Metal monatomic catalyst and preparation method thereof

A catalyst and atomic technology, applied in the field of metal single-atom catalysts and their preparation, can solve problems such as the inability to achieve high single-atom loading, many synthesis steps, and complex synthesis processes, and achieve high active site density and metal utilization. The process is simple and the effect of improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

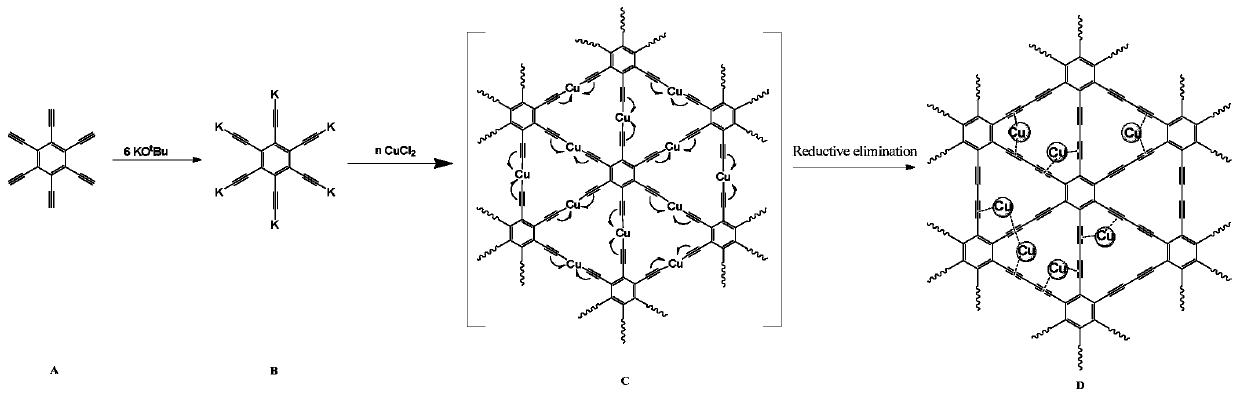

[0038] A metal single-atom catalyst, its specific preparation method:

[0039] Under inert gas conditions, the polyacetylenic compound hexaethynylbenzene (22 mg, 0.1 mmol) was added to a Schlenk bottle filled with 20 mL of n-hexane, and at -80 ° C, solid sodium methoxide (32.4 mg, 0.6 mmol) was added, At this temperature, add ferric chloride (32.4 mg, 0.2 mmol) in n-hexane, stir for 2 h, heat and stir in an oil bath at 80°C for 6 h to obtain a black mixture; cool the mixture to room temperature, and centrifuge to remove the supernatant solution, add 30mL deionized water, ultrasonically disperse, and centrifuge again, repeat the above operations once with ethanol and acetone respectively, to obtain a gray-black solid, which is dried and ground to obtain 33.2 mg of the black target product, which is the metal mono An atomic catalyst, specifically a graphyne material supporting single-atom metal iron. The loading of iron was measured to be 16.4wt% by inductively coupled plasma o...

Embodiment 2

[0041] A metal single-atom catalyst, its specific preparation method comprises:

[0042]Under inert gas conditions, polyacetylenic compound hexaethynylbenzene (22 mg, 0.1 mmol) was added to a Schlenk bottle filled with 20 mL of tetrahydrofuran, and at -80 ° C, solid sodium ethoxide (40.8 mg, 0.6 mmol) was added to the At this temperature, add a tetrahydrofuran solution of cobalt dichloride (39.0mg, 0.3mmol), stir the reaction for 2h, heat and stir in an oil bath at 70°C for 12h, and obtain a black suspension; cool the suspension to room temperature, and centrifuge to remove the supernatant solution, add 30mL deionized water, ultrasonically disperse, and centrifuge again, repeat the above operations once with ethanol and acetone respectively, to obtain a gray-black solid, which is dried and ground to obtain 39.7 mg of the target product. The black target product is a metal single atom The catalyst is specifically a graphyne material supporting monoatomic metal cobalt. The load...

Embodiment 3

[0044] A metal single-atom catalyst, its specific preparation method comprises:

[0045] Under the condition of inert gas, the polyacetylenic compound 1,3,5-triethynylbenzene (15 mg, 0.1 mmol) was added to a Schlenk bottle containing 20 mL of chloroform, and at -80 ° C, potassium tert-butoxide was added (33.6mg, 0.3mmol), at this temperature, add cuprous chloride (29.7mg, 0.3mmol) in chloroform, stir for 2h, heat and stir in an oil bath at 60°C for 24h, to obtain a dark reddish-brown mixture; Cool the mixture to room temperature, centrifuge to remove the supernatant, add 30mL of deionized water, ultrasonically disperse, centrifuge again, repeat the above operations once with ethanol and acetone, respectively, to obtain a dark reddish brown solid, dry and grind to obtain the target product 34.0 mg, the black target product is a metal single-atom catalyst, specifically a graphyne material supporting single-atom metal copper. The loading of copper was measured to be 40.3wt% by i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com