Preparation method and applications of bamboo knot-like nitrogen-doped graphite carbon nanotube electrode material

An electrode material and nitrogen doping technology, applied in the fields of nanomaterials and electrochemistry, can solve the problems of insignificant influence of capacitance, and achieve the effects of being conducive to market promotion, easy to enlarge, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

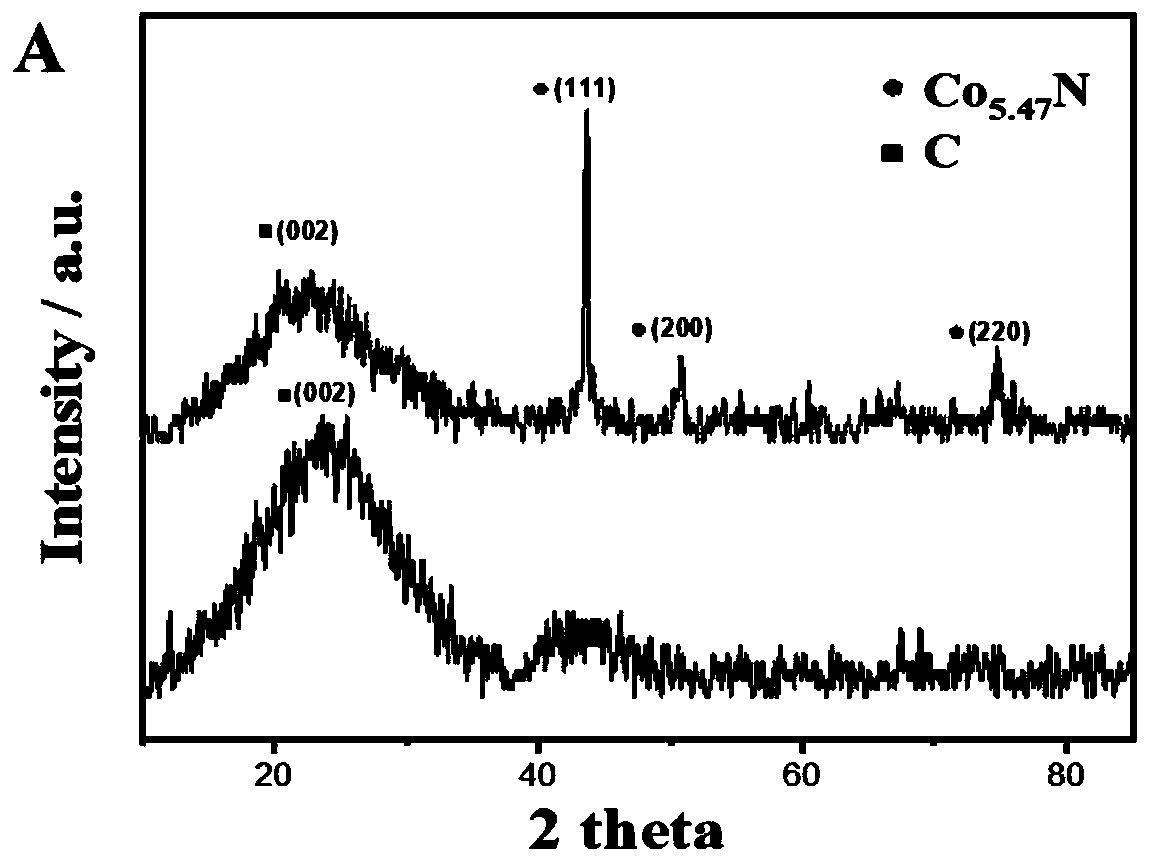

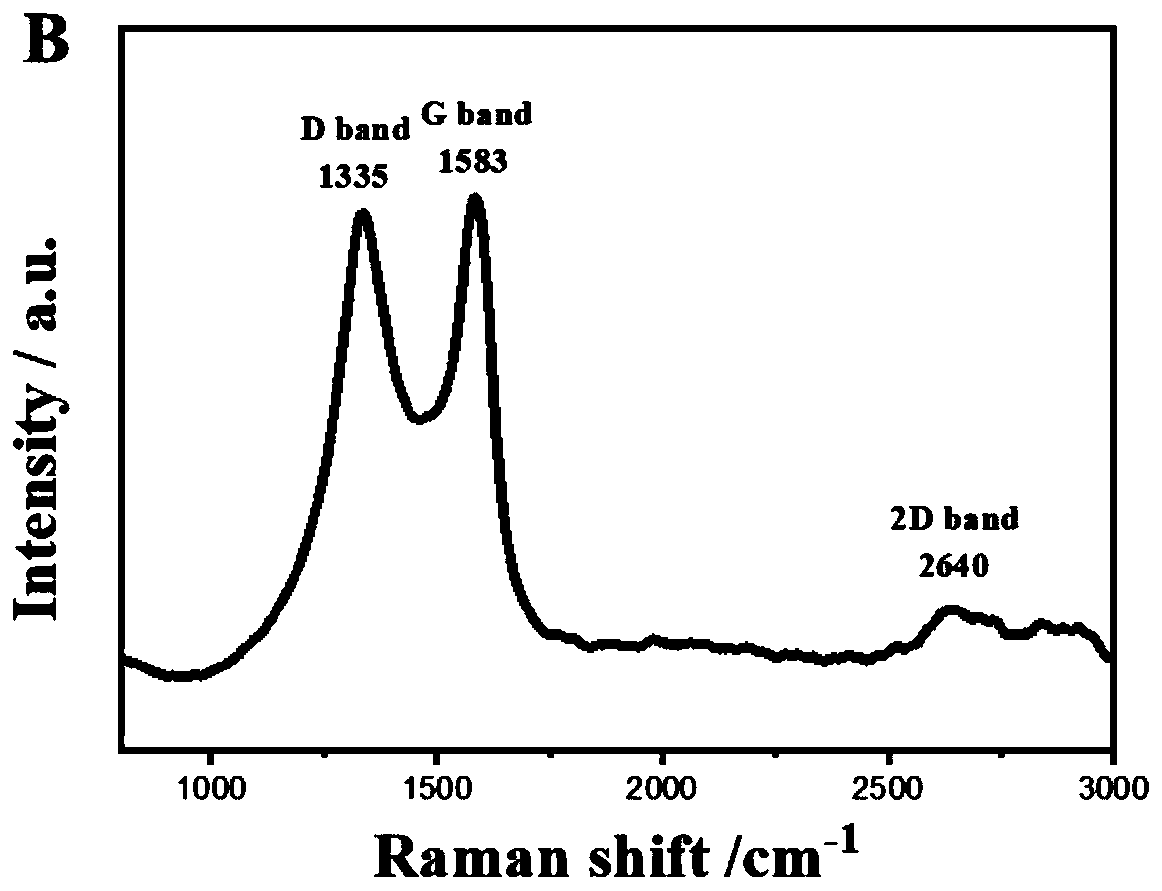

[0036] The preparation method of bamboo-shaped nitrogen-doped carbon nanotube electrode material includes the following steps:

[0037] S1. Add 3g of melamine and 15.12g of 37% formaldehyde solution in 14g of water, add 0.1mol / L of NaOH solution, adjust its pH to 8.5, and stir at 65°C until it is transparent to obtain MF. Polymer solution, as A solution.

[0038] S2, to 14g SiO 2 Ammonium hydroxide was added to the nanoparticle suspension, the pH of the suspension was adjusted to 8.5, and after 10 minutes of ultrasonic treatment, 0.11 g of a 37% formaldehyde solution was added as liquid B. The SiO 2 The density of the nanoparticle suspension is 1.4 g / mL.

[0039] S3. Add liquid B to liquid A drop by drop, stir for a few minutes, adjust the pH to 5.0 with glacial acetic acid, and collect MF / SiO after 10 minutes 2 , Wash with ethanol by centrifugation several times.

[0040] S4, prepared MF / SiO 2 Disperse in 50ml ethanol, stir vigorously at 65℃, add 1.13g CoCl 2 The solution was stirre...

Embodiment 2

[0052] S1. Add 3g of melamine and 15.12g of 37% formaldehyde solution in 14g of water, add 0.1mol / L NaOH aqueous solution, adjust its pH to 8.5, and stir at 65°C until it is transparent to obtain MF Polymer solution, as A solution.

[0053] S2, to 14g SiO 2 Ammonium hydroxide was added to the nanoparticle suspension, the pH of the suspension was adjusted to 8.5, and after 10 minutes of ultrasonic treatment, 0.11 g of a 37% formaldehyde solution was added as liquid B. The SiO 2 The density of the nanoparticle suspension is 1.4 g / mL.

[0054] S3. Add liquid B to liquid A drop by drop, stir for a few minutes, adjust the pH value to 5.0 with glacial acetic acid, collect MF / SiO2 after 10 minutes, and wash with ethanol for several times.

[0055] S4, prepared MF / SiO 2 Disperse in 50ml ethanol, stir vigorously at 65℃, add 0ml CoCl 2 The solution was stirred for 40 minutes and dried at 120°C for 2 hours to obtain a uniform precursor.

[0056] S5. The precursor is initially at 1℃min in a nitr...

Embodiment 3

[0060] S1. Add 3g of melamine and 15.12g of 37% formaldehyde solution in 14g of water, add 0.1mol / L of NaOH solution, adjust its pH to 8.5, and stir at 65°C until it is transparent to obtain MF. Polymer solution, as A solution.

[0061] S2, to 0ml SiO 2 Ammonium hydroxide was added to the nanoparticle suspension, the pH of the suspension was adjusted to 8.5, and 0.1 ml of formaldehyde solution was added after ultrasonic treatment for 10 minutes as liquid B.

[0062] S3. Add liquid B to liquid A drop by drop, stir for a few minutes, adjust the pH to 5.0 with glacial acetic acid, and collect MF / SiO after 10 minutes 2 , Wash with ethanol by centrifugation several times.

[0063] S4, prepared MF / SiO 2 Disperse in 50ml ethanol, stir vigorously at 65℃, add 1.13g CoCl 2 The solution was stirred for 40 minutes and dried at 120°C for 2 hours to obtain a uniform precursor. The CoCl 2 The concentration of the solution is 1mol / L.

[0064] S5. The precursor is initially at 1℃min in a nitrogen atm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com