Electroslag fusion casting manufacture method of rotating wheel blanks of impact type hydraulic generator

A hydroelectric generator, electroslag casting technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of high manufacturing cost of runners, material utilization rate of less than 50%, large amount of forging processing, etc., to achieve processing The effect of short cycle time, high runner output, and compact casting structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

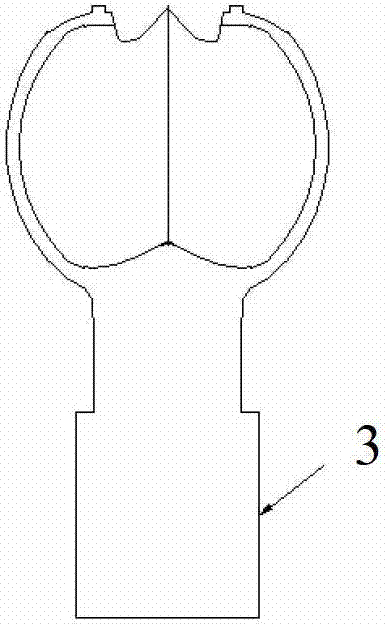

[0073] The low alloy steel 20SiMn was used to prepare the electroslag casting blank of the impact runner.

[0074] 1) Slag-based ingredients: CaF 2 70%, Al 2 o 3 30%, the amount of slag is 3% of the weight of the casting.

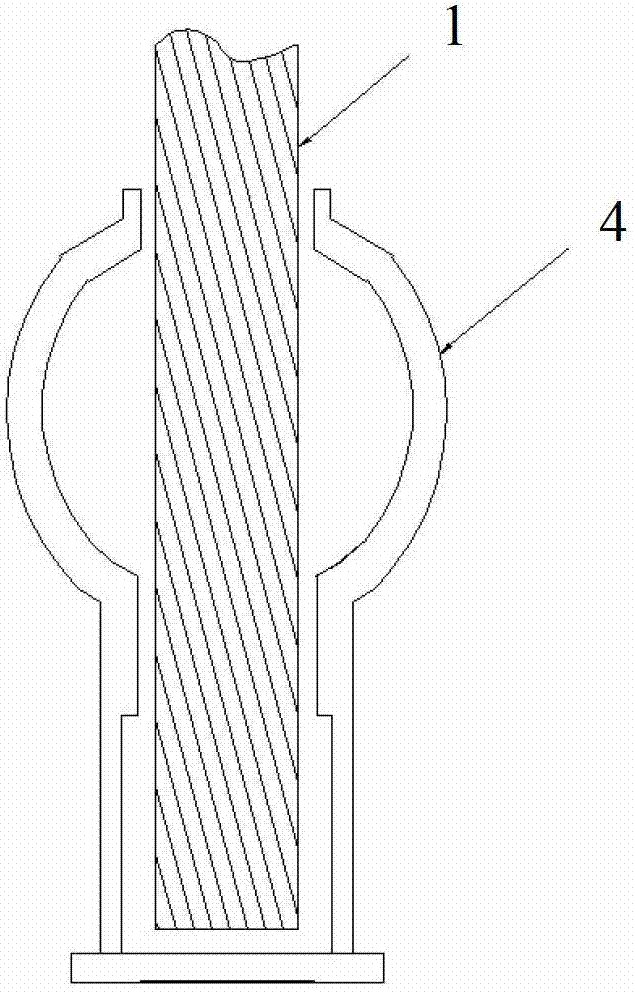

[0075] 2) Ignition method: The consumable electrode is ignited by solid slag in the crystallizer, and its chemical composition is TiO in weight percentage 2 : 50%, CaF 2 : 50%.

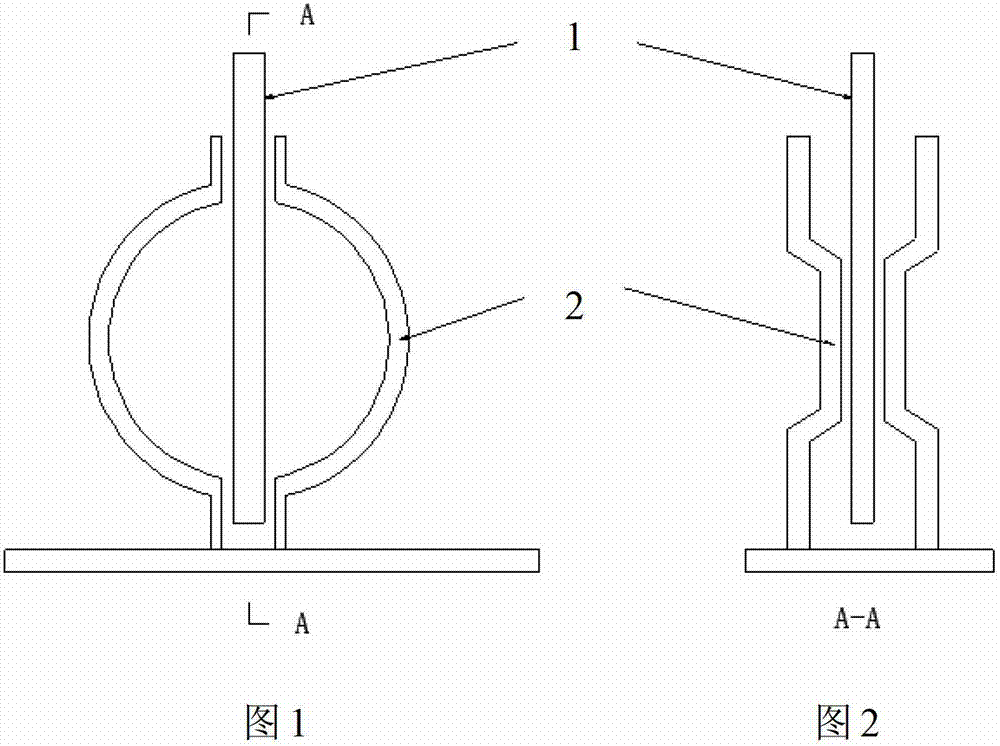

[0076] 3) Selection of crystallizer: Copper-steel composite crystallizer is adopted, and its structure adopts integral type.

[0077] 4) Power parameters: According to the size of the casting, the geometry of the electrode and the crystallizer, the casting voltage is 50V and the current is 6500A.

[0078] Through the electroslag casting process, the 20SiMn steel impact runner blank is formed by a crystallizer with a set shape. Its chemical composition is:

[0079] C

[0080] In order to eliminate the internal stress of castings and develop the potential of mec...

Embodiment 2

[0086] The blank of 06Cr13Ni4Mo steel impact runner was prepared by electroslag casting.

[0087] 1) Slag-based ingredients: CaF 2 55wt%, Al 2 o 3 45wt%, the amount of slag is 3.4% of the casting weight.

[0088] 2) Ignition method: The consumable electrode is ignited by solid slag in the crystallizer, and its chemical composition is TiO in weight percentage 2 : 50%, CaF 2 : 50%.

[0089] 3) Selection of crystallizer: Copper-steel composite crystallizer is adopted, and its structure adopts block combination type.

[0090] 4) Power parameters: According to the size of the casting, the geometry of the electrode and the crystallizer, the casting voltage is 75V and the current is 12000A.

[0091] Through the electroslag casting process, the 06Cr13Ni4Mo steel impact runner blank is formed by a crystallizer with a set shape. Its chemical composition is:

[0092]

[0093] In order to eliminate the internal stress of castings and develop the potential of mechanical proper...

Embodiment 3

[0098] The blank of 06Cr13Ni5Mo steel impact runner was prepared by electroslag casting.

[0099] 1) Slag-based ingredients: CaF 2 65wt%, Al 2 o 3 35wt%, the amount of slag is 2.5% of the casting weight.

[0100] 2) Ignition method: The consumable electrode is ignited by solid slag in the crystallizer, and its chemical composition is TiO in weight percentage 2 : 45%, CaF 2 : 55%.

[0101] 3) Selection of crystallizer: Copper-steel composite crystallizer is adopted, and its structure adopts block combination type.

[0102] 4) Power parameters: According to the size of the casting, the geometry of the electrodes and the crystallizer, the casting voltage is 50V and the current is 7500A.

[0103] Through the electroslag casting process, the 06Cr13Ni5Mo steel impact runner blank is formed by a crystallizer with a set shape. Its chemical composition is:

[0104]

[0105] In order to eliminate the internal stress of castings and develop the potential of mechanical proper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com