Nitrogen-doped carbon-loaded palladium catalyst as well as preparation method and application thereof

A nitrogen-doped carbon and palladium catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as complex process, poor recyclability, and poor catalyst stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

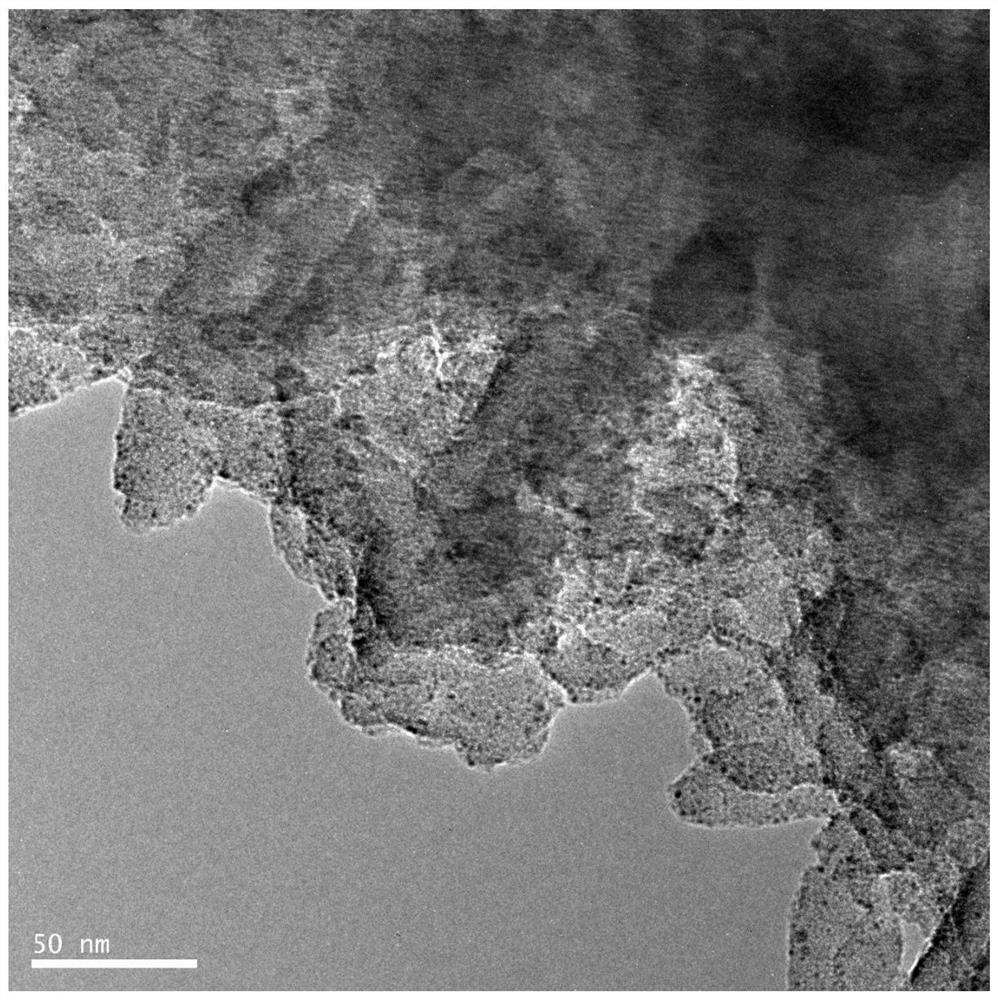

[0024] The invention provides a method for preparing a nitrogen-doped carbon-supported palladium catalyst, comprising the following steps:

[0025] Mix the carbon material with a strong acid solution and perform acid treatment to obtain an acid-activated carbon material;

[0026] The acid-activated carbon material, the water-soluble palladium salt solution and the nitrogen-containing ionic liquid are mixed and then dried to obtain a catalyst precursor;

[0027] The catalyst precursor is calcined and then reduced under a protective atmosphere to obtain a nitrogen-doped carbon-supported palladium catalyst.

[0028] The invention mixes the carbon material with a strong acid solution and performs acid treatment to obtain the acid-activated carbon material.

[0029] In the present invention, the carbon material preferably includes activated carbon, mesoporous carbon, carbon nanotube or graphene, more preferably activated carbon. In the present invention, the strong acid solution ...

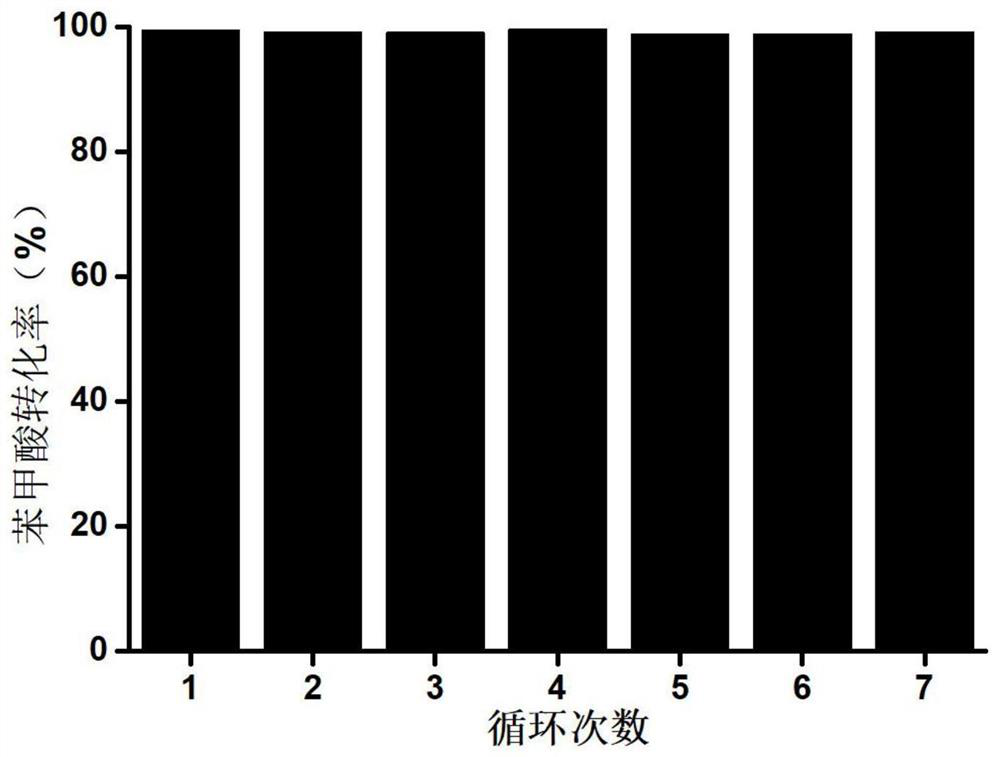

Embodiment 1

[0055] (1) Put 1 g of activated carbon in 30 mL of nitric acid-hydrochloric acid mixed solution, carry out acid treatment under stirring conditions for 10 h and then filter, wash and dry the obtained solid components to obtain acid-activated activated carbon, wherein the nitric acid in the mixed solution of nitric acid-hydrochloric acid And the concentration of hydrochloric acid is 2mol / L;

[0056] (2) Dissolve 1g of palladium chloride in 2mL of concentrated hydrochloric acid, transfer to a 100mL volumetric flask, add deionization to constant volume, and obtain a chloropalladium acid solution with a concentration of 10mg / mL;

[0057] (3) 1 g of the acid-activated activated carbon, 1.71 mL of the chloropalladium acid solution and 300 mg of 1,3-diethylimidazole acetate were mixed and stirred at room temperature for 1 h, and then dried at 130° C. for 10 h while stirring, Obtain catalyst precursor;

[0058] (4) The catalyst precursor is heated to 800°C at a rate of 5°C / min in a n...

Embodiment 2

[0061] (1) Put 1 g of activated carbon in 30 mL of nitric acid-hydrochloric acid mixed solution, carry out acid treatment under stirring conditions for 10 h and then filter, wash and dry the obtained solid components to obtain acid-activated activated carbon, wherein the nitric acid in the mixed solution of nitric acid-hydrochloric acid And the concentration of hydrochloric acid is 2mol / L;

[0062] (2) Dissolve 1g of palladium chloride in 2mL of concentrated hydrochloric acid, transfer to a 100mL volumetric flask, add deionization to constant volume, and obtain a chloropalladium acid solution with a concentration of 10mg / mL;

[0063] (3) 1 g of the acid-activated activated carbon, 1.71 mL of the chloropalladium acid solution and 400 mg of 1,3-diethylimidazole acetate were mixed and stirred at room temperature for 1 h, and then dried at 130° C. for 10 h while stirring, Obtain catalyst precursor;

[0064] (4) The catalyst precursor is heated to 800°C at a rate of 5°C / min in a n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com