Zirconium-based metal organic framework material UiO-66 (Zr) as well as room-temperature rapid preparation method and application thereof

An organic framework, uio-66 technology, applied in the field of metal-organic framework materials, can solve the problems of cumbersome washing and activation process, difficult microwave-assisted heating, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

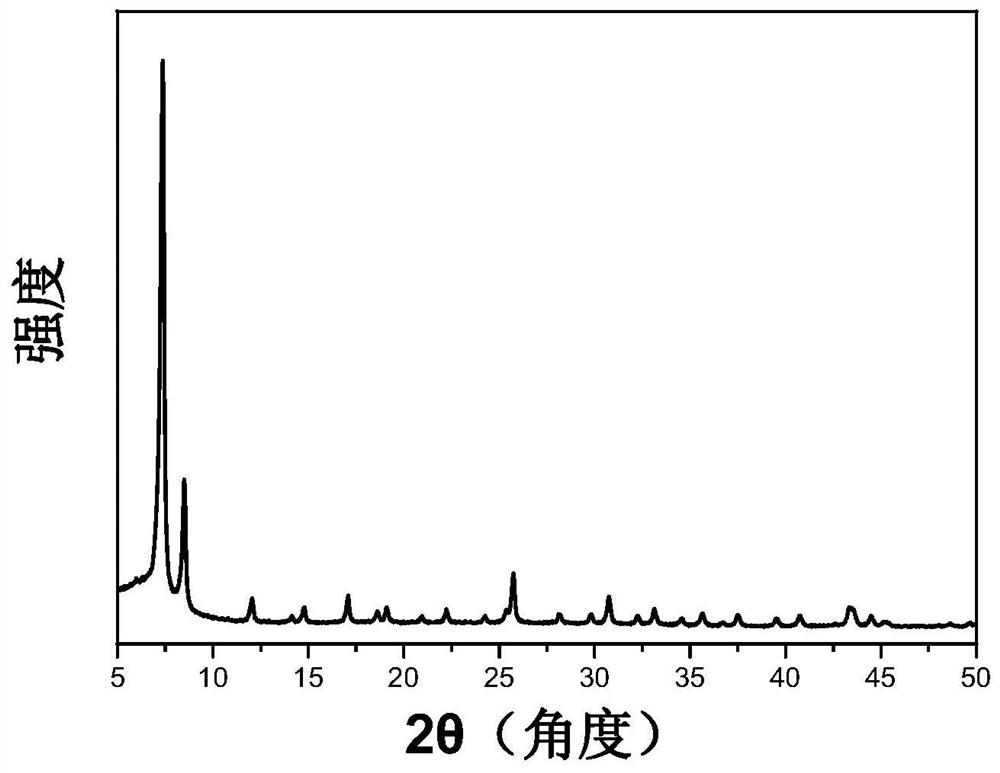

[0048] Weigh 0.996g of terephthalic acid and 1.932g of zirconium oxychloride octahydrate into a 150ml beaker, add 100ml of methanol, and stir for 1 hour under magnetic stirring conditions and 350rpm. After the reaction is finished, centrifuge the white emulsion liquid obtained after stirring, and discard the transparent gel state intermediate product obtained after the supernatant liquid is discarded. The intermediate product was transferred to a blast oven, and heated and dried at 80° C. for 1 h to obtain 1.421 g of the final product with a yield of 85%. Characterized by XRD analysis ( figure 2 ), indicating that the product synthesized in this example is a typical zirconium-based metal-organic framework material UiO-66(Zr).

Embodiment 2

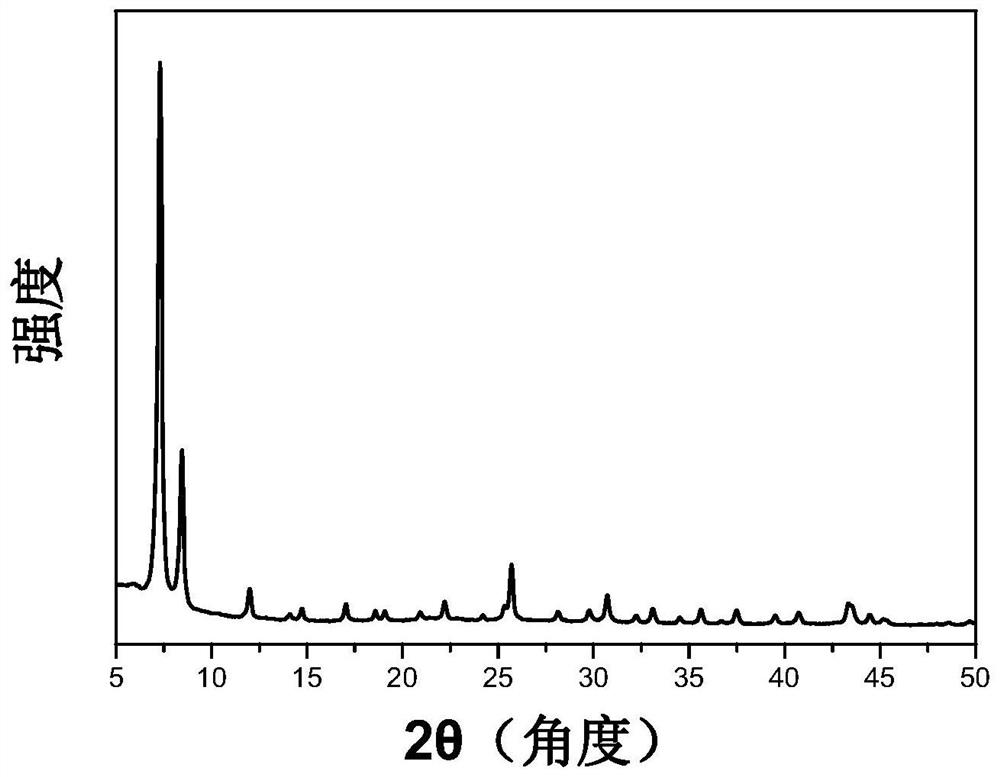

[0050] Weigh 0.996g of terephthalic acid and 1.932g of zirconium oxychloride octahydrate respectively into a 150ml beaker, add 100ml of methanol, and stir for 1h under magnetic stirring conditions at 350rpm. After the reaction, the white emulsion obtained after stirring was centrifuged, and the supernatant was discarded to obtain an intermediate product in a transparent gel state. The intermediate product was transferred to a blast oven, and heated and dried at 40° C. for 4 h to obtain 1.036 g of the final product with a yield of 62%. Characterized by XRD analysis ( image 3 ), indicating that the product synthesized in this example is a typical zirconium-based metal-organic framework material UiO-66(Zr).

Embodiment 3

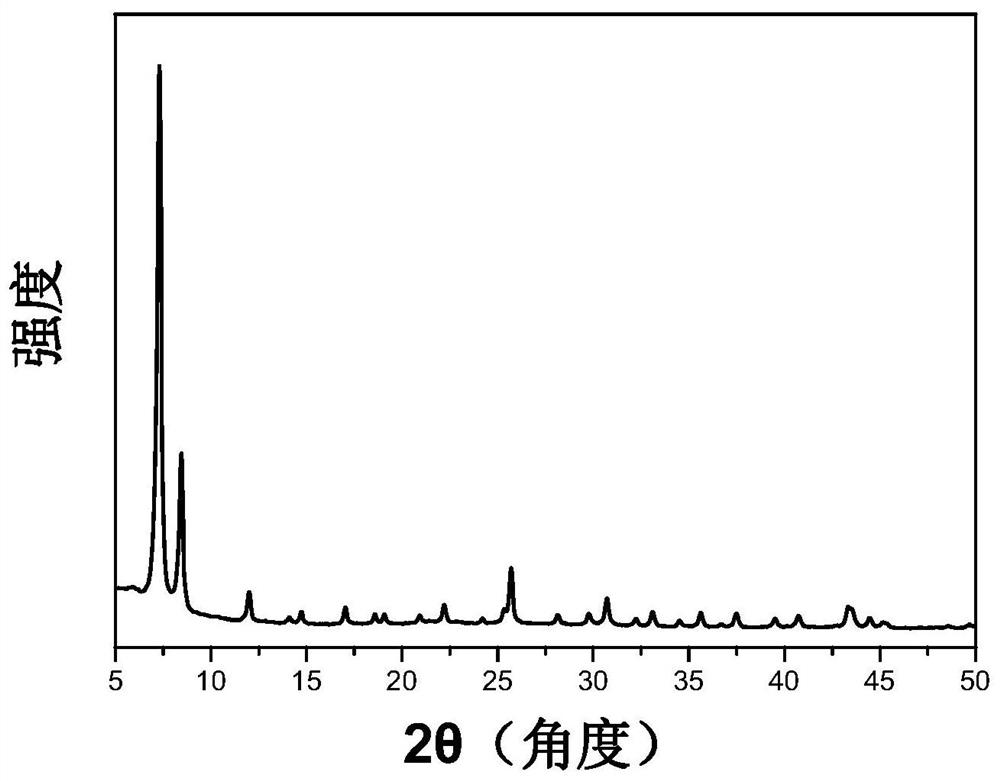

[0052] Weigh 1.992g of terephthalic acid and 1.932g of zirconium oxychloride octahydrate into a 150ml beaker, add 100ml of methanol, and stir for 1 hour under magnetic stirring conditions at 350rpm. After the reaction, the white emulsion obtained after stirring was centrifuged, and the supernatant was discarded to obtain an intermediate product in a transparent gel state. The intermediate product was transferred to a blast oven, and heated and dried at 80° C. for 4 h to obtain 1.487 g of the final product with a yield of 89%. Characterized by XRD analysis ( Figure 4 ), indicating that the product synthesized in this example is a typical zirconium-based metal-organic framework material UiO-66(Zr).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com