Prevention method of shallow-buried steeply-inclined coal seam rock burst

A technology of rock burst and steep inclination, which is applied in the field of prevention and control of rock burst in coal mining, and can solve problems such as accidents, lack of preventive measures, and coal seam burst pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A method for preventing and controlling rockburst in shallowly buried steeply inclined coal seams, comprising the following steps:

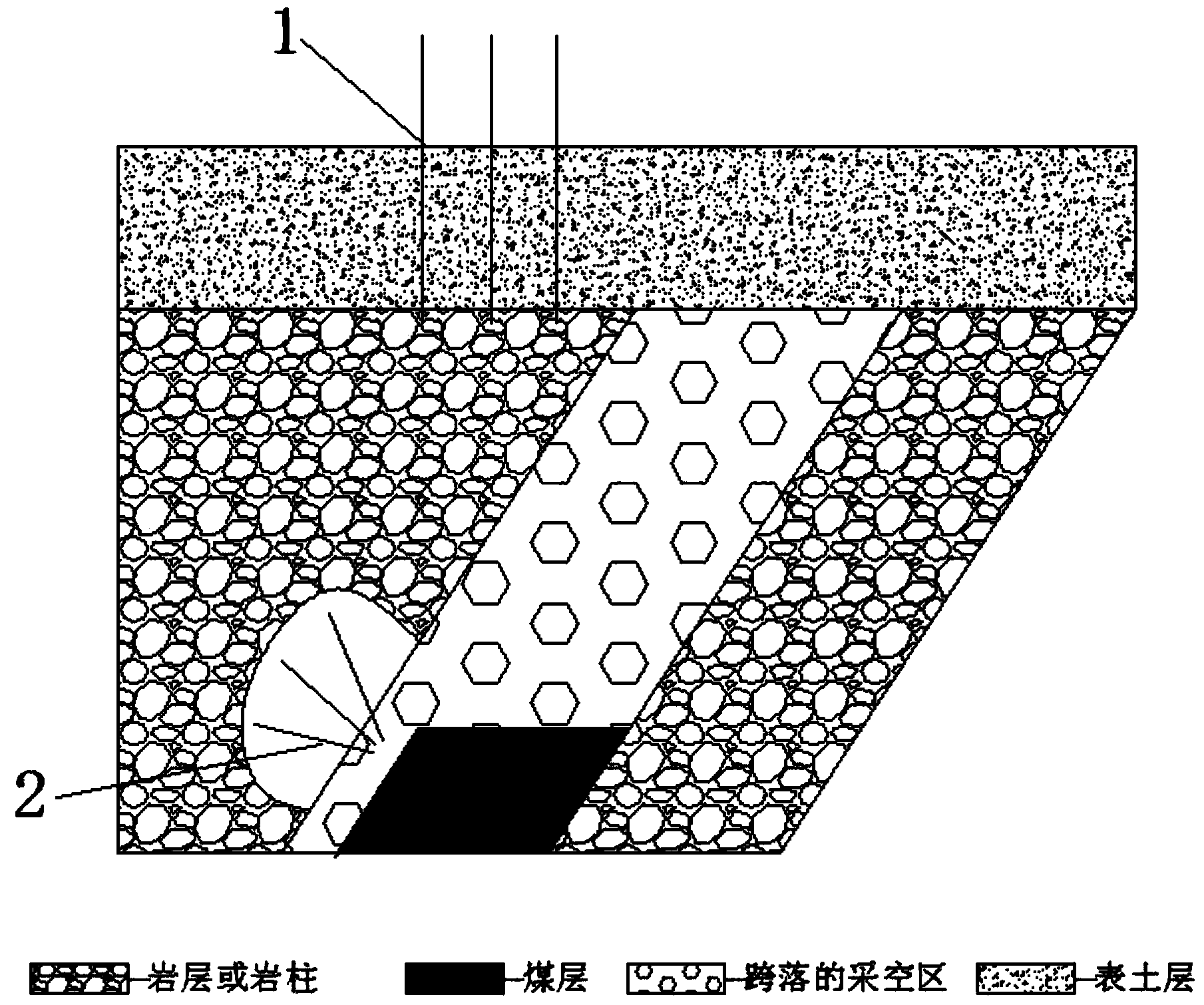

[0029] A. If image 3 As shown, before the mining of the coal seam, drill holes from the ground to pre-split and blast the roof and floor rock layers or rock pillars of the coal seam, and 1 is the location of the ground drilling and blasting before the coal seam mining;

[0030] Pressure relief blasting is a pressure relief measure that changes the stress distribution by drilling and blasting in rock pillars. Vibratory blasting in the rock pillar can release the elastic energy accumulated in the rock pillar to the greatest extent, forming a pressure relief damage zone and reducing the integrity. Pressure relief blasting is the most commonly used method in rock burst hazard relief measures. The rock mass after blasting fills the goaf, which increases the stability of the rock mass or rock pillar and reduces the possibility of rock burst. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com