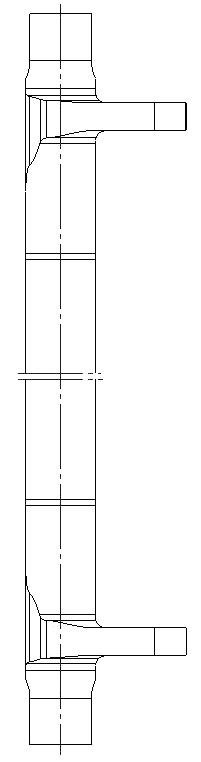

MW grade wind-powered torsion shaft and preparation technology thereof

A preparation process and technology of torsion shaft, applied in the field of torsion shaft and its preparation, can solve problems such as affecting the operation safety and life of wind turbines, difficult to meet high performance, high flaw detection level indicators, unstable internal quality of products, etc. The effect of small deformation, dendrite refinement and dense organization

Active Publication Date: 2012-08-01

SHENYANG RES INST OF FOUNDRY

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The quality of sand casting castings is closely related to the quality of molten steel and the casting process. Although high-quality molten steel is provided for casting production through out-of-furnace refining technology (AOD or VOD), sand casting inevitably produces looseness, shrinkage cavities, sand inclusions, inclusions, etc. Defects make the internal quality of the product unstable, and it is difficult to meet the requirements of high performance and high flaw detection level indicators, which not only causes a large number of castings to be scrapped, but also directly affects the safety and life of the wind turbine operation

The forging method usually uses refined steel ingots (including electroslag remelted steel ingots) to produce wind power torsion shafts. The blank parts are obtained by forging, and the quality is improved compared with sand castings. However, due to the special shape of the torsion shaft, the material utilization rate is very low and the process is complicated. Low quality and high cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention aims to provide a torsion shaft for an aerogenerator, and an electroslag refusion casting method thereof, and the torsion shaft combines technical advantages of arc metallurgy and technical advantages of electroslag refusion casting (ESRC). A casting produced by adopting the preparation technology of the MW grade wind-powered torsion shaft provided in the invention has the advantages of uniform and compact crystal tissue, high purity, less nonmetallic inclusions, possessing of excellent compactness and fatigue resistance, reaching of forging flaw detection quality standards, realization of near net-shape forming, and low cost. The internal quality of the produced torsion shaft is obviously better than that of torsion shafts produced through sand casting.

Description

technical field [0001] The invention relates to a torsion shaft for a MW-level wind power generator and a preparation process thereof. Background technique [0002] With my country's economic development and environmental protection needs, the demand for clean energy has further increased, and wind power has become one of the important energy sources. With the development and construction of wind power generation, wind power generation is developing in the direction of high efficiency and large scale, and the quality requirements for important components of wind power generation are getting higher and higher. At the same time, wind turbines are used in complex environments such as land and sea (required operating ambient temperature: normal temperature type -15°C to +45°C; low temperature type -30°C to +45°C; living environment temperature: normal temperature type -25°C to +45°C ℃; low temperature type -45 ℃ to +45 ℃) The application of wind turbine components is very dem...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16C3/02B22D23/10

Inventor 娄延春王大威唐骥弥尚林王安国蒋国森马洪波王云霞

Owner SHENYANG RES INST OF FOUNDRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com