Metallurgical bonding stainless steel cladding thermometal profile steel and preparing technology

A technology of metallurgical bonding and preparation process, applied in the field of metal composite materials and metallurgical steel rolling, can solve the problems of poor corrosion resistance and high cost, and achieve the effects of low price, beautiful appearance, excellent corrosion resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

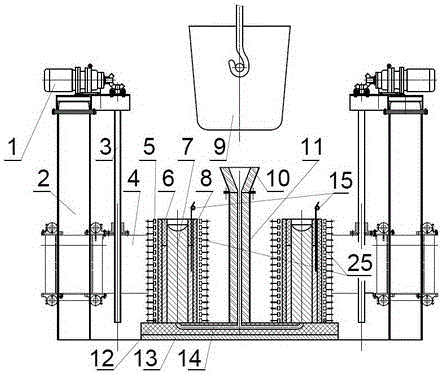

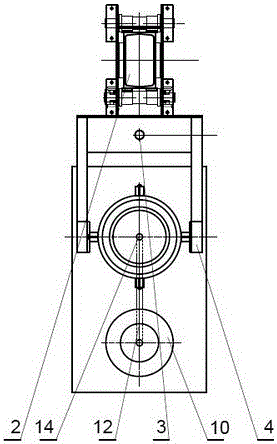

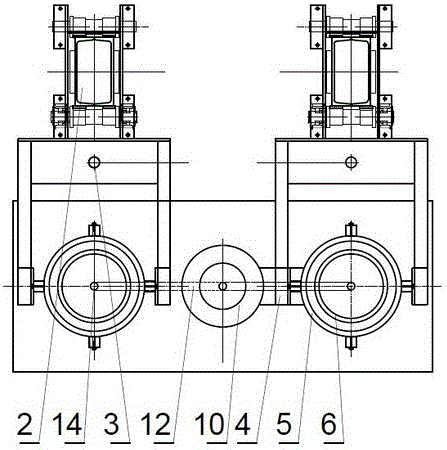

[0076] Example 1: Preparation of metallurgically bonded stainless steel clad bimetallic angle steel.

[0077] Figure 17 Among them, the metallurgical combination of stainless steel clad bimetallic angle steel, its product specification is an equilateral bimetallic angle steel with a side length of 40mm and a thickness of 5nnn, which is composed of a carbon steel core metal 7 and a stainless steel cladding along the length direction of the core metal 7 Layer 6, between the stainless steel cladding 6 and the carbon steel core metal 7 is a metallurgically bonded fusion interface layer formed by melting and casting;

[0078] A metallurgically bonded stainless steel-clad bimetallic angle steel is prepared, the core 7 is carbon steel Q235A steel, the thickness of the stainless steel alloy layer 6 is 5 mm, and the stainless steel alloy layer 6 is selected from 06Cr19Ni10 austenitic stainless steel. Figure 17 It is a schematic structural diagram of a transverse cross-sectional view...

Embodiment 2

[0096] Example 2: Preparation of metallurgically bonded stainless steel clad bimetallic channel steel.

[0097] Figure 19 Among them, metallurgically combined stainless steel clad bimetallic channel steel, the product specification is 5# bimetallic channel steel, which is composed of carbon steel core metal 7 and stainless steel cladding 6 clad along the length direction of core metal 7, said Between the stainless steel cladding 6 and the carbon steel core metal 7 is a metallurgically bonded fusion interface layer formed by melting and casting;

[0098] The metallurgically bonded stainless steel clad bimetallic channel steel is prepared, and the core part 7 is the blank used for producing the HRB400 channel steel. The thickness of the stainless steel alloy layer 6 is 10 mm, and the stainless steel alloy layer 6 is made of 304 austenitic stainless steel. Figure 19 It is a schematic diagram of the basic structure of a bimetallic channel provided by the embodiment of the pres...

Embodiment 3

[0115] Example 3: Preparation of metallurgically bonded stainless steel-clad bimetallic H-shaped steel.

[0116] Figure 21 Among them, metallurgically combined stainless steel clad bimetallic channel steel, the product specification is 150×150×6 bimetallic H-shaped steel, which is composed of carbon steel core metal 7 and its stainless steel cladding 6 along the length direction of the core metal 7 , between the stainless steel cladding 6 and the carbon steel core metal 7 is a metallurgically bonded fusion interface layer formed by melting and casting;

[0117] The metallurgically bonded stainless steel clad bimetallic channel steel is prepared, and the core part 7 is the blank used for producing the HRB400 channel steel. The thickness of the stainless steel alloy layer 6 is 12 mm, and the stainless steel alloy layer 6 is made of 304 austenitic stainless steel. Figure 19 It is a schematic diagram of the basic structure of a bimetallic channel provided by the embodiment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com