Patents

Literature

39results about How to "Reduce the radial distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

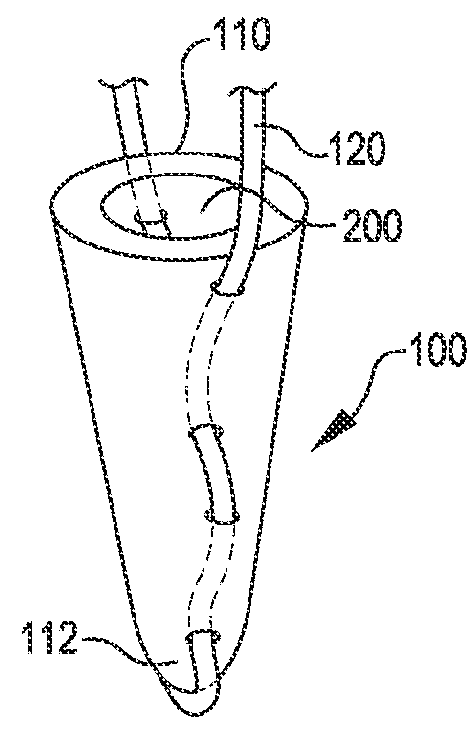

Tissue repair assembly

ActiveUS20130123810A1Reduce the radial distanceIncrease the angleSuture equipmentsDiagnosticsTissue repairBiomedical engineering

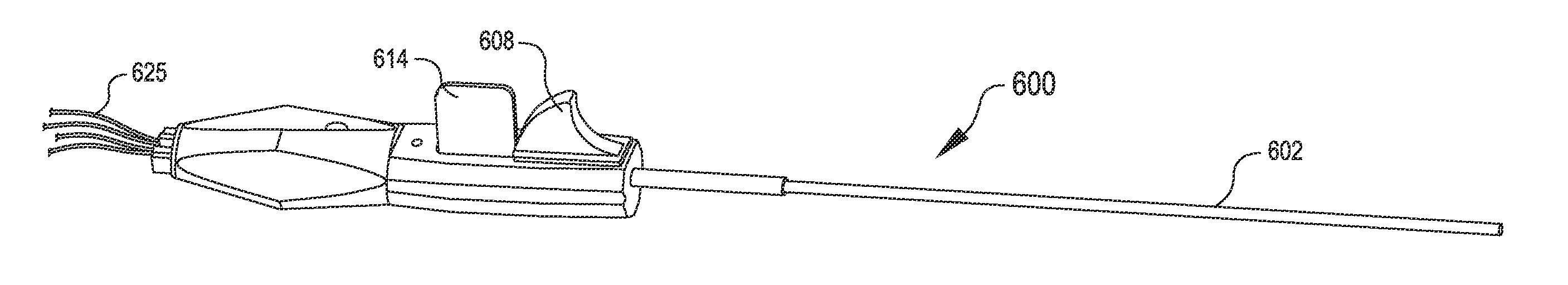

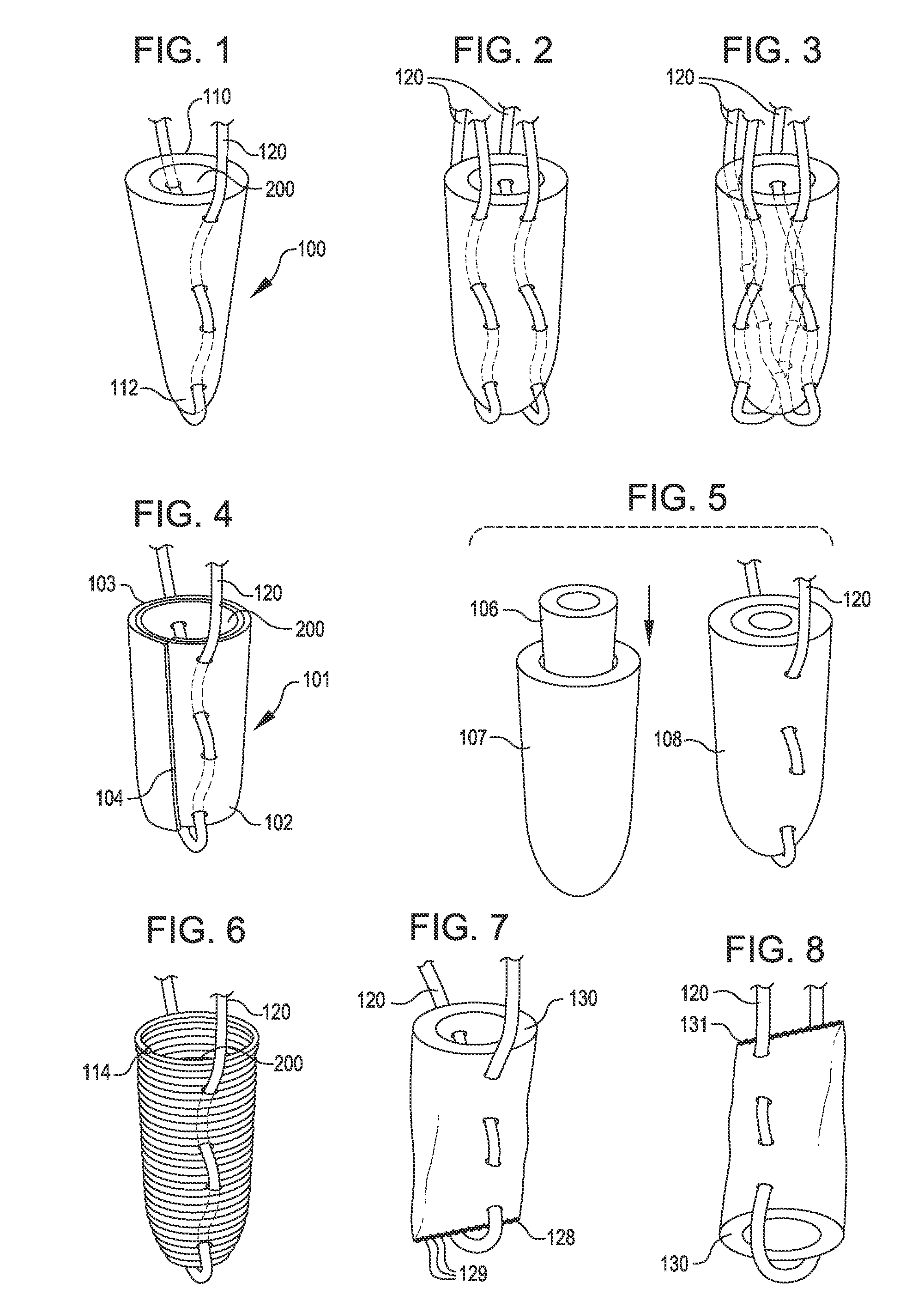

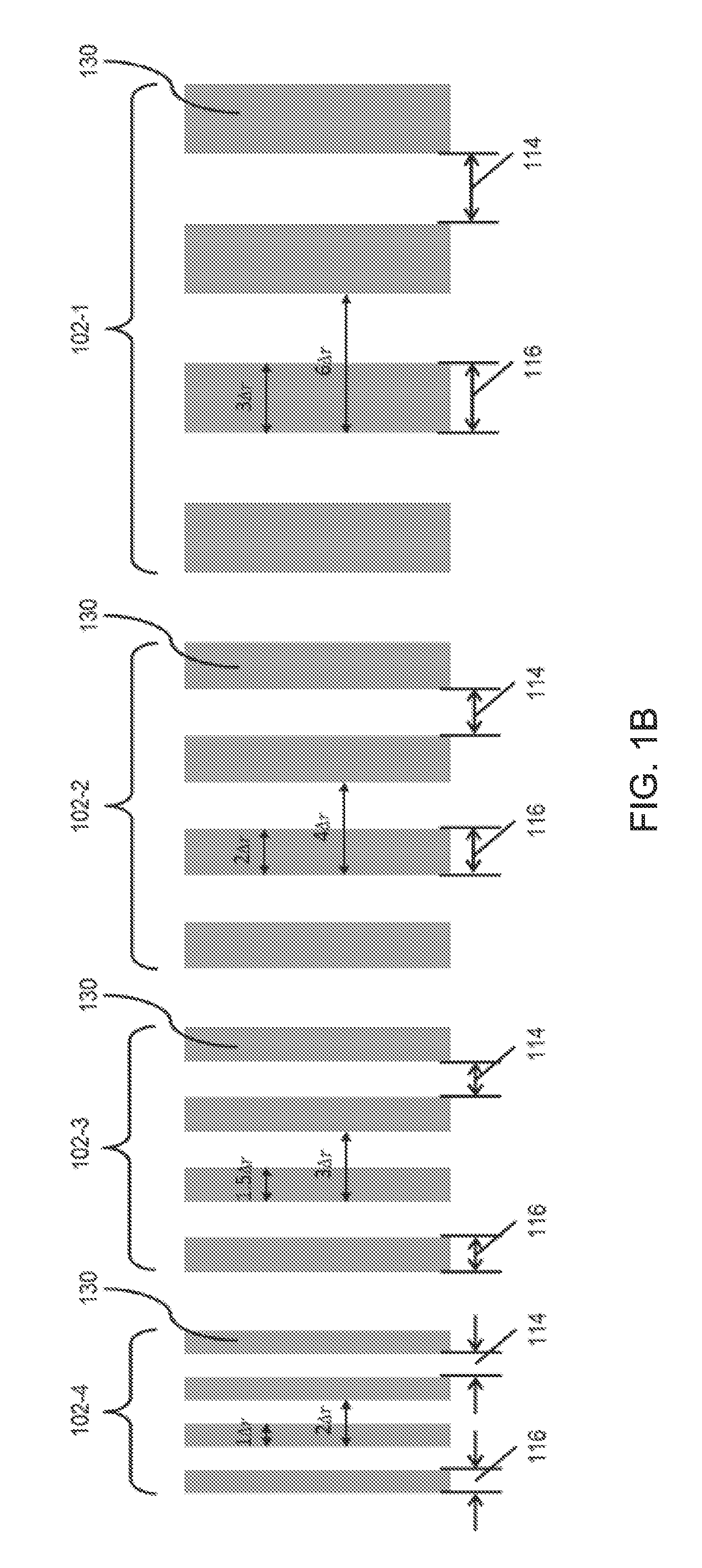

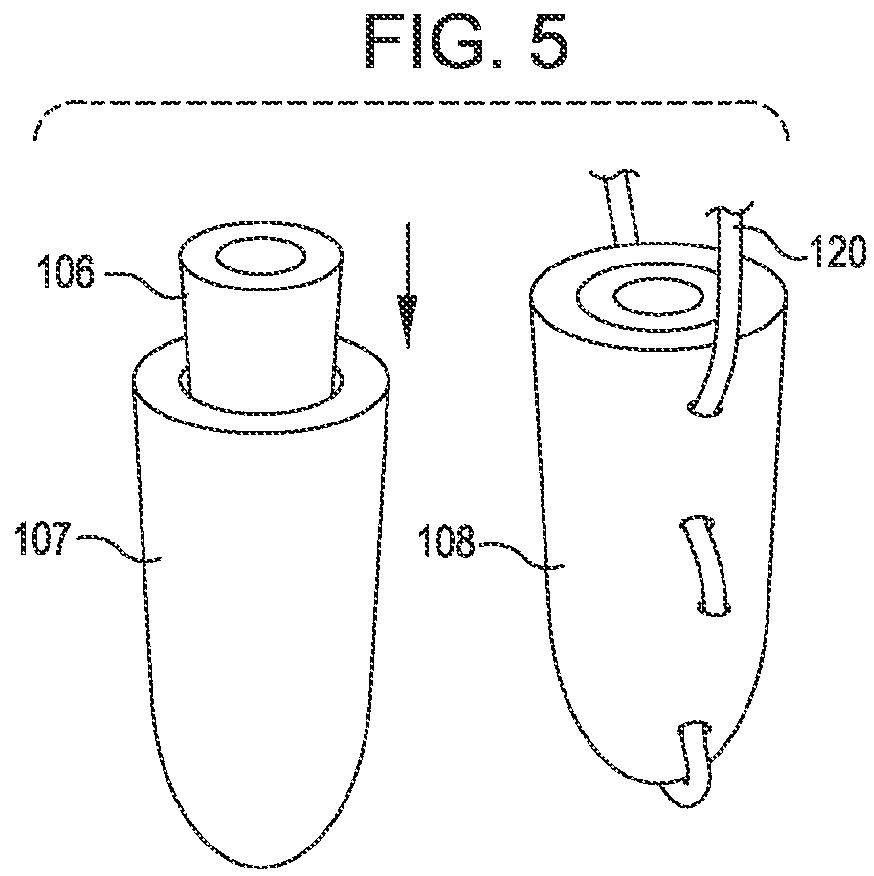

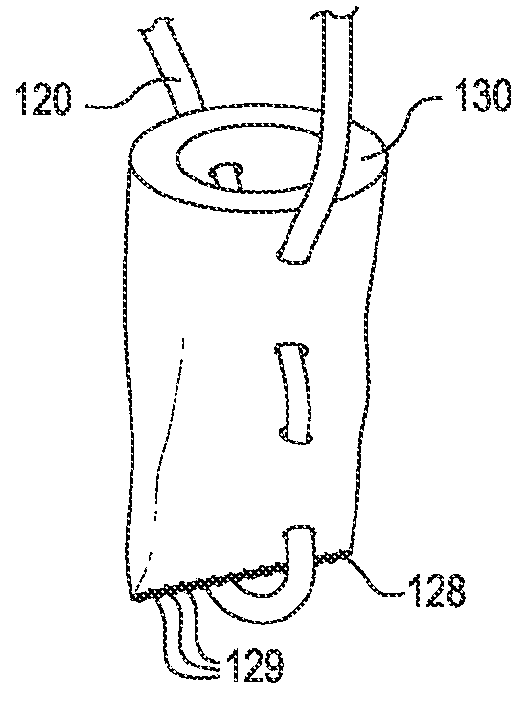

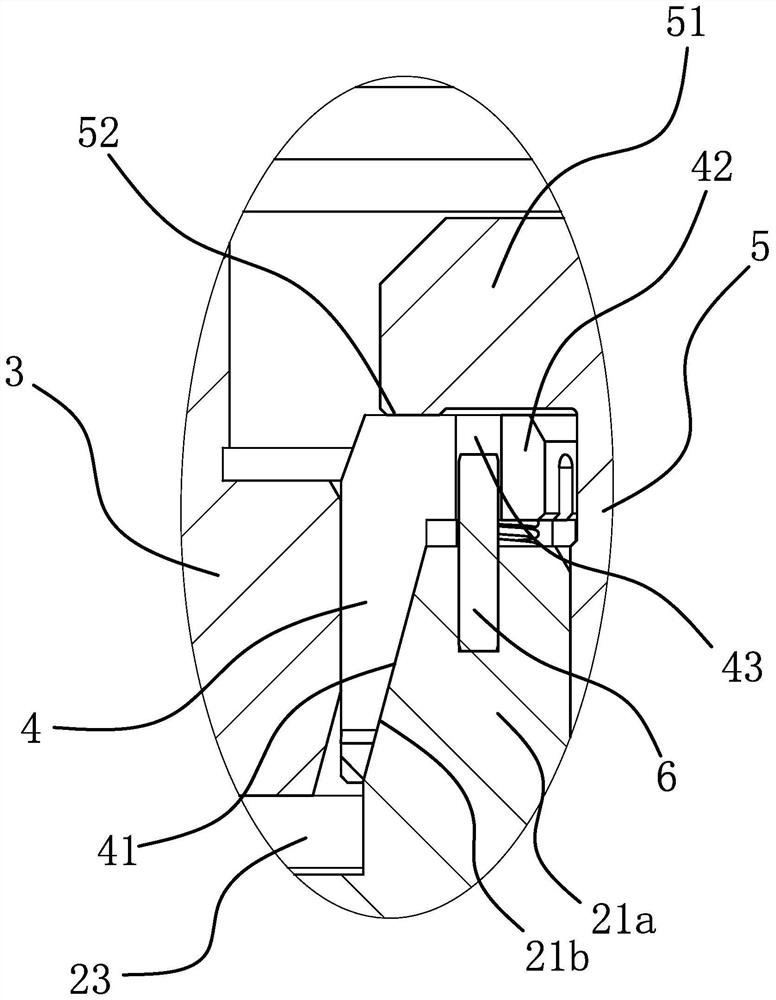

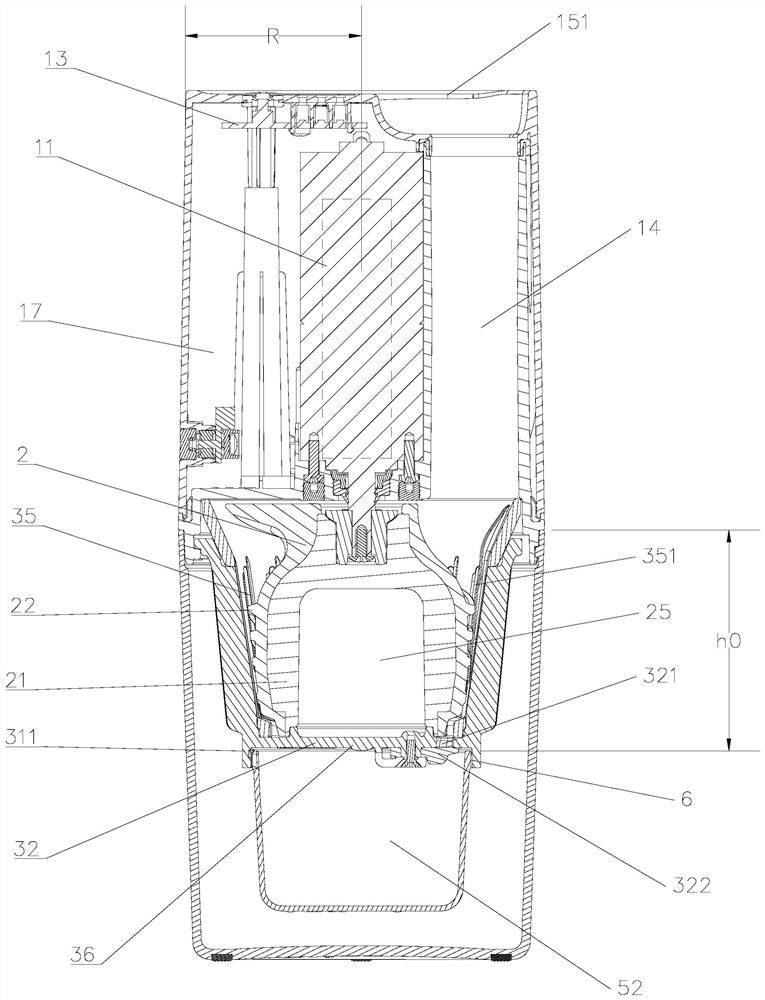

A tissue repair assembly for attachment of tissue to bone or tissue to tissue having a soft anchoring implant 100 with a length of suture 120 there through for tensioning the implant and facilitating attachment of other tissue. The implant 100 is a soft, flexible, three-dimensional structure that has a resident volume 200. An inserter tube 310 facilitates the placement of the implant 100 into bone or adjacent soft tissue where it may be deployed. Upon deployment, the soft anchoring implant 100 shortens axially and expands radially, achieving a larger diameter than the hole through which it was placed, thus resisting pull out.

Owner:ARTHROCARE

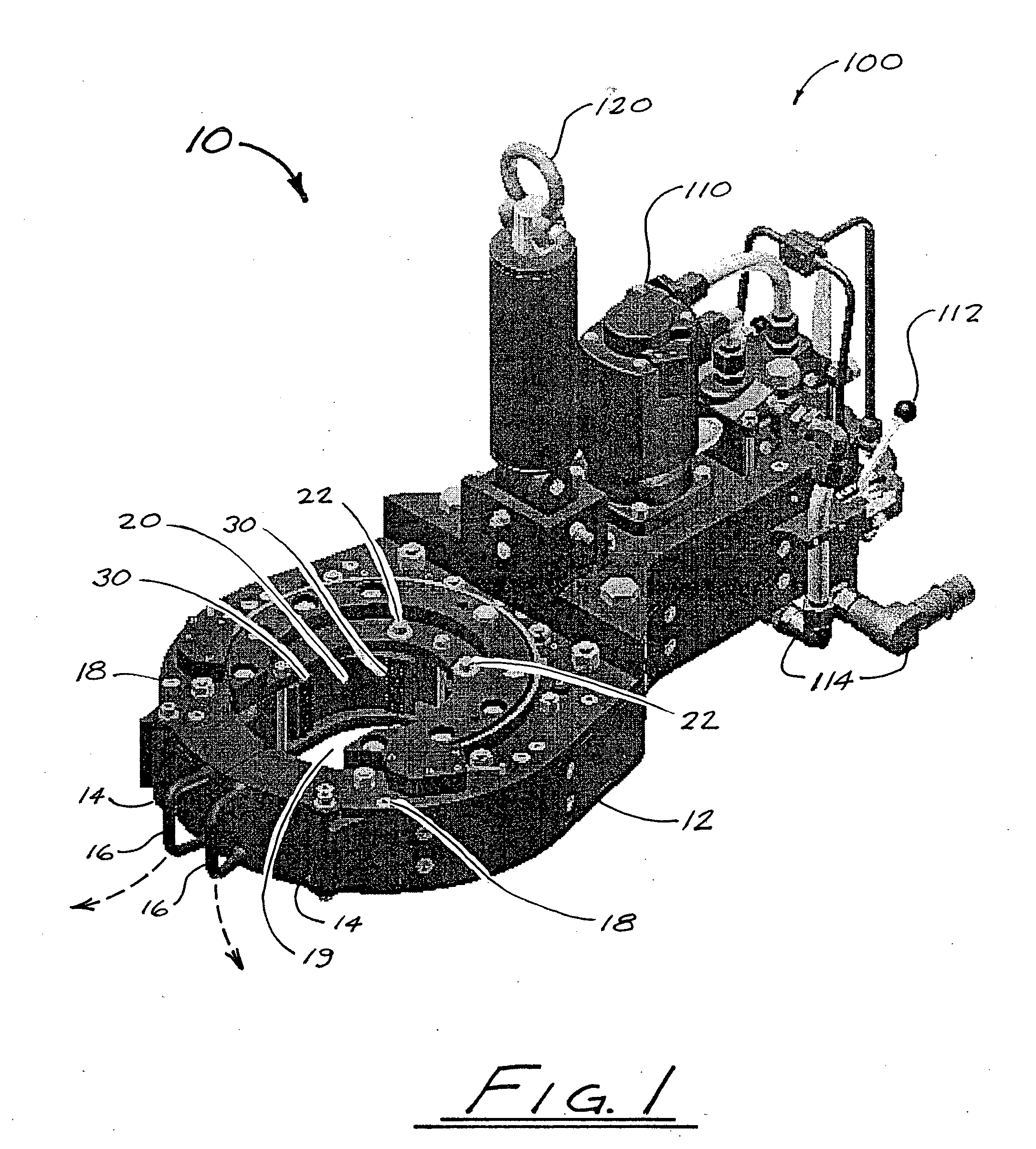

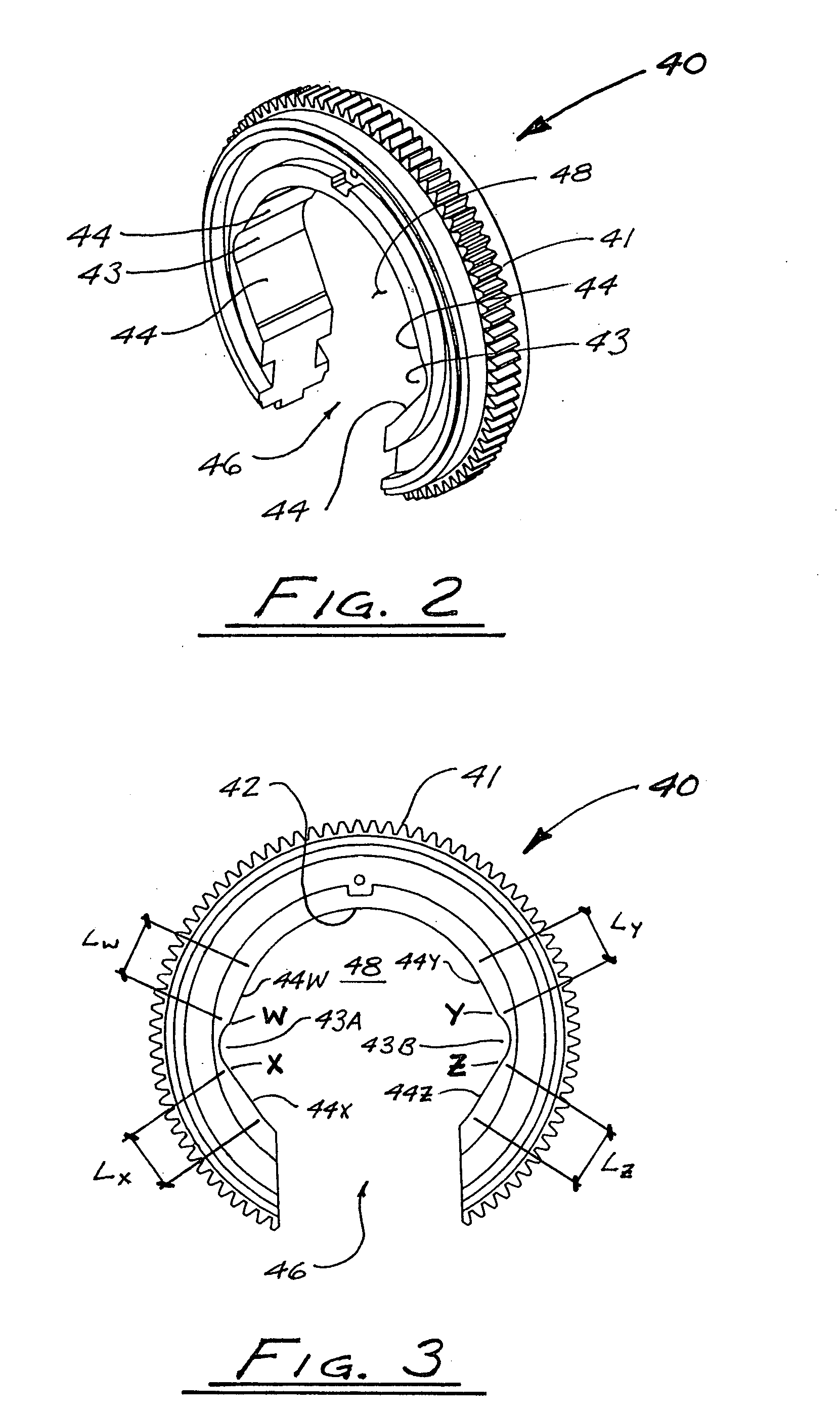

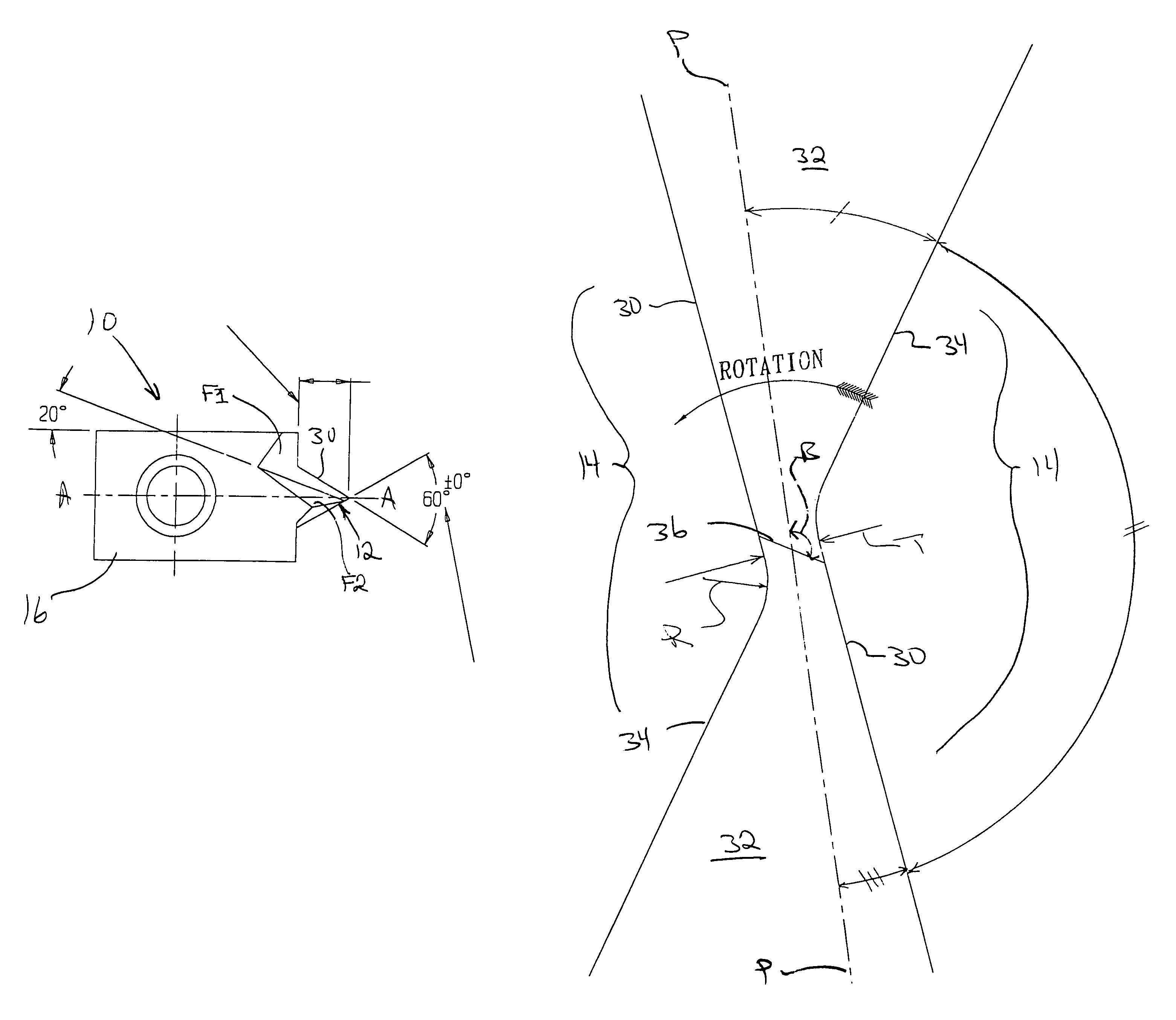

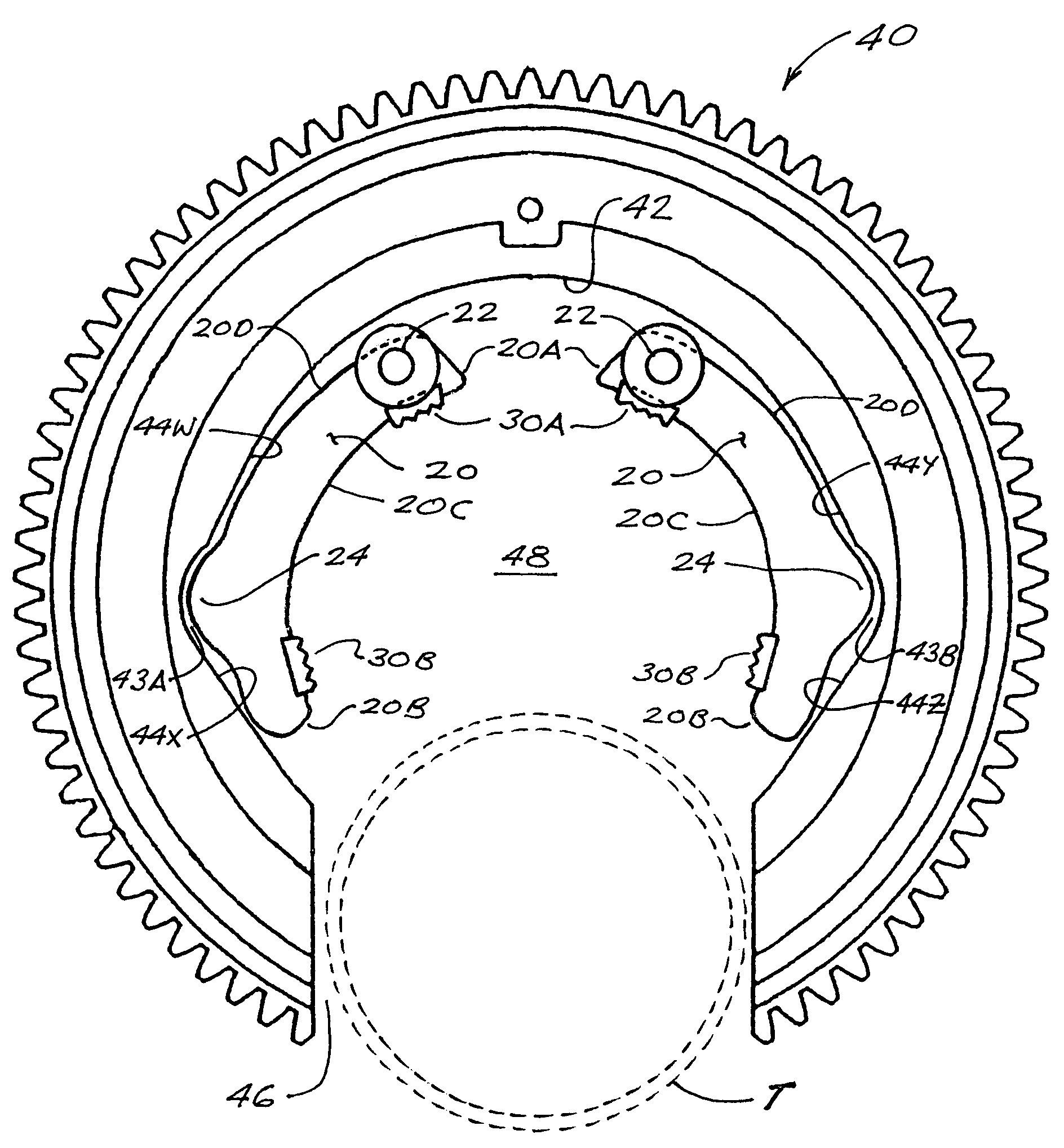

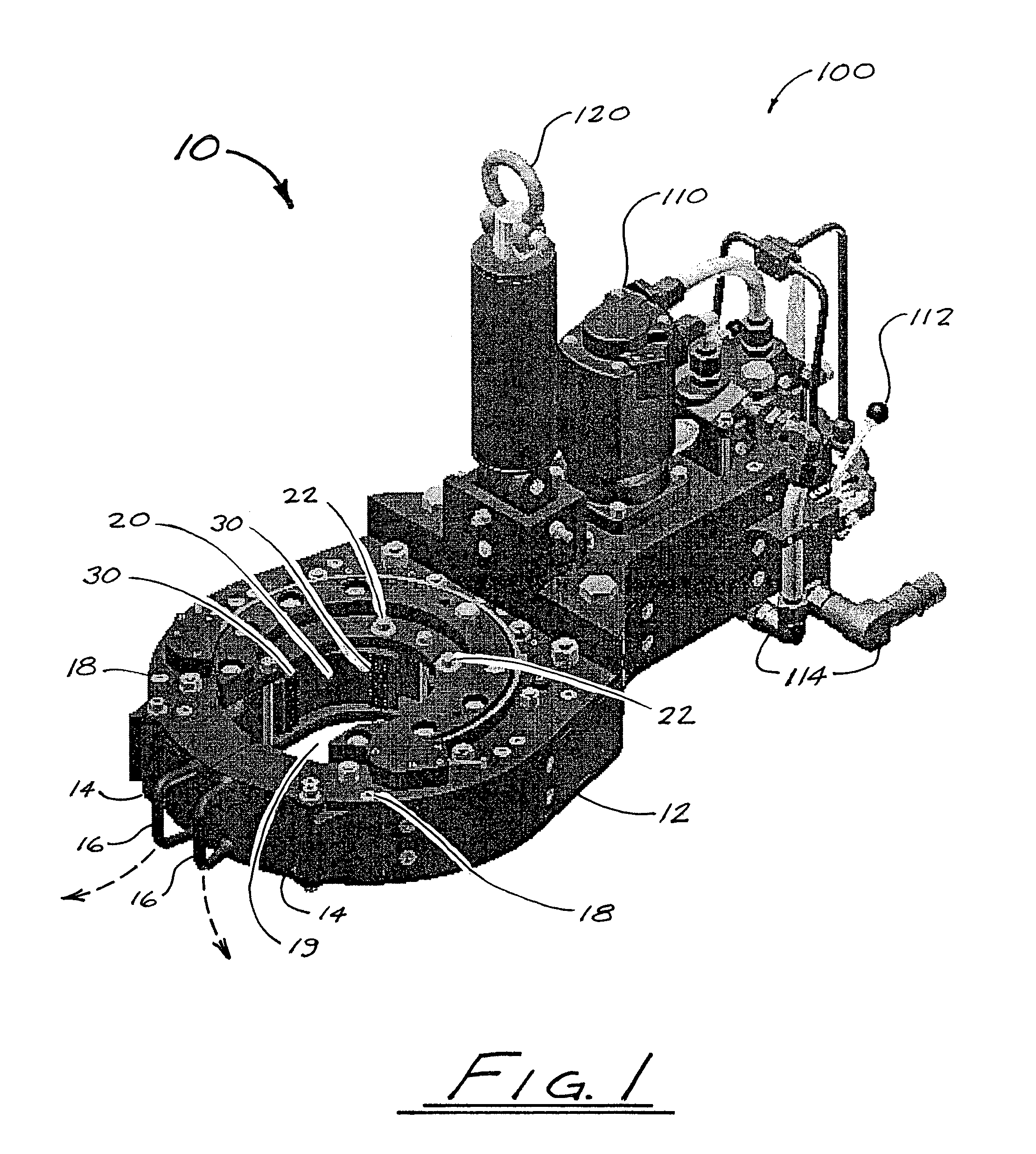

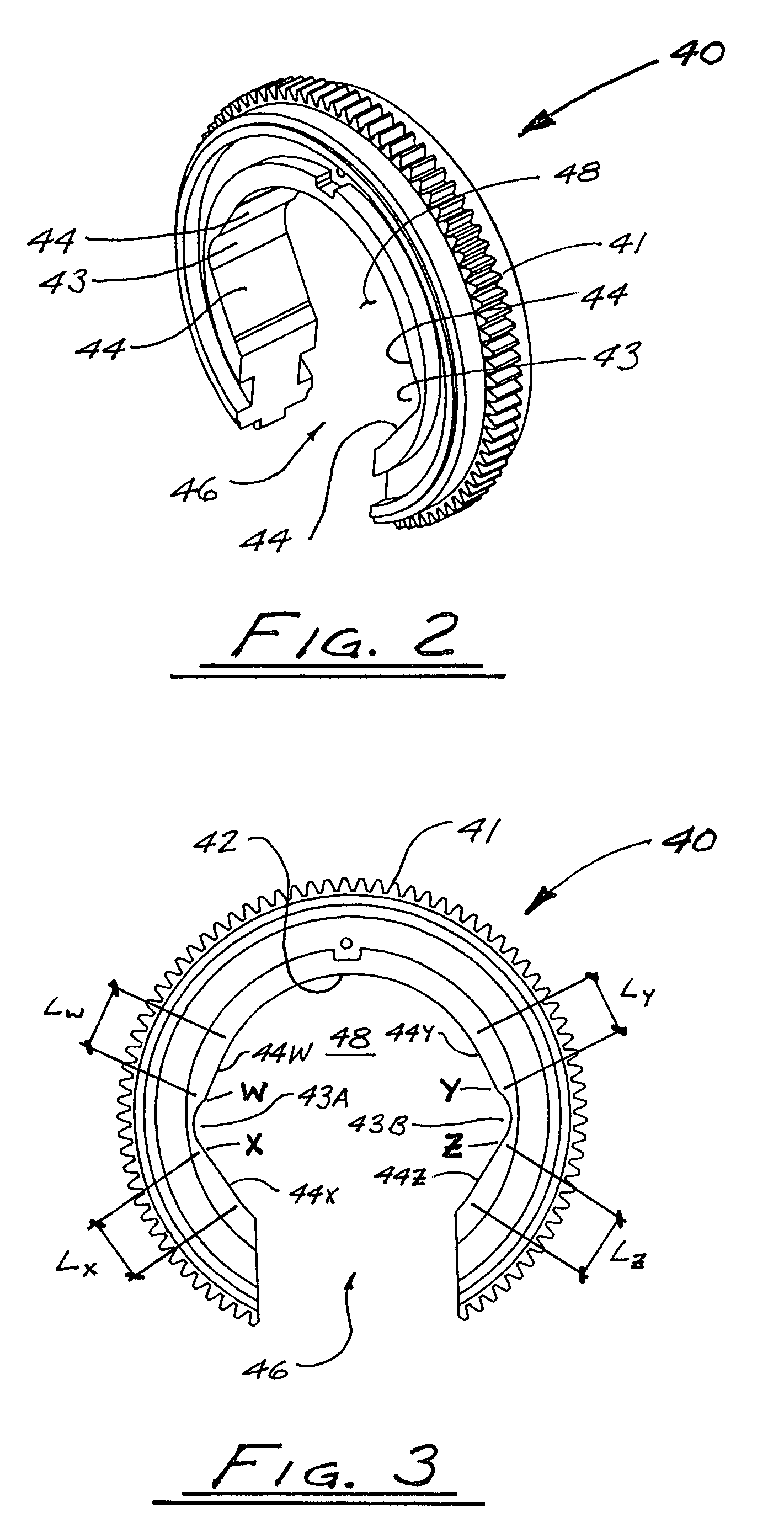

Power tong with linear camming surfaces

InactiveUS20060011017A1High strengthRadial distance to a pointDrilling rodsSpannersGrip forceAcute angle

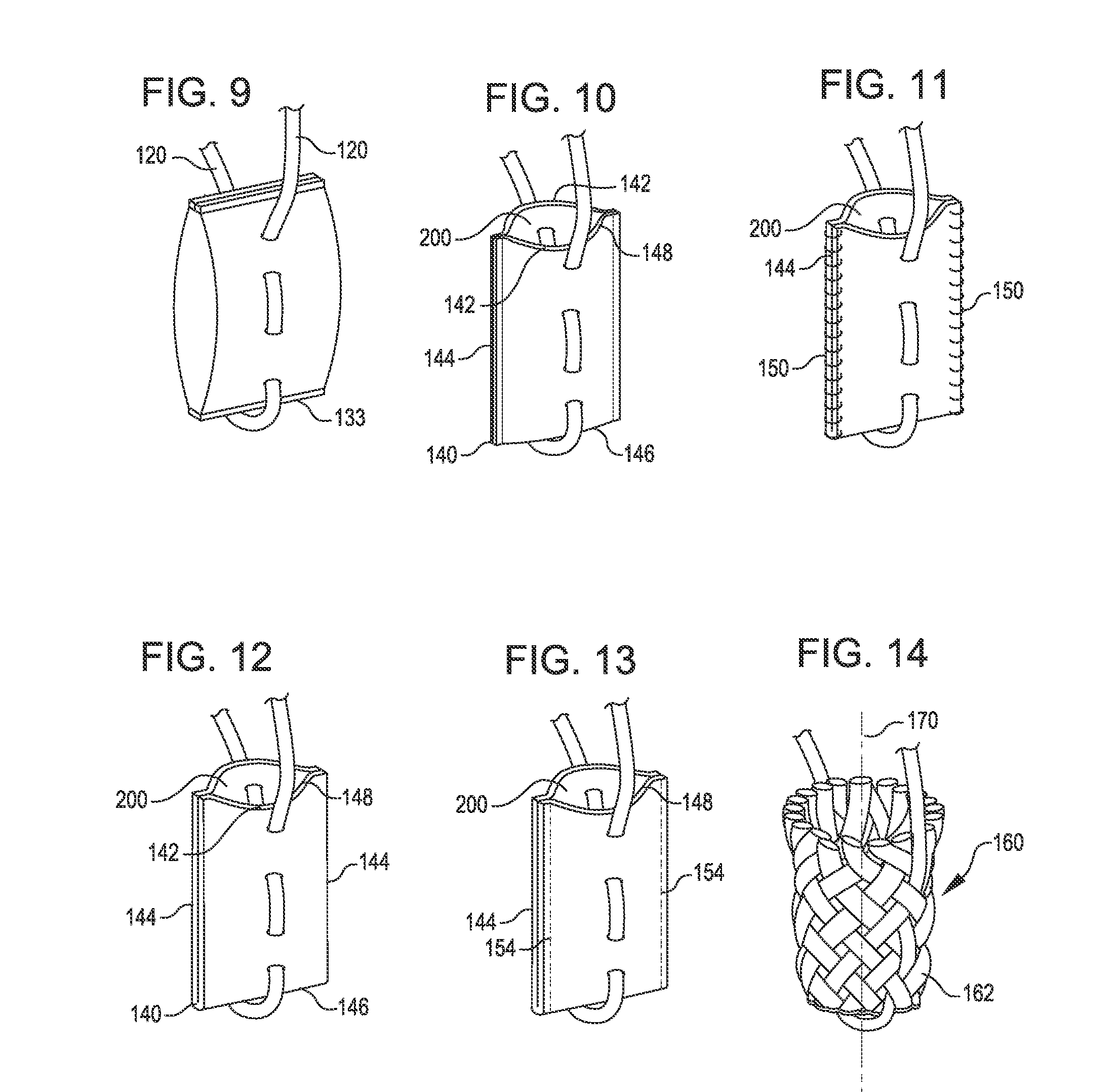

In a pivoting-jaw power tong, each primary camming surface of the rotary gear has a substantially linear rather than curved configuration. Each primary camming surface forms an acute angle with a radial line extending from the rotary gear centerline to the point where the primary camming surface transitions to its associated neutral recess. Accordingly, the radial distance to a point on any of the primary camming surfaces reduces linearly with increased distance from the neutral recess. Rotation of the rotary gear in either direction away from the neutral position thus results in a linearly progressive reduction in the distance from the center of rotation to the points where the pivoting jaws' cam followers contact the camming surfaces, thus increasing the force exerted by the dies of the jaws upon a tubular disposed within the jaws. This camming surface geometry allows the power tong to automatically adjust for wear in the mechanism such that the contact force between the rollers and the camming surfaces, and the gripping force applied by the dies, will be substantially uniform.

Owner:KATHAN MURRAY

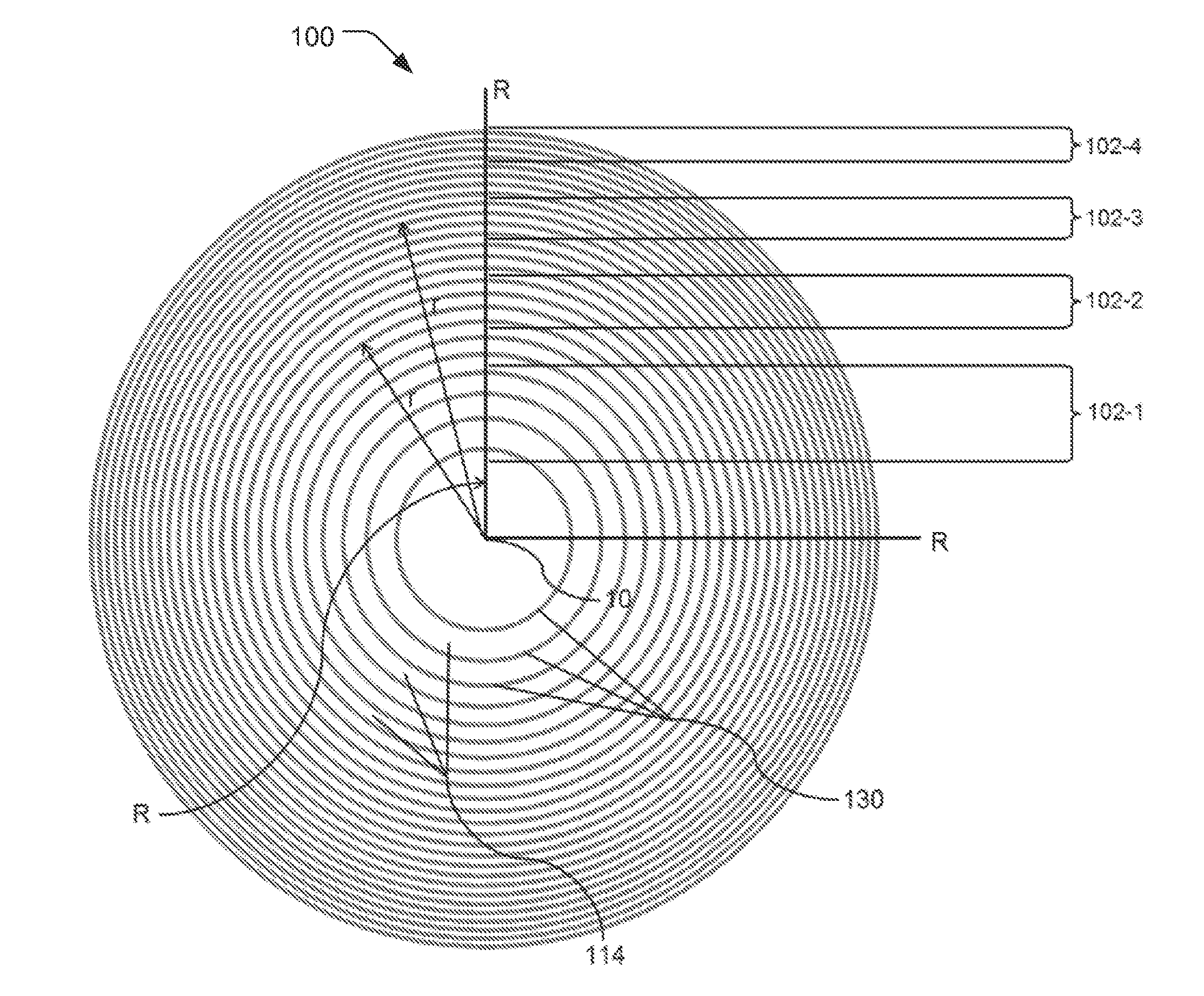

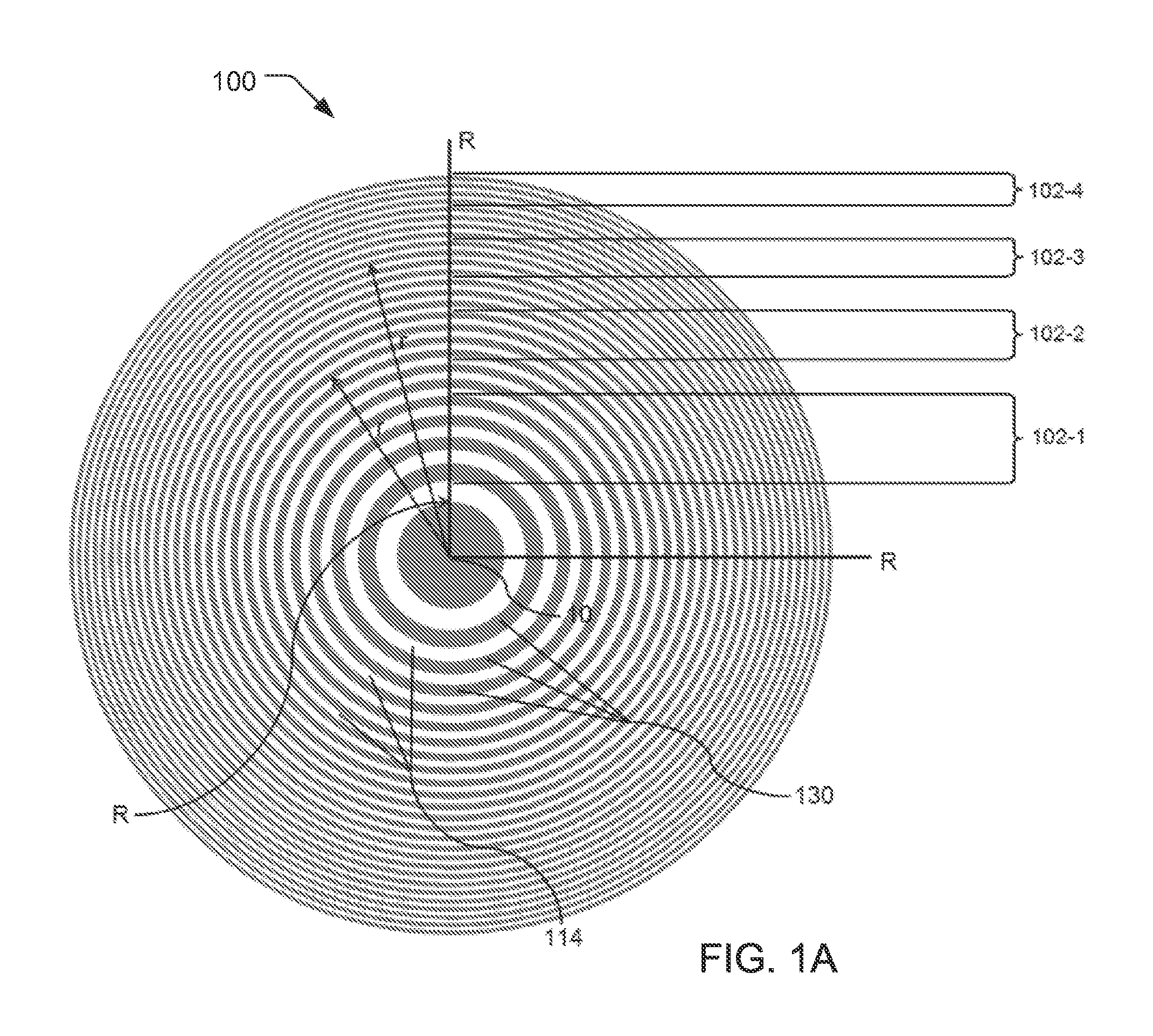

Zone Plate and Method for Fabricating Same Using Conformal Coating

InactiveUS20160086681A1Improve efficiencySpatial frequency is enlargedHandling using diffraction/refraction/reflectionElectrostatic spraying apparatusConformal coatingZone plate

A system and method for improving efficiency of zone plates fabricated by conformal layer coatings is disclosed. In embodiments, the inventive conformal layer coating zone plates provide increased zone widths from one times a deposited conformal layer coating thickness up to and including two times the conformal layer coating thickness. By designing a template that increases a mark-to-space ratio of the annular rings of the template, coating sidewalls of the annular rings with an conformal layer coating to form the zones, and then substantially filling annular channels defined by the annular rings with the conformal layer coating to form wider zones, significant efficiency increases can be achieved over conventional conformal layer coating zone plates, especially for innermost zones.

Owner:CARL ZEISS X RAY MICROSCOPY

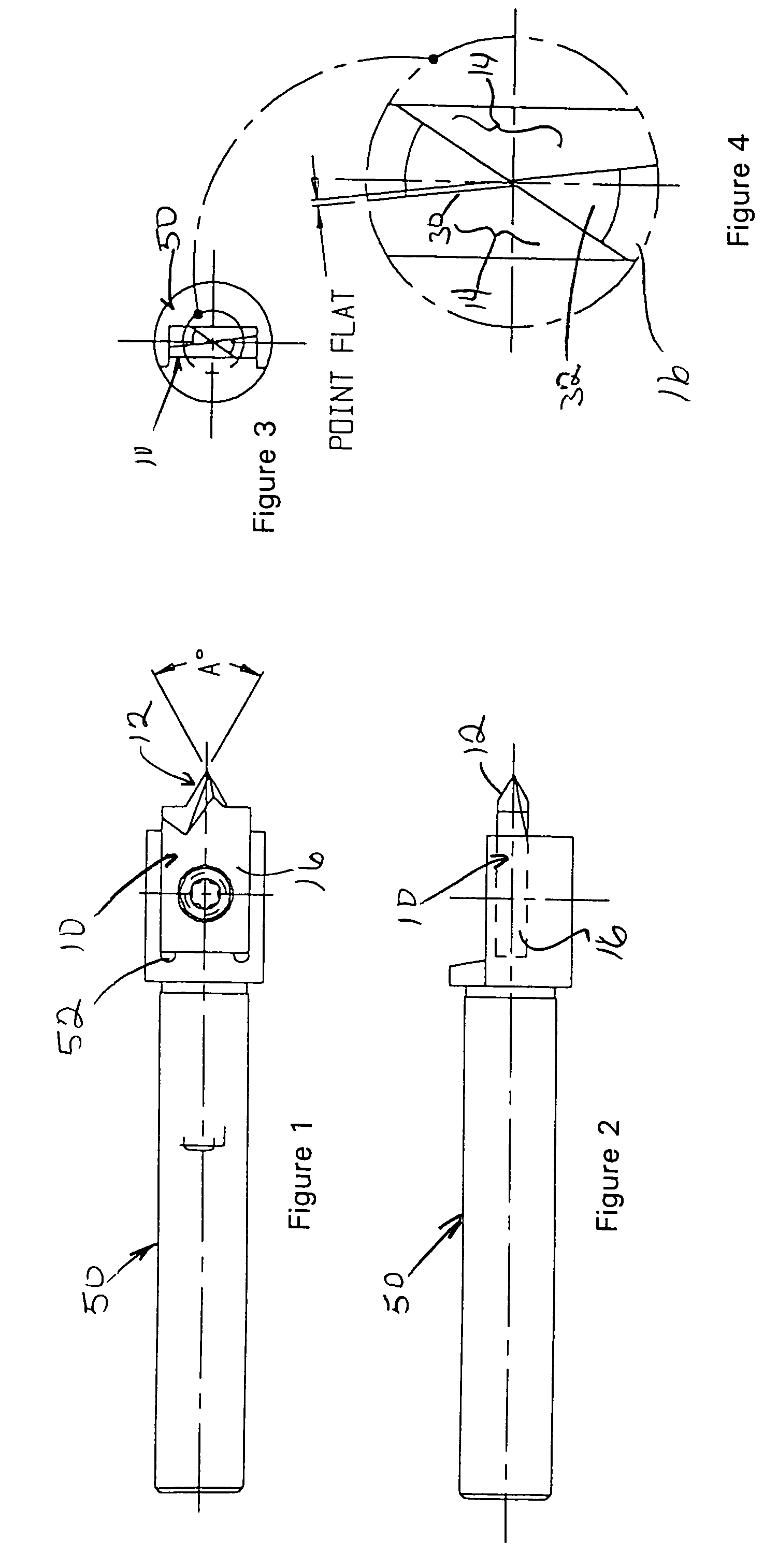

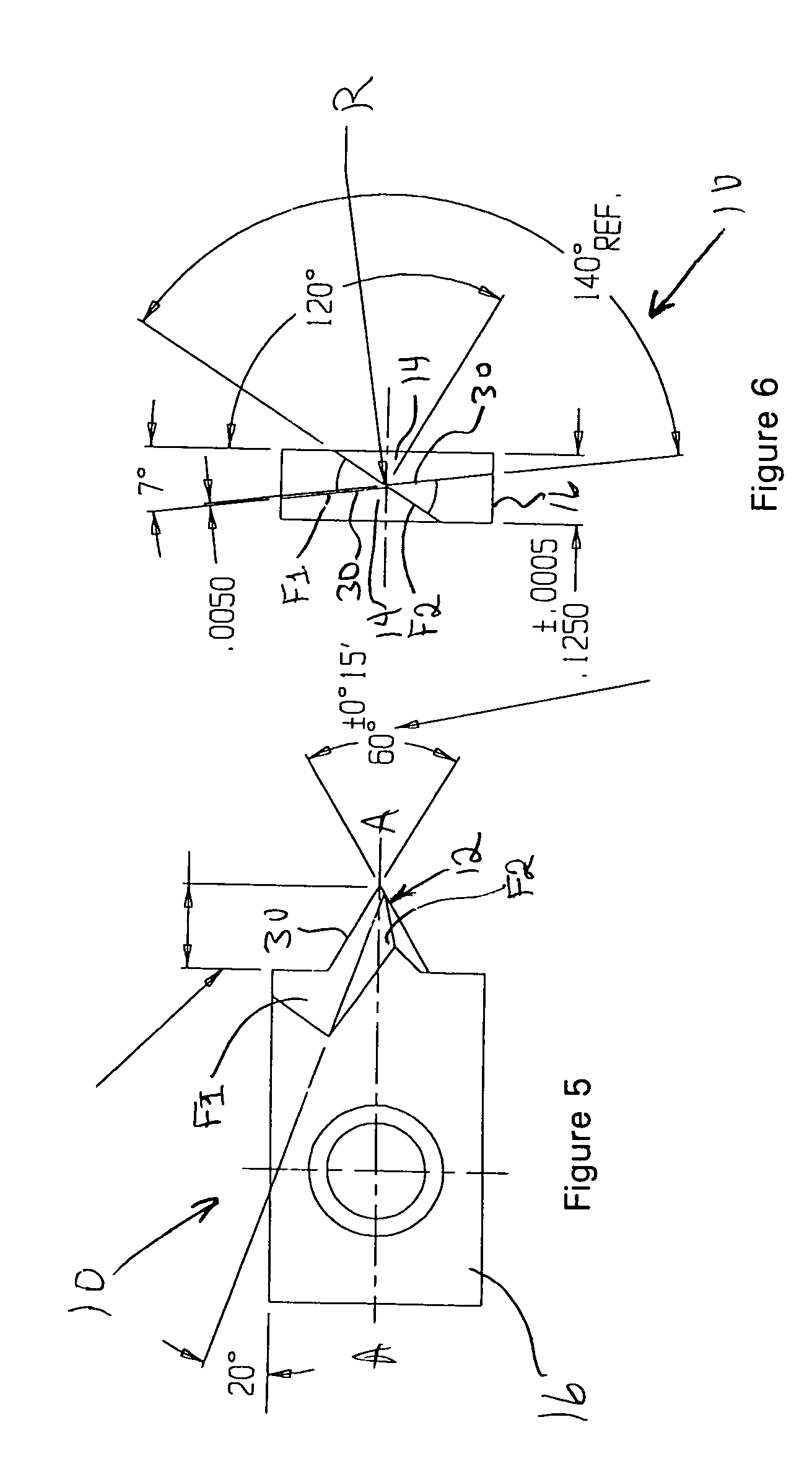

Spot drilling insert

ActiveUS7540696B1Reduce the radial distanceWood turning toolsTransportation and packagingFluteRotational axis

A spot drilling tool includes a drill holder and an insert removably mounted to the holder. The insert is a standardized part configured to support a drill point in a predetermined position forward of the drill holder and centered on the rotational axis of the drill holder. The drill point has two flutes and two substantially conical land surfaces extending between the flutes. The land surfaces have centers of curvature offset from the rotational axis of the insert to provide radial clearance for the trailing portion of the land. A chisel edge at the tip of the drill point is supported by a tapered web defined between the diagonally opposed and offset flutes. Linear cutting edges are formed at the junction of a planar flute surface and the conical land surface. The cutting edges define a narrow included point angle of between 50° and 80°.

Owner:CENTURY TOOL & DESIGN

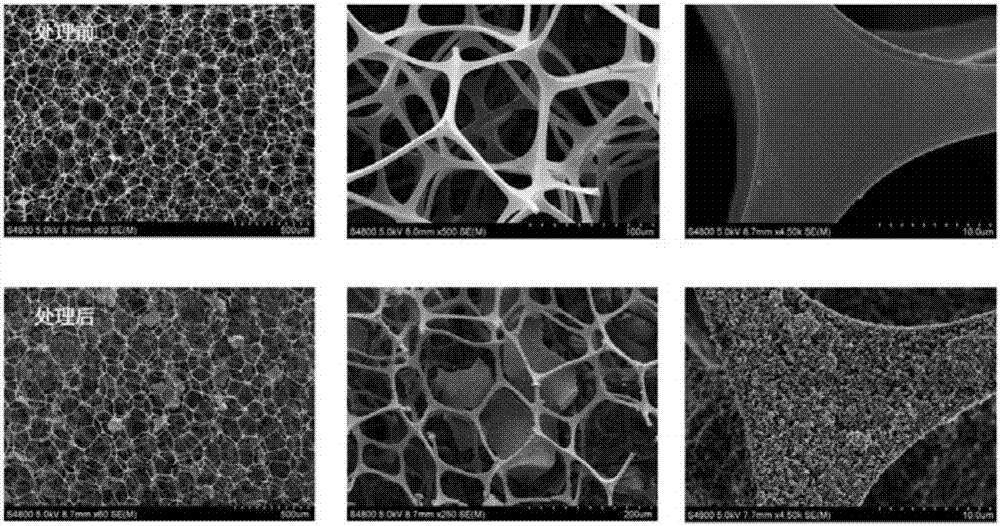

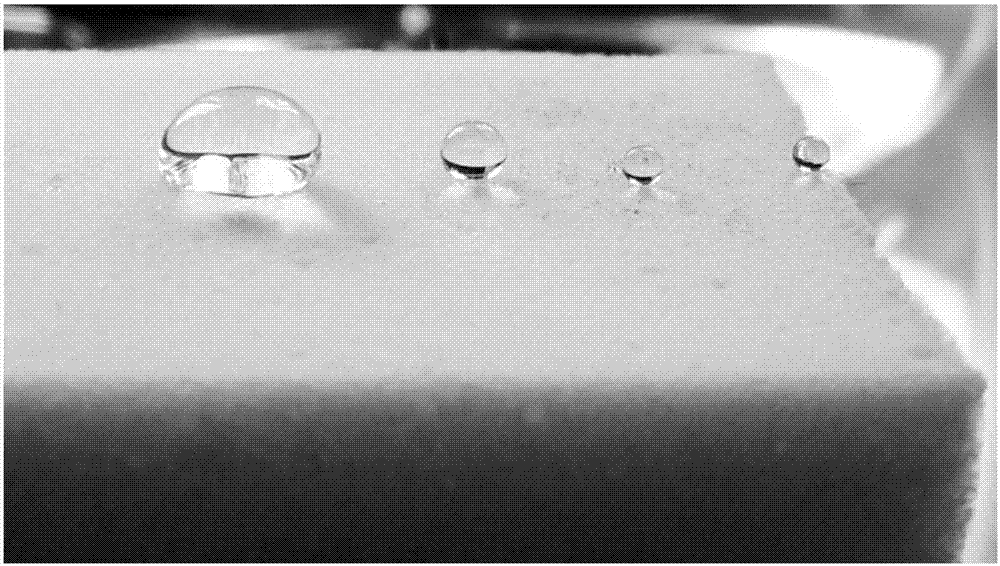

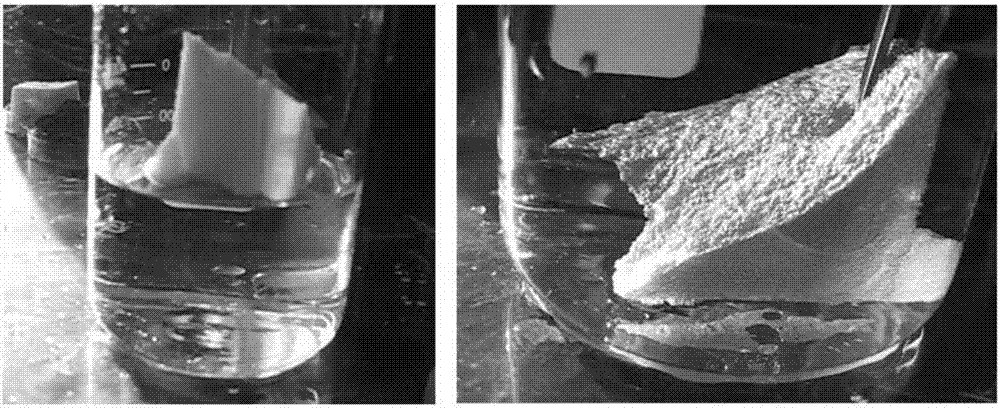

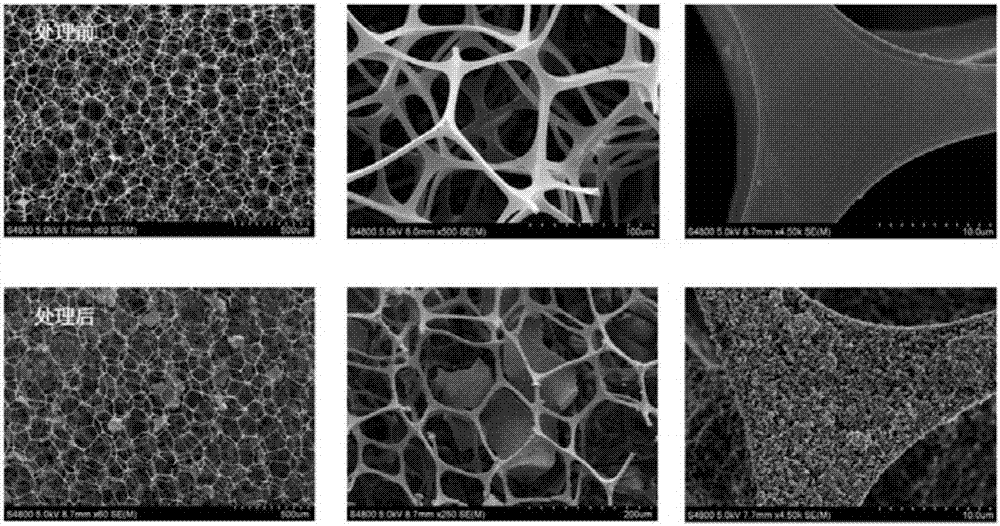

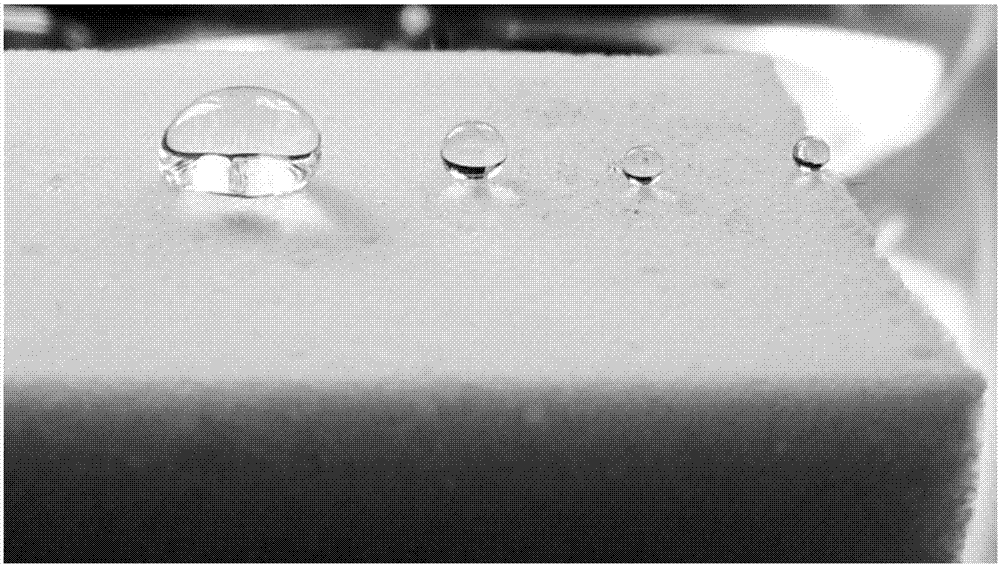

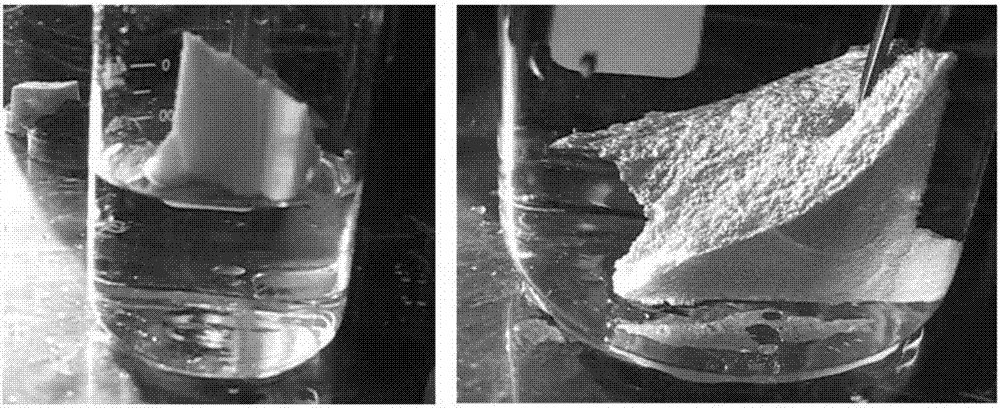

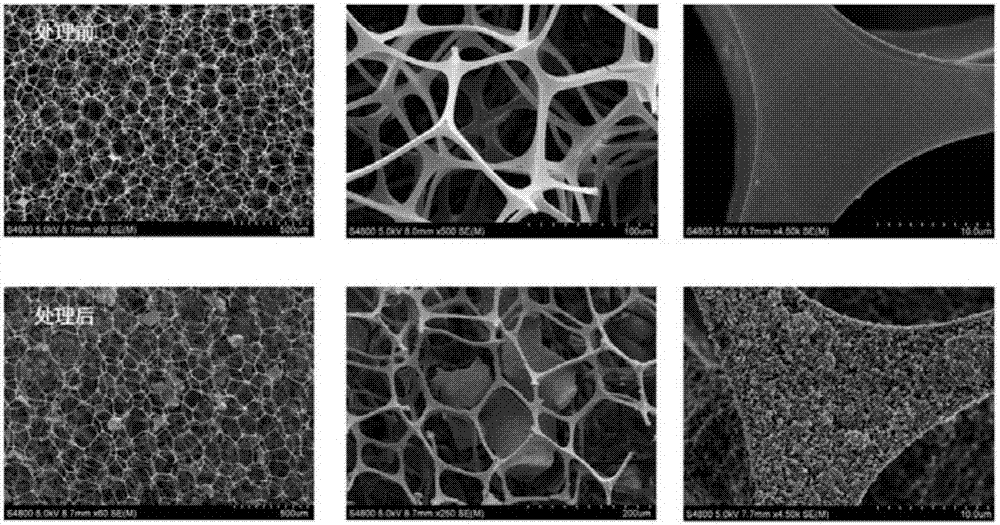

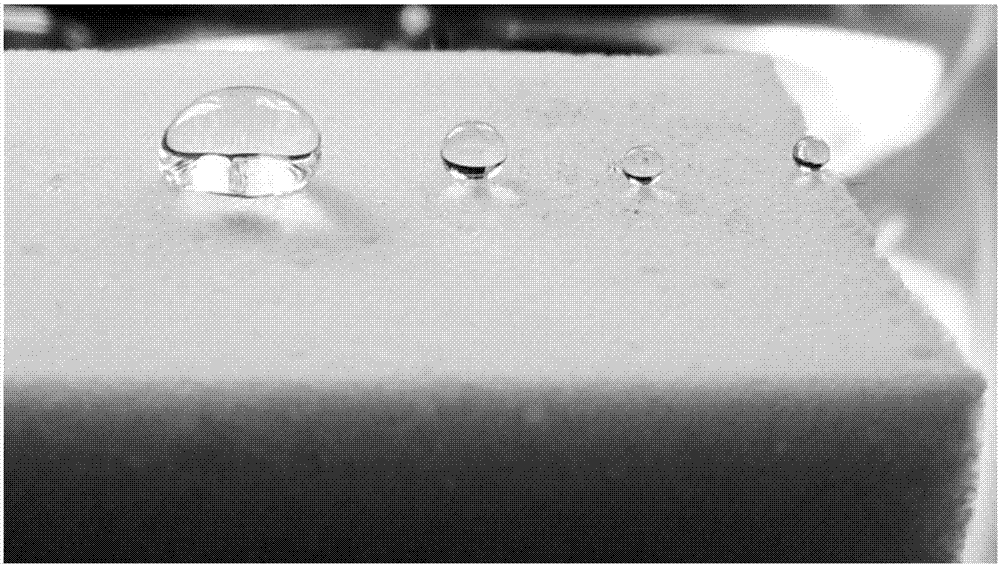

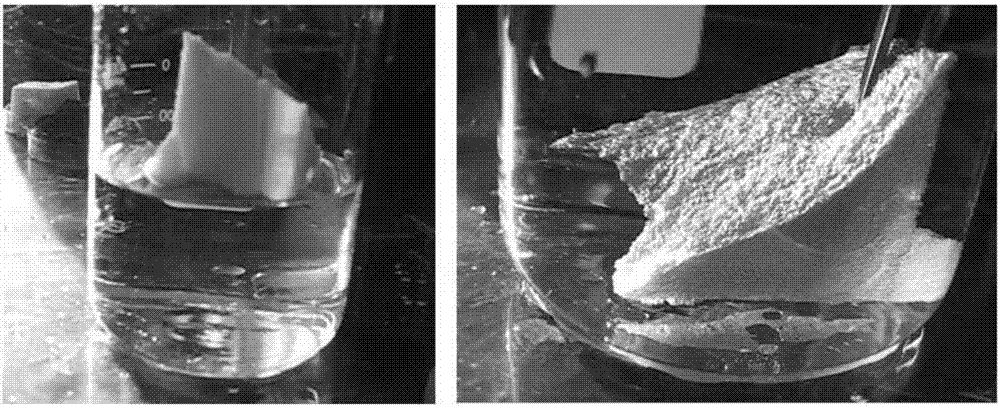

Superhydrophobic sponge body and preparation method thereof

The present invention relates to a superhydrophobic sponge body and a preparation method thereof. A purpose of the present invention is to mainly solve the problem of poor hydrophobic effect of the existing adsorption recovery material. The technical scheme of the present invention comprises a superhydrophobic sponge body and a preparation method thereof, wherein the superhydrophobic sponge body comprises a sponge body and a nanometer modifier, the sponge body is a melamine sponge or a polyurethane sponge, and the nanometer modifier preparation method comprises: dissolving a nanometer material in a hydrophobic organosilicon compound agent, and stirring until completely dissolving so as to obtain the nanometer modifier. With the technical scheme of the present invention, the problem in the prior art is well solved. The preparation method of the present invention can be used in the preparation of superhydrophobic sponge bodies.

Owner:CHINA PETROLEUM & CHEM CORP +1

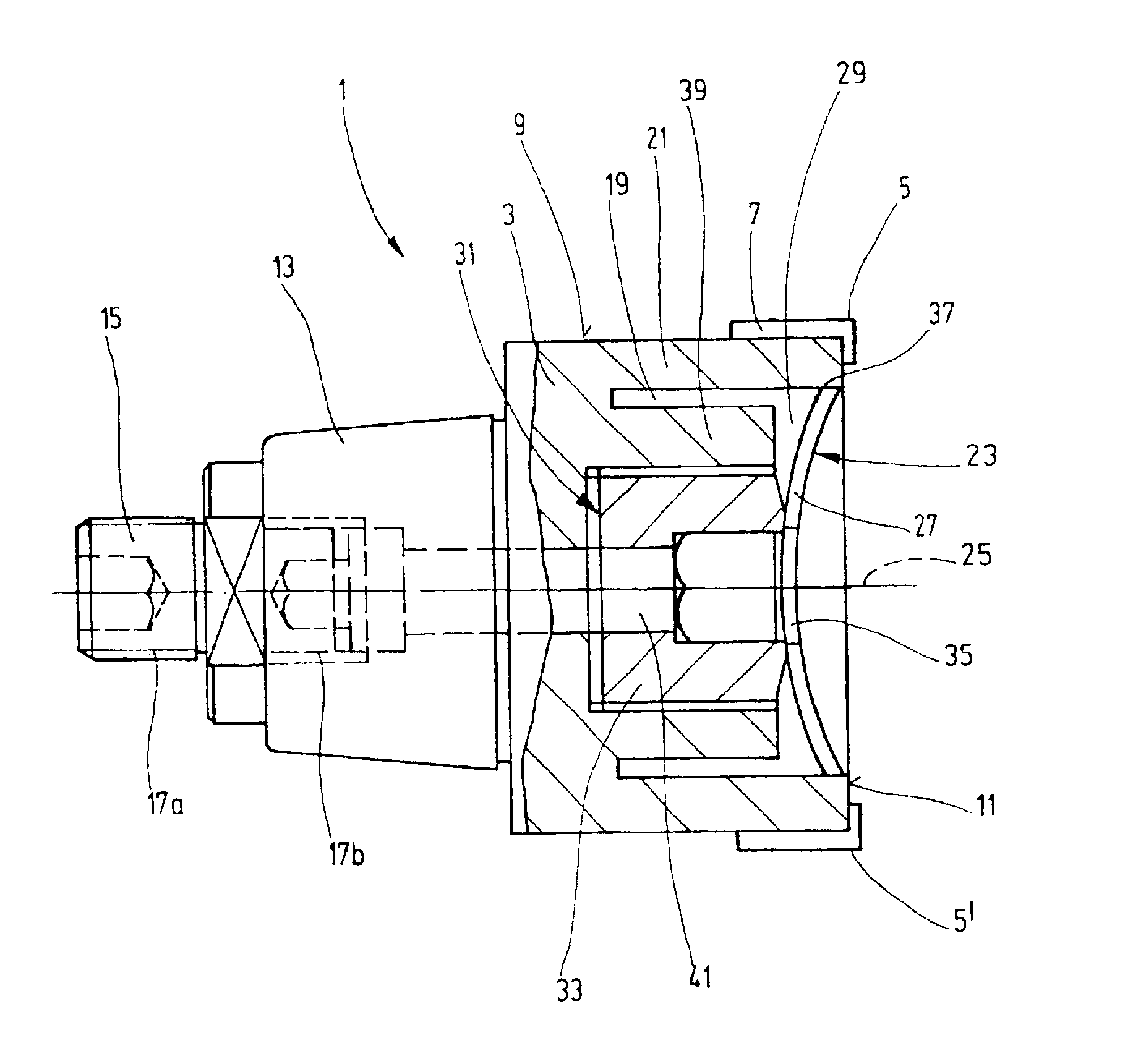

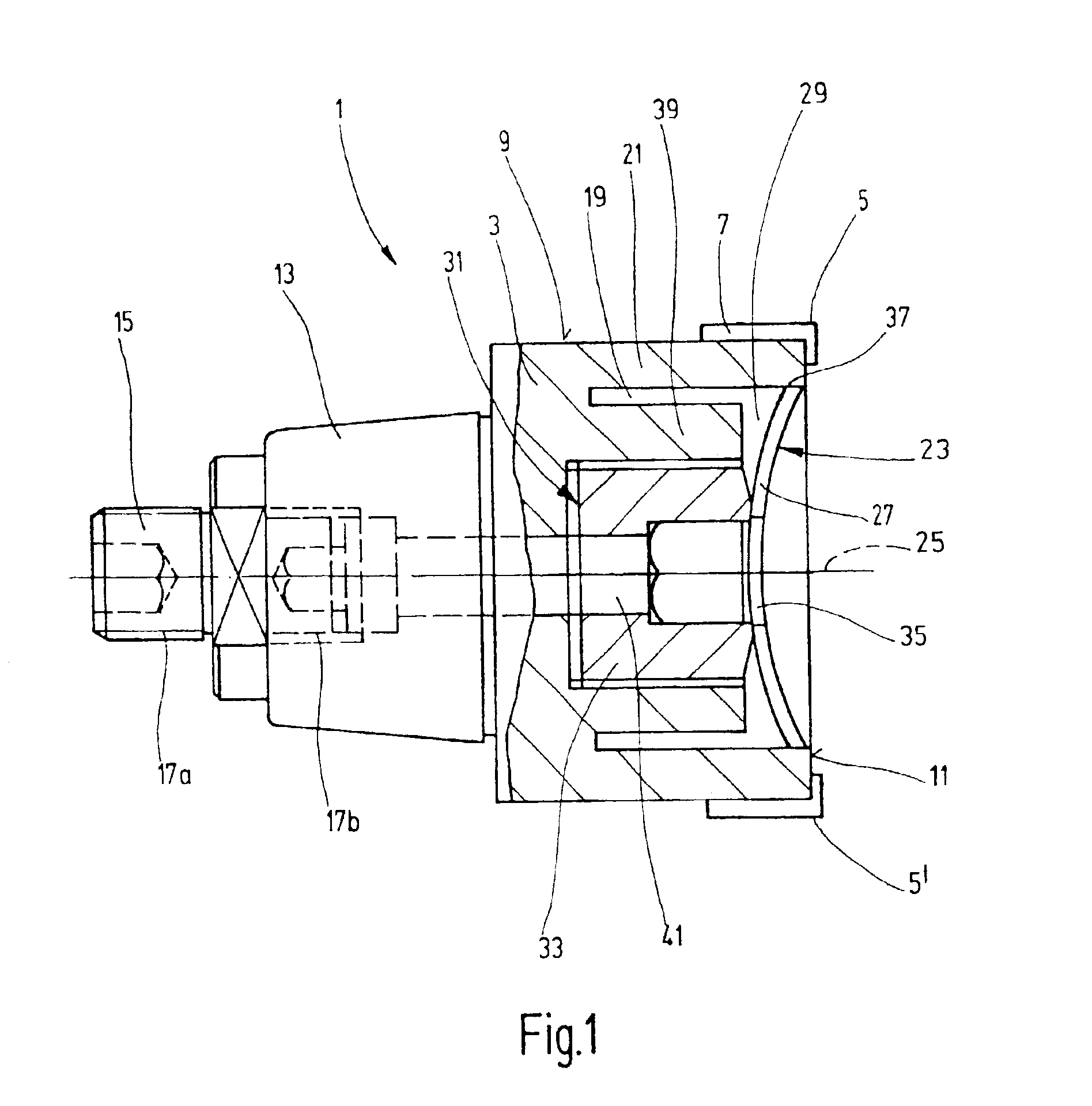

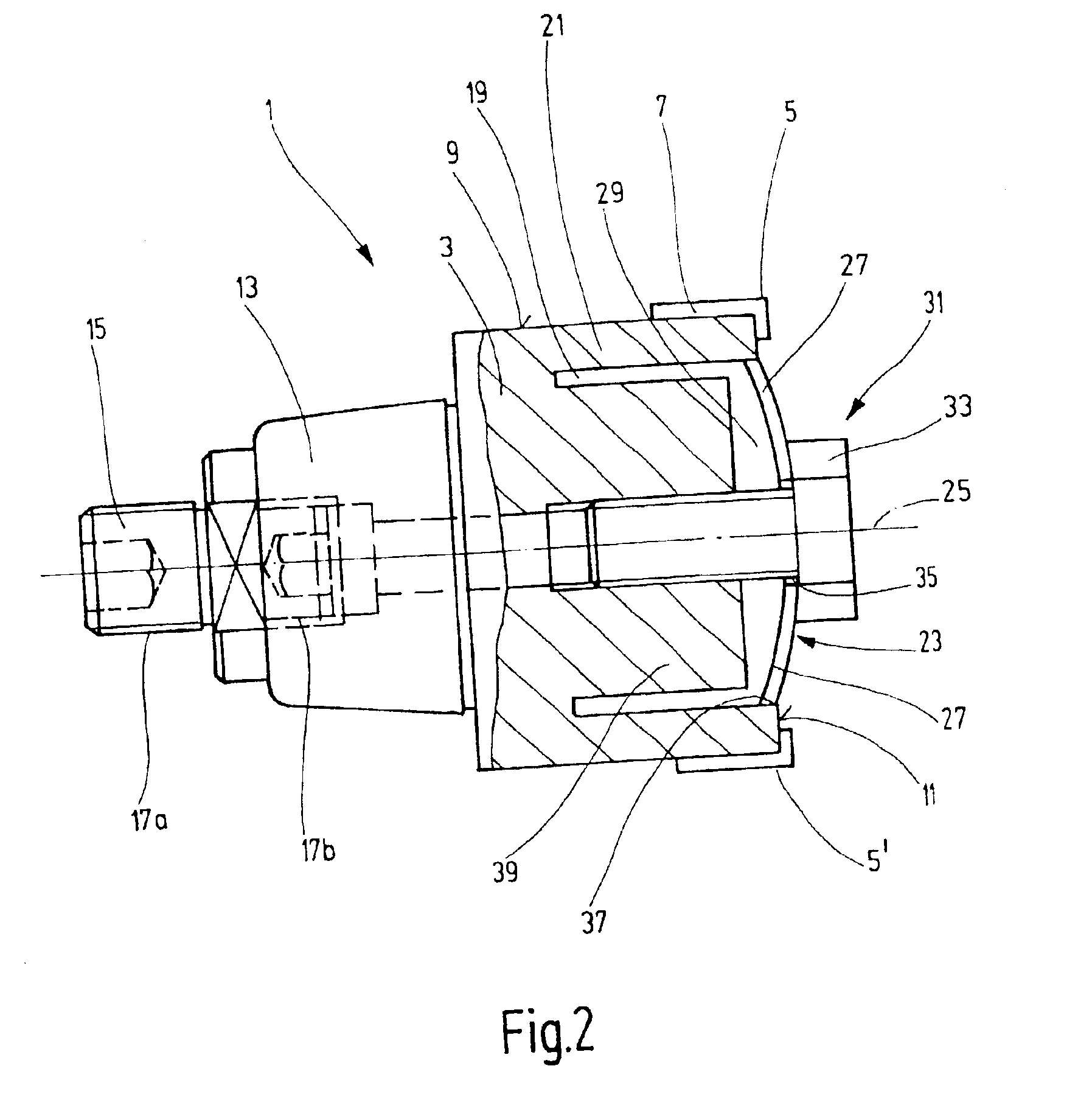

Tool for machining workpieces

InactiveUS6926475B2Avoid displacementIncrease and reduce radial distanceThread cutting toolsTransportation and packagingEngineeringMechanical engineering

A tool for machining workpieces, having a parent body which can be expanded at least zonally, having at least one geometrically defined cutting edge projecting beyond a circumferential surface of the tool, and having a setting device influencing the radial distance of the cutting edge from the center axis of the tool. The setting device has a setting element, and an adjusting device which sets the degree of bending of the setting element. The setting element is inserted into the parent body of the tool in such a way that, when the bending of the setting element is varied, the radial distance of the cutting edge is varied.

Owner:MAPAL

Tissue repair assembly

ActiveUS9962149B2Reduce the radial distanceIncrease the angleSuture equipmentsDiagnosticsTissue repairBiomedical engineering

A tissue repair assembly for attachment of tissue to bone or tissue to tissue having a soft anchoring implant 100 with a length of suture 120 there through for tensioning the implant and facilitating attachment of other tissue. The implant 100 is a soft, flexible, three-dimensional structure that has a resident volume 200. An inserter tube 310 facilitates the placement of the implant 100 into bone or adjacent soft tissue where it may be deployed. Upon deployment, the soft anchoring implant 100 shortens axially and expands radially, achieving a larger diameter than the hole through which it was placed, thus resisting pull out.

Owner:ARTHROCARE

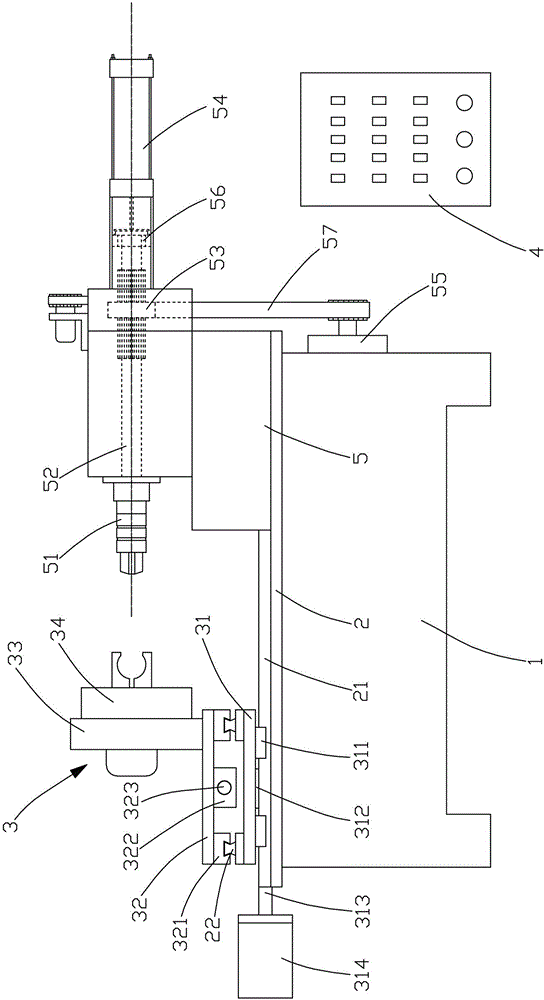

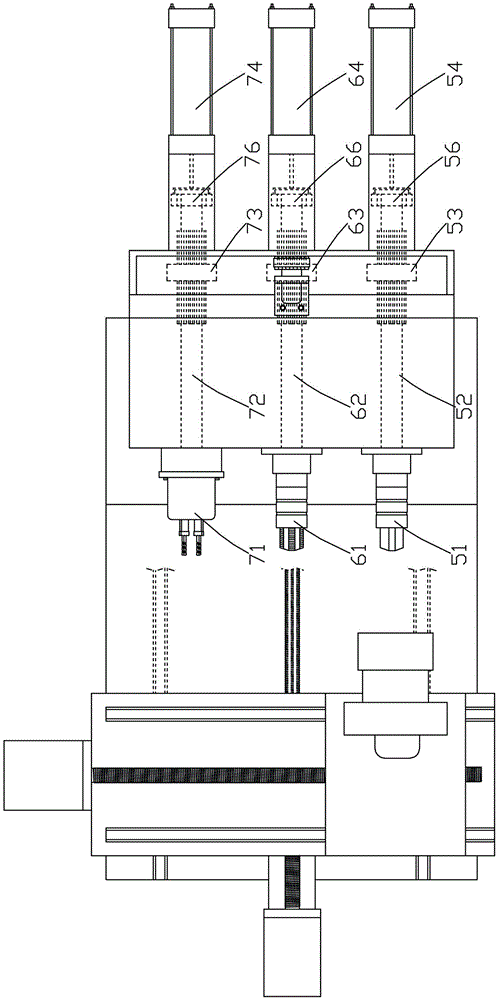

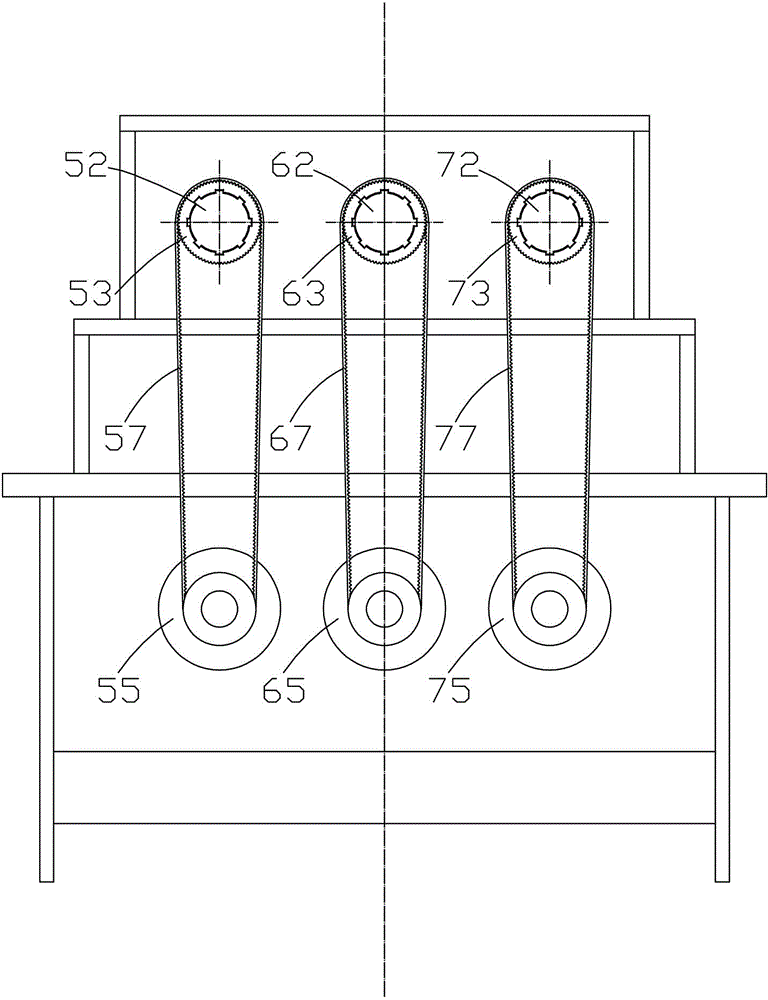

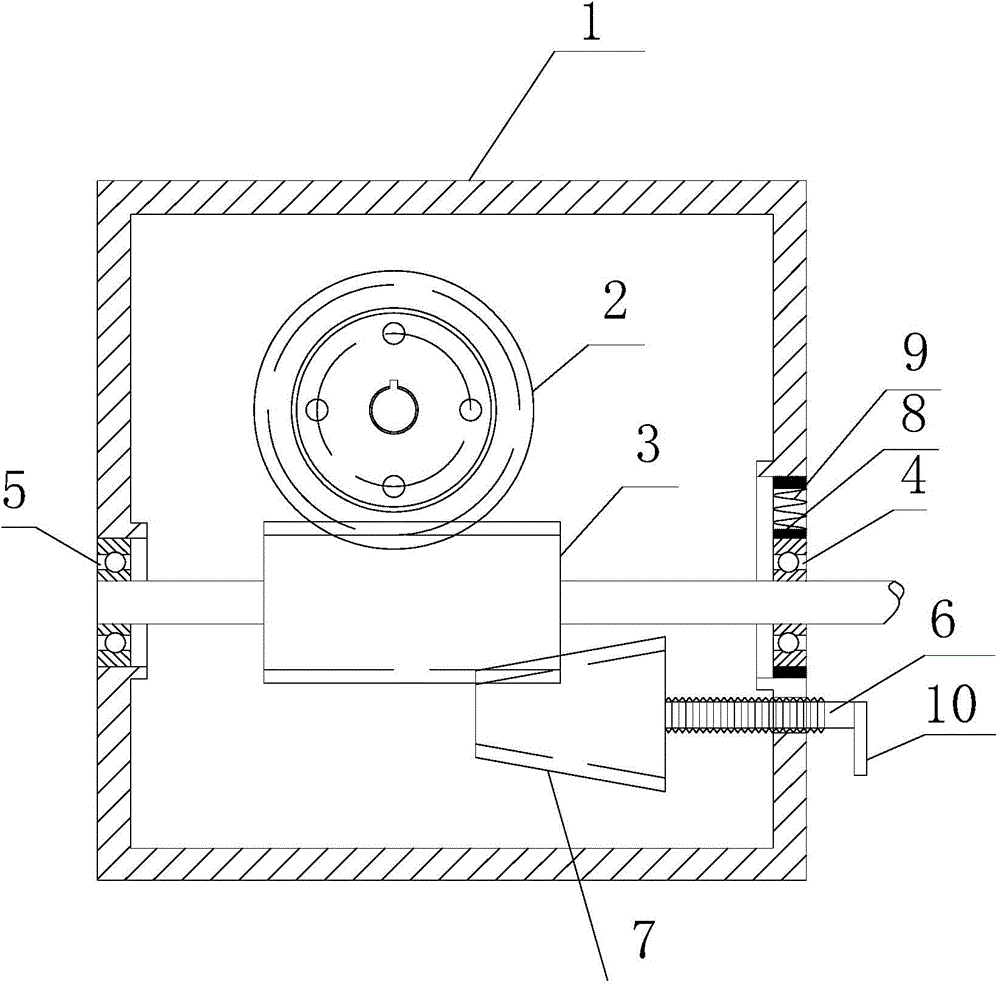

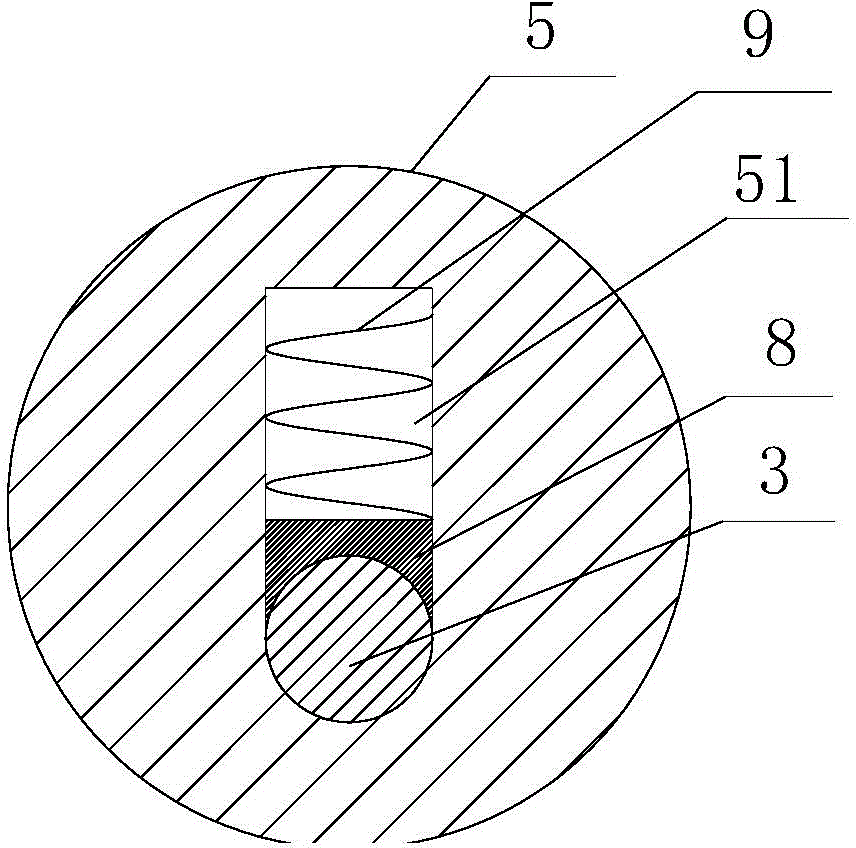

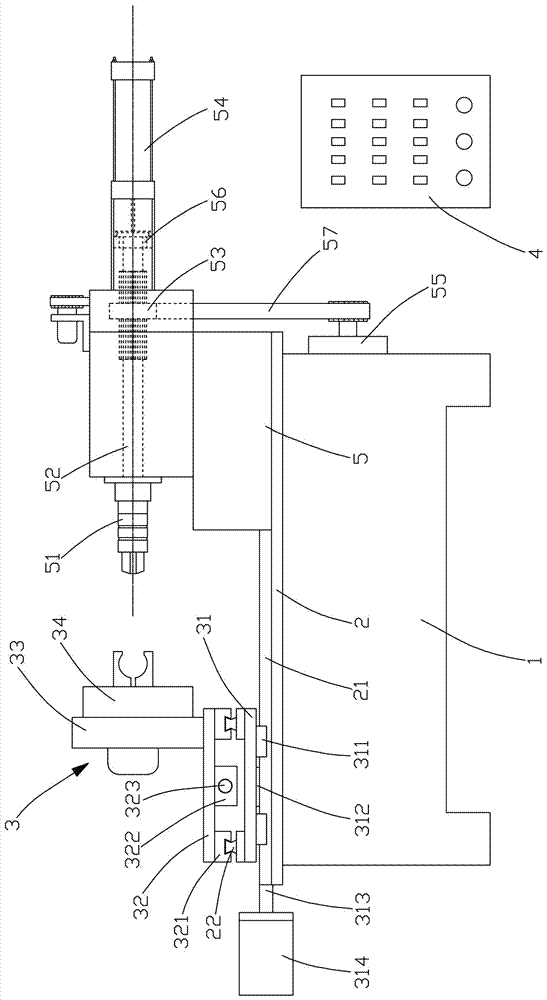

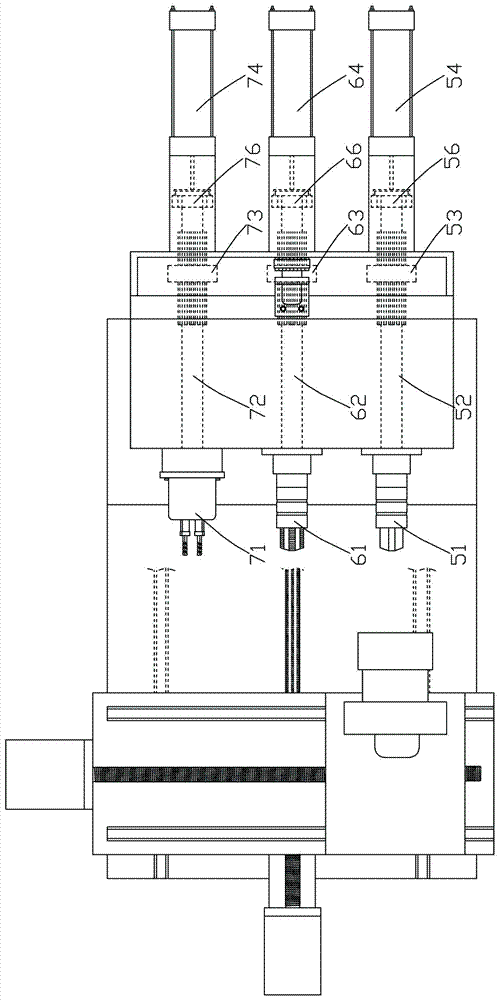

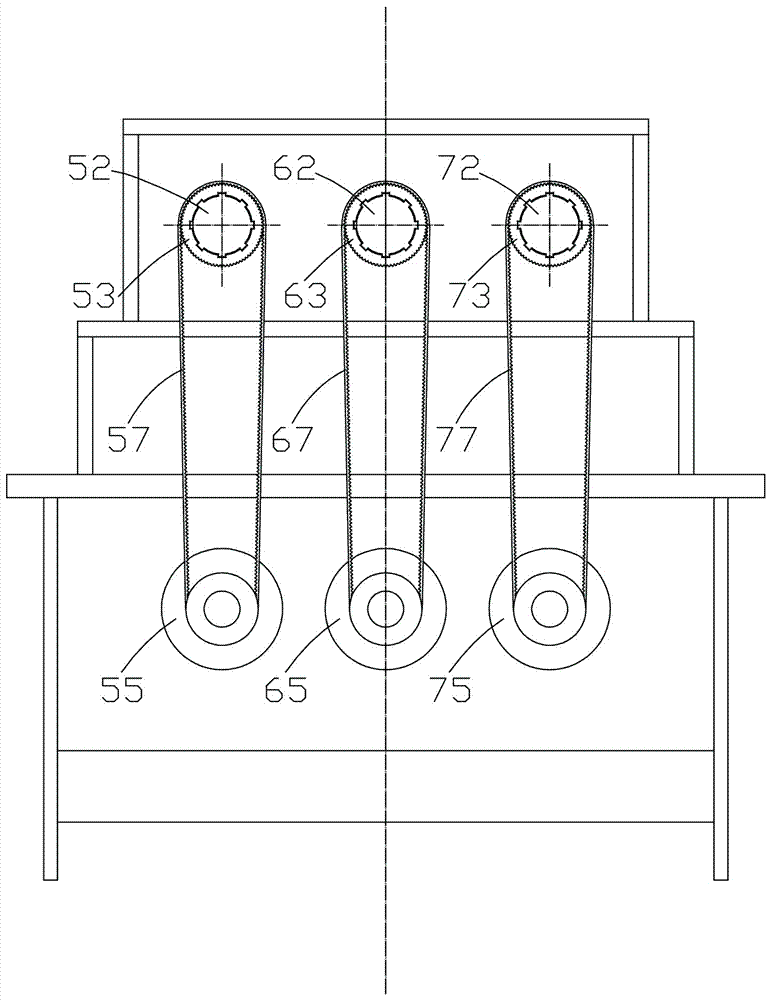

Numerical control horizontal type three-axis drilling and milling tapping machine

InactiveCN104907829AImprove processing efficiencyReduce the radial distanceOther manufacturing equipments/toolsNumerical controlEngineering

A numerical control horizontal type three-axis drilling and milling tapping machine comprises a machine base, a workbench, a workpiece clamping device, a drilling, milling and tapping device and a control cabinet, wherein the workbench is fixed on a machine frame; the workpiece clamping device is arranged on the workbench in the mode of moving in the X-axis and Z-axis directions of the workbench; the drilling, milling and tapping device comprises a fixed base fixed to the workbench; the fixed base is provided with a milling mechanism, a tapping mechanism and a multi-axis drilling mechanism in sequence at intervals in the X-axis direction; the milling mechanism, the tapping mechanism and the multi-axis drilling mechanism can automatically carry out feeding and retracting along the Z axis of the workbench; the workpiece clamping mechanism, the milling mechanism, the tapping mechanism and the multi-axis drilling mechanism are connected with the control cabinet. So long as rotation of all the machining mechanisms is not affected, the radial direction between the machining mechanisms can be reduced to the minimum. Meanwhile, the workpiece clamping device moves only in the radial direction and the movement distance in the radial direction is greatly reduced, the machining time is saved, and the workpiece machining efficiency is improved.

Owner:福建泉州市汇群智能卫浴设备有限公司

Superhydrophobic sponge body material and preparation method thereof

InactiveCN107312197AEasy to prepareImprove hydrophobicityOther chemical processesMelamineHydrophobic effect

The present invention relates to a superhydrophobic sponge body material and a preparation method thereof. A purpose of the present invention is to mainly solve the problem of poor hydrophobic effect of the existing adsorption recovery material. The technical scheme of the present invention comprises a superhydrophobic sponge body material and a preparation method thereof, wherein the superhydrophobic sponge body material comprises a sponge body and a nanometer modifier, the sponge body is a melamine sponge or a polyurethane sponge, and the nanometer modifier preparation method comprises: dissolving a nanometer material in a hydrophobic organosilicon compound agent, and stirring until completely dissolving so as to obtain the nanometer modifier. With the technical scheme of the present invention, the problem in the prior art is well solved. The preparation method of the present invention can be used in the preparation of superhydrophobic sponge bodies.

Owner:CHINA PETROLEUM & CHEM CORP +1

Power tong with linear camming surfaces

InactiveUS6988428B1High strengthRadial distance to a pointDrilling rodsSpannersGrip forceAcute angle

In a pivoting-jaw power tong, each primary camming surface of the rotary gear has a substantially linear rather than curved configuration. Each primary camming surface forms an acute angle with a radial line extending from the rotary gear centerline to the point where the primary camming surface transitions to its associated neutral recess. Accordingly, the radial distance to a point on any of the primary camming surfaces reduces linearly with increased distance from the neutral recess. Rotation of the rotary gear in either direction away from the neutral position thus results in a linearly progressive reduction in the distance from the center of rotation to the points where the pivoting jaws' cam followers contact the camming surfaces, thus increasing the force exerted by the dies of the jaws upon a tubular disposed within the jaws. This camming surface geometry allows the power tong to automatically adjust for wear in the mechanism such that the contact force between the rollers and the camming surfaces, and the gripping force applied by the dies, will be substantially uniform.

Owner:KATHAN MURRAY

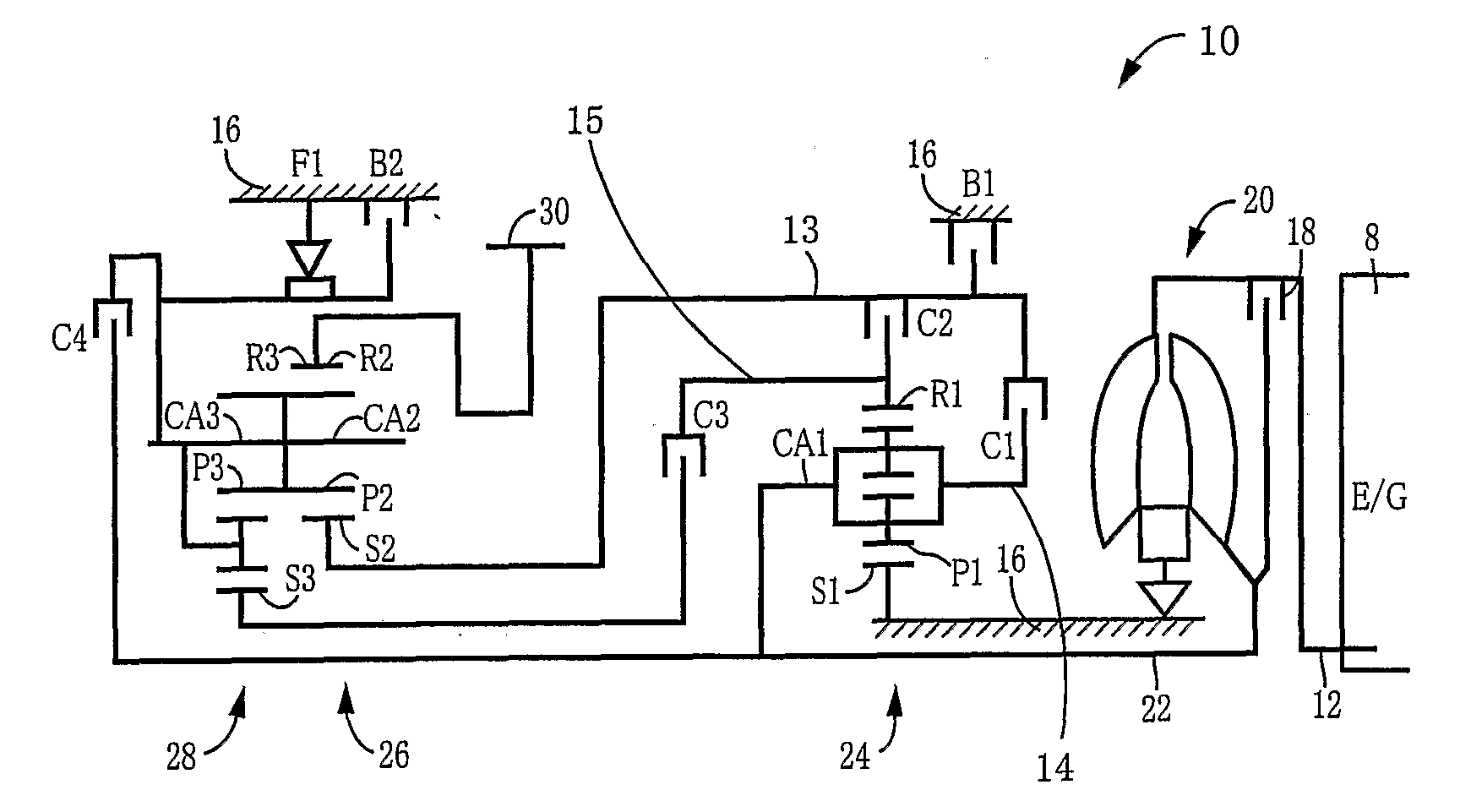

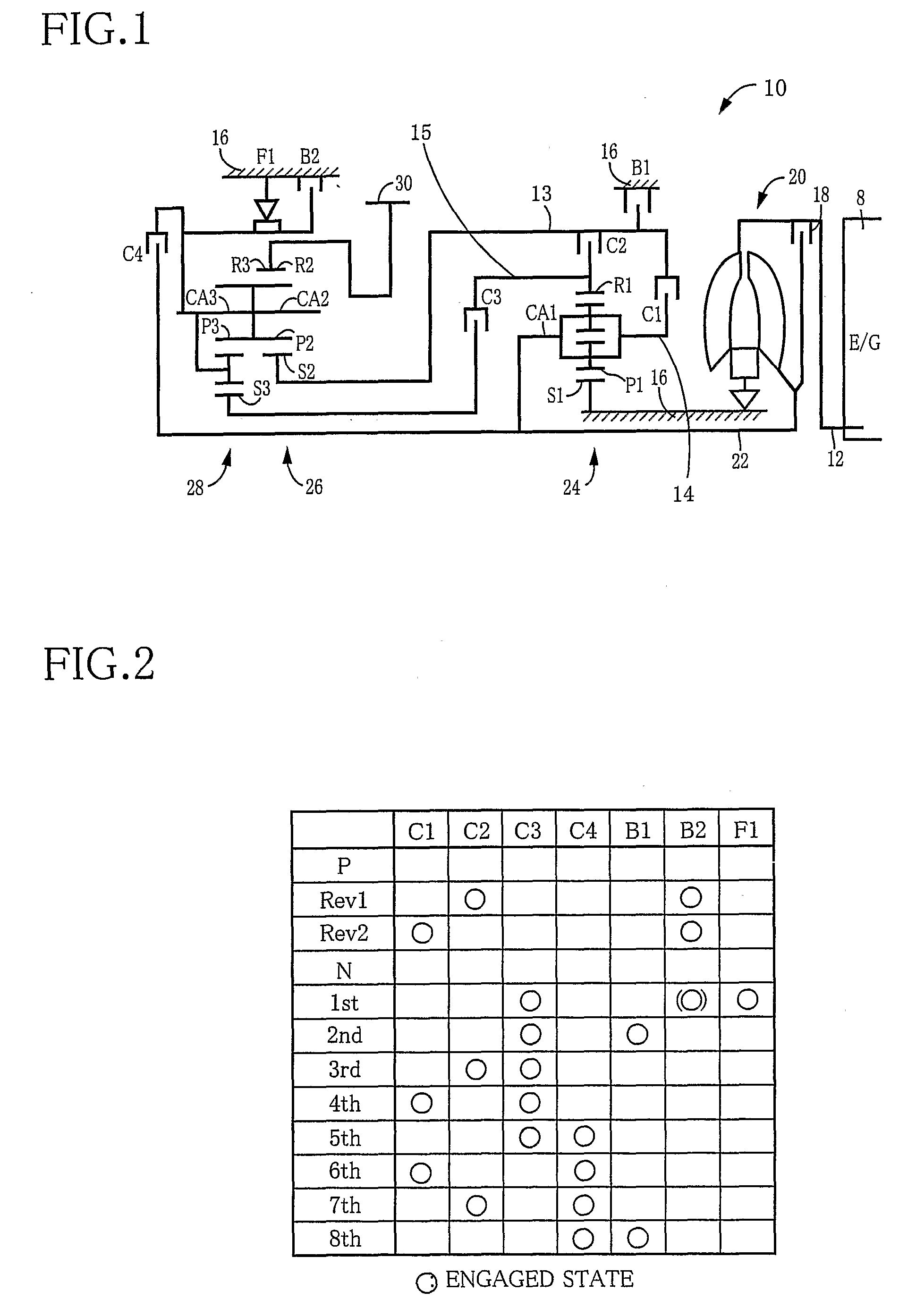

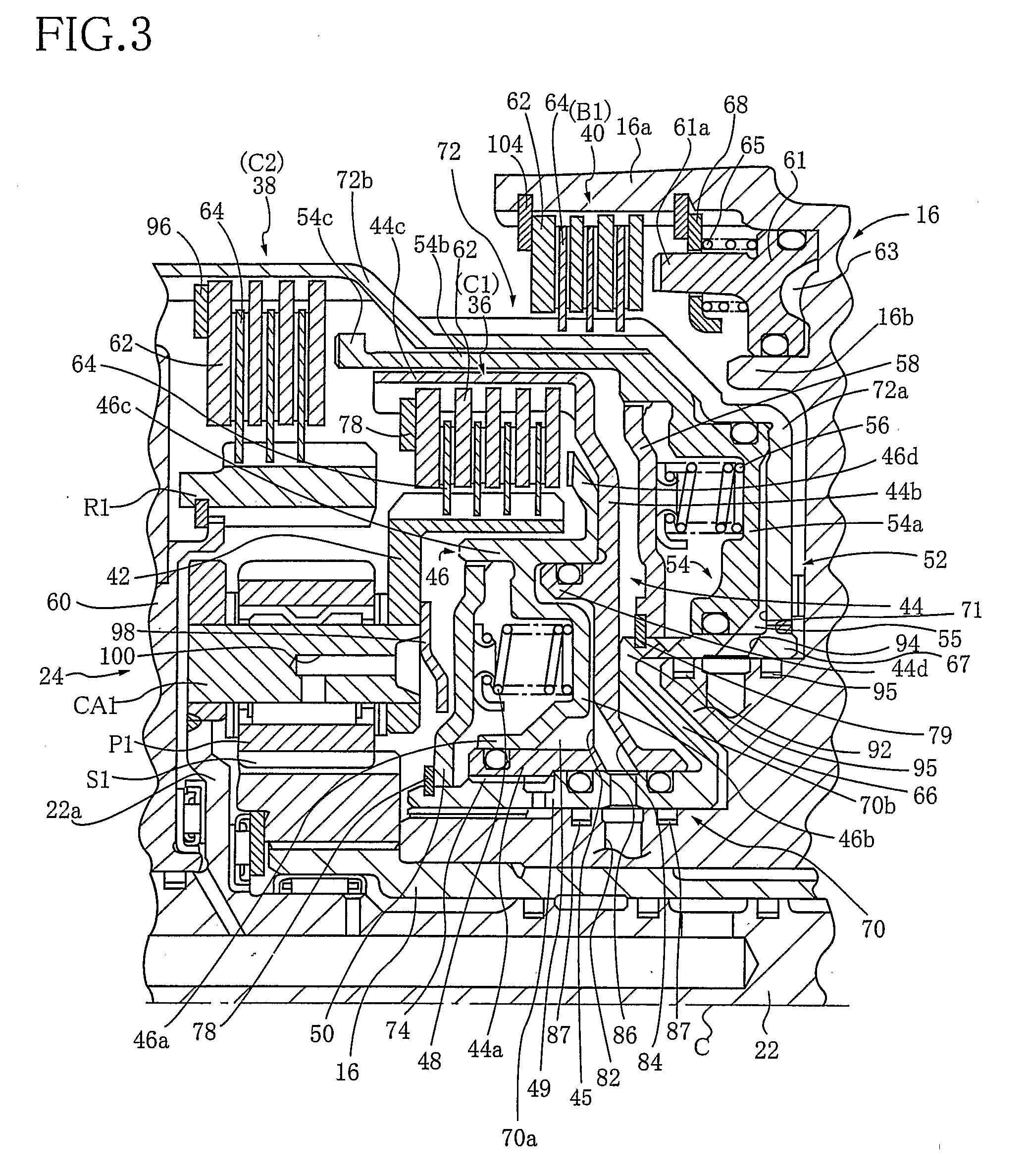

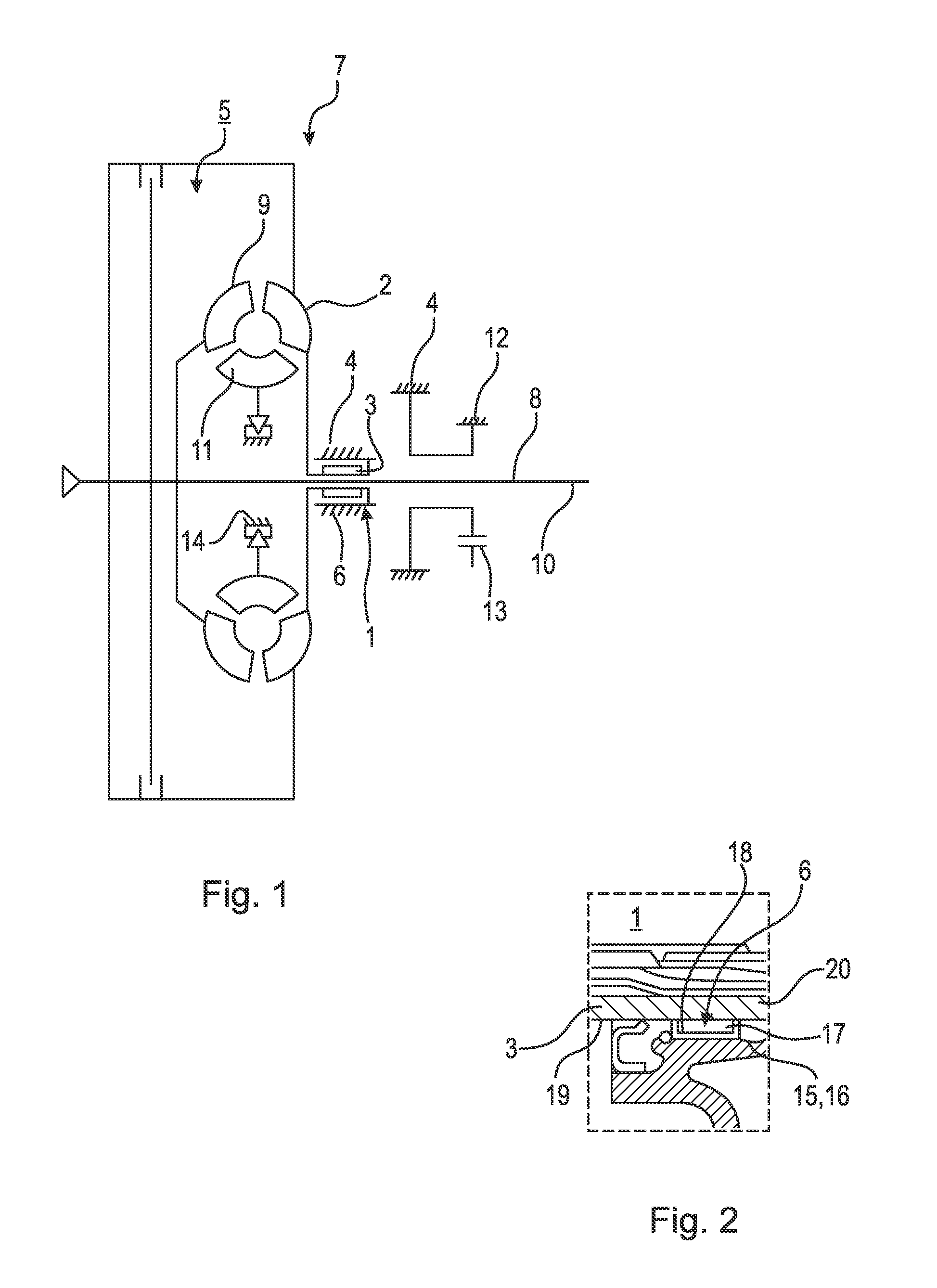

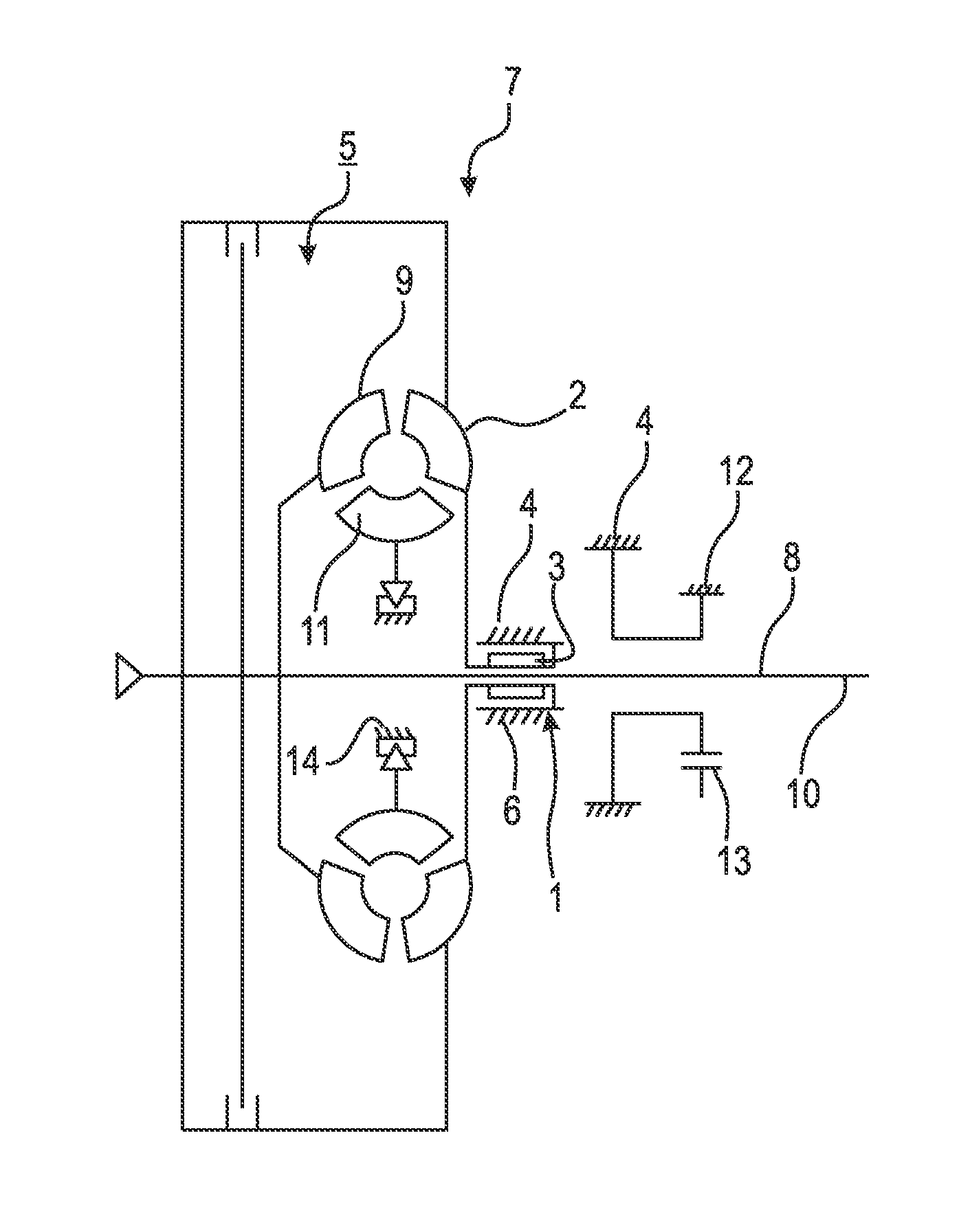

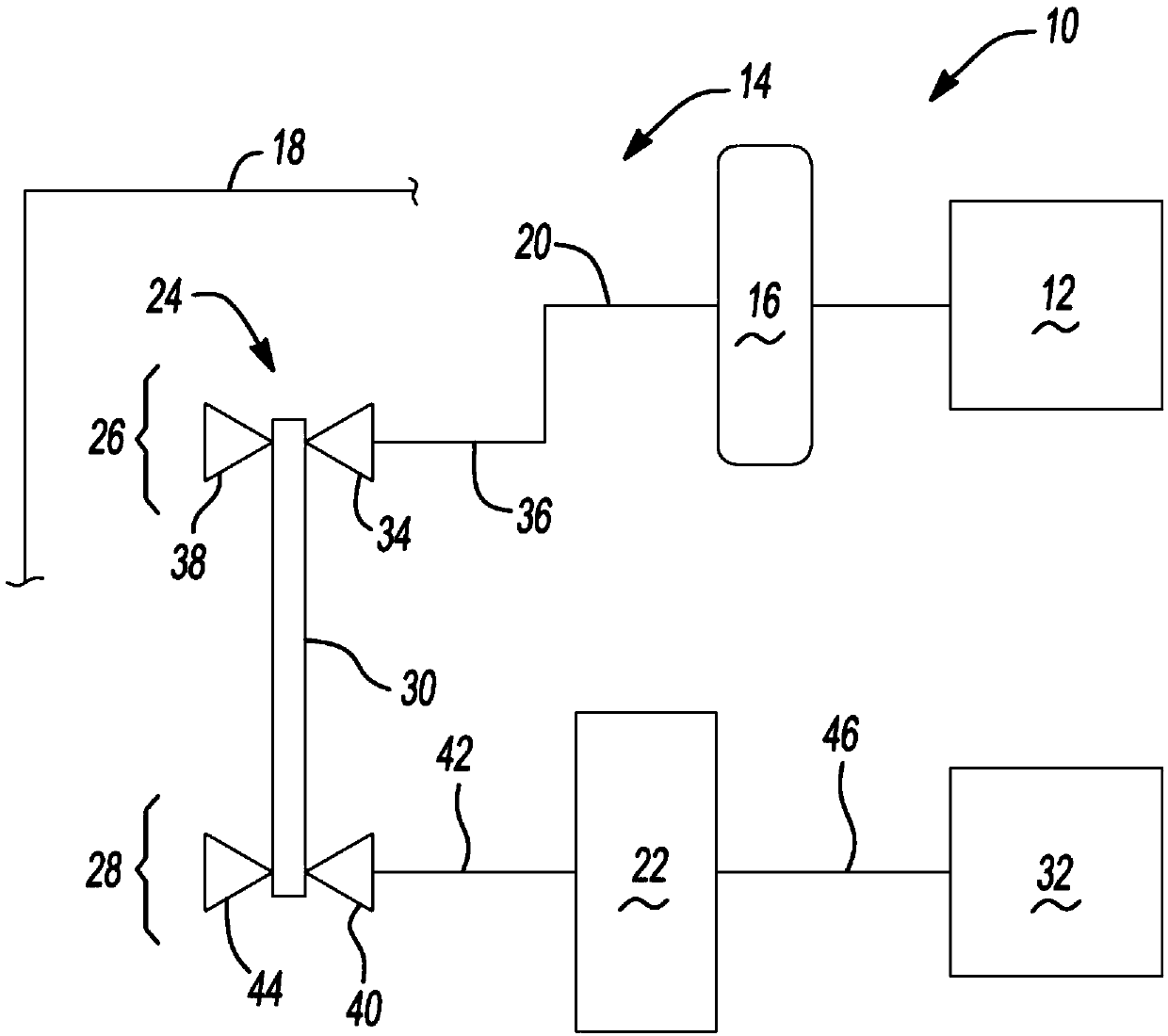

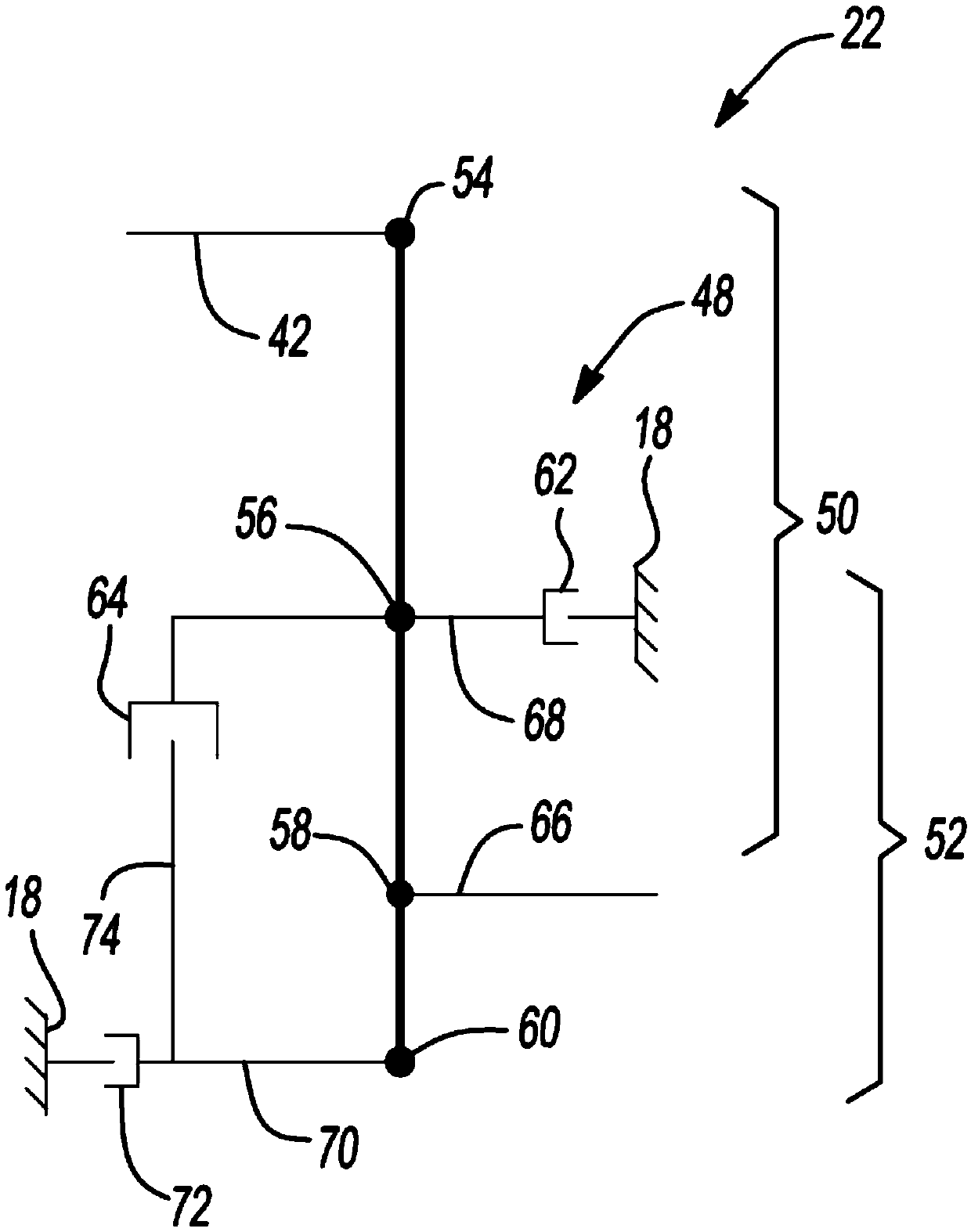

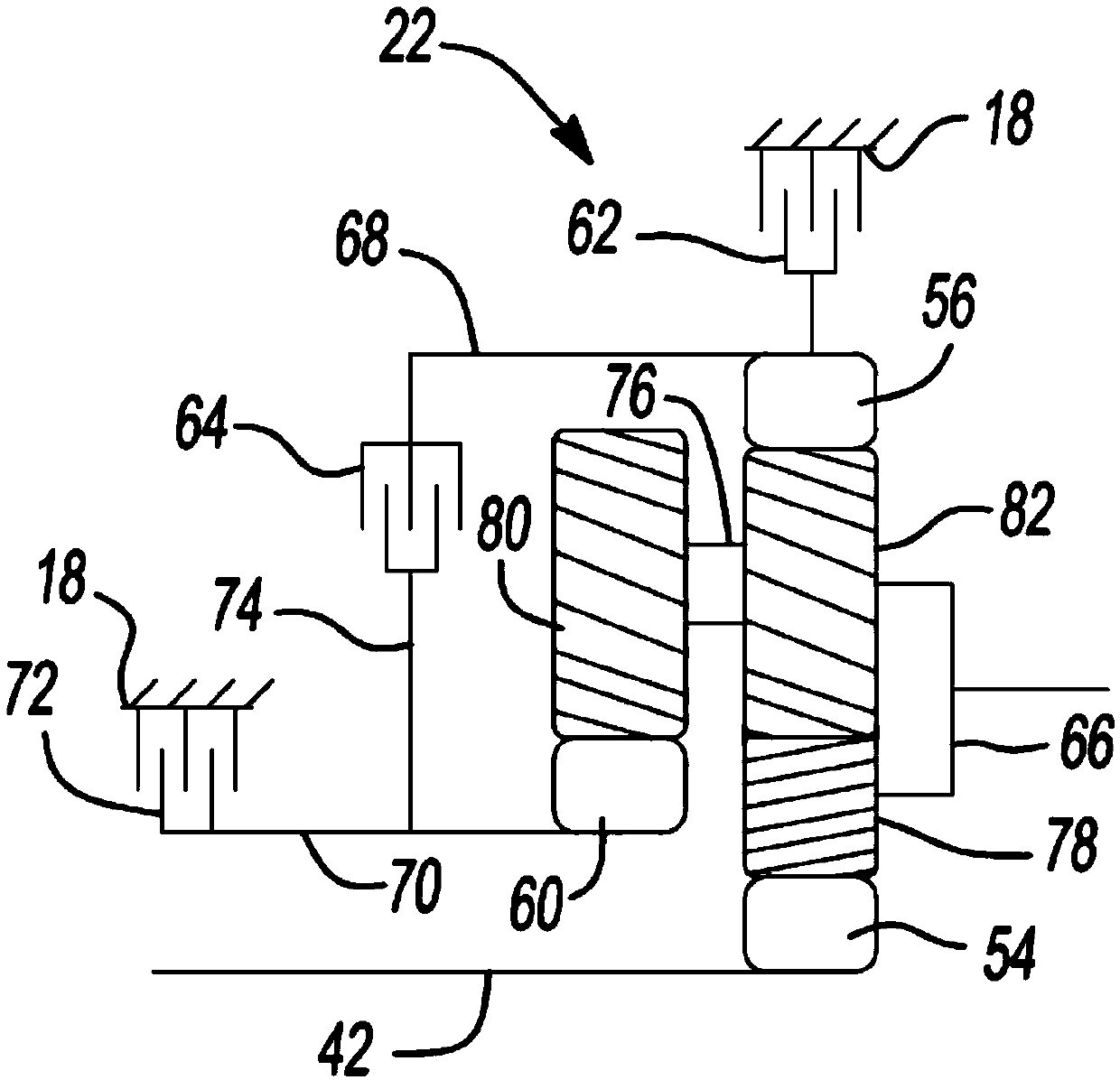

Automatic transmission including clutch devices

InactiveUS20090020386A1Low costPrevent rotationFluid couplingsGearboxesAutomatic transmissionEngineering

An automatic transmission including a first clutch selectively connecting a first rotary member and a second rotary member disposed coaxially with the first rotary member, a second clutch selectively connecting the first rotary member and a third rotary member disposed coaxially with the first rotary member, a first drum in which a first piston of the first clutch is axially slidably received, a second drum disposed coaxially with the first drum, to accommodate the first drum, and in which a second piston of the second clutch is axially slidably received, an abutting portion abutting contact of the first and second drums with each other in an axial direction of the first and second drums, and a fitting portion at which the first drum is fitted in the second drum and that inhibits relative rotation of the first and second drums about a common axis of the first and second drums.

Owner:TOYOTA JIDOSHA KK

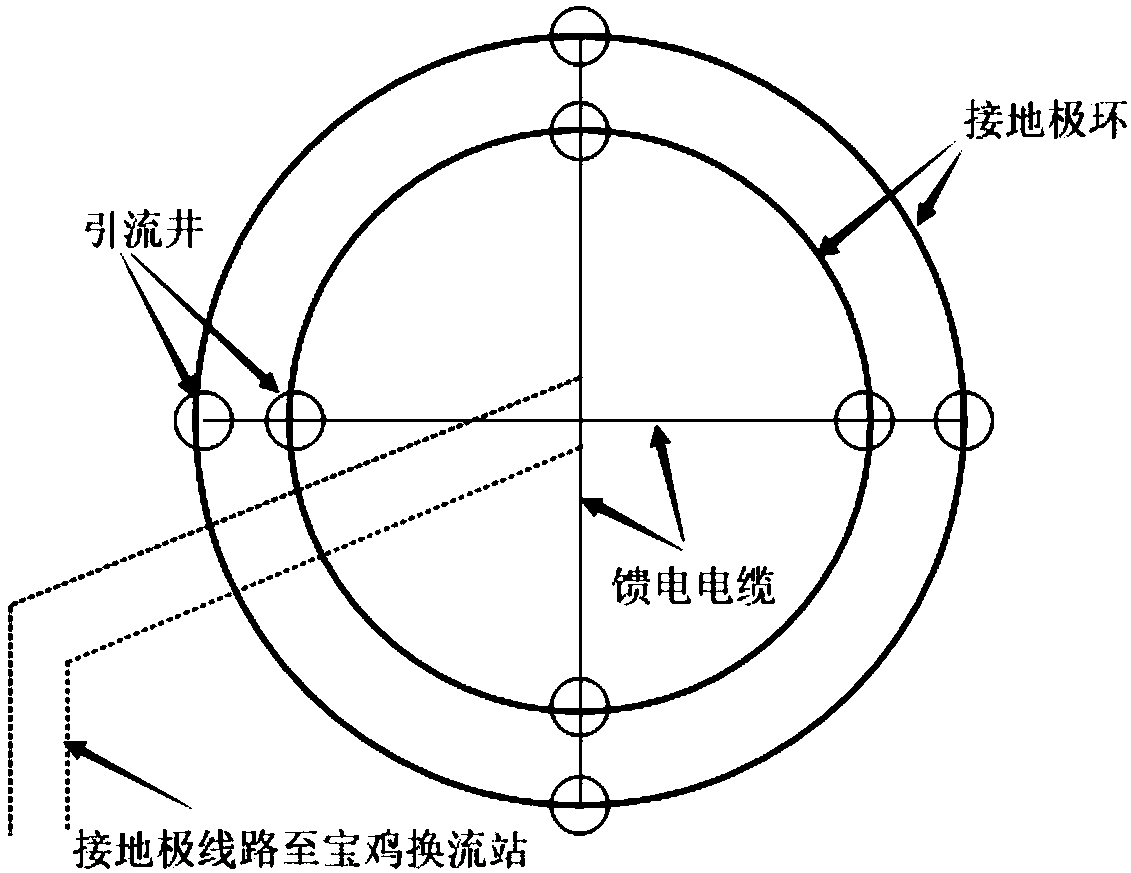

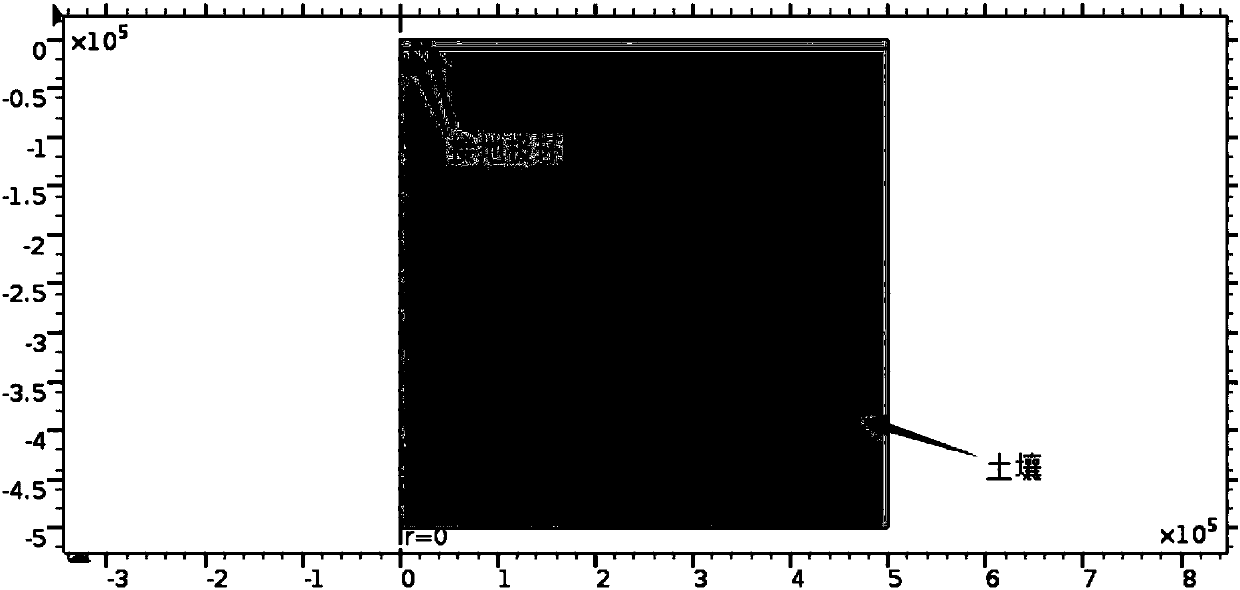

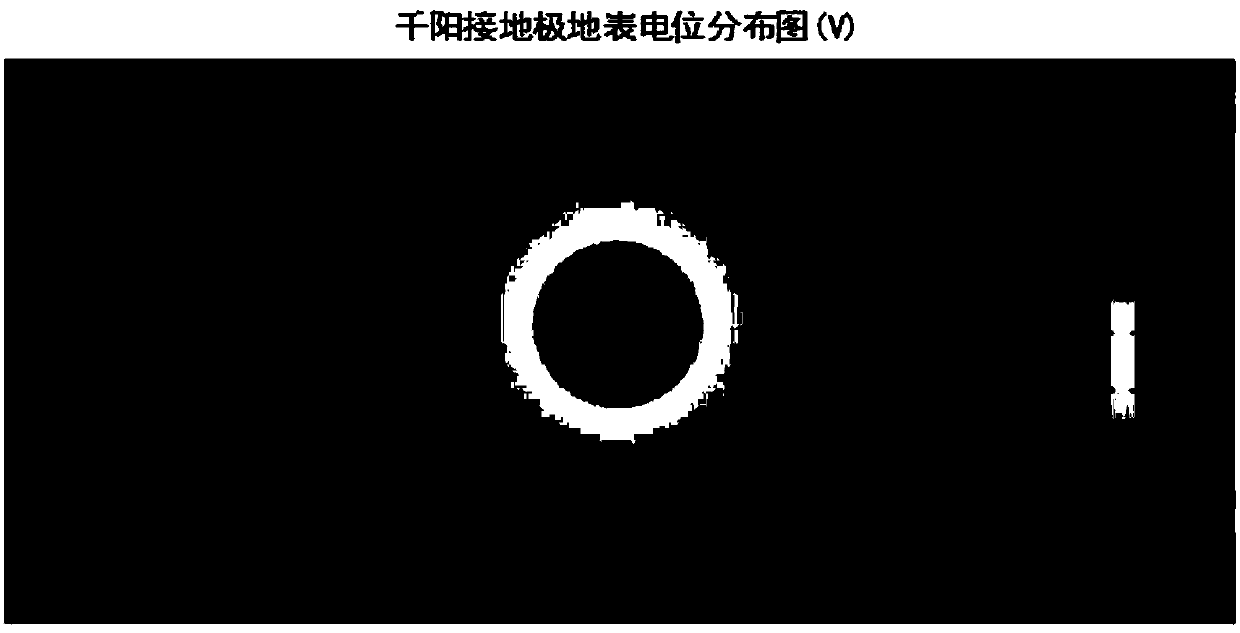

Finite element analysis method of electromagnetic fields near direct-current grounding electrode and tower grounding grid

ActiveCN107831370AReduce the radial distanceLow leakage current densityElectromagentic field characteristicsGrounding gridLeakage current density

The invention discloses a finite element analysis method of electromagnetic fields near a direct-current grounding electrode and a tower grounding grid. Model establishment, relevant parameter setting, material attribute adding, boundary condition adding, grid division, and electromagnetic field distribution calculation are carried out to obtain the following conclusions: potentials of two groundpolar rings are the highest and the voltage of the inner ring is slightly higher than that of the outer ring, the potentials are reduced gradually along the radial direction by using the circle centerof the ground polar ring as the starting point, and the potential of the soil of the inner ring is higher than that of the soil of the outer ring; and the potential of a tower grounding grid body isthe highest, the potential of the tower grounding rid is increased gradually when the distance to the tower grounding rid is reduced, the potential of the soil inside the tower grounding rid is higherthan that of the soil outside the tower grounding rid, the potential near the tower grounding rid is symmetric because of the symmetry of the tower grounding rid, the leakage current density at the tail end of a ray of the grounding grid is the largest and the current density at the front end of the ray is the lowest, and the current density at the connection part between the rectangle and the ray of the grounding grid changes suddenly. Therefore, a problem of an incomprehensive finite element analysis of electromagnetic fields near a direct-current grounding electrode and a tower grounding grid is solved.

Owner:XIAN UNIV OF TECH

Superhydrophobic sponge material and preparation method thereof

The present invention relates to a superhydrophobic sponge material and a preparation method thereof. A purpose of the present invention is to mainly solve the problem of poor hydrophobic effect of the existing adsorption recovery material. The technical scheme of the present invention comprises a superhydrophobic sponge material and a preparation method thereof, wherein the superhydrophobic sponge material comprises a sponge material and a nanometer modifier, the sponge material is a melamine sponge or a polyurethane sponge, and the nanometer modifier preparation method comprises: dissolving a nanometer material in a hydrophobic organosilicon compound agent, and stirring until completely dissolving so as to obtain the nanometer modifier. With the technical scheme of the present invention, the problem in the prior art is well solved. The preparation method of the present invention can be used in the preparation of superhydrophobic sponge materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

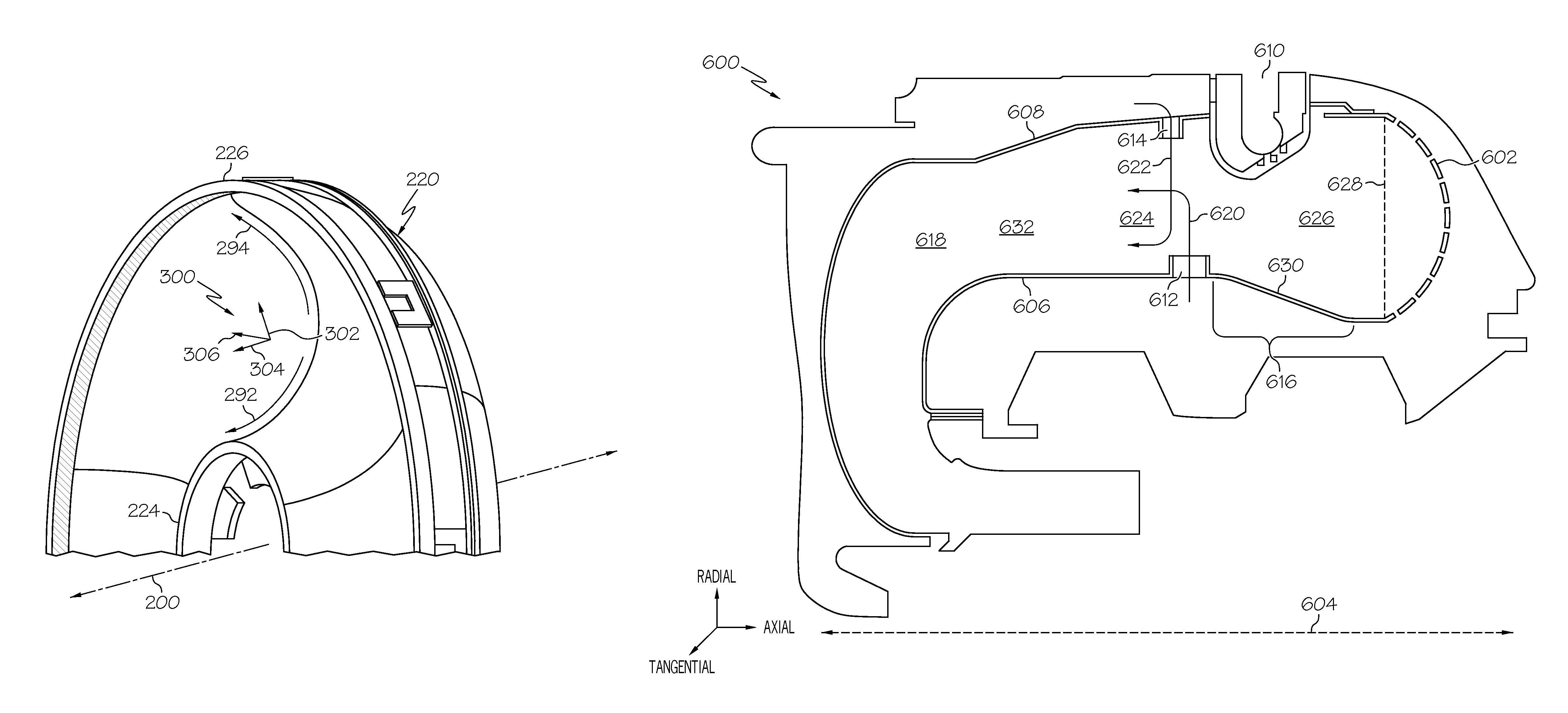

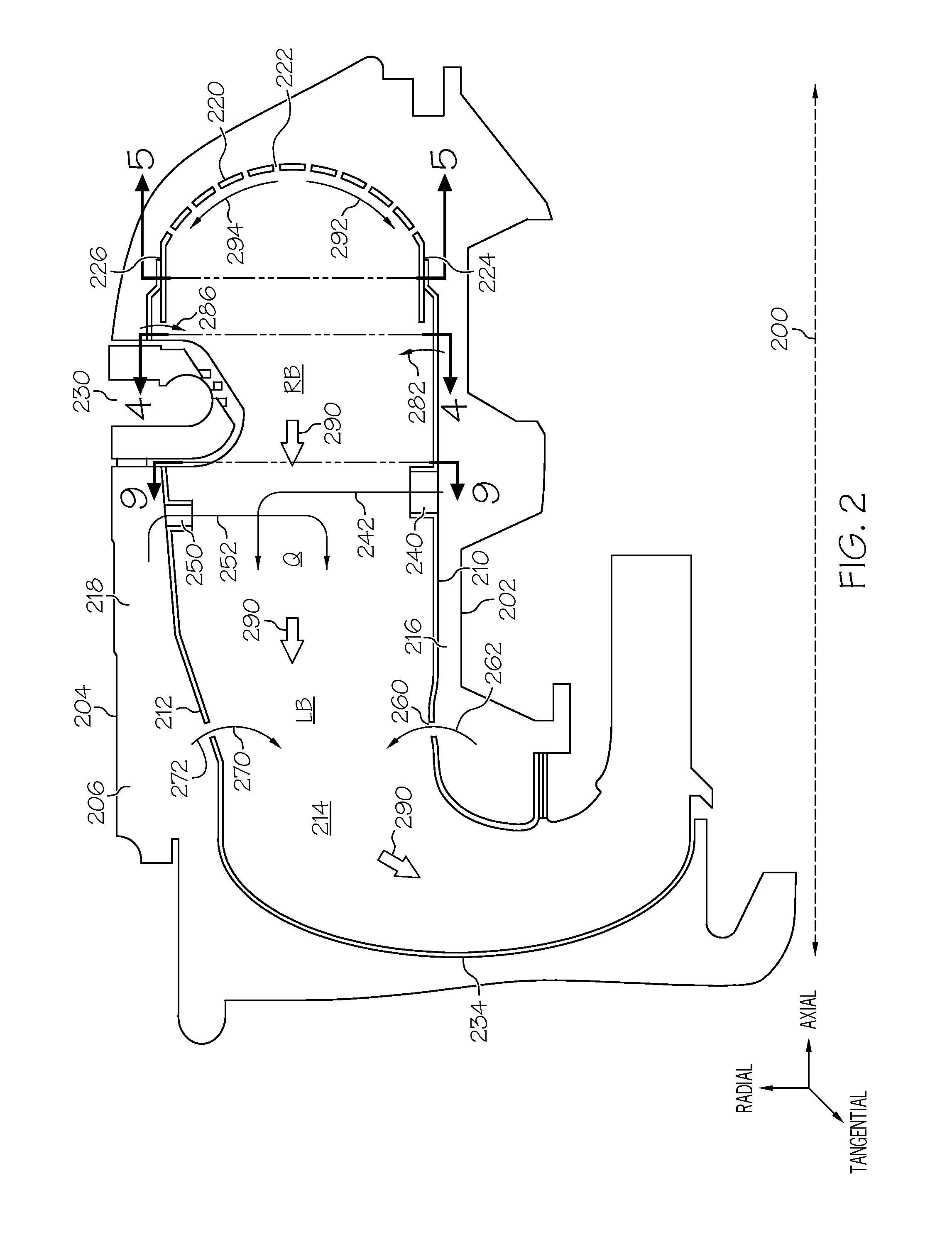

Reverse-flow annular combustor for reduced emissions

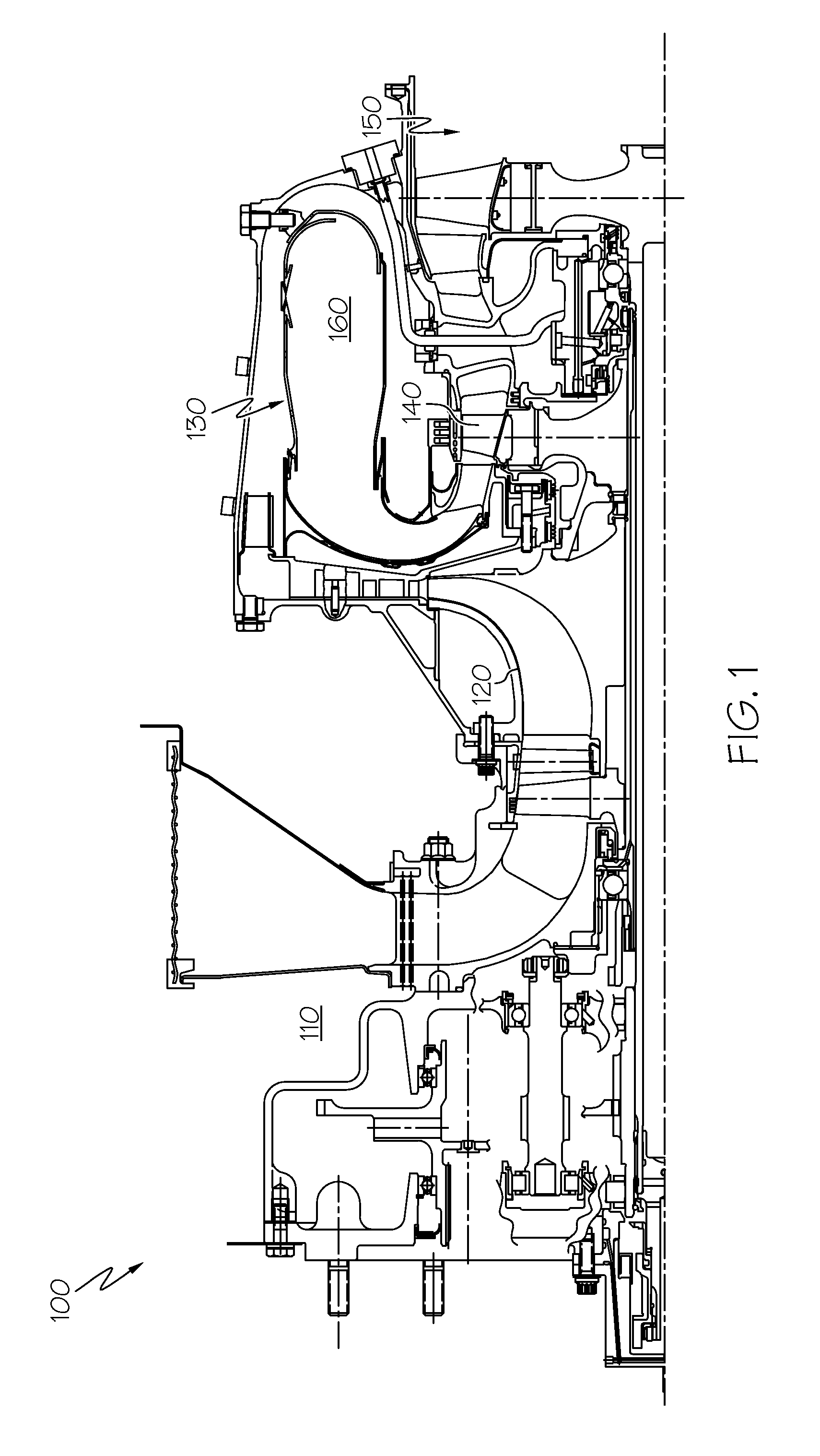

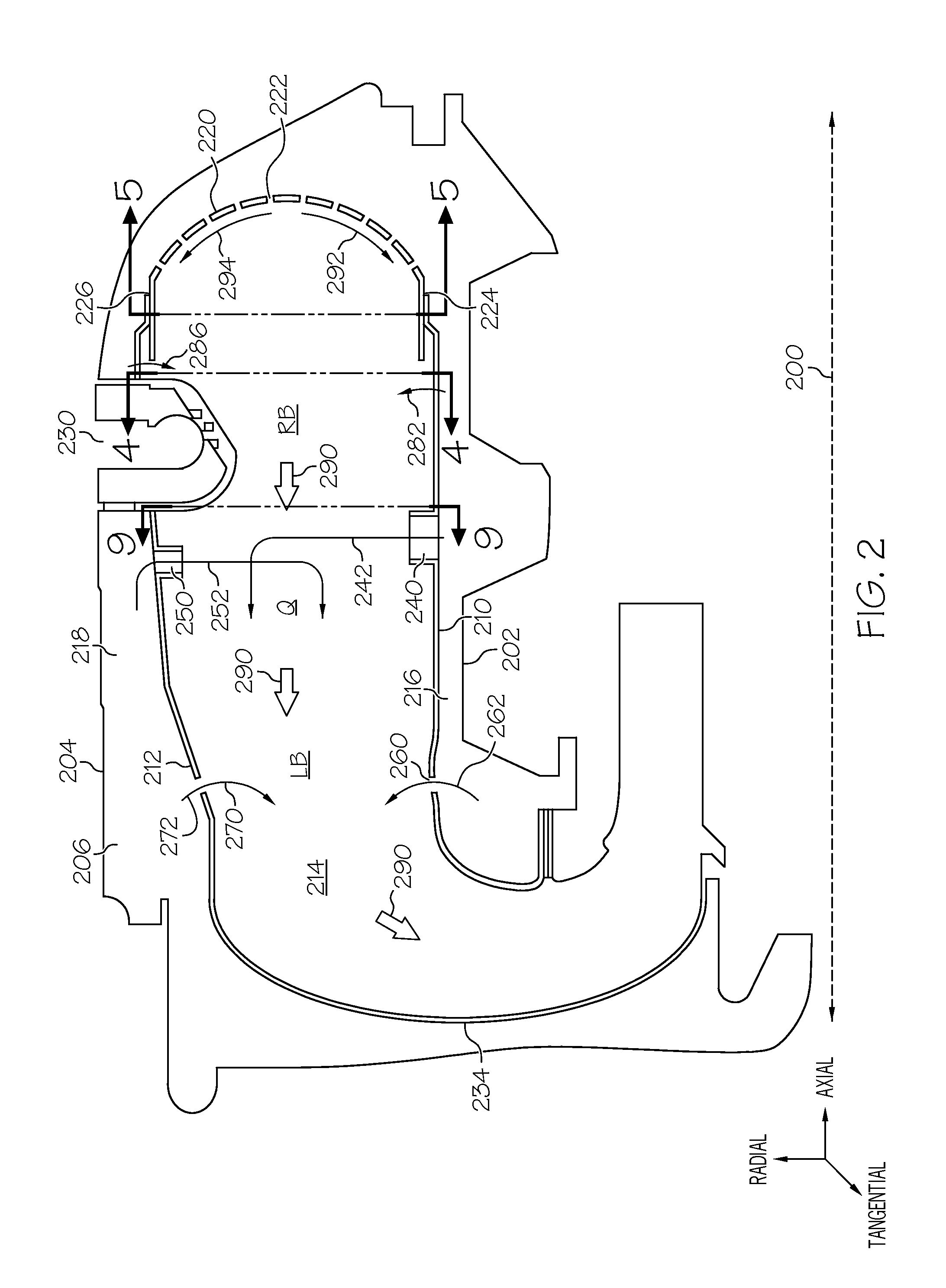

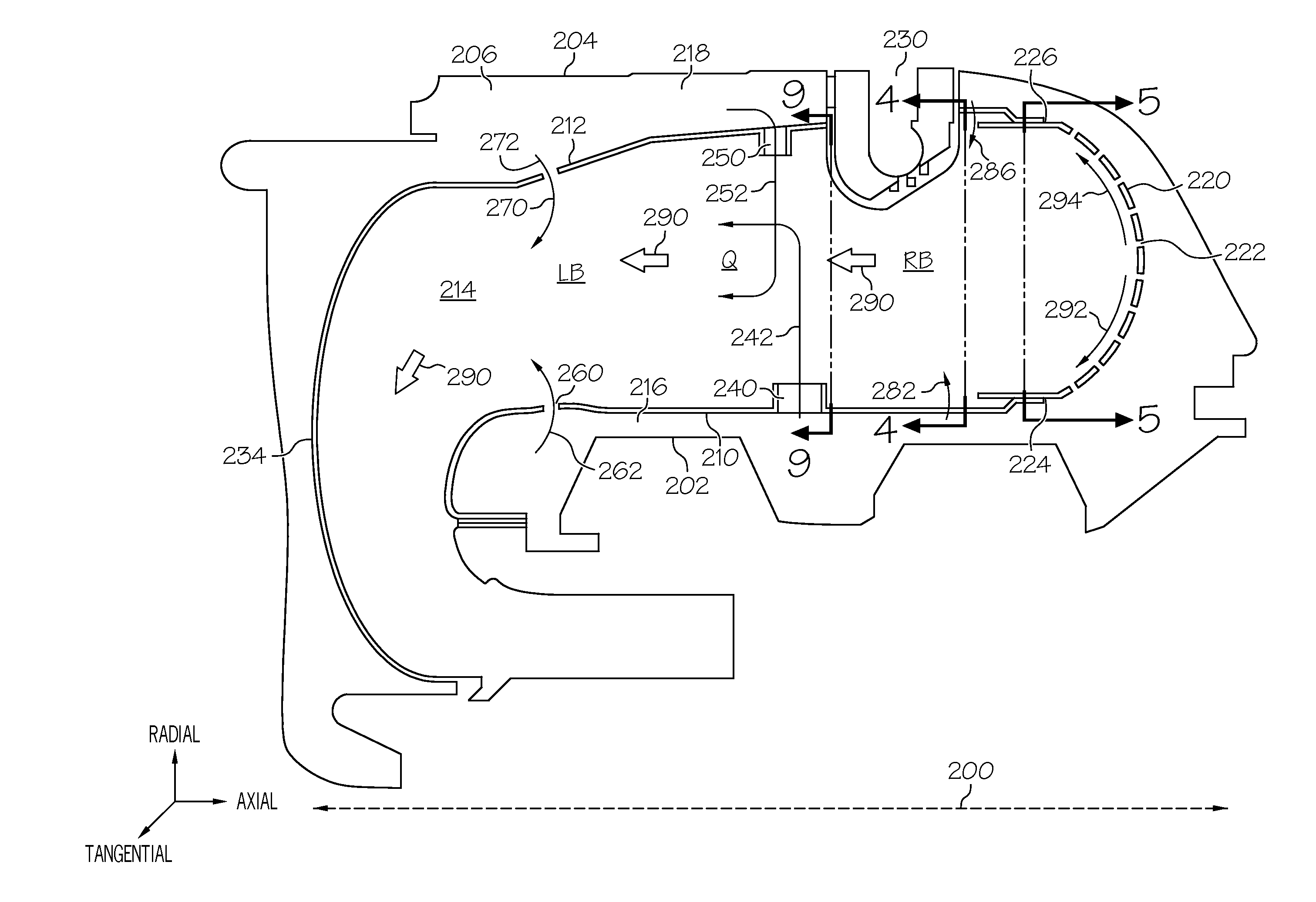

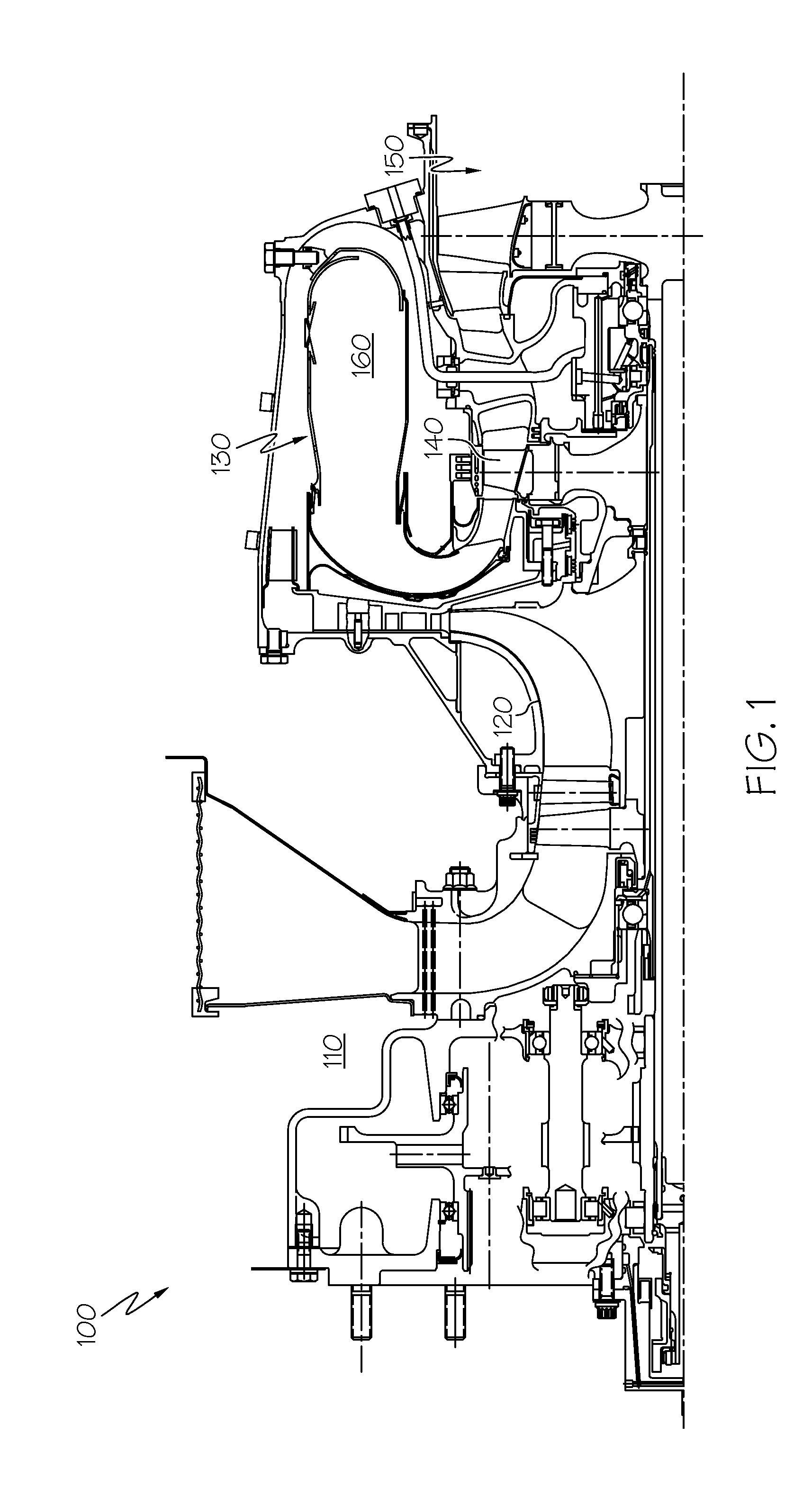

ActiveUS9400110B2Decrease passage heightReduce the overall diameterContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

A combustor for a gas turbine engine is provided. The combustor includes an annular inner liner; an annular outer liner circumscribing the annular inner liner; and a combustor dome having a first edge coupled to the annular inner liner and a second edge coupled to the annular outer liner, the combustor dome forming a combustion chamber with the annular inner liner and the annular outer liner. The combustion chamber accommodates fluid flow through the annular inner and annular outer liners. The combustion chamber converges in the direction of the air flow to reduce a diameter of the combustion chamber. The combustor dome is configured to bifurcate the air flow at the combustor dome into a first stream directed to the annular inner liner and a second stream directed to the annular outer liner.

Owner:HONEYWELL INT INC

Reverse-flow annular combustor for reduced emissions

ActiveUS20140109581A1Decrease passage heightReduce the overall diameterContinuous combustion chamberEfficient propulsion technologiesCombustion chamberCombustor

A combustor for a gas turbine engine is provided. The combustor includes an annular inner liner; an annular outer liner circumscribing the annular inner liner; and a combustor dome having a first edge coupled to the annular inner liner and a second edge coupled to the annular outer liner, the combustor dome forming a combustion chamber with the annular inner liner and the annular outer liner. The combustion chamber accommodates fluid flow through the annular inner and annular outer liners. The combustion chamber converges in the direction of the air flow to reduce a diameter of the combustion chamber. The combustor dome is configured to bifurcate the air flow at the combustor dome into a first stream directed to the annular inner liner and a second stream directed to the annular outer liner.

Owner:HONEYWELL INT INC

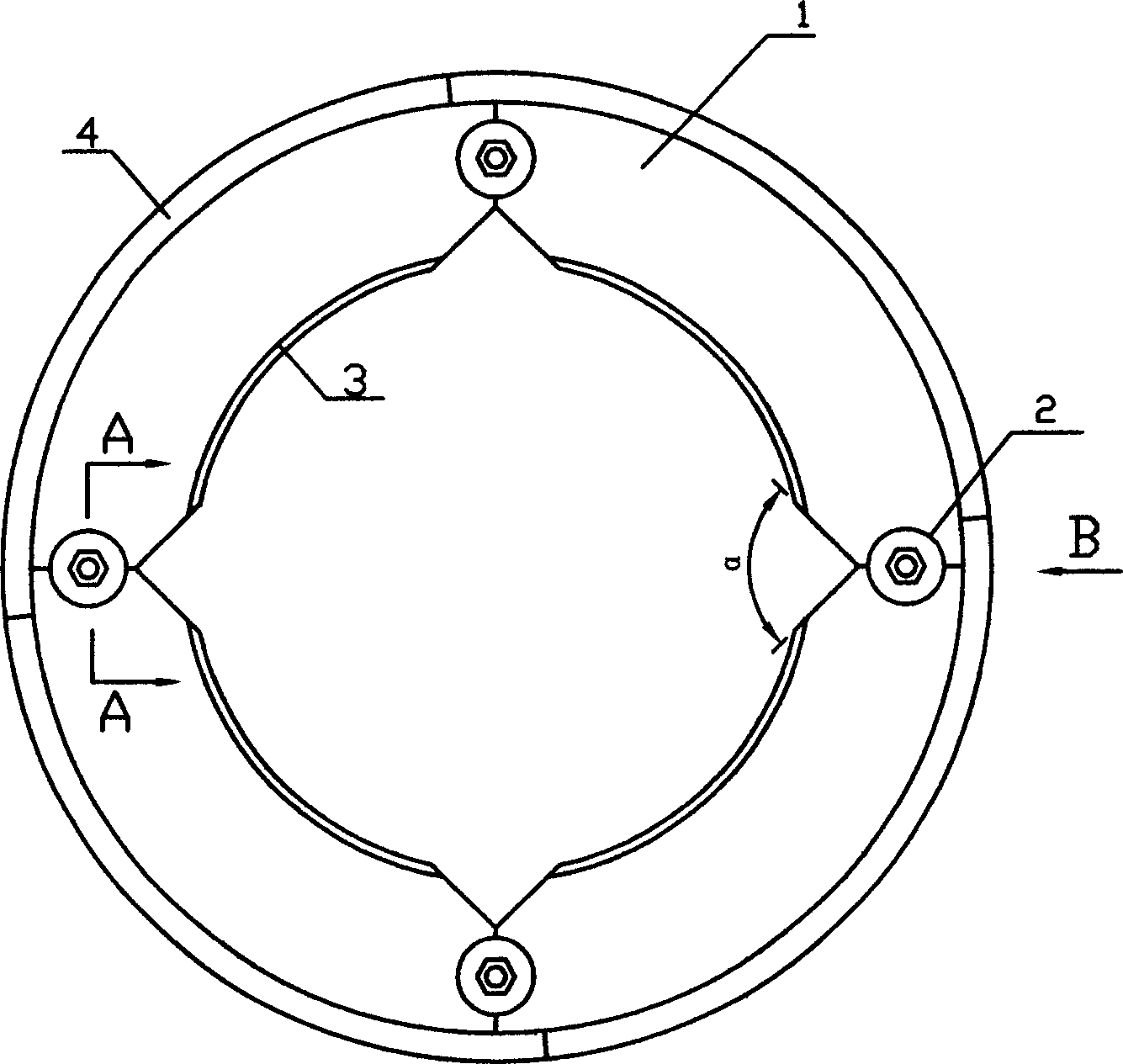

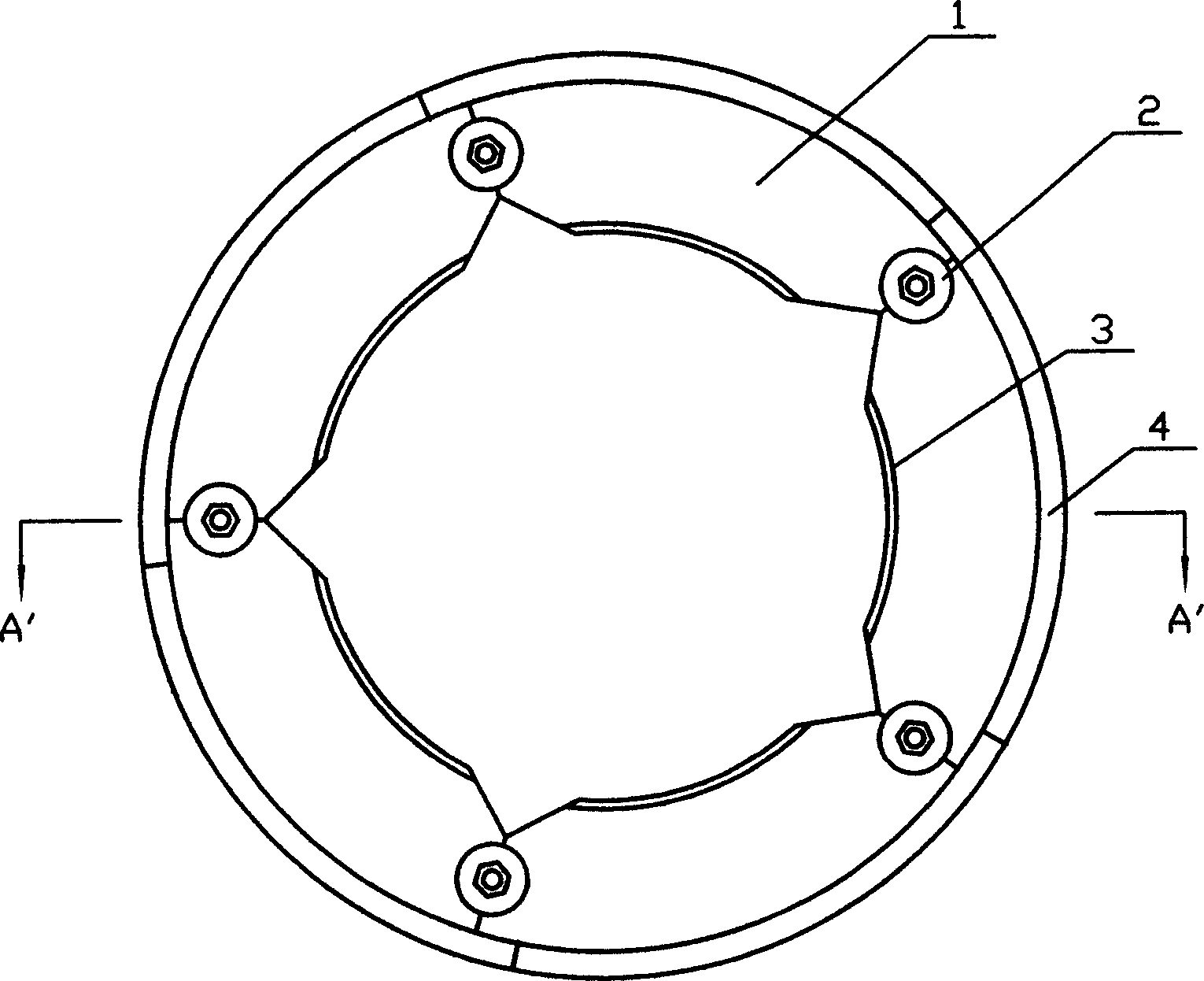

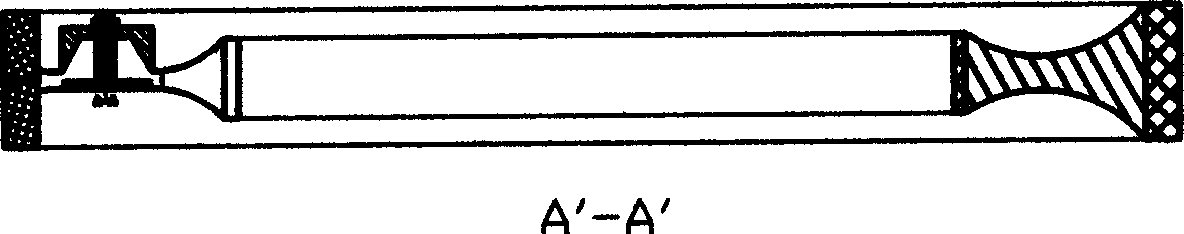

Safety device of vehicle tyre

InactiveCN1817671AReduce line speed differenceReduce steeringTyre partsMultiple wheel assemblyLocking mechanismEngineering

A high-safety safeguard on the hub in the car tyre without internal tube for continuous running after the tyre is exploded is composed of 4-6 or more T-shaped flap blocks made of alloy steel, and axial locking mechanisms consisting of fastening screw bolt with baseplate and nut for splicing said flap blocks to become a circular ring.

Owner:梁檬

Radial clearance adjusting structure of worm gear and worm

InactiveCN104832633AReduce gapReduce the radial distanceToothed gearingsGearing detailsEngineeringThreaded rod

The invention discloses a radial clearance adjusting structure of a worm gear and worm. The radial clearance adjusting structure comprises a shell, a worm gear and a worm, wherein the worm gear and the worm are arranged in the shell and are mutually meshed; two ends of the worm are arranged on the shell through a first bearing and a second bearing in a supporting way; the outer part of the first bearing is provided with an adjusting sleeve in a sleeving way; an adjusting zone which is used for enabling the first bearing to move in the radial direction is arranged in the adjusting sleeve; a threaded hole is formed in the shell and is positioned under the adjusting sleeve; an adjusting screw rod is arranged in the threaded rod; one end, which is positioned in the shell, of the adjusting screw rod is provided with a meshing part; the meshing part is a circular truncated cone body; spiral teeth are arranged at the periphery of the meshing part; root diameters of the spiral teeth on the meshing part are gradually increased from one end which is far away from the adjusting screw rod to one end which is close to the adjusting screw rod; the spiral teeth on the meshing part are partially meshed with the worm. According to the radial clearance adjusting structure disclosed by the invention, the adjustment on a clearance between the worm gear and the worm can be realized through the matching of the adjusting screw rod which is arranged under the adjusting sleeve and the meshing part which is arranged at one end of the adjusting screw rod with the adjusting sleeve, and thus the clearance which is not beneficial for the transmission of the worm gear and worm can be removed.

Owner:芜湖意维利科技有限公司

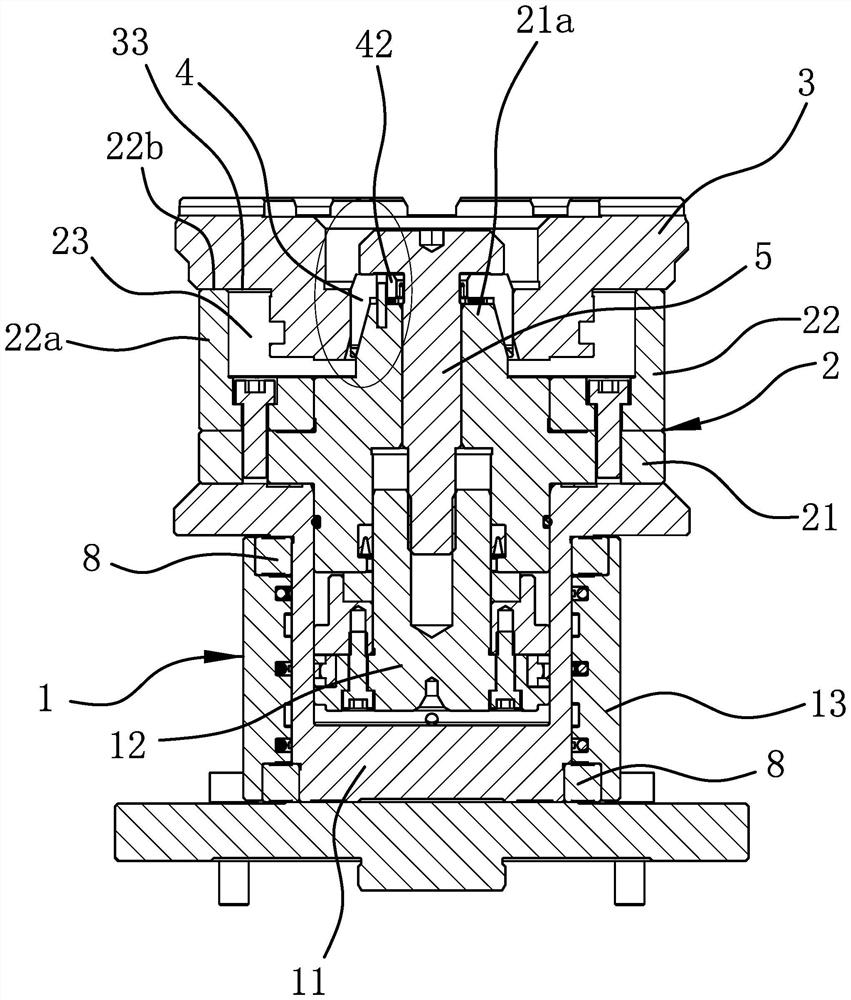

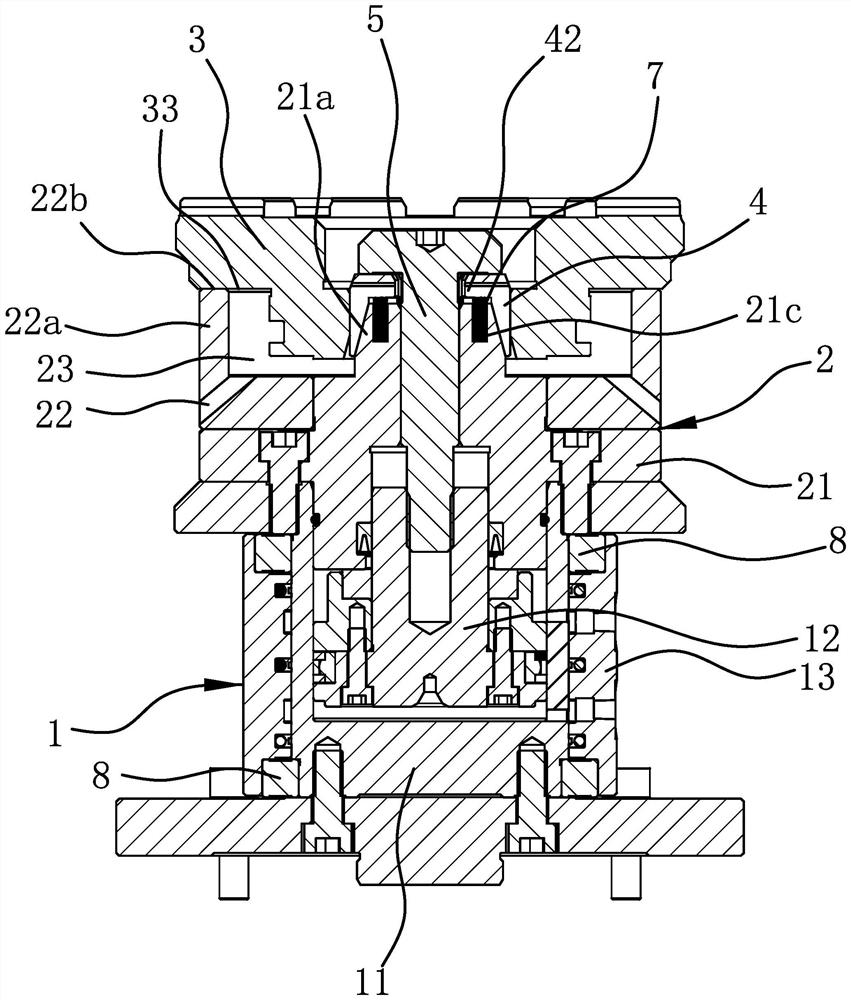

Grinding and positioning mechanism for indexing fluted disc

PendingCN114453998AEasy to operatePrevent axial movementRevolution surface grinding machinesGrinding work supportsEngineeringPhysics

The invention provides an indexing fluted disc grinding and positioning mechanism, and belongs to the technical field of machinery. The problem that an existing indexing fluted disc is low in clamping and positioning efficiency is solved. The indexing fluted disc grinding and positioning mechanism comprises a driving piece and an annular clamp body, the end portion of one end of the clamp body is provided with an annular inner ring portion and an annular outer ring portion located outside the inner ring portion, the inner ring portion and the outer ring portion are coaxially arranged, and a concave annular limiting groove used for allowing the end portion of an indexing fluted disc to stretch into is formed between the inner ring portion and the outer ring portion. The end face of the outer ring part is an annular positioning face, an expansion sleeve is arranged on the inner ring part, and the driving piece can drive the pull rod penetrating through an inner hole of the clamp body to axially move and enable the expansion sleeve to elastically deform outwards. The indexing fluted disc grinding and positioning mechanism has the advantage of being high in positioning effect.

Owner:浙江海德曼智能装备股份有限公司

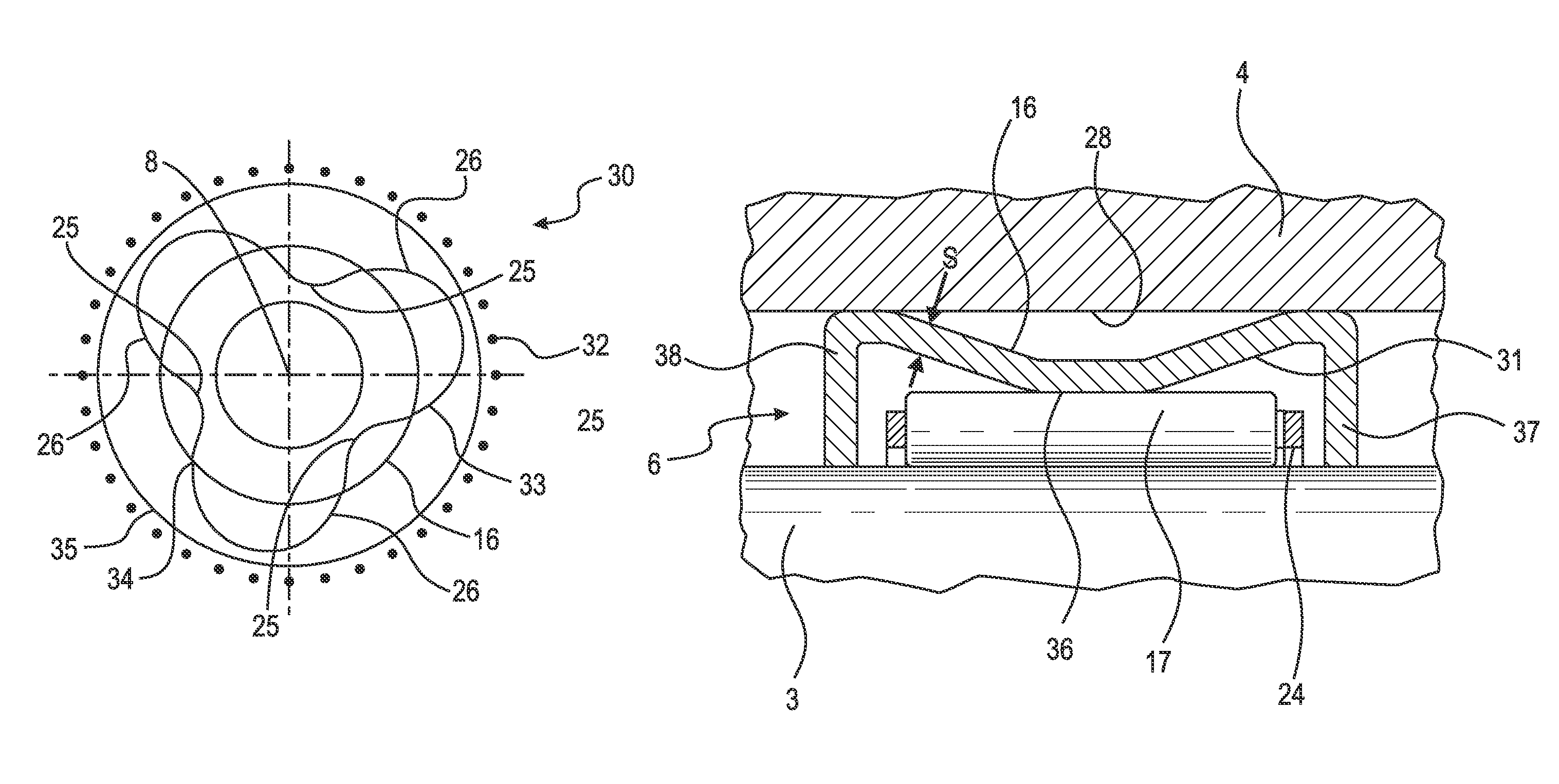

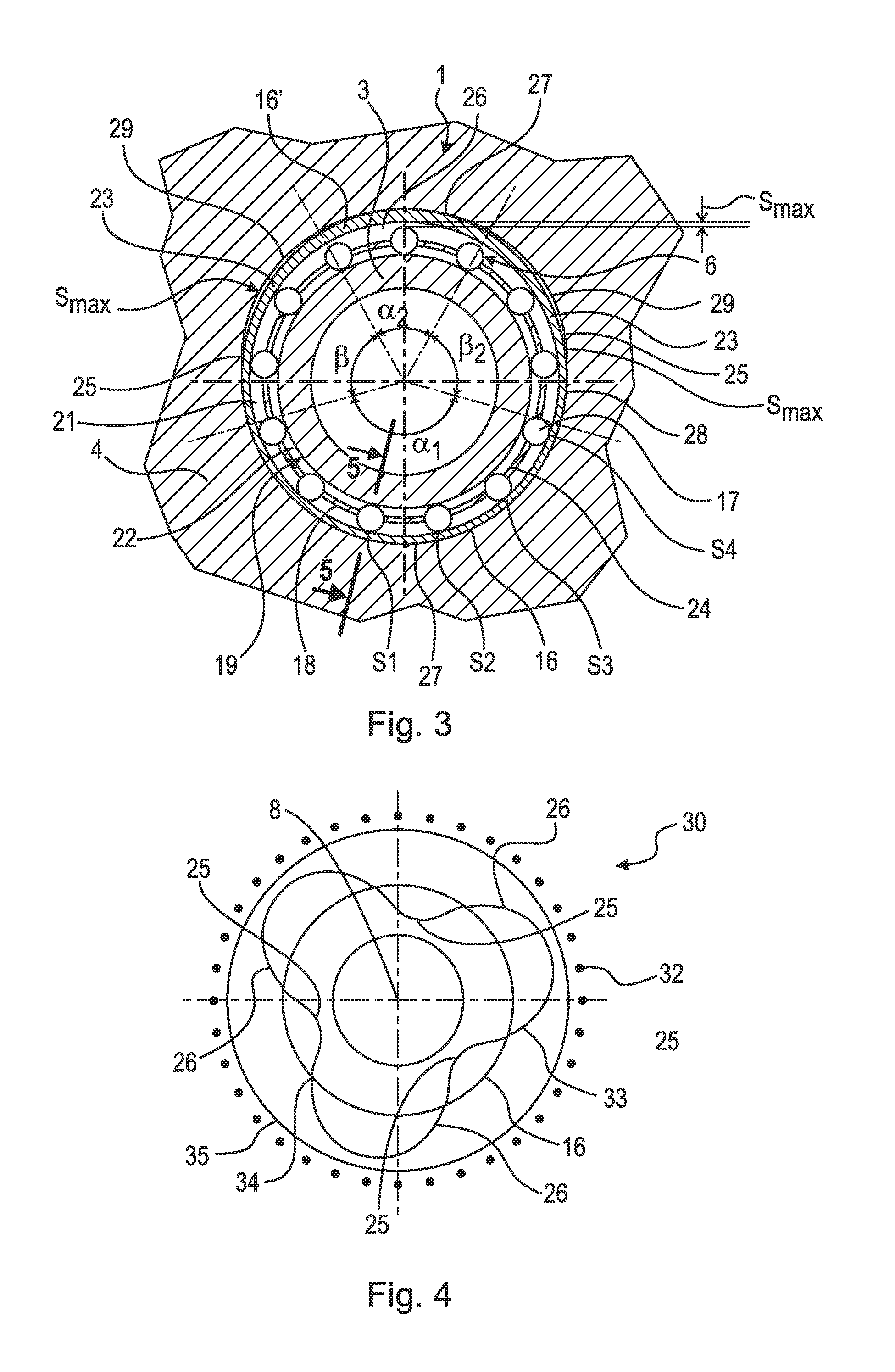

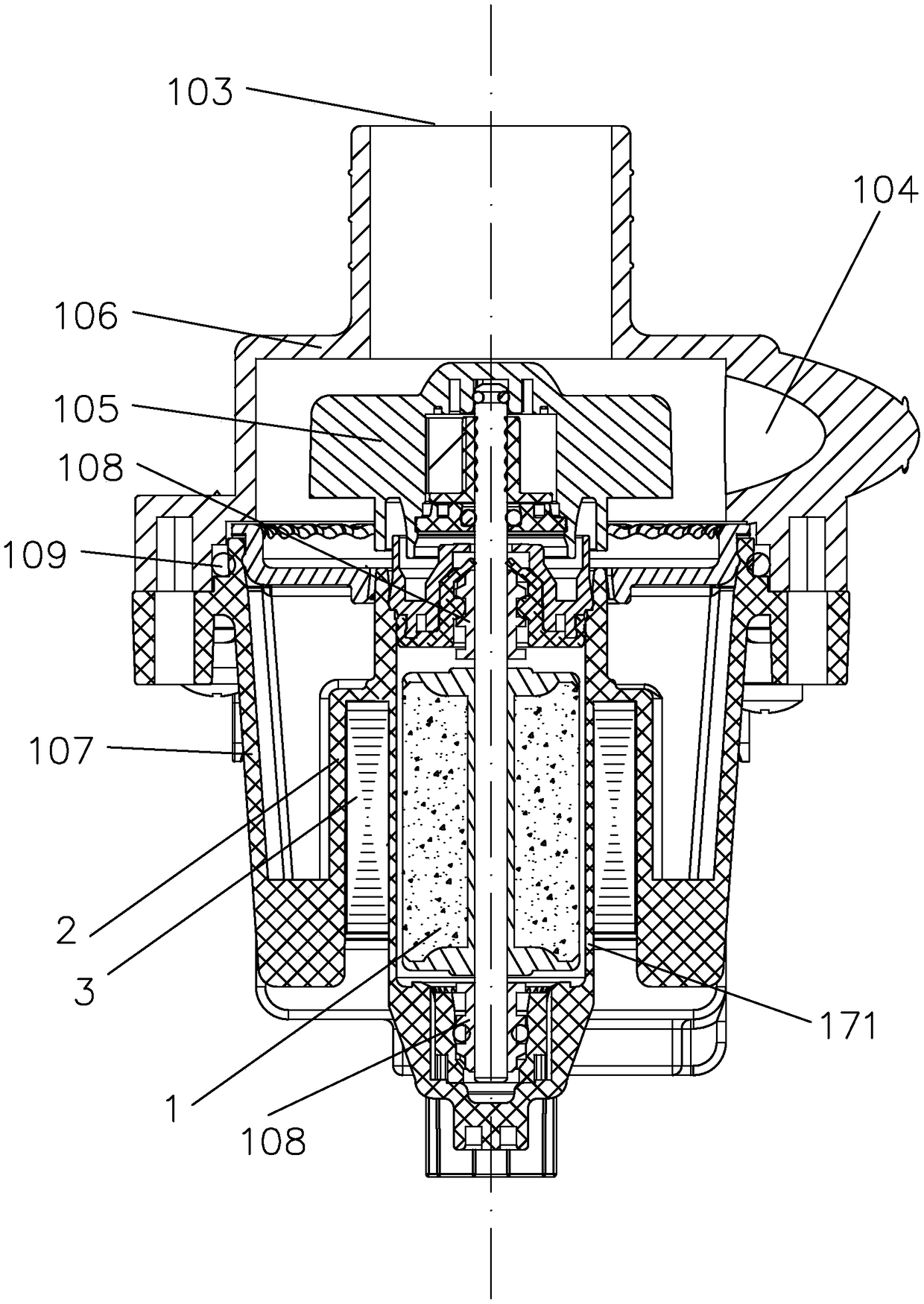

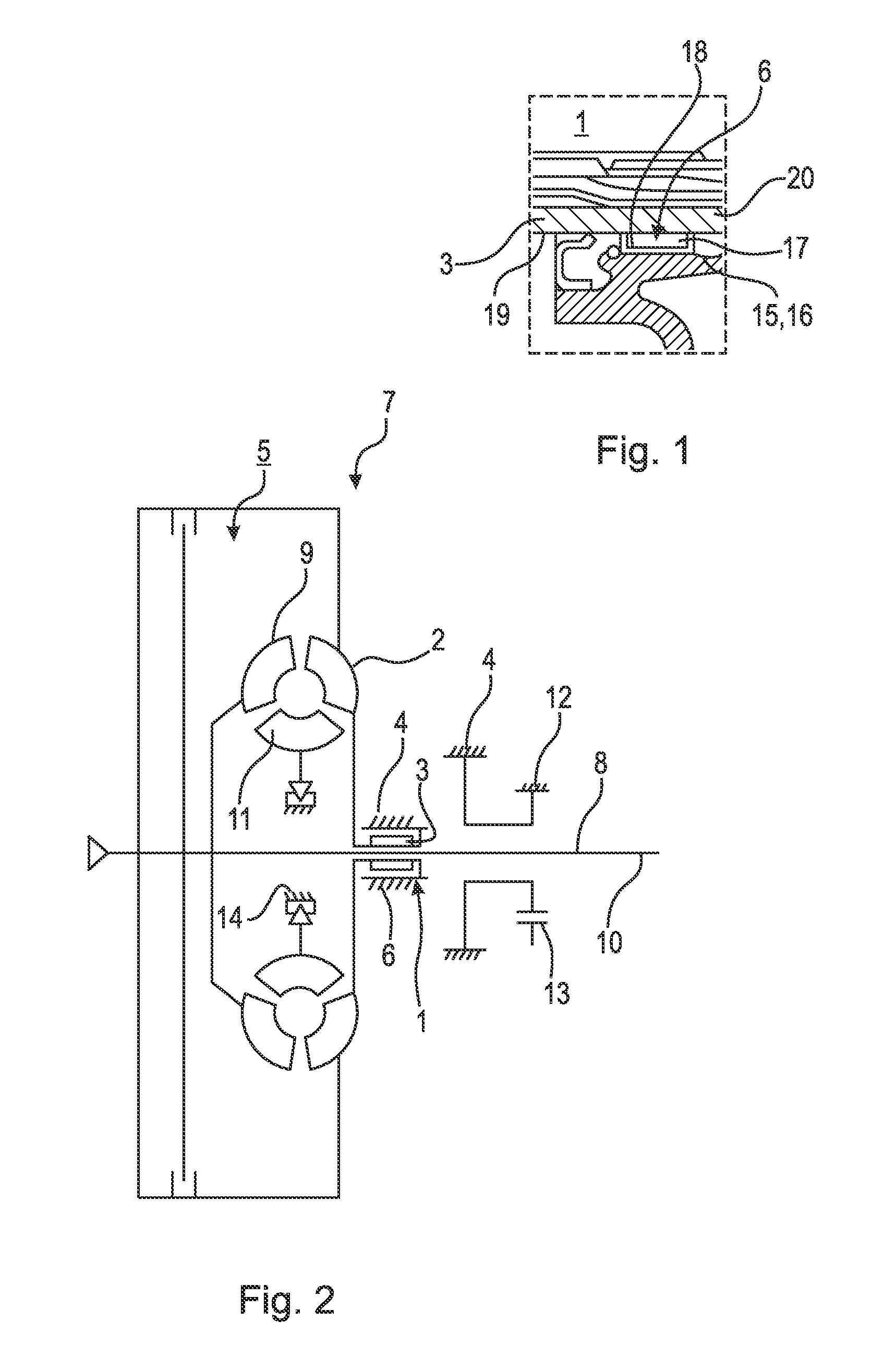

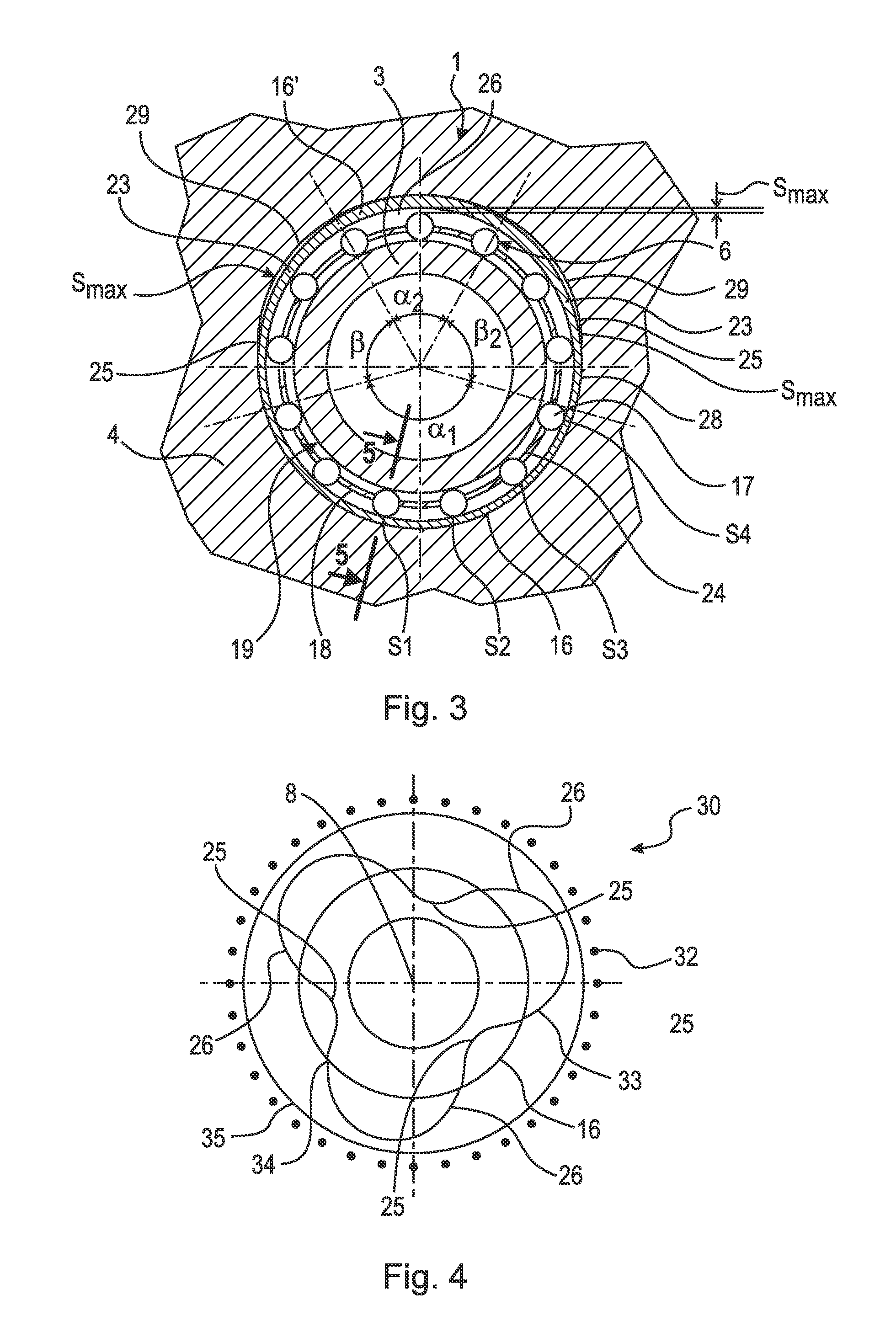

Converter collar bearing for a torque converter

InactiveUS9353794B2Reduce the radial distanceEliminate gapsShaftsBearing componentsImpellerEngineering

A bearing position for a torque converter, wherein a pump impeller is connected to a converter neck, and the pump impeller is rotatably mounted on the bearing position by at least one roller bearing in a housing, wherein the roller bearing comprises an outer rolling raceway, assigned to the converter neck and facing radially outwards, and an inner rolling raceway, assigned to the housing and facing radially inwards, and rollers disposed radially between the rolling raceways, wherein the bearing position comprises at least one radially elastically designed section of a sleeve of the roller bearing, where the sleeve is provided with the inner rolling raceway, wherein the section, enclosing an elastic convex raceway curvature, is resiliently prestressed in the radial direction against at least a first roller of the rollers, the first roller supported on the outer rolling raceway, and supported in the opposite radial direction on the housing.

Owner:SCHAEFFLER TECH AG & CO KG

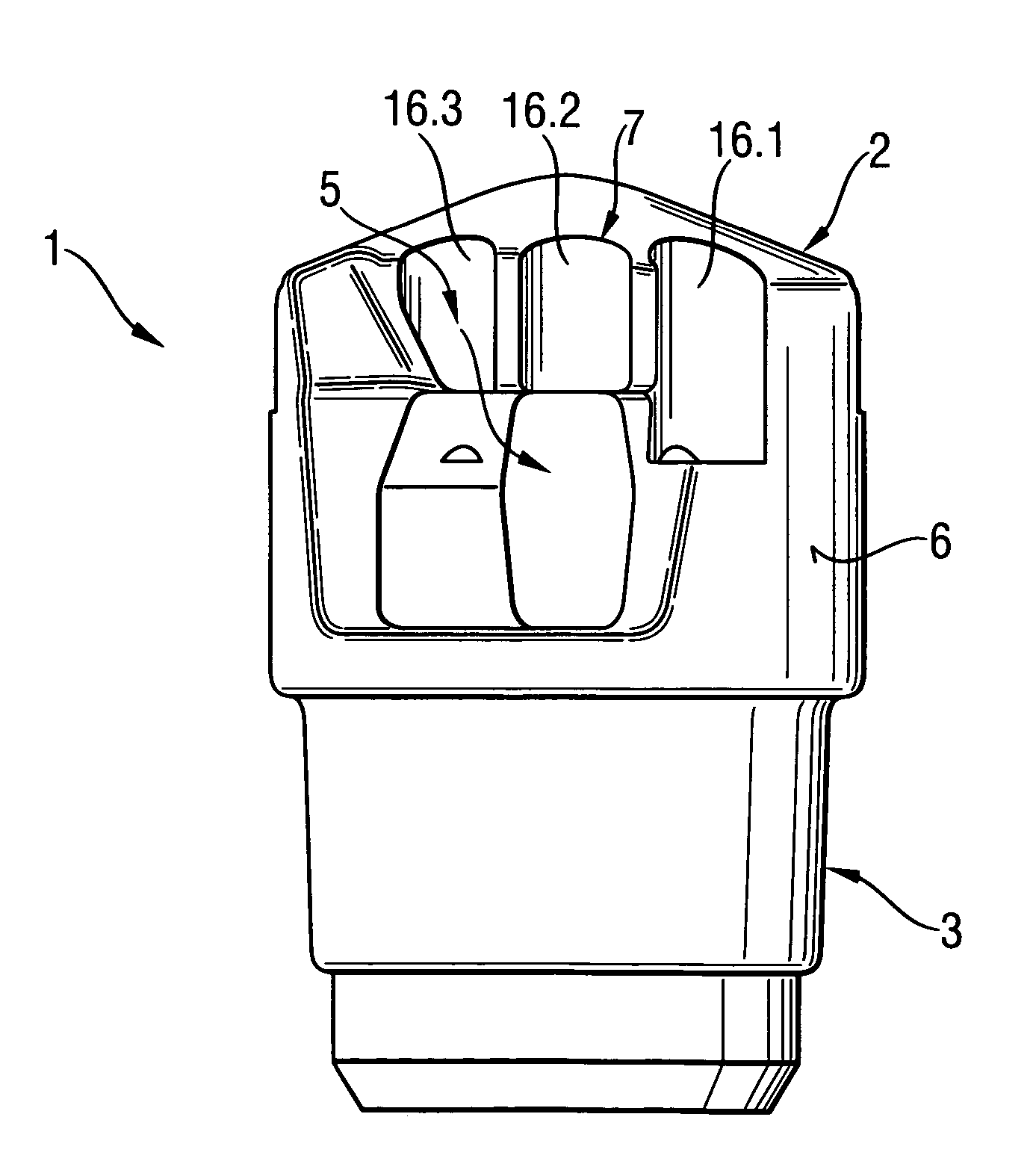

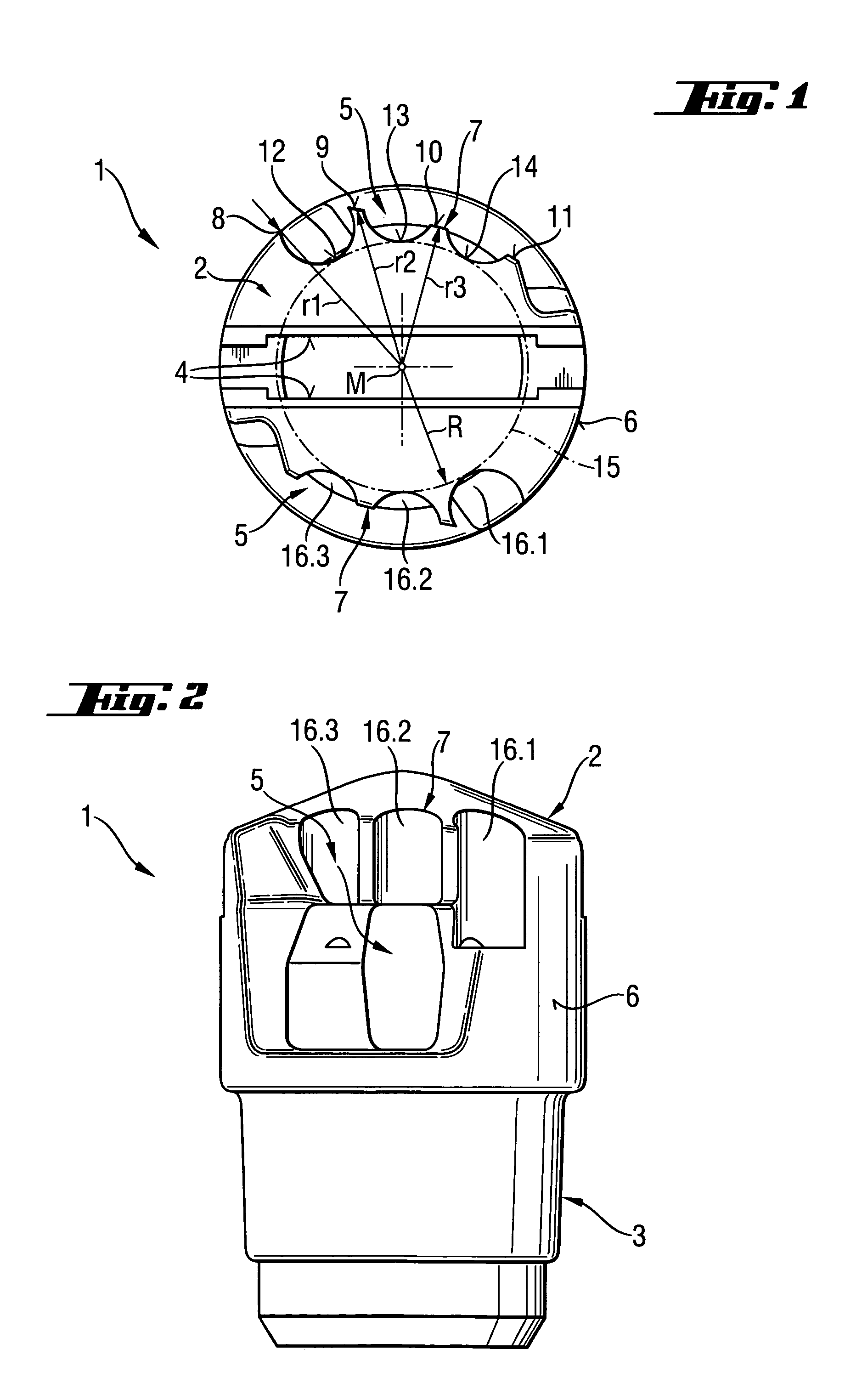

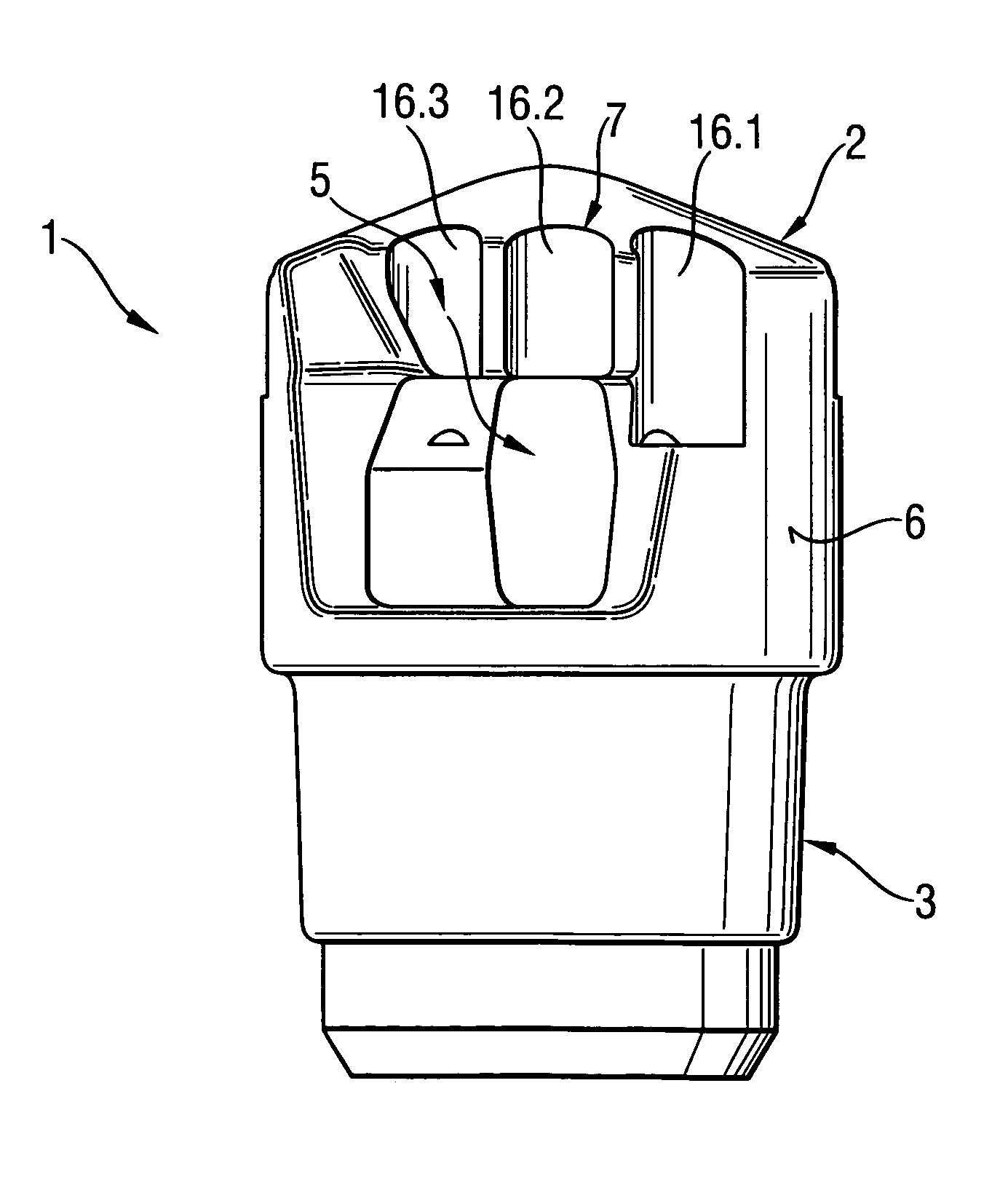

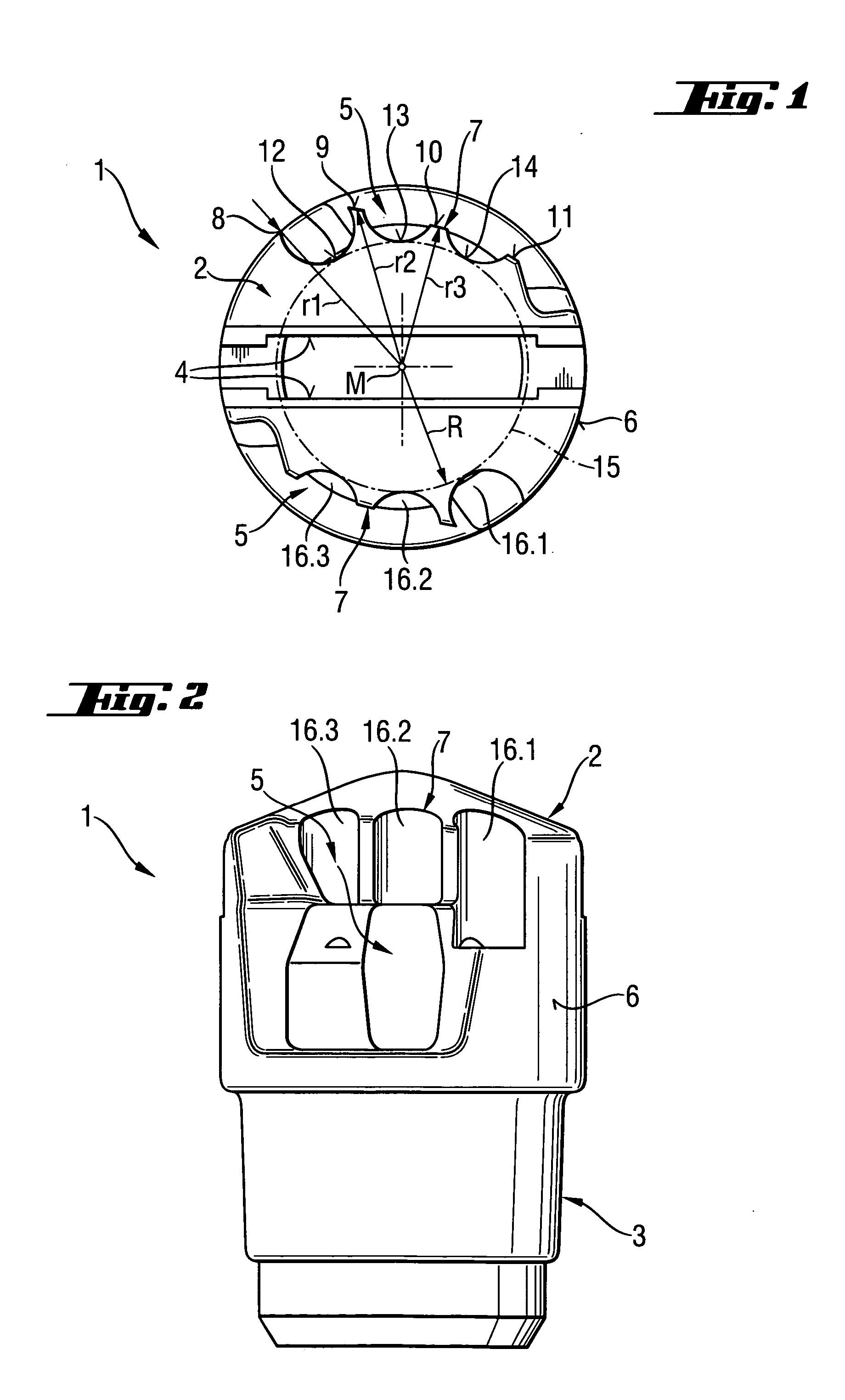

Drill head

A drill head for use in drilling bores in mines and tunnels has a bit and at least one suction opening (5) for removing drillings and having a crushing profile.

Owner:HILTI AG

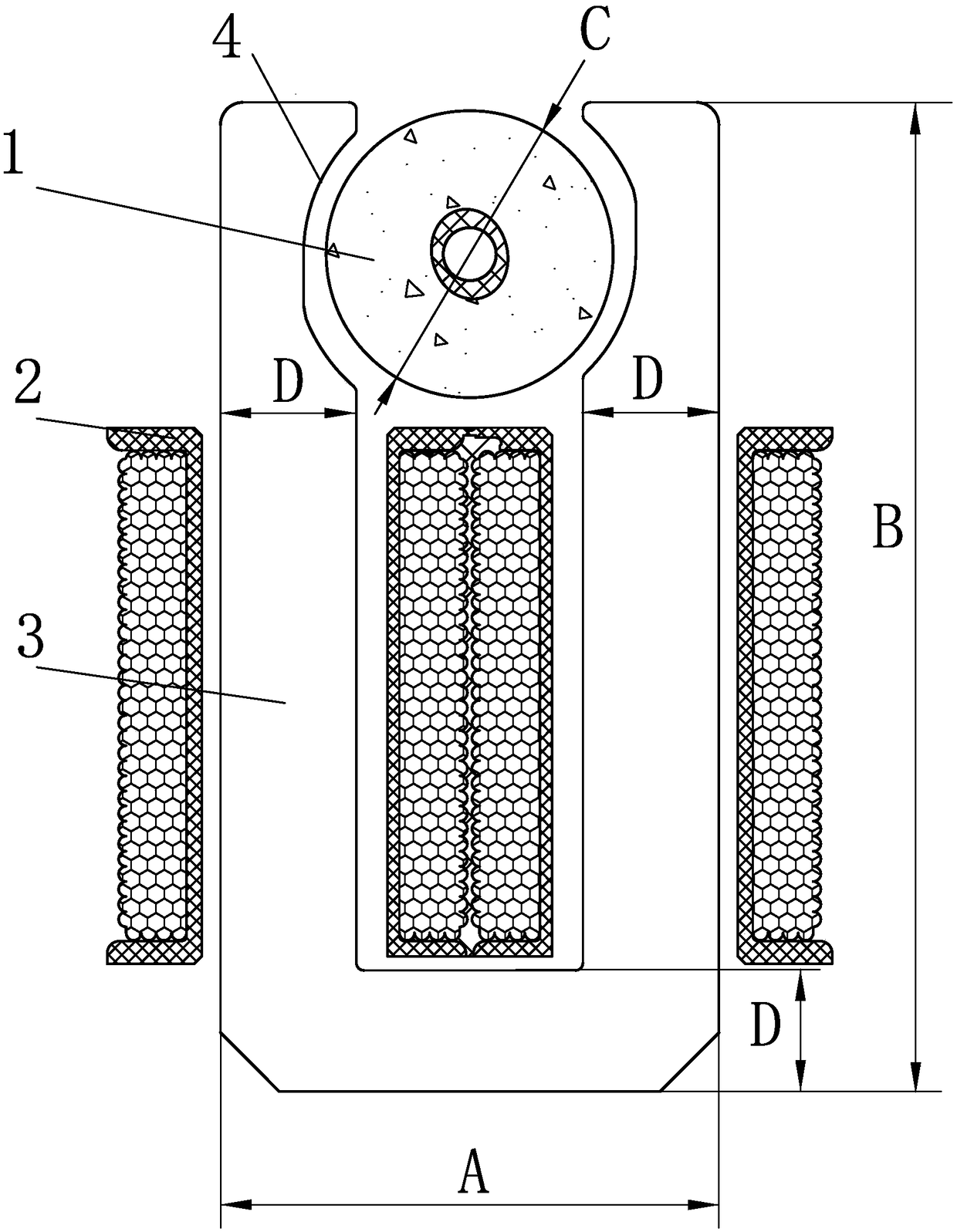

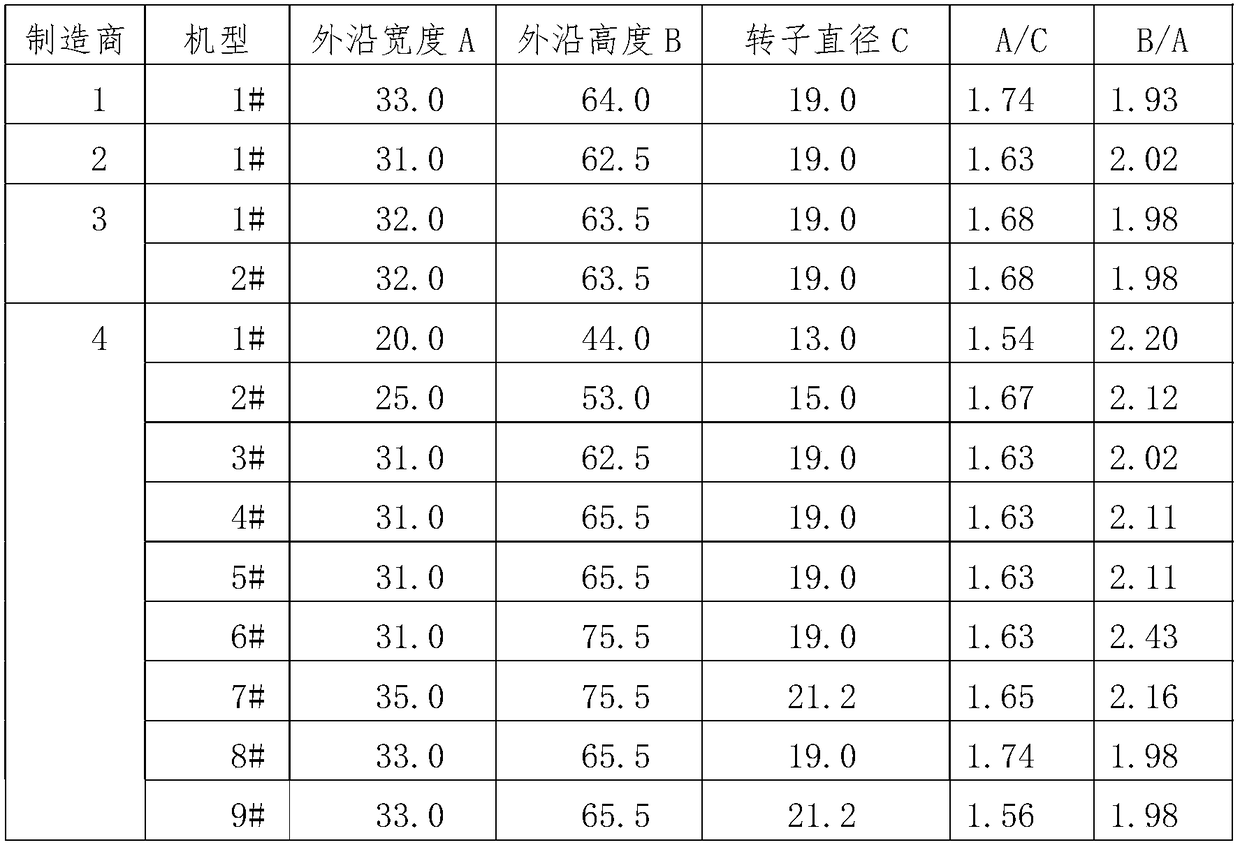

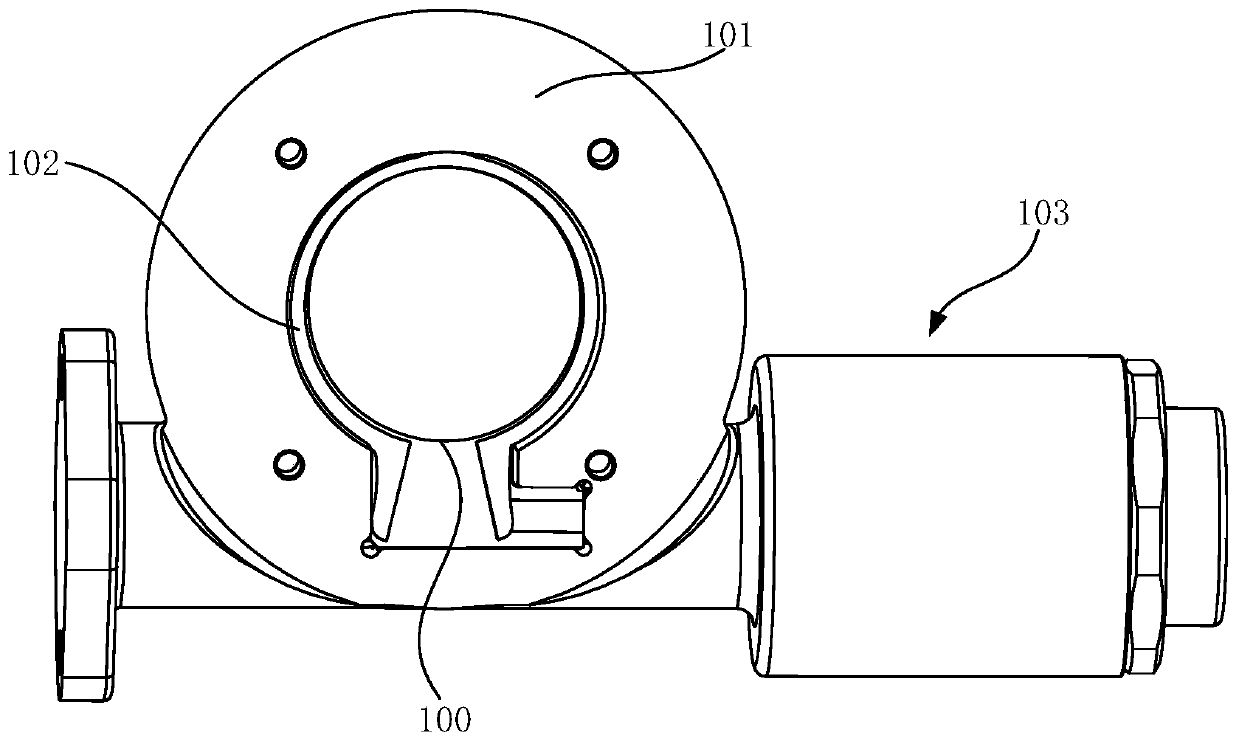

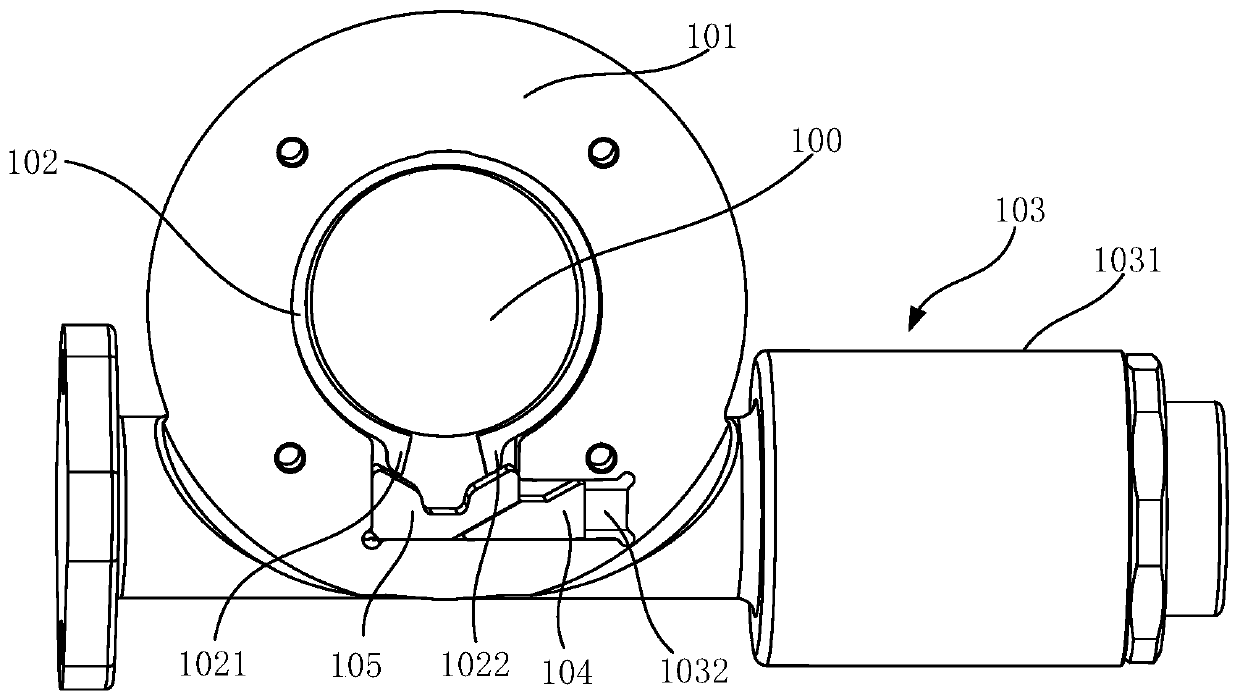

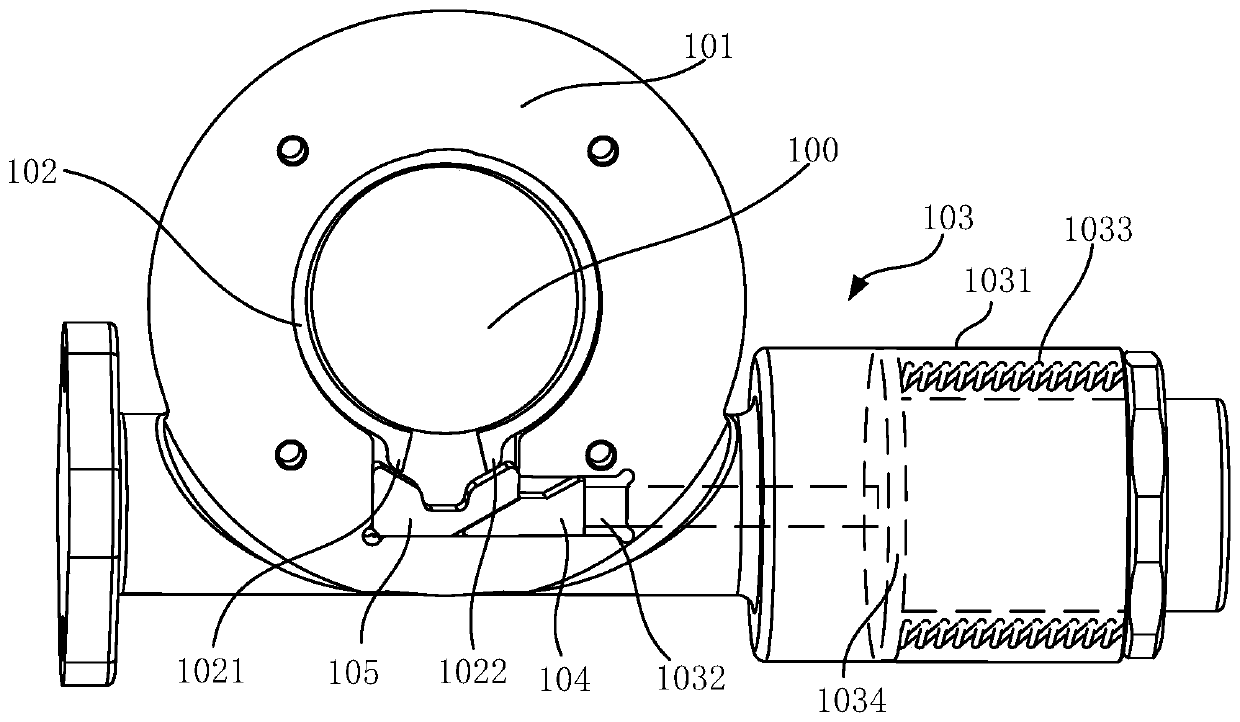

U-core single-phase permanent magnet synchronous motor driven miniature centrifugal pump

PendingCN109088528AReduce the radial distanceGood value for moneyMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorPermanent magnet synchronous motor

A micro centrifugal pump driven by a U-shaped iron core single-phase permanent magnet synchronous motor, comprises a pump cover having an axial inlet and a radial or tangential outlet, a centrifugal impeller and a U-shaped iron core single-phase permanent magnet synchronous motor coaxially driving the impeller; the impeller has a diameter of 20 to 70mm in ; The motor comprises a permanent magnet rotor which is a cylindrical shape magnetized by two radial poles and has a diameter of 10-40mm; a stator comprising a U-shaped laminated iron core and a stator winding through which the iron core passes; The upper part of the U-shaped two arms is formed to abut on the left and right pole boots of the cylindrical surface of the permanent magnet rotor; The ratio (A / C) of the width (A) of the U-shaped outer edge to the diameter (C) of the permanent magnet rotor is not less than 1.75. The design can shorten the radial dimension of the pump, which is advantageous to the installation and use of thepump, and the comprehensive cost of the electromagnetic material is reduced, so that the performance-price ratio is better.

Owner:JIANGMEN TIANDE ELECTRICAL APPLIANCE CO LTD

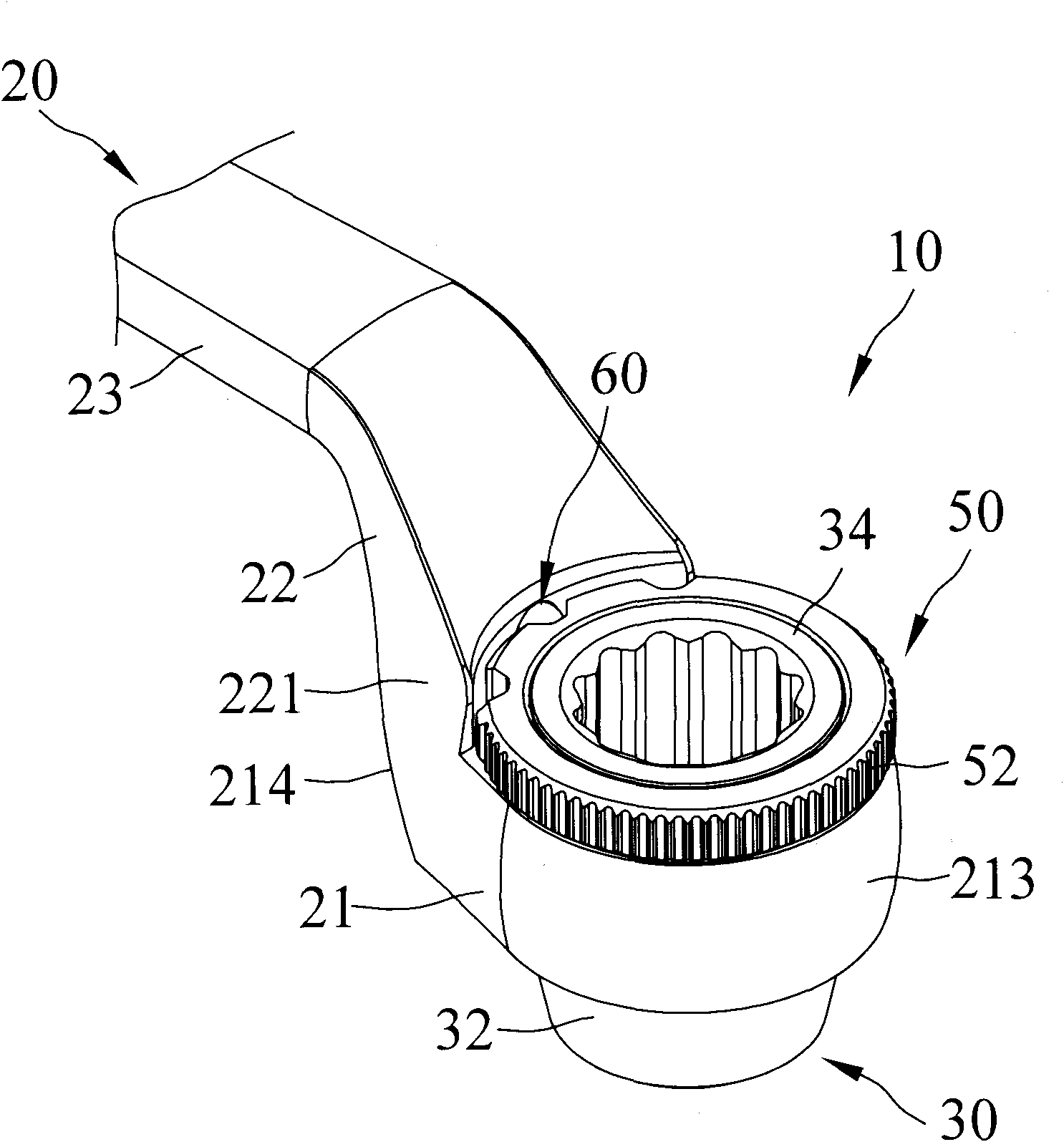

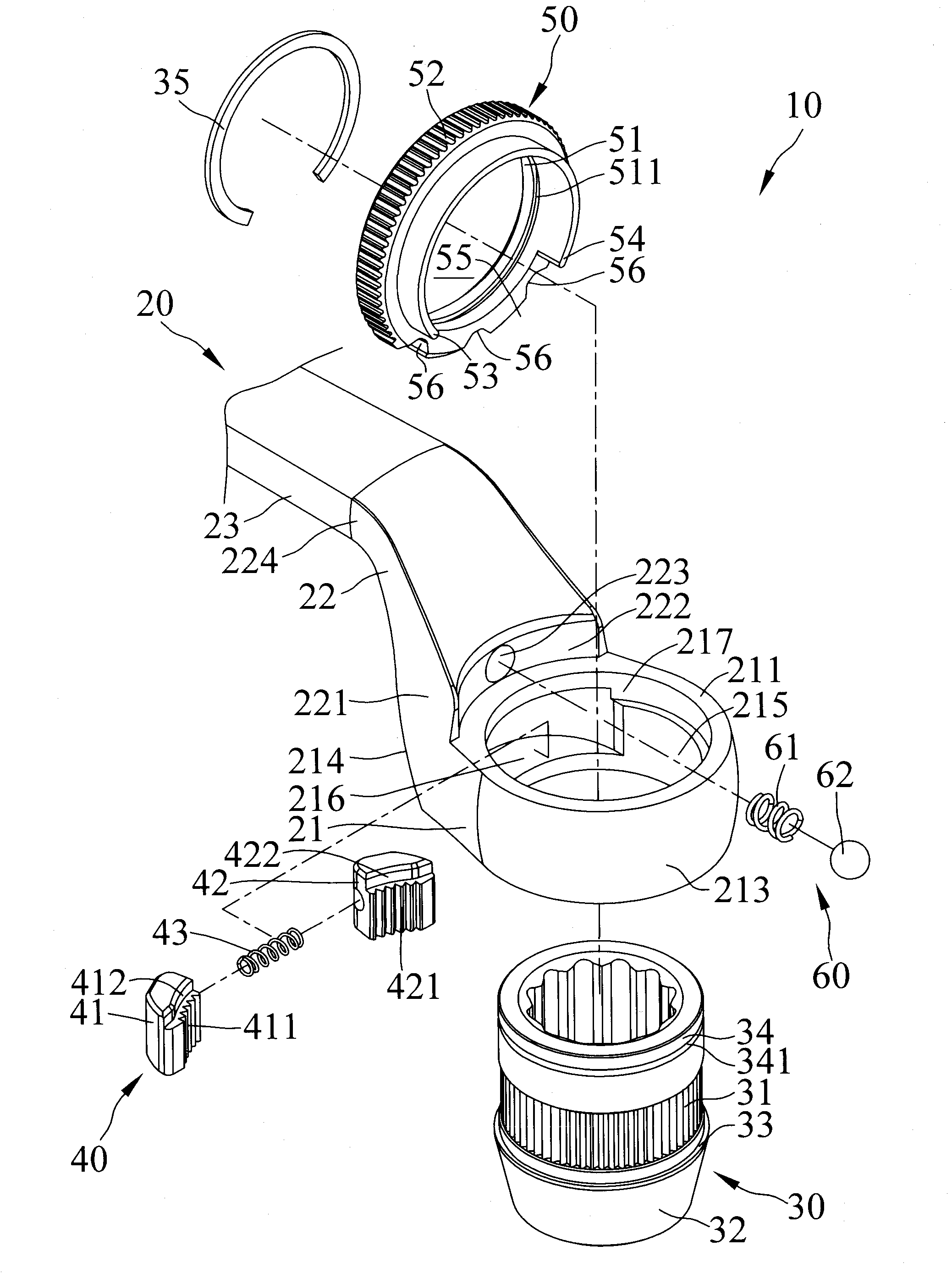

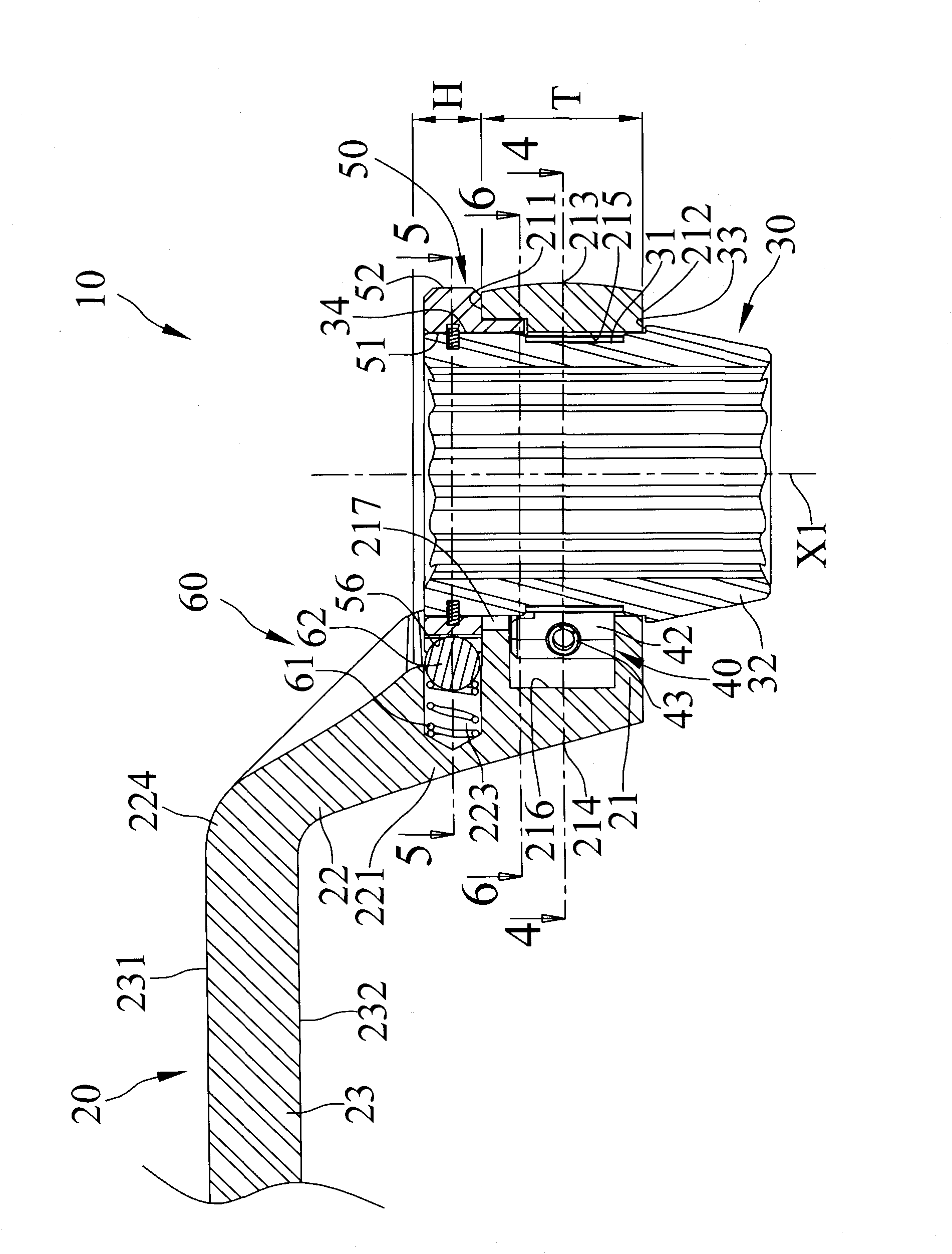

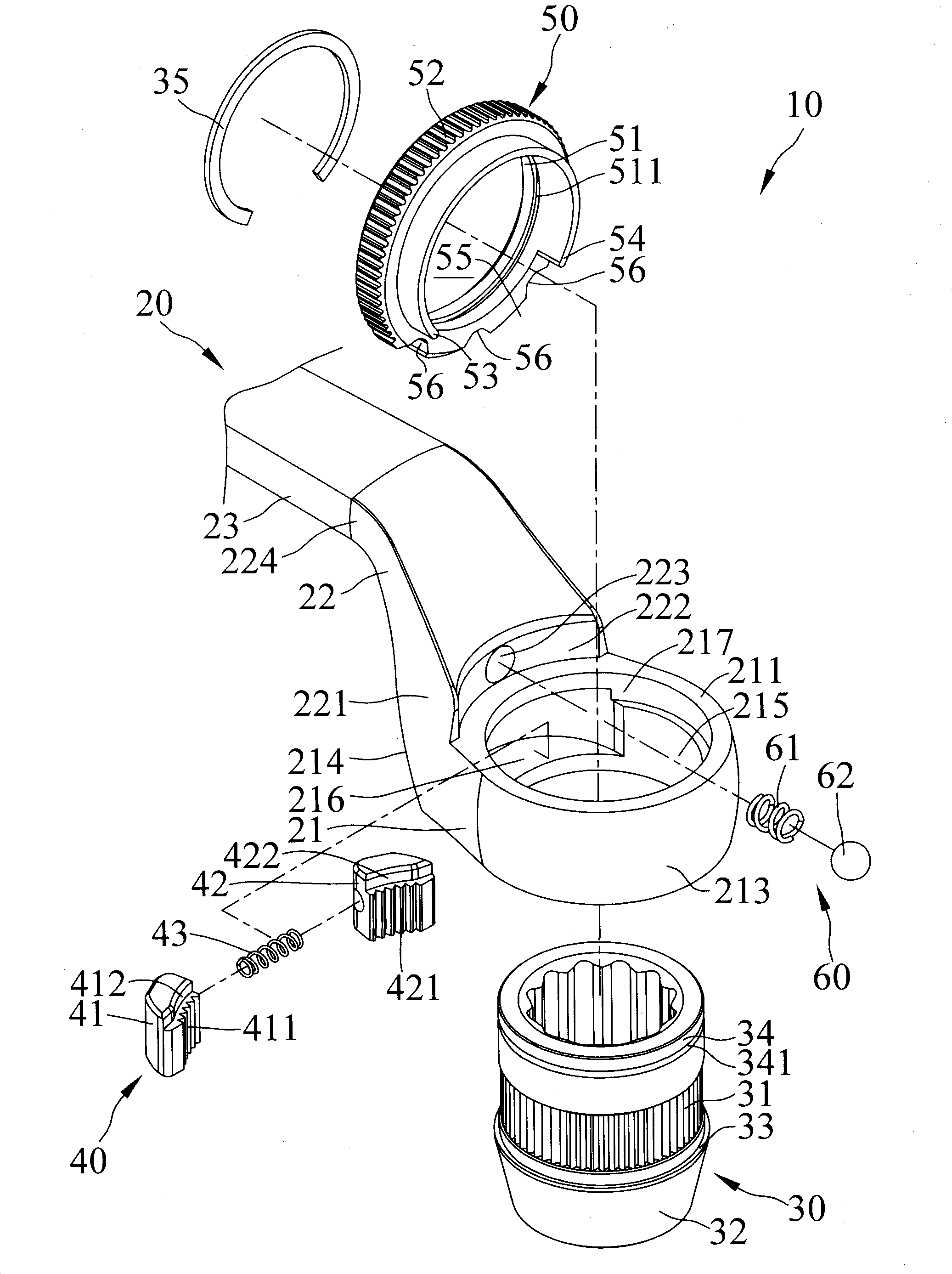

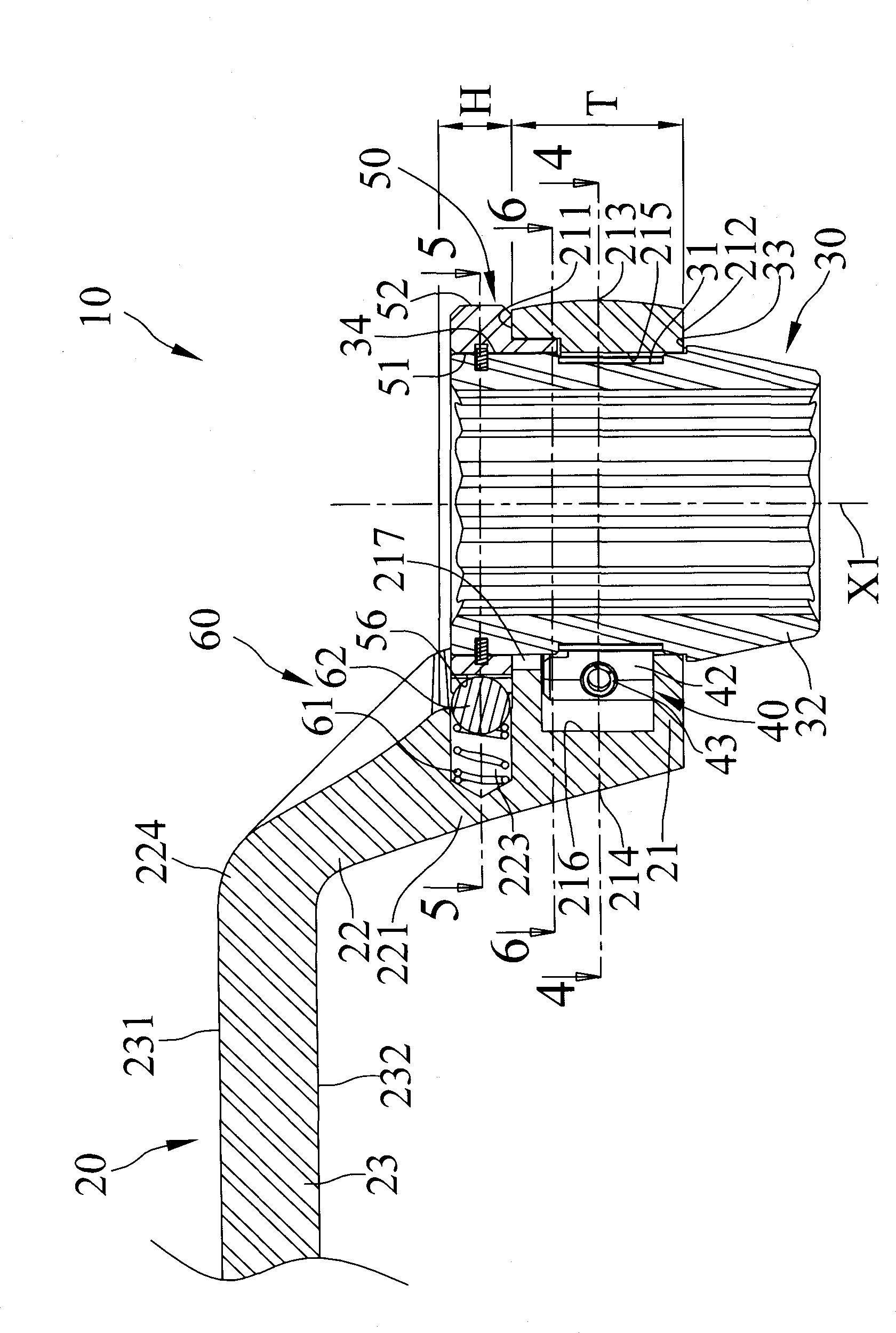

Ratchet wrench with head capable of being shrunk

The invention relates to a ratchet wrench with a head capable of being shrunk. The ratchet wrench comprises a body, a driving piece, a ratchet device and a reversing switch, wherein the body comprises the head, a connecting segment connected with one surface of the head, and a handle body arranged at the connecting segment oppositely to one end of the head, and a longitudinal connecting part connected with one surface of the head is formed at one end of the connecting segment; the driving piece is rotatably arranged at the head of the body; the ratchet device can be selectively meshed with the driving piece; and the reversing switch is pivoted with the driving piece and can control the ratchet device, a stirring ring of the reversing switch is tied and exposed outside the first surface of the head of the body and corresponds to the outer surface of the head of the body, and therefore, a user can stir the stirring ring of the reversing switch by the outer surface of the head of the body, thereby effectively reducing the radial distance of the head and achieving the effect of shrinking the head of the body.

Owner:胡厚飞

Braking device

ActiveCN110185722AReduce the radial distanceImprove automationFluid actuated drum brakesBrake actuating mechanismsLinear driveEngineering

The invention provides a braking device, and relates to the technical field of braking. The braking device comprises a base provided with a through hole, a lock ring arranged on the wall of the through hole, and a driving device. A to-be-braked part passes through the through hole, and the lock ring is used for sleeving the to-be-braked part. When the to-be-braked part needs to be braked, becausethe lock ring is provided with a notch, a linear driving device is controlled to push one end part, with the notch, of the lock ring to approach to the other end part, so that the inner diameter of the lock ring is reduced, and the lock ring is tightly attached to the to-be-braked part to limit the to-be-braked part to stop moving or limit the to-be-braked part to move. The braking device can stopand brake the to-be-braked part for a long time, the automation is improved by controlling the driving device, the low-efficiency operation that an operator needs to tighten a brake system one by oneis avoided, and the application range of the braking device is improved.

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

Converter collar bearing for a torque converter

InactiveUS20150055908A1Avoid rattling noiseReduce the radial distanceRoller bearingsShaftsImpellerEngineering

A bearing position for a torque converter, wherein a pump impeller is connected to a converter neck, and the pump impeller is rotatably mounted on the bearing position by at least one roller bearing in a housing, wherein the roller bearing comprises an outer rolling raceway, assigned to the converter neck and facing radially outwards, and an inner rolling raceway, assigned to the housing and facing radially inwards, and rollers disposed radially between the rolling raceways, wherein the bearing position comprises at least one radially elastically designed section of a sleeve of the roller bearing, where the sleeve is provided with the inner rolling raceway, wherein the section, enclosing an elastic convex raceway curvature, is resiliently prestressed in the radial direction against at least a first roller of the rollers, the first roller supported on the outer rolling raceway, and supported in the opposite radial direction on the housing.

Owner:SCHAEFFLER TECH AG & CO KG

Drill head

InactiveUS20050051365A1Speed up drillingIncrease pressureDrill bitsDrilling rodsEngineeringDrill bit

A drill head for use in drilling bores in mines and tunnels has a bit and at least one suction opening (5) for removing drillings and having a crushing profile.

Owner:HILTI AG

A CNC horizontal three-axis drilling, milling and tapping machine

InactiveCN104907829BImprove processing efficiencyReduce the radial distanceOther manufacturing equipments/toolsNumerical controlEngineering

A numerical control horizontal type three-axis drilling and milling tapping machine comprises a machine base, a workbench, a workpiece clamping device, a drilling, milling and tapping device and a control cabinet, wherein the workbench is fixed on a machine frame; the workpiece clamping device is arranged on the workbench in the mode of moving in the X-axis and Z-axis directions of the workbench; the drilling, milling and tapping device comprises a fixed base fixed to the workbench; the fixed base is provided with a milling mechanism, a tapping mechanism and a multi-axis drilling mechanism in sequence at intervals in the X-axis direction; the milling mechanism, the tapping mechanism and the multi-axis drilling mechanism can automatically carry out feeding and retracting along the Z axis of the workbench; the workpiece clamping mechanism, the milling mechanism, the tapping mechanism and the multi-axis drilling mechanism are connected with the control cabinet. So long as rotation of all the machining mechanisms is not affected, the radial direction between the machining mechanisms can be reduced to the minimum. Meanwhile, the workpiece clamping device moves only in the radial direction and the movement distance in the radial direction is greatly reduced, the machining time is saved, and the workpiece machining efficiency is improved.

Owner:福建泉州市汇群智能卫浴设备有限公司

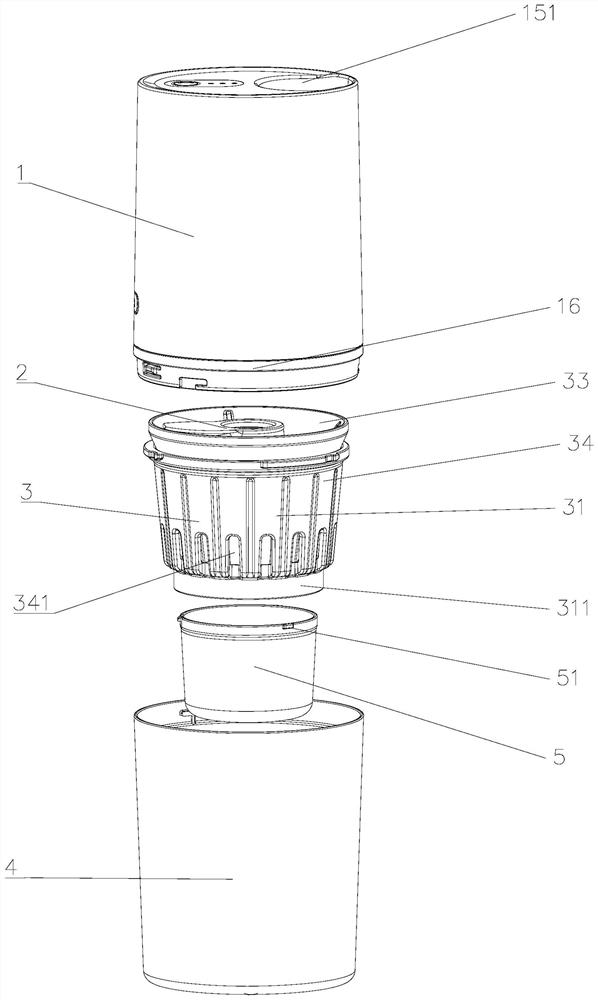

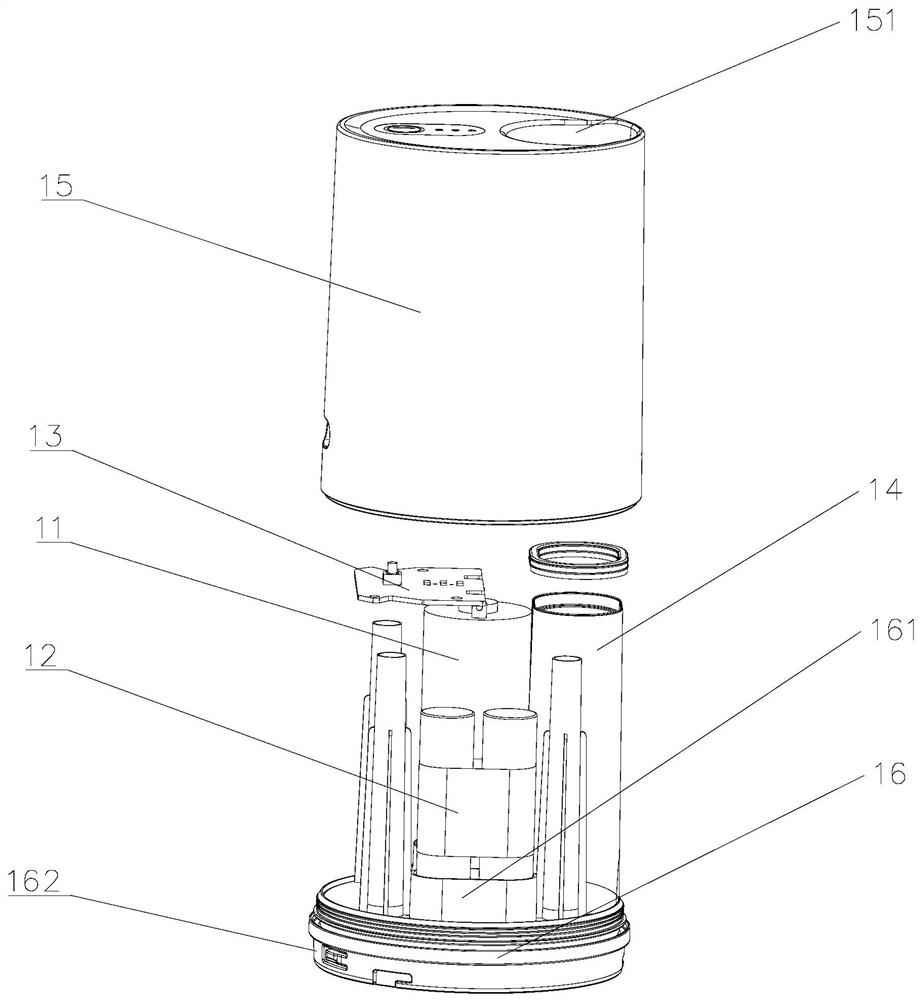

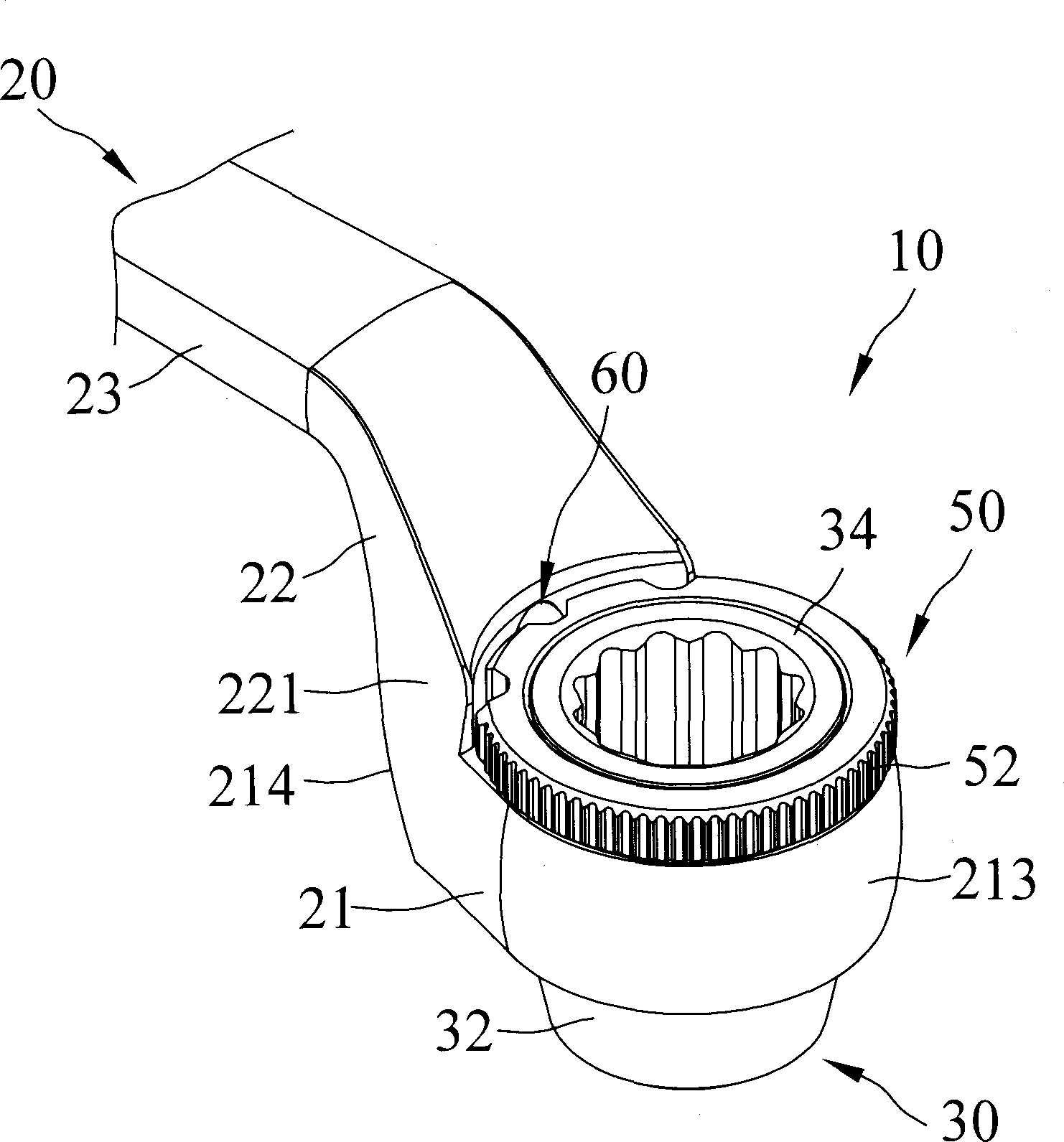

Portable screw extrusion juicer

The invention provides a portable screw extrusion juicer which comprises a main machine and an extrusion assembly arranged below a machine base. A motor and a circuit board are arranged in the main machine, the extrusion assembly comprises an extrusion cylinder and a screw, an output shaft of the motor is in transmission connection with the screw, the main machine is provided with a longitudinally-through feeding channel, the main machine comprises a shell and a base, a sealing cavity is defined by the shell, the base and the side wall of the feeding channel, the gravity center of the juicer is arranged on the central axis of the output shaft of the motor in an offset mode and located in the area outside the feeding channel, and therefore the portable juicer with the upper-arranged main machine is more stable in the running process and not prone to shaking or toppling over.

Owner:JOYOUNG CO LTD

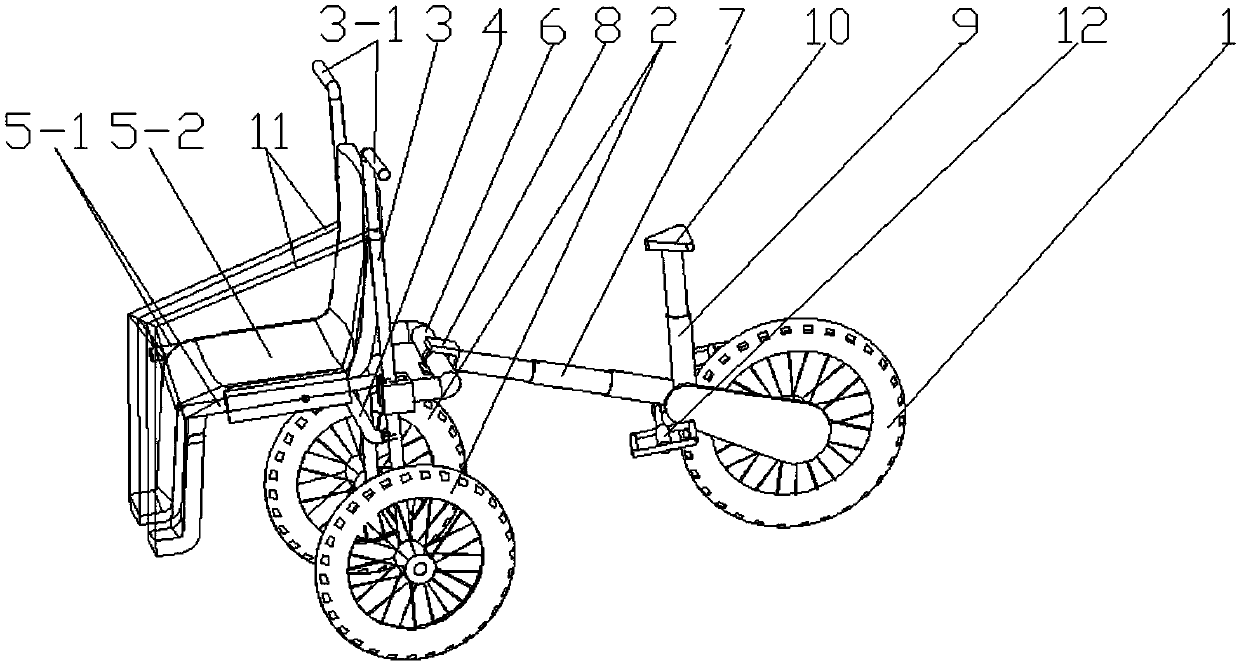

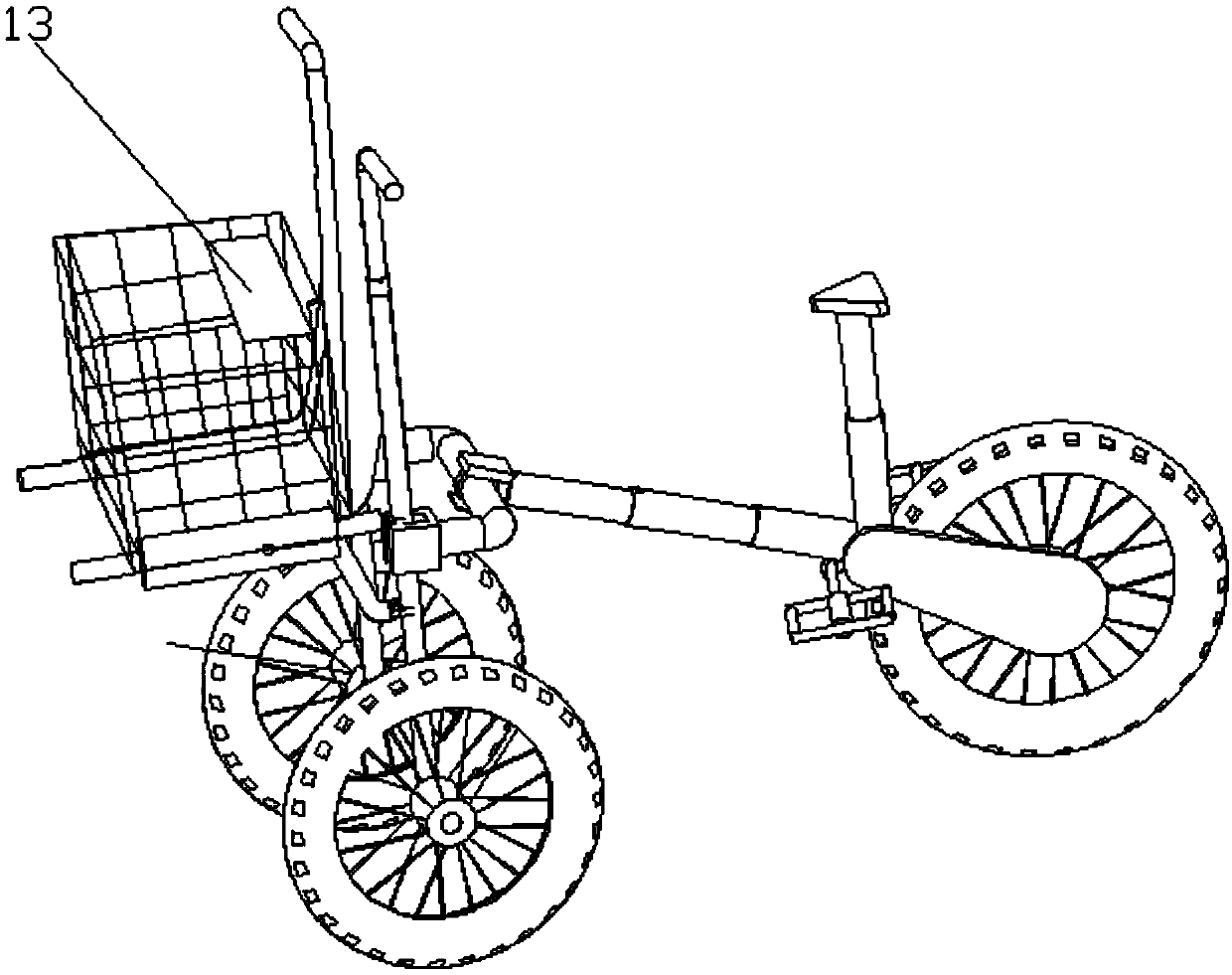

Pushing and riding an integrated children cart and method of using the same

InactiveCN109080749AModerate heightReduce harmChildren cyclesCycle saddlesVehicle frameSteering wheel

The utility model relates to a pushing and riding integrated child cart and a method for using the pushing and riding integrated child cart, which relates to the technical field of the child cart, inparticular to a pushing and riding integrated child cart and a method for using the pushing and riding integrated child car. Including frame, At that rear end of the frame is installed a rear vehicledrive wheel, The front end of the vehicle frame is provided with two front vehicle steering wheels arranged in parallel, the wheel frame bodies of the two front vehicle steering wheels extend upward to form two handle frames, and two handles are formed on the top end of the handle frame, and a seat is arranged on the front side of the handle frame, the seat comprises a support bar and a seat bodymounted on the support bar, and the support bar is connected and fixed with the handle frame through cylindrical roller bearings; At that other side of the handle and the horizontal direction of the seat body, a connecting rod is arrange, the connecting rod is connected with the rear end of the vehicle frame through an expansion rod, and the connecting rod and the expansion rod are connected through a universal joint, wherein, the rear end of the vehicle frame extend upward out of the vehicle seat fixing rod, and the upper end of the vehicle seat fixing rod is fixed with a vehicle seat. The pushing and riding integrated child cart has the positive effect of multi-purpose and diversified functions of one vehicle.

Owner:LIAOCHENG UNIV

Dual-shaft dual-mode continuously variable transmission

InactiveCN106704539BReduce the radial distanceToothed gearingsTransmission elementsGear wheelDual mode

A continuously variable transmission (CVT) for a motor vehicle includes a transmission input shaft rotatably connected to an engine through a torque converter, the transmission input shaft defining a first CVT axis. A continuously variable transmission unit connected for rotation through a transmission input shaft includes a first pulley assembly, a second pulley assembly, and a flexible member wound around the first pulley assembly and the second pulley assembly. The dual mode transfer gear assembly is connected to the second pulley assembly and is coaxially aligned for rotation on the second CVT axis. A clutch assembly having at least one clutch is connected to the transfer gear assembly. A final drive unit connected to the transfer gear assembly is coaxially aligned with respect to the second CVT axis.

Owner:GM GLOBAL TECH OPERATIONS LLC

Ratchet wrench with head capable of being shrunk

The invention relates to a ratchet wrench with a head capable of being shrunk. The ratchet wrench comprises a body, a driving piece, a ratchet device and a reversing switch, wherein the body comprises the head, a connecting segment connected with one surface of the head, and a handle body arranged at the connecting segment oppositely to one end of the head, and a longitudinal connecting part connected with one surface of the head is formed at one end of the connecting segment; the driving piece is rotatably arranged at the head of the body; the ratchet device can be selectively meshed with the driving piece; and the reversing switch is pivoted with the driving piece and can control the ratchet device, a stirring ring of the reversing switch is tied and exposed outside the first surface of the head of the body and corresponds to the outer surface of the head of the body, and therefore, a user can stir the stirring ring of the reversing switch by the outer surface of the head of the body, thereby effectively reducing the radial distance of the head and achieving the effect of shrinking the head of the body.

Owner:胡厚飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com