Hot-rolled inequilateral channel steel and application thereof

An edge channel steel, unequal technology, used in lifting devices, slender elements, building elements, etc., can solve the problems of large usage, high production cost, and heavy gantry system, so as to improve service life and reduce self-weight. , the effect of saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

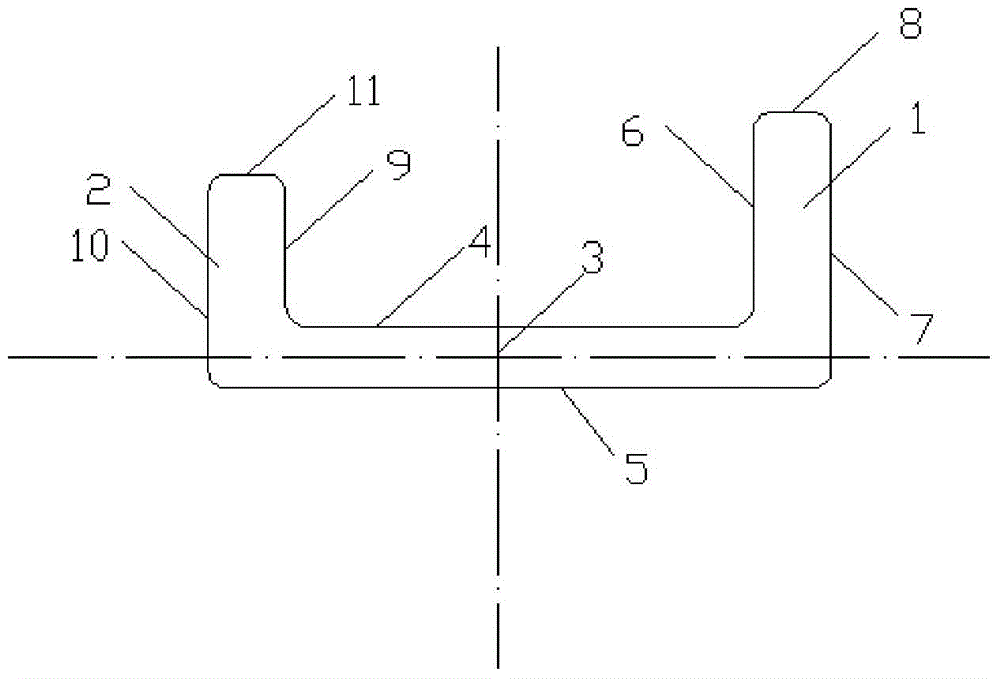

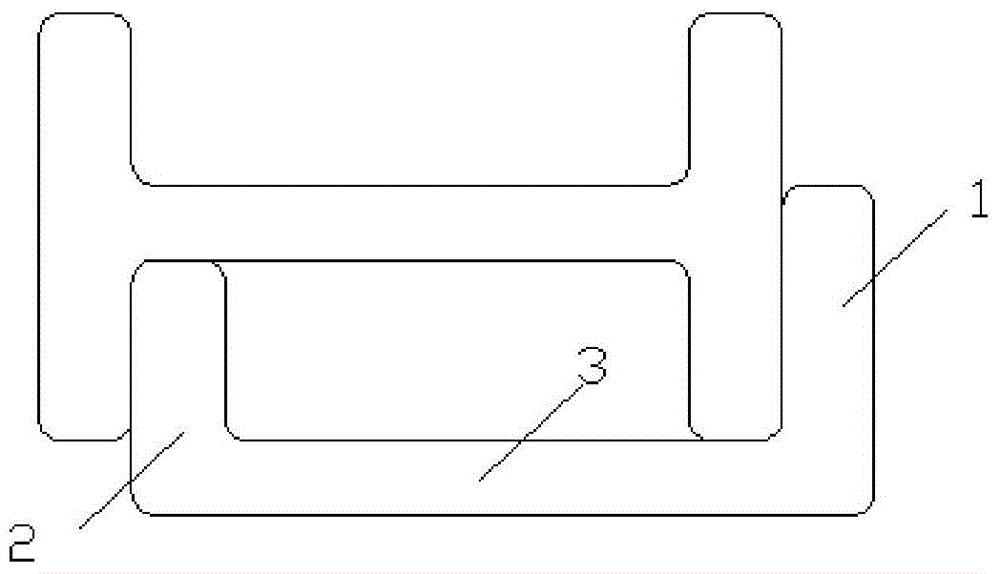

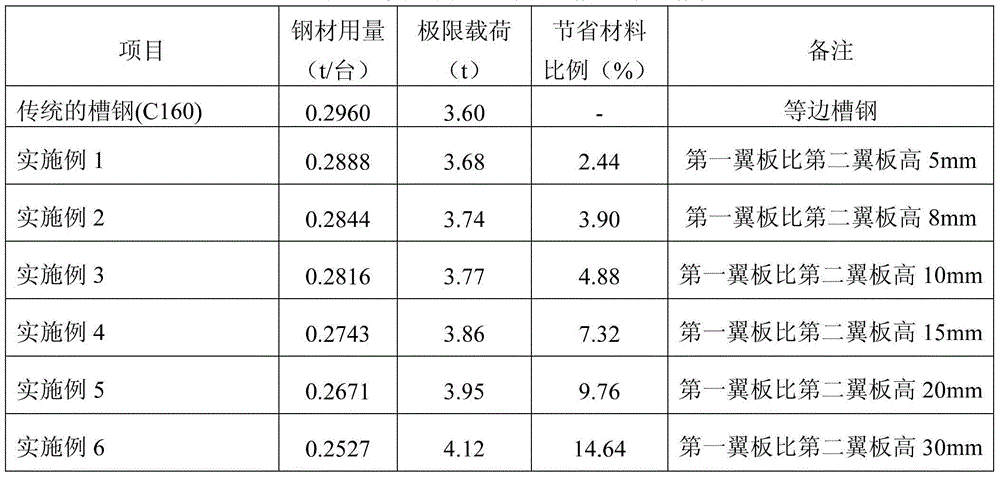

[0026] A hot-rolled unequal-sided channel steel for a forklift mast, the structure is as follows figure 1 As shown, it includes a web 3 and a wing, the wing includes a first wing 1 and a second wing 2, the two ends of the web 3 are respectively connected with the first wing 1 and the second wing 2, the first wing The plate 1 and the second wing plate 2 are located on the same side of the web plate 3. The first wing plate 1 and the second wing plate 2 are parallel to each other and are both perpendicular to the web plate 3. The height of the first wing plate 1 is higher than that of the second wing plate 2. The height is 5mm high, the connection between the inner side 6 of the first wing plate and the upper side 4 of the web is a smooth curve transition, and the connection between the inner side 9 of the second wing plate and the upper side 4 of the web is a smooth curve transition. The hot-rolled unequal-sided channel steel is integrally formed with a hot-rolled structure. Th...

Embodiment 2

[0029] A kind of hot-rolled unequal channel steel, the structure is as shown in embodiment 1, the difference is;

[0030] The height of the first wing plate 1 is 8 mm higher than the height of the second wing plate 2 .

Embodiment 3

[0032] A kind of hot-rolled unequal channel steel, the structure is as shown in embodiment 1, the difference is;

[0033] The height of the first wing plate 1 is 10 mm higher than the height of the second wing plate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com