Patents

Literature

83results about How to "High metal utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

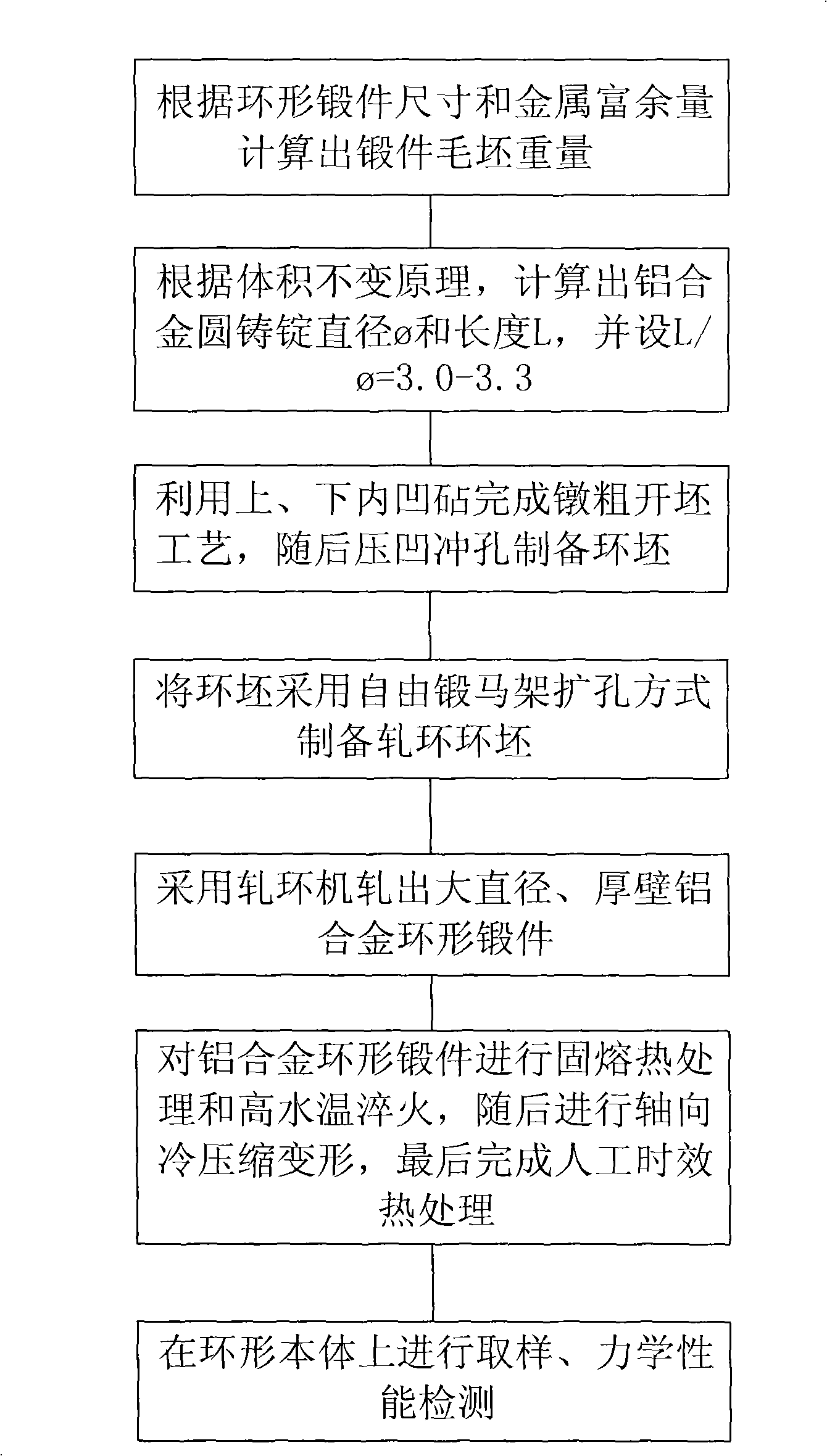

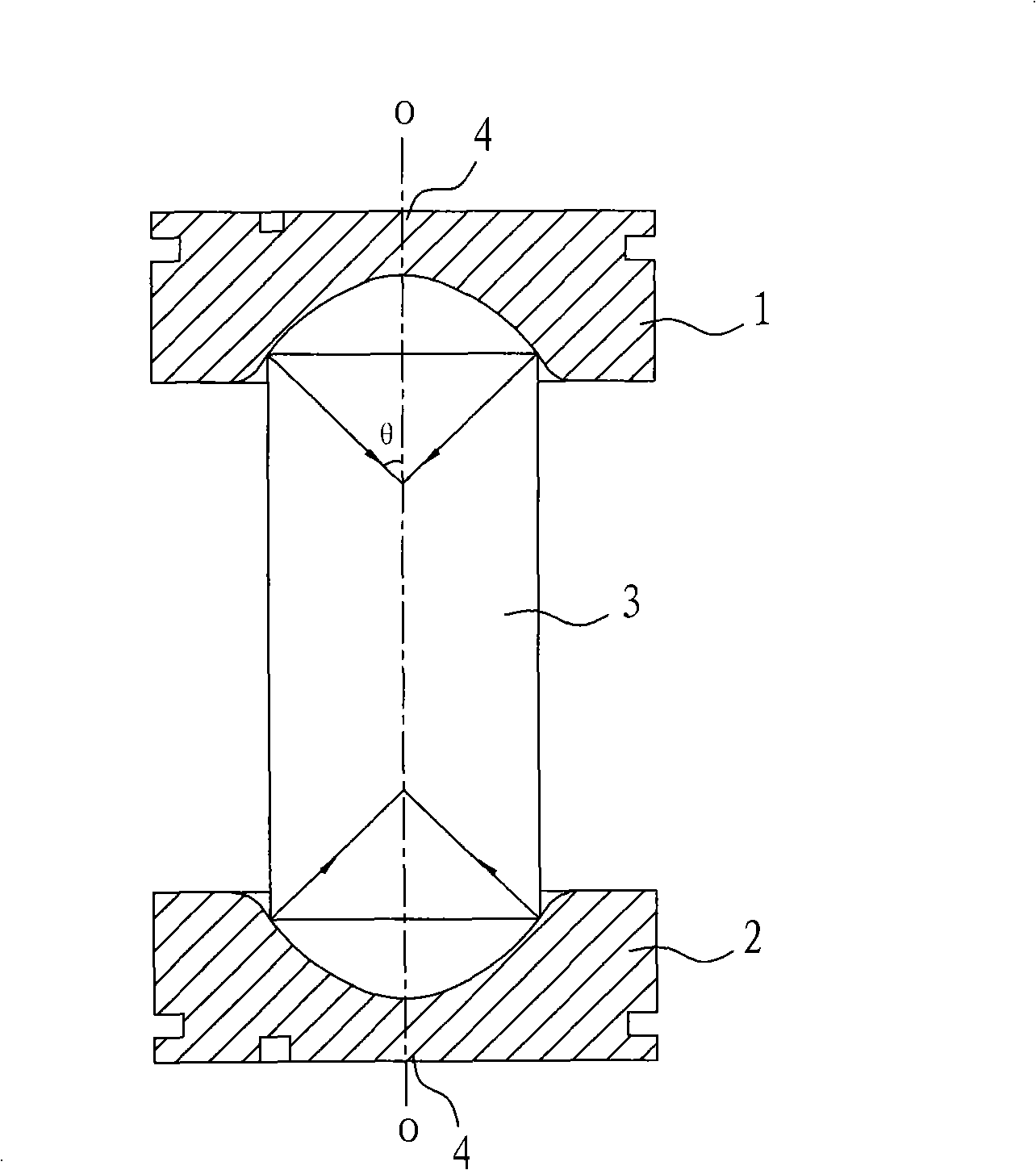

Method for manufacturing aluminium alloy rings with high performance and low residual stress

ActiveCN101537466AImprove performanceFully deformedRoll mill control devicesMetal rolling arrangementsThick wallQuenching

The invention discloses a method for manufacturing aluminium alloy rings with high performance and low residual stress, comprising the following technical steps: 1) calculating blank weight of forgings according to size and metal residual content of ring forgings; 2) calculating the diameter Phi and length L of aluminium alloy round ingots according to the volume constancy principle; 3) finishing the upsetting and cogging processes by using upper and lower recessed anvils, and preparing ring blank by shallow recessing and punching; 4) preparing rolling ring blank by using flat-die forging trestle broaching on the ring blank; 5) rolling out aluminium ring forgings with big diameter and thick wall by using a ring rolling mill; 6) carrying out solution heat treatment and high water temperature quenching, then carrying out axial cold compression and deformation, and finally finishing artificial aging heat treatment; and 7) carrying out crack detection on the ring by using ultrasonic according to the standard requirement, and carrying out sampling and mechanic performance detection on the main body of the ring complying with the standard requirement. The method has the advantages of high metal utilization rate, complete and uniform deformation from the surface to the core of the ring, high performance, low residual stress and the like.

Owner:SOUTHWEST ALUMINUM GRP

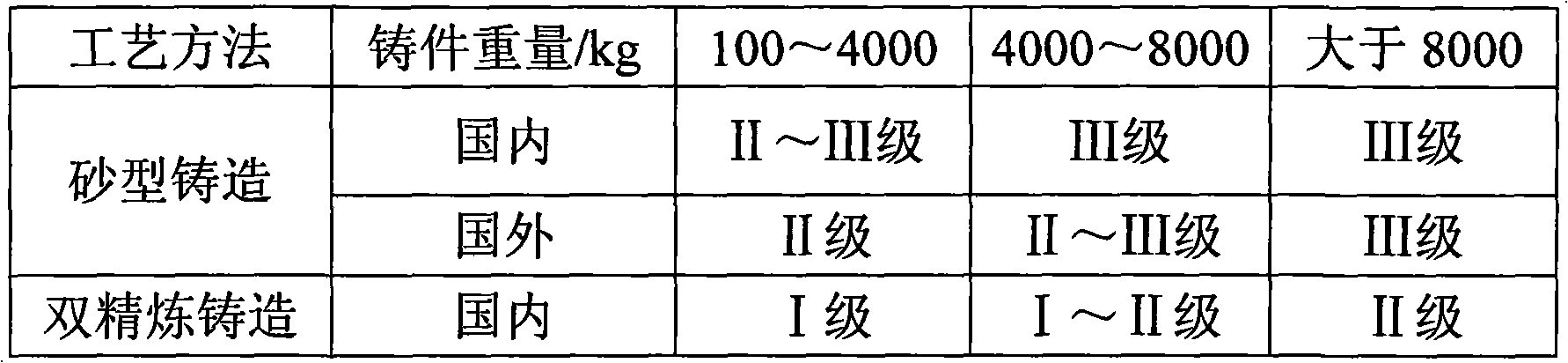

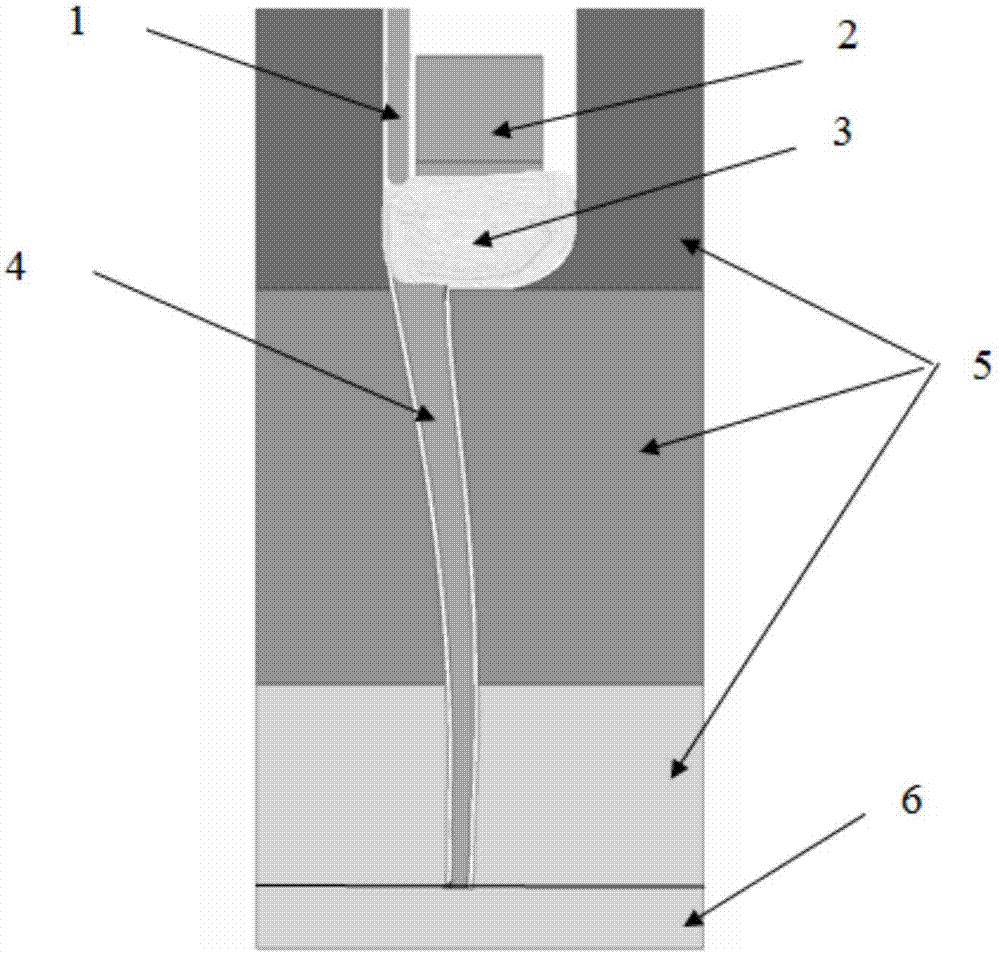

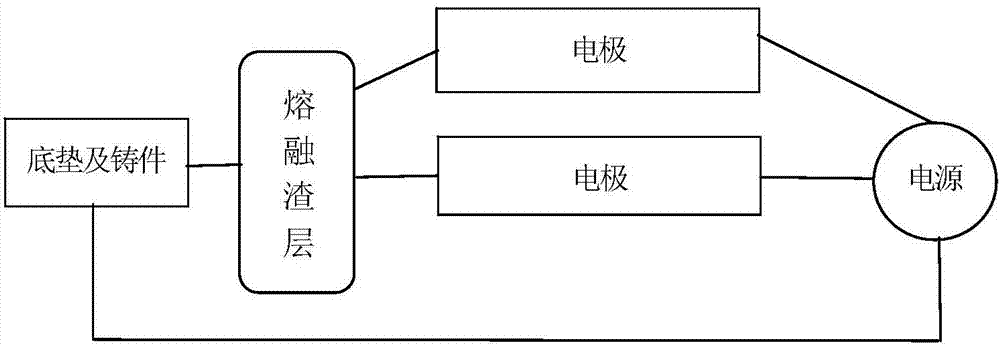

Electroslag smelting casting method of fixed blades of water turbine

The invention relates to an electroslag smelting casting method of fixed blades of a water turbine. Consumable electrodes are prepared by adopting a voltaic arc furnace refining method and the fixed blades are prepared by adopting an electroslag smelting casting process through a mould. The chemical components of the consumable electrodes are controlled as follows: C is 0.14-0.19 percent, Si is less than or equal to 0.6 percent, Mn is 1.5-1.9 percent, P is less than or equal to 0.035 percent, S is less than or equal to 0.035 percent, V is 0.02-0.15 percent, Nb is 0.015-0.06 percent, Ti is 0.15-0.25 percent, Al is more than or equal to 0.015 percent, O is less than or equal to 0.0040 percent, N is less than or equal to 0.0080 percent, H is less than or equal to 0.00035 percent, and the balance is Fe. The electroslag smelting casting system and the electroslag guide are controlled as follows: CaF2 is 60-80 percent, Al2O3 is 40-20 percent, or less MgO and CaO (the total is less than or equal to 20 percent); and the electroslag amount is usually 1.5-5 percent of the weight of a casting. The invention has less amount of oxide and sulfide, small size, even distribution, clean casting base body, high cooling speed, large crystallization temperature gradient at the front of solid and fluid, compact casting texture, high size precision and little distortion, and can greatly improve the product property of the refined casting.

Owner:SHENYANG RES INST OF FOUNDRY

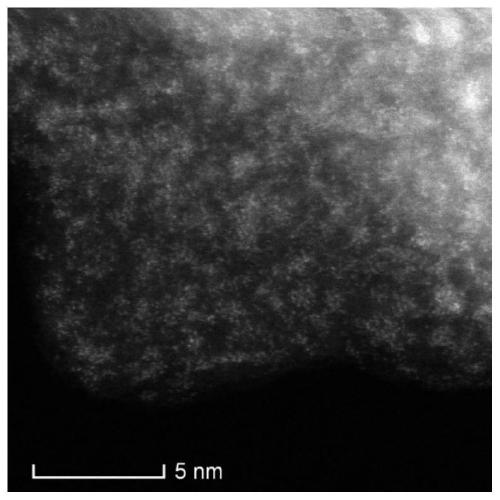

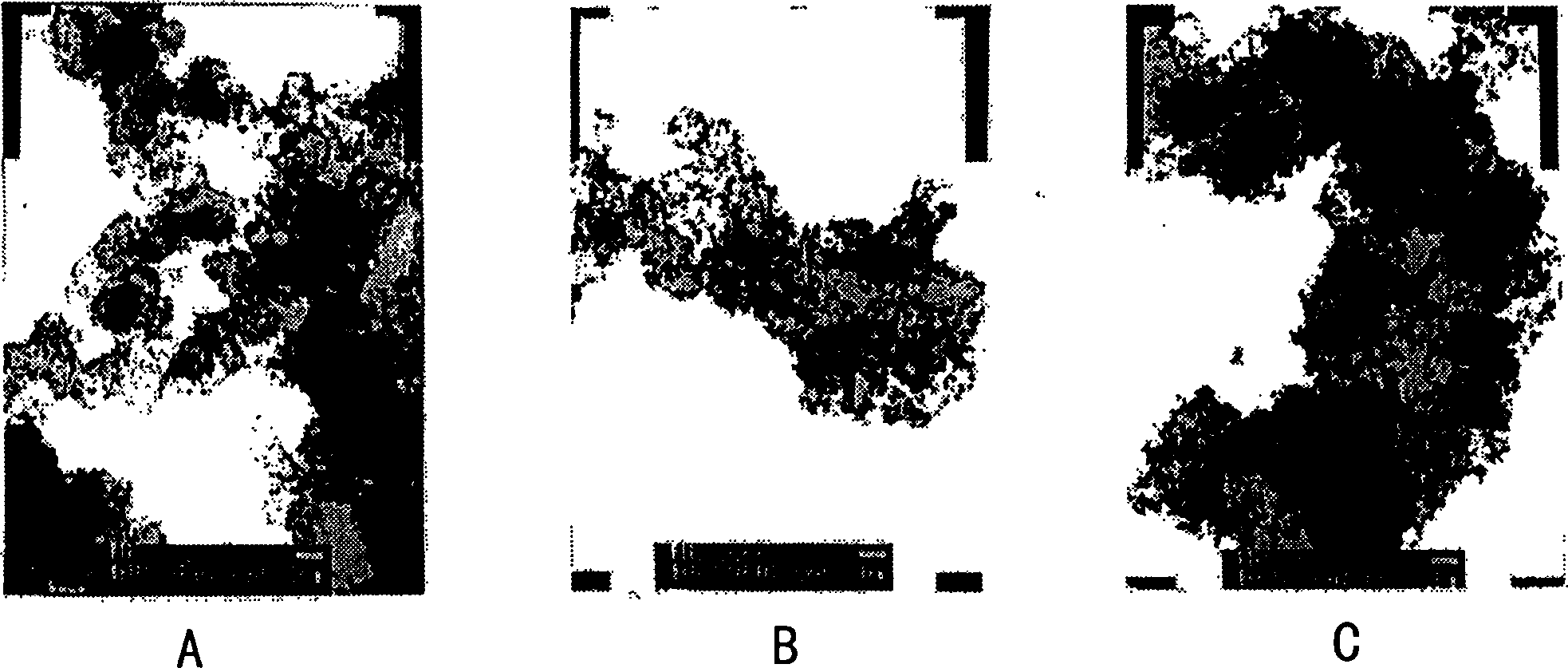

Preparation method for non-Pt non-H anode catalyst of proton exchange membrane fuel cell (PEMFC)

ActiveCN103331172AEvenly distributedUniform chemical compositionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrogen atmosphere

The invention aims to provide a preparation method for a non-Pt non-H anode catalyst of a proton exchange membrane fuel cell (PEMFC) to solve the problems of the conventional Ir-based catalyst preparation method. The method comprises the following steps: Ni ammonia complex cations are formed by taking strong ammonia solution as a complexant; Ni-Ir precursor is uniformly deposited on the surface of conductive carbon carrier due to the static attraction function between the Ni ammine complex cations and Ir complex anions under a water bath drying evaporation condition; finally, Ir and Ni are slowly released, reduced and alloyed from the complex compounds through hydrogen atmosphere heat treatment so as to form carbon carried Ir-Ni alloy catalyst of which the ingredients are uniform and the nano particles are distributed uniformly. According to the invention, the conventional Ir-based catalyst preparation method is greatly simplified; the surface of prepared catalyst is clean; the particle size of the catalyst is small; the catalyst is high in dispersion; the metal utilization ratio as well as the hadrogen and oxidization activity is effectively improved.

Owner:重庆铈坦新材料技术研究院有限公司

Vacuum seal modeling method for refrigerator cold closet plastic uptake mould casting

ActiveCN103658527AIncrease freedomHigh dimensional accuracyFoundry mouldsFoundry coresNumerical controlEvanescent mode

The invention relates to a vacuum seal modeling method for a refrigerator cold closet plastic uptake mould casting, and relates to the technical field of casting. The method comprises the following steps: 1) drawing up a cold closet solid model on three-dimensional software, and then utilizing a numerically-controlled machine tool to automatically process a polyurethane model; 2) putting the polyurethane model in the middle position of a template, coating a heated and softened plastic film on the surfaces of the template and the polyurethane model, and vacuumizing in an aspirating chamber; 3) putting an aspirating sand box on the polyurethane model and the template coated with the plastic film, sticking a gating system made of evanescent mode foam material on the polyurethane model, adding dry sand to ram-jolt, vacuumizing the aspirating sand box; 4) drawing, overturning the aspirating sand box, removing a supporting plate in the model, adding resin sand in the inner chamber of the model, and manufacture resin sand core; 5) orderly putting a normal sand box on the aspirating sand box, adding clay sand in the normal sand box to compact, and forming a sprue; 6) lifting the normal sand box, enabling the normal sand box to be separated from the aspirating sand box, removing the model, performing mould assembling, and waiting to pour. Through the adoption of the structure that the model is manufactured by three-dimensional drawing numerical control machining, the freedom degree of the model is improved, the stability of the size is kept, the labor is saved, and the pollution to the environment is low.

Owner:CHUZHOU JINNUO INDAL

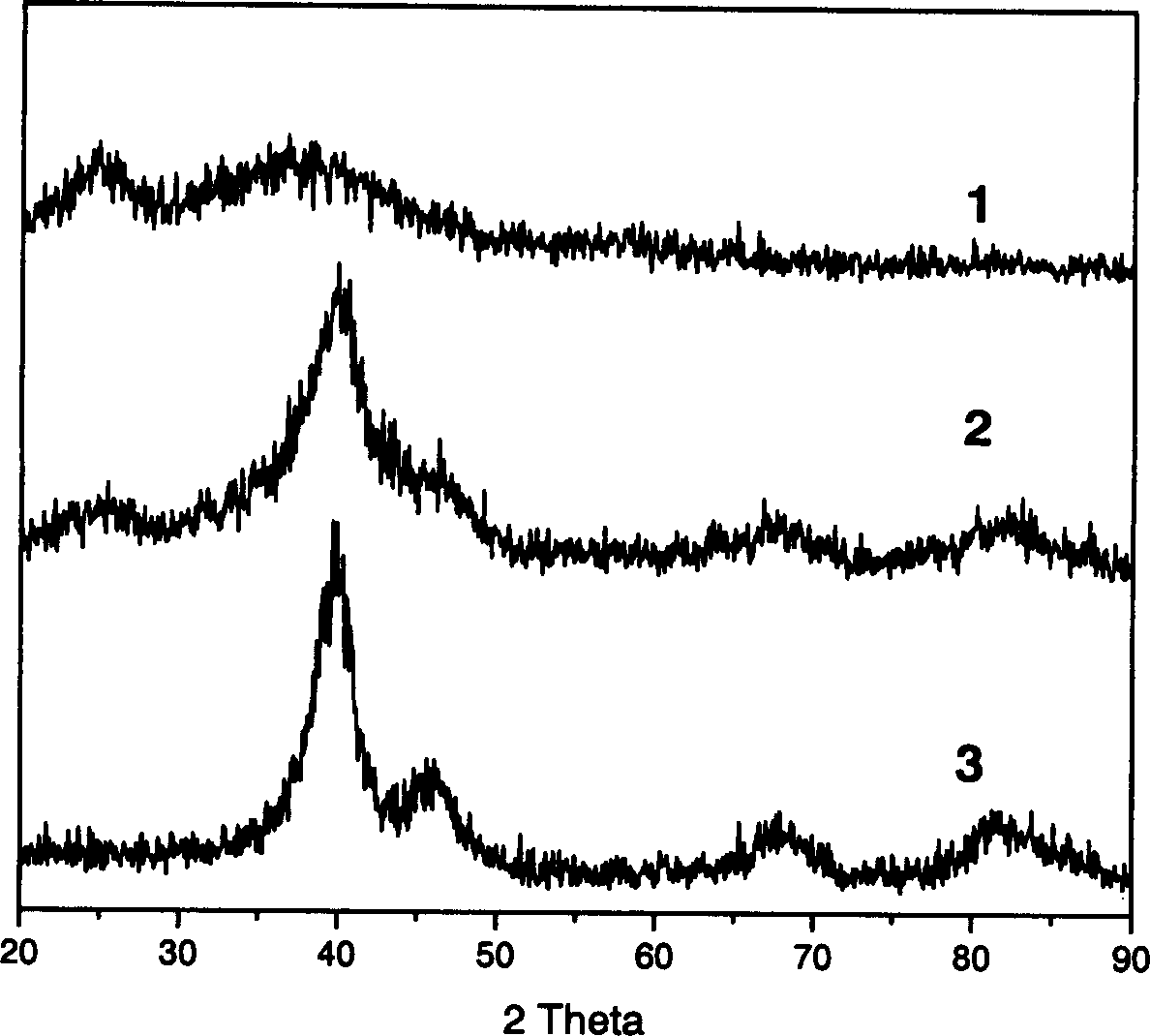

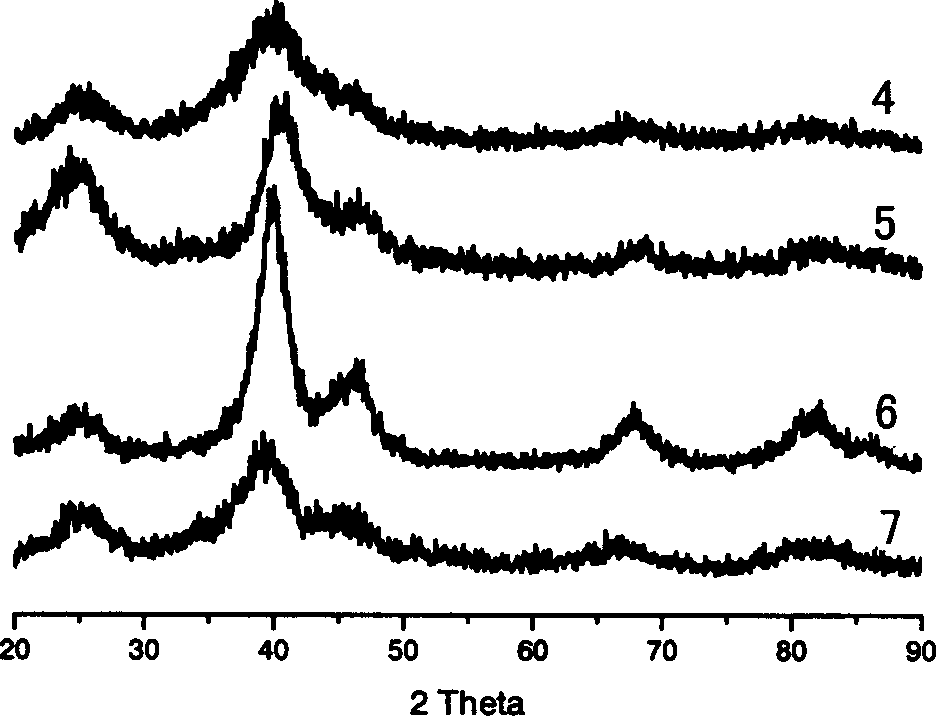

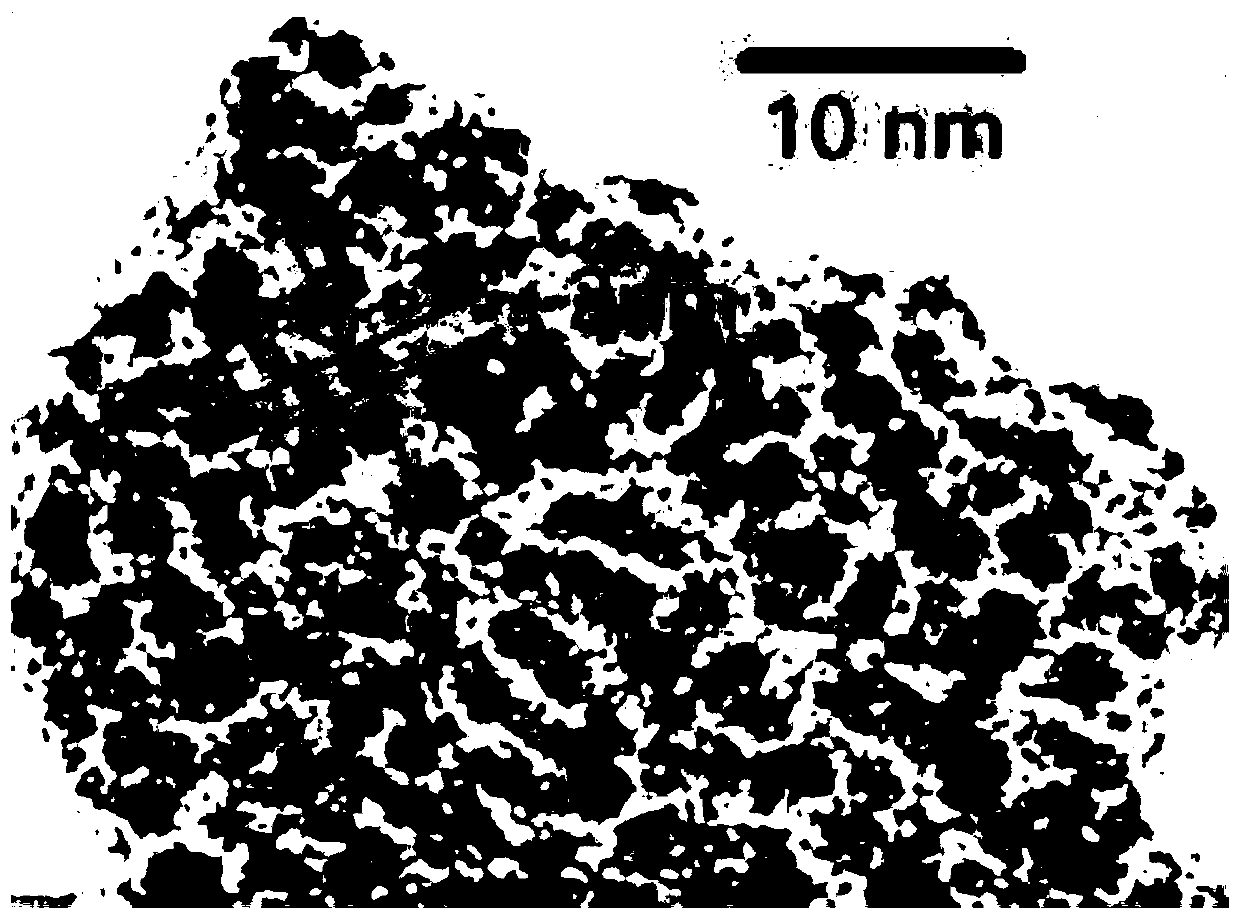

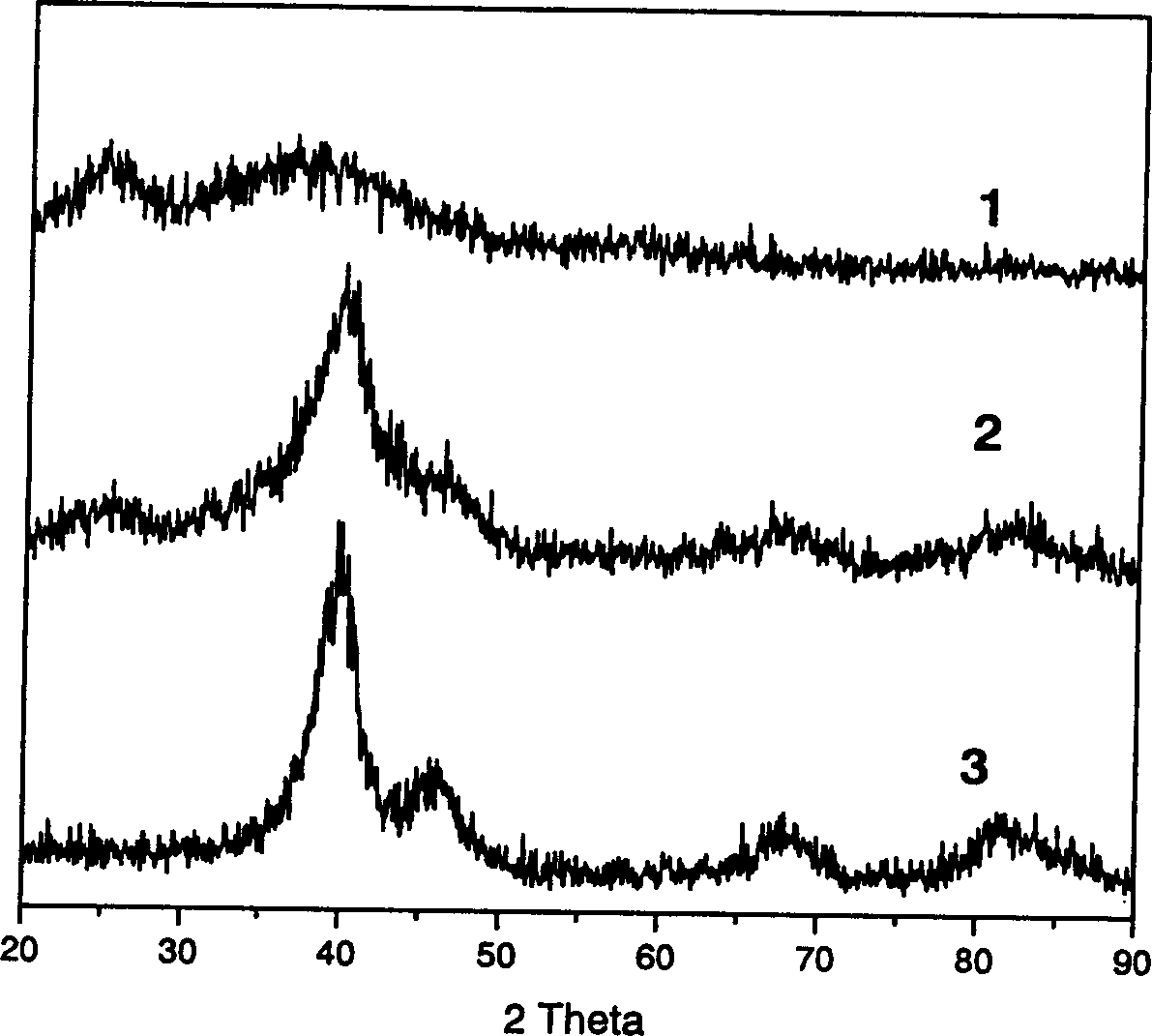

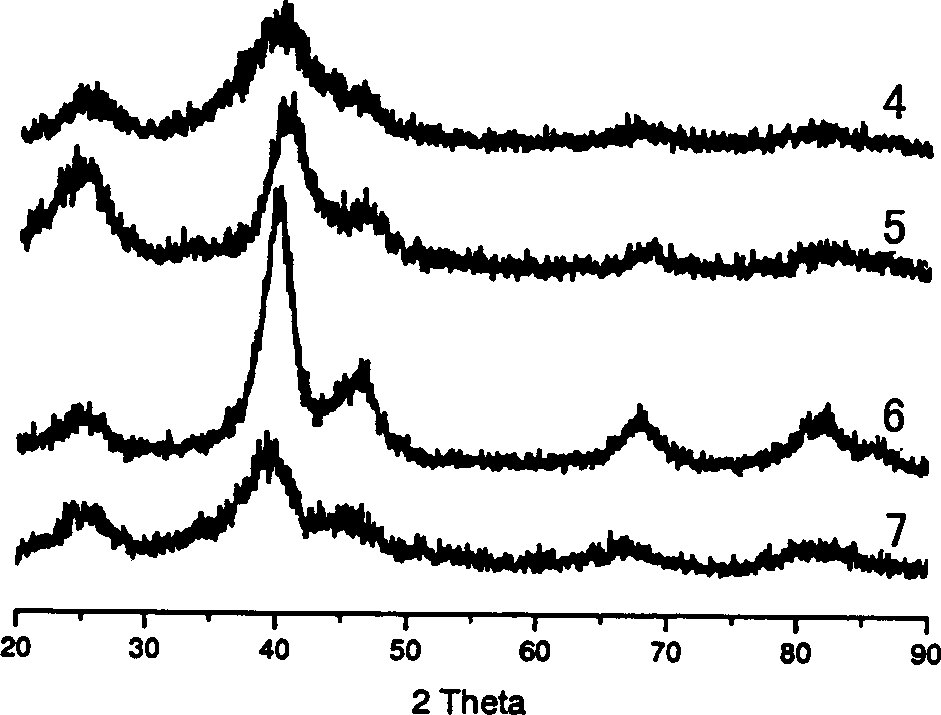

Prep. of high-load bi-and multi-component precious metallic catalyst

InactiveCN1448216AHigh metal utilizationEasy to operateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsChemistryPrecious metal

The present invention is preparation process of two-component and multiple-component loaded catalyst with relatively high loaded amount and containing noble metal(s) of Pt, Pd, Ru, Os, Ir, Rh, Re, etc. and other transition metal(s). By means of altering the solvent composition in dispersion system, raising the viscosity of solvent and lowering the diffusion rate of metal particles inside the solution effectively, it is possible to prevent the mutual polymerization and enlarging of metal particles without adopting macro molecule surfactant in preparing two-component and multiple-component loaded nanometer-level noble metal-based catalyst with high dispersivity and great loaded amount. Several kinds of metal may be loaded onto the carrier in once process while ensuring high metal dispersivity even in case of high metal loading amount.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

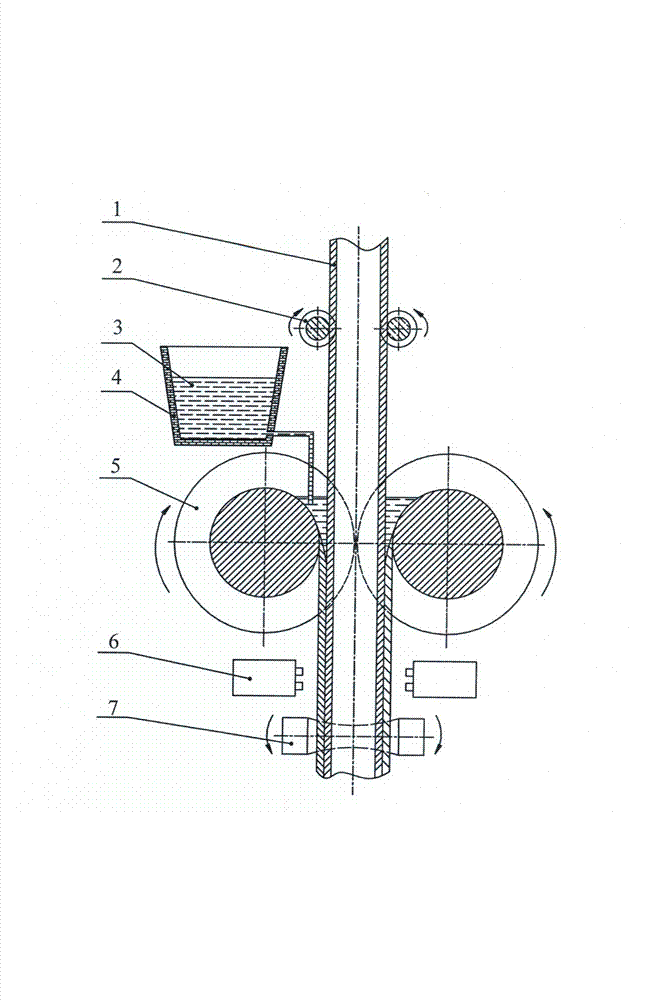

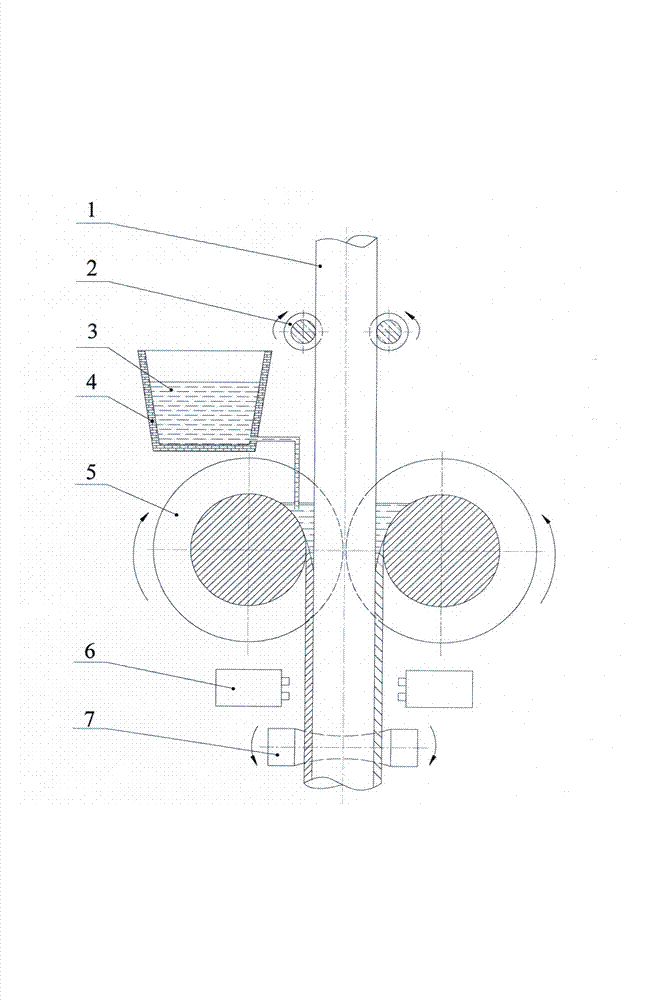

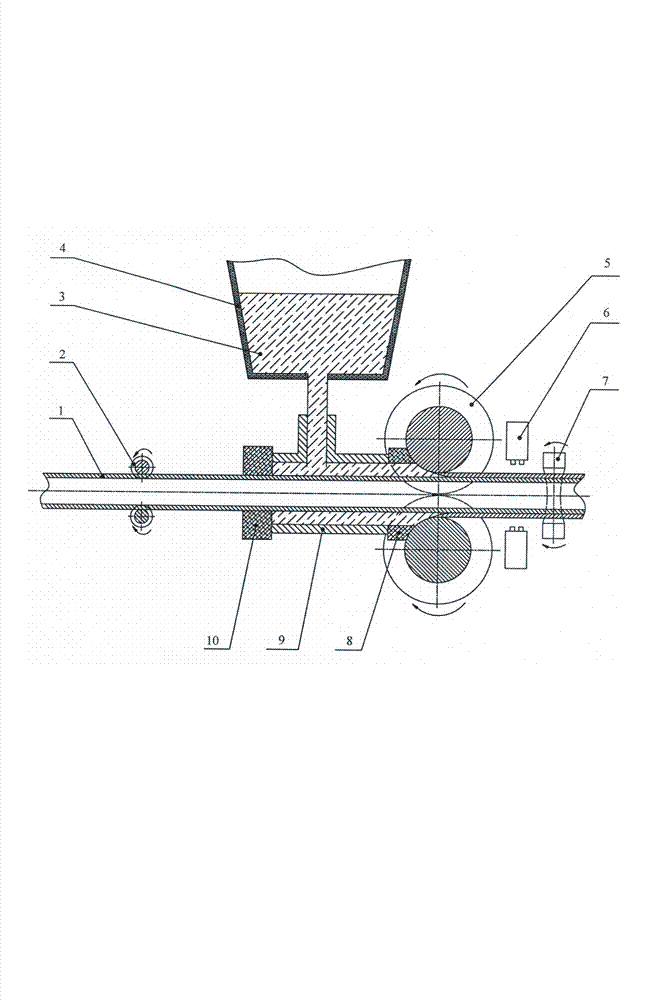

Method for producing bimetal composite material by adopting cold core continuous casting and rolling process

ActiveCN102825067ALow requirements for billet size and shape accuracyHigh yield and metal utilizationMetal rolling arrangementsManufacturing engineeringPipe

The invention relates to a method for producing a bimetal composite material by adopting a cold core continuous casting and rolling process. The method is characterized by comprising the following steps of: using an inlet pinch and guide device to feed a cold core base material into a groove of a casting and rolling roller, continuously pouring a molten-state covering material in a ladle into an annular crystallizer constituted by the base material and the groove of the casting and rolling roller, driving the casting and rolling roller, continuously and uniformly coating the molten-state covering material on the surface of the cold core base material, and arranging a secondary cooling device and an outlet pinch and guide device on the outlet side so as to realize cold core continuous casting and rolling composite molding of a bimetal composite pipe or rod. The method has the advantages that the bimetal composite pipe or rod produced by the technological method has the advantages of low requirements on size and shape precision of a stock, no need of pre-assembly, high finished product rate, high metal utilization rate, no limitations on length and thickness of a covering layer of a product, a wide range of specifications of the product and the like, and the method is of a high-efficient production technological method. The product can be directly used as a finished product or be used as the stock for pipe rolling, cold drawing and other process steps.

Owner:YANSHAN UNIV

Metallurgical bonding double-metal stainless steel cladding reinforcing steel bar and preparation process thereof

InactiveCN106825515AHas comprehensive mechanical propertiesHigh strengthInduction heaterSS - Stainless steel

The invention discloses a metallurgical bonding double-metal stainless steel cladding reinforcing steel bar and a preparation process thereof. The metallurgical bonding double-metal stainless steel cladding reinforcing steel bar comprises a carbon steel core part and a stainless steel cladding. The composite forming process comprises the following steps: integrally heating an outer-layer stainless steel pipe to 600 to 1000 DEG C by using an induction heater, pouring into inner-layer carbon steel, performing metal liquid casting and manufacturing an interface metallurgical bonding cladding type double-metal composite blank; hot-rolling the cast double-metal blank to form cladding double-metal round steel and threaded steel. The metallurgical bonding interface of the stainless steel layer and the carbon steel core is formed by casting, and the advantages of high bonding strength, excellent processing property, dense structure, high quality, few procedures, low cost, high efficiency and the like are achieved. The integral stainless steel reinforcing steel bar is replaced by the double-metal reinforcing steel bar, so on the premise of guaranteeing the corrosion-resistant characteristic of the reinforcing steel bar, the stainless steel material is saved, the engineering cost is reduced, the strength of the reinforcing steel bar is effectively improved, waste of resource and energy and environmental pollution are reduced, and a wide application prospect is achieved.

Owner:丹阳恒庆复合材料科技有限公司

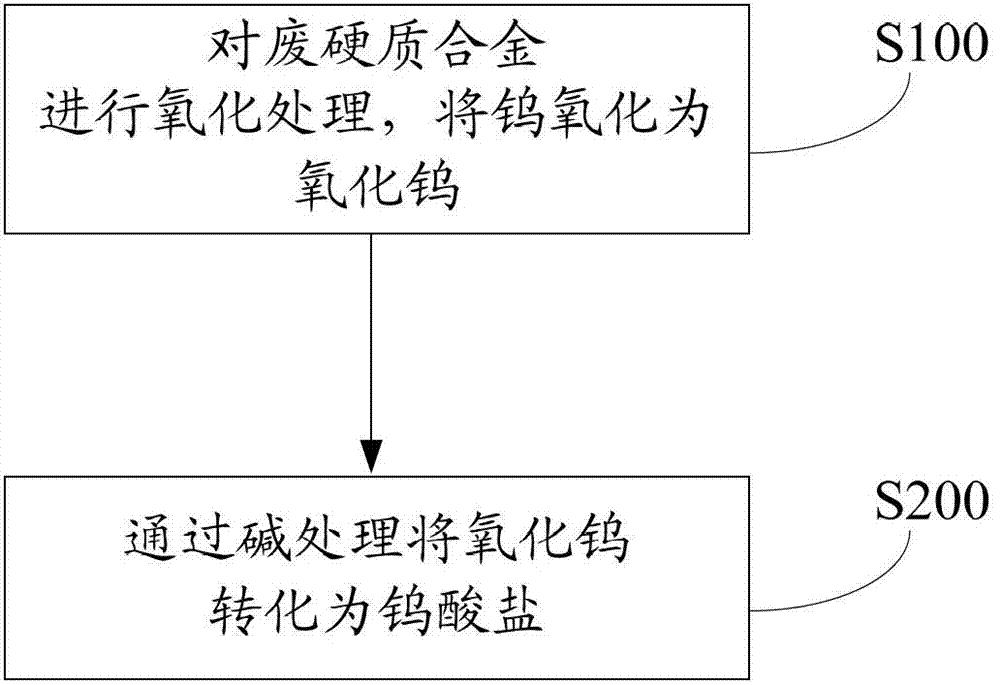

Method for treating waste hard alloy

InactiveCN102925692AHigh recycling valueImprove oxidation efficiencyProcess efficiency improvementCemented carbideTungstate

The invention provides a method for treating waste hard alloy. The method comprises the following steps of: oxidizing the waste hard alloy to convert tungsten into tungsten oxide; and reacting the oxidized waste hard alloy with alkali to convert the tungsten oxide into tungstate. By the method, the waste hard alloy can be effectively treated.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

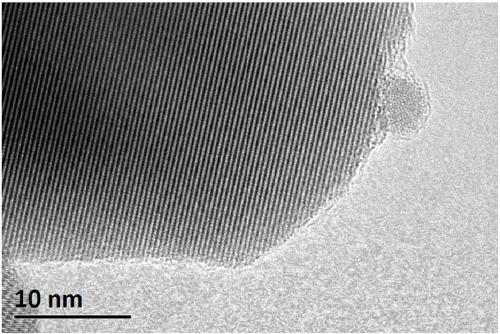

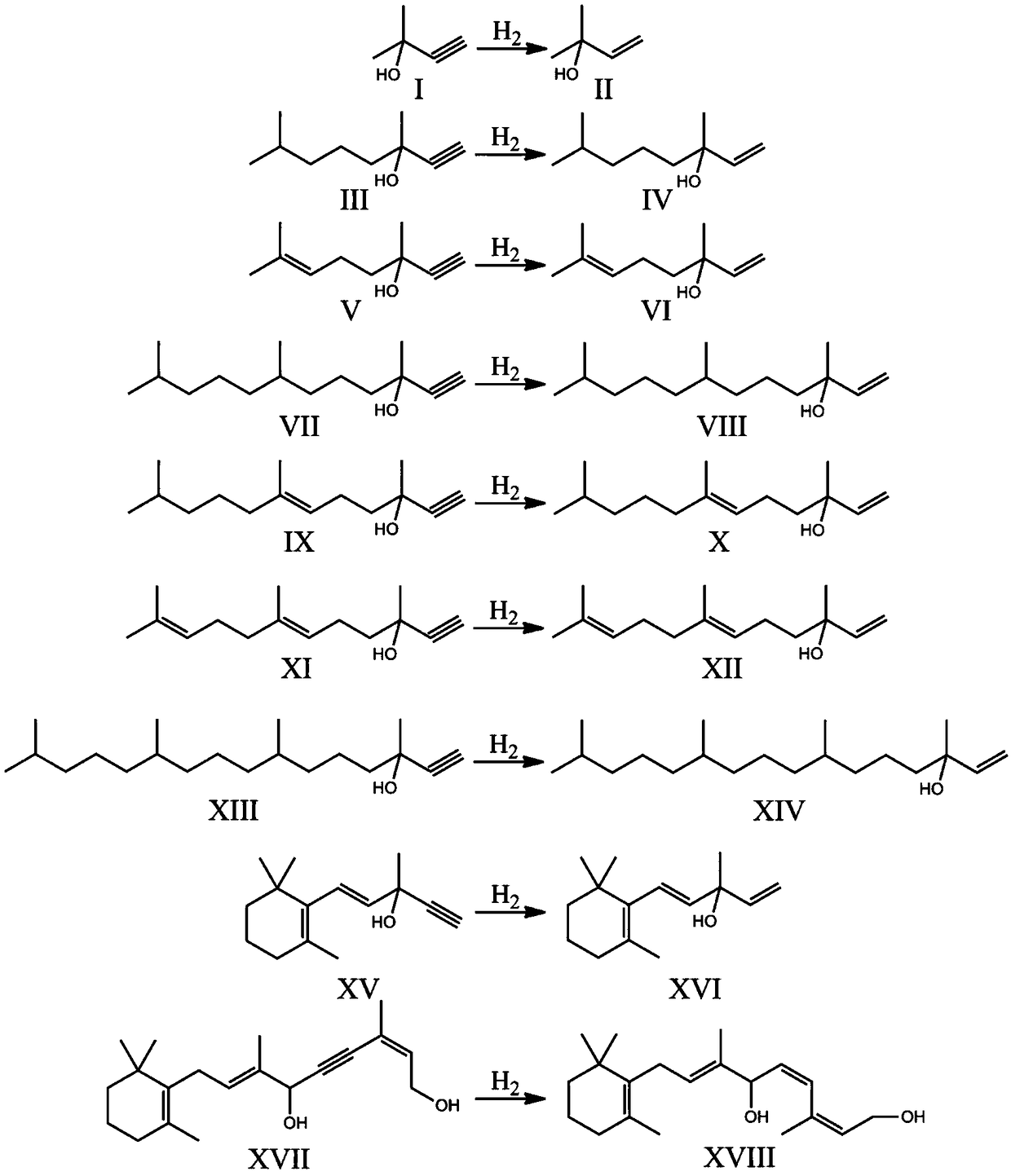

Alkynol selective hydrogenation catalyst as well as preparation method and application thereof

ActiveCN109317175AWide variety of sourcesEasy to preparePhysical/chemical process catalystsPreparation by hydrogenationReduction treatmentPorous carbon

The invention discloses a preparation method of an alkynol selective hydrogenation catalyst. The preparation method comprises the following steps: (1), agitating and mixing a nitrogen-containing biomass with a surfactant, next adding an indium-containing metallic salt and acid liquor, mixing uniformly, and then performing drying and high-temperature calcination to obtain an indium oxide compoundednitrogen-doped porous carbon material; and (2), impregnating the indium oxide compounded nitrogen-doped porous carbon material in a Pd precursor solution, and then performing agitation, oven-drying,calcination and hydrogen reduction treatment in sequence to obtain the alkynol selective hydrogenation catalyst. The invention also discloses the alkynol selective hydrogenation catalyst prepared by the preparation method and application of the alkynol selective hydrogenation catalyst to an alkynol selective hydrogenation reaction in a vitamin industrial chain. The preparation method is simple; the prepared alkynol selective hydrogenation catalyst is compact in structure; nano particles of a Pd-In alloy are highly dispersed; and the alkynol selective hydrogenation catalyst has excellent catalytic performance.

Owner:ZHEJIANG UNIV

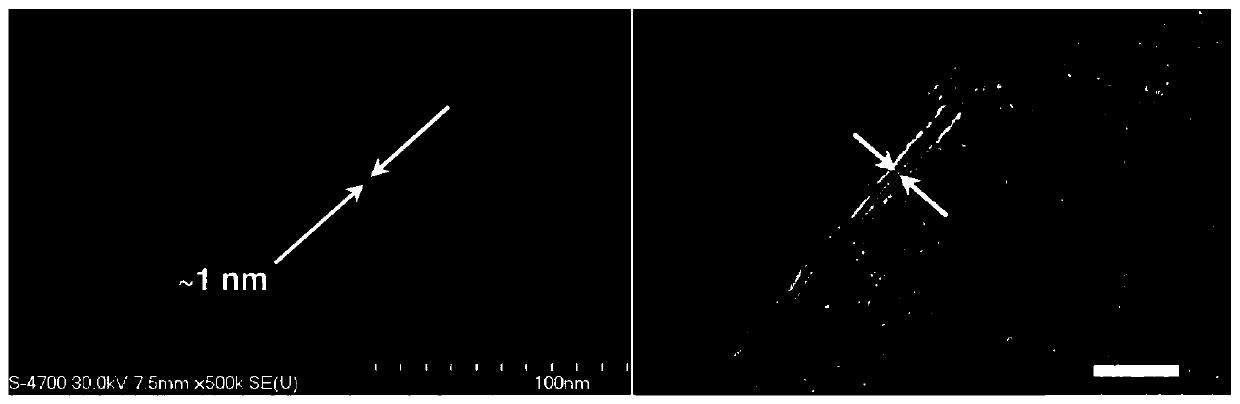

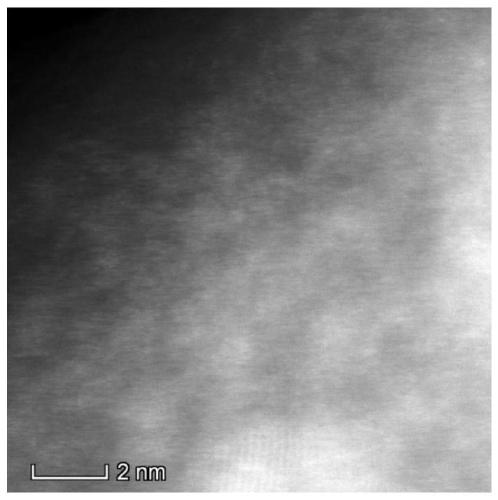

Upright few-layer graphene-metal nanoparticle composite catalytic electrode

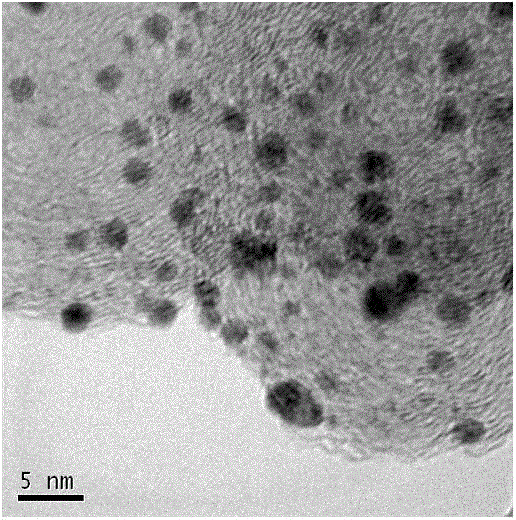

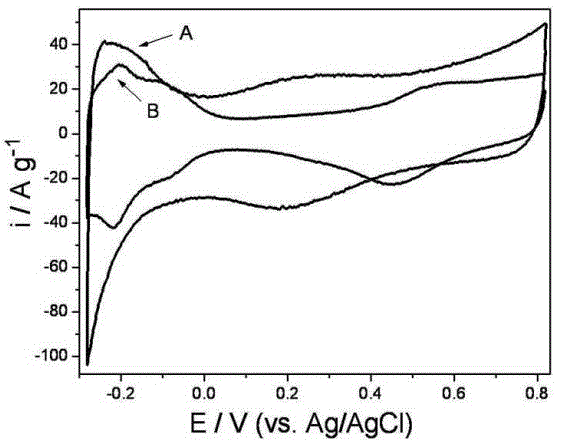

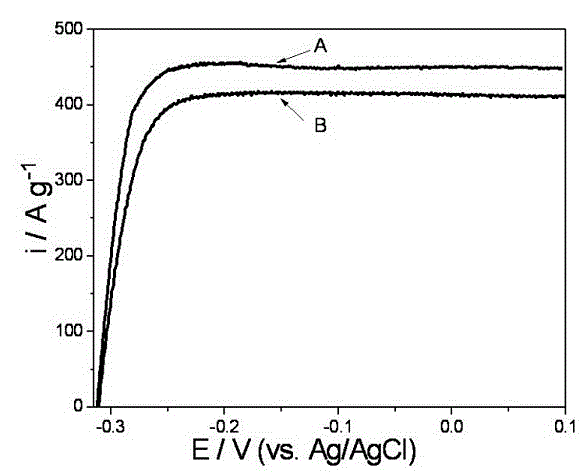

ActiveCN110550597AImprove conductivityHigh specific surface areaTelevision system detailsImpedence networksCvd grapheneAmount of substance

The invention discloses a substance structure taking metal nanoparticle modified upright few-layer graphene as a nano-electrode and a preparation method of the substance structure. Upright few-layer graphene is called upright graphene for short, is obviously different from other carbon materials, and has the characteristic of great available surface. The metal nanoparticles are uniformly distributed on the surface of the upright graphene through a physical vapor deposition method, the average diameter of the particles can be controlled within the range of 0.5-100 nanometers, the coverage ratecan be controlled within 0-100%, and the particles are connected with the surface of the graphene through chemical bonds, so that the adhesive force is high, and the conductivity is good. The particles can be gathered at the edge of the graphene. The nanoelectrode has the advantages of improving the utilization rate of noble metal and increasing the catalytic efficiency, so that the noble metal consumption and the industrial cost are greatly reduced. The preparation method is energy-saving, efficient, quick and cheap, is suitable for mass production, and can be widely applied to electrochemistry, analytical chemistry, biochemistry, medical treatment, environment and energy related industries.

Owner:SHENZHEN YICK XIN TECH DEV CO LTD

Aluminum alloy die-casting motor flange forming process

The forming process of aluminum alloy die-casting motor flange is characterized in that the specific process is: (1) smelting aluminum material, setting the temperature at 700-750 ° C, and purifying the molten aluminum; (2) spraying strong force on the surface of the mold cavity Release agent; (3) Pour the purified aluminum liquid into the mold cavity; (4) Adjust the various mechanisms and pressure gauges of the die-casting machine; (5) Die-casting; (6) A small amount of machining; (7) Inspection, Packaging and storage. Compared with the original centrifugal casting process, this technical solution can be directly formed, which reduces the subsequent processing allowance, reduces the cost, and ensures the quality stability of the product, avoids secondary environmental pollution, eliminates potential safety hazards, and improves The production efficiency is improved, the equipment is simple, and the labor intensity of the operators is reduced.

Owner:WUJIANG TIANLONG MACHINERY

Preparation method of catalyst for efficient gas-phase conversion of furfural into 2-methylfuran

InactiveCN110180553AEasy to produceImprove performanceOrganic chemistryHeterogenous catalyst chemical elementsAlkaline earth metalGas phase

The invention relates to a preparation method of a catalyst for efficient gas-phase conversion of furfural into 2-methylfuran, and relates to a catalyst preparation method, which specifically comprises: preparing a solution from a soluble Cu salt, one or two materials selected from Ni salts, Pd salts and Au salts, and one selected from alkaline earth metals or alkali metals such as Mg, Ca, Ba, Na,K and the like; adding a silica sol or orthosilicate or silica gel powder to a concentrated ammonia water solution, adding a certain amount of an aluminum sol, and stirring for 1-5 h; and adding theprepared salt solvent to the ammonia water colloid solution, further stirring for 1-6 h, carrying out heating evaporation, washing, and calcining to synthesize the novel catalyst for hydrogen transfergas-phase conversion of furfural into 2-methylfuran. According to the present invention, the production process is simple, and the prepared catalyst has stable performance and good repeatability; andthe alcohol is used as the hydrogen transfer reagent, such that various dangers caused by the use of hydrogen are overcome.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for vacuum auxiliary gravity pouring investment casting thin wall piece

The invention relates to a vacuum assisted gravity pouring fuse cast thin wall casting method. It fixes the baked fuse mold casting shell inside the container with sealing device between the shell and the container, capped the top cover of the container, adjusting the fixed device, forming enclosed space between the shell and the container, turning on the heating device to retain the temperature requirement if necessary, turning on the vacuum system to establish the vacuum degree, pouring metal fluid into the cavity after the generation of negative pressure inside the shell, closing the vacuum system, release the vacuum, cleaning the shell to get the complete casting piece. The equipment structure is simple, small in investment, convenient in operation, being able to improve the final product rate of the thin wall casting piece and metal utilization rate to reduce production cost.

Owner:TSINGHUA UNIV

Preparation method capable of modifying nickel-based ternary non-supported catalyst by adding aids PEG and SB powder

InactiveCN106925288AFine particle sizeHigh metal utilizationMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatment productsAmmonium metatungstateNickel based

The invention relates to a preparation method capable of modifying a nickel-based ternary non-supported catalyst by adding aids PEG and SB powder. Two different aids are introduced in the process of preparing a non-supported catalyst by a coprecipitation method and active components and the aids are combined, namely the PEG and the SB powder with different molecular weights are added into a mixed solution of nickel molybdate and ammonium metatungstate to serve as a dispersant surfactant and a dispersant correspondingly. According to the preparation method of the modified non-supported catalyst, the dispersing property of active metal components and the hydrogenation property of the catalyst can be improved effectively, the mechanical strength of the non-supported catalyst is remarkably improved, and the modified catalyst can meet the strict requirement of national standard on the deep desulfurization of diesel after hydrogenation reaction.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

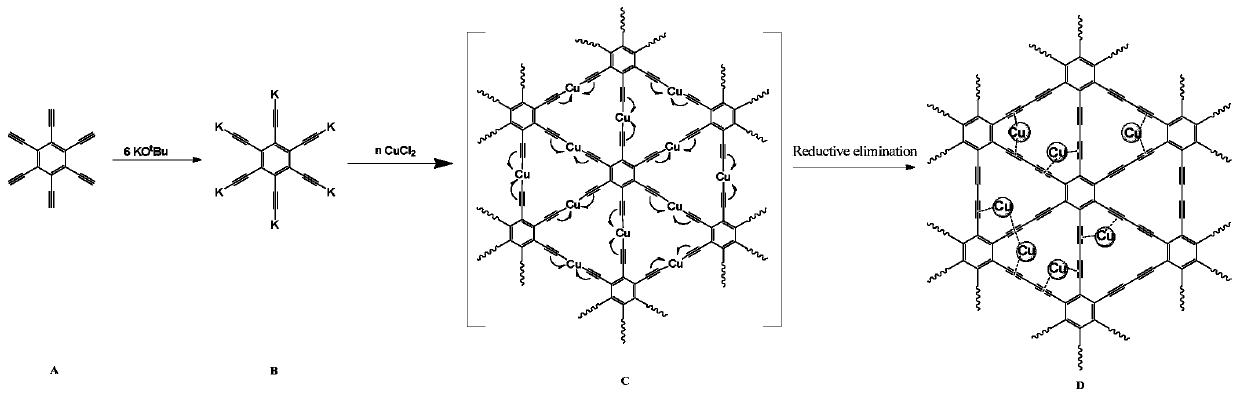

Metal monatomic catalyst and preparation method thereof

ActiveCN111389394AImprove general performanceSimple preparation processMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOrganic chemistry

The invention discloses a metal monatomic catalyst and a preparation method thereof. The preparation method comprises the following steps: under the protection of inert atmosphere, dissolving a polyacetylene compound in an aprotic solvent; adding organic strong base and a metal salt precursor under the condition of -40 DEG C or below, performing heating and stirring for reaction, and then carryingout solid-liquid separation to obtain a precipitate; and washing, drying and grinding the precipitate to obtain a target product. The preparation method of the metal monatomic catalyst is simple, short in synthesis period and high in universality, and the obtained metal monatomic catalyst is good in thermal stability and high in metal monatomic loading capacity.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA +1

Metallurgical bonding stainless steel cladding thermometal profile steel and preparing technology

The invention discloses a metallurgically bonded stainless steel-coated bimetallic section steel and its preparation process, which includes a carbon steel core and a stainless steel cladding. Its composite forming process includes using an induction heater to integrally heat the outer stainless steel pipe to 600-1000°C. The inner layer of carbon steel is poured into molten metal and cast to produce a clad bimetal composite billet with a metallurgical bonding interface; the cast bimetal billet is hot-rolled into a clad bimetal steel section. The metallurgical bonding interface between the stainless steel layer and the carbon steel core is formed by melting and casting, and has the advantages of high bonding strength, excellent process performance, dense structure, good quality, few processes, low cost, and high efficiency. The present invention uses bimetallic section steel to replace the integral stainless steel section steel. On the premise of ensuring the corrosion resistance properties of the section steel, it not only saves stainless steel materials and reduces project costs, but also effectively improves the strength of steel bars, reduces waste of resources and energy and environmental pollution, and has Broad application prospects.

Owner:丹阳恒庆复合材料科技有限公司

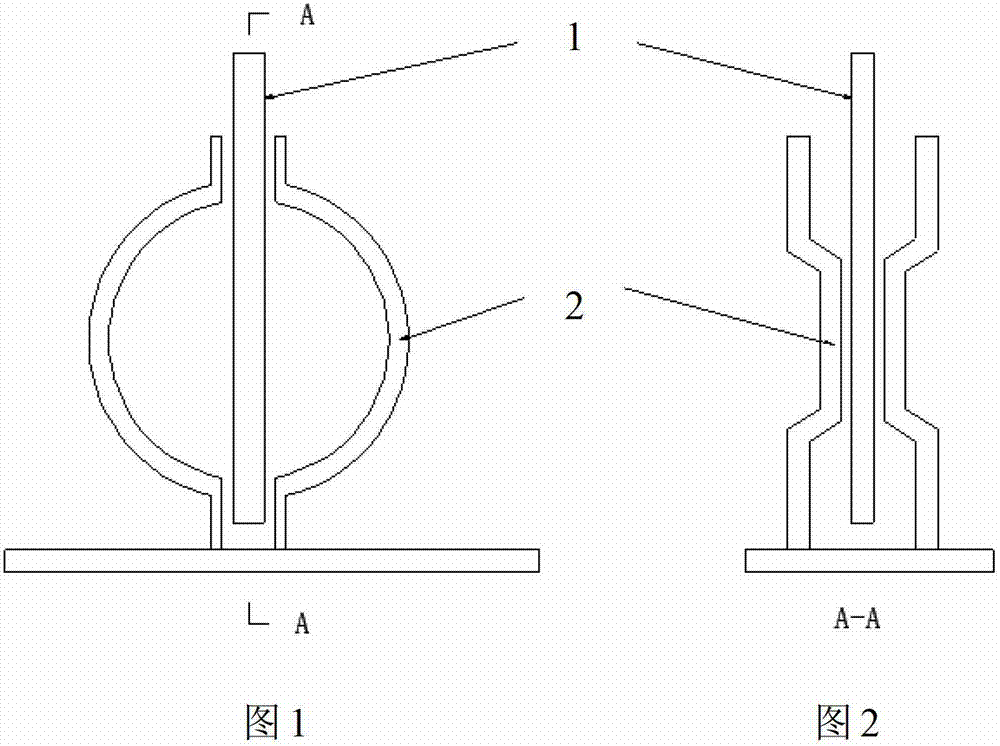

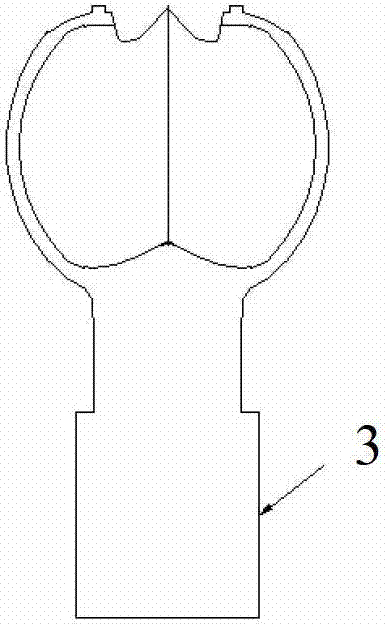

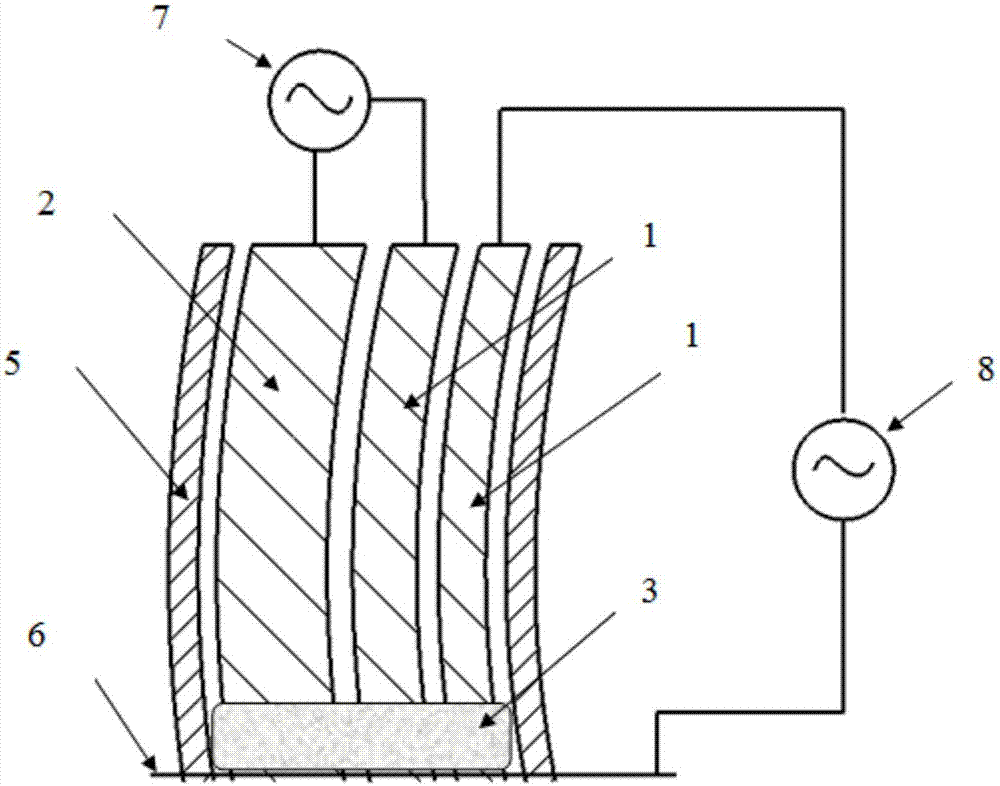

Electroslag fusion casting manufacture method of rotating wheel blanks of impact type hydraulic generator

ActiveCN102756111AImprove qualityEasy for CNC machiningFurnace typesHeat treatment furnacesElectricityManufacturing technology

The invention relates to the manufacture field of impact type rotating wheels, and in particular relates to an electroslag fusion casting manufacture method of rotating wheel blanks of an impact type hydraulic generator. The electroslag fusion casting manufacture method is an electroslag fusion casting technology for impact type rotating wheel integral casting blanks and individual rotating wheel water tank blanks. According to the method, self-consumable electrodes and the electroslag fusion casting technology are adopted; the rotating wheel integral casting blanks are produced by rotating wheel integral casting circular type blank crystallizers under an integral structure or an individual combined structure; and the individual rotating wheel water tank blanks are produced by rotating wheels water tank crystallizers under the integral structure or the individual combined structure. With the adoption of the method, the shortcomings of the current production technology of high water head impact type rotating wheel blanks can be solved; the near net forming impact type rotating wheel integral casting blank manufacture technology and the individual rotating wheel water tank blank manufacture technology are adopted; the produced rotating wheel blanks and the water tank blanks are high in fatigue resistance, high in crack generation and expansion resistance, long in service lives and high in use safety; and the quality and performance of the produced rotating wheel blanks and the water tank blanks are in line with those of forged blanks obtained by using the same materials; and the method has the advantages of low production cost, short production period and the like.

Owner:沈阳市盛华特种铸造有限公司

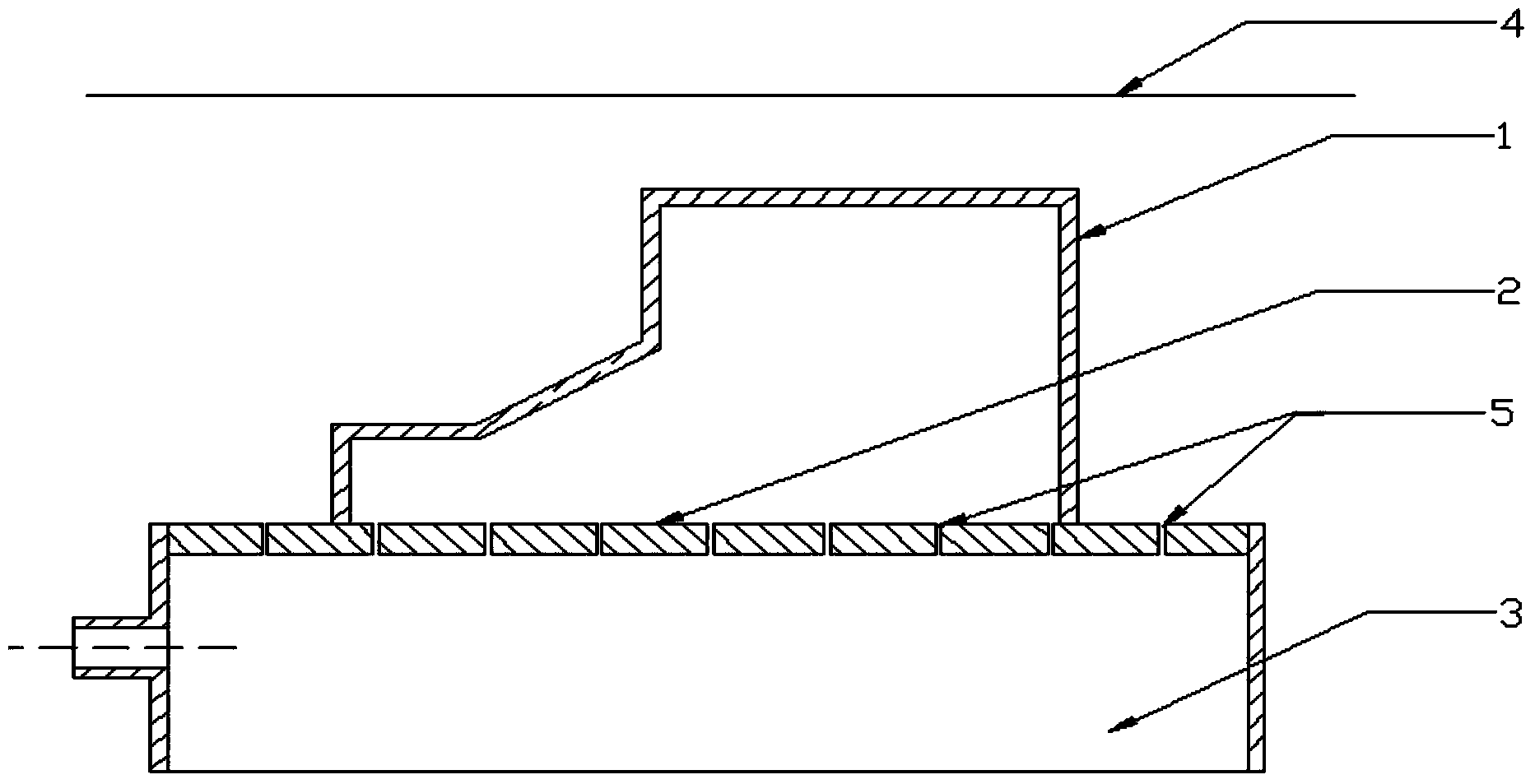

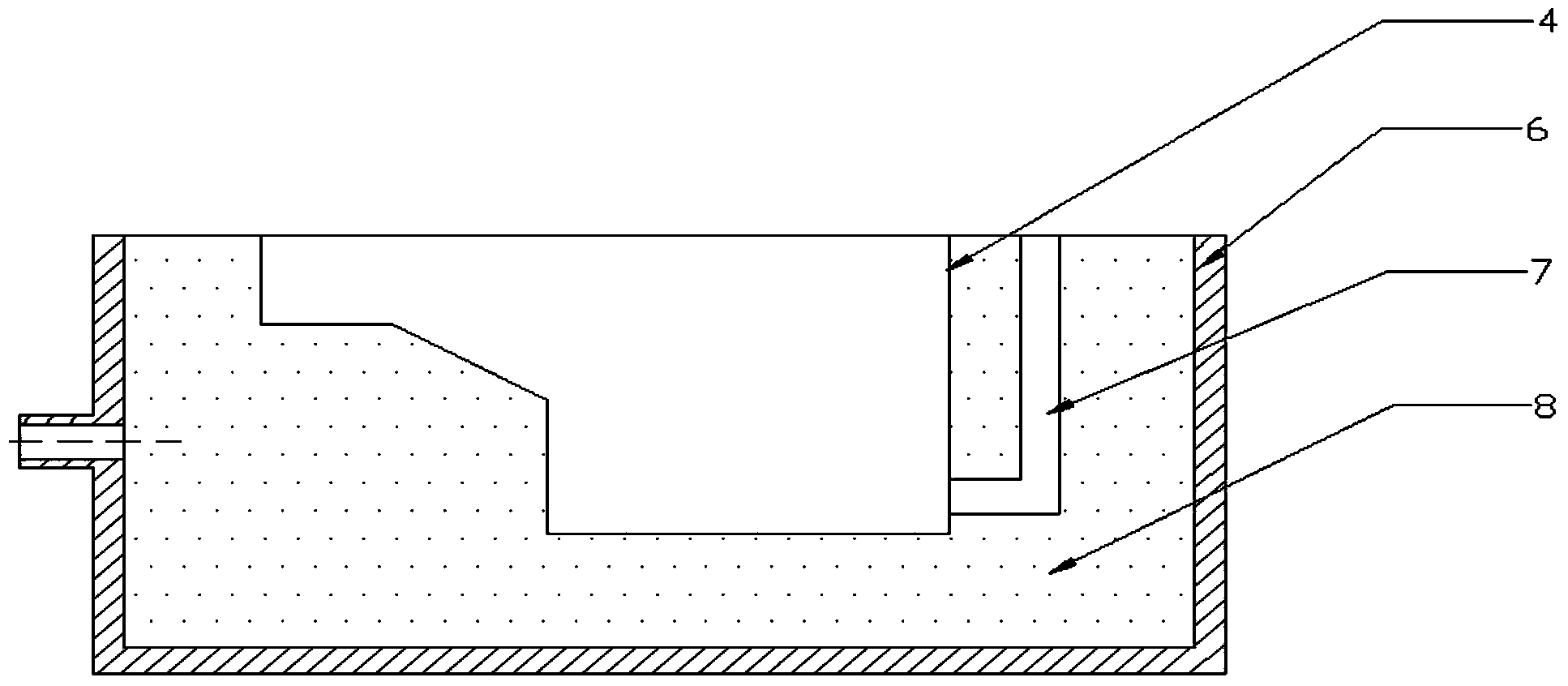

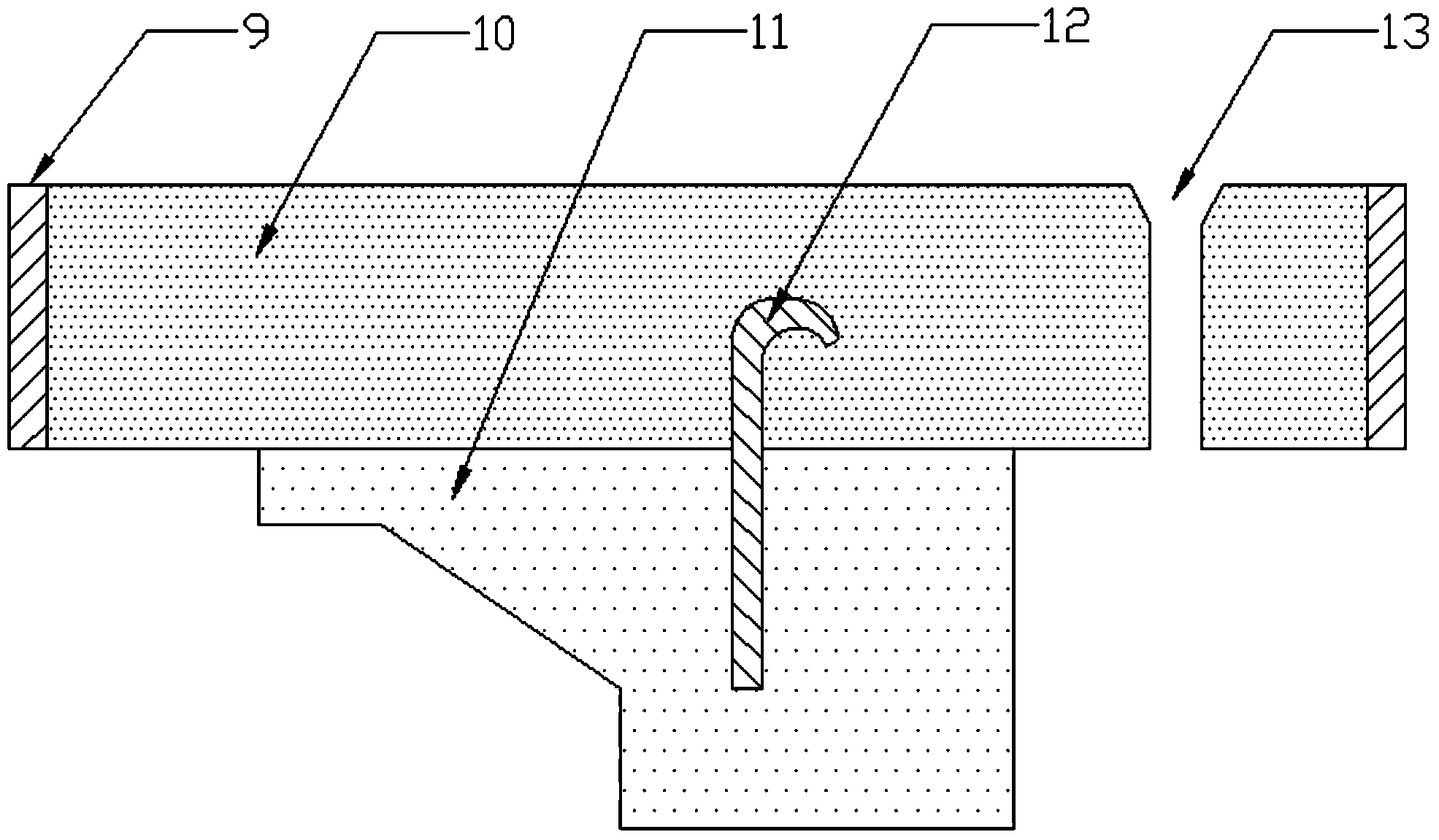

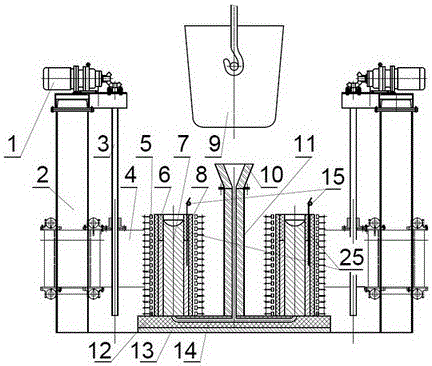

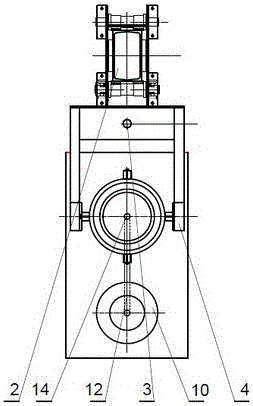

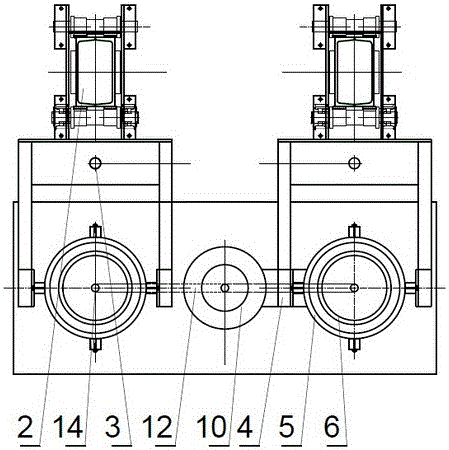

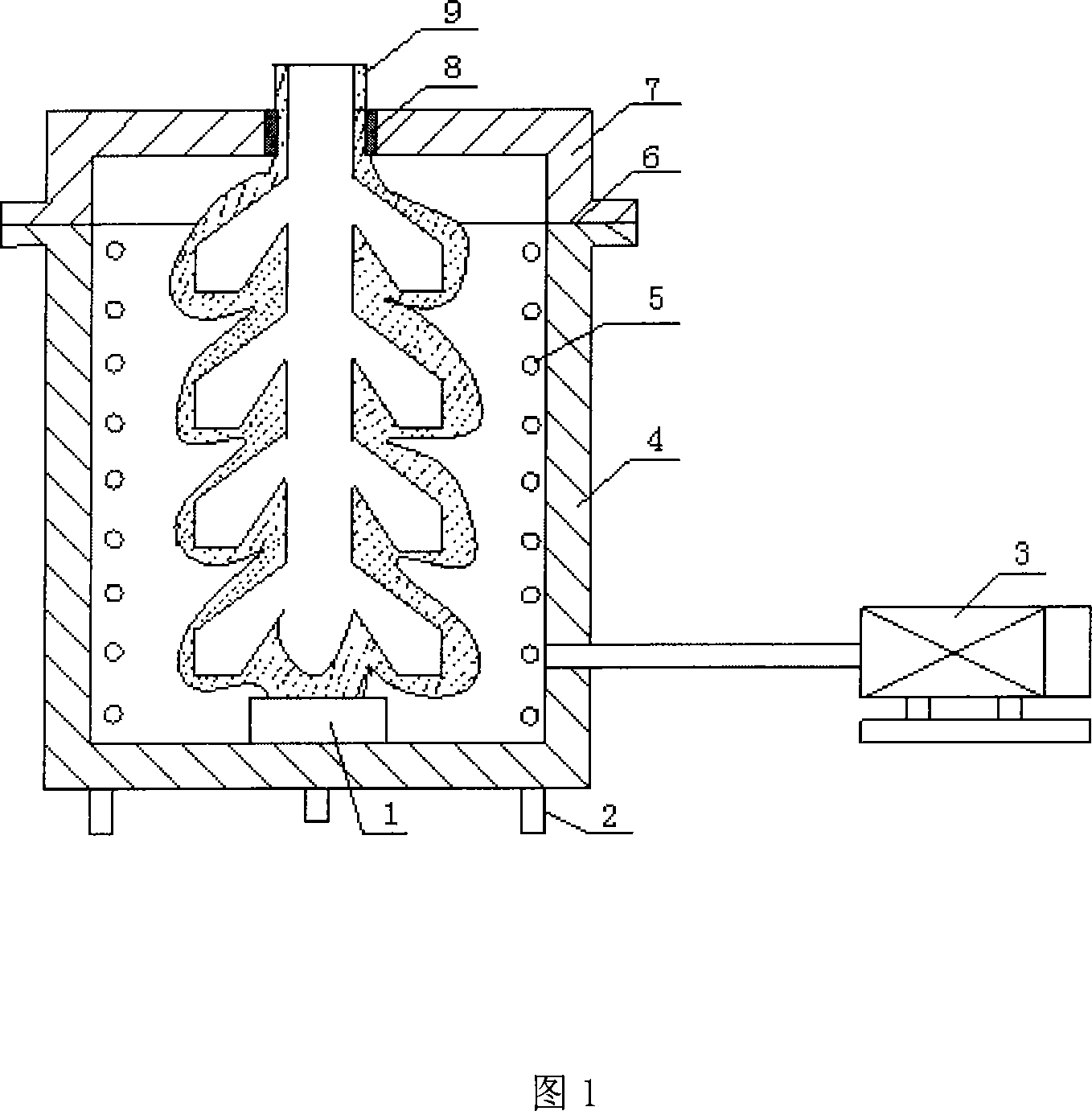

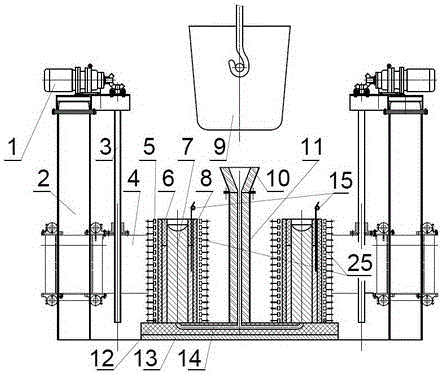

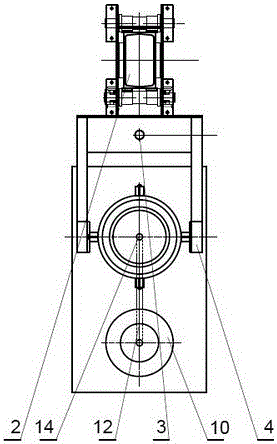

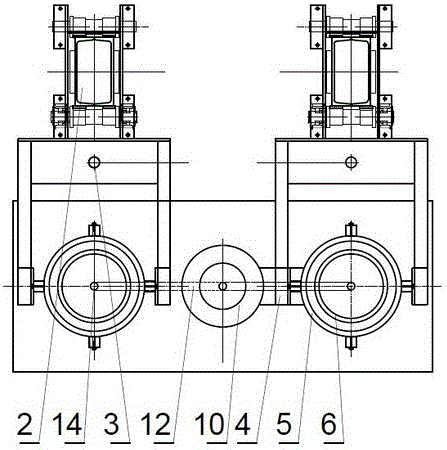

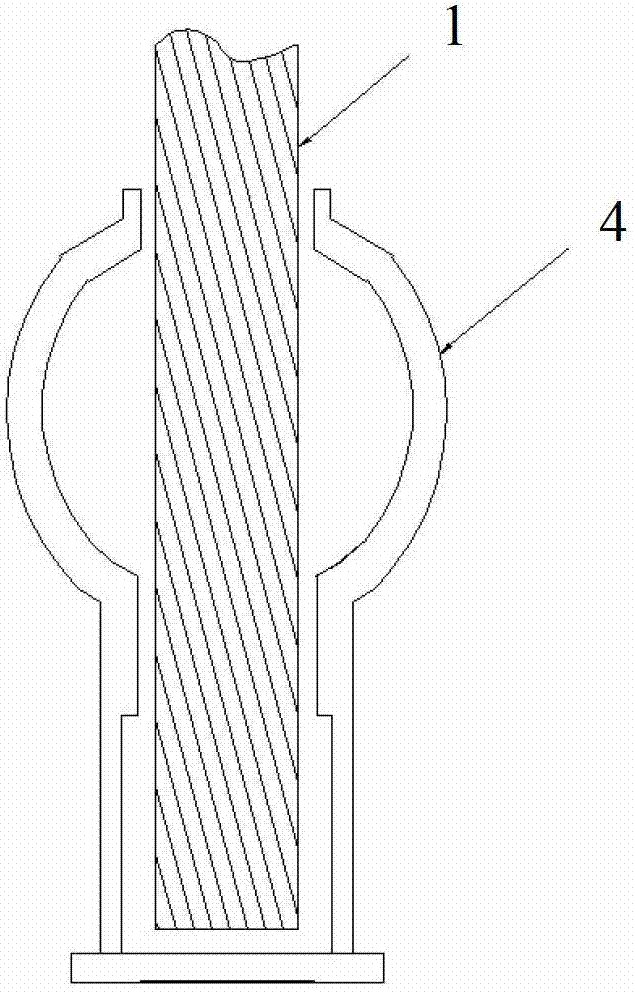

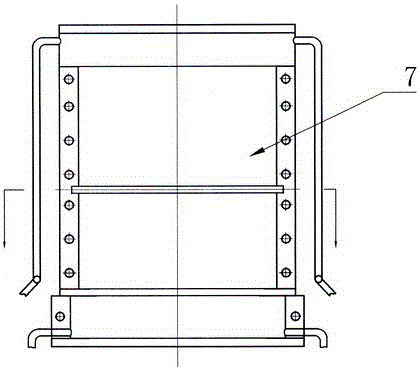

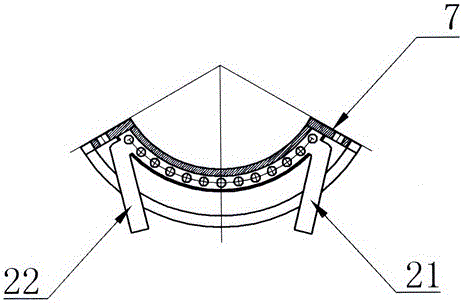

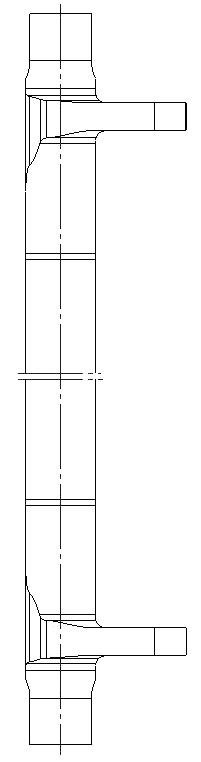

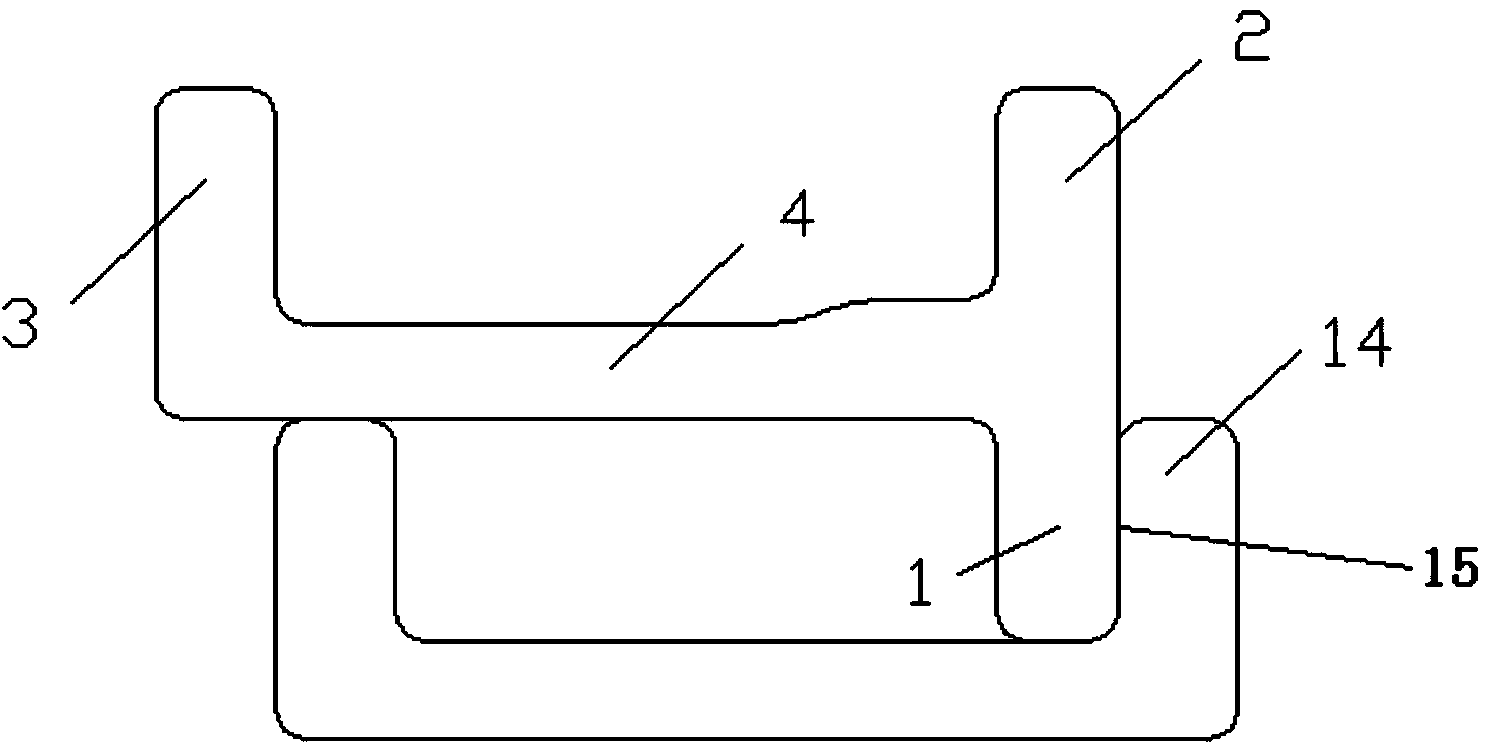

Manufacturing technology of composite roll sleeve, and equipment

The invention discloses a manufacturing technology of a composite roll sleeve, and equipment. The manufacturing technology comprises the steps of integrally heating a thick-wall hollow steel tube core rod mounted in a combined water-cooling crystallizer to be 800-1000 DEG C by an induction heater, pouring a roll shaft working layer melt, continuing to heat for 10-50min, starting a lifting device to lift the heater at a certain speed, stopping lifting when the heater is lifted to a heat preservation ring by 5-15min, continuing to heat for 10-50min, feeding a feeder head, and supplying water to cool for 30min-24h after heating stop. The composite roll sleeve manufactured by the technology is few in controllable technology parameter; an interface of a composite layer is easy to control; the technology is simple; the efficiency is high; power consumption is low; the composite layer has no component segregation; the service life is long; the defects of structure segregation of a centrifugal method and poor performance and high cost of a traditional embedding method are overcome.

Owner:丹阳恒庆复合材料科技有限公司

MW grade wind-powered torsion shaft and preparation technology thereof

The invention aims to provide a torsion shaft for an aerogenerator, and an electroslag refusion casting method thereof, and the torsion shaft combines technical advantages of arc metallurgy and technical advantages of electroslag refusion casting (ESRC). A casting produced by adopting the preparation technology of the MW grade wind-powered torsion shaft provided in the invention has the advantages of uniform and compact crystal tissue, high purity, less nonmetallic inclusions, possessing of excellent compactness and fatigue resistance, reaching of forging flaw detection quality standards, realization of near net-shape forming, and low cost. The internal quality of the produced torsion shaft is obviously better than that of torsion shafts produced through sand casting.

Owner:SHENYANG RES INST OF FOUNDRY

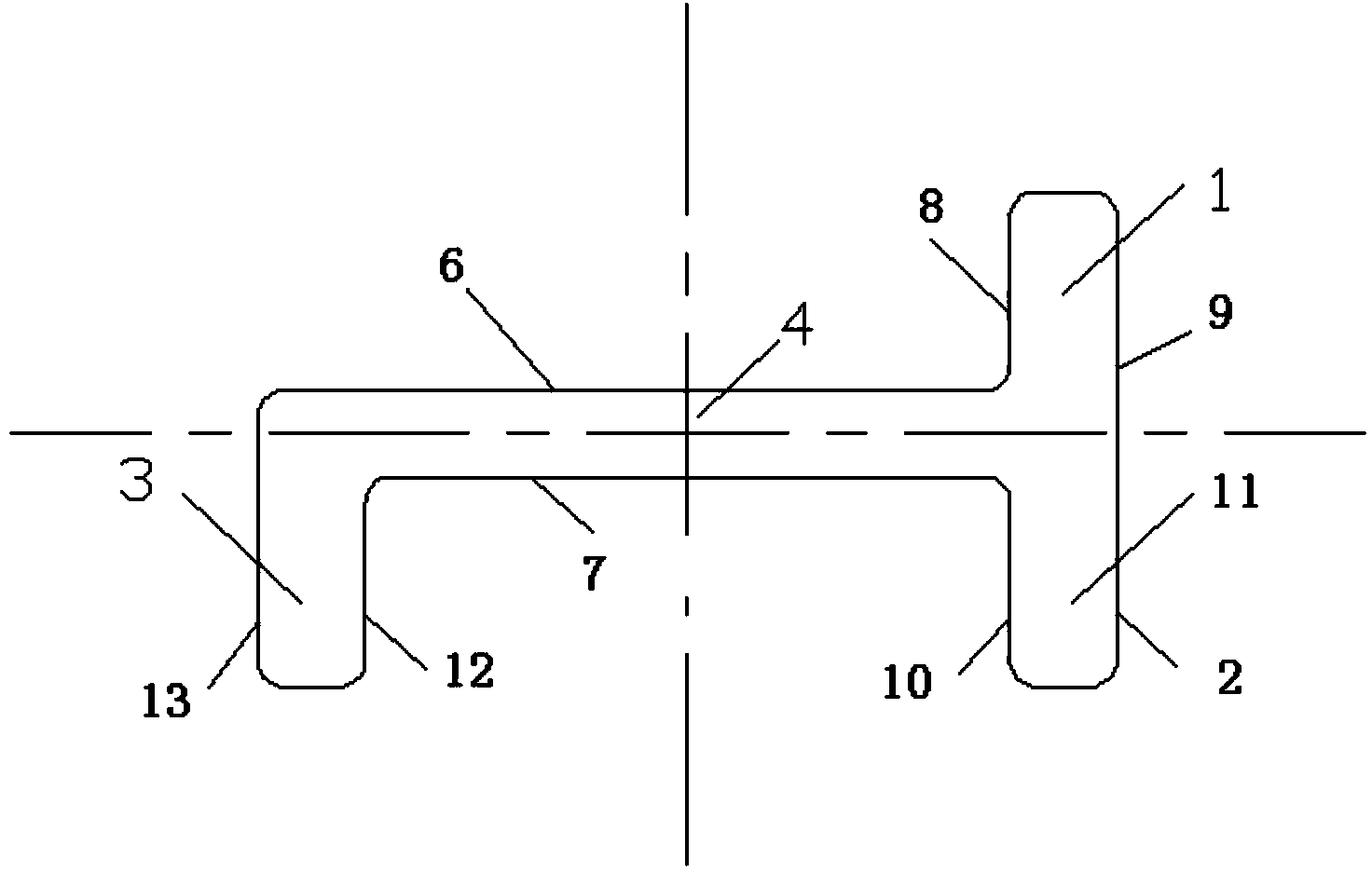

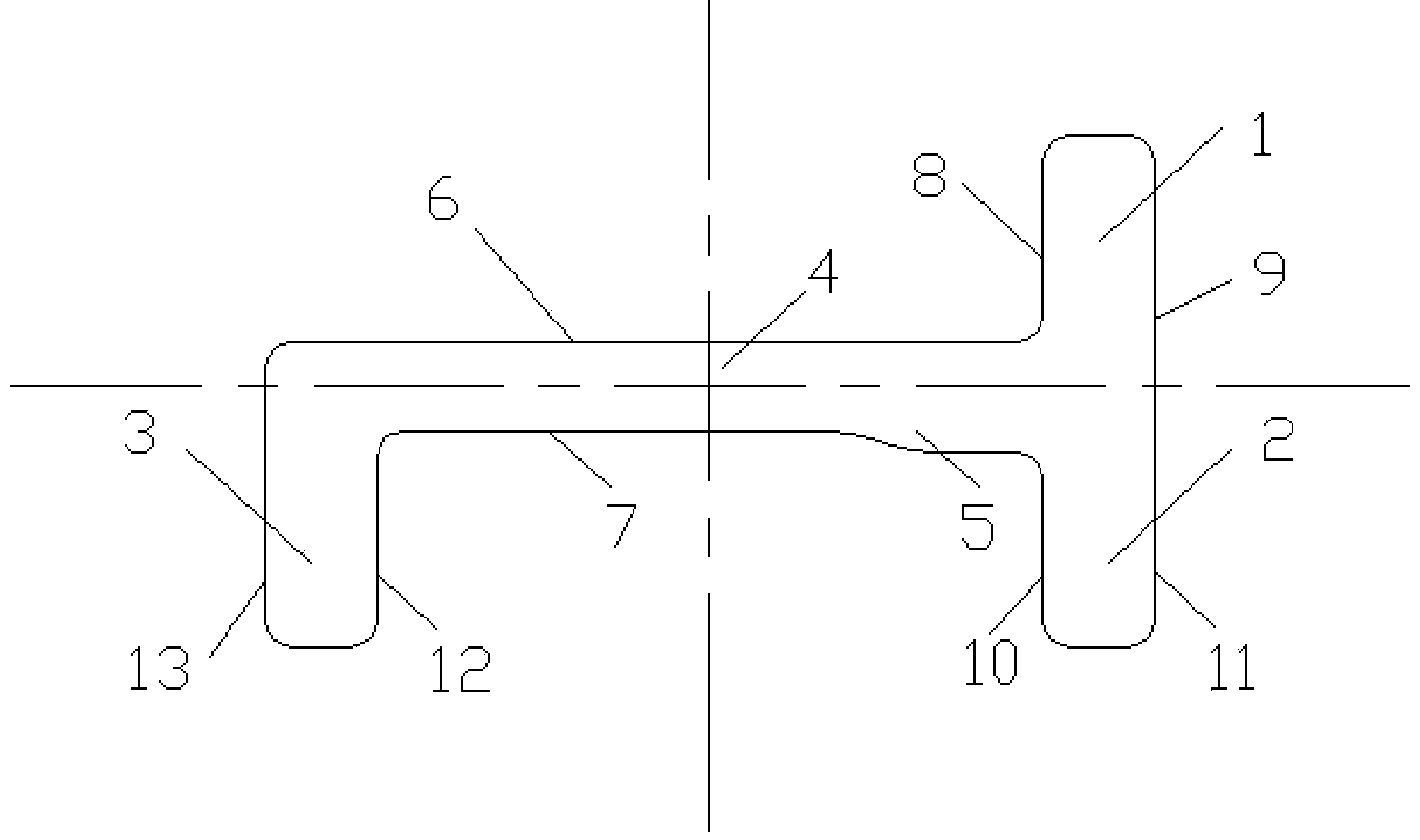

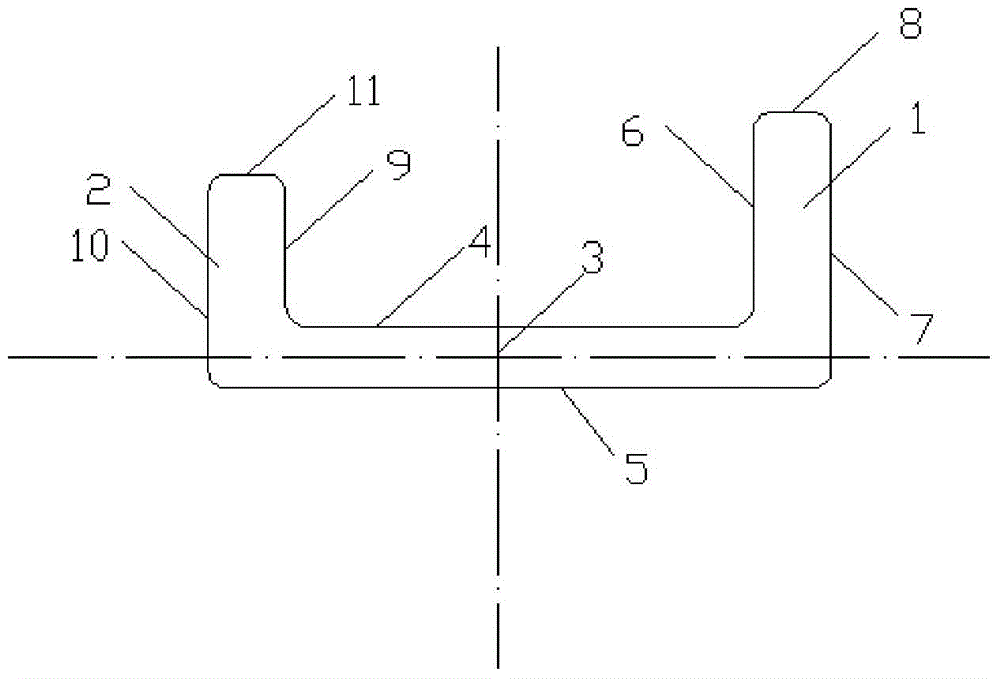

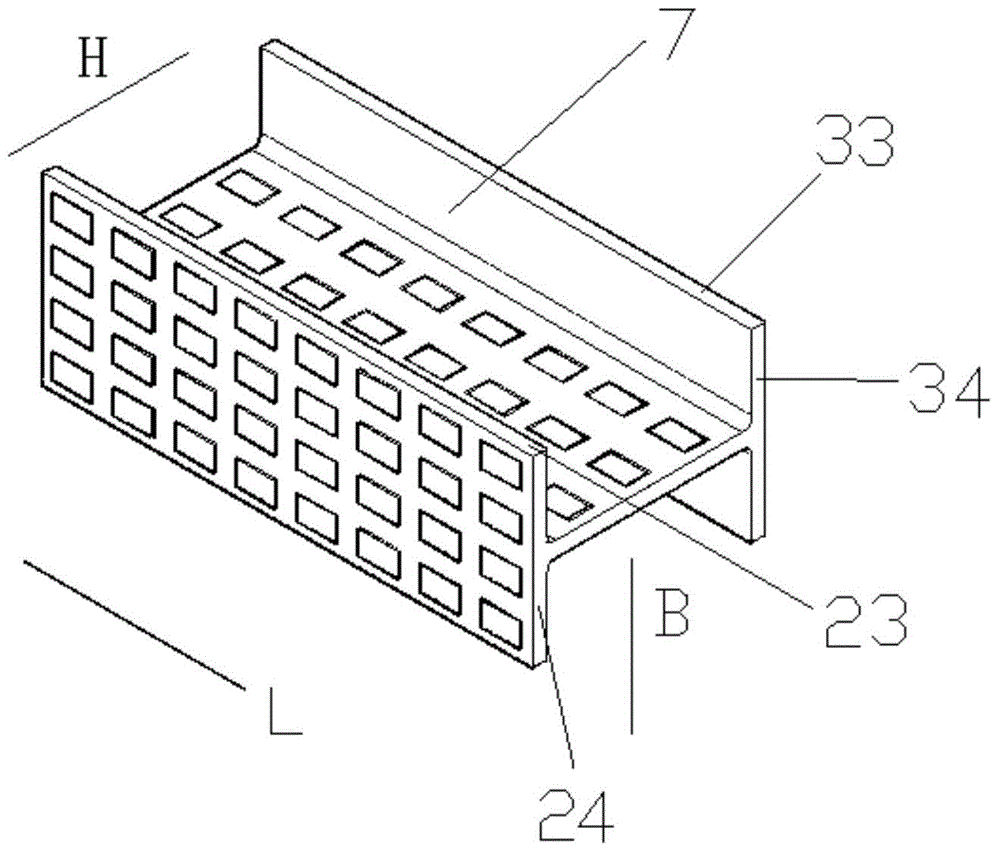

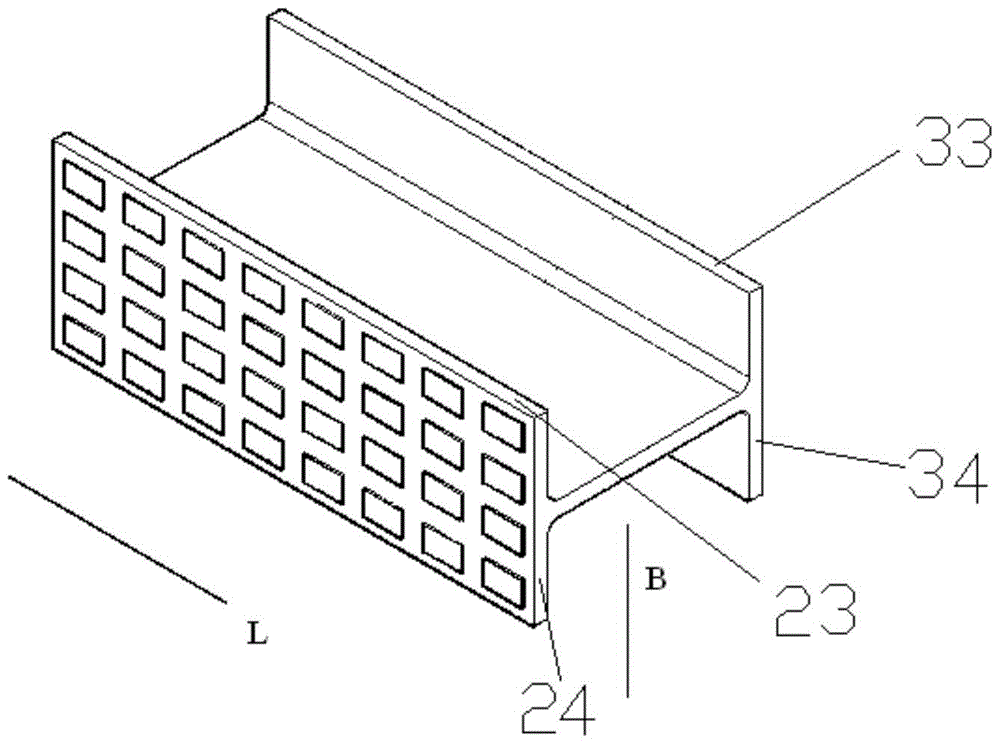

Hot-rolled J-type steel and application of hot-rolled J-type steel

The invention relates to hot-rolled J-type steel which comprises a web plate and wing plates. The wing plates include the first wing plate, the second wing plate and the third wing plate. The two ends of the web plate are connected with the first wing plate and the third wing plate respectively, the first wing plate and the third wing plate are located on the same side of the web plate, are mutually parallel and are perpendicular to the web plate, the second wing plate is connected with the first wing plate and connected with the end portion of the web plate, and the second wing plate and the first wing plate are located on the same vertical plane and also perpendicular to the web plate. The hot-rolled J-type steel is used for manufacturing forklift portals, in the hot-rolling production process, a groove is not required to be formed in a finish-rolling plain roller, the first wing plate and the second wing plate are located on the same vertical plane, and therefore the size, the position and the appearance of the formed groove are easily controlled; compared with existing hot-rolled J-type steel, the hot-rolling production difficulty is reduced, a hot-rolling technical device is simplified, the investment cost is reduced, the hot-rolling production efficiency is greatly improved, the rigidity of a formed-steel structure is improved, and the production cost is reduced.

Owner:LAIWU IRON & STEEL GRP

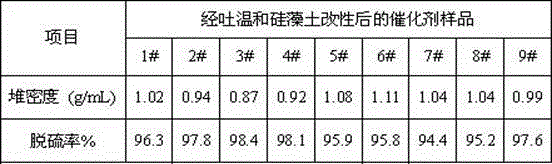

Preparation method for modified ternary metal bulk phase catalyst added with accessory ingredients

InactiveCN106824216AFine particle sizeSmall sizeHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsMolybdateAdditive ingredient

The invention relates to a preparation method for a modified ternary metal bulk phase catalyst added with accessory ingredients. Two different accessory ingredients are introduced into a process that a non-supported catalyst is prepared by a coprecipitation method, and active ingredients and the accessory ingredients are combined, i.e., tween and kieselguhr are added into a mixed solution of nickel molybdate and ammonium metatungstate to respectively serve as a dispersant surfactant and a dispersant. According to the preparation method for the modified non-supported catalyst provided by the invention, the dispersibility of active metal ingredients and the hydrogenation property of the catalyst can be effectively improved, the mechanical strength of the non-supported catalyst is obviously improved, and meanwhile, the strict requirement of the modified catalyst for the deep desulfurization of diesel by the national standard after hydrogenation reaction is carried out can be guaranteed.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

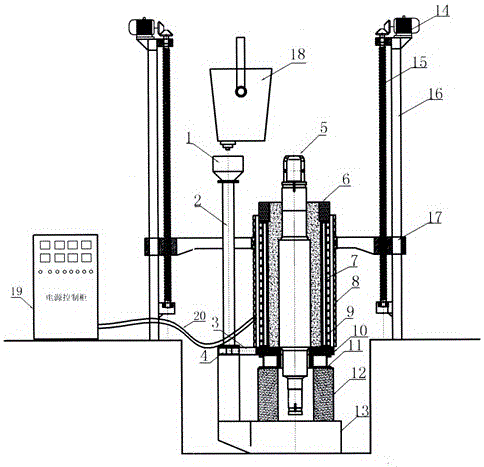

Turbine runner three-dimensional curved surface blade electroslag smelting casting direct forming method

The invention relates to the field of electroslag smelting casting production of turbine runner blade castings, in particular to a turbine runner three-dimensional curved surface blade electroslag smelting casting direct forming method. Electroslag smelting casting is used for completing secondary refining purification and casting near net forming of consumable electrode materials. The specific process comprises the following steps that 1) the structure form of a casting blank crystallizer is of an assembled type or a split type; 2) consumable electrodes in the smelting casting process consistof two parts, namely the fixed electrodes and the movable electrodes; and 3) a power supply mode adopts an alternating current single-electrode series loop and double-electrode series loop mixed power supply mode, by means of a power loop formed between double-electrode series electrodes, the slag layer temperature of an electroslag smelting casting area is increased, the metal fluidity of the area is improved, the solidification speed of the area is controlled, and blade smelting casting forming is achieved. The technology provided by the invention is applicable to manufacturing of the castings of tubular turbine generator runner blades or mixed-flow turbine generator runner blades or axial flow turbine generator runner blades.

Owner:沈阳市盛华特种铸造有限公司

Method for preparing cold-pressed ball for iron-making blast furnace and improving waste utilization rate

The invention discloses a method for preparing a cold-pressed ball for an iron-making blast furnace and improving a waste utilization rate. The method for preparing the cold-pressed ball comprises the following steps of S1, adding steelmaking precipitator dust, converter slurry fine particles and waste steelmaking suspended slurry into a powerful mixer to form basic mixtures; S2, letting the basic mixtures stand, and digesting for more than 24 hours; S3, adding iron-making gas ash when the mixtures after standing passes through a belt and an ash tank with a weighing device, remixing the mixture after entering a double-shaft stirrer, letting the mixtures stand for the second time and digesting for more than 24 hours; S4, adding a binder into the digested basic mixtures, and stirring the binder and the mixtures twice to form aggregate mixtures; S5, adding the aggregate mixtures into a ball press machine to prepare the cold-pressed ball; and S6, naturally stacking and airing a cold-pressed block for more than 24 hours. According to the method for preparing the cold-pressed ball for the iron-making blast furnace and improving the resource utilization rate of solid wastes, the waste of resources is reduced, and the metal utilization rate in the solid wastes is improved.

Owner:YANGCHUN NEW STEEL CO LTD

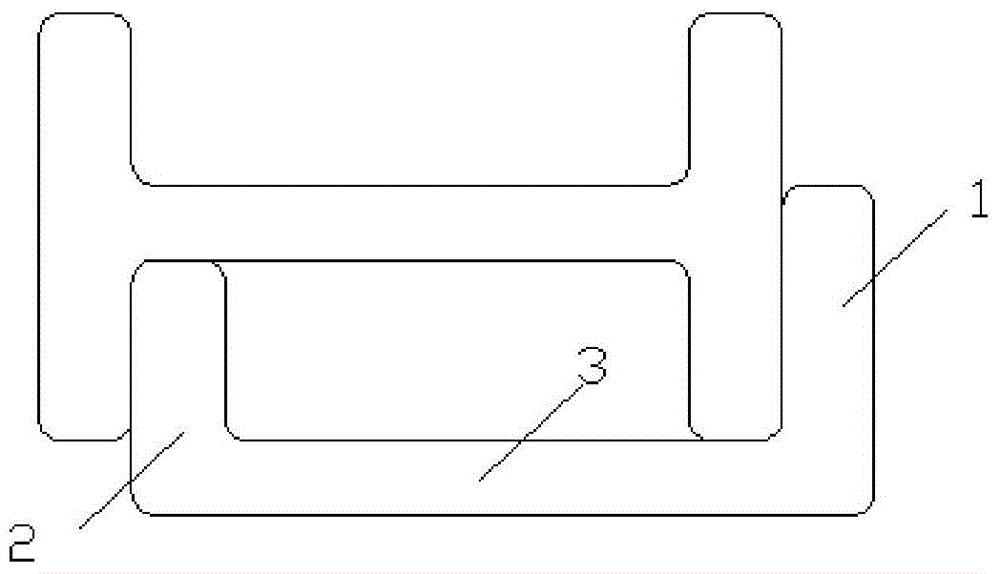

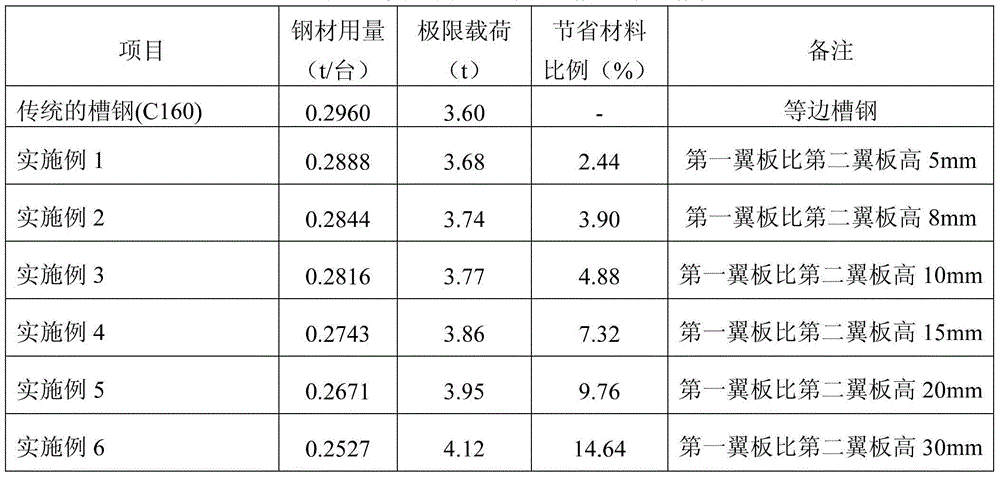

Hot-rolled inequilateral channel steel and application thereof

InactiveCN103557428AIncrease stiffnessAvoid deformationElongated constructional elementsLifting devicesMaterial consumptionSteel design

The invention relates to hot-rolled inequilateral channel steel. The hot-rolled inequilateral channel steel comprises a web and wing plates, wherein the wing plates comprise a first wing plate and a second wing plate; two ends of the web are connected with the first wing plate and the second wing plate respectively; the first wing plate and the second wing plate are located on the same side of the web, are parallel to each other and perpendicular to the web; and the height of the first wing plate is larger than that of the second wing plate. According to the hot-rolled inequilateral channel steel, the first wing plate and the second wing plate adopt an inequilateral design, the first wing plate is higher than the second wing plate by 5-30 mm, so that in combination production of a forklift truck gantry and under the same bearing capacity, steel material consumption is reduced, dead weight of a gantry system is reduced wholly, and the manufacturing cost of the gantry is reduced; and meanwhile, due to the inequilateral channel steel design, the inequilateral channel steel is attractive in appearance, not easy to deform and higher in bending resistibility, stable running of the roller is guaranteed, friction period between the roller and section steel is prolonged, and the service life of the channel steel is prolonged.

Owner:LAIWU IRON & STEEL GRP

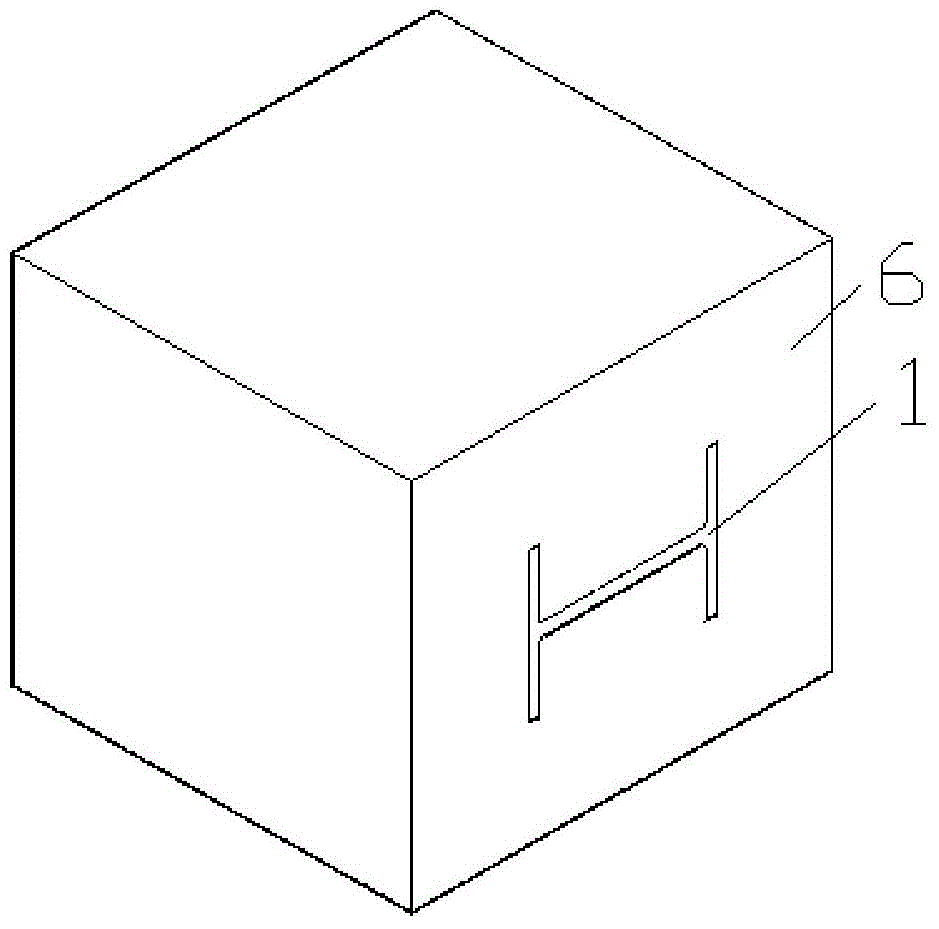

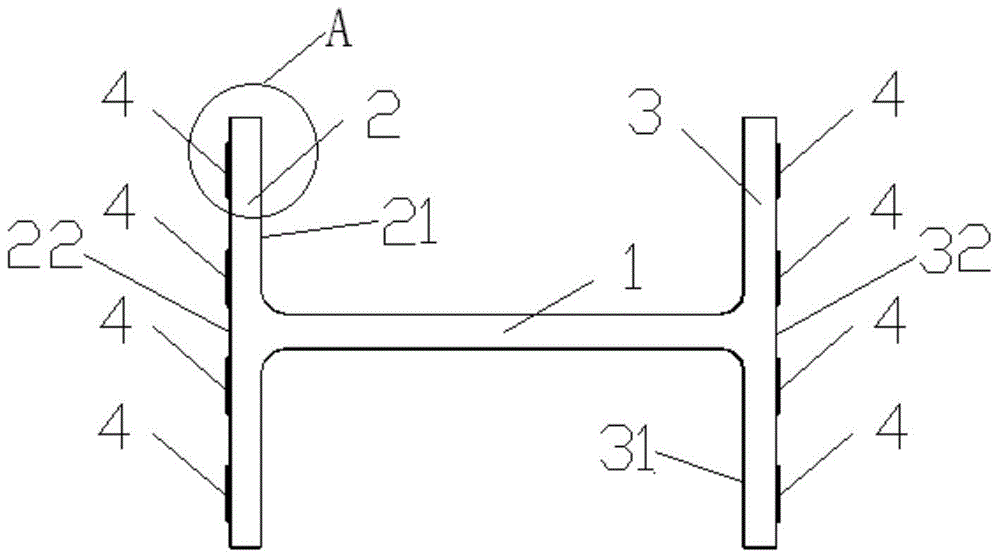

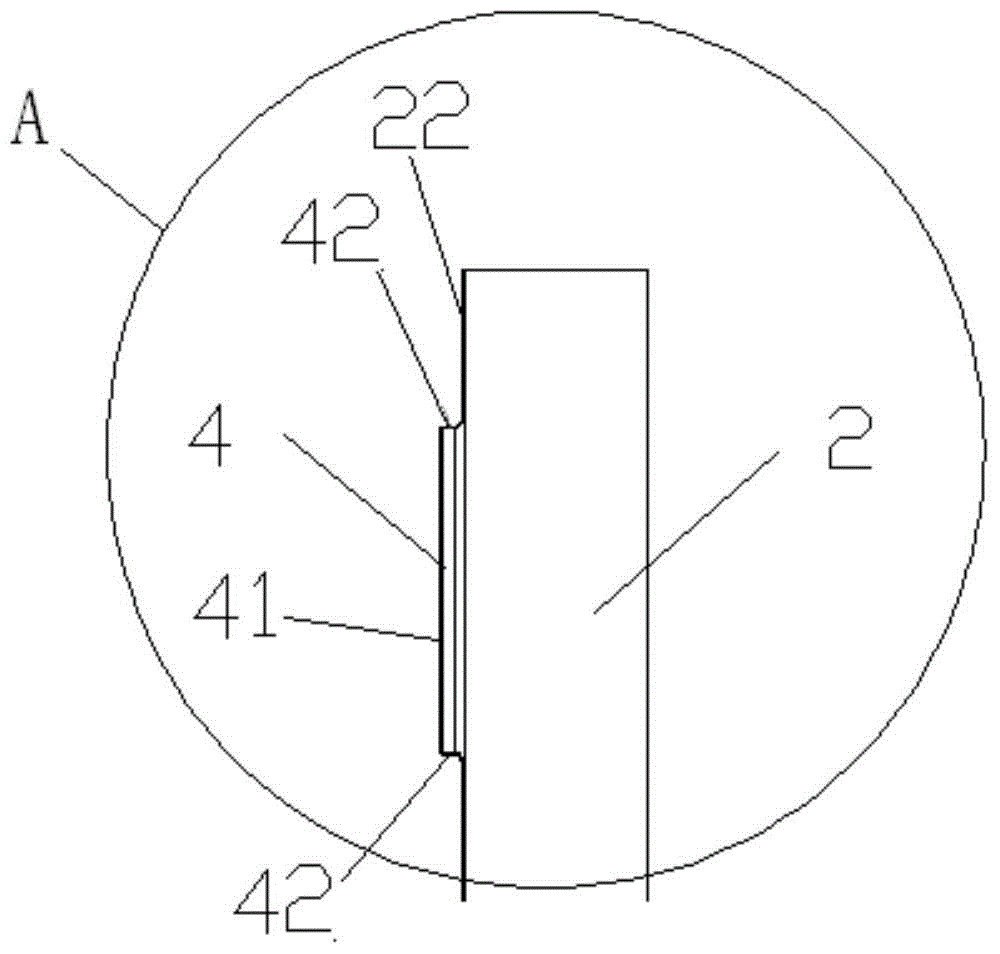

H-type steel concrete structure

InactiveCN104563285ADimensional parameters are stableShorten the production cycleBuilding constructionsAdhesion strengthConcrete cover

The invention discloses an H-type steel concrete structure. The H-type steel concrete structure comprises an H-type steel and concrete covered outside the H-type steel, wherein the H-type steel comprises a web, a top flange and a bottom flange; the web is arranged between the top flange and the bottom flange; the surfaces of the top flange and the bottom flange respectively include an inner side surface and an outer side surface opposite to the inner side surface, and the outer sides of the top flange and the bottom flange are respectively connected with the web; the outer sides of the top flange and / or the bottom flange are provided with a projection; the outer side of the web is provided with a groove, and the outer side of the web is served as the web surface extended along the length direction of the top flange. Through the technical solution, the adhesion strength between the H-type steel and the concrete is improved.

Owner:SHANDONG IRON & STEEL CO LTD

Full mold casting method

InactiveCN104874734AReasonable designImprove the finishFoundry mouldsFoundry coresSurface finishDry sand

The invention relates to the field of the casting technology and in particular relates to a full mold casting method. The full mold casting method comprises the following steps: I. manufacturing a foam plastic pattern, combining a casting system, brushing and spraying special high-temperature paint on the surface of a gasified pattern and drying; II. arranging an interlayered sand box on a worktable, filling with dry sands, compacting, striking off, arranging the dried gasified pattern on base sand, fully filling with dry sands, slightly compacting for an appropriate time period, and striking off the opening of the sand box; III. covering a plastic film, placing a pouring cup, connecting a vacuum system for vacuumizing, securing the dry sand, forming, casting, gasifying the foam plastic pattern, and filling the position by molten metal; and IIIV. releasing vacuum, condensing a casting, overturning the box, and taking out the casting from loose dry sands. According to the full mold casting method, the process route design is reasonable, the surface finish of the produced casting is high, the size precision is high, the production procedure is simple, the metal utilization rate is high, used sand is completely recycled, and the molding cost is reduced.

Owner:LIUZHOU KEERTE FORGING MACHINERY

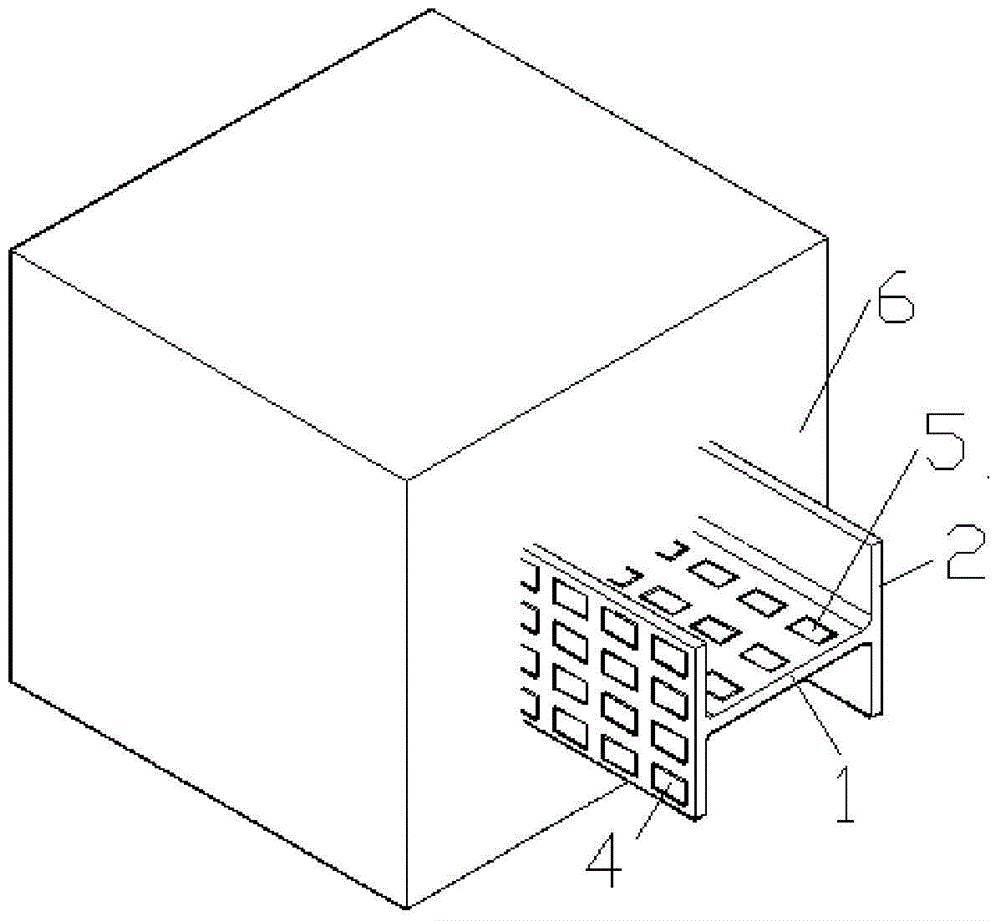

H-shaped steel

ActiveCN104499643BDimensional parameters are stableShorten the production cycleTemporary pavingsGirdersEngineeringFlange

The invention discloses an H-section steel. The H-section steel comprises a web, a top flange and a bottom flange; the web is located between the top flange and the bottom flange, and connected with the top flange and the bottom flange, respectively; the surface of each of the top flange and the bottom flange comprises an inner side surface and an outer side surface opposite to the inner side surface; the inner side surfaces of the top flange and the bottom flange both are connected with the web; lugs are arranged on the outer surface of the top flange and / or the outer surface of the bottom flange. According to the H-section steel, the surface of a component using the H-section steel is skid-resistant, sound-proof, and capable of relieving impact load.

Owner:SHANDONG IRON & STEEL CO LTD

Lost foam casting process

InactiveCN104874733AReasonable designImprove the finishFoundry mouldsFoundry coresPolystyrenePlastic film

The invention relates to the technical field of casting, and particularly relates to a lost foam casting process. The lost foam casting process comprises the following steps: step 1. producing a foam plastic lost foam pattern by adopting polystyrene resin beads, combining a pouring system, brushing and spraying a special high-temperature resistant coating on the surface of a gasified pattern, and drying; step 2. arranging an interlayer sand box on a workbench, filling dry sand for compacting and leveling, placing the oven-dried gasified pattern on base sand, filling the dry sand, and carrying out micro-vibration for leveling a box mouth; step 3. covering by using a plastic film, placing a sprue cup, connecting a vacuum system for vacuum absorption, and pouring after fastening and molding the dry sand; and step 4. releasing vacuum, turning the box after a casting is condensed, and taking out the casting from the loose dry sand. According to the lost foam casting process disclosed by the invention, the process route design is reasonable, the surface smoothness and dimensional accuracy of the produced casting are high, the production working procedures are simple, the utilization rate of metal is high, all used sand is basically recycled, and the modelling cost is lowered.

Owner:LIUZHOU KEERTE FORGING MACHINERY

Prep. of high-load bi-and multi-component precious metallic catalyst

InactiveCN1171670CImprove carrying capacityHigh metal utilizationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetal particleHigh load

The present invention is preparation process of two-component and multiple-component loaded catalyst with relatively high loaded amount and containing noble metal(s) of Pt, Pd, Ru, Os, Ir, Rh, Re, etc. and other transition metal(s). By means of altering the solvent composition in dispersion system, raising the viscosity of solvent and lowering the diffusion rate of metal particles inside the solution effectively, it is possible to prevent the mutual polymerization and enlarging of metal particles without adopting macro molecule surfactant in preparing two-component and multiple-component loaded nanometer-level noble metal-based catalyst with high dispersivity and great loaded amount. Several kinds of metal may be loaded onto the carrier in once process while ensuring high metal dispersivity even in case of high metal loading amount.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

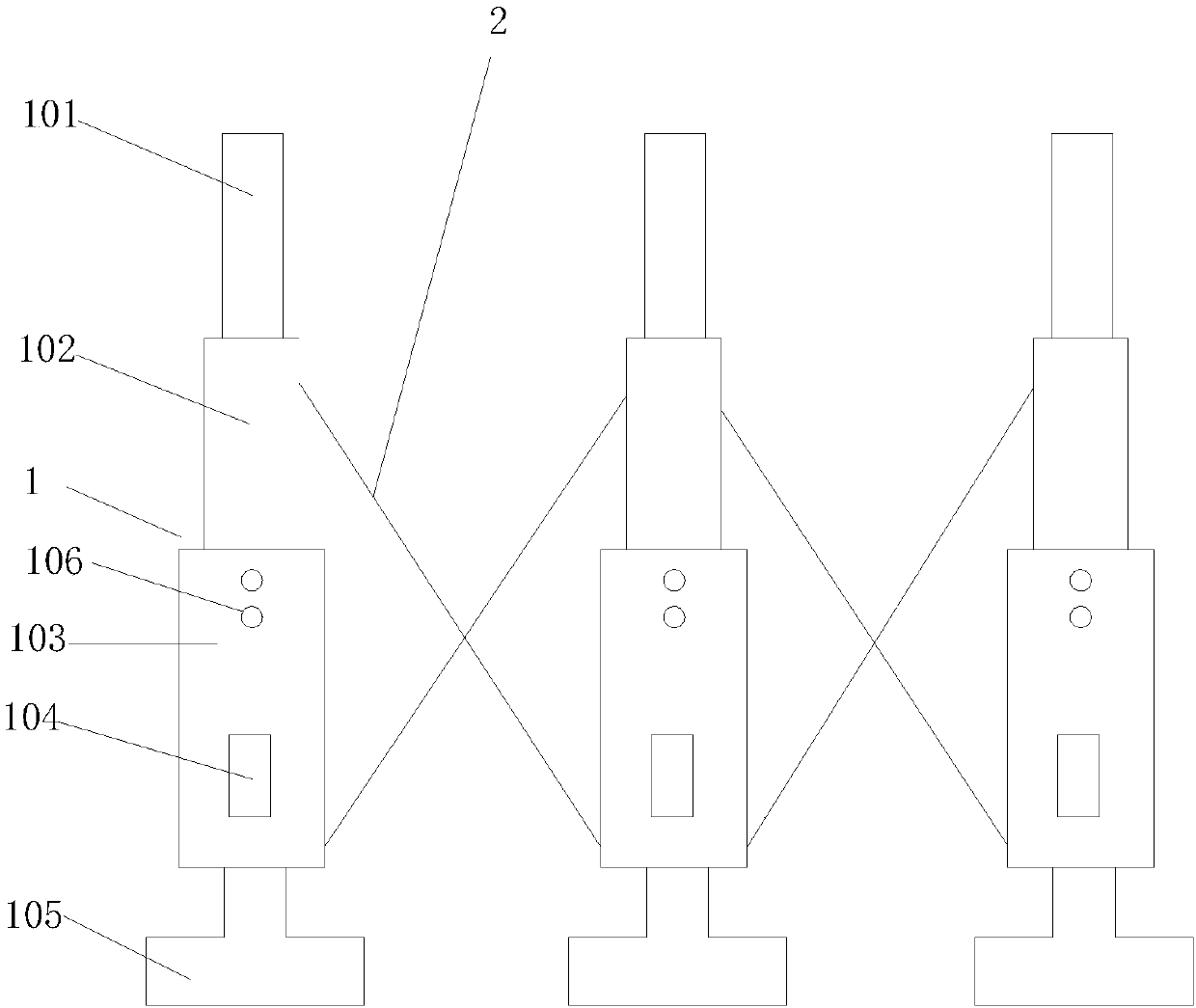

Semi-solid formed folding support mechanism

ActiveCN109518945AImplement collapsible functionalityImprove construction efficiencyForms/shuttering/falseworksShoresSemi solidMechanical engineering

The invention discloses a semi-solid formed folding support mechanism comprising a plurality of sets of support members arranged side by side. Each support member comprises a sleeve and a support tube, wherein the lower end of the support tube is inserted into the upper end of the sleeve and in sliding connection with the sleeve for supporting an above template, the support tube of any support member is connected with the sleeve of an adjacent support member through a connecting rod, and the cross sections of two connecting rods are hinged. By means of the connecting rods, the folding supportmechanism can be unfolded during use, and the distance between the support members can be adjusted as needed; after use, the folding support mechanism can be folded up. The folding support mechanism is flexible to transfer and convenient to use.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com