Hot-rolled J-type steel and application of hot-rolled J-type steel

A technology of section steel and wing plate, applied in the direction of lifting device, etc., can solve the problems of difficult control of dimensional accuracy and shape, difficult roll processing, increased roll consumption, etc., and achieve the effect of simplifying equipment, reducing weight and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

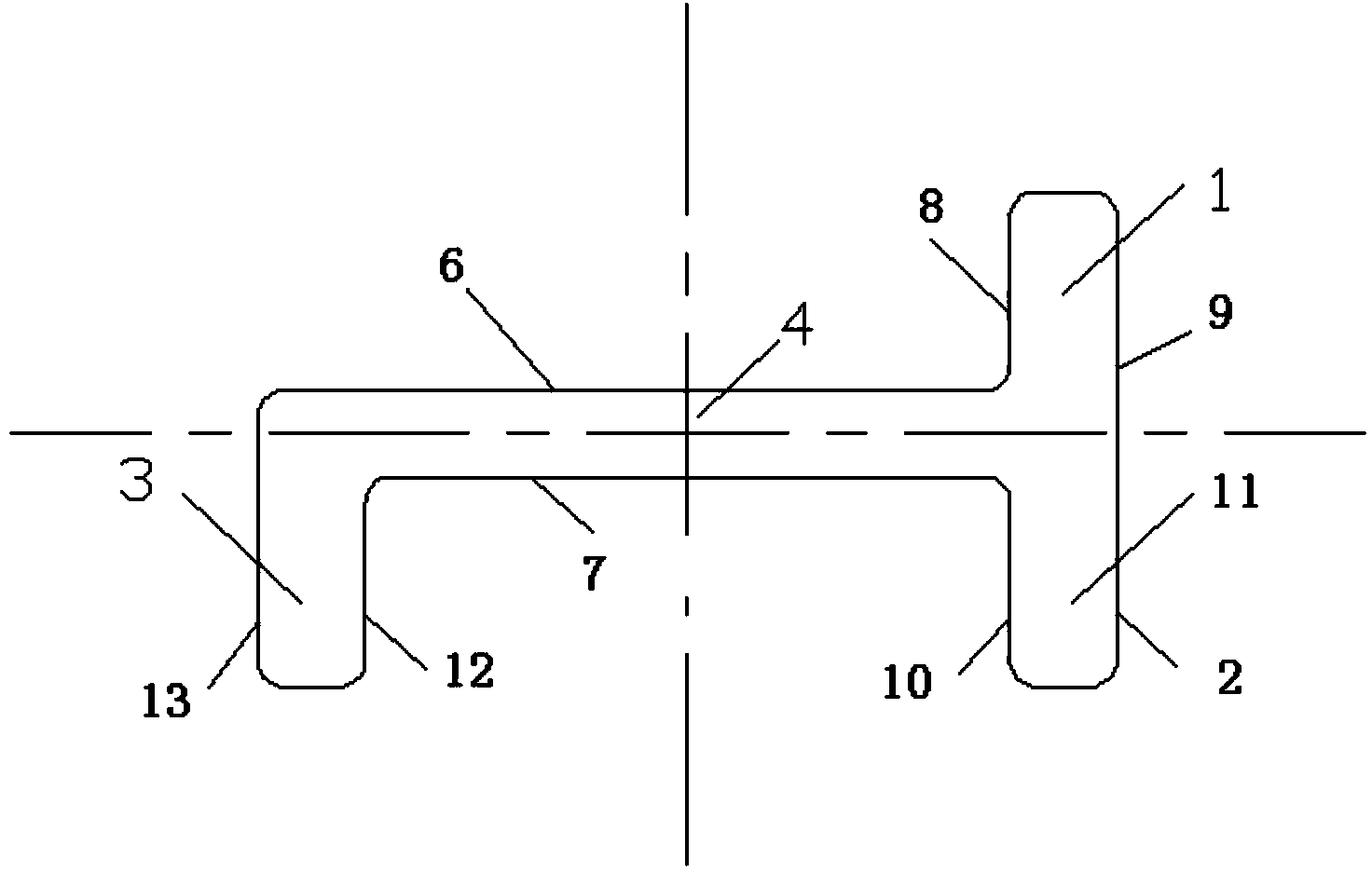

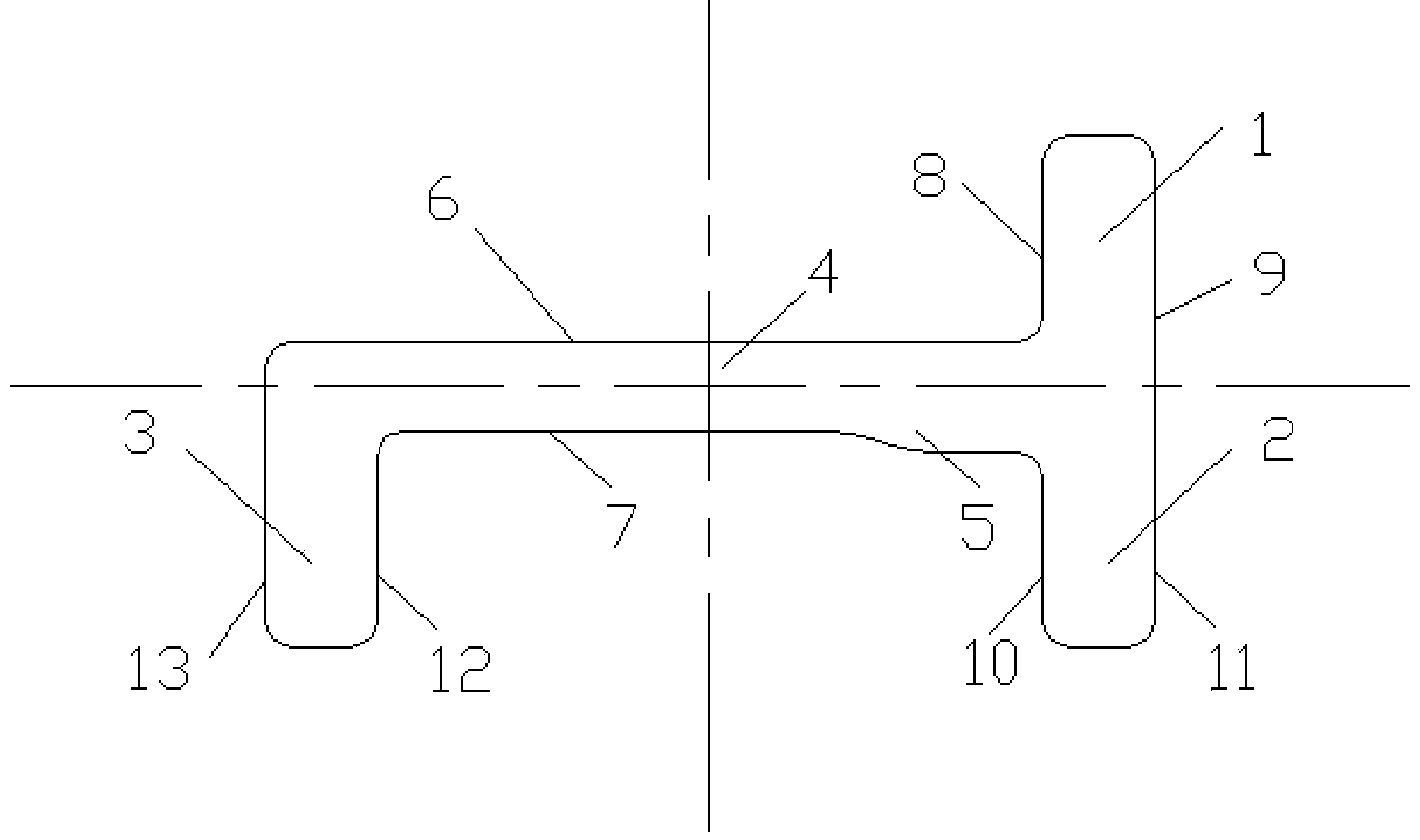

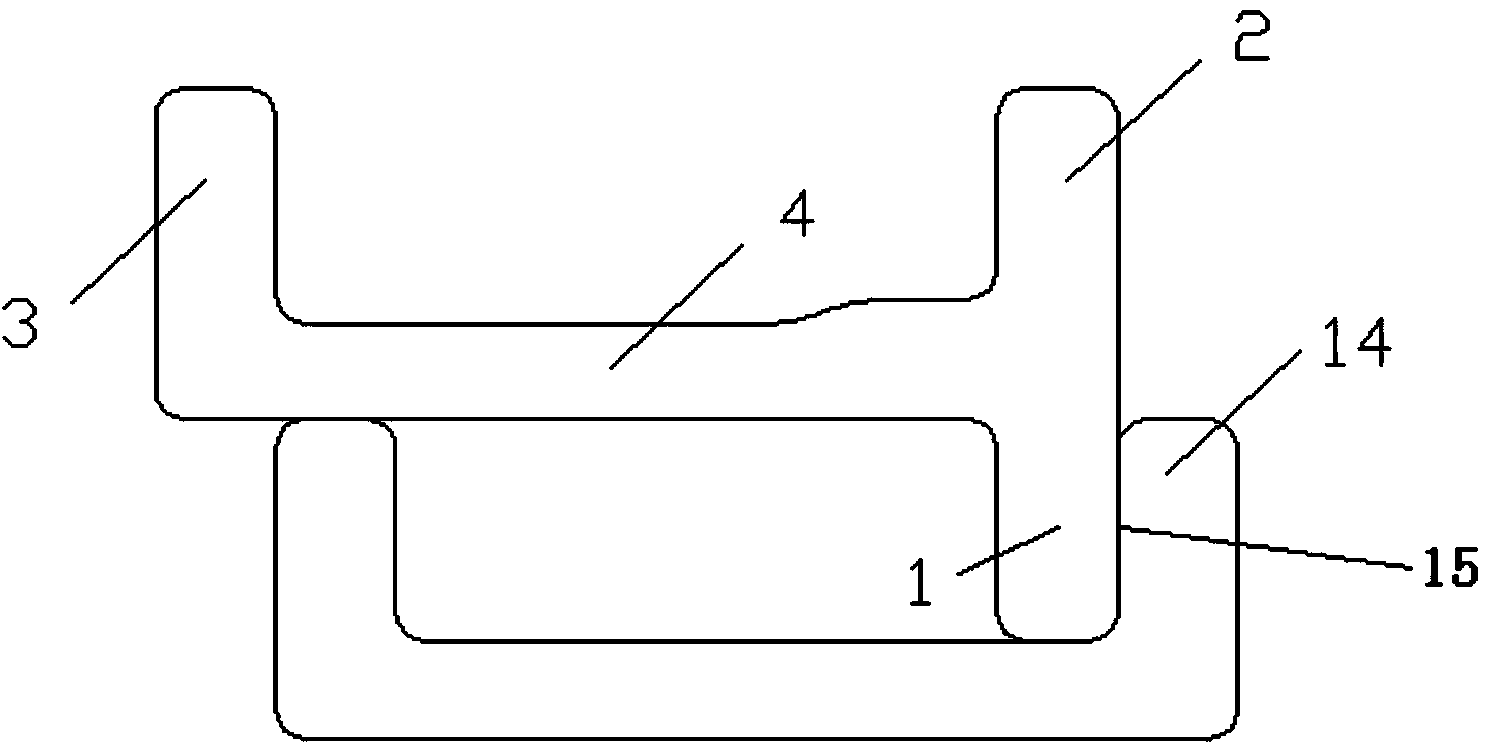

[0032] A hot-rolled J-shaped steel with a structure such as figure 1 Shown, comprise web 4, wing plate, wing plate comprises first wing plate 1, second wing plate 2 and the 3rd wing plate 3, the two ends of web plate 4 are connected with first wing plate 1 and the 3rd wing plate respectively 3 connected, the first wing 1 and the third wing 3 are located on the same side of the web 4, the first wing 1 and the third wing 3 are parallel to each other and are perpendicular to the web 4, the second wing 2 and the second One wing 1 is connected to the end of the web 4 , and the second wing 2 is on the same vertical plane as the first wing 1 and also perpendicular to the web 4 . The connection between the inner side 12 of the third wing plate and the bottom side 7 of the web is a smooth curve transition, the connection between the outer side 13 of the third wing plate and the upper side 6 of the web is a smooth curve transition, and the inner side 10 of the second wing plate and The c...

Embodiment 2

[0037] A kind of hot-rolled J section steel, structure is the same as embodiment 1, difference is:

[0038] The shape and height of the second wing plate 2 and the third wing plate 3 are the same. The cross sections of the second wing plate 2 and the third wing plate 3 are both rectangular, and the four corners of the rectangle are rounded. The ratio of the thickness of the first wing plate 1 to the thickness of the web 4 is 1:1, and the second wing plate The ratio of the thickness of 2 to the thickness of the web 4 is 1.2:1, the ratio of the thickness of the third wing 3 to the thickness of the web 4 is 1.3:1, and the ratio of the height of the first wing 1 to the length of the web 4 is 1 :3, the height of the second wing plate 2 and the length ratio of the web 4 are 1:2.5, and the height of the third wing plate 3 and the length ratio of the web 4 are 1:2.5.

Embodiment 3

[0040] A kind of hot-rolled J section steel, structure is the same as embodiment 1, difference is:

[0041] The shape, thickness and height of the first wing plate 1 , the second wing plate 2 and the third wing plate 3 are the same. The cross sections of the first wing plate 1, the second wing plate 2, and the third wing plate 3 are all rectangular, the four corners of the rectangle are rounded, and the ratio of the thickness of the first wing plate 1 to the thickness of the web 4 is 1: 1. The ratio of the thickness of the second wing 2 to the thickness of the web 4 is 1:1, the ratio of the thickness of the third wing 3 to the thickness of the web 4 is 1:1, the height of the first wing 1 and the web The length ratio of 4 is 1:2.5, the ratio of the height of the second flange 2 to the length of the web 4 is 1:2.5, and the ratio of the height of the third flange 3 to the length of the web 4 is 1:2.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com