Grinding and positioning mechanism for indexing fluted disc

A technology of positioning mechanism and indexing teeth, which is applied in the field of machinery, can solve the problems of low clamping and positioning efficiency of indexing tooth discs, and achieve the effects of high positioning accuracy, simple operation, and guaranteed radial accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

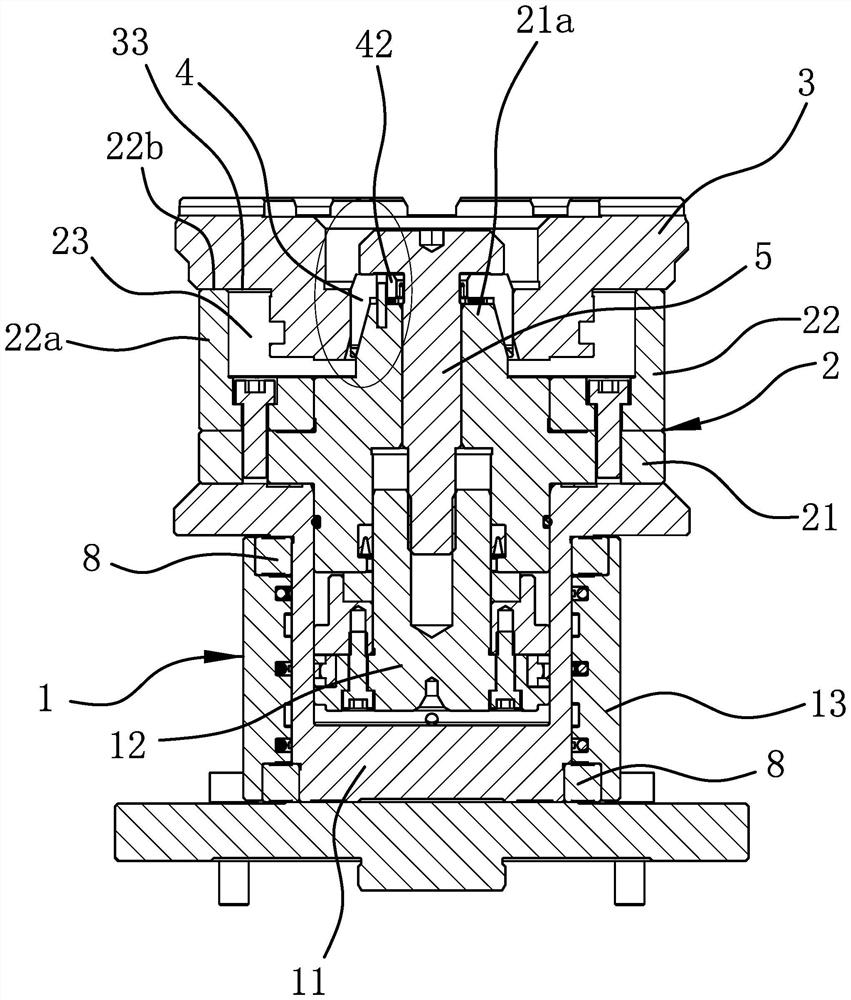

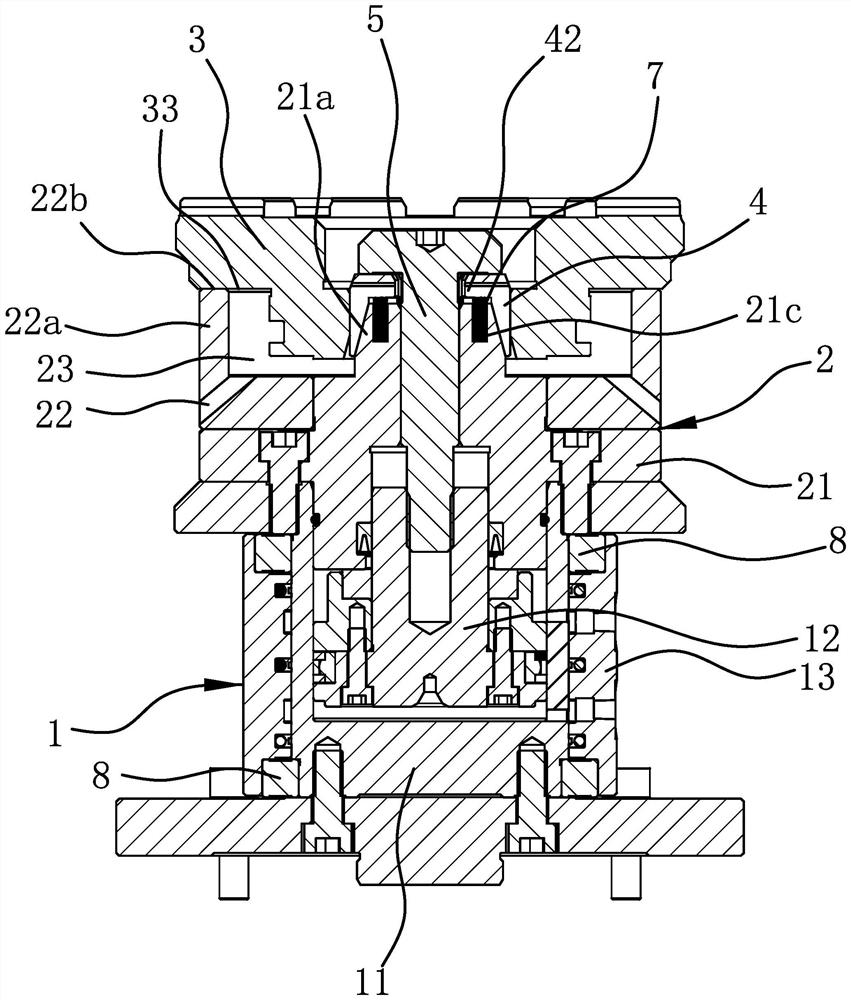

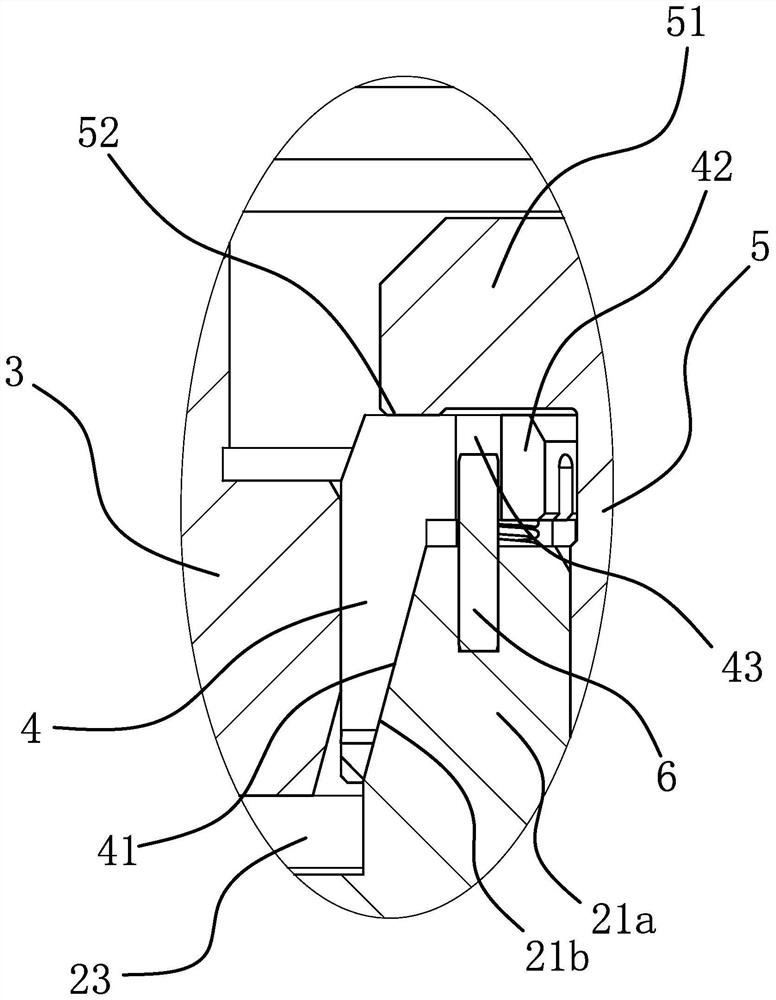

[0027] Such as figure 1 , figure 2 and image 3 As shown, the index tooth disc grinding positioning mechanism includes a driving member 1 and an annular clamp body 2 . Wherein, the driving member 1 includes a cylinder body 11, a piston rod 12 disposed in the cylinder body 11, and a cylindrical rotating housing 13 sleeved outside the cylinder body 11, the clamp body 2 is fixedly connected with the cylinder body 11, and rotates A bearing 8 is provided between the housing 13 and the cylinder 11 , and the rotating housing 13 can rotate circumferentially relative to the cylinder 11 . In this embodiment, multiple sealing structures are provided between the inner side of the rotating housing 13 and the outer side of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com