Method for vacuum auxiliary gravity pouring investment casting thin wall piece

A technology of investment casting and gravity casting, which is used in the production of various thin-walled, casting casting, and complex investment casting parts. It can solve the problems of complex equipment structure, large equipment investment and high equipment requirements, and achieve simple equipment structure and investment. Small, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

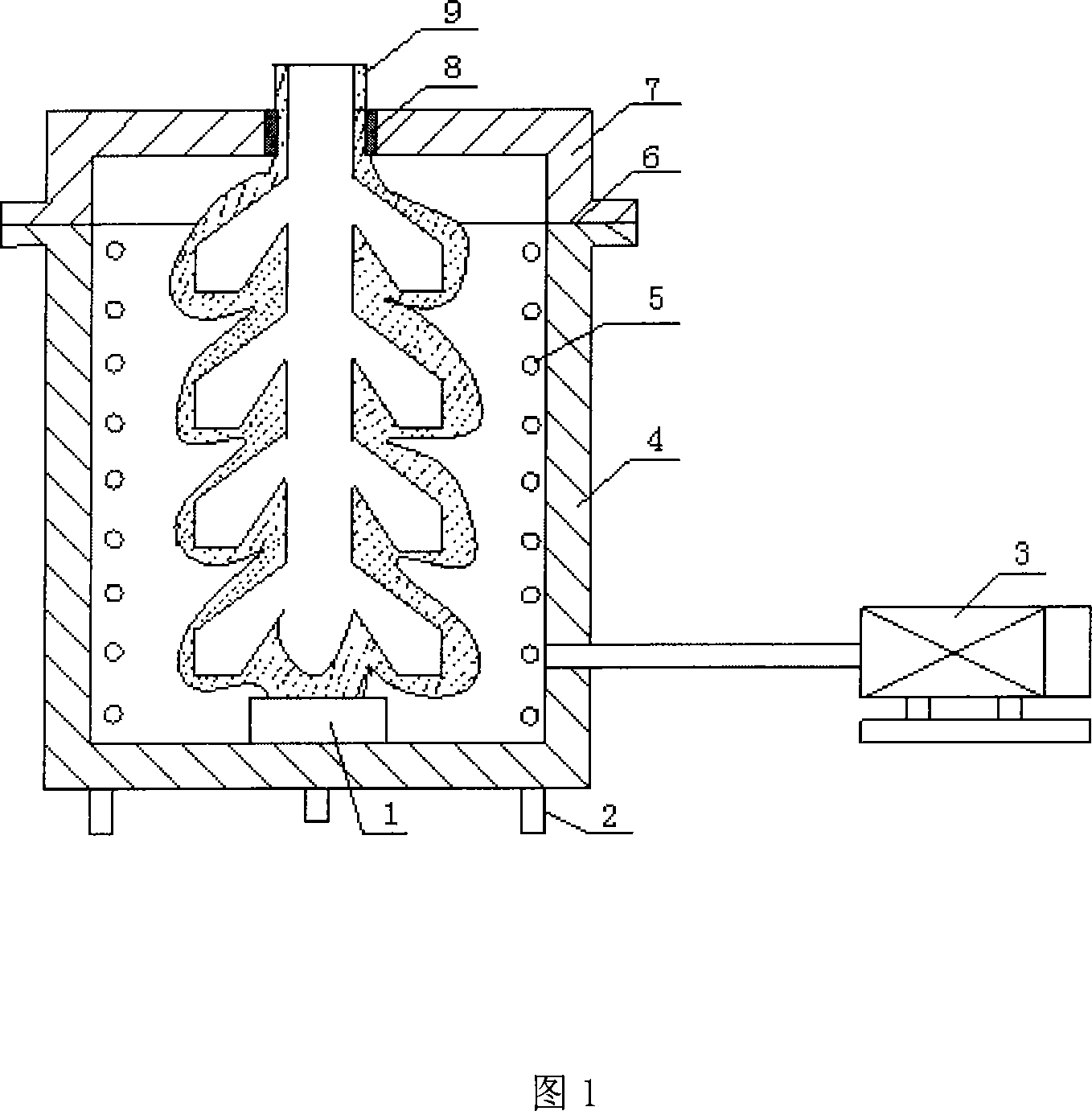

Image

Examples

Embodiment 1

[0012] A casting method for vacuum-assisted gravity casting investment casting special-shaped pipe castings for automobiles (material ZG35, outline size 65mm×70mm×75mm, minimum wall thickness 2mm), the specific steps are as follows:

[0013] 1. Put the baked shell on the fixture of the container;

[0014] 2. A sealing device is placed between the shell and the upper cover, and the upper cover of the container is covered;

[0015] 3. Adjust the fixing device to ensure that the shell and the container form a closed space;

[0016] 4. Turn on the heating device and control the shell temperature at 1050°C;

[0017] 5. Turn on the vacuum system to stabilize the vacuum in the container at 0.03MP;

[0018] 6. Pour cast steel molten metal with a melting temperature of 1600°C into the shell;

[0019] 7. After the molten metal fills the shell for 2 seconds, turn off the vacuum system;

[0020] 8. After keeping for a period of time, release the vacuum;

[0021] After cleaning the sh...

Embodiment 2

[0023] A casting method for a vacuum-assisted gravity pouring investment casting six-way pipe fitting casting (material stainless steel 304, outline size 70mm×75mm×50mm, minimum wall thickness 1.8mm), the specific steps are as follows:

[0024] 1. Put the baked shell on the fixture of the container;

[0025] 2. A sealing device is placed between the shell and the upper cover, and the upper cover of the container is covered;

[0026] 3. Adjust the fixing device to ensure that the shell and the container form a closed space;

[0027] 4. Turn on the heating device and control the shell temperature at 1050°C;

[0028] 5. Turn on the vacuum system to stabilize the vacuum in the container at 0.03MP;

[0029] 6. Pouring molten stainless steel with a melting temperature of 1600°C into the shell;

[0030] 7. After the molten metal fills the shell for 3 seconds, turn off the vacuum system;

[0031] 8. After keeping for a period of pouring time, release the vacuum;

[0032] After cl...

Embodiment 3

[0034] A casting method for vacuum-assisted gravity casting investment casting of bicycle connector castings (material ZL101, outline size 70mm×40mm×60mm, minimum wall thickness 1.9mm), the specific steps are as follows:

[0035] 1. Put the baked shell on the fixture of the container;

[0036] 2. A sealing device is placed between the shell and the upper cover, and the upper cover of the container is covered;

[0037] 3. Adjust the fixing device to ensure that a closed space is formed between the shell and the container;

[0038] 4. Turn on the heating device and control the shell temperature at 400°C;

[0039] 5. Turn on the vacuum system to stabilize the vacuum degree in the closed space of the container and the shell at 0.04MP;

[0040] 6. Pour aluminum alloy molten metal with a melting temperature of 700°C into the shell;

[0041] 7. After the molten metal fills the shell for 4 seconds, turn off the vacuum system;

[0042] 8. Release the vacuum;

[0043] After cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com