Radial clearance adjusting structure of worm gear and worm

A radial clearance and structure adjustment technology, which is applied to gear transmissions, belts/chains/gears, transmission parts, etc., can solve problems such as uneven transmission of worm gears, failure of worm gears, and transmission noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the technical solution of the present invention will be described in detail through specific examples.

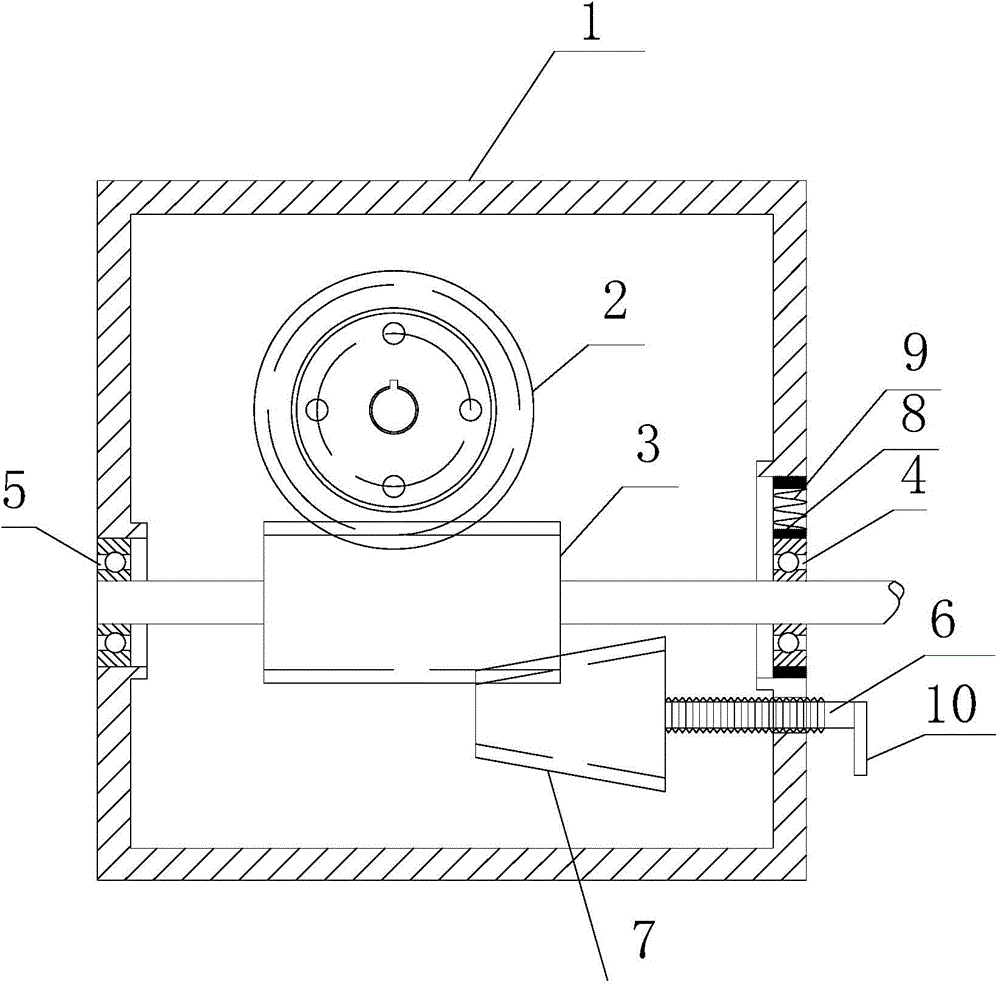

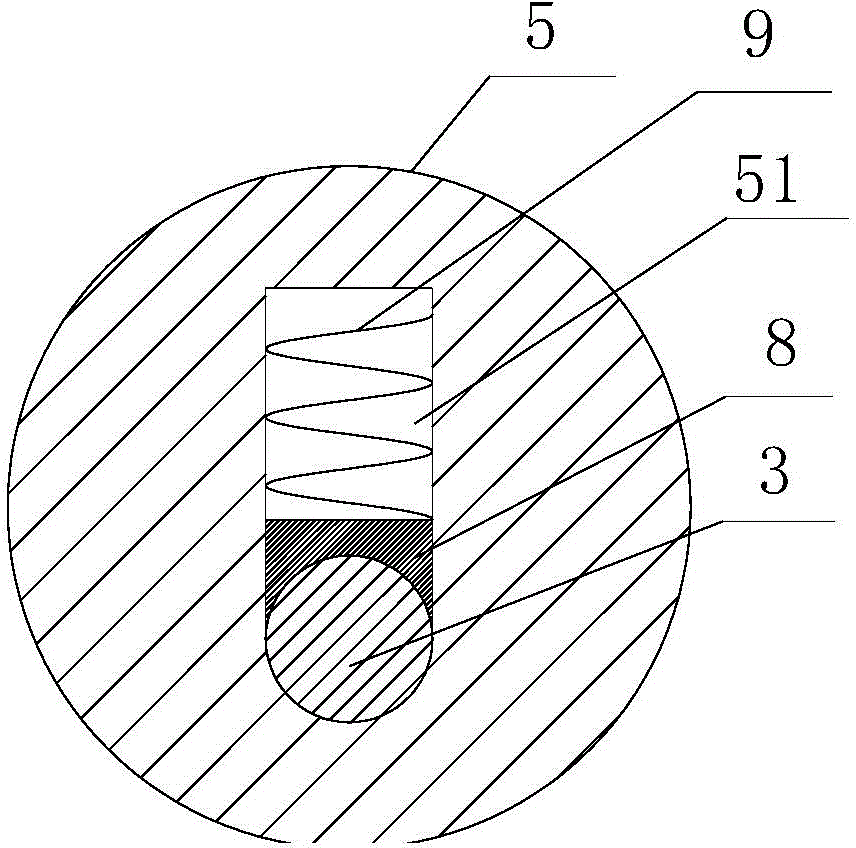

[0018] like Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a worm gear radial clearance adjustment structure proposed by the present invention; figure 2 It is a structural schematic diagram of an adjusting sleeve in a worm wheel radial clearance adjusting structure proposed by the present invention.

[0019] refer to Figure 1-2 , a worm gear radial clearance adjustment structure proposed by the embodiment of the present invention includes: a housing 1 and a worm wheel 2 and a worm 3 arranged in the housing 1 and intermeshing with each other, wherein:

[0020] The two ends of the worm 3 are supported on the casing 1 through the first bearing 4 and the second bearing 5, wherein the second bearing 5 is a self-aligning bearing, the first bearing 4 is covered with an adjustment sleeve 5, and the adjustment sleeve 5 is provided with Gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com