A hydrogenation valve and its processing method

A processing method and technology of hydrogenation valve, applied in the direction of sliding valve, valve device, engine components, etc., can solve problems such as valve stem fracture, hydrogen leakage, pressure plate wear, etc., to avoid scratches and avoid excessive eccentricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

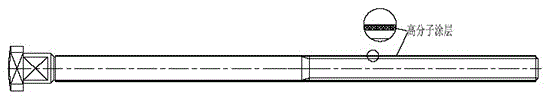

[0020] Such as figure 2 As shown, the self-lubricating polymer material is sprayed on the surface of the valve stem of the hydrogenation valve. Specifically, 1 is the valve stem of the hydrogenation valve. The material of the valve stem of the hydrogenation valve of the present invention is 0Cr18Ni12Mo2Ti, which is directly machined from bar stock with a diameter of 20mm. The material of the stem connecting nut is D-2C. The PTFE spray material is sprayed on the surface of the hydrogenation valve stem 1 by spraying technology, and cured at room temperature for 2 hours or at a curing temperature of 180°C for 0.5 hours to make The Rockwell hardness of the valve stem surface of the hydrogenation valve is lower than the hardness of the stem connecting nut material D-2C, and then the hydrogenation valve stem 1 is subjected to conventional processing to ensure that the coaxiality of the cones at both ends is within 0.08mm, and finally The valve stem 1 of the hydrogenation valve and th...

Embodiment 2

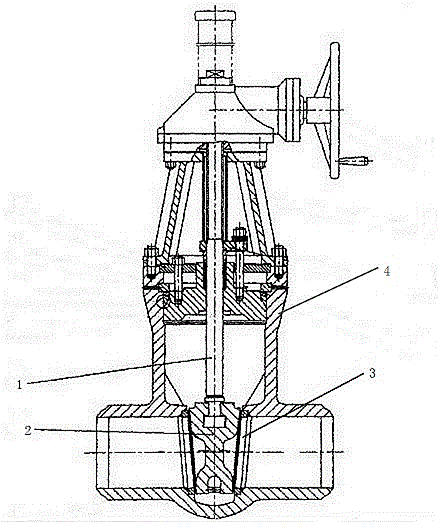

[0023] Such as figure 1 As shown, a hydrogenation valve of the present invention includes a valve body 4, a hydrogenation valve stem 1, a valve stem connecting nut 2, and a pressure plate 3. The hydrogenation valve uses a polymer material on the surface of the existing hydrogenation valve stem Surface spraying technology sprays a layer of PTFE material and cures at room temperature for 2 hours or at a curing temperature of 180°C for 0.5 hours to make the surface of the hydrogenation valve stem have a lower Rockwell hardness than that of the nut material, and then The valve stem 1 of the hydrogenation valve and the valve stem connecting nut 2 are run-in and self-aligning to ensure that the eccentricity of the hydrogenation valve stem 1 and the valve stem connecting nut 2 is within the allowable range, and the thickness of the PTFE coating is maintained at 0.02 ~0.04mm. When the hydrogenation valve is switched on and off, the valve stem 1 of the hydrogenation valve moves up and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com