Safety device of vehicle tyre

A technology for safety insurance and automobile tires, applied to wheels, tire parts, wheels that can support multiple tires, etc., can solve the problems of large sloshing vibration, tire damage, inconvenience, etc., to increase the force and reduce the line The effect of poor speed and durable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

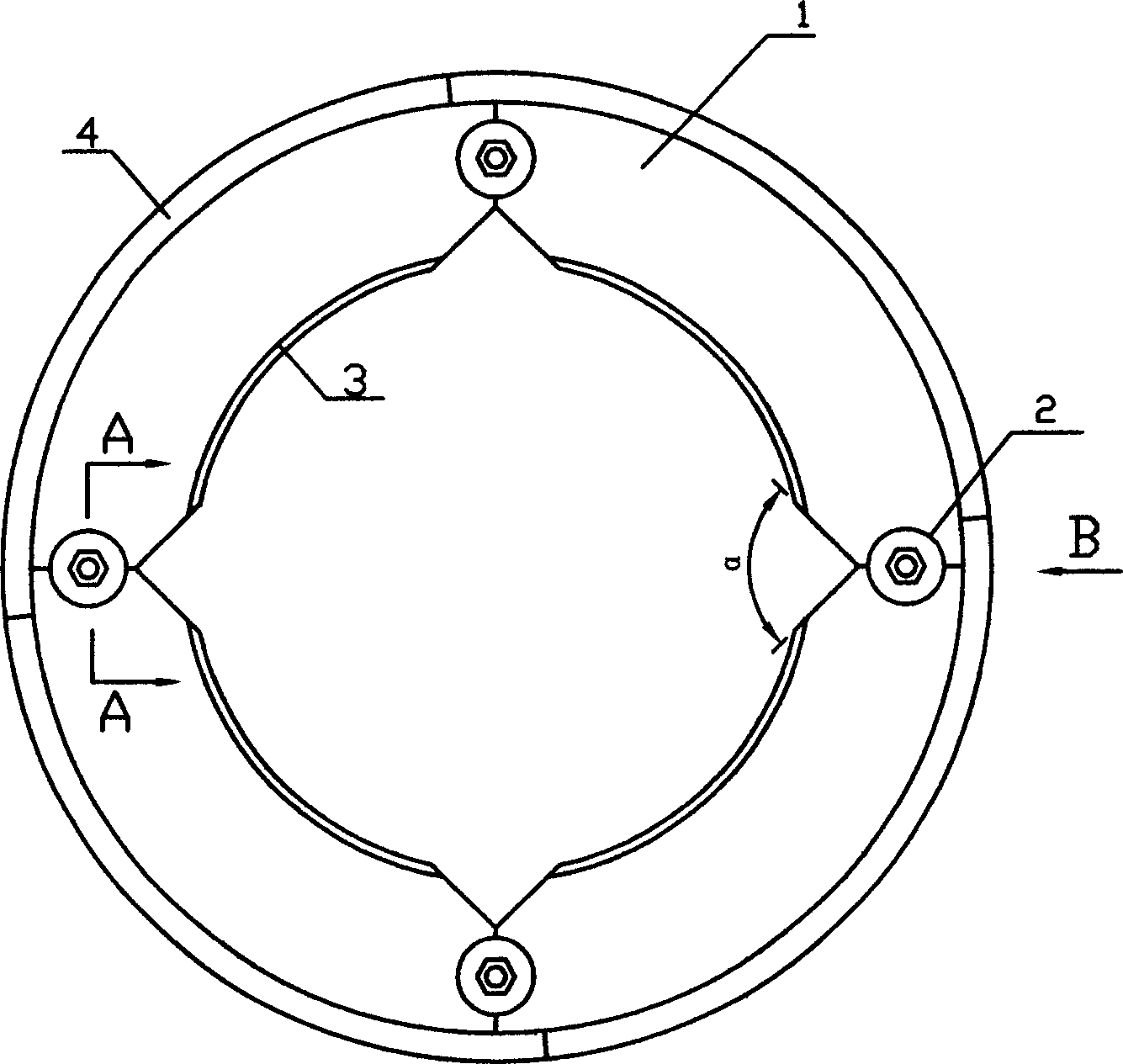

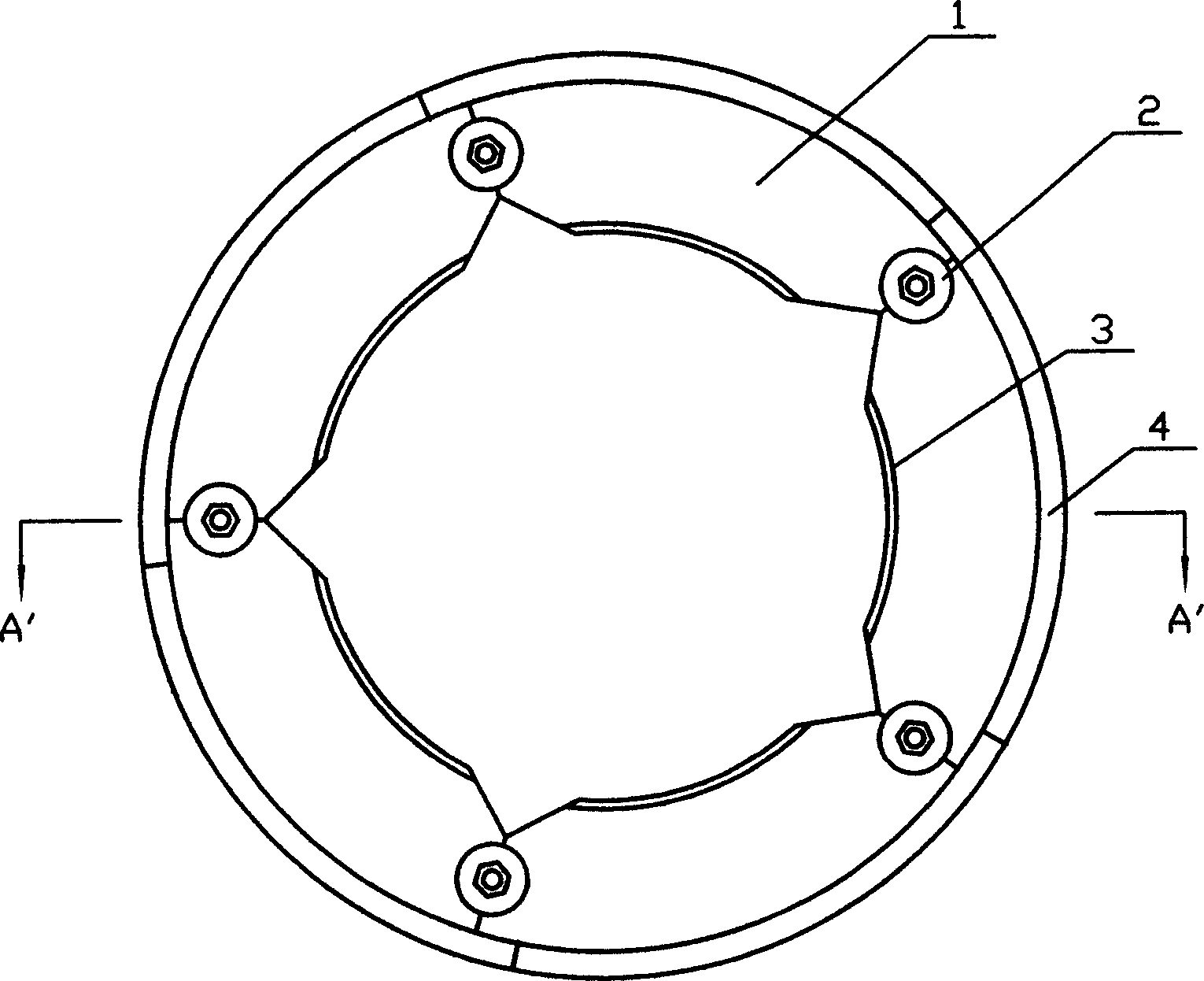

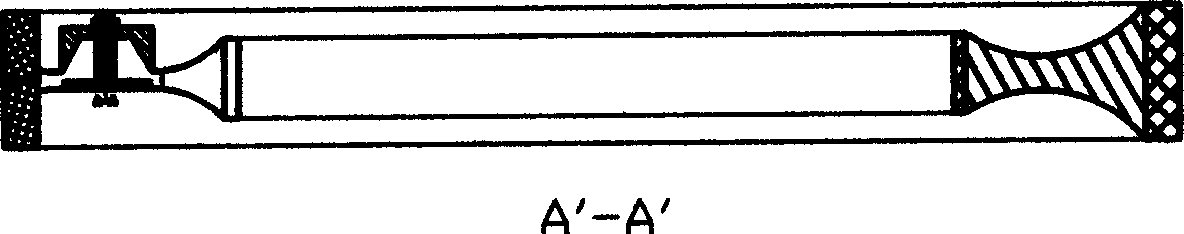

[0029] As shown in the accompanying drawings, the petals 1 with an I-shaped skeleton are made of alloy steel, and 4 to 6 petals 1 are combined into a ring, such as figure 1 Use 4 blocks, such as figure 2 Use 5 petals, such as Figure 12 With 6 petal pieces; The inboard surface of the annulus that they are combined is suitable with the surface of automobile hub, and is close to on the wheel hub by lining sheet 3. The connection between the petals 1 is realized by an axial locking mechanism 3, which includes a bottom plate 2-1, a compression screw 2-3, a nut 2-4, a briquetting block 2-5, and a compression screw 2. -3 is connected to the bottom plate 2-1. On both sides of each petal 1, there are semi-bosses 1-1, 1-1', and there is an axial semi-cylindrical hole in the middle of the semi-boss, when every two petals 1 merge, Two above-mentioned semi-bosses 1-1, 1-1' form a boss, and a screw hole 2-2 is formed in the middle of the boss, when the bottom plate 2-1 is placed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com