Nitrogen-doped activated carbon supported noble metal catalyst and application thereof

A precious metal catalyst, activated carbon technology, applied in metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, organic chemistry, etc., can solve the problems of high preparation cost, waste gas generation, low yield, etc. The effect of low catalyst dosage, lower use cost and high metal utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

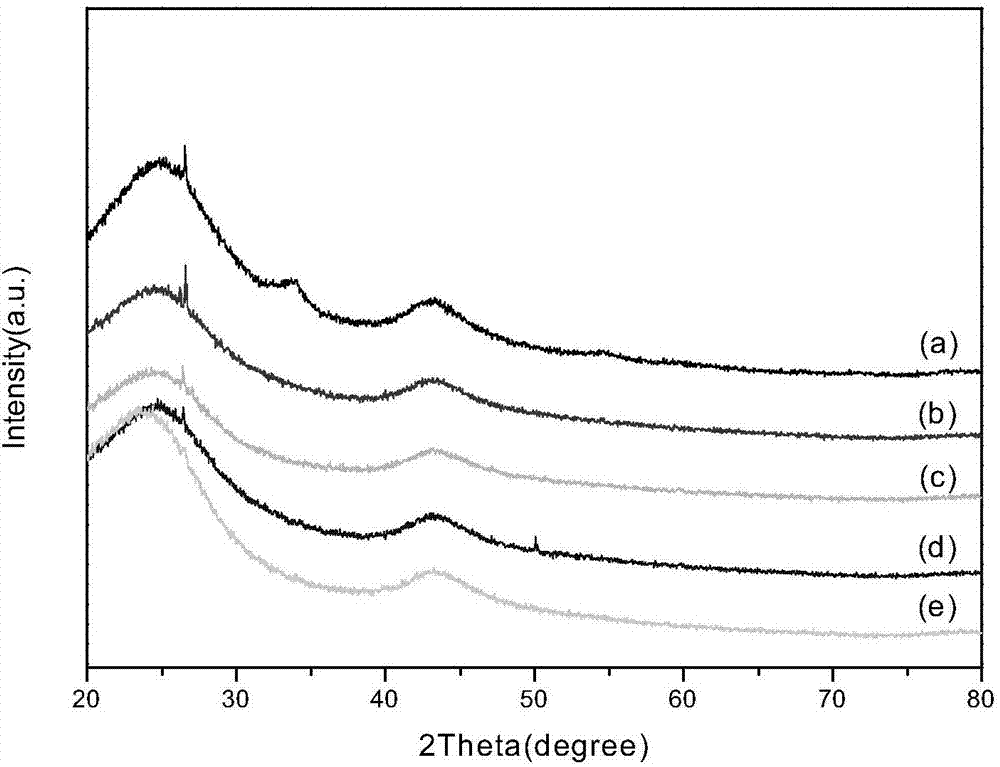

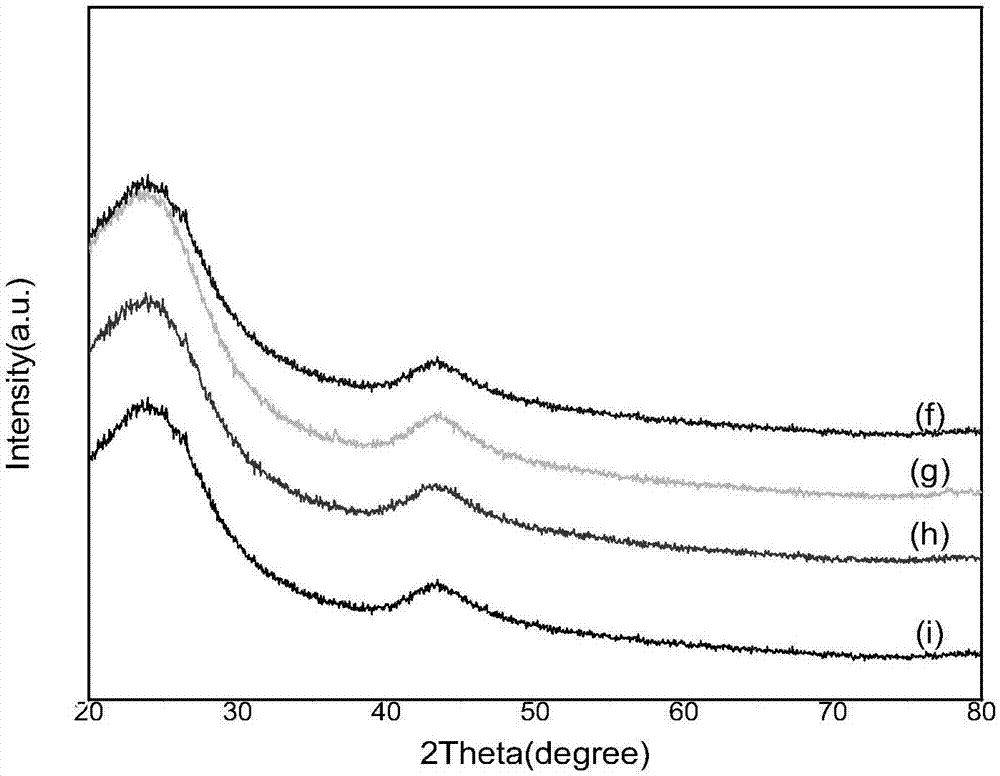

[0048] Activated carbon physical parameters and treatment: the ash content is 6.0wt%, the specific surface area is 500m 2 / g, 150-1000 mesh activated carbon, made of coconut shell. Each gram of the activated carbon was soaked and boiled in 5ml of 0.1mol / L hydrochloric acid for 1h, then treated with 3.5ml of concentrated nitric acid (10%), stirred at 35°C for 1h, and dried for later use.

[0049] Dissolve 0.08g of dicyandiamide in 40mL of water at 75°C, add 0.56g of activated carbon into the nitrogen source solution under stirring (at this time, the mass ratio of nitrogen to activated carbon is 0.1:1), and ultrasonically treat for 10 minutes, during which the temperature is 75 ℃, keep the temperature and continue mechanical stirring for 1h. Transfer the obtained slurry to a hydrothermal kettle, fill it with air and seal it under normal pressure, heat-treat it at 80°C for 2 hours, and after cooling to room temperature, wash the obtained nitrogen-containing activated carbon slur...

Embodiment 2

[0052] The physical parameters and treatment of the carrier activated carbon: the ash content is 1.0wt%, and the specific surface area is 1500m 2 / g, 200-800 mesh activated carbon, made of coconut shell. Each gram of the activated carbon was soaked and boiled in 10ml of 1.0mol / L hydrochloric acid for 1h, then treated with 15ml of concentrated nitric acid (10%), stirred at 35°C for 1h, and dried for later use.

[0053] Dissolve 0.34g of dicyandiamide in 40mL of water at 95°C, and add 0.238g of activated carbon into the nitrogen source solution under stirring. 75°C, keep the temperature and continue mechanical stirring for 10h. Transfer the obtained slurry to a hydrothermal kettle, fill it with air and seal it under normal pressure, heat-treat it at 120°C for 10 hours, and after cooling to room temperature, wash the obtained nitrogen-containing activated carbon slurry with a 50% volume fraction of ethanol-water mixture until pH=7~ 8. Dry in vacuum (-0.05Mpa) at 80°C for 10h. ...

Embodiment 3

[0056] The physical parameters and treatment of the carrier activated carbon: the ash content is 3.0wt%, and the specific surface area is 1500m 2 / g, 200-800 mesh activated carbon, made of coconut shell. Each gram of the activated carbon was soaked and boiled in 10ml of 3.0mol / L hydrochloric acid for 4h, then treated with 15ml of hydrogen peroxide (15wt%), stirred at 35°C for 15h, and dried for later use.

[0057] Dissolve 0.67g of dicyandiamide in 40mL of water at 95°C, add 0.45g of activated carbon into the nitrogen source solution, at this time, the mass ratio of nitrogen to activated carbon is 1:1, and ultrasonically treat for 20min at a temperature of 75°C, then The temperature was raised to 95°C, and the temperature was maintained to continue mechanical stirring for 24h. Transfer the obtained slurry to a hydrothermal kettle, fill it with nitrogen and seal it under normal pressure, heat-treat at 180°C for 12 hours, and after cooling to room temperature, wash the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com