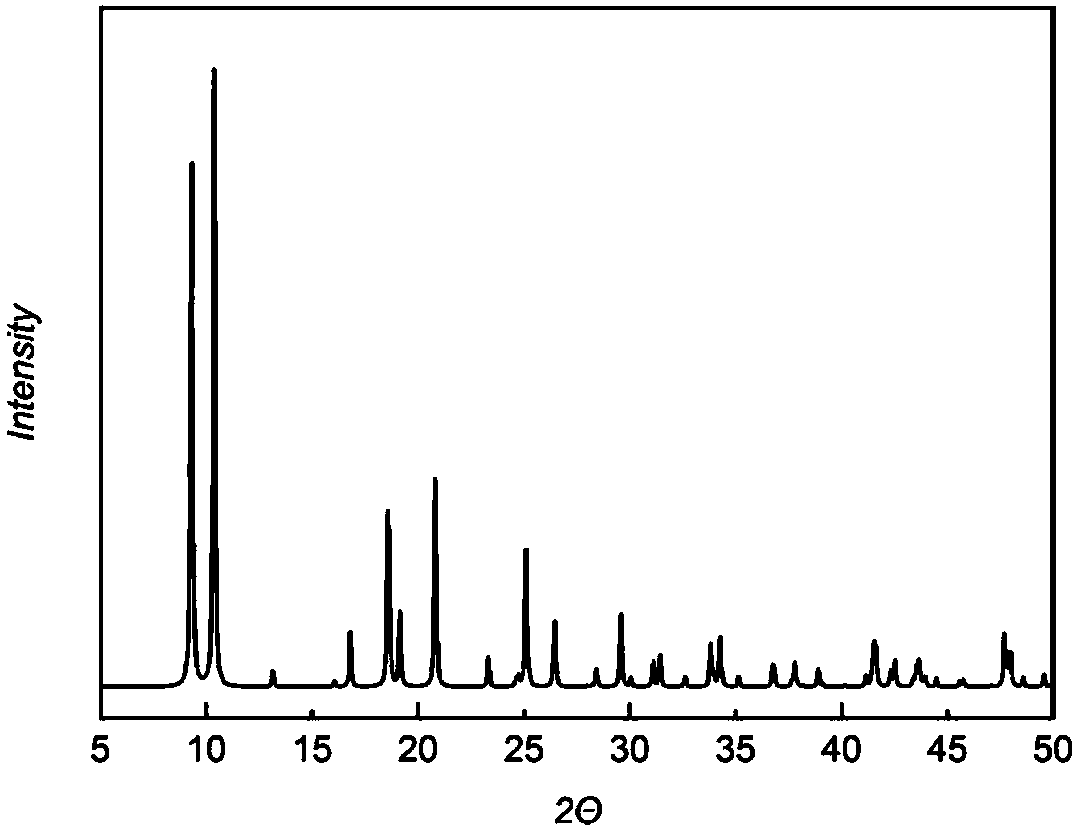

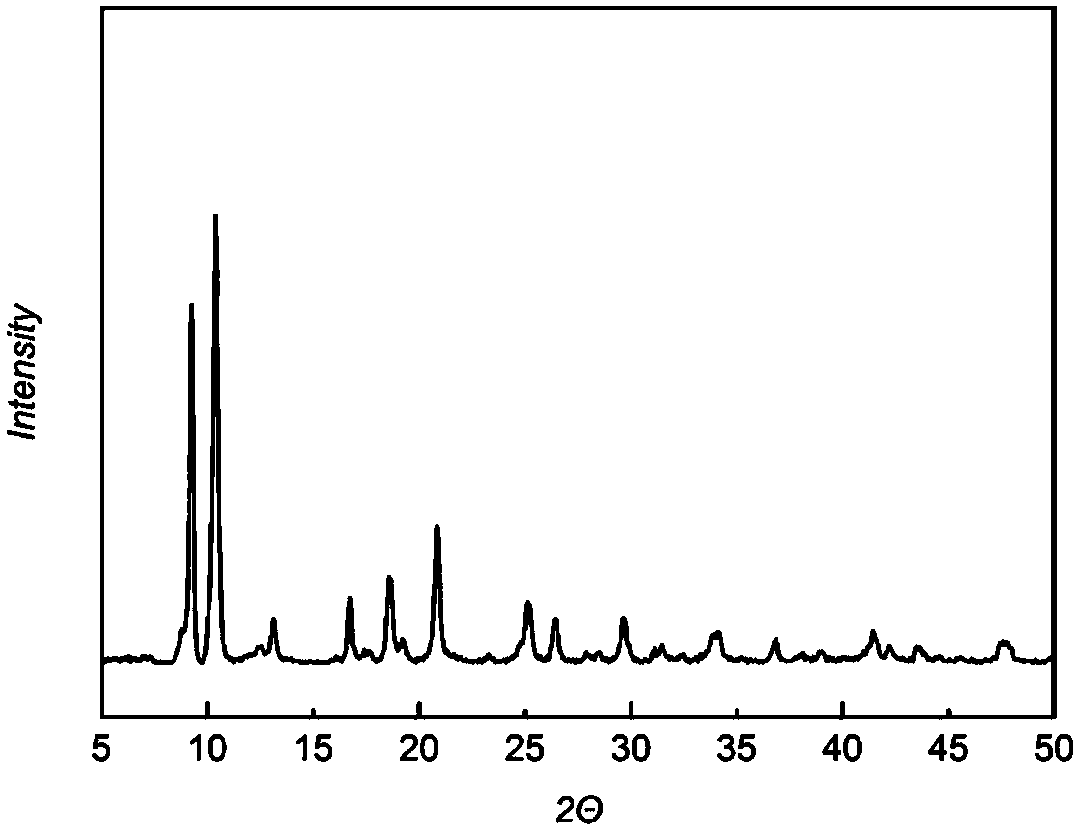

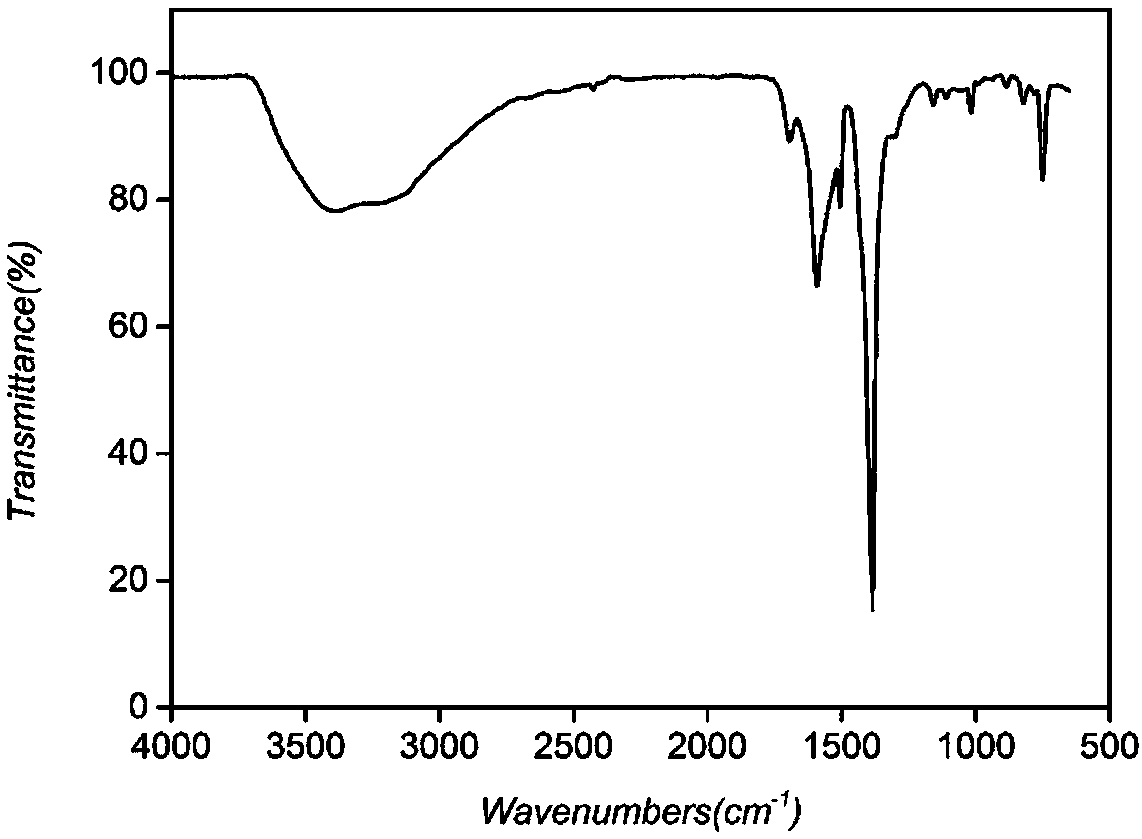

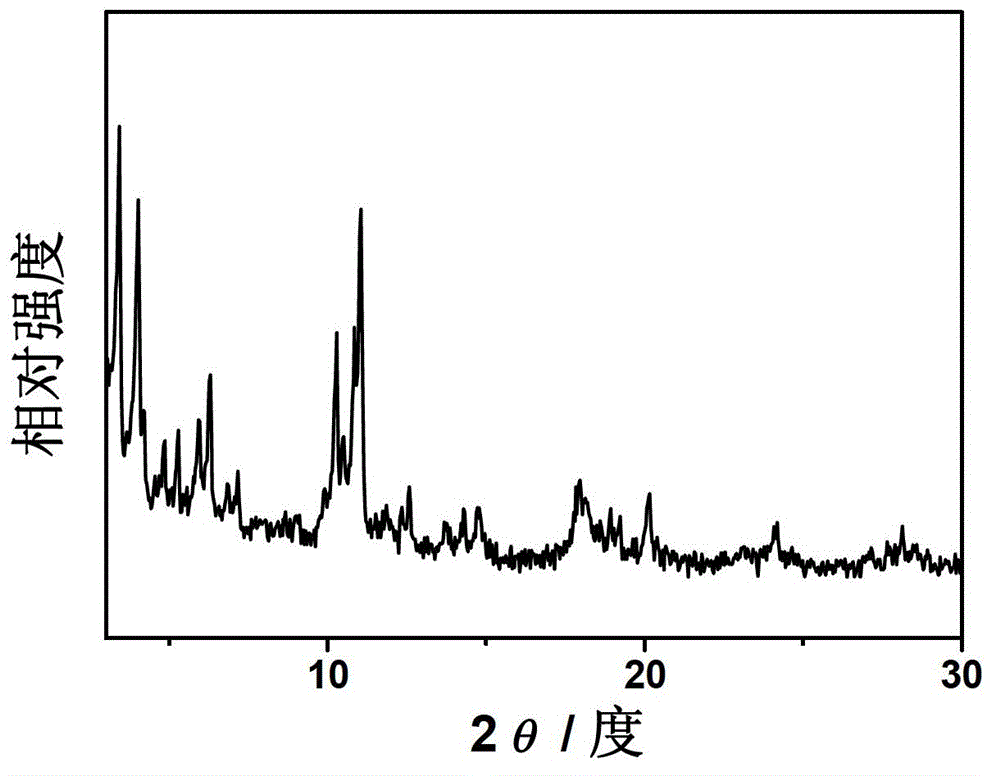

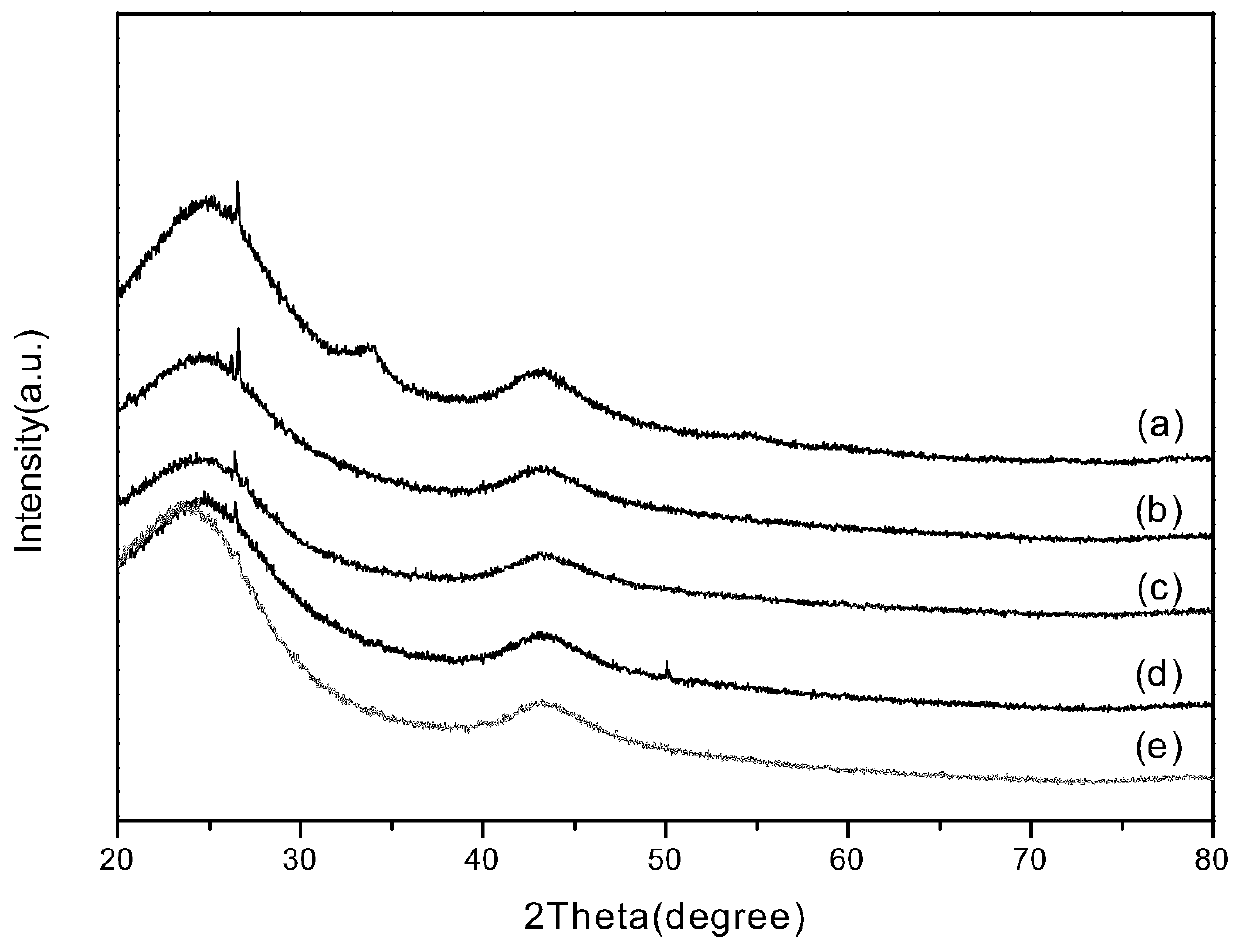

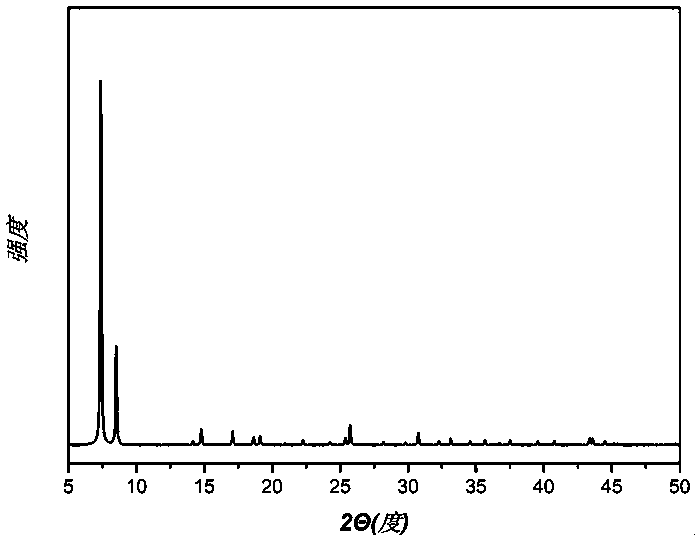

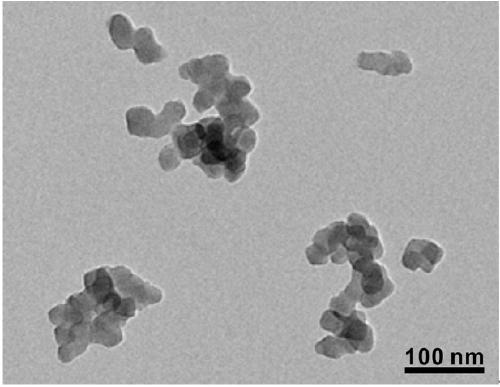

Preparation method of metal organic framework material MIL-88B(Fe)

The invention relates to a preparation method of a metal organic framework material MIL-88B(Fe). The preparation method comprises following steps: 1, an iron source and an organic ligand are mixed to be uniform, and are subjected to pretreatment for 1 to 3h so as to obtain an intermediate; 2, the intermediate is added into ethanol solvent, and an obtained mixture is stirred at room temperature, and then is subjected to centrifugation so as to obtain a crude product; 3, the crude product is washed with ethanol for a plurality of times, and then is dried so as to obtain the metal organic framework material MIL-88B(Fe). Compared with the prior art, toxic organic solvents such as N,N-dimethylformamide used in conventional solvothermal method is not used, ethanol is taken as a solvent, the raw material is subjected to pretreatment, synthesis of MIL-88B(Fe) is realized at room temperature, the conditions are mild, yield is relatively high, and it is possible to realize large-scale synthesis of metal organic framework materials.

Owner:TONGJI UNIV

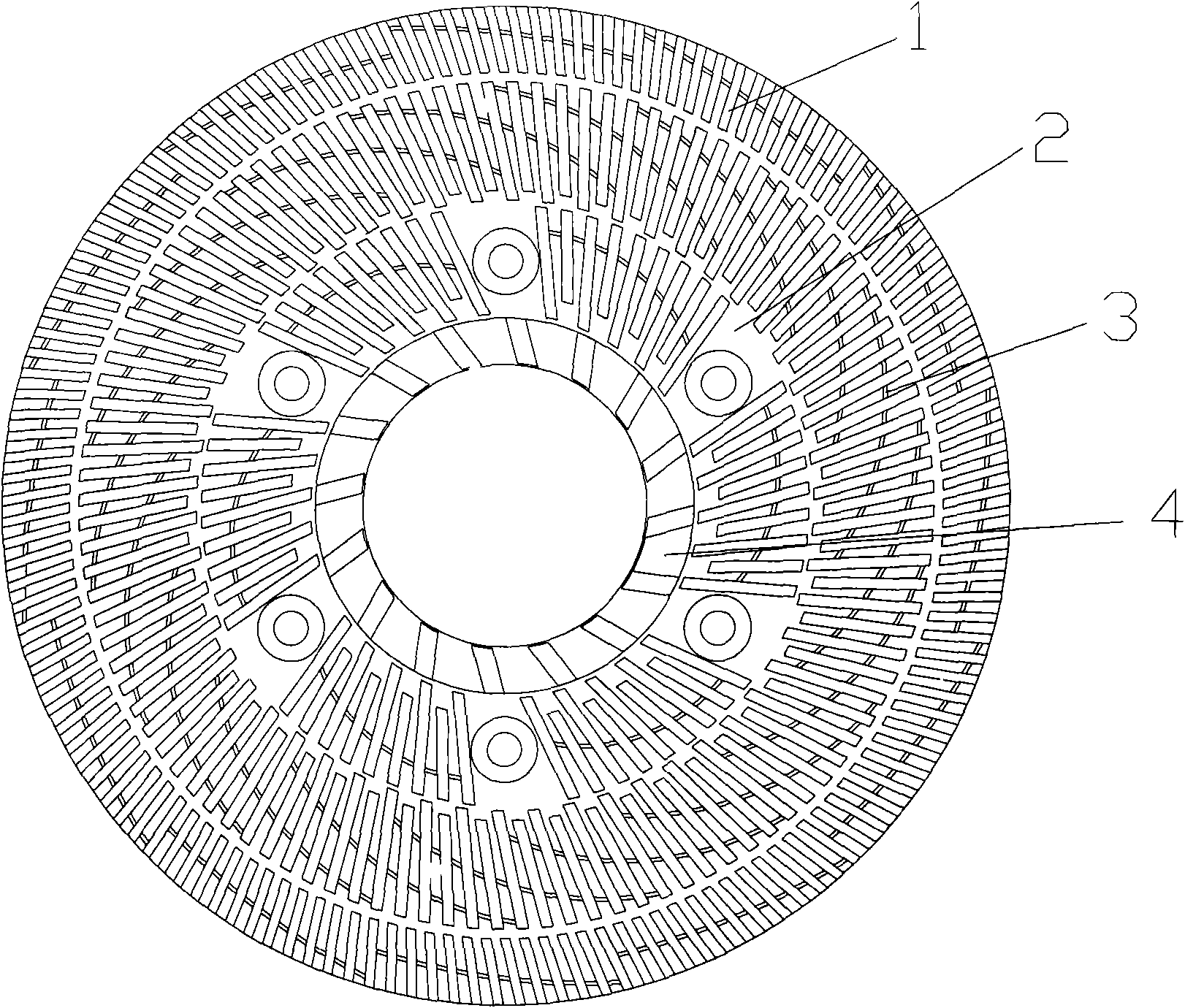

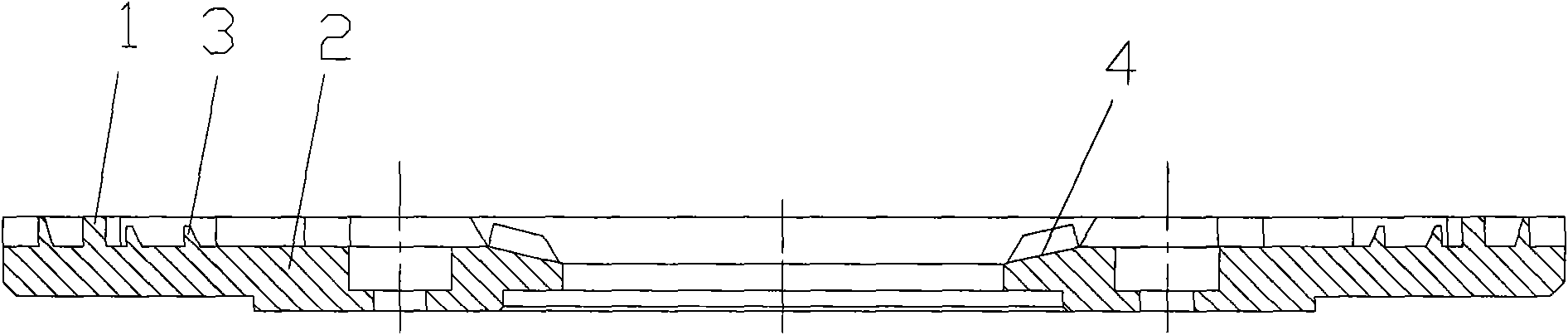

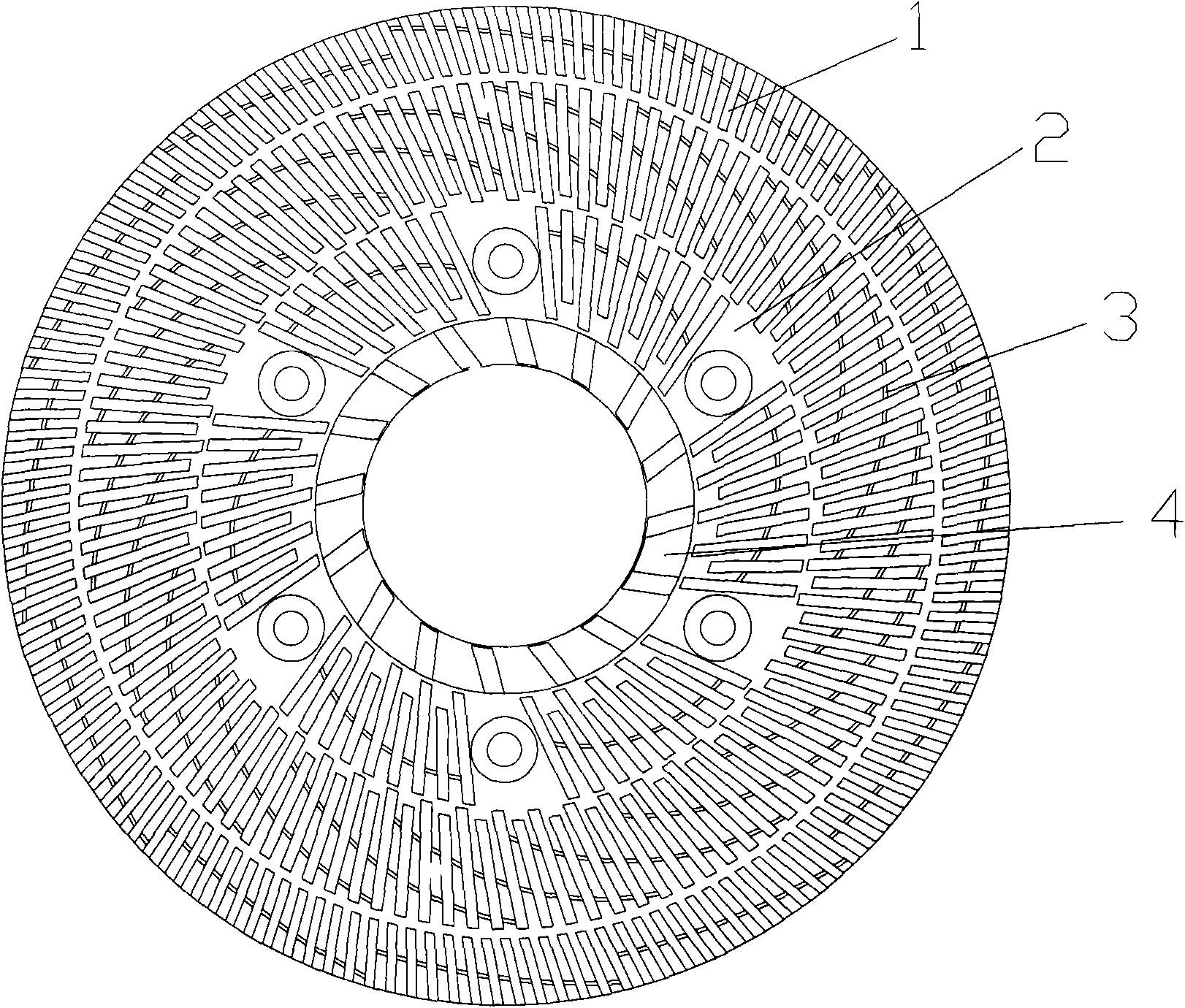

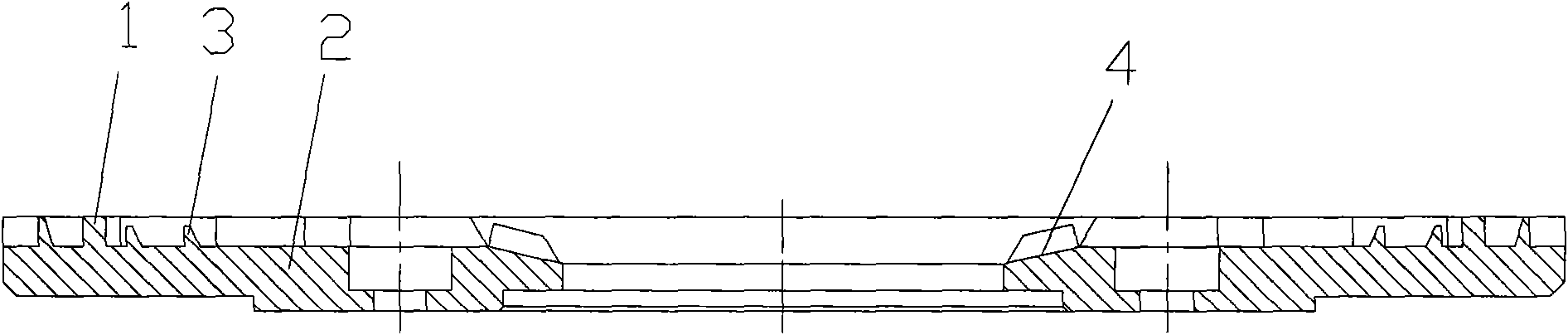

Grinding sheet for disc grinder and manufacturing method thereof

InactiveCN101654888AReduce wasteImprove yieldSolid state diffusion coatingFurnace typesEngineeringSurface processing

The invention provides a grinding sheet for a disc grinder and a manufacturing method thereof. The grinding sheet comprises grinding teeth and grinding sheet base body which are respectively processed twice for forming, wherein the grinding teeth which are arranged into a plurality of concentric circles are uniformly distributed on the grinding sheet base body around a center shaft of the grinding sheet base body, pulp baffle plates are arranged among the grinding teeth, and the pulp baffle plates positioned on a same circle form spiral pulp baffling lines on the surface of the grinding sheetbase body. The manufacturing method of the grinding sheet comprises the following steps: firstly, manufacturing the grinding teeth needed by the grinding sheet, and carrying out the surface processing of the grinding teeth; then processing a mould according to the designed form of the grinding sheet, installing the grinding teeth and the pulp baffle plates on the mould, and then casting or vulcanizing the mould provided with the grinding teeth; forming the grinding sheet base body, and simultaneously fixing the grinding teeth on the grinding sheet base body; and finally cooling a taper to finish the manufacturing process. The grinding sheet has good pulp grinding effect and long service life; in addition, the grinding sheet adopts a post forming method, thereby greatly reducing the material cost of the grinding sheet and the waste of materials.

Owner:SOUTH CHINA UNIV OF TECH

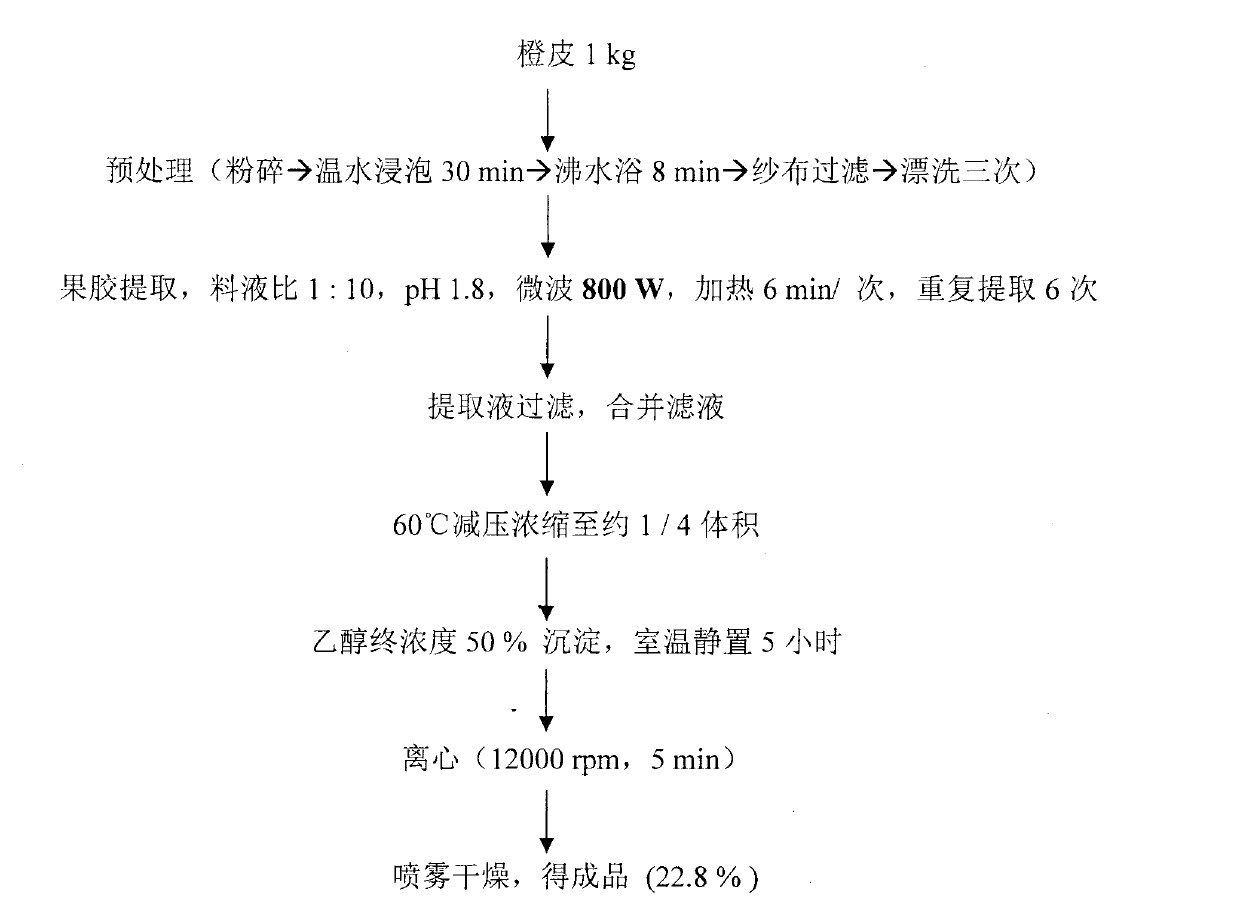

Extraction and preparation process of citrus pectin

InactiveCN102702379AOvercome the disadvantages of low extraction yield and long heating timeHigh yieldStrong acidsCitrus Pectin

The invention relates to an extraction and preparation process of citrus pectin. The extraction and preparation process of citrus pectin includes additionally pretreating dried citrus peel, and extracting pectin from the citrus peel by multiple microwave-heating. By the extraction and preparation process of citrus pectin, extraction time is shortened, and the defect of low pectin yield due to the fact that pectin degrades under long-term heating in strong acid extraction is overcome. By the extraction and preparation process of citrus pectin, the yield is higher with less extraction time and simple extraction steps, the pectin has better gloss, energy consumption is lowered, and production cost is reduced.

Owner:赛珂睿德生物医药科技(上海)有限公司

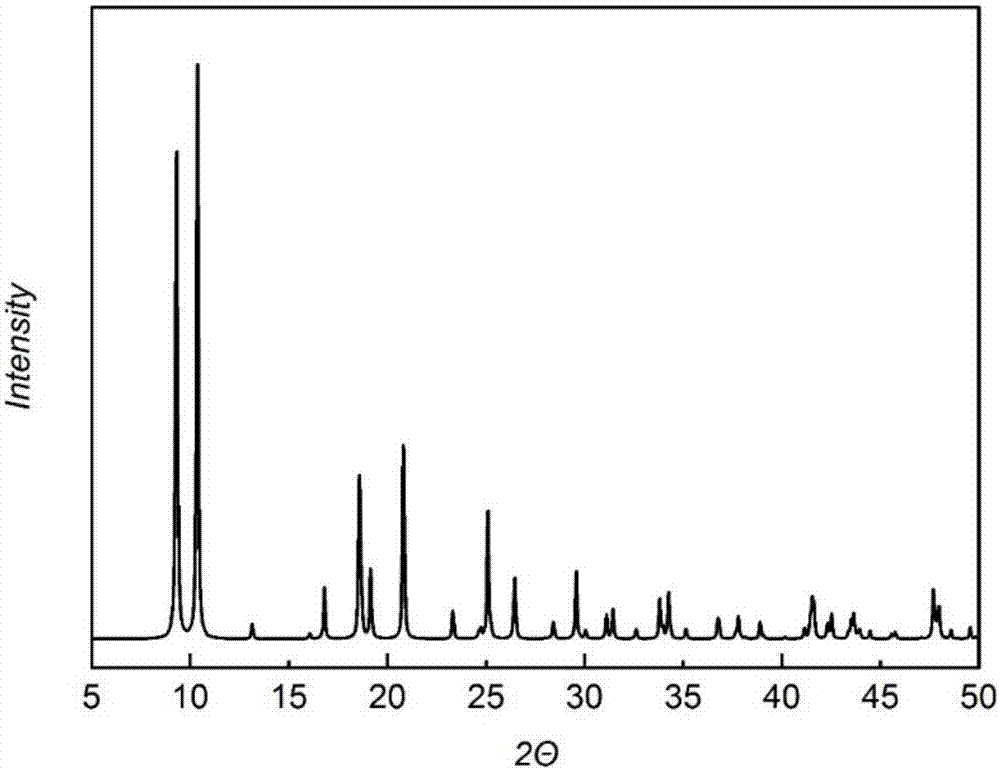

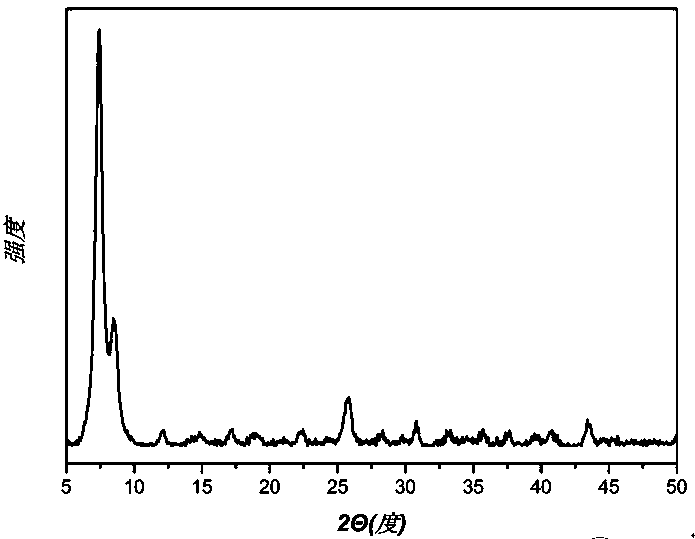

Method for preparing metal organic framework material UiO-66 in ethanol phase

The invention relates to a method for preparing a metal organic framework material UiO-66 (Zr) in an ethanol phase. The method comprises the following steps: (1) uniformly mixing a zirconium source and an organic ligand, and pretreating for 1-3 hours so as to obtain an intermediate; (2) adding the intermediate into ethanol, stirring under a normal temperature condition, and centrifuging so as to obtain a crude product; and (3) washing the crude product for multiple times with ethanol, and drying, thereby obtaining the metal organic framework material UiO-66 (Zr). Compared with the prior art, the method is not involved with toxic organic solvents such as N,N-dimethyl formamide used in a conventional solvent thermal method, after the raw materials are pretreated, the UiO-66 (Zr) can be synthesized by using the ethanol as a solvent under the room temperature condition, the condition is gentle, the yield is relatively high, and large-scale synthesis of metal organic framework materials is possible.

Owner:TONGJI UNIV

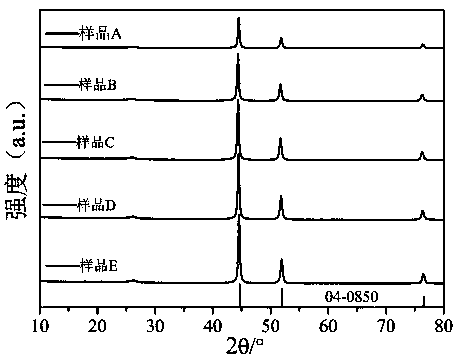

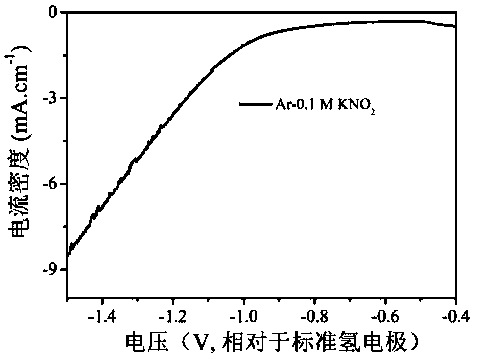

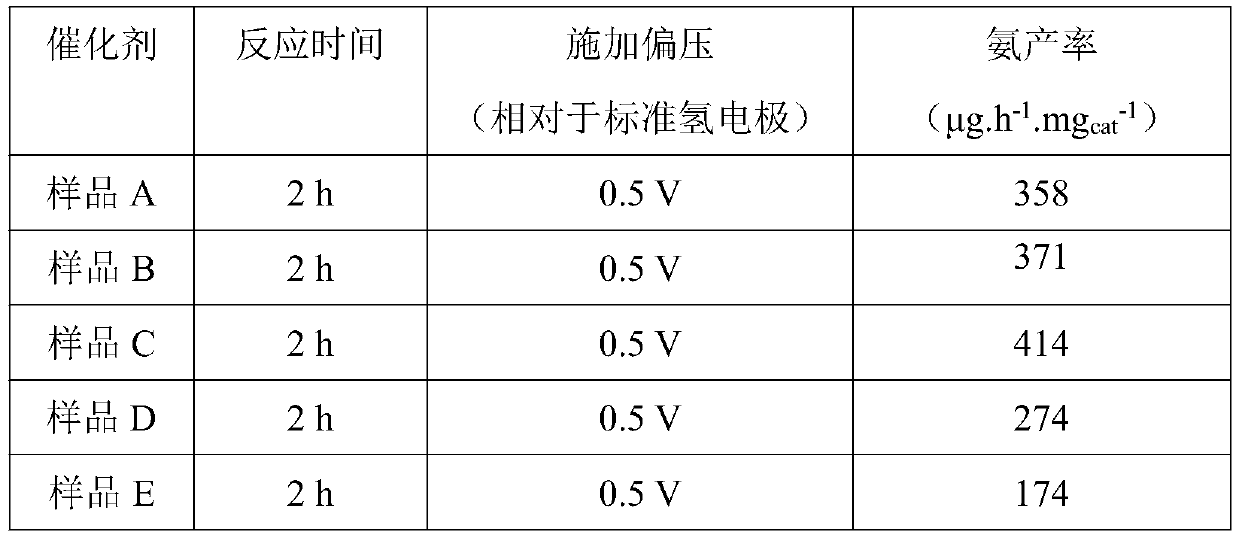

Doped carbon material catalyst as well as preparation method and application thereof

InactiveCN111359615AOvercome the disadvantage of low yieldAvoid hydrolysisCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPolyvinyl alcohol

The invention provides a doped carbon material catalyst as well as a preparation method and application thereof, and belongs to the fields of material preparation and electro-catalysis. The Ni-doped carbon material is prepared by an electrostatic spinning and a calcining method, and is prepared from at least the following raw materials: a nickel source, which is one or more of nickel acetate, nickel chloride and nickel nitrate; an organic additive, which is one or more of polyacrylamide, polyvinylpyrrolidone and polyvinyl alcohol; and glacial acetic acid. An H-type reactor is used for separating a cathode chamber from an anode chamber; two chambers are separated by a proton exchange membrane, the prepared Ni-doped carbon material catalyst is prepared into an electrode plate, the electrodeplate is filled in the cathode chamber, nitrite in water is electrochemically reduced into ammonia by the catalyst under a constant potential condition, and the catalyst has the advantages of normal temperature, normal pressure, no need of introducing H2 in the reaction process, and simple operation.

Owner:FUZHOU UNIV

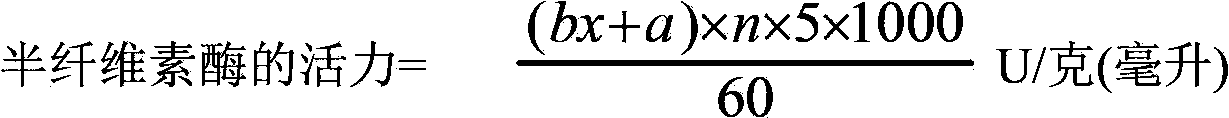

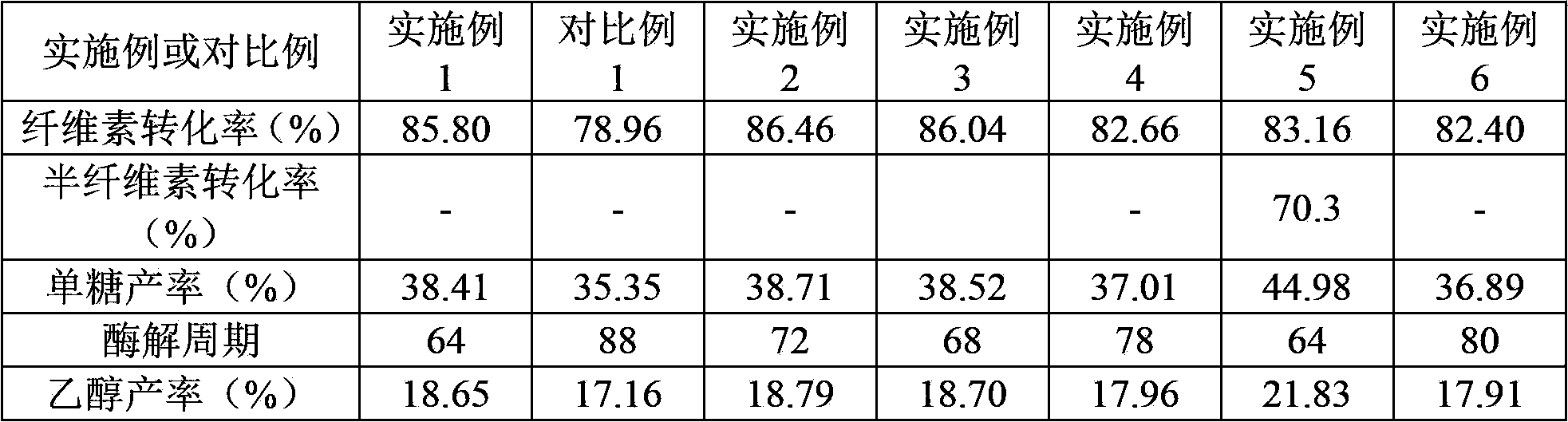

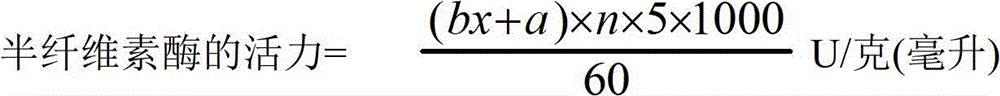

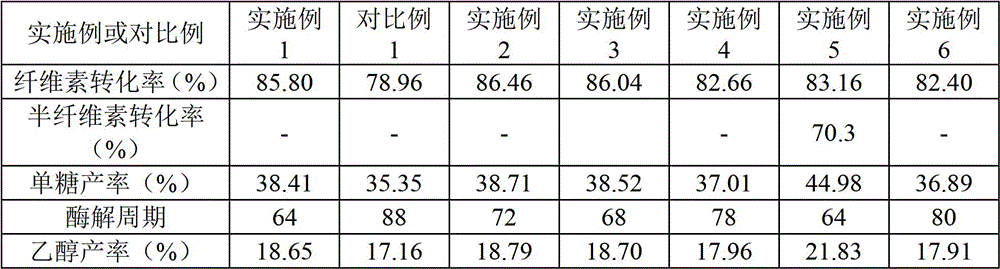

Method for preparing ethanol from cellulose-containing raw material

ActiveCN103789354AImprove sugar conversion rateHigh yieldBiofuelsMicroorganism based processesChemistryEnzyme

The invention discloses a method for preparing ethanol from a cellulose-containing raw material, which comprises the following steps: in the presence of water, mixing a cellulose-containing raw material with enzyme, carrying out enzymolysis on the cellulose-containing raw material to obtain an enzymolysis product, and fermenting the enzymolysis product. The enzymolysis comprises a main enzymolysis stage and an intermitted enzymolysis stage after the main enzymolysis stage which are continuously performed, wherein in the main enzymolysis stage, proper amounts of the cellulose-containing raw material and enzyme are continuously added into an enzymolysis tank so that the monosaccharide content in the enzymolysis product in the main enzymolysis stage is 50-100 g / L, and the enzymolysis products of the main enzymolysis stage respectively and continuously flow into enzymolysis tanks of the subsequent stage to perform intermitted enzymolysis until the monosaccharide content in the enzymolysis products in the enzymolysis tanks in the subsequent stage at the enzymolysis end point is greater than or equal to 105 g / L. The method can effectively enhance the saccharide conversion rate of the raw material, and therefore, greatly enhances the yield of ethanol.

Owner:COFCO NUTRITION & HEALTH RES INST +2

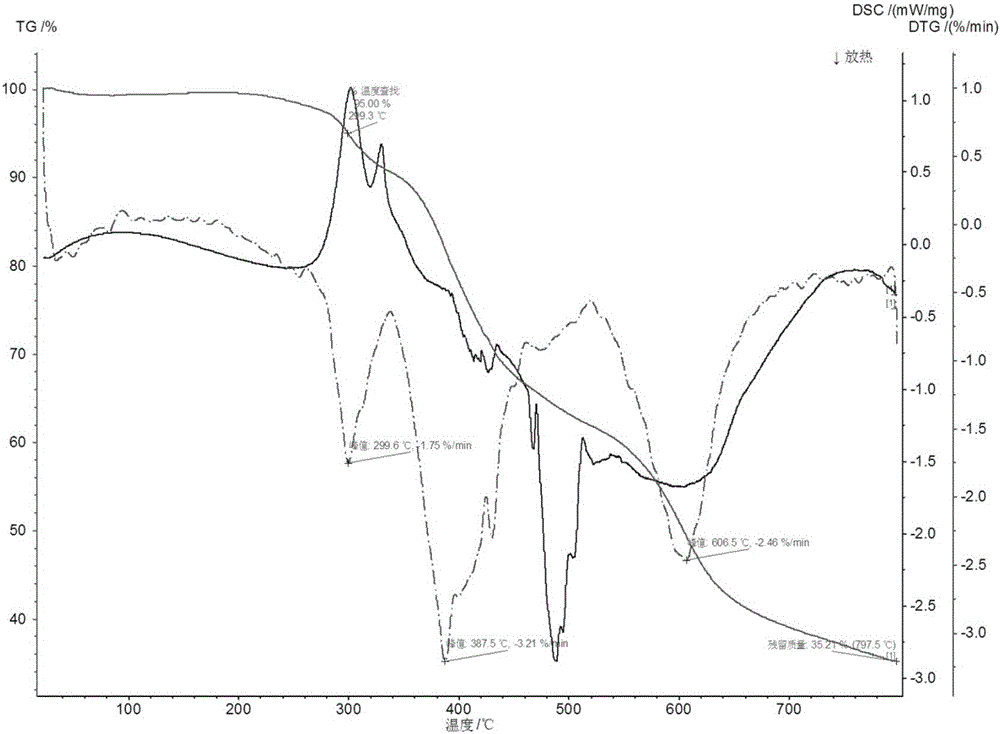

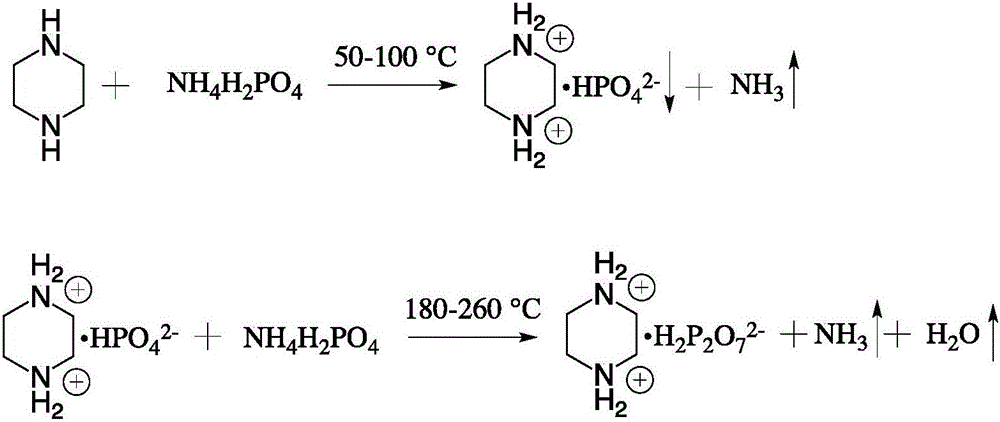

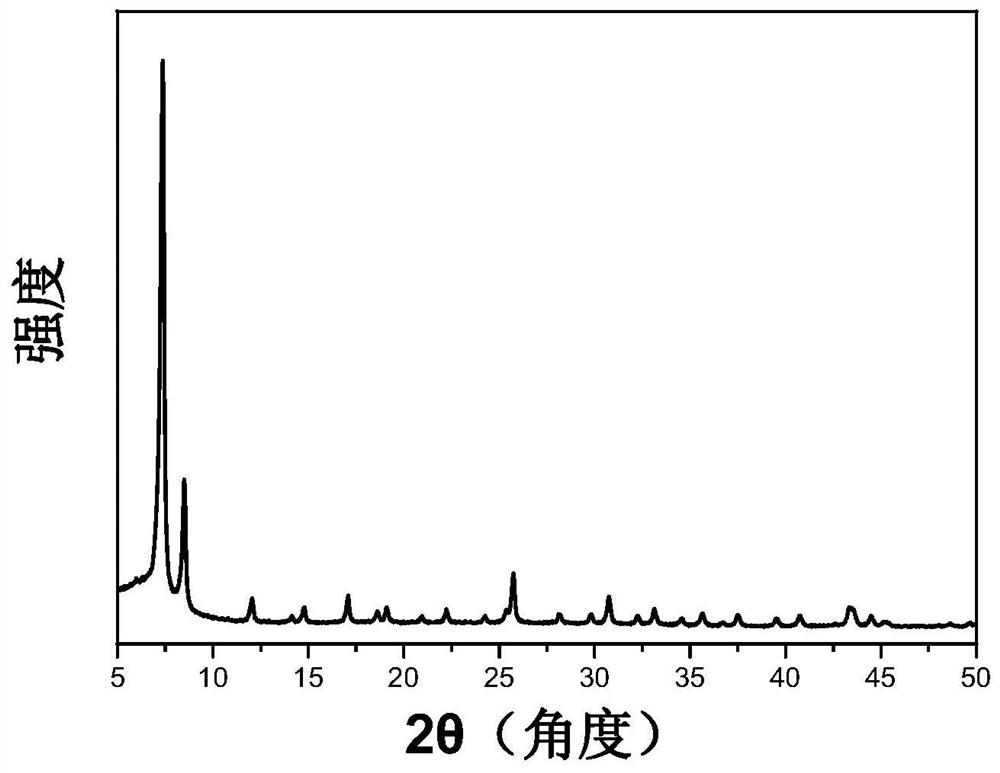

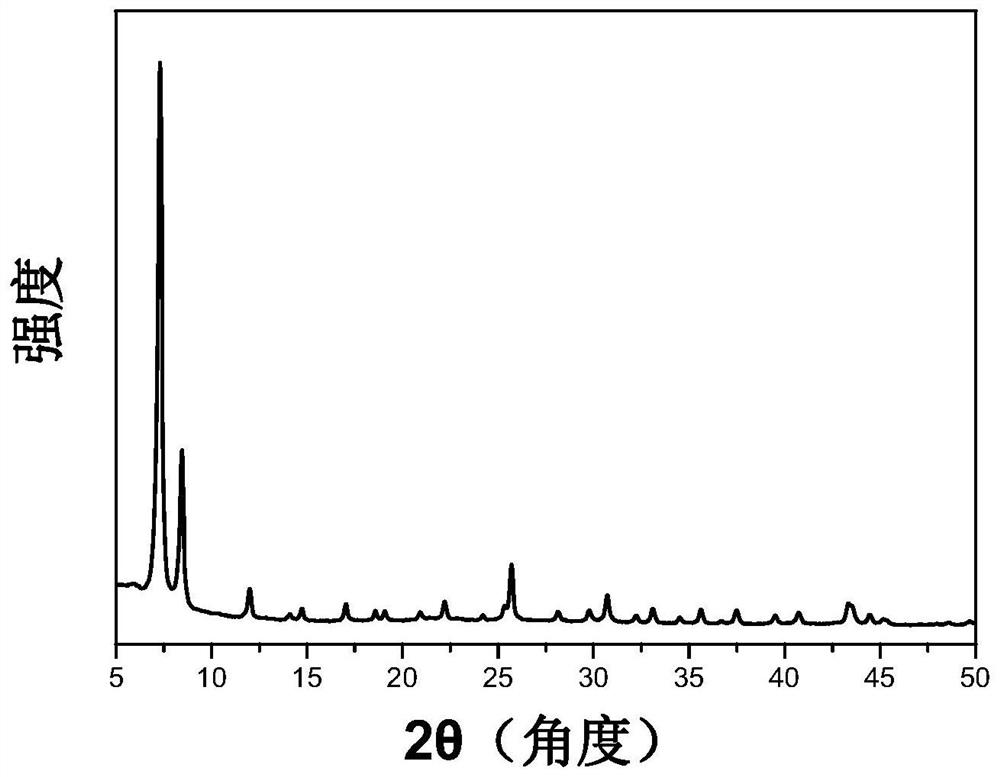

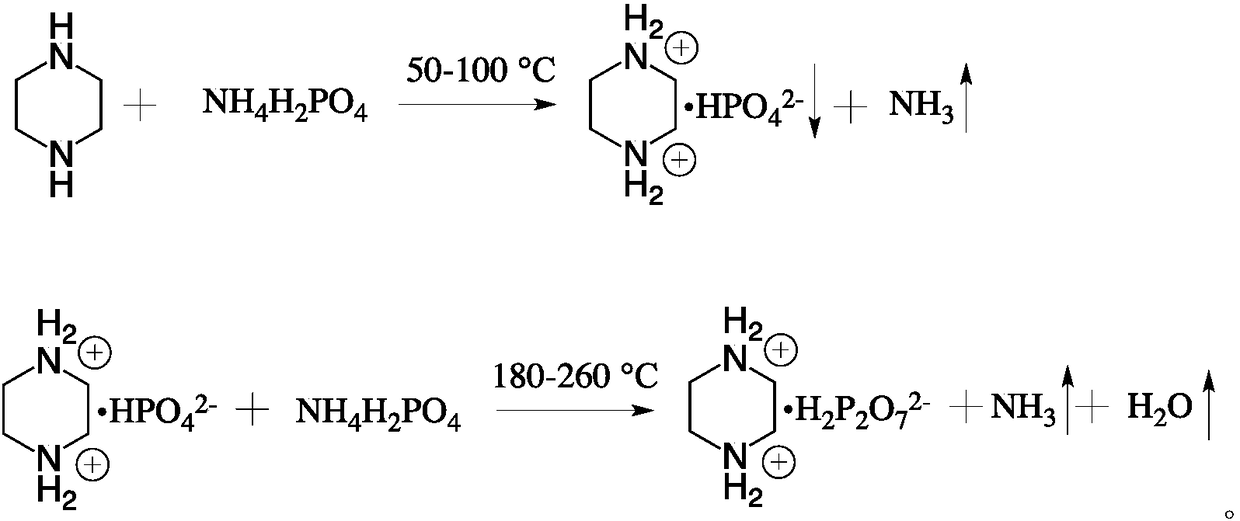

Preparation method of pyrophosphate piperazine

The invention discloses a preparation method of pyrophosphate piperazine. The preparation method comprises the following steps: mixing ammonium dihydrogen phosphate and piperazine in an aqueous solution according to a mole ratio of 2:1, heating to remove ammonia, and dewatering for condensation to obtain the pyrophosphate piperazine. According to the preparation method, the shortcomings that conventional liquid phosphoric acid serving as a phosphorous source is difficult to transport and store are overcome; a reaction system is a weak-alkaline environment, so that erosion of the phosphoric acid serving as the phosphorous source to equipment is avoided; ammonia released during reaction can be used as protection atmosphere of the reaction system, and the whiteness value of a product meets the market requirement. Compared with a phosphoric acid-piperazine method, the preparation method has the advantage of saving the raw material cost by 10 to 15 percent.

Owner:寿光普尔化工有限公司

Zirconium-based metal organic framework material UiO-66 (Zr) as well as room-temperature rapid preparation method and application thereof

ActiveCN113354825AHigh purityReduce usageOther chemical processesGroup 4/14 organic compounds without C-metal linkagesChemistryMetal-organic framework

The invention relates to a zirconium-based metal organic framework material UiO-66 (Zr) as well as a room-temperature rapid preparation method and application thereof. The preparation method comprises the following steps of: (1) uniformly mixing a zirconium source and an organic ligand, placing the mixture in methanol, stirring the mixtureat room temperature, performing centrifuging, and discarding clear liquid to obtain a transparent gel-state intermediate product; and (2) heating and drying the intermediate product to obtain the UiO-66 (Zr). Compared with the prior art, the UiO-66 (Zr) can be synthesized only by performing stirring in methanol at room temperature and performing drying without using toxic organic solvents such as N, N-dimethylformamide and the like in a traditional solvothermal method, the conditions are mild, the yield is higher, the synthesis time is greatly shortened, the product purity is extremely high, the step of activating the product can be omitted, the large-scale synthesis of the metal organic framework material is highly possible; and the material has good adsorption performance on fluorine ions in water, and can be applied to adsorption treatment of fluorine-containing wastewater.

Owner:TONGJI UNIV

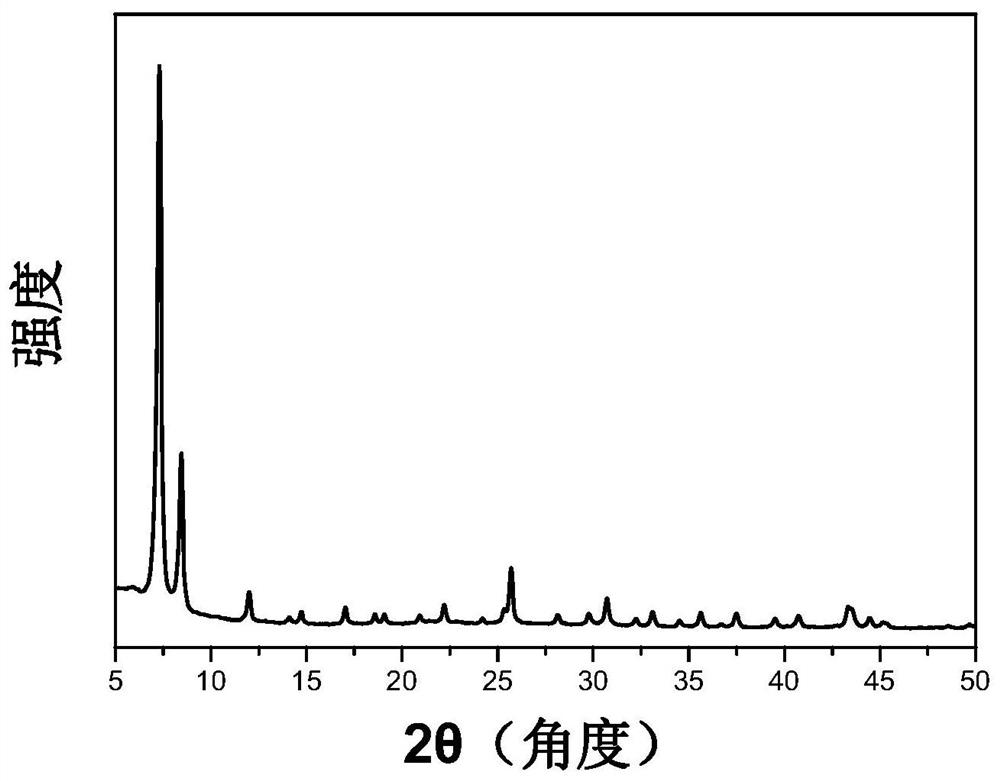

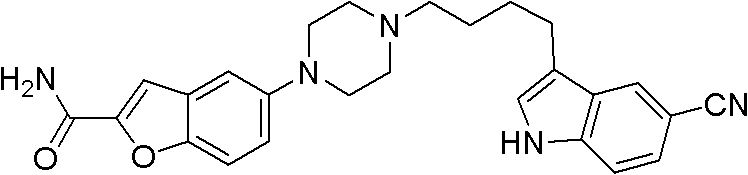

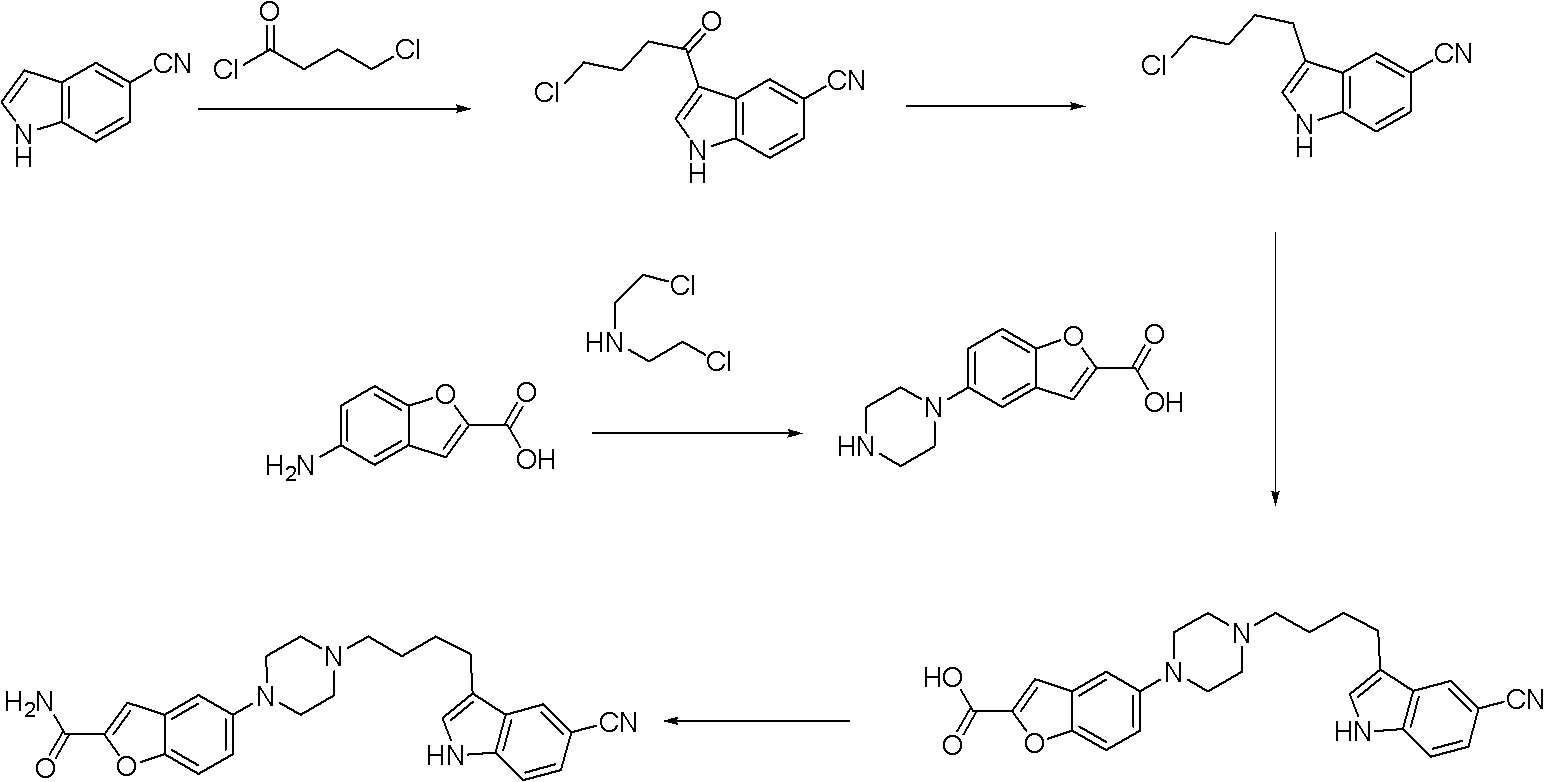

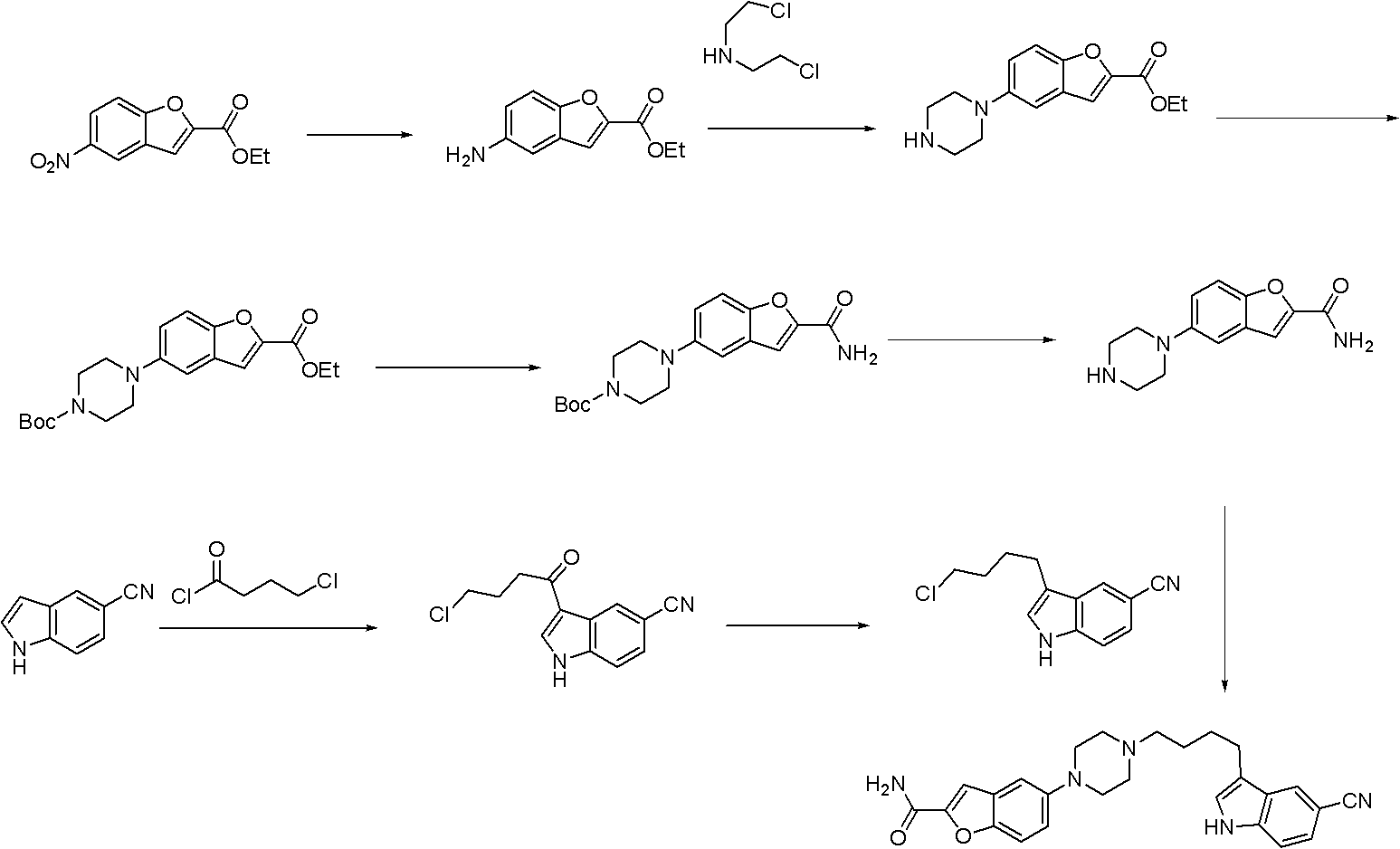

Synthesis method for antidepressant drug vilazodone

InactiveCN103159749AOvercome the disadvantage of low yieldOrganic chemistrySynthesis methodsCarboxylic acid

The present invention provides a synthesis method for an antidepressant drug vilazodone, belonging to the technical field of drug synthesis, and the method comprises the steps of: reacting 5-nitrosalicylaldehyde as a raw material with ethyl bromoacetate under the action of potassium carbonate by heating, to obtain a compound 5-nitrobenzofuran-2-carboxylic acid via hydrolysis; adding in aqueous ammonia after the reaction between 5-nitro-benzofuran-2-carboxylic acid and isobutyl chloroformate is completed, to give 5-nitrobenzofuran-2-carboxamide; reducing the 5-nitrobenzofuran-2-carboxamide by using sodium hydrosulfite to give an intermediate 5-aminobenzofuran-2-carboxamide; cyclizing the 5-aminobenzofuran-2-carboxamide with bis(2-chloroethyl)amine in the action of an alkaline to give 5-piperazinyl-benzofuran-2-carboxamide; and subjecting the 5-piperazinyl-benzofuran-2-carboxamide and 3-(4-chloro-butyl)-5-cyano indole to a substitution reaction to obtain the vilazodone. According to the synthesis method of the invention, the raw materials are cheap, and the reaction process is simple.

Owner:南京正济医药销售有限公司

Novel method for efficiently extracting total alkaloids from wild thermopsis lanceolata in Greater Khingan Mountains

ActiveCN103626770AFast extractionOvercome purityOrganic chemistryCountercurrent chromatographyThermopsis lanceolata

The invention belongs to the field of natural organic chemistry and relates to a method for extracting and purifying total alkaloids from wild thermopsis lanceolata in Greater Khingan Mountains and particularly relates to a method for finally obtaining high-purity total alkaloids by using a biological enzymolysis technology and through ultrahigh pressure coupled subcritical water extraction, separation and refining by using an enzymatic method as well as separation and purification by using a high-speed counter-current chromatography. The method has the advantages that 1, the effective components of the alkaloids are rapidly dissolved out and the high activity is kept by using a biological exine detaching technology, and the method is carried out at normal temperature and is low in energy consumption and capable of realizing industrial production; 2, the subcritical water is nontoxic and pollution-free, so that the activity of an extract is not damaged; the operation cost is low, the extract is easy to be separated from a product, and large-scale industrial production can be realized; 3, the high-speed counter-current chromatography has the advantages of flexibility in operation, high efficiency, high separation speed, large preparation amount, low expense and the like, and can be used for industrial application. By using the method, the obtained total alkaloids are high in content and high in purity up to 95.8%.

Owner:HEILONGJIANG DINGHENGSHENG PHARM CO LTD

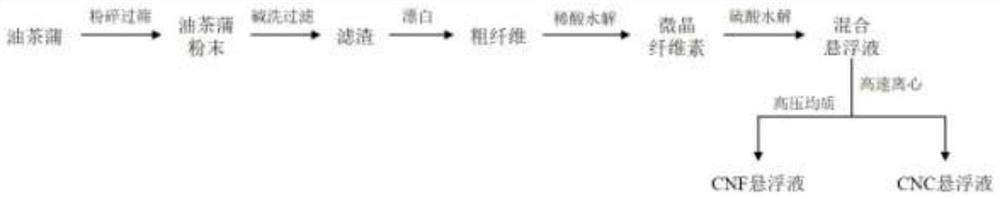

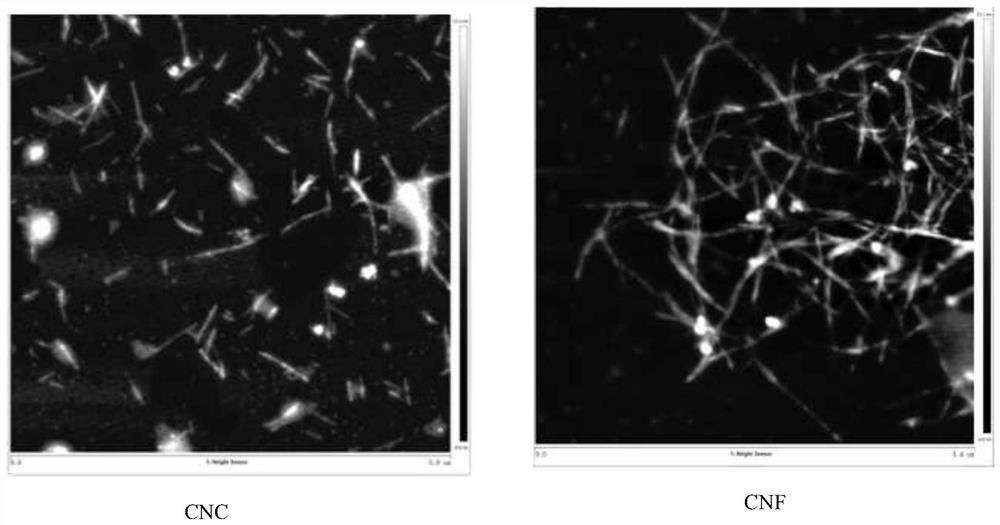

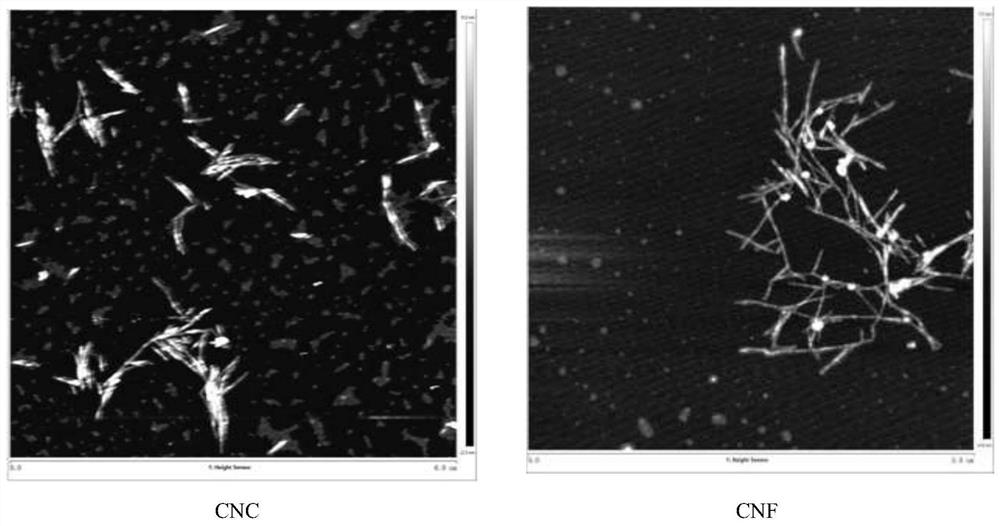

Method for simultaneously preparing cellulose nanocrystals and cellulose nanofibers from oil-tea camellia husk

PendingCN113004426AReduce energy consumptionOvercome the disadvantage of low yieldMonocomponent cellulose artificial filamentPaper material treatmentFiberCrude fibre

The invention relates to a method for simultaneously preparing cellulose nanocrystals and cellulose nanofibers from oil-tea camellia husk, which comprises the following steps: by taking the oil-tea camellia husk as an initial raw material, firstly carrying out alkali washing and bleaching to obtain crude fibers, carrying out preliminary hydrolysis on the crude fibers by using diluted hydrochloric acid to obtain microcrystalline cellulose, and then carrying out acidolysis on the microcrystalline cellulose by using a sulfuric acid hydrolysis method; washing and centrifuging at a high speed to obtain a cellulose nanocrystal suspension on the upper layer, and further performing high-pressure homogenization on the lower layer to obtain a cellulose nanofiber suspension. According to the method, CNC and CNF are prepared at the same time according to the difference of the crosslinking degree of cellulose, a sparse structure in a cellulose crystalline region is broken into CNC under the action of sulfuric acid, the tightly-combined part in the crystalline region swells through acidolysis, and CNF can be obtained through homogenization under low pressure. The method is beneficial to improving the yield of the oil-tea camellia husk nano cellulose and reducing the production cost of the process.

Owner:JIANGNAN UNIV

Extracting process of lavender essential oil

InactiveCN109370780AEasy to operateOvercome the disadvantage of low yieldEssential-oils/perfumesOrganic solventWater vapor

The invention discloses an extracting process of lavender essential oil and belongs to the technical field of essential oil extraction. The extracting process comprises the following steps that newly-picked lavenders are dried and crushed, the crushed lavenders are divided into three parts, distilled water is added, and the liquid-solid ratios of three parts of liquid-solid mixtures are (10 to 22):1 and are increased sequentially; and then the three parts of liquid-solid mixtures are sequentially subjected to ultrasonic enhancement treatment, and then then steam distillation is conducted. According to the extracting process of the lavender essential oil, the mixtures, with the different liquid-solid ratios, of the distilled water and the lavenders are subjected to ultrasonic enhancement step by step, steam distillation is conducted finally, thus the defect of low yield of a traditional steam distillation method is overcome, and effective components in the lavender essential oil are notdamaged; and the extracting process is easy to operate and low in production cost, no organic solvent is adopted, thus medicine residue is avoided, the equipment requirement is low, and the extracting process is completely suitable for industrial production.

Owner:福建农业职业技术学院

Efficient and fast method for extracting shrimp head inclusions

InactiveCN101773188AAdd lessReduce manufacturing costProtein composition from fishAmino acid compositionBiology

The invention relates to an efficient and fast method for extracting shrimp head inclusions, comprising the following steps: a shrimp head of a plurality of shrimps such as fresh Litopenaeus vannamei, penaeuschinensis, metapenaeusensis and penaeusjaponicus serves as the raw material; adding a small amount of exogenous enzyme; fully activating activity of endogenous enzyme by adjusting pH value and temperature; employing coordinate hydrolytic action of the exogenous enzyme and the endogenous enzyme for efficiently extracting inclusions in the shrimp head; competing extracting inclusions in the shrimp head in 3h; in the invention, proteolysis degree of the shrimp head is more than 48%, protein recovery rate is more than 87%, the extractive is free from bitter taste, content of flavor-presenting amino acids is high, amino acid composition is balanced and nutrition is comprehensive; therefore the shrimp head inclusions are a good material for preparing seasoner and nutritional food.

Owner:GUANGDONG OCEAN UNIVERSITY

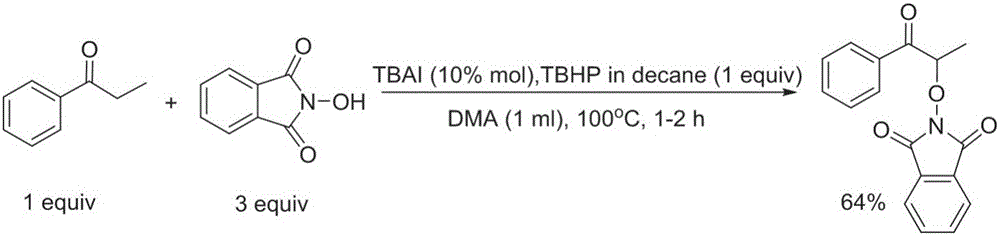

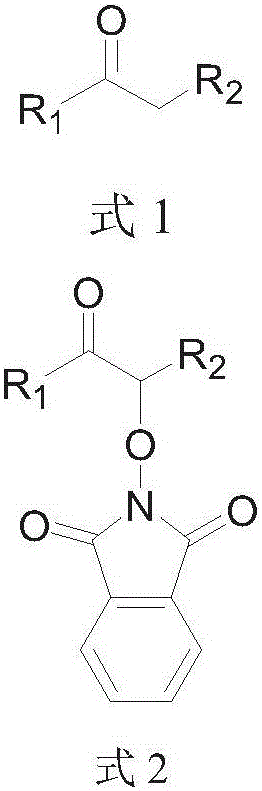

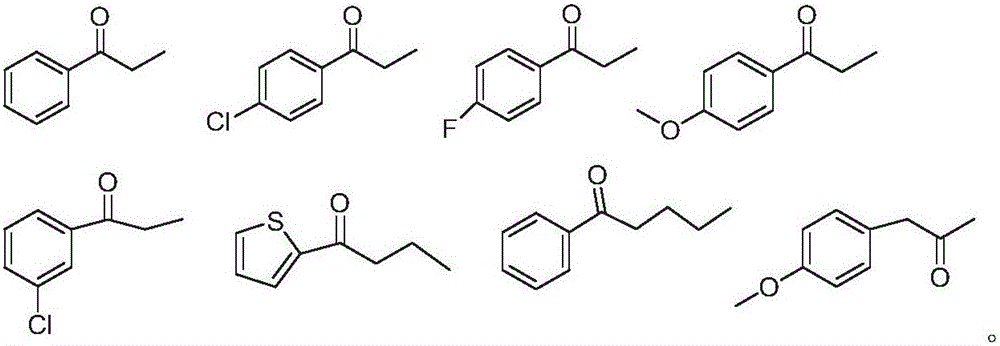

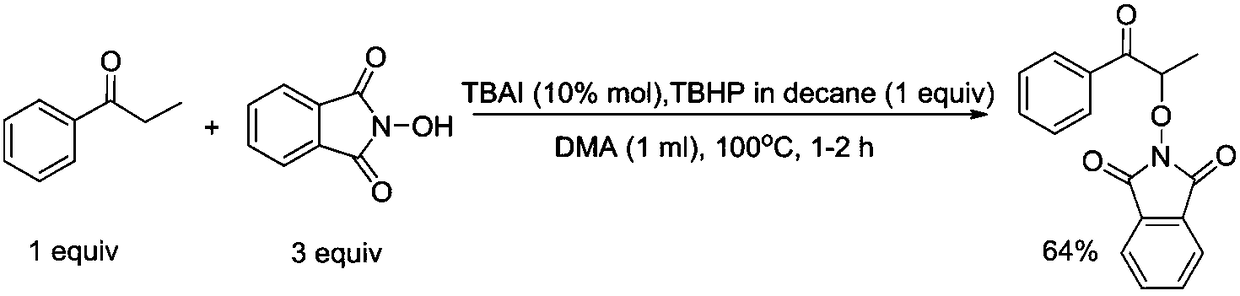

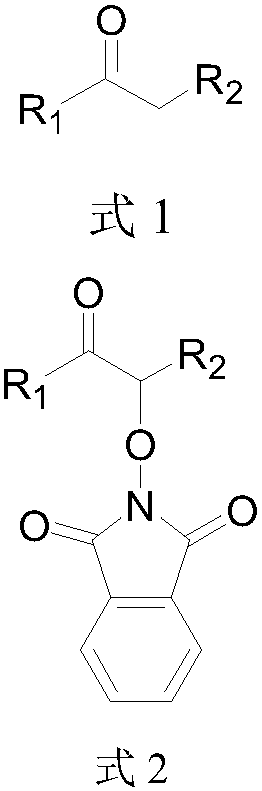

Method for preparing PINO (phthimide-N-oxyl) derivatives by direct coupling of NHPI (N-hydroxyphthalimide) and ketone compounds

ActiveCN106349149AOvercome the disadvantage of low yieldSimple stepsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsNitrogenDirect coupling

The invention discloses a method for preparing (phthimide-N-oxyl) derivatives by direct coupling of NHPI (N-hydroxyphthalimide) and ketone compounds. The method includes that, under the protection of nitrogen, the ketone compounds react with N- hydroxyphthalimide and K2S2O8 under catalyzing of tetraalkyl ammonium salt to generate the PINO derivatives. With the method, the PINO derivatives are synthesized with high yield by one-step reaction under the moderate condition, low cost is achieved, simpleness in operation is realized, and industrial production requirements are met.

Owner:王学军

A kind of preparation method of piperazine pyrophosphate

The invention discloses a preparation method of pyrophosphate piperazine. The preparation method comprises the following steps: mixing ammonium dihydrogen phosphate and piperazine in an aqueous solution according to a mole ratio of 2:1, heating to remove ammonia, and dewatering for condensation to obtain the pyrophosphate piperazine. According to the preparation method, the shortcomings that conventional liquid phosphoric acid serving as a phosphorous source is difficult to transport and store are overcome; a reaction system is a weak-alkaline environment, so that erosion of the phosphoric acid serving as the phosphorous source to equipment is avoided; ammonia released during reaction can be used as protection atmosphere of the reaction system, and the whiteness value of a product meets the market requirement. Compared with a phosphoric acid-piperazine method, the preparation method has the advantage of saving the raw material cost by 10 to 15 percent.

Owner:寿光普尔化工有限公司

A method for preparing pino derivatives by direct coupling of nhpi and ketones

ActiveCN106349149BOvercome the disadvantage of low yieldSimple stepsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemical compoundNitrogen

Owner:王学军

Preparation method of metal-organic framework material mil-88b(fe)

Owner:TONGJI UNIV

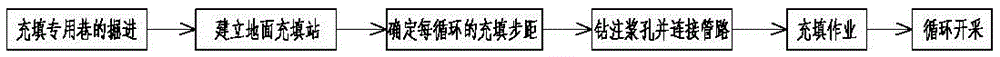

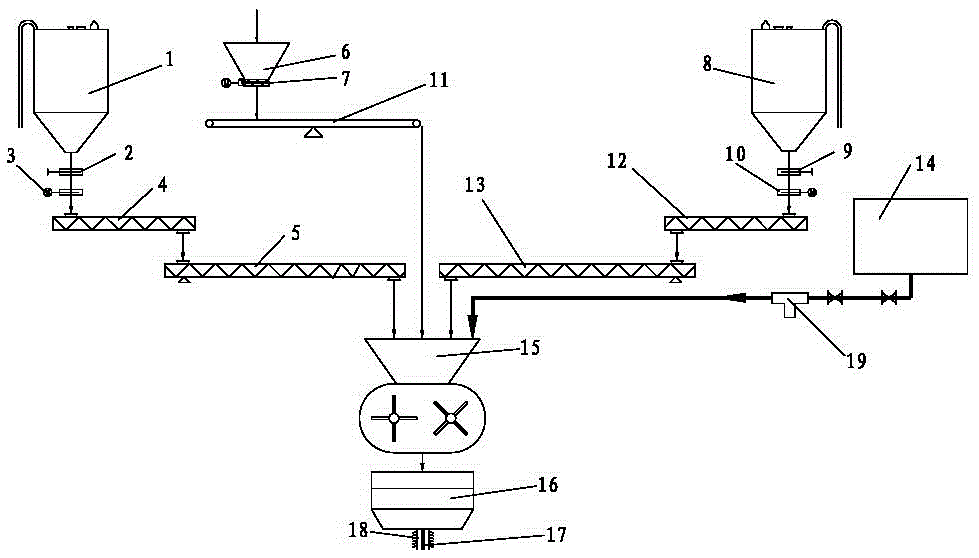

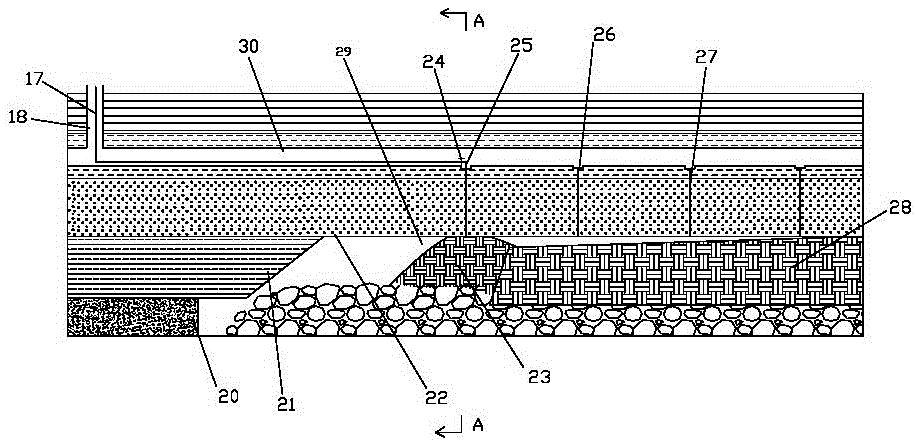

The method of filling and mining in the caving area of coal mining face

InactiveCN104251139BEasy to achieve high production efficiencyOvercome the disadvantage of low yieldUnderground miningSurface miningSpelunkingMining engineering

The invention relates to a filling mining method for a caving zone on a coal face and the method can effectively solve the problems that coal filling mining is greatly limited by space of the coal face, time and floor space, and the coal mining efficiency on the coal face is low. The invention adopts the technical scheme that the method comprises the following steps: (1) excavating a special filling roadway; (2) establishing ground filling stations; (3) determining the filling interval of each cycle; (4) drilling grouting holes and connecting pipelines; (5) conducting filling operation; and (6) conducting cycle mining. Compared with other filling methods, the method provided by the invention is free from limits of space of the coal face, time and floor space, can be matched with any coal mining technology under appropriate conditions, can easily achieve high yield and high efficiency on a filling face through the combination with a fully mechanized top coal caving mining method, overcomes the defect of low yield of the conventional filling face, and has favorable social and economic benefits.

Owner:HENAN POLYTECHNIC UNIV

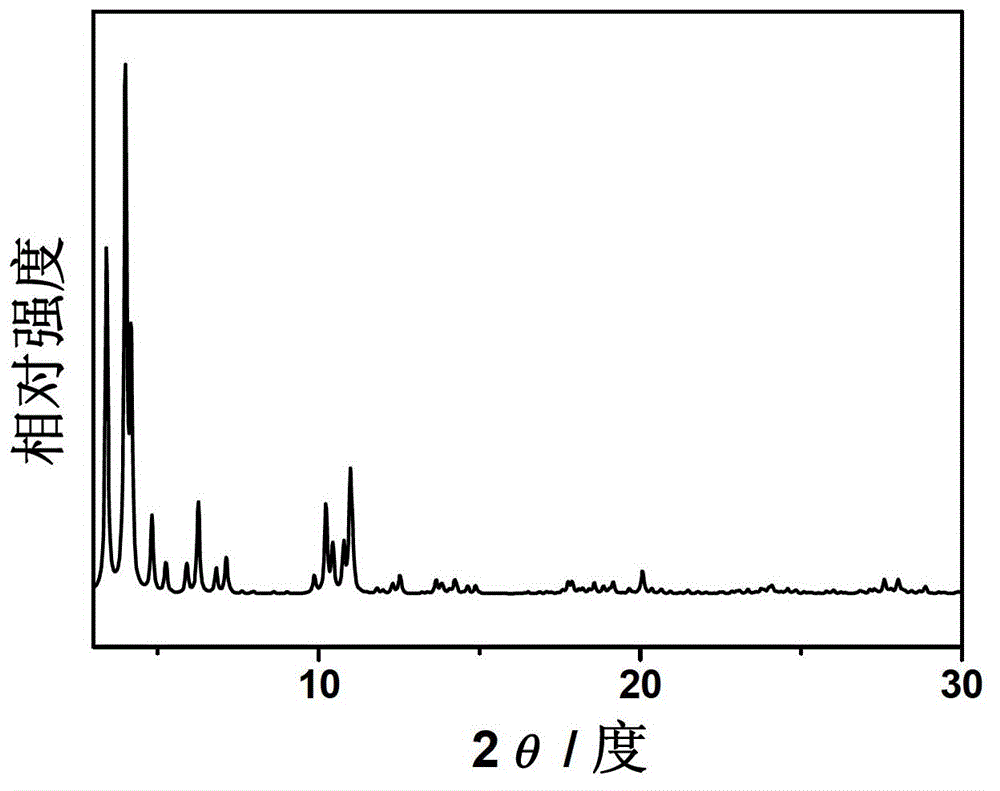

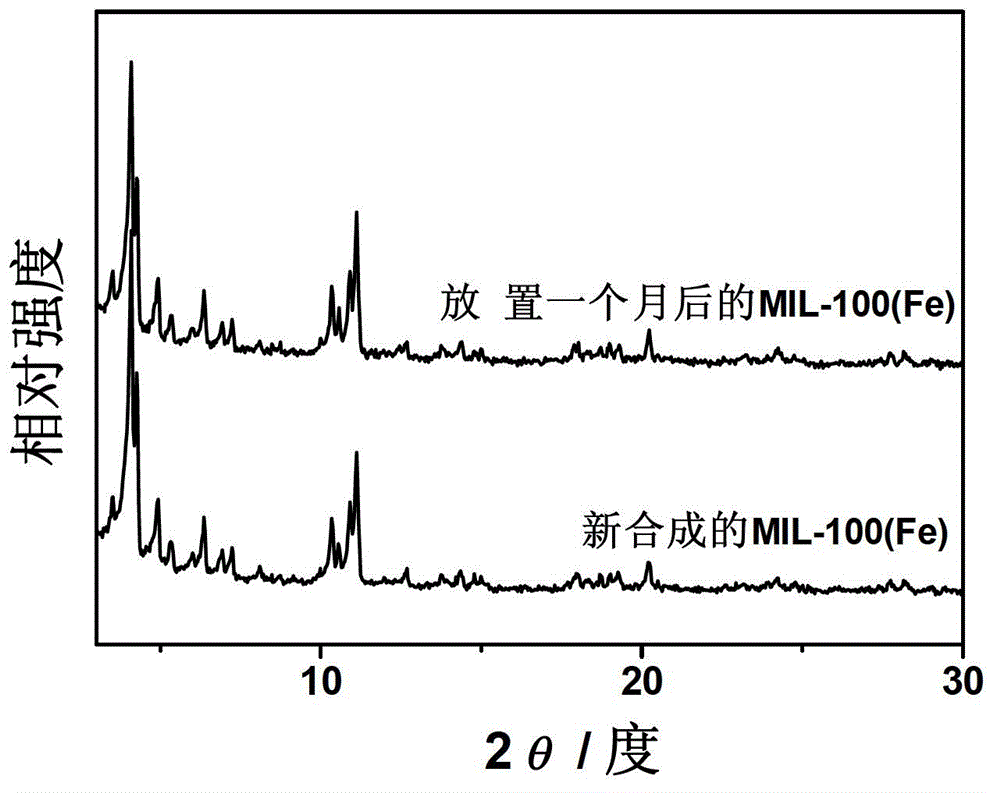

A kind of preparation method of metal organic framework material mil-100 (fe)

ActiveCN103242374BImprove qualityOvercome the disadvantage of low yieldIron organic compoundsAnhydrous ethanolMetal-organic framework

The invention relates to a preparation method of a metal organic framework material MIL-100 (Fe), which comprises the following steps: proportionally adding an organic ligand and an iron source into a certain amount of deionized water, and mixing for 30 minutes; mixing the mixture obtained in the step (1) at 80-95 DEG C under atmospheric pressure to react for 5-20 hours; and filtering the solid obtained in the step (2), washing with anhydrous ethanol at 60-80 DEG C for 10-20 hours, treating with a 30-60 mmol / L ammonium fluoride solution at 60-80 DEG C for 10-20 hours, sufficiently washing with deionized water, and finally, drying at 100-200 DEG C for 5-10 hours to obtain the pure MIL-100 (Fe). The method has the advantages of mild synthesis conditions, high product yield and high product quality.

Owner:孪生(海口)投资有限公司

A method for secondary immobilization of Debaria hansenii by using composite materials

ActiveCN106967708BIncrease productionOvercome the shortcoming of low yield of 3-hydroxypropionic acidMicroorganism based processesOn/in organic carrierBiotechnologyActivated carbon

Owner:XUZHOU UNIV OF TECH

Nitrogen-doped activated carbon supported noble metal catalyst and its application

ActiveCN107413331BImprove transfer abilityStrengthen the effect of suppressing dehalogenationOrganic compound preparationAmino compound preparationNitro compoundPtru catalyst

The invention discloses a nitrogen-doped activated carbon supported noble metal catalyst and an application thereof. The catalyst is composed of a carrier and an active component; the carrier is nitrogen-doped activated carbon; the active component is one of palladium, platinum, rhodium, ruthenium and iridium; and the load of the active component is not higher than 15wt% based on the mass of the carrier. The invention provides the application of the nitrogen-doped activated carbon supported noble metal catalyst to reaction for preparing an alkyl-containing halogenated aromatic aminocompound shown as a formula (II) by carrying out catalytic hydrogenation reduction on an alkyl-containing halogenated aromatic nitrocompound shown as a formula (I) to show that the nitrogen-doped activated carbon supported noble metal catalyst has the characteristics of high hydrogenation reaction rate, high catalytic activity, high selectivity and high stability.

Owner:ZHEJIANG UNIV OF TECH

A kind of preparation method of metal organic framework material uio-66 in ethanol phase

The invention relates to a method for preparing a metal organic framework material UiO-66 (Zr) in an ethanol phase. The method comprises the following steps: (1) uniformly mixing a zirconium source and an organic ligand, and pretreating for 1-3 hours so as to obtain an intermediate; (2) adding the intermediate into ethanol, stirring under a normal temperature condition, and centrifuging so as to obtain a crude product; and (3) washing the crude product for multiple times with ethanol, and drying, thereby obtaining the metal organic framework material UiO-66 (Zr). Compared with the prior art, the method is not involved with toxic organic solvents such as N,N-dimethyl formamide used in a conventional solvent thermal method, after the raw materials are pretreated, the UiO-66 (Zr) can be synthesized by using the ethanol as a solvent under the room temperature condition, the condition is gentle, the yield is relatively high, and large-scale synthesis of metal organic framework materials is possible.

Owner:TONGJI UNIV

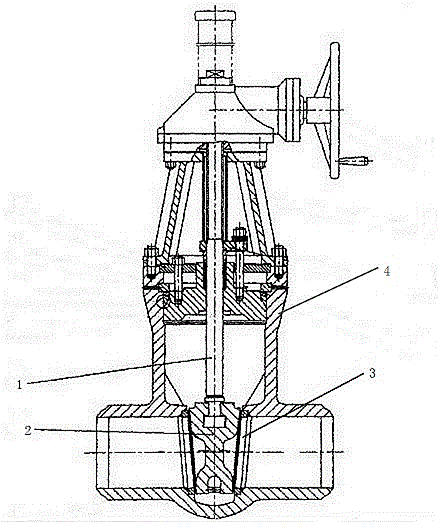

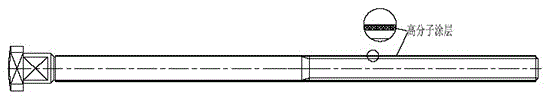

A hydrogenation valve and its processing method

ActiveCN103807458BOvercome the disadvantage of low yieldAvoid wear and tearSlide valvePolymer sciencePolymer chemistry

The invention discloses a hydrogenation valve and a machining method thereof. The machining method comprises the steps of preparing or selecting suitable self-lubricating high polymer materials according to the characteristic requirements for a hydrogenation valve pressing plate and a valve rod connecting nut, utilizing the high polymer material coating surface treatment technology for coating the surface of a valve rod with the self-lubricating high polymer materials, solidifying the coated self-lubricating high polymer materials for more than 30 min at room temperature, and then conducting automatic friction center adjusting cooperation on the hydrogenation valve movable joint nut and the valve rod with the surface coated with the self-lubricating high polymer materials. The hydrogenation valve and the machining method of the hydrogenation valve have the advantages that the coaxiality of the conical surfaces of the two ends of the valve rod of the hydrogenation valve does not need to be ensured; the self-lubricating high polymer materials coating the surface of the valve rod have good friction resistance and good wear resistance, and the hardness of the self-lubricating high polymer materials is lower than that of the valve rod connecting nut making contact with the self-lubricating high polymer materials, so that the automatic friction center adjusting cooperation is carried out on the valve rod and the valve rod connecting nut, the phenomena that due to the facts that eccentricity is excessive and the valve rod is extruded, the valve rod is abraded and broken, and the valve rod connecting nut is abraded are avoided, and meanwhile the pressing plate is prevented from being scratched.

Owner:JIANGSU SHENGTAI VALVE CO LTD

Clone, expression and application for lactic acid bacteria glutamic acid decarboxylase gene

InactiveCN101063144BClone full-length geneAchieve heterologous expressionFermentationGenetic engineeringBiotechnologyRestriction enzyme digestion

Owner:NANJING AGRICULTURAL UNIVERSITY

A kind of method that adopts cellulose-containing raw material to prepare ethanol

ActiveCN103789354BOvercome the disadvantage of low yieldHigh yieldBiofuelsMicroorganism based processesCelluloseEnzyme

The invention discloses a method for preparing ethanol from a cellulose-containing raw material, which comprises the following steps: in the presence of water, mixing a cellulose-containing raw material with enzyme, carrying out enzymolysis on the cellulose-containing raw material to obtain an enzymolysis product, and fermenting the enzymolysis product. The enzymolysis comprises a main enzymolysis stage and an intermitted enzymolysis stage after the main enzymolysis stage which are continuously performed, wherein in the main enzymolysis stage, proper amounts of the cellulose-containing raw material and enzyme are continuously added into an enzymolysis tank so that the monosaccharide content in the enzymolysis product in the main enzymolysis stage is 50-100 g / L, and the enzymolysis products of the main enzymolysis stage respectively and continuously flow into enzymolysis tanks of the subsequent stage to perform intermitted enzymolysis until the monosaccharide content in the enzymolysis products in the enzymolysis tanks in the subsequent stage at the enzymolysis end point is greater than or equal to 105 g / L. The method can effectively enhance the saccharide conversion rate of the raw material, and therefore, greatly enhances the yield of ethanol.

Owner:COFCO NUTRITION & HEALTH RES INST +2

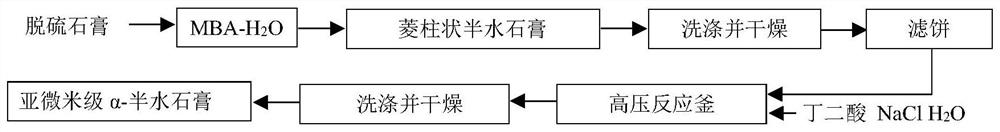

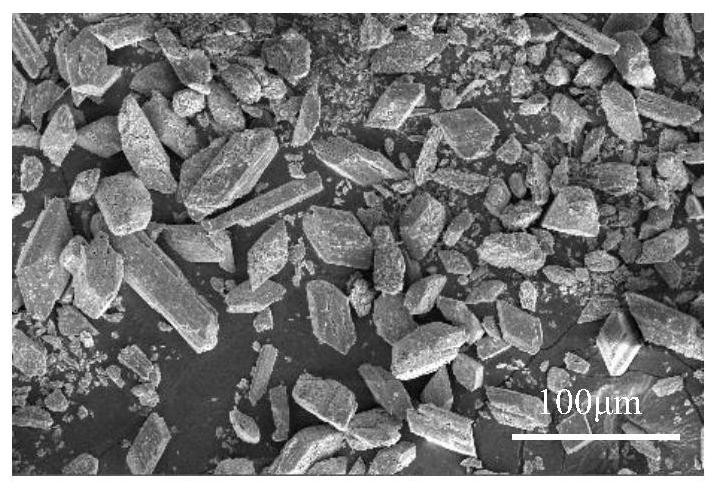

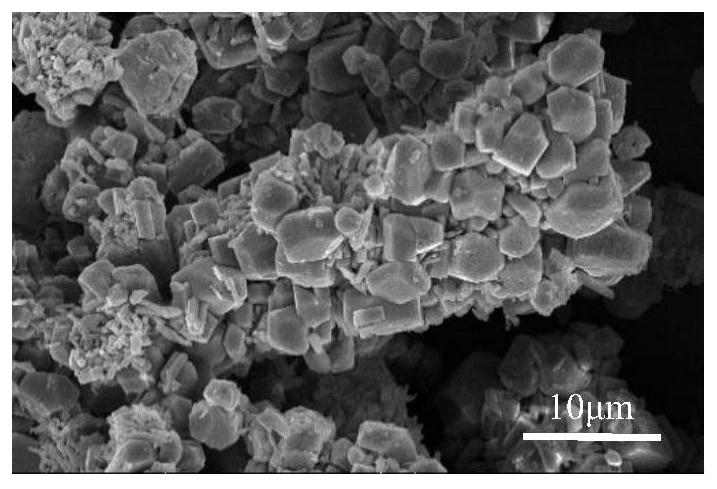

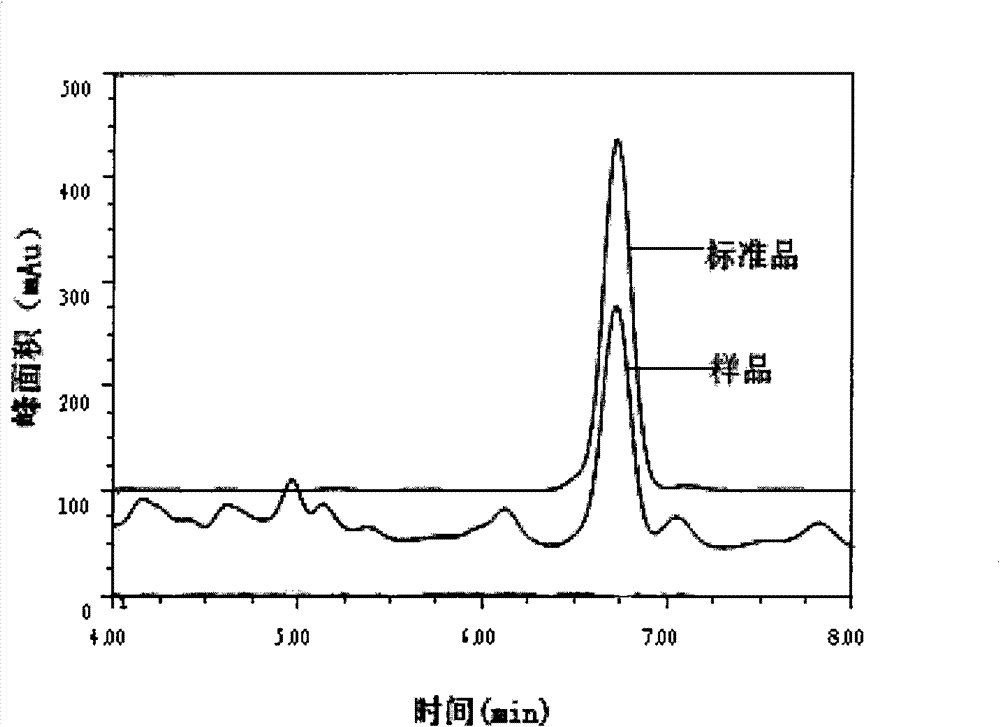

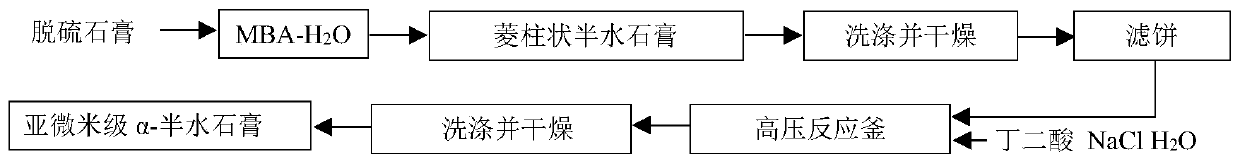

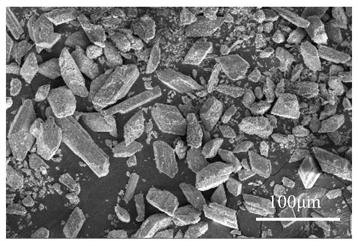

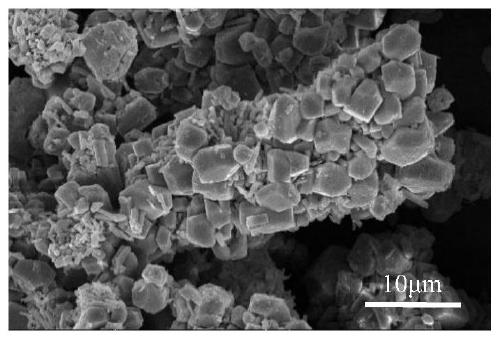

A method for preparing high whiteness short columnar submicron α-hemihydrate gypsum from desulfurized gypsum

The invention discloses a method for preparing high-whiteness short columnar submicron α-hemihydrate gypsum from desulfurized gypsum. The method comprises the following steps: adding N.N'-methylenebisacrylamide, water, and desulfurized gypsum into a reaction vessel for mixing to prepare a reaction slurry, and heating the slurry to 120-125°C for 2-5 hours; filtering , washed to neutral and then dried to obtain an intermediate product; mix water, intermediate product, NaCl, succinic acid, and ethylene glycol to prepare a reaction slurry; then react the reaction slurry at a temperature of 120°C to 125°C and stir for a homogeneous reaction The reaction is carried out in a device for 3 to 4 hours; after filtration and drying, a short columnar submicron α-hemihydrate gypsum with high whiteness is obtained. The invention not only solves the problem of accumulation and secondary pollution of waste resource desulfurized gypsum, but also provides a new method for producing small particle gypsum with high whiteness and certain strength.

Owner:HEBEI UNIV OF TECH

Method of double enzymatic coupling reaction for assisting extraction of solanesol

InactiveCN102154376BEmission reductionOvercome the disadvantage of low yieldFermentationIsomerizationCellulase

The invention discloses a method of double enzymatic coupling reaction assisted extraction of solanesol. In the method, a cellulase is used for changing the permeability of cell walls of potato leaves and then lipase is used for hydrolyzing combined solanesol. The method overcomes the shortcoming of the lower yield caused by the degradation or isomerization of solanesol as the solanesol is extracted by the traditional process, then is purified or extracted with a reagent and finally is saponified with alkali.

Owner:TIANSHUI NORMAL UNIV

Method for preparing high-whiteness short-column submicron-scale alpha-hemihydrate gypsum by using desulfurized gypsum

The invention provides a method for preparing high-whiteness short-column submicron-scale alpha-hemihydrate gypsum by using desulfurized gypsum. The method comprises the following steps: adding N,N'-methylene bisacrylamide, water and desulfurized gypsum into a reaction container, carrying out mixing to prepare reaction slurry, and heating the slurry to 120-125 DEG C for a reaction for 2-5 hours; carrying out filtering, carrying out washing to neutrality, and carrying out drying to obtain an intermediate product; mixing the water, the intermediate product, NaCl, succinic acid and ethylene glycol to prepare reaction slurry; then carrying out a reaction on the reaction slurry in a stirring homogeneous reactor at a temperature of 120-125 DEG C for 3-4 hours; and carrying out filtering and drying to obtain the high-whiteness short-column submicron-scale alpha-hemihydrate gypsum. According to the invention, a problem of accumulation and secondary pollution of waste resource desulfurized gypsum is solved, and a novel method is also provided for producing small-particle gypsum with high whiteness and certain strength.

Owner:HEBEI UNIV OF TECH

Grinding sheet for disc grinder and manufacturing method thereof

InactiveCN101654888BExtended service lifeReduce material costsSolid state diffusion coatingFurnace typesEngineeringGRINDING TOOTH

The invention provides a grinding sheet for a disc grinder and a manufacturing method thereof. The grinding sheet comprises grinding teeth and grinding sheet base body which are respectively processed twice for forming, wherein the grinding teeth which are arranged into a plurality of concentric circles are uniformly distributed on the grinding sheet base body around a center shaft of the grinding sheet base body, pulp baffle plates are arranged among the grinding teeth, and the pulp baffle plates positioned on a same circle form spiral pulp baffling lines on the surface of the grinding sheetbase body. The manufacturing method of the grinding sheet comprises the following steps: firstly, manufacturing the grinding teeth needed by the grinding sheet, and carrying out the surface processing of the grinding teeth; then processing a mould according to the designed form of the grinding sheet, installing the grinding teeth and the pulp baffle plates on the mould, and then casting or vulcanizing the mould provided with the grinding teeth; forming the grinding sheet base body, and simultaneously fixing the grinding teeth on the grinding sheet base body; and finally cooling a taper to finish the manufacturing process. The grinding sheet has good pulp grinding effect and long service life; in addition, the grinding sheet adopts a post forming method, thereby greatly reducing the material cost of the grinding sheet and the waste of materials.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com