Micro-nano reinforcing steel bar anti-rusting agent for autoclaved aerated concrete slab and preparation method of micro-nano reinforcing steel bar anti-rusting agent

A concrete slab, autoclaved aerated technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems affecting the structural performance and quality control of autoclaved aerated concrete slabs, low bonding force of steel bars, and large specificity of ground sand , to avoid sinking problems, improve the bonding force of steel bars, and achieve the effect of high degree of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

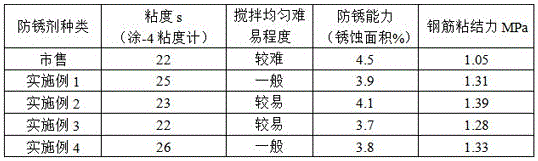

Examples

Embodiment 1

[0042] Raw materials and performance requirements of micro-nano steel bar rust inhibitor for autoclaved aerated concrete slabs:

[0043] Silicone-modified acrylic emulsion with a solid content of 30% (LR-308A of Guangzhou Baiyun Henghe Fine Chemical Factory); silica sol emulsion, SiO 2 The content is 20%; the specific surface area of silica fume is 20m 2 / g, when silica fume is preferably smelting industrial silicon or silicon-containing alloys, it is obtained by reducing high-purity quartz and coke in a high-temperature electric arc furnace. Commercially available products such as those produced by the Norwegian Elkem Group; lime is slaked lime powder; The cement is PO42.5 Portland cement; the fineness of light calcium silicate is 1000 mesh; The agent is silicone emulsion defoamer; the dispersant is sodium hexametaphosphate.

[0044] The autoclaved aerated concrete slab is made of the following raw materials in terms of the mass percentage of the raw materials:

[0045] ...

Embodiment 2

[0061] Raw materials and performance requirements of micro-nano steel bar rust inhibitor for autoclaved aerated concrete slabs:

[0062] Silicone-modified acrylic emulsion has a solid content of 30% (Dongguan Longqin Chemical Co., Ltd. 9908A); silica sol emulsion SiO 2 The content is 30%; the specific surface area of silica fume is 18m 2 / g; lime is slaked lime powder; cement is PO42.5 Portland cement; the fineness of light calcium silicate is 800 mesh; film-forming aid is alcohol ester twelve; 6000; the defoamer is a silicone emulsion defoamer; the dispersant is sodium hexametaphosphate.

[0063] The autoclaved aerated concrete slab uses a micro-nano steel antirust agent, which is composed of the following components in terms of mass percentage of raw materials:

[0064] Silicone modified acrylic emulsion: 25%;

[0065] Silica sol emulsion: 15%;

[0066] Lime: 8%;

[0067] Silica fume: 8%;

[0068] Cement: 12%;

[0069] Light calcium carbonate: 8%;

[0070] Film-form...

Embodiment 3

[0080] Raw materials and performance requirements of micro-nano steel bar rust inhibitor for autoclaved aerated concrete slabs:

[0081] The solid content of the silicone modified acrylic emulsion is 50%; the silica sol emulsion SiO 2 The content is 25%; the specific surface area of silica fume is 20m 2 / g; lime is slaked lime powder; cement is PO42.5 Portland cement; light calcium silicate fineness is 800 mesh; film-forming aid is alcohol ester twelve; viscosifier is hydroxypropyl methylcellulose Ether, 100,000 viscosity; defoamer is silicone emulsion defoamer; dispersant is sodium hexametaphosphate.

[0082] The autoclaved aerated concrete slab uses a micro-nano steel antirust agent, which is composed of the following components in terms of mass percentage of raw materials:

[0083] Silicone modified acrylic emulsion: 20%;

[0084] Silica sol emulsion: 15%;

[0085] Lime: 10%;

[0086] Silica fume: 12%;

[0087] Cement: 12%;

[0088] Light calcium carbonate: 10%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com