Upright few-layer graphene-metal nanoparticle composite catalytic electrode

A technology of metal nanoparticles and few-layer graphene, applied in the field of electrochemistry, can solve the problems of difficulty in controlling the size and shape of nanoparticles, complicated preparation steps, etc., achieve good and stable physical and chemical properties, simple preparation steps, and large pores content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

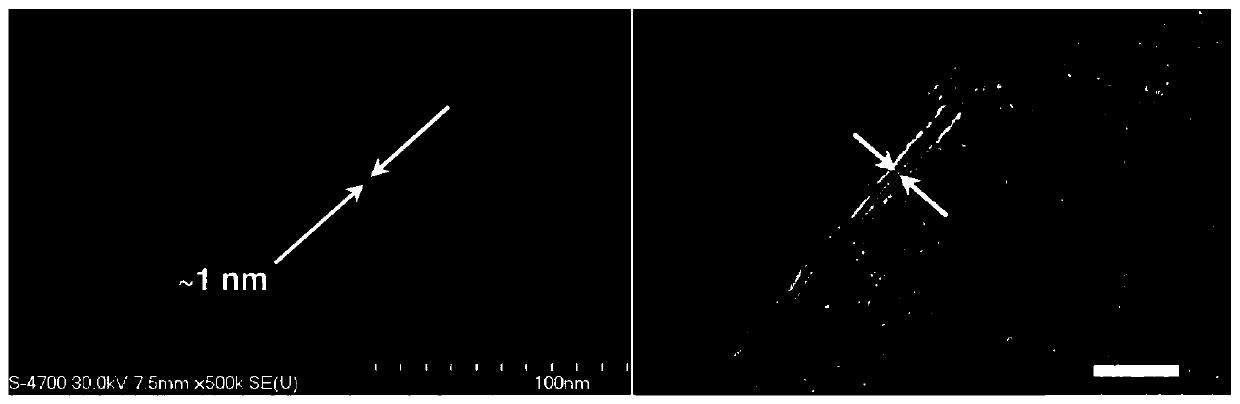

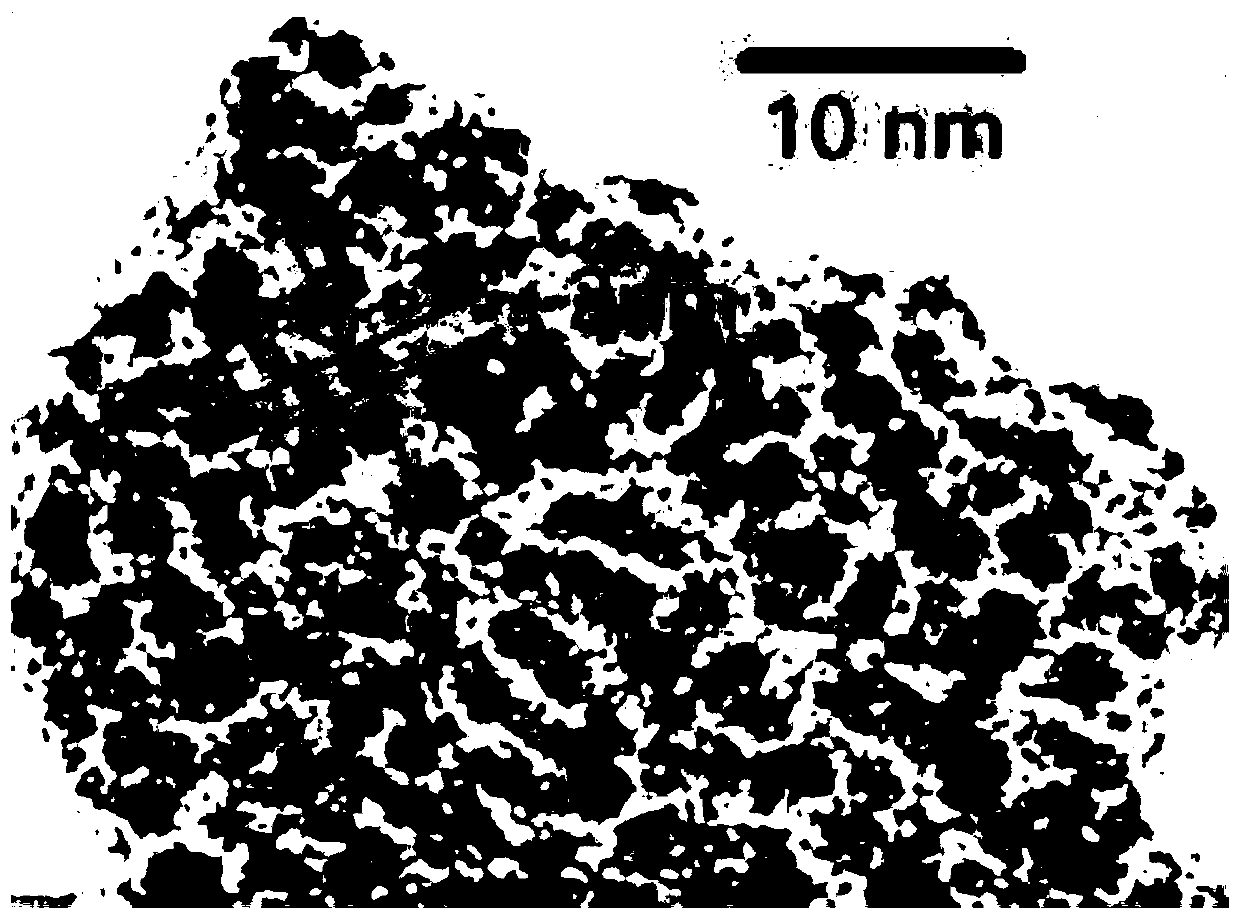

[0037] Such as figure 1 As shown, vertical few-layer graphene has a unique morphology: carbon nanosheets grow vertically and have a large surface area. figure 2 It is revealed that the edge thickness is between 0.34 and 0.37 nm, and it is a graphene structure with one to two layers. image 3 It shows that the size and shape of platinum particles are uniform, and the average diameter is about 2 nanometers.

[0038] A kind of preparation method of upright few-layer graphene-metal nanoparticle composite catalytic electrode, comprises the following steps at least:

[0039] In the first step, put the high-conductivity carbon paper into the vacuum chamber of the plasma chemical vapor deposition device, feed the reducing gas hydrogen and argon at 1:1, and maintain the low pressure state in the device through flow adjustment, so that the vacuum degree is stable at 15Pa, perform plasma etching reaction on the substrate, the reaction time is 10min, and the power density of the plasma...

Embodiment 2

[0047] Different from Example 1 is the preparation method and application of gold nanoparticles on the surface of upright graphene, the method at least includes the following steps:

[0048] The first step is to select a gold target and place the material prepared in the first step to the third step in Example 1 in a physical vapor deposition device, and vacuumize to 3x10 -3 Pa, filled with argon to stabilize the pressure at 5pa, start magnetron sputtering, where the power is 5W / cm 2 , time 300s;

[0049] In the second step, after the magnetron sputtering is finished, flush argon to 1x10 5 Pa, raise the temperature to 450°C and keep it for 40min for annealing;

[0050] In the third step, after the annealing reaction is completed, the temperature in the equipment drops to room temperature, and the sample is taken out;

[0051] After testing, in this embodiment, gold nanoparticles with a particle diameter of about 13 nm are loaded on the upright graphene. Differential pulse ...

Embodiment 3

[0053] Different from Examples 1 and 2 are the preparation method and application of the silver nanoparticles on the surface of the upright graphene, the method at least includes the following steps:

[0054] The first step is to select a silver target and place the material prepared in the first step to the third step in Example 1 in a physical vapor deposition device, and vacuumize to 2x10 -3 Pa, filled with argon to stabilize the pressure at 5.2pa, start magnetron sputtering, the power is 4W / cm 2 , time 240s;

[0055] In the second step, after the magnetron sputtering is finished, flush argon to 1x10 5 pa, raise the temperature to 250°C and keep it for 30min for annealing;

[0056] In the third step, after the annealing reaction is completed, the temperature in the equipment drops to room temperature, and the sample is taken out.

[0057] After testing, in this embodiment, the vertical graphene supports nano-silver particles with a particle diameter of about 5 nm. Weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com