Preparation method for modified ternary metal bulk phase catalyst added with accessory ingredients

A bulk catalyst, ternary metal technology, applied in heterogeneous catalyst chemical elements, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of poor mechanical strength, poor dispersion of catalyst metal active components, and pore structure. Insufficient development and other problems, to achieve the effect of improving the removal rate, improving the diesel desulfurization rate, and improving the hydrodesulfurization reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

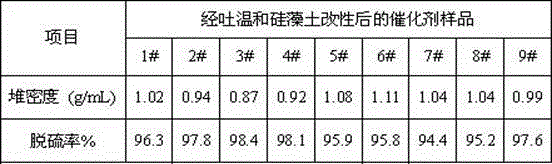

Embodiment 1

[0029] According to the metal molar ratio of Ni:Mo:W=2:1:1, 9.954 g of nickel acetate tetrahydrate, 5.071 g of ammonium heptamolybdate, and 3.531 g of ammonium metatungstate were weighed. Pour 5.071 g of ammonium heptamolybdate and 3.531 g of ammonium metatungstate into a three-necked flask with a capacity of 500 ml, and dissolve them completely with 300 ml of deionized water at 50 °C to obtain solution A. Use ammonia water as the precipitant to adjust the pH of solution A to 9, and heat the temperature of solution A to 90 °C in a water bath. Pour nickel acetate tetrahydrate into a beaker and dissolve in 20 ml deionized water to obtain solution B. At the same temperature, slowly change solution B and drop it into solution A, and it can be seen that a precipitate is gradually formed. After the dropwise addition, the solution was stirred at 90 °C for 5 h to fully compound the active components. During the stirring process, 1.856 g of Tween and 1.523 g of diatomaceous earth wer...

Embodiment 2

[0031] According to the metal molar ratio of Ni:Mo:W=2:1:1, 11.632 g of nickel nitrate hexahydrate, 5.071 g of ammonium heptamolybdate, and 3.531 g of ammonium metatungstate were weighed. Pour the Mo and W compounds into a three-neck flask with a capacity of 500 ml, and completely dissolve them with 300 ml of deionized water at 50°C to obtain solution A. Use ammonia water as the precipitant to adjust the pH of solution A to 9, and heat the temperature of solution A to 90 °C in a water bath. Pour nickel nitrate hexahydrate into a beaker and dissolve in 20 ml deionized water to obtain solution B. At the same temperature, slowly change solution B and drop it into solution A, and it can be seen that a precipitate is gradually formed. After the dropwise addition, the solution was stirred at 90 °C for 5 h to fully compound the active components. During the stirring process, 2.023 g of Tween and 4.047 g of diatomaceous earth were added to the solution respectively. After the stirri...

Embodiment 3

[0033]According to the metal molar ratio of Ni:Mo:W=2:1:1, 9.520 g of nickel chloride hexahydrate, 5.071 g of ammonium heptamolybdate, and 3.531 g of ammonium metatungstate were weighed. Pour the Mo and W compounds into a three-necked flask with a capacity of 500 ml, and completely dissolve them with 300 ml of deionized water at 50 °C to obtain solution A. Use ammonia water as the precipitant to adjust the pH of solution A to 9, and heat the temperature of solution A to 90°C in a water bath. Pour nickel chloride hexahydrate into a beaker and dissolve in 20 ml deionized water to obtain solution B. At the same temperature, slowly change solution B and drop it into solution A, and it can be seen that a precipitate is gradually formed. After the dropwise addition, the solution was stirred at 90 °C for 5 h to fully compound the active components. During the stirring process, 1.208 g of Tween and 2.416 g of diatomaceous earth were added to the solution respectively. After the stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com