Extraction and preparation process of citrus pectin

A technology of pectin and extracting solution, which is applied in the field of extracting and preparing pectin, which can solve the problems of low pectin extraction yield and long heating time, and achieve the effects of high yield, reduced energy consumption, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

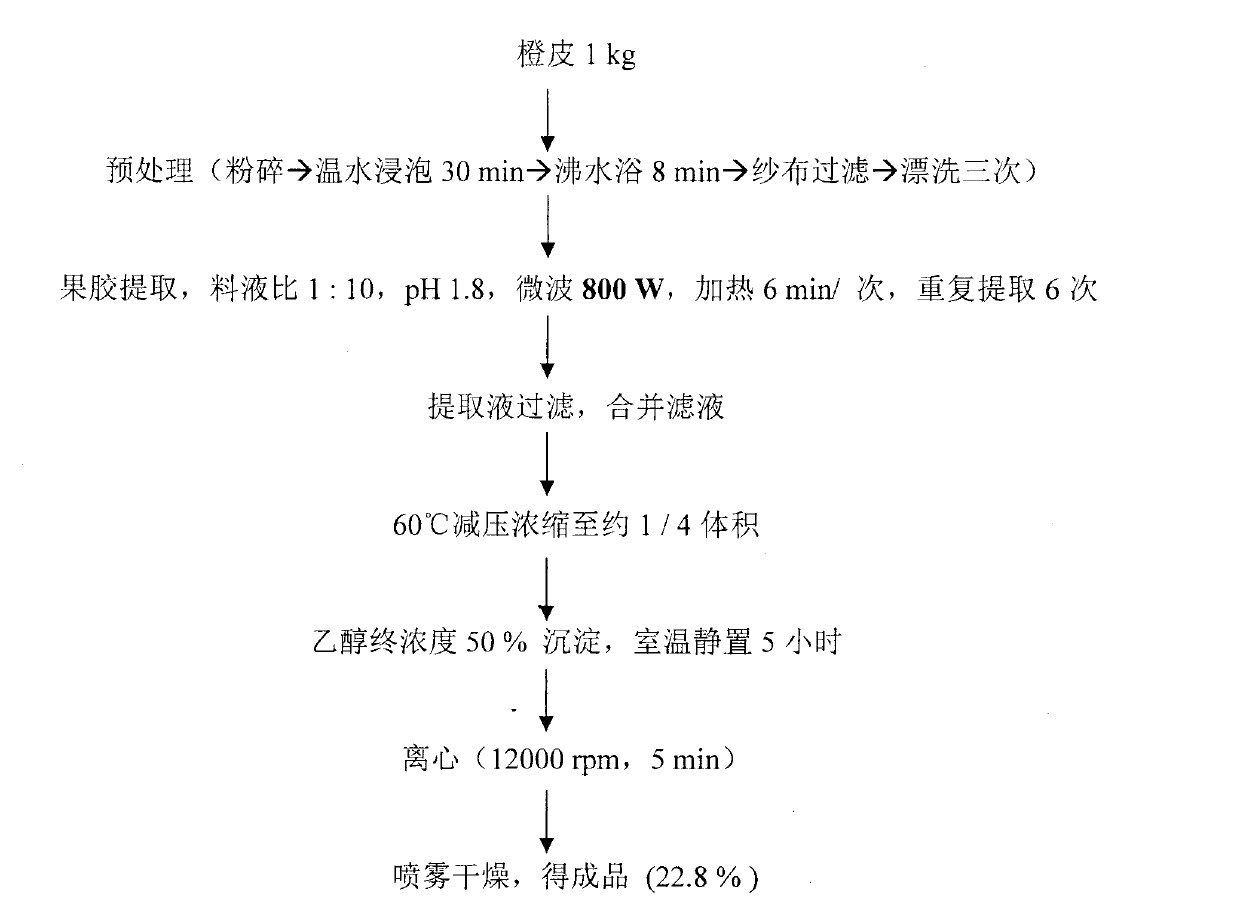

[0044] The preparation of embodiment 1 pectin:

[0045] (1) Crush 1 kg of dried orange peel to a particle size of 2-3 mm, soak in warm water for 30 minutes, heat to boil after the surface swells and rehydrate, and heat in a boiling water bath for 8 minutes to passivate pectinase Afterwards, filter with gauze to press out the juice; rinse with water for 3 times.

[0046] (2) Weigh 100g of the pretreated orange peel, add 1000ml of distilled water according to the ratio of material to liquid 1:10, adjust the pH to 1.8 with an acidity meter, place it in a microwave oven at 800W to heat for 6min, and then filter. Repeat this method for 6 times of 800W microwave heating extraction, and filter to obtain about 5500ml of 6 times of extract. Stack 2 layers with dried gauze, add cotton, put it in a Buchner funnel, collect the filtrate by suction filtration with a decompression vacuum pump, and combine the filtrates to obtain a pectin extract.

[0047] (3) Concentrate 5500ml of the pect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com