Patents

Literature

80results about How to "Save radial space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

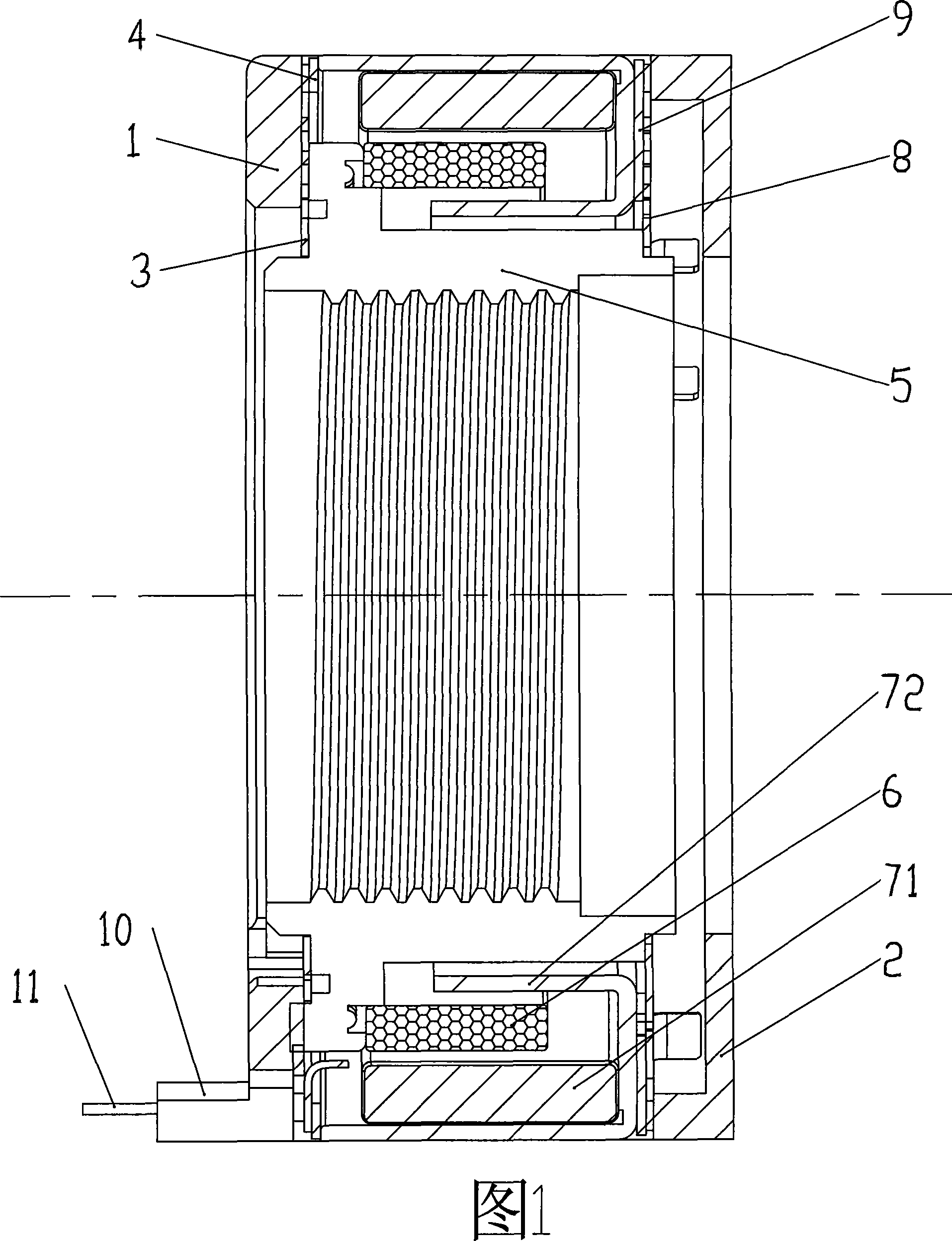

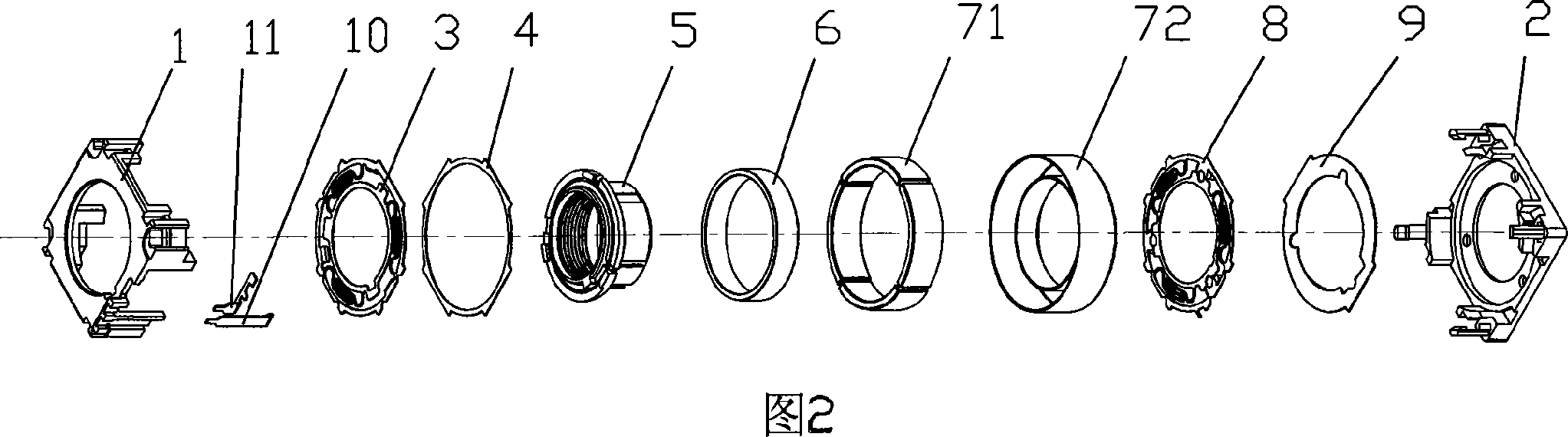

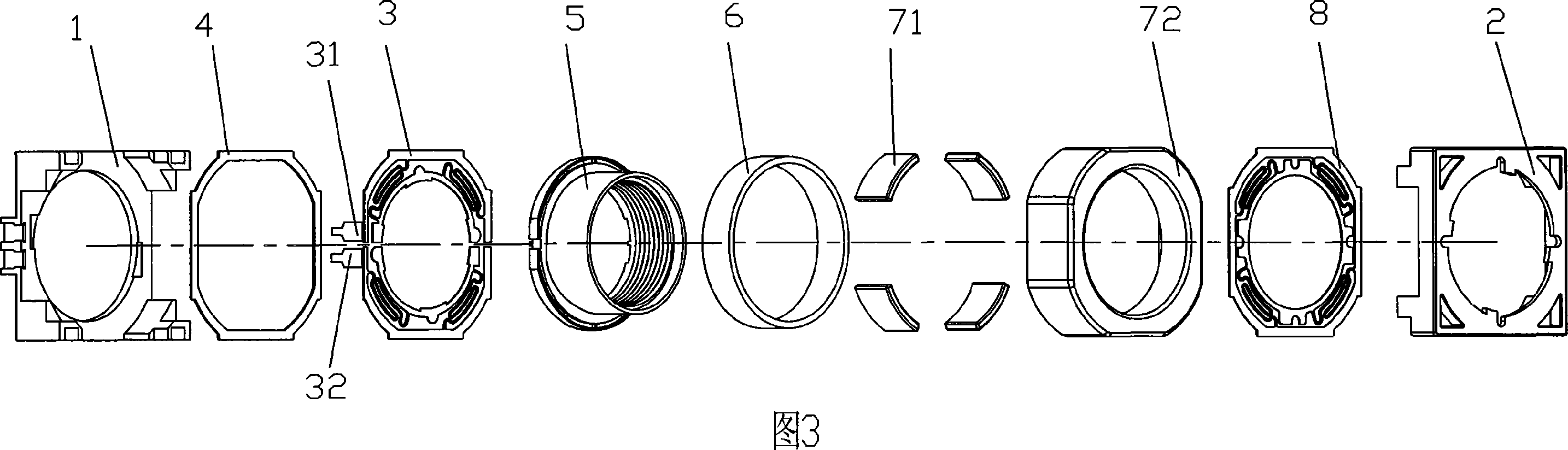

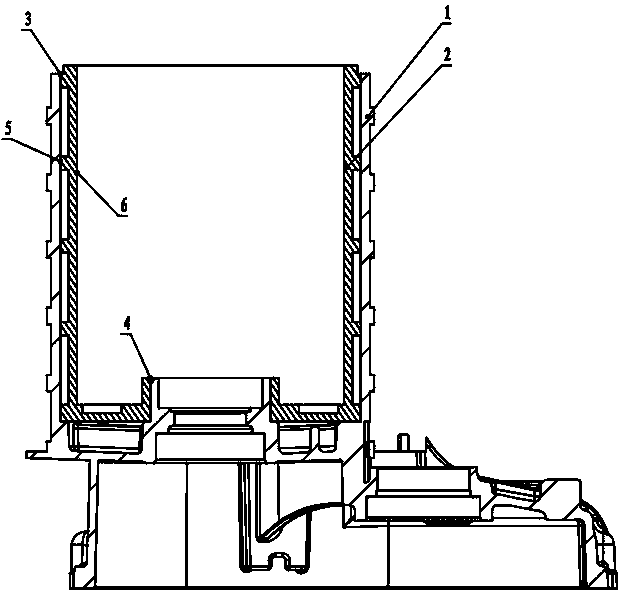

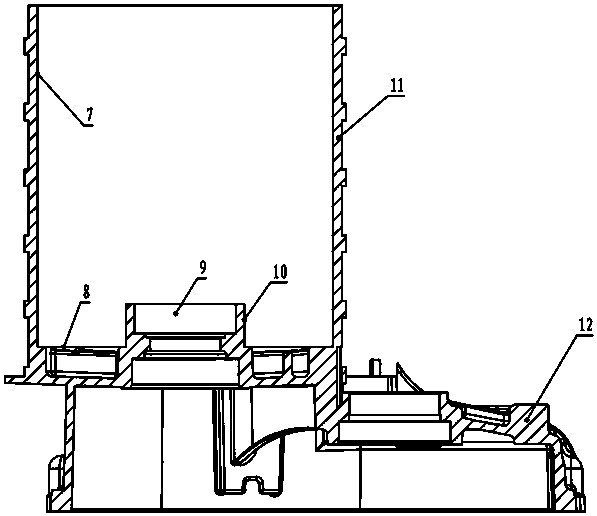

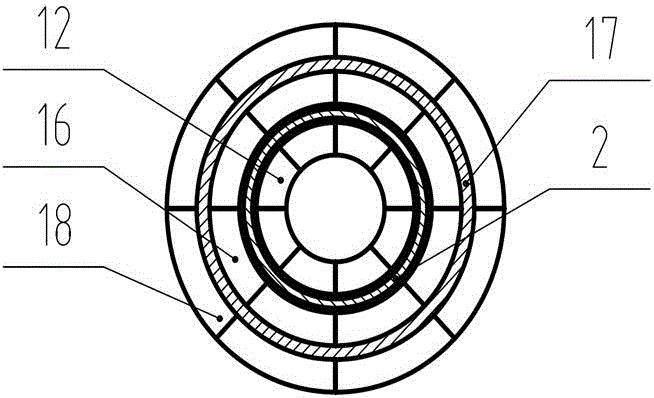

Ultrasmall type voice coil motor

A voice coil motor of miniaturized type is featured as applying simple design on radial size of motion-carry base and new material for front and rear spring plates, using separation design on left and right branch plates of said rear spring plate and optimum design on shape as well as distribution of permanent magnetic unit, applying convex-concave fastening design on front-back cover of shell and between front covers for realizing miniatured- size of voice coil motor.

Owner:YIXING GUIXIN MAGNETOELECTRIC HI TECH

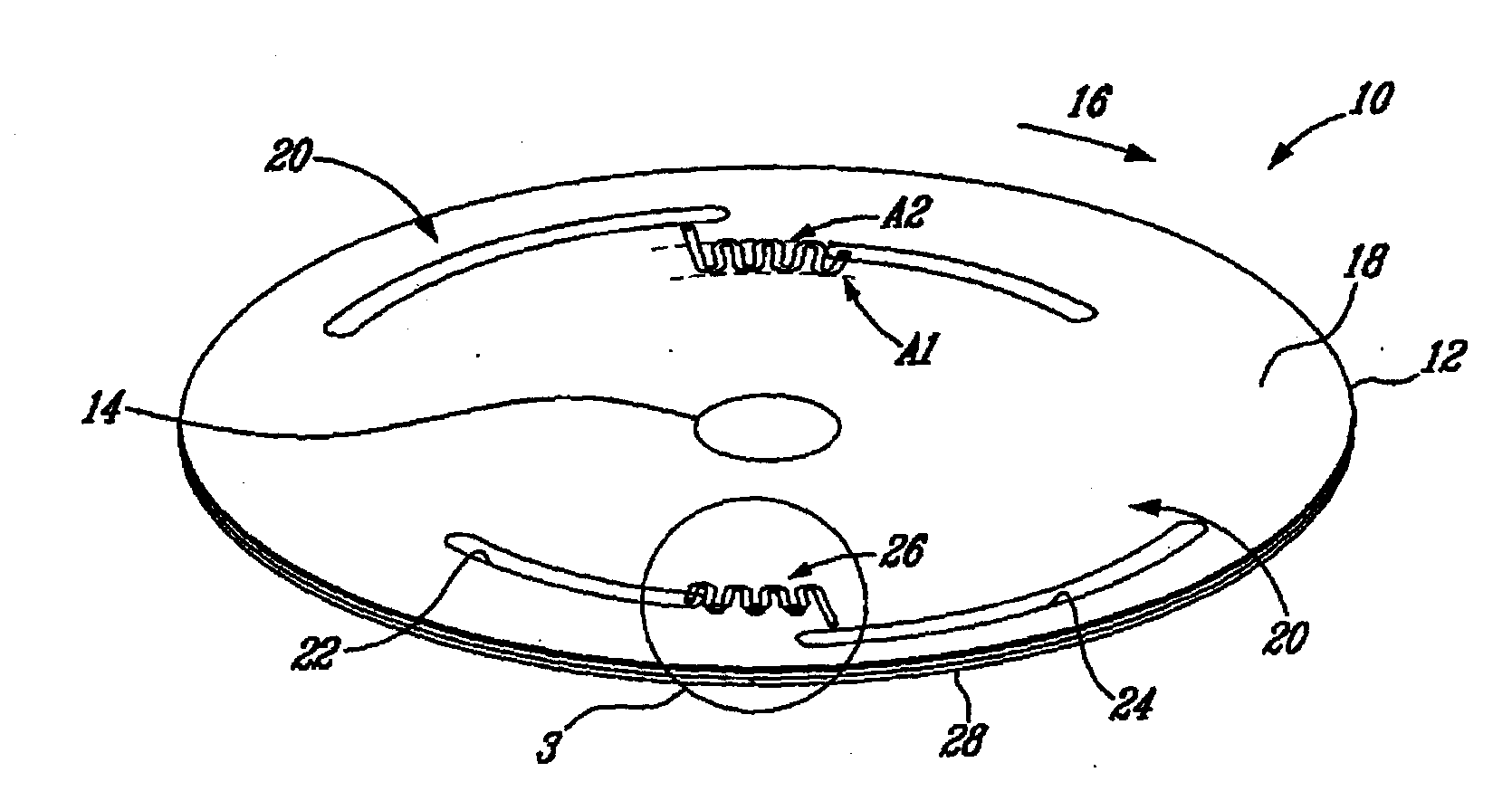

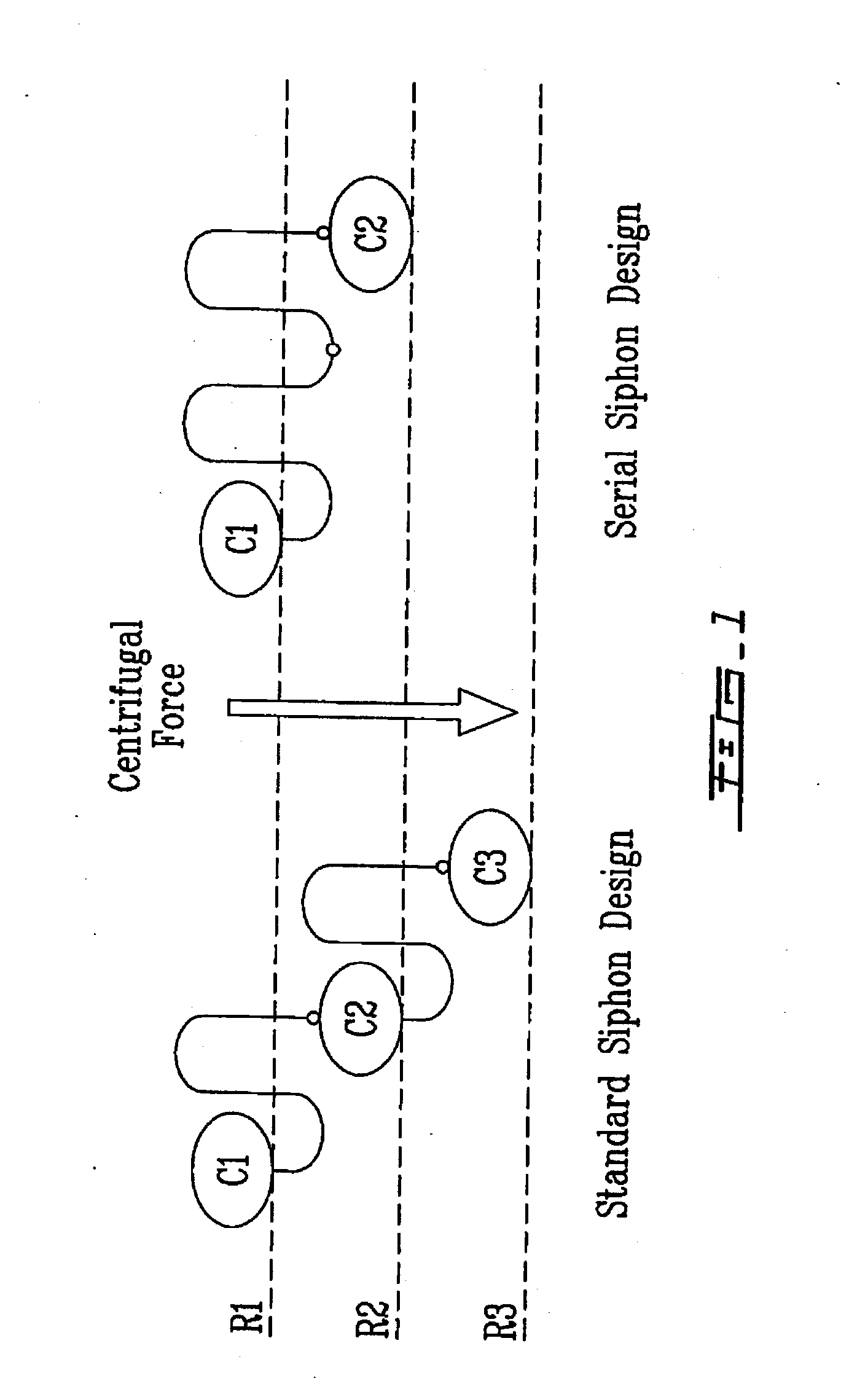

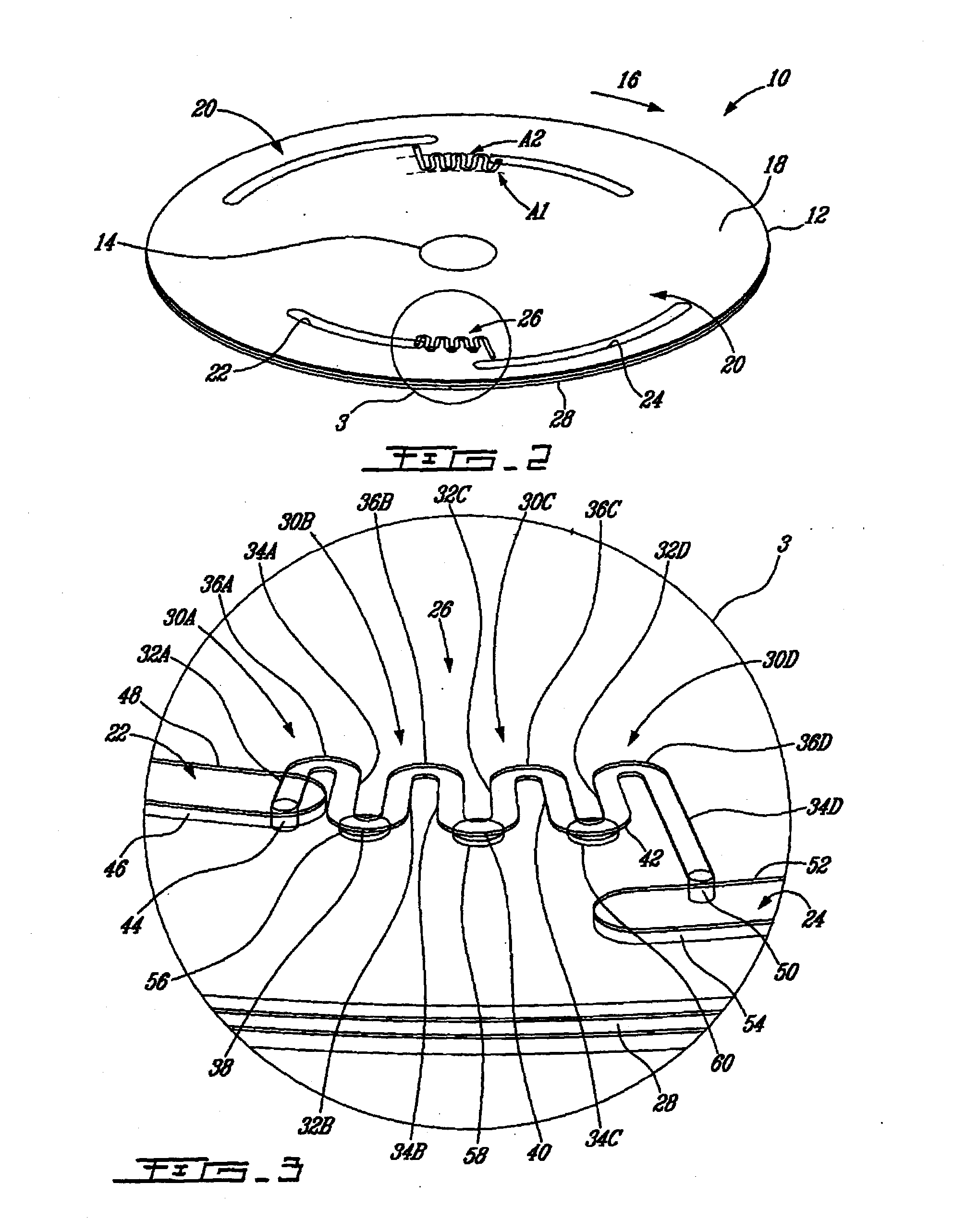

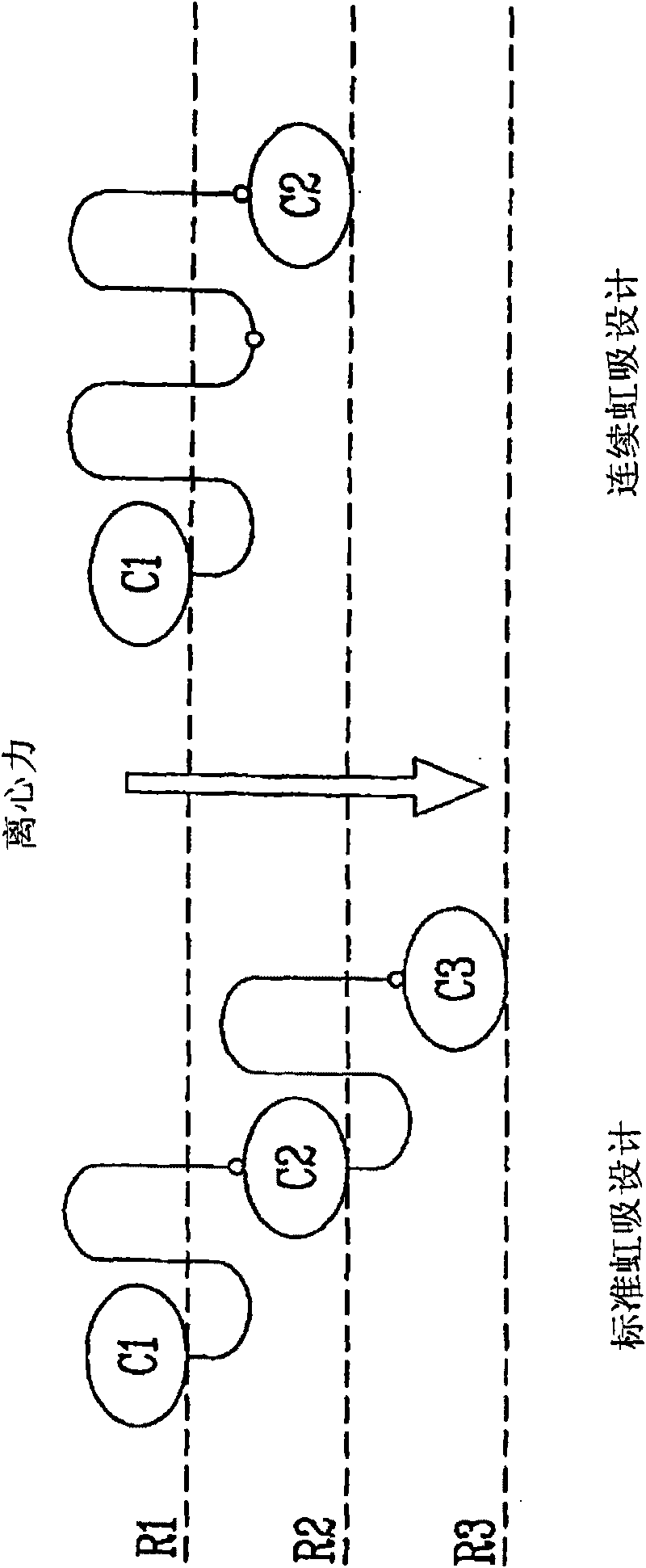

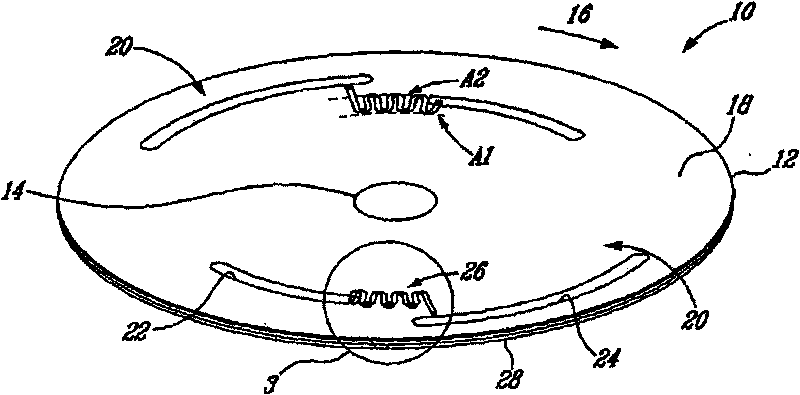

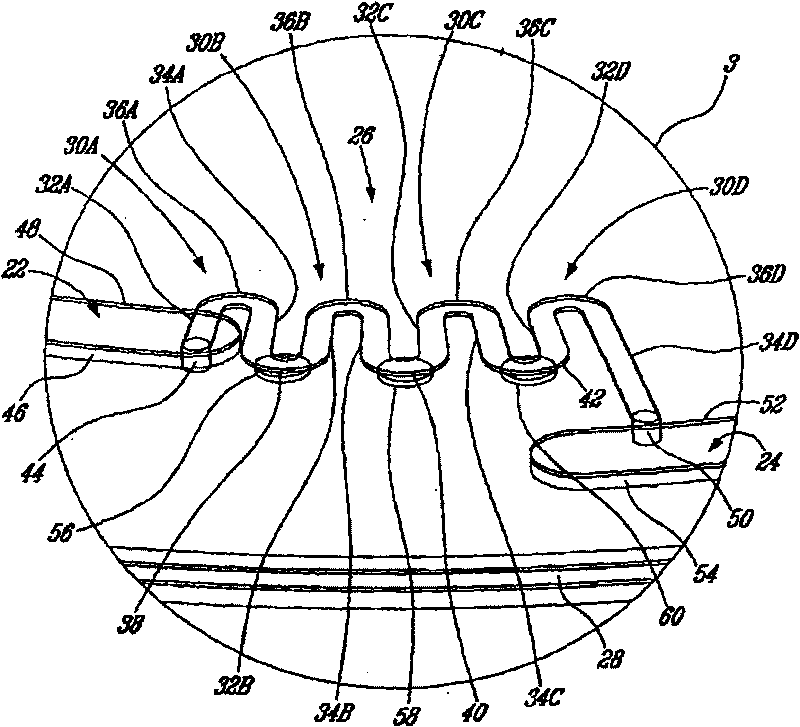

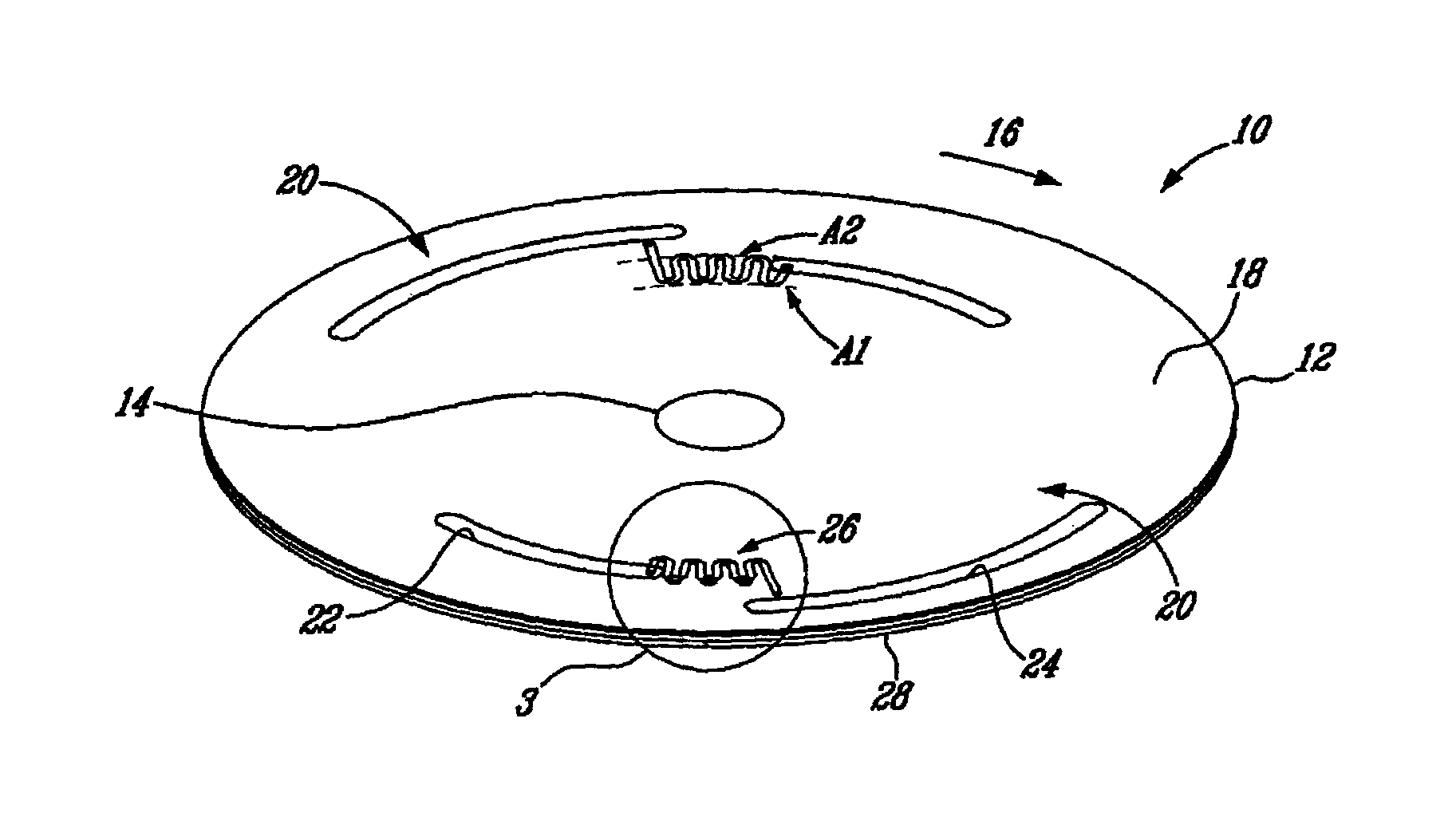

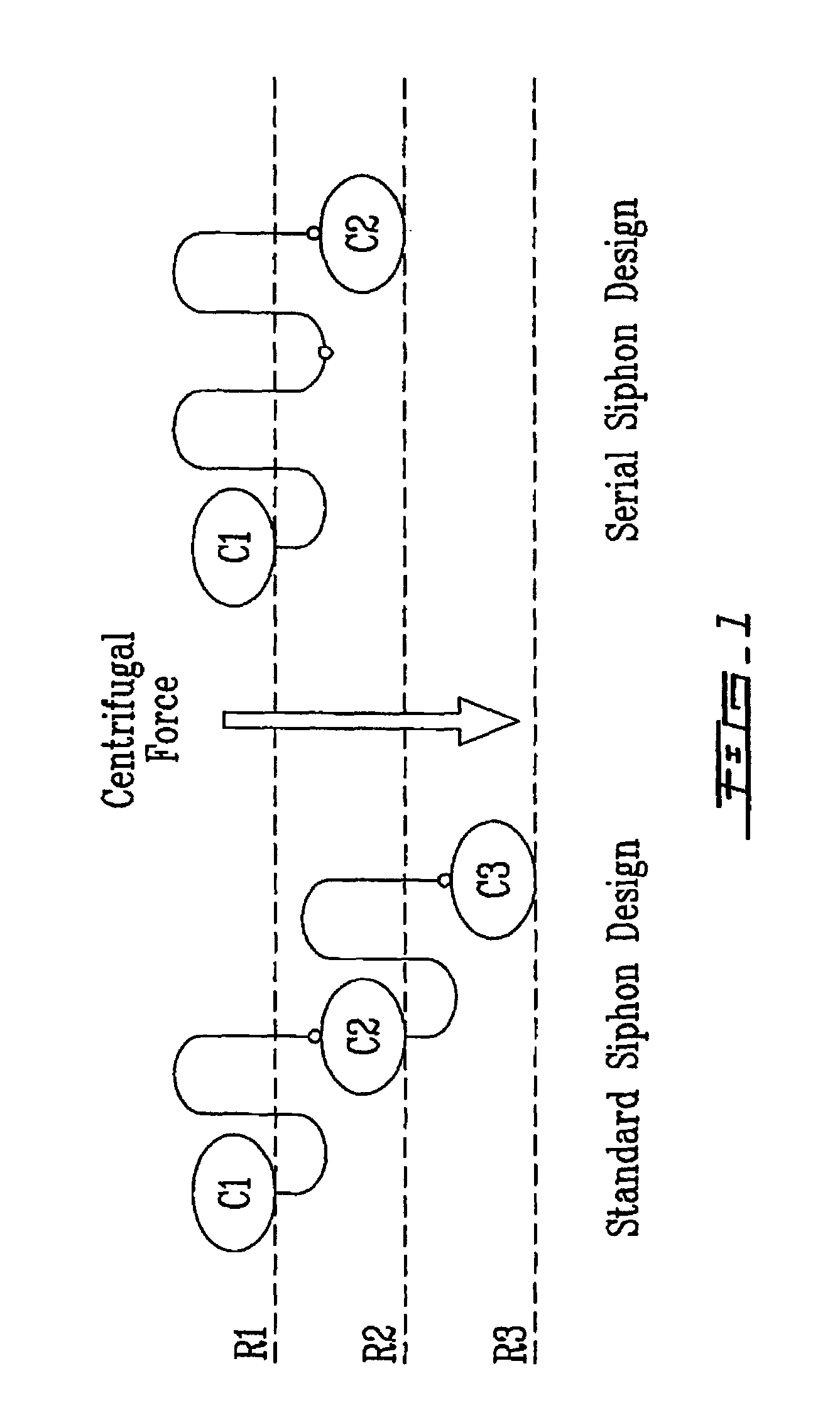

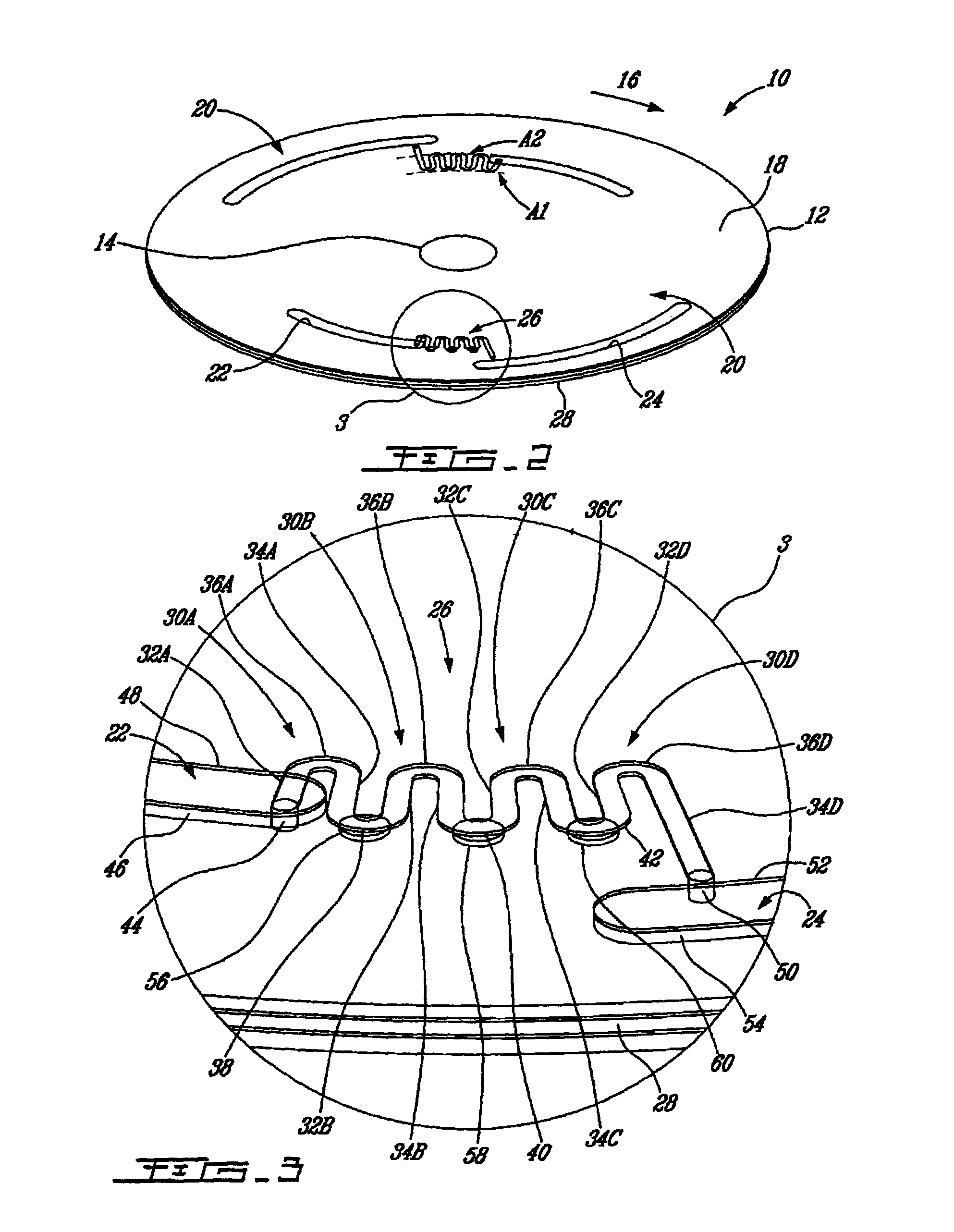

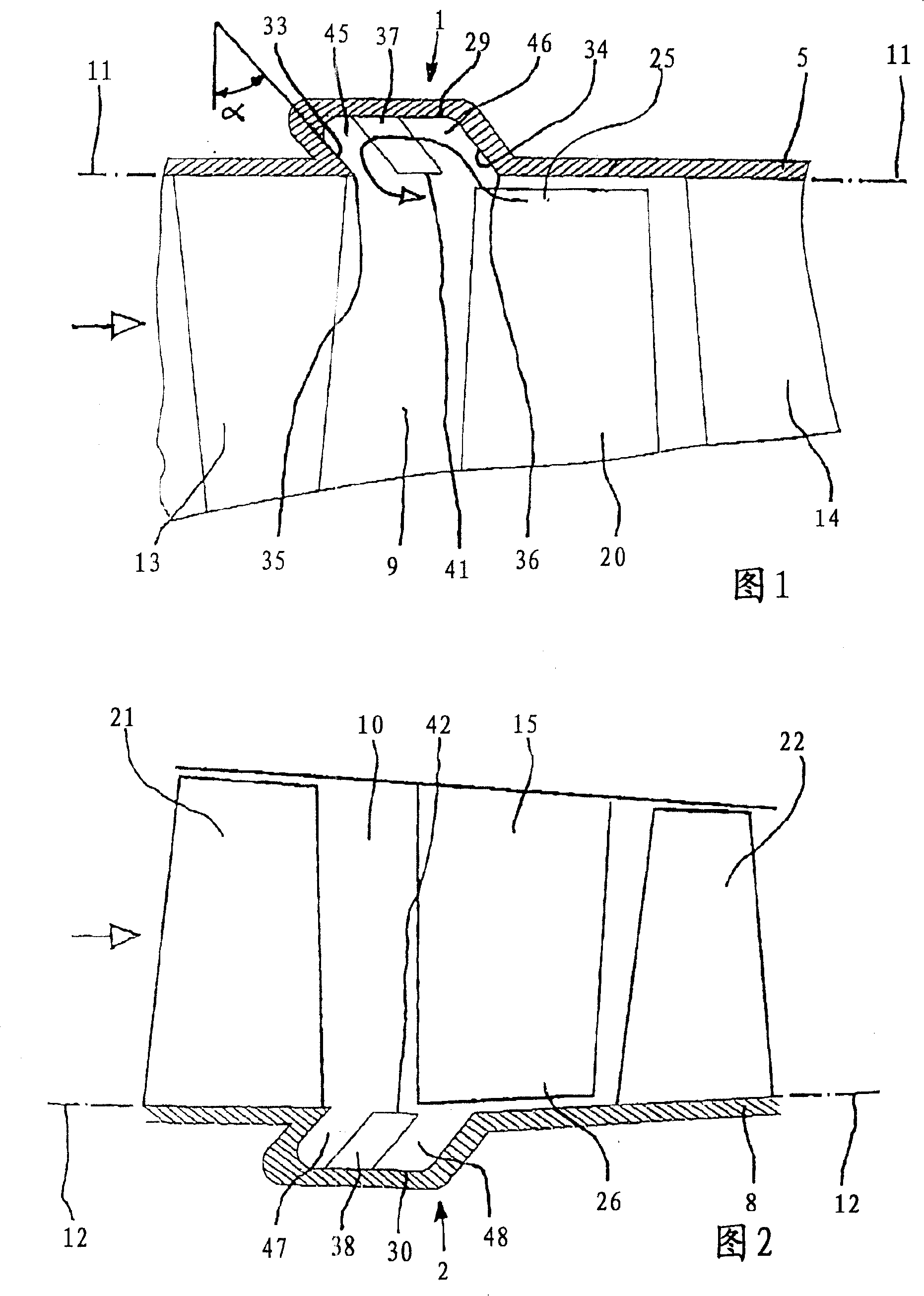

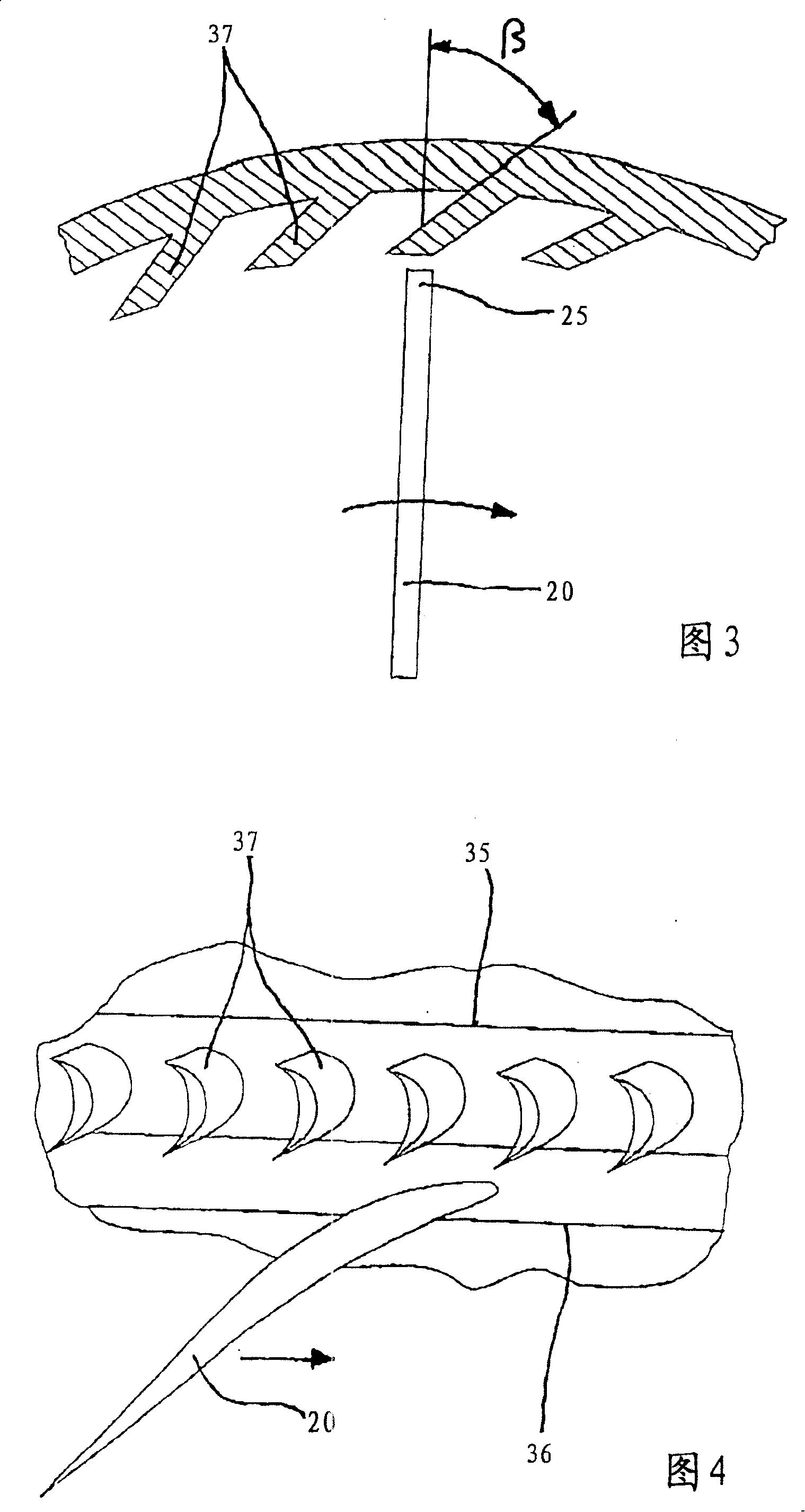

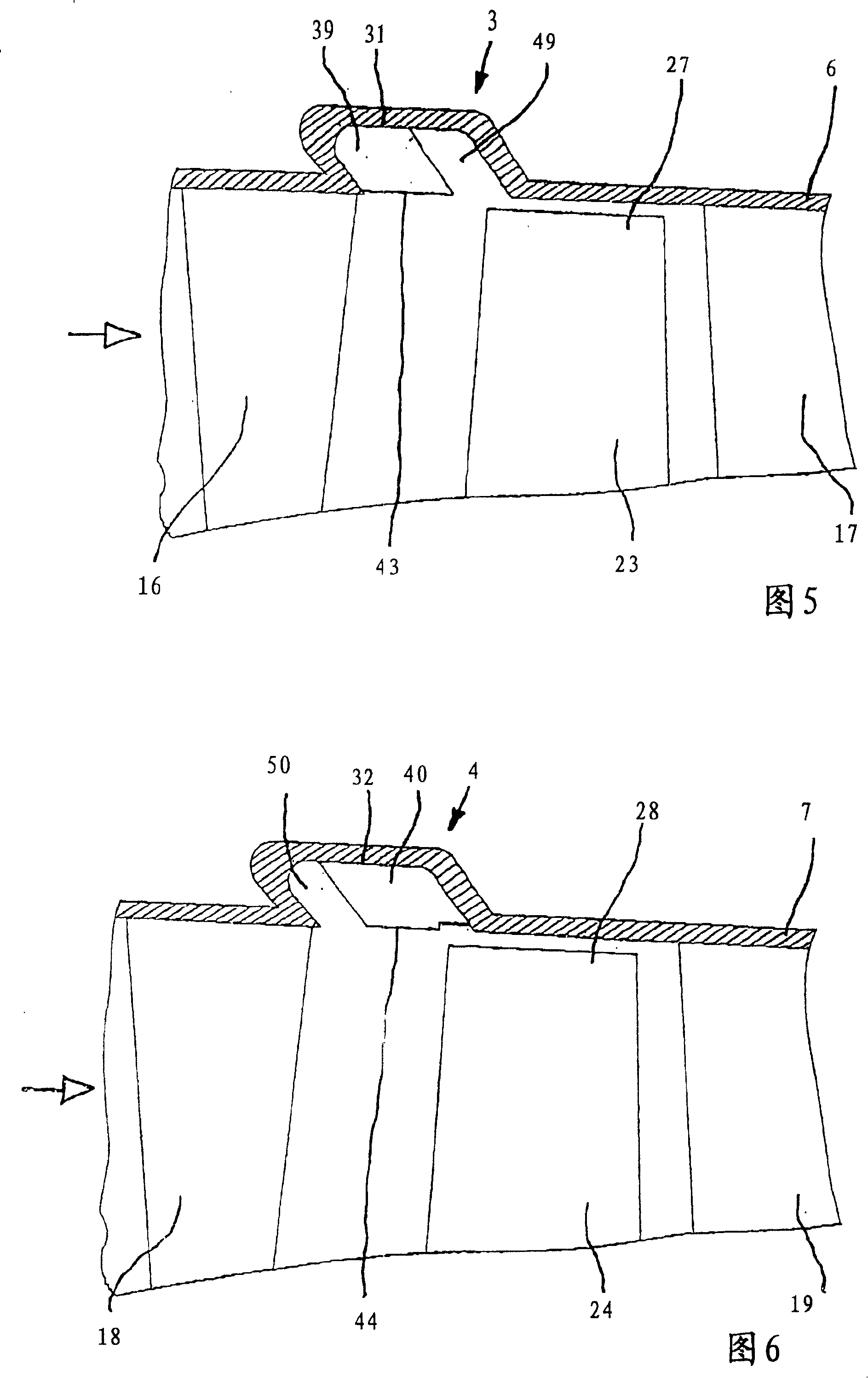

Serial siphon valves for fluidic or microfluidic devices

ActiveUS20110094600A1Save radial spaceMore featureCircuit elementsMaterial analysis by optical meansSiphonFluid system

Methods and devices using a co-radial arrangement of serial siphon structures composed of siphon valves each separated by a capillary valve to save radial space in a fluidic system. Such serial siphon valves allow to sequentially distribute liquids in a fluidic system upon application of successive centripetal accelerations and decelerations applied to a rotary platform.

Owner:RGT UNIV OF CALIFORNIA +1

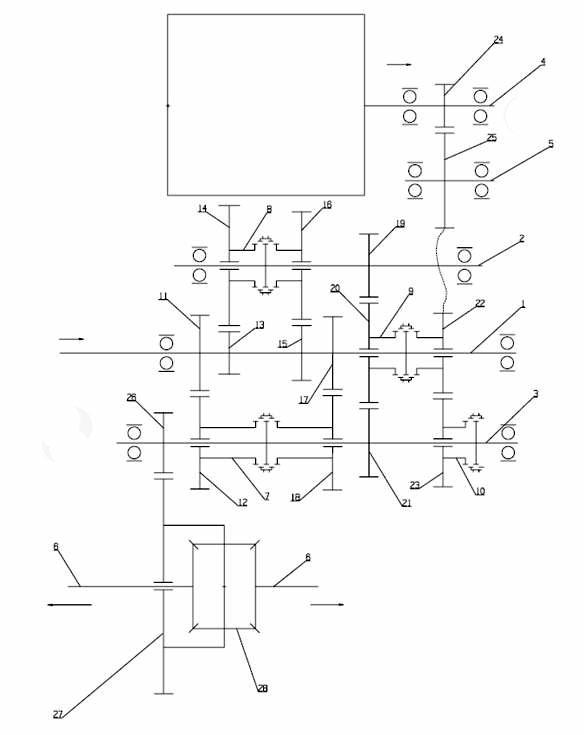

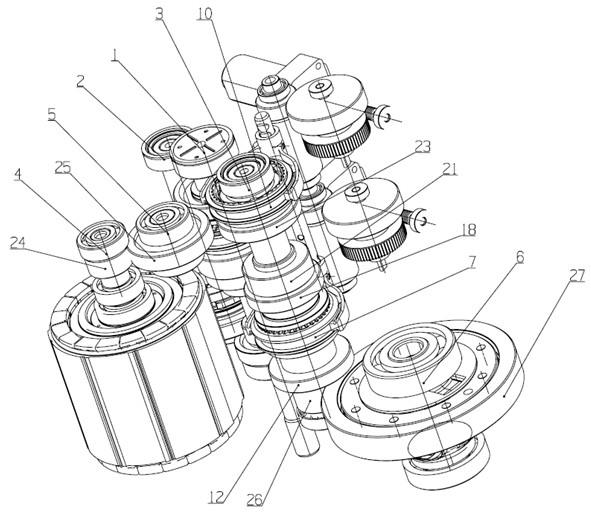

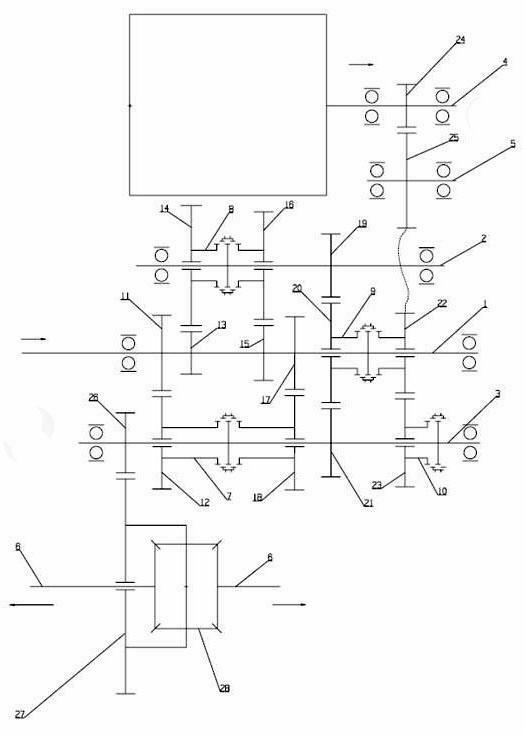

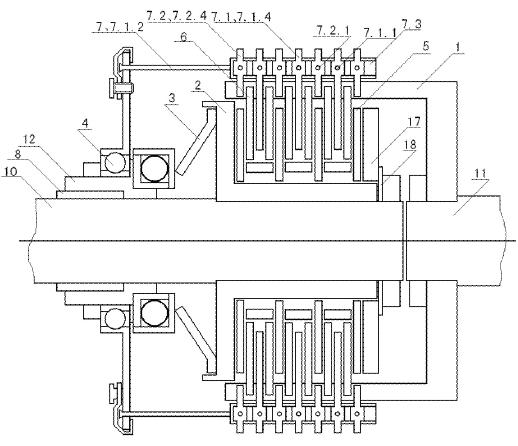

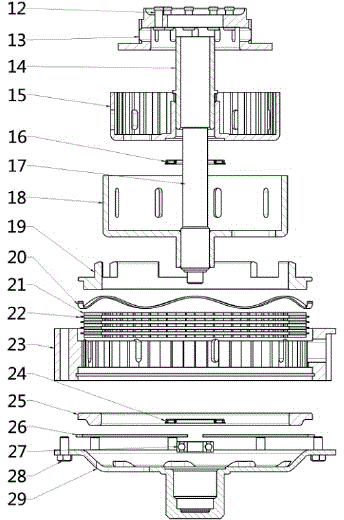

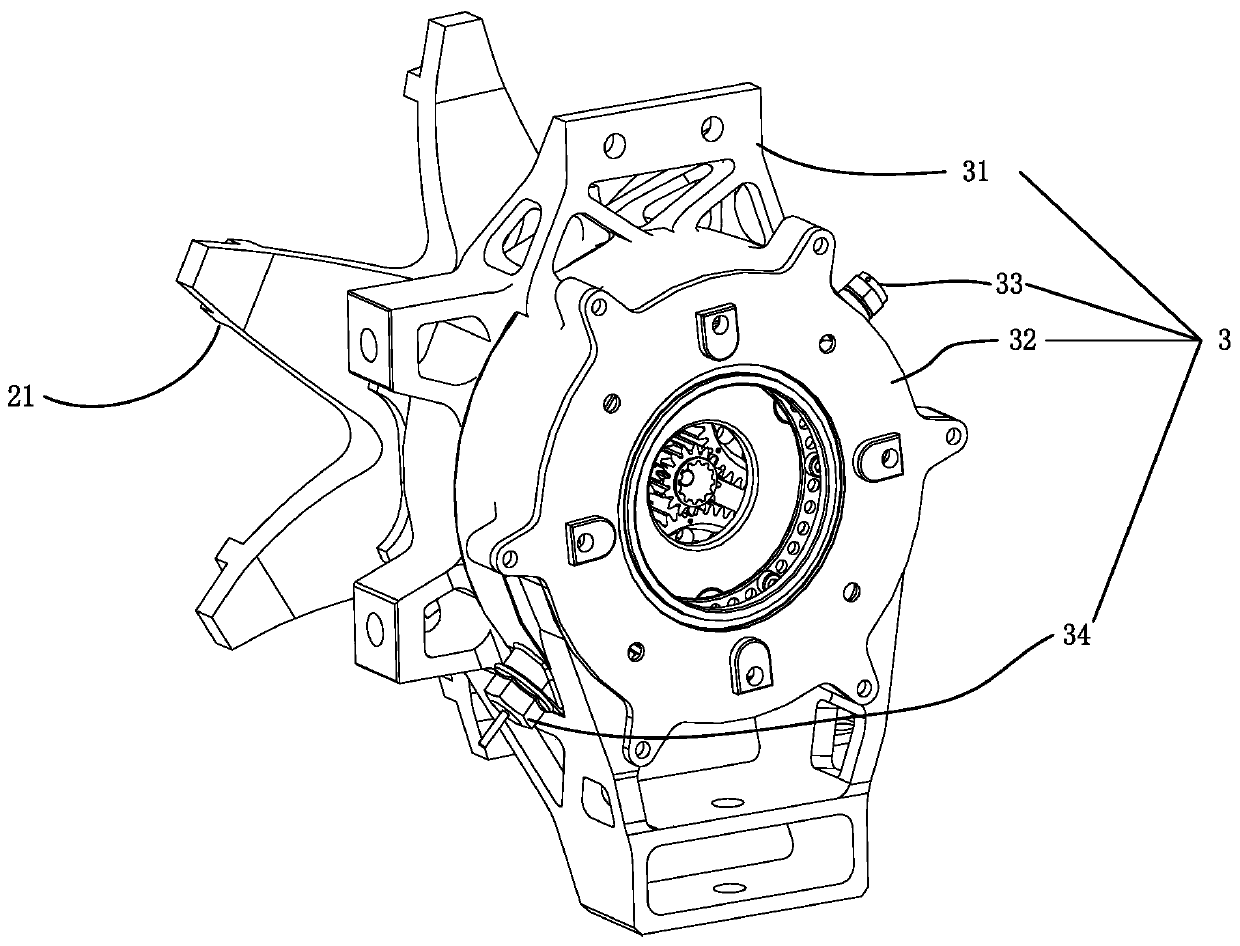

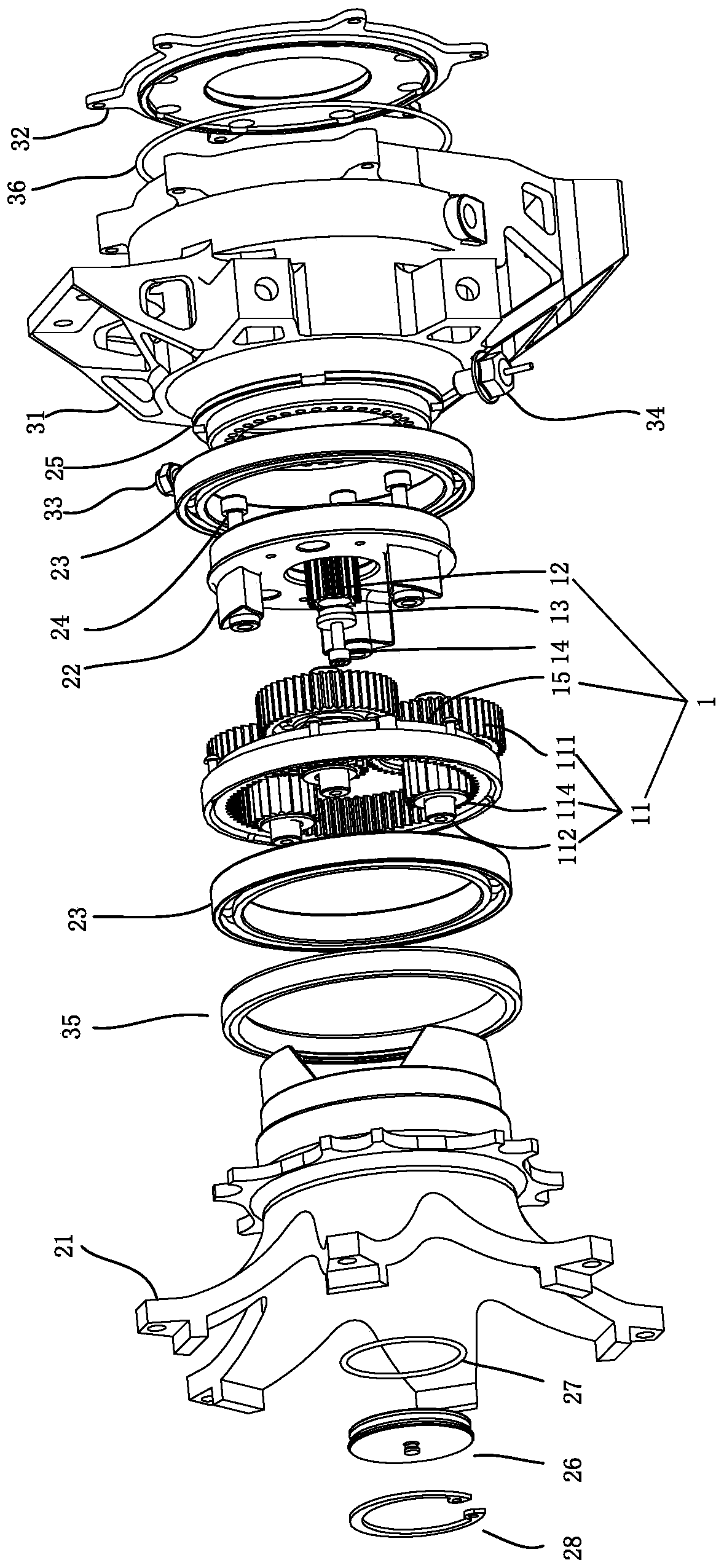

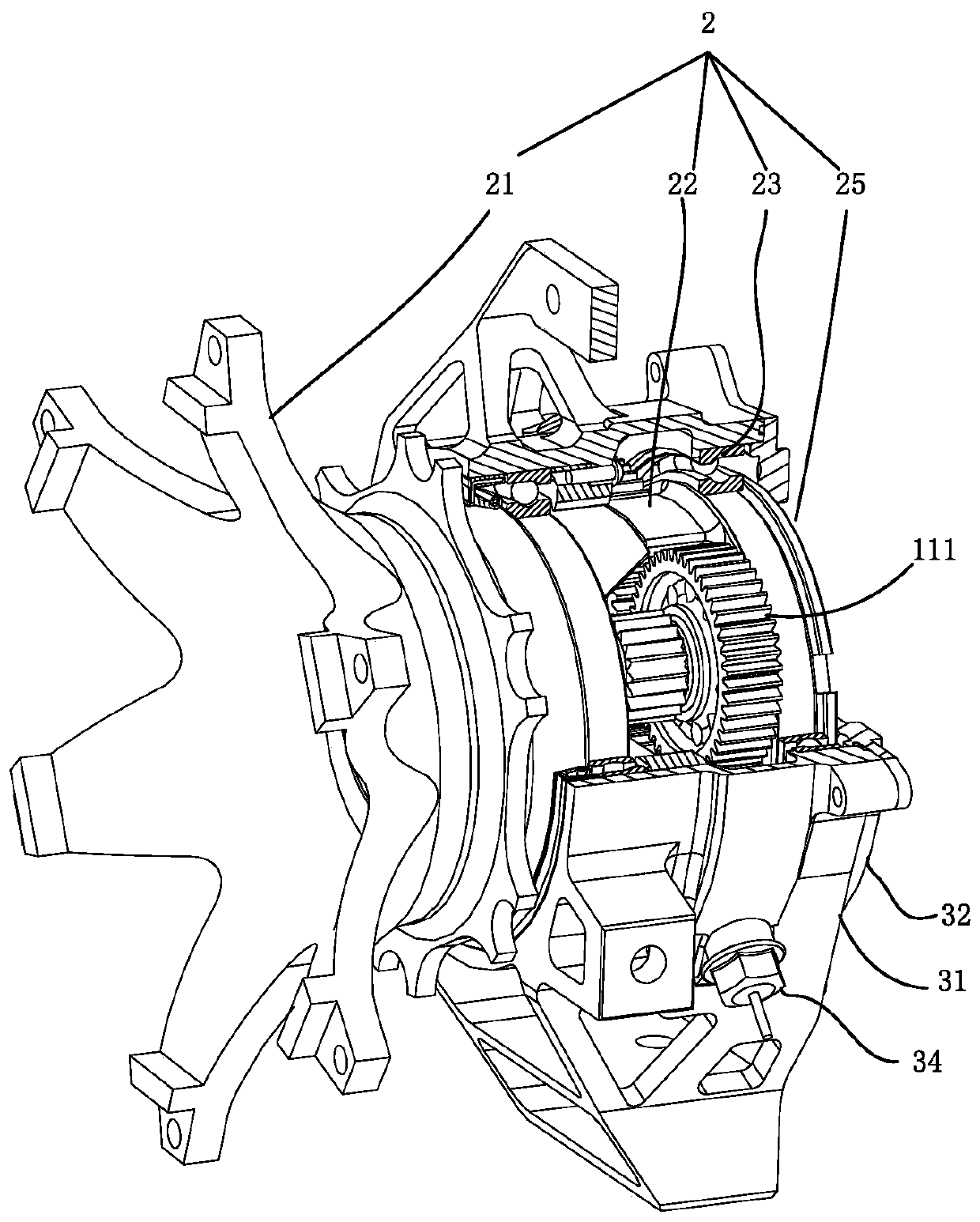

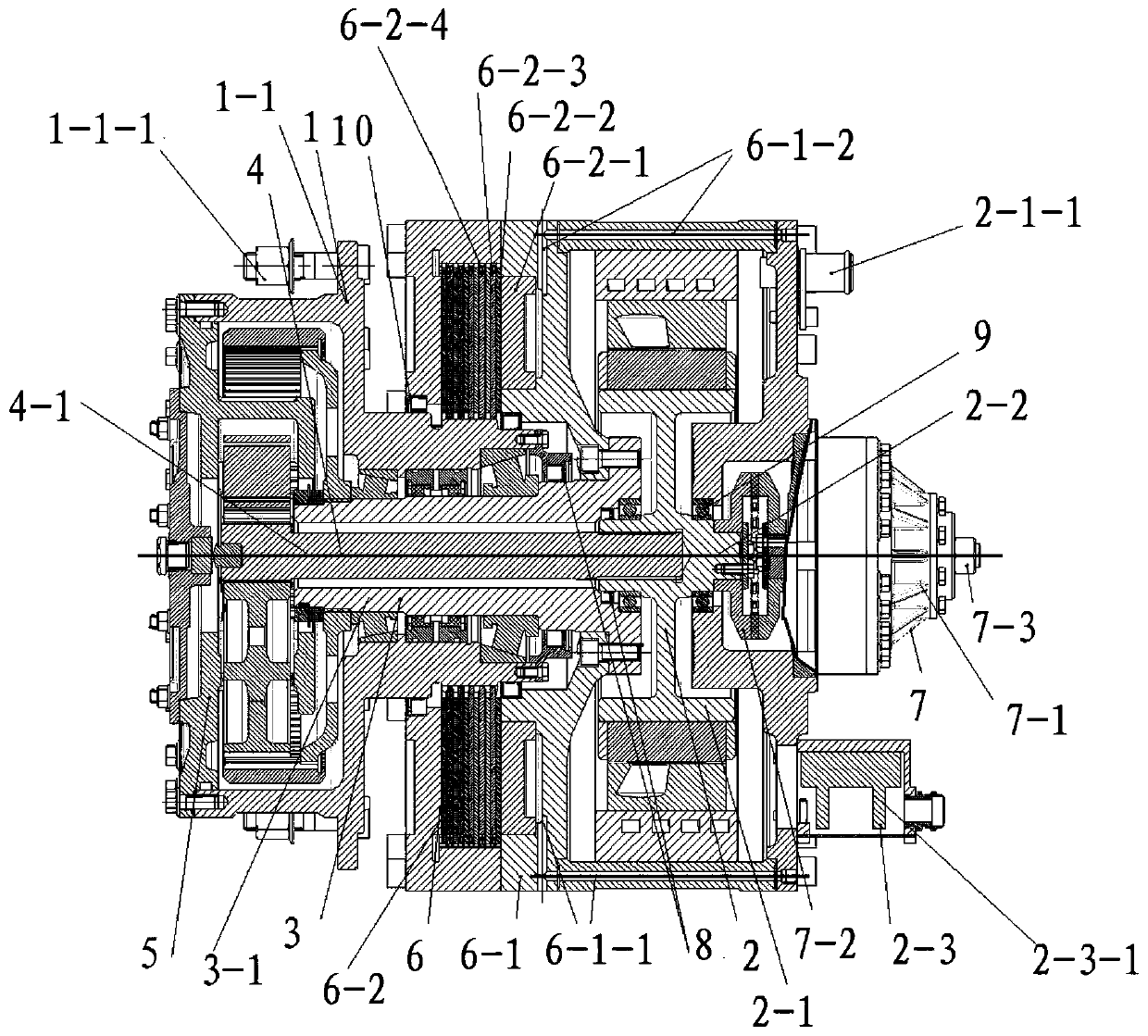

Automobile hybrid power assembly

InactiveCN102490585ASave radial spaceReduce weightGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingEngineeringIdler-wheel

The invention relates to an automobile hybrid power assembly, which comprises a motor and an automated mechanical transmission (AMT). The AMT comprises an input shaft, a first middle shaft, a second middle shaft, a motor shaft, a motor idler shaft and an output shaft which are in location matching connection on a case body and parallelly arranged in space, wherein the input shaft is provided with driving gears from a first gear to a sixth gear and a five-gear motor synchronizer; the first middle shaft is provided with driven gears from a first gear to a second gear, one-two-gear synchronizer and a five-gear input gear; the second middle shaft is provided with driven gears from a third gear to a sixth gear, a driving speed reducing gear and a motor synchronizer; the motor shaft is provided with a motor output driving gear; the motor idler shaft is provided with an idler shaft; and the output shaft is provided with a driven speed reducing gear and a differential mechanism. The automobile hybrid assembly resolves the problem of power interruption during shifting of the AMT, greatly improves comfortableness, is compact in structure, saves axial space of the transmission and guarantees installation arrangement in the whole automobile.

Owner:CHONGQING TSINGSHAN IND

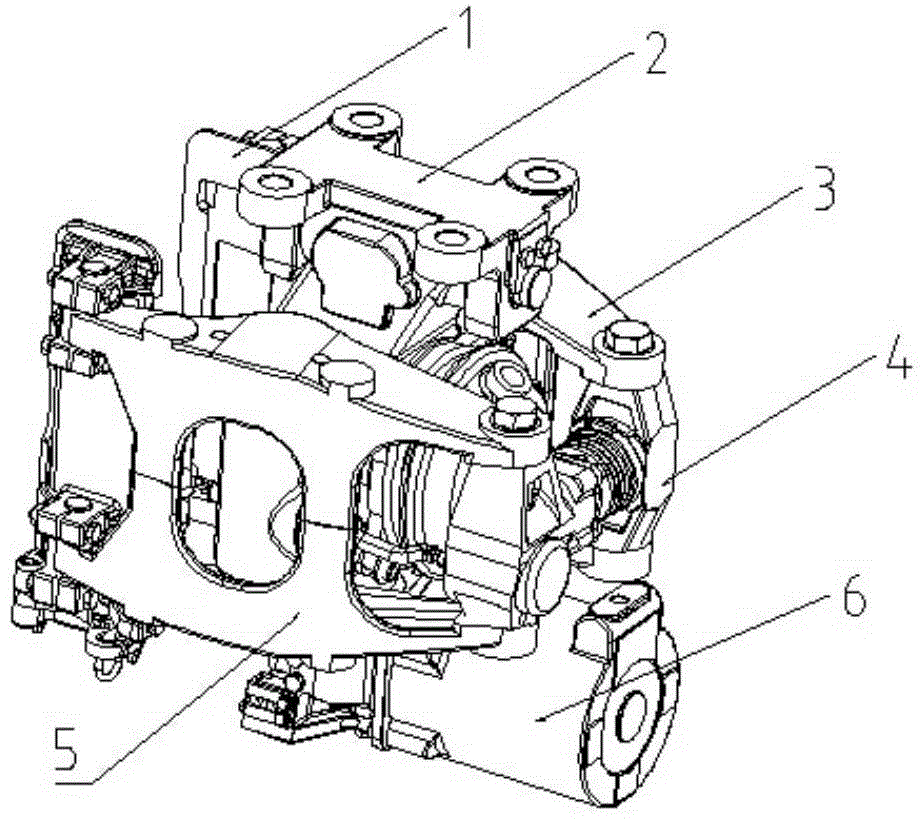

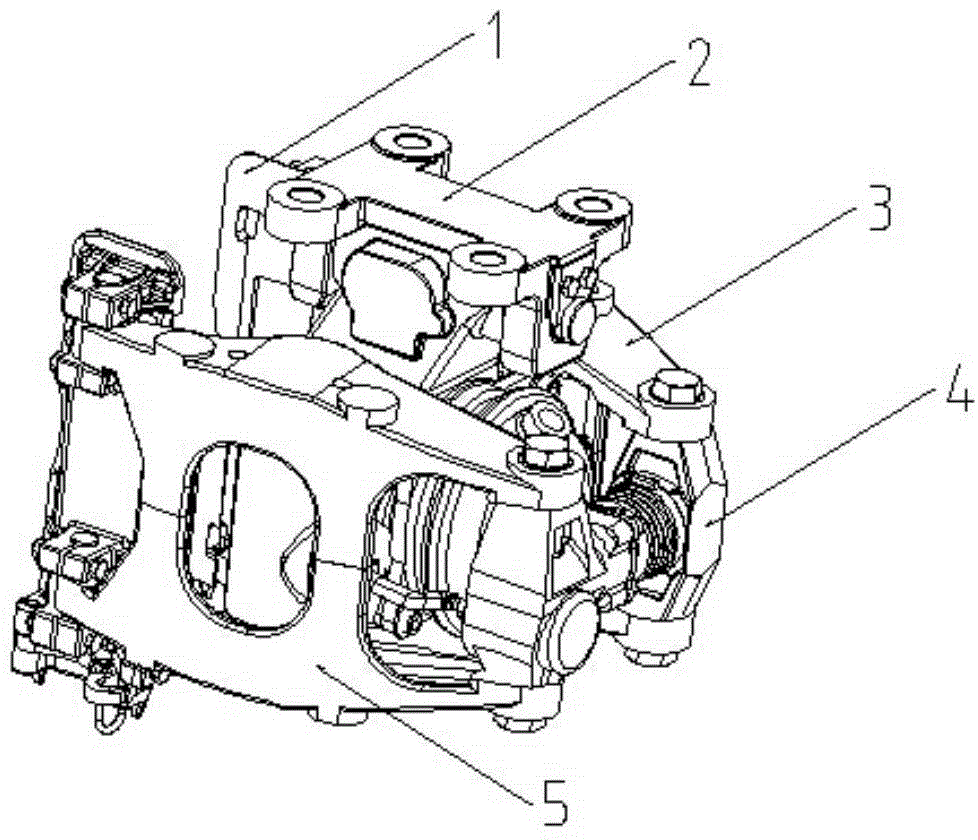

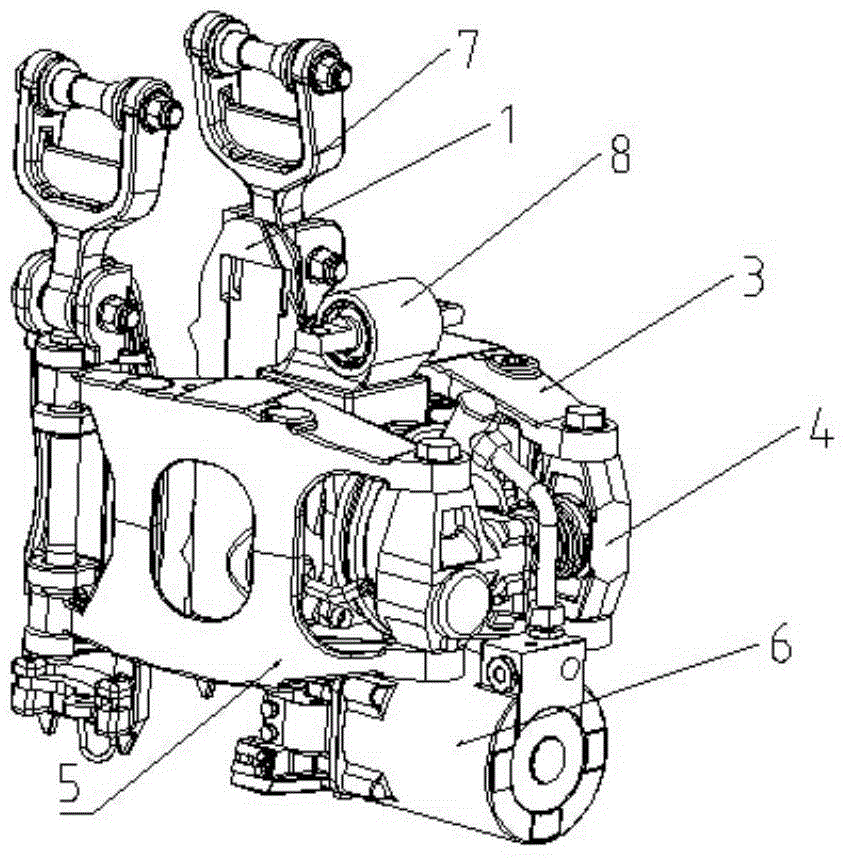

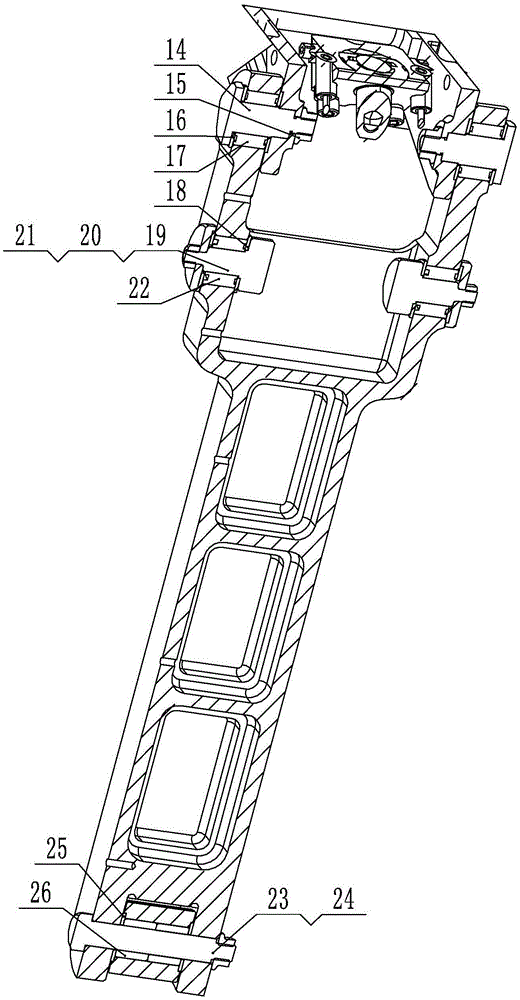

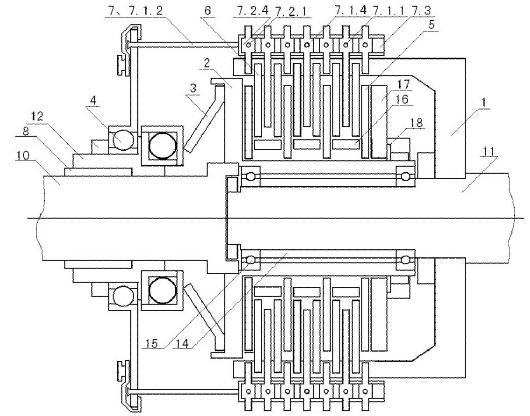

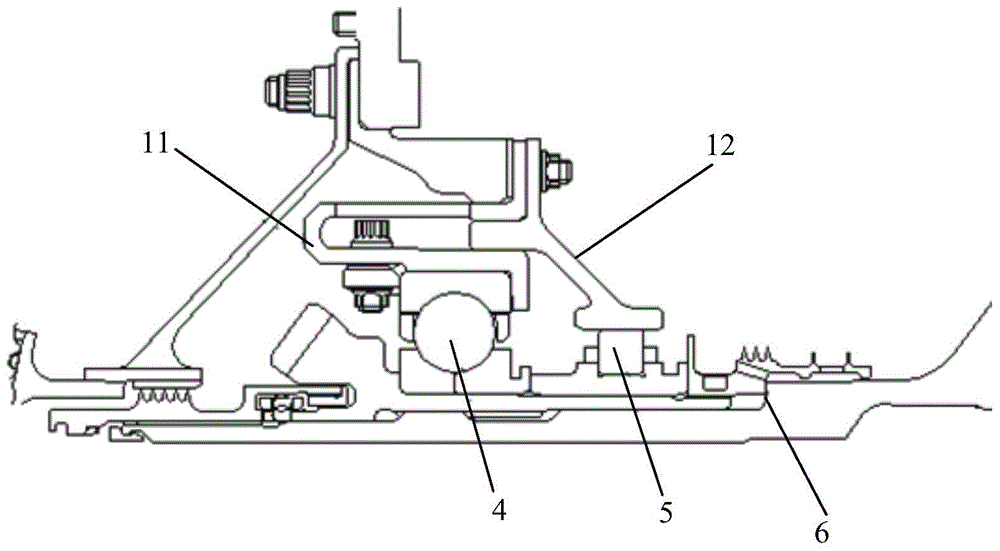

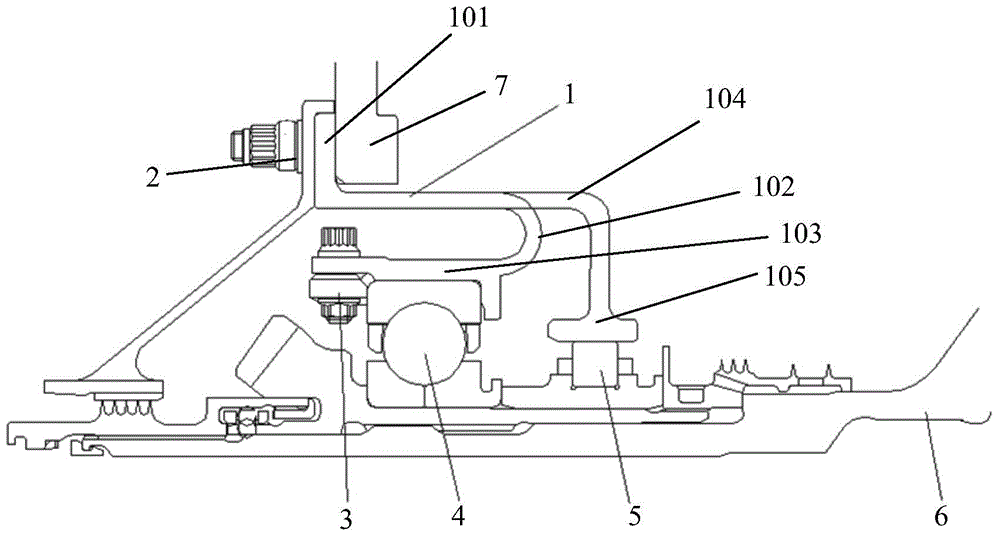

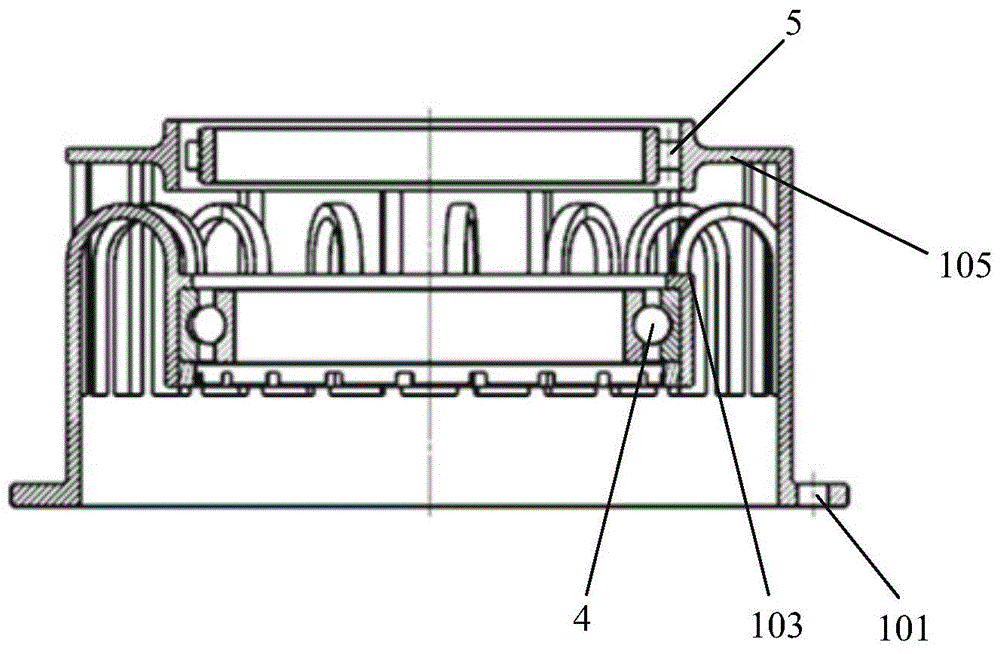

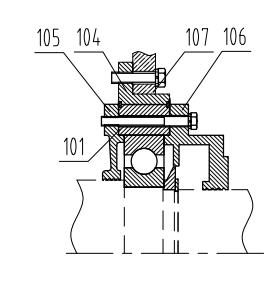

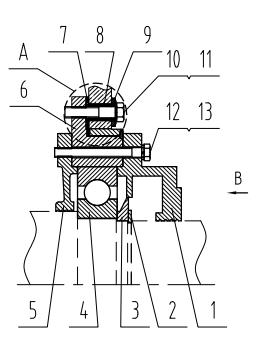

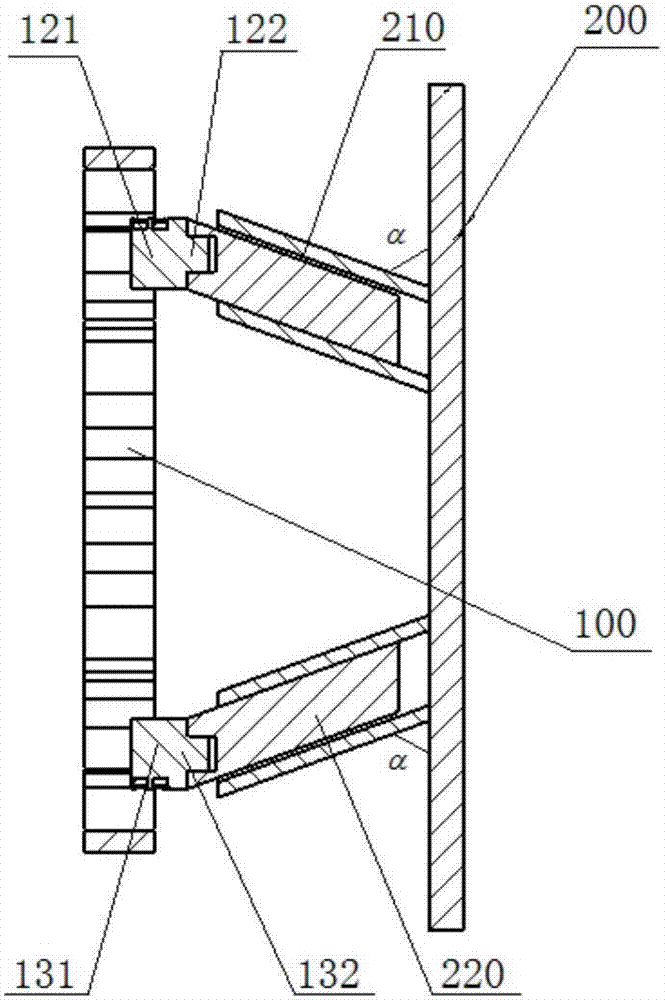

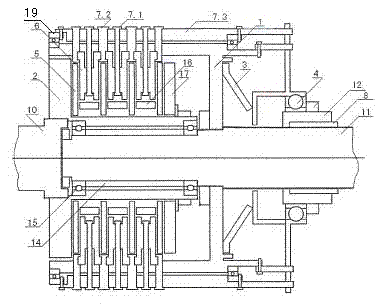

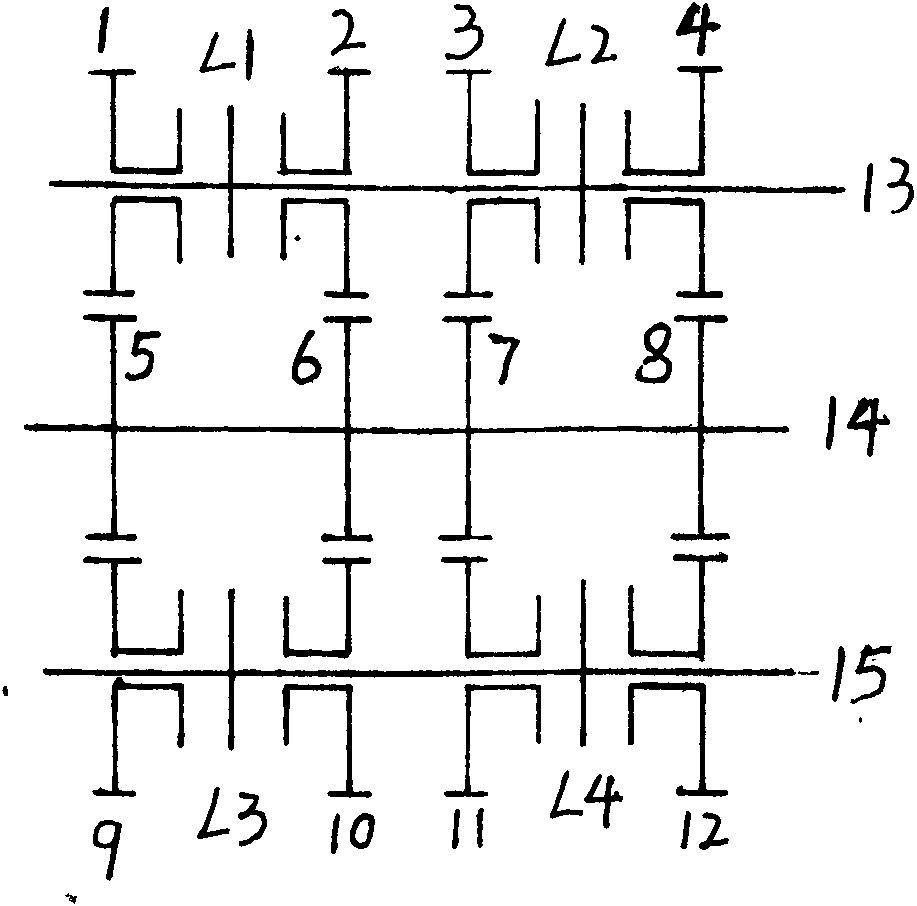

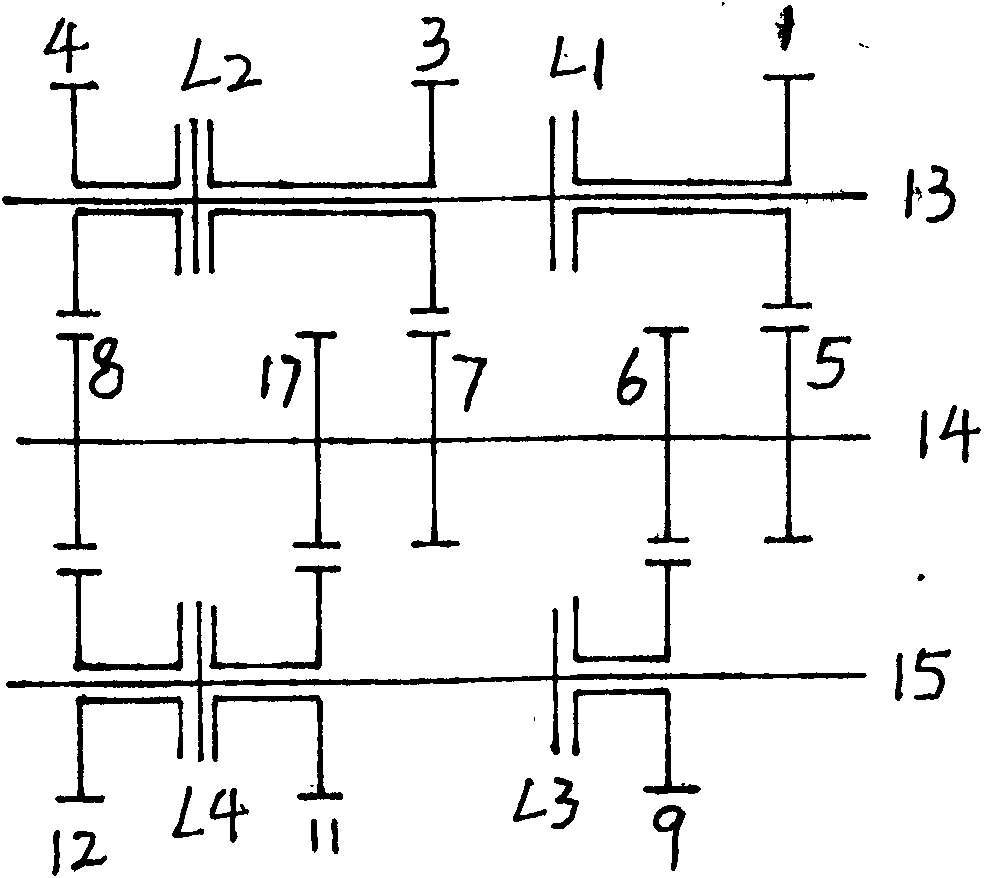

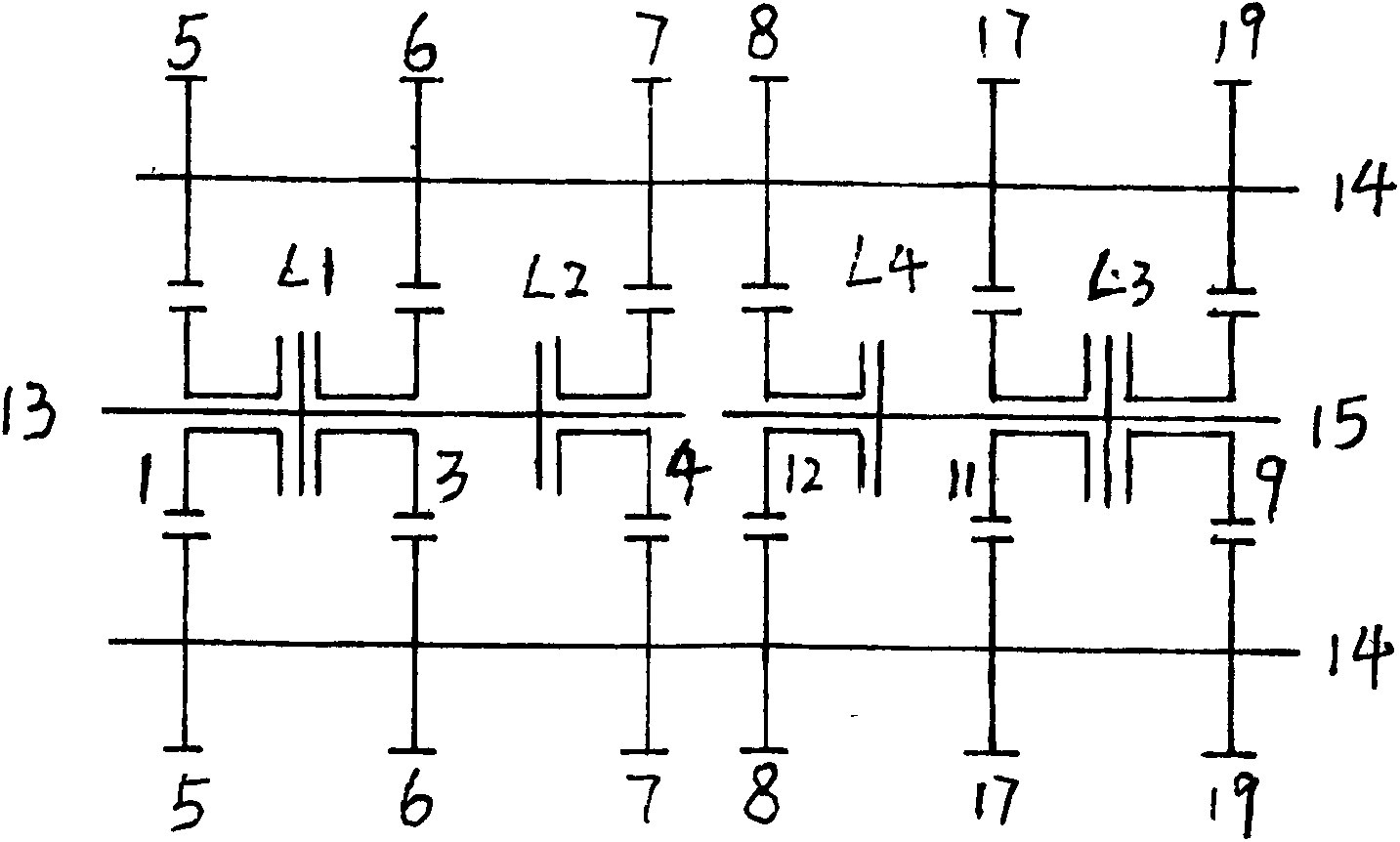

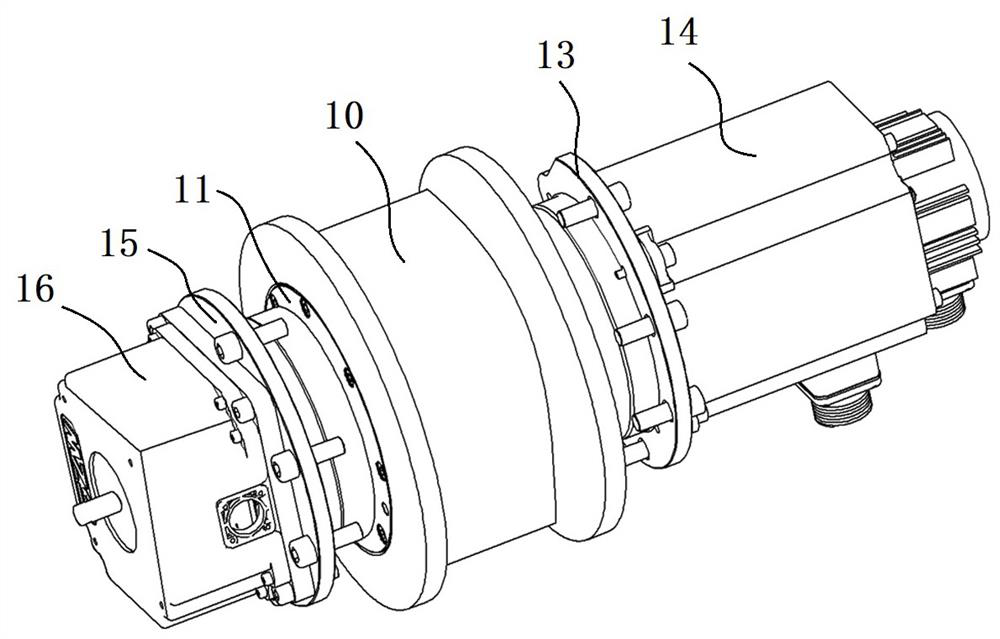

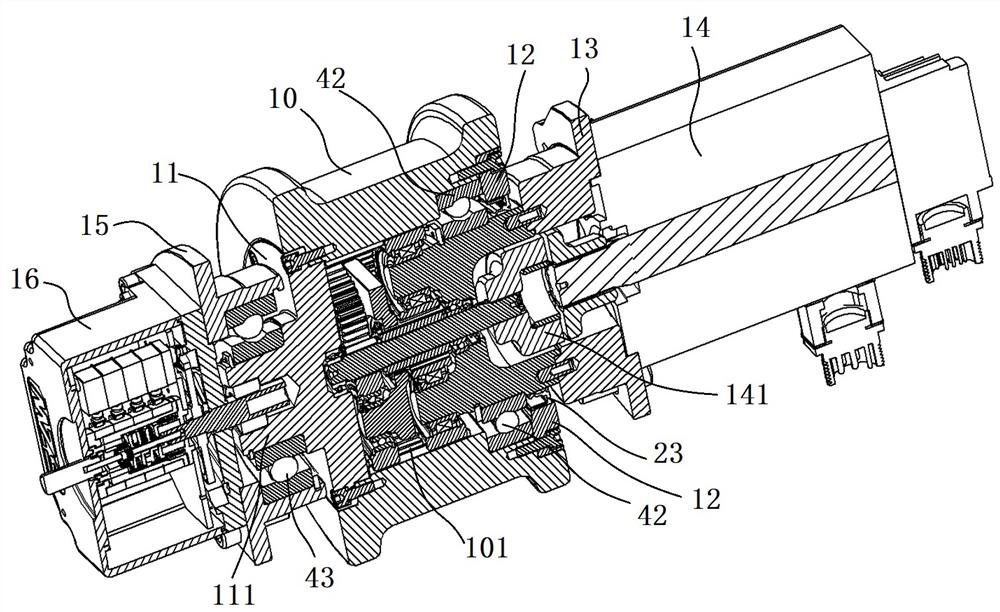

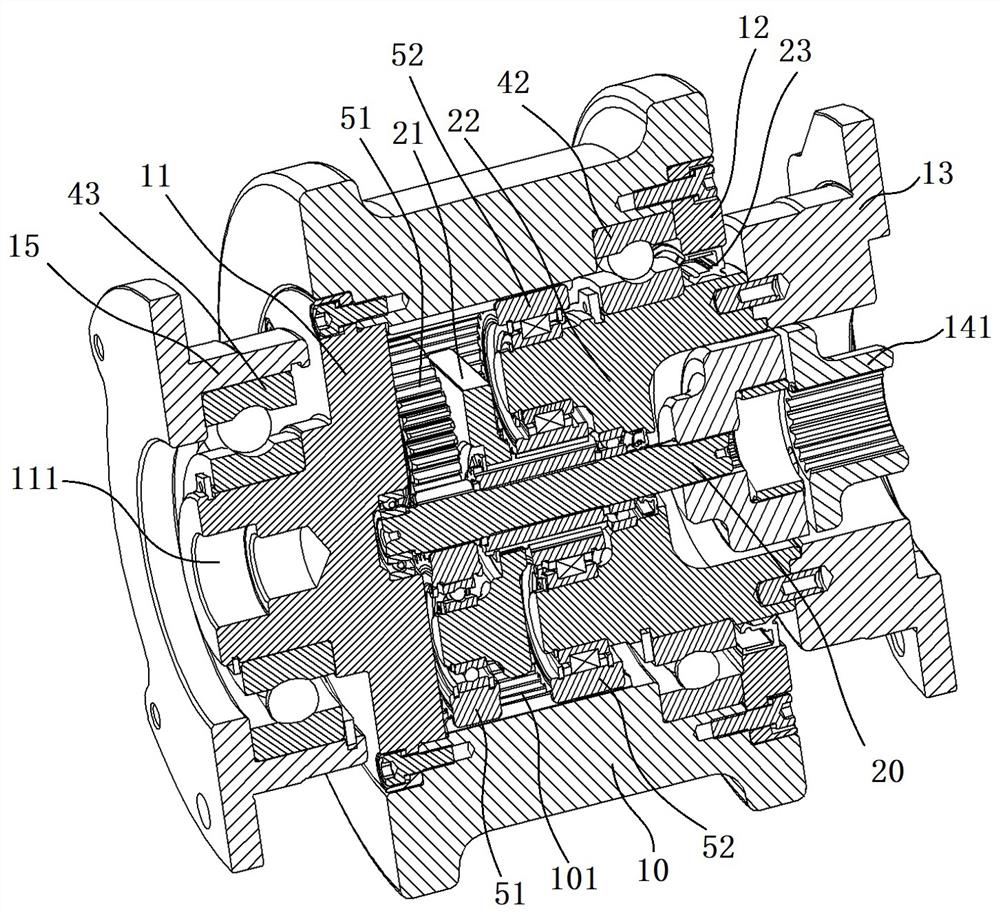

Railway locomotive vehicle braking clamp unit

ActiveCN104455113AReduce horizontal widthSave radial spaceBrake actuating mechanismsSlack adjustersPistonAutomotive engineering

The invention belongs to the field of railway locomotive vehicle braking technologies, and relates to a railway locomotive vehicle braking clamp unit. The clamp unit comprises a box body, a braking cylinder, a braking force multiplication mechanism, braking clamp arms, a buffering device and a brake lining gap adjustor, wherein the braking cylinder is fixedly connected with the box body, a reset taper spring is located between a cylinder cover of the braking cylinder and a diaphragm plate, an eccentric shaft and a connecting rod form an eccentric shaft type lever, the driving braking clamp arm is hinged to the eccentric shaft, the driven braking clamp arm is hinged to the box body, the force bearing end of a lever hook and the end of a connecting rod of the braking force multiplication mechanism are spaced with a certain distance, the force applying end of the lever hook is connected with a push rod, and the buffering device is located between the box body and the force bearing end of the lever hook. The transverse width of the braking clamp unit is small, the piston diameter and the multiplying power of the clamp arms are reduced, the requirement of a spring stopping braking cylinder for an energy accumulating spring is lowered, and the size of the railway locomotive vehicle braking clamp unit is reduced. The railway locomotive vehicle braking clamp unit is wide in application range, high in modularization degree and complete in function.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

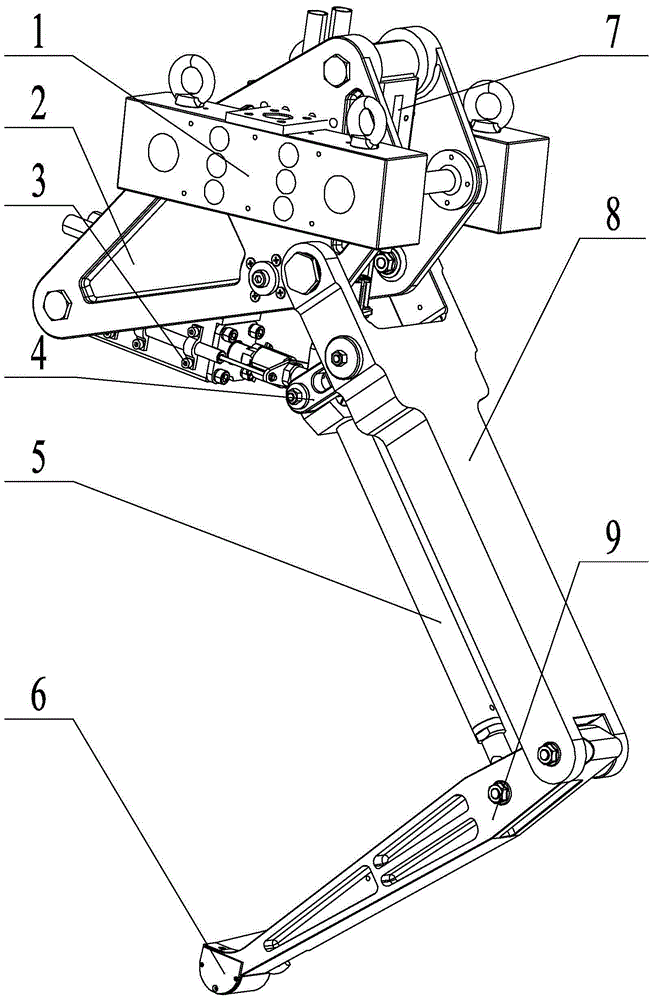

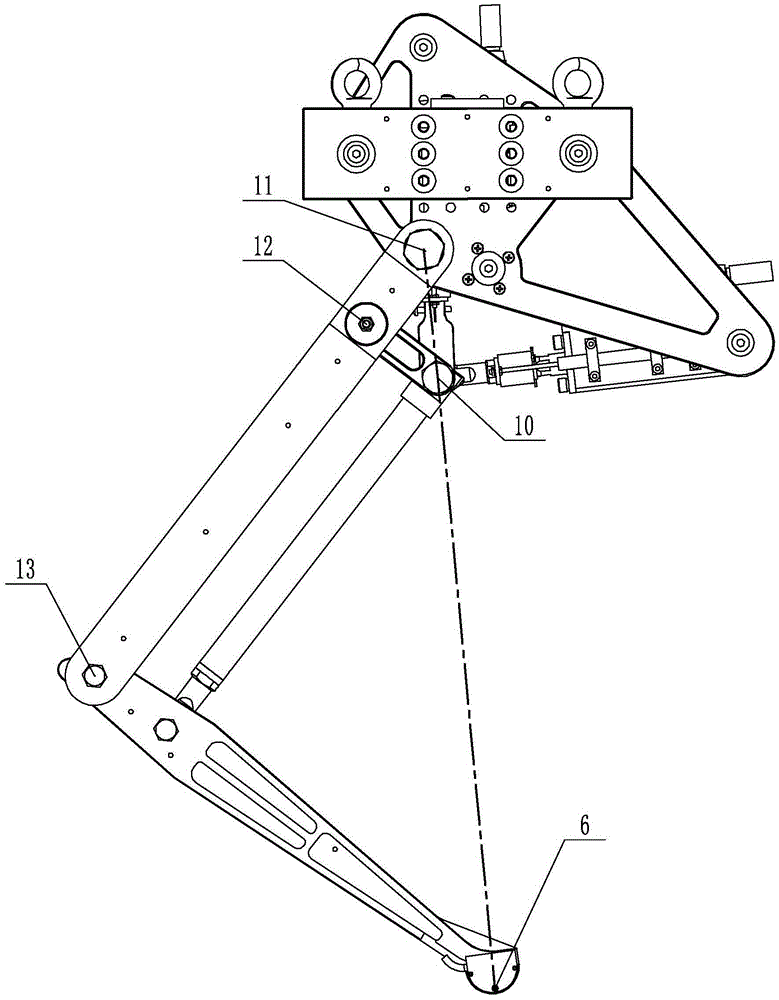

Parallel leg structure for legged robot capable of running at high speed

The invention provides a parallel leg structure for a legged robot capable of running at a high speed, relating to a parallel leg structure. The parallel leg structure provided by the invention solves the problem of relatively large energy consumption of the existing legged robot capable of running at a high speed because of the movement rule of periodic acceleration and deceleration. Two joint leg loading and hoisting steel plates are symmetrically and fixedly arranged on outer walls of two sides of a scapula; the upper end of a thigh is articulated with the lower part of the scapula; the lower end of the thigh is articulated with the upper end of a shank; a sole is fixedly arranged at the lower end of the shank; a parallel short connecting rod is articulated with the upper part of the thigh; the other end of the parallel short connecting rod is articulated with the upper end of a parallel long connecting rod; a horizontal valve controlled hydraulic cylinder is installed on the scapula and is horizontally arranged; a hydraulic rod of the horizontal valve controlled hydraulic cylinder is connected with the articulated point of the parallel short connecting rod and the parallel long connecting rod; a vertical valve controlled hydraulic cylinder is installed on the scapula and is vertically arranged; and a hydraulic rod of the vertical valve controlled hydraulic cylinder is connected with the articulated point of the parallel short connecting rod and the parallel long connecting rod. The parallel leg structure provided by the invention is used for the legged robot.

Owner:SHENZHEN LONGHAITE ROBOT TECH CO LTD

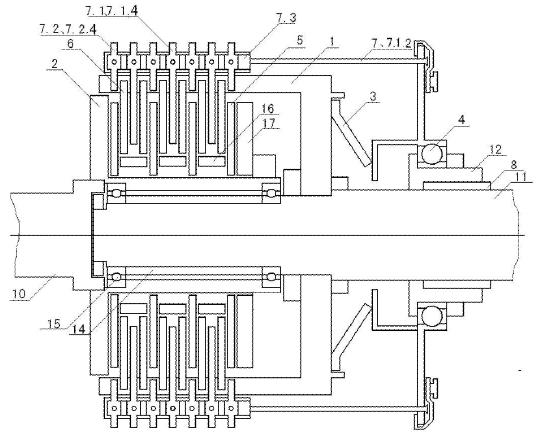

A New Type of Friction Clutch and Its Separation and Combination Device

InactiveCN102278383AImprove transmission efficiencyStable clutch functionFriction clutchesFailure rateDrive shaft

The invention provides a friction clutch, comprising an externally moving disc cover, an internally moving disc, a separating bearing, internal friction sheets, external friction sheets, a driving shaft, and a driven shaft, the externally moving disc cover is in a sleeve joint on the driving shaft, the separating bearing is in a sleeve joint at the external of a sliding sleeve, the sliding sleeve is in a sleeve joint at the external of a lining, the sliding sleeve and the lining sleeve the driving shaft or the driven shaft, the external friction sheets are connected with the externally moving disc cover, and disposed between two adjacent internal friction sheets, and a thick gasket is disposed between the two adjacent internal friction sheets, a separating and combining device is connected on the separating bearing, the separating and combining device comprises a fixed connecting mechanism and a combining mechanism composed of a big connecting rod, a small connecting rod, porous connecting plate and shafts, and a separating mechanism, wherein the combining mechanism and the separating mechanism are respectively connected with the fixed connecting mechanism. The friction clutch is advantageous in that: clutch function is stable, transmission torque is big, wear is little, transmission efficiency is high, heat radiation performance is good, failure rate of a separator is low, and radial space is small; when the friction clutch is used, a current manual operating system or a pedal operating system can be used to complete combining and separating functions.

Owner:姜成立

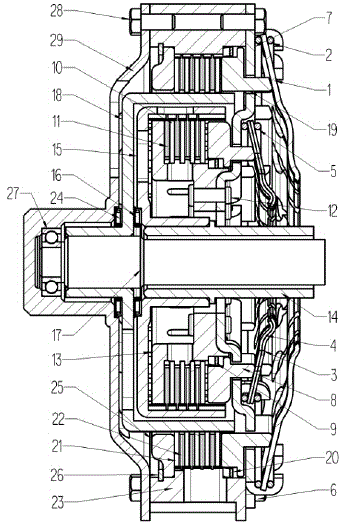

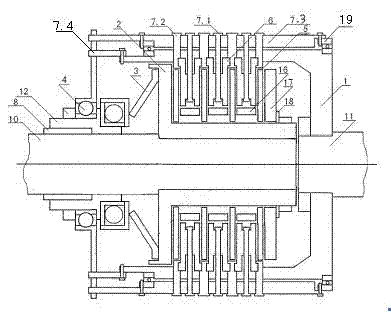

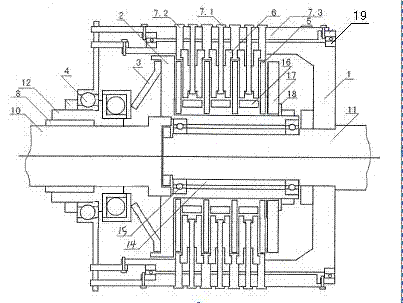

Wet type double-clutch unit

ActiveCN104879397AReduce machining tolerancesEasy to processFluid actuated clutchesTransmitted powerEngineering

The invention discloses a wet type double-clutch unit which comprises an odd-numbered shaft clutch and an even-numbered shaft clutch, wherein the two clutches work independently; each clutch comprises a diaphragm spring which is contacted with a hill-like supporting bulge of an axial pressing disc, and the axial pressing disc is forced by deformation of the diaphragm spring to move axially, so that a friction plate below the axial pressing disc is compressed to transmit power to dual discs. The wet type double-clutch unit has the advantages as follows: compression force is transmitted through deformation of the diaphragm springs, and compared with the conventional compression force transmission under hydraulic control, higher response speed is provided during gear shifting; the structure facilitates mounting, and the wet type double-clutch unit has good reliability and fatigue durability.

Owner:华域动力总成部件系统(上海)有限公司

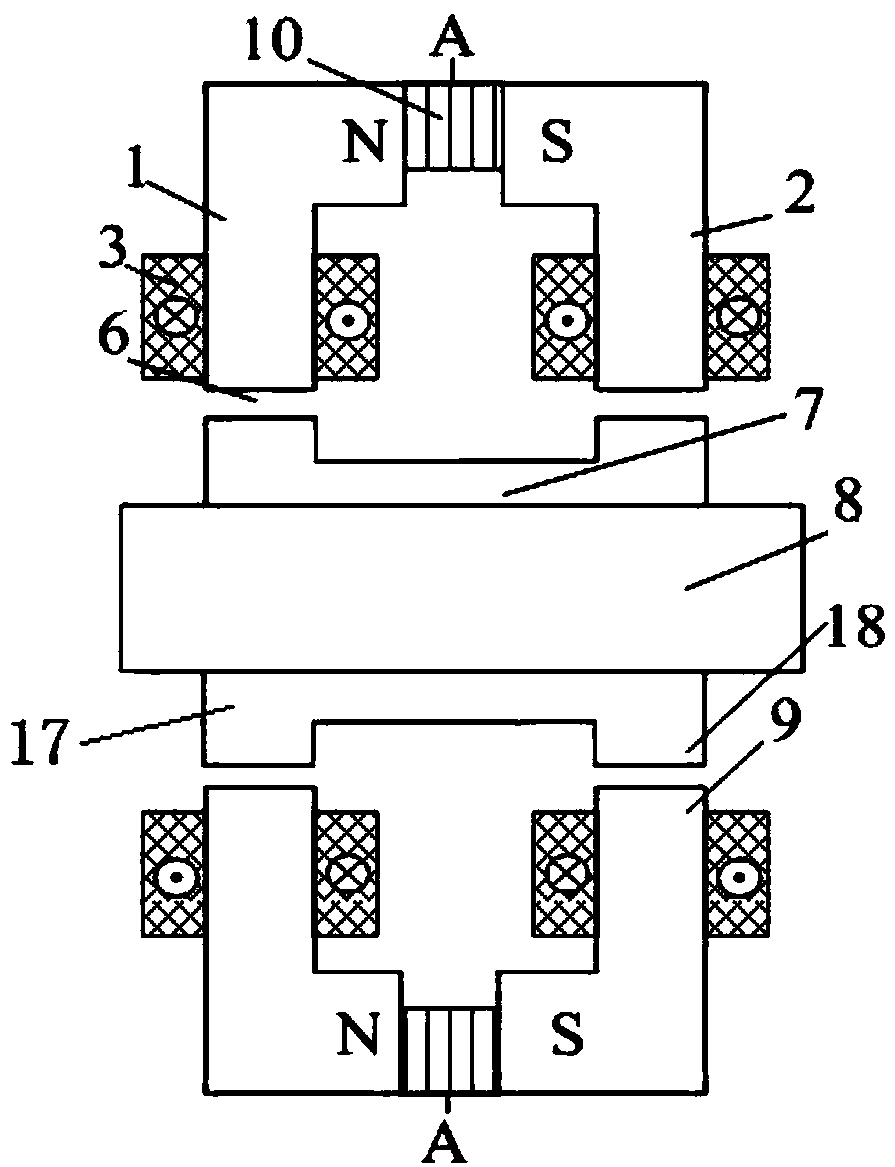

Six-pole mixed magnetic bearing

InactiveCN108050156AIncrease the number of ampere turnsIncrease layout spaceBearingsMagnetic bearingMagnetic poles

The invention discloses a six-pole mixed magnetic bearing. The rotors are coaxially sleeved with left stator iron cores and right stator iron cores which are symmetrically arranged in the axial direction, left stress discs are arranged at the left ends of the rotors, and right stress discs are arranged at the right ends of the rotors, and circular ring-shaped permanent magnets are laminated between yoke portions of the left stator iron cores and the right stator iron cores; the permanent magnets are axially magnetized, six stator magnetic poles are uniformly distributed in each of the left stator iron cores and the right stator iron cores in the circumferential direction, the six stator magnetic poles of each left stator iron core are aligned with the corresponding left stress disc in theradial direction, and the six stator magnetic poles of each right stator iron core are aligned with the corresponding right stress disc in the radial direction; and the two radial control coils whichare in face-to-face and radial direction on the same stator iron core in the left stator iron core and the right stator iron core are connected in series with a same winding direction, and the two radial control coils which are in axial-facing direction on the left stator iron core and the right stator iron core are connected in series with an opposite winding direction. According to the six-polemixed magnetic bearing, suspension force and displacement characteristics and suspension force and current characteristics tend to be linear, and coupling between two radial degrees of freedom is reduced.

Owner:JIANGSU UNIV

Serial siphon valves for fluidic or microfluidic devices

InactiveCN101715553ASave radial spaceValve arrangementsPiezoelectric/electrostriction/magnetostriction machinesSiphonBiomedical engineering

Methods and devices using a co-radial arrangement of serial siphon structures composed of siphon valves each separated by a capillary valve to save radial space in a fluidrc system. Such serial siphon valves allow to sequentially distribute liquids in a fluidic system upon application of successive centripetal accelerations and decelerations applied to a rotary platform.

Owner:UNIV LAVAL

Integrated bearing supporting structure used for aviation engine

The invention relates to an integrated bearing supporting structure for an aviation engine. The integrated bearing supporting structure comprises a mounting edge, a first bearing supporting spoke, a second bearing supporting spoke, a first bearing supporting seat and a second bearing supporting seat, one end of the first bearing supporting spoke is connected to the mounting edge, the other end of the first bearing supporting spoke is connected to the first bearing supporting seat, one end of the second bearing supporting spoke is connected to the mounting edge, the other end of the second bearing supporting spoke is connected to the second bearing supporting seat, the first bearing supporting seat is used for supporting a first bearing, the second bearing supporting seat is used for supporting a second bearing, and the quantity of the mounting edge is 1. The integrated bearing supporting structure for an aviation engine has the advantages of part quantity reduction, occupied space reduction, reduced weight, and convenience for dismounting and maintaining.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

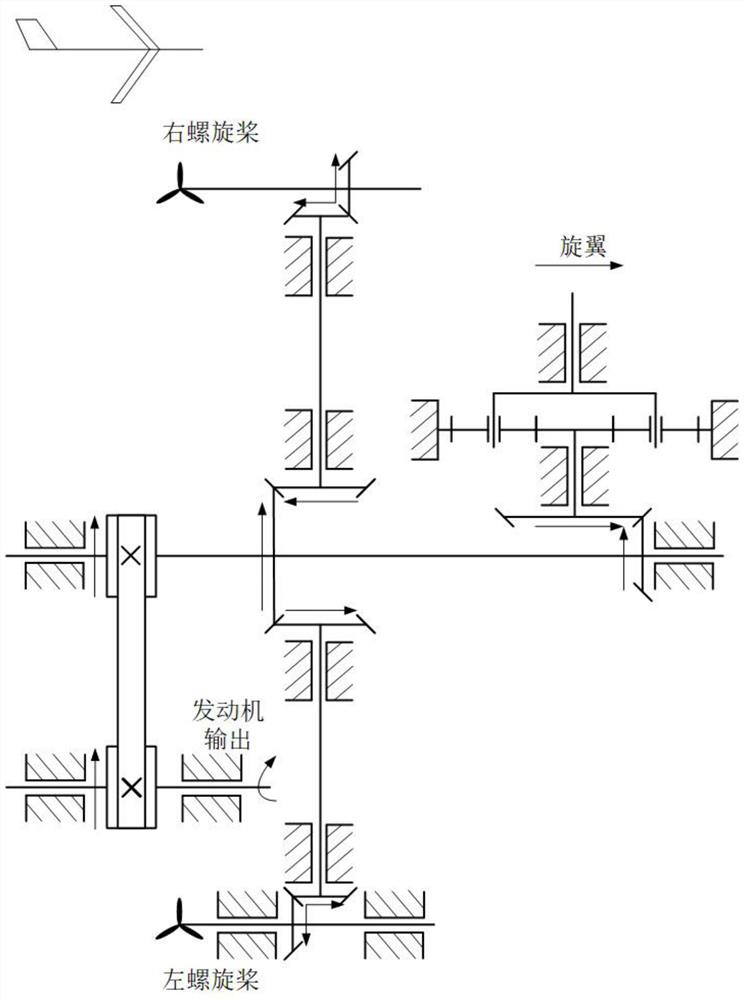

Composite propulsion helicopter transmission system

InactiveCN113389864AImprove transmission performanceImprove transmission efficiencyGearingGear lubrication/coolingAviationPropeller

The invention discloses a composite propulsion helicopter transmission system which comprises a main rotor transmission system and a two-wing propeller transmission system in transmission connection with the main rotor transmission system, and further comprises a belt transmission system in transmission connection with the main rotor transmission system. The problems that an aviation piston engine is large in vibration, low in reliability, poor in transmission performance and the like during non-load starting in the prior art are solved.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

Serial siphon valves for fluidic or microfluidic devices

ActiveUS8534319B2Save radial spaceMore featureCircuit elementsMaterial analysis by optical meansSiphonEngineering

Methods and devices using a co-radial arrangement of serial siphon structures composed of siphon valves each separated by a capillary valve to save radial space in a fluidic system. Such serial siphon valves allow to sequentially distribute liquids in a fluidic system upon application of successive centripetal accelerations and decelerations applied to a rotary platform.

Owner:RGT UNIV OF CALIFORNIA +1

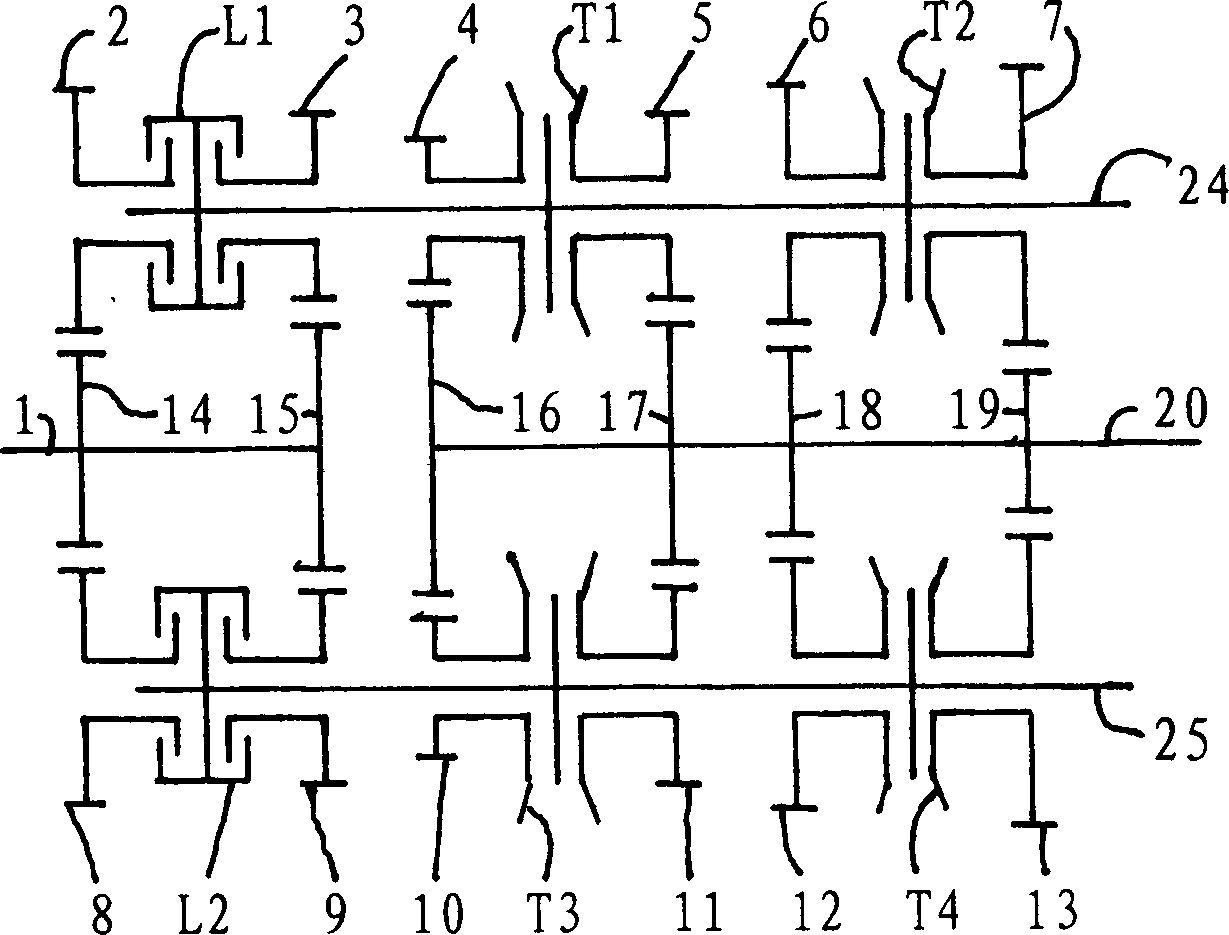

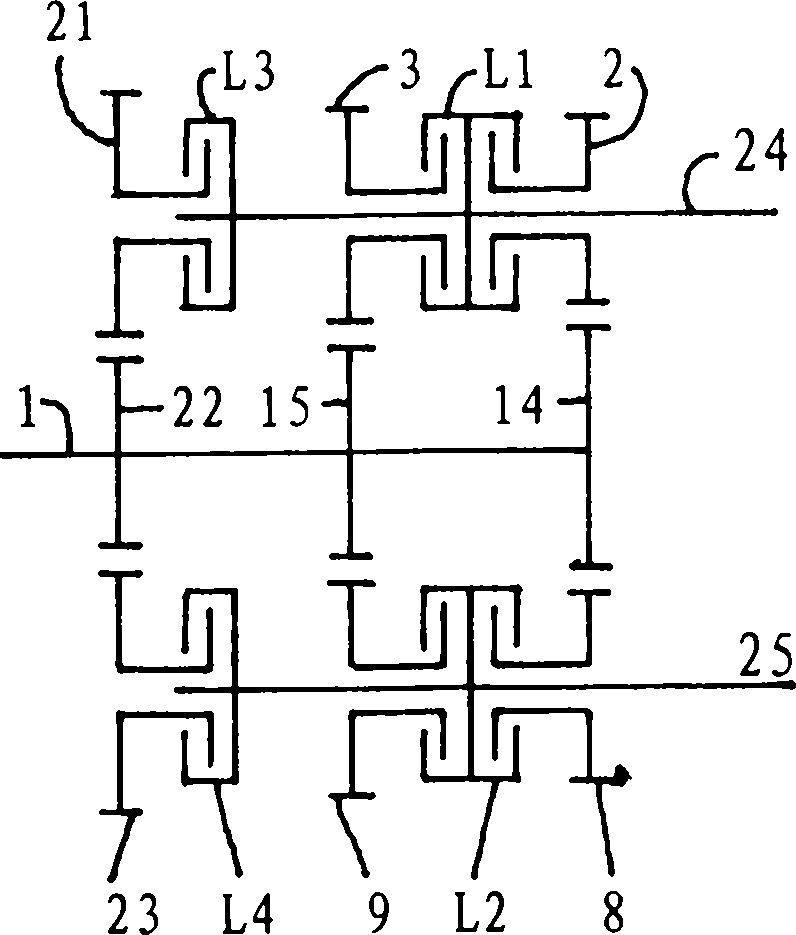

Multi-clutch type variable transmission device

The invention relates to a multi-clutch type variable transmission device and relates to a double-clutch variator. The multi-clutch type variable transmission device comprises an input shaft, a first auxiliary shaft, a second auxiliary shaft, an output shaft, double clutches, a synchronizer and gears. According to the multi-clutch type variable transmission device provided by the invention, by virtue of the combination of the two double clutches, the synchronizer and the gears, the gear is automatically and smoothly changed; by virtue of the structure of sharing the gears and adding one double clutch, the gear number is greatly increased, and the amount of gear shifting gear is reduced; and as each pair of gears adopt a small velocity ratio and a short transmission shaft structure, the rigidity of a variator is strengthened, the radial and axial sizes of the variator are reduced, and the structure of the variator is compact.

Owner:郭质刚

Motor and speed reducer integrated case and casting and welding method thereof

InactiveCN108539897AHigh degree of integrationLow costManufacturing dynamo-electric machinesSupports/enclosures/casingsWater channelReduction drive

The invention discloses a motor and speed reducer integrated case and a casting and welding method thereof. The case comprises an outer case body and an inner case body, wherein the outer case body comprises a motor case body and a speed reducer case body which are integrally formed through high-pressure casting; the inner case body is nested in the motor case body, a spiral water channel rib is arranged on the outer surface of the inner case body, and spaces of the spiral water channel rib form a spiral water channel by being matched with an outer wall of the inner case body and the inner wall of the motor case body. According to the motor and speed reducer integrated case, the integration degree is increased, end covers are reduced, the cost is reduced, the axial space is compressed, andthe NVH characteristic of a system is improved. According to the casting and welding method, the complexity of a manufacturing process is reduced through high-pressure casting, the batch efficiency is high, the wall thickness of the case is reduced, structures of process holes are omitted, and the radial space is compressed.

Owner:HEFEI JUYI POWER SYST CO LTD

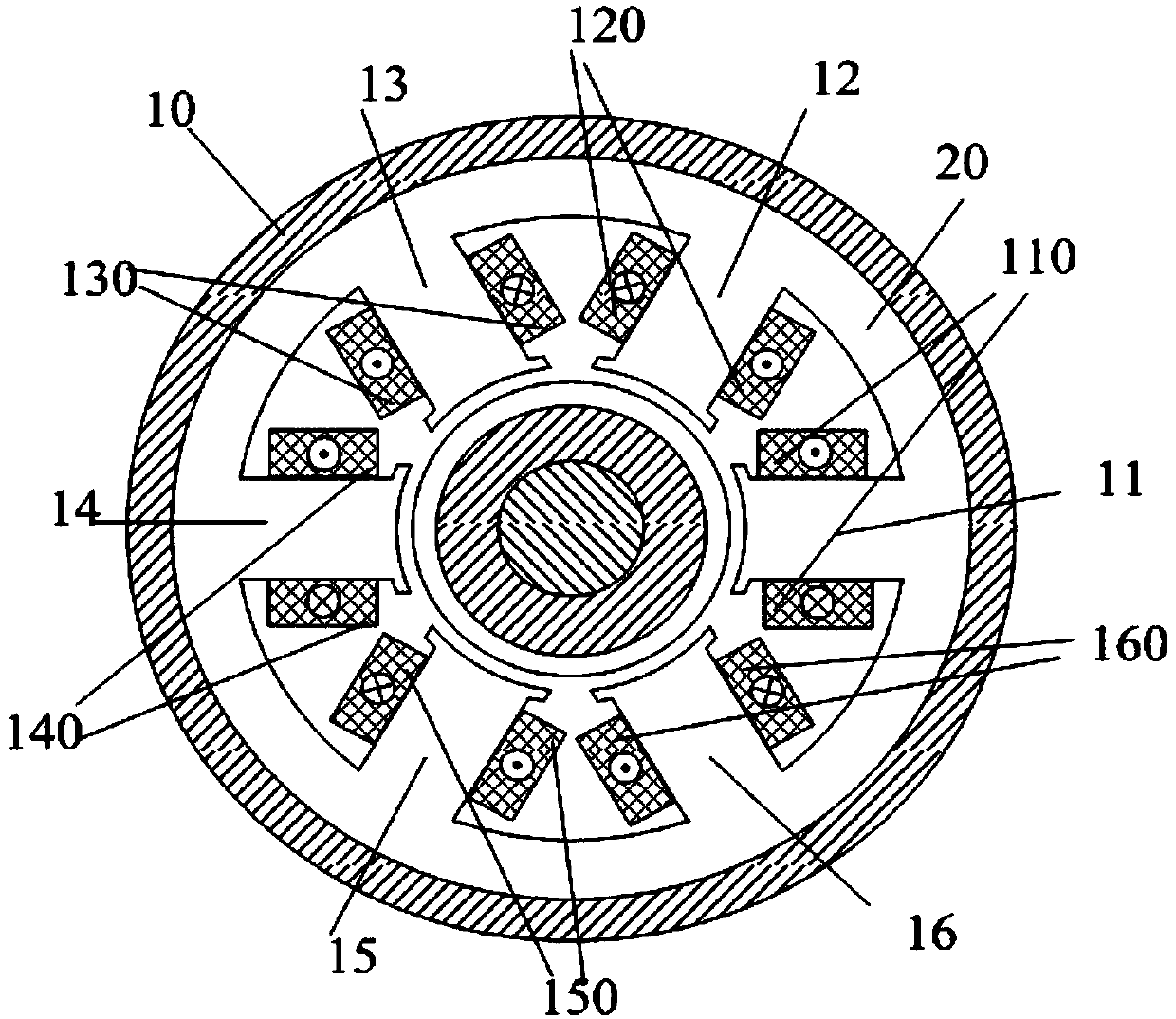

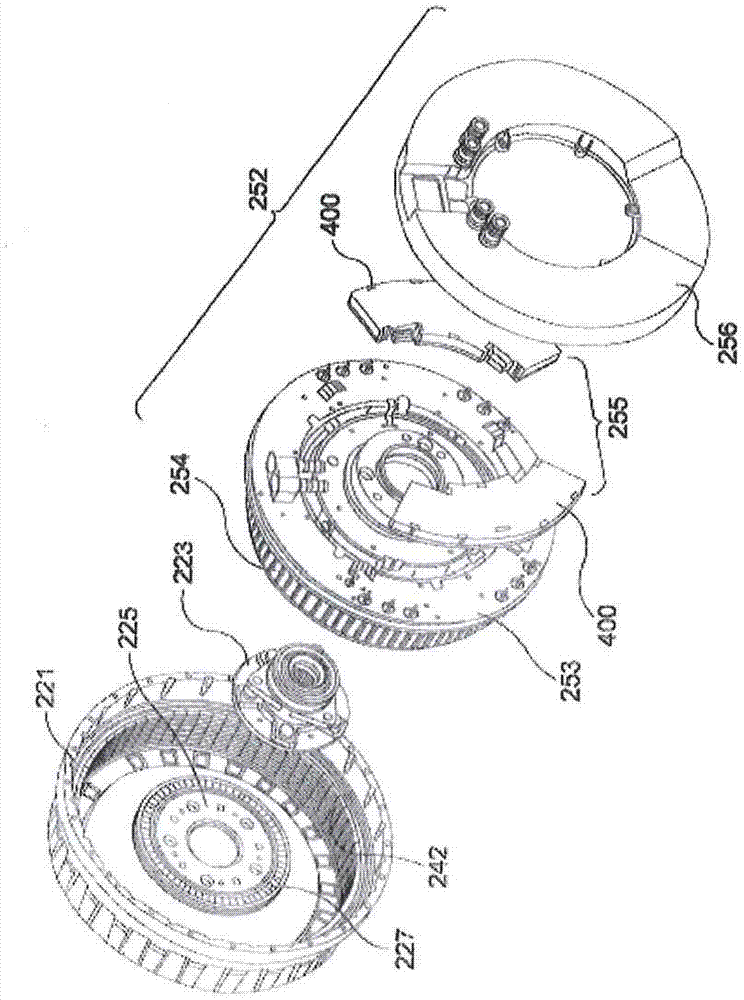

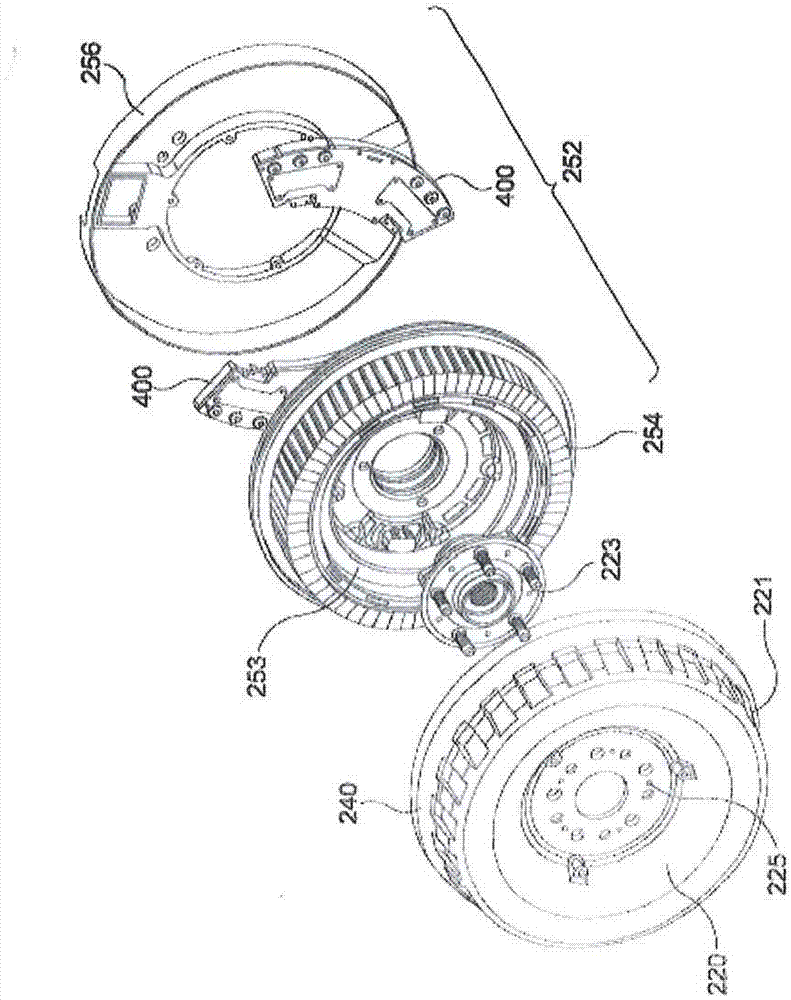

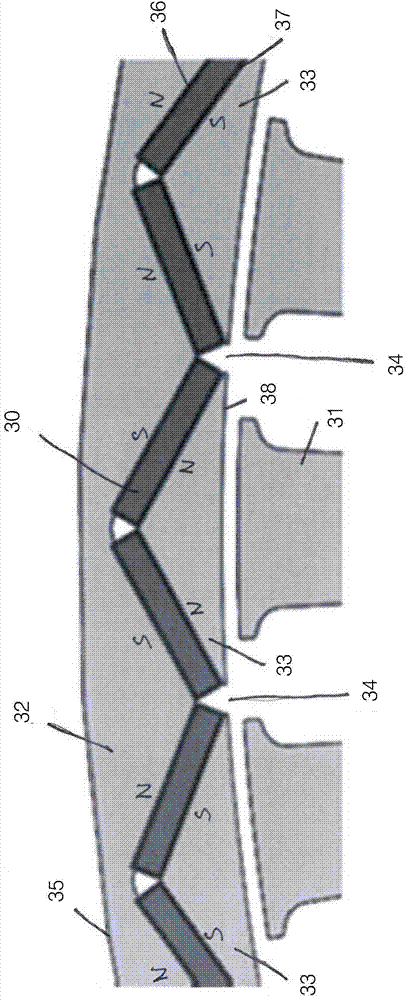

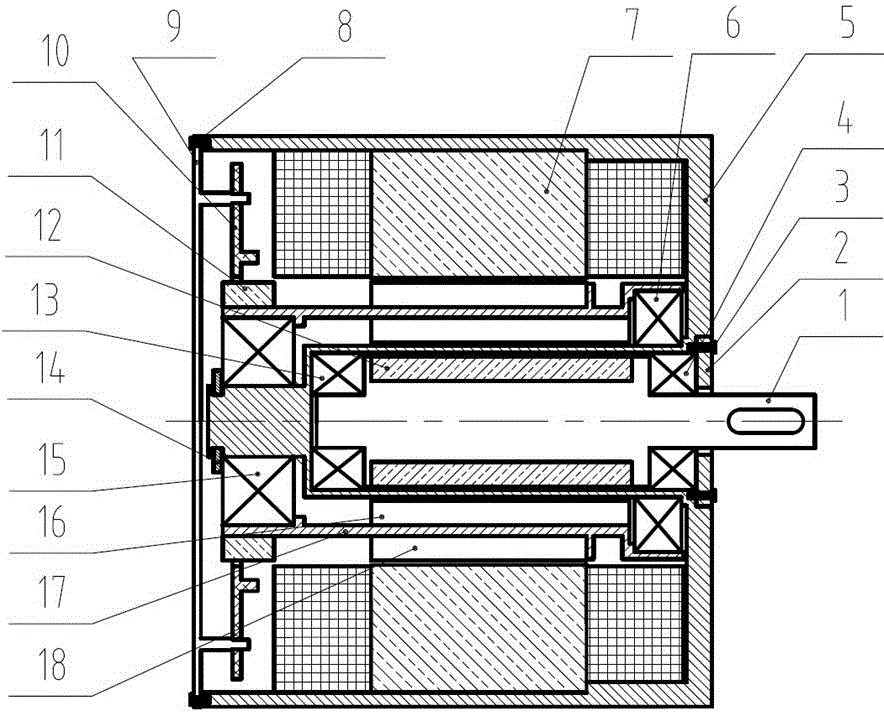

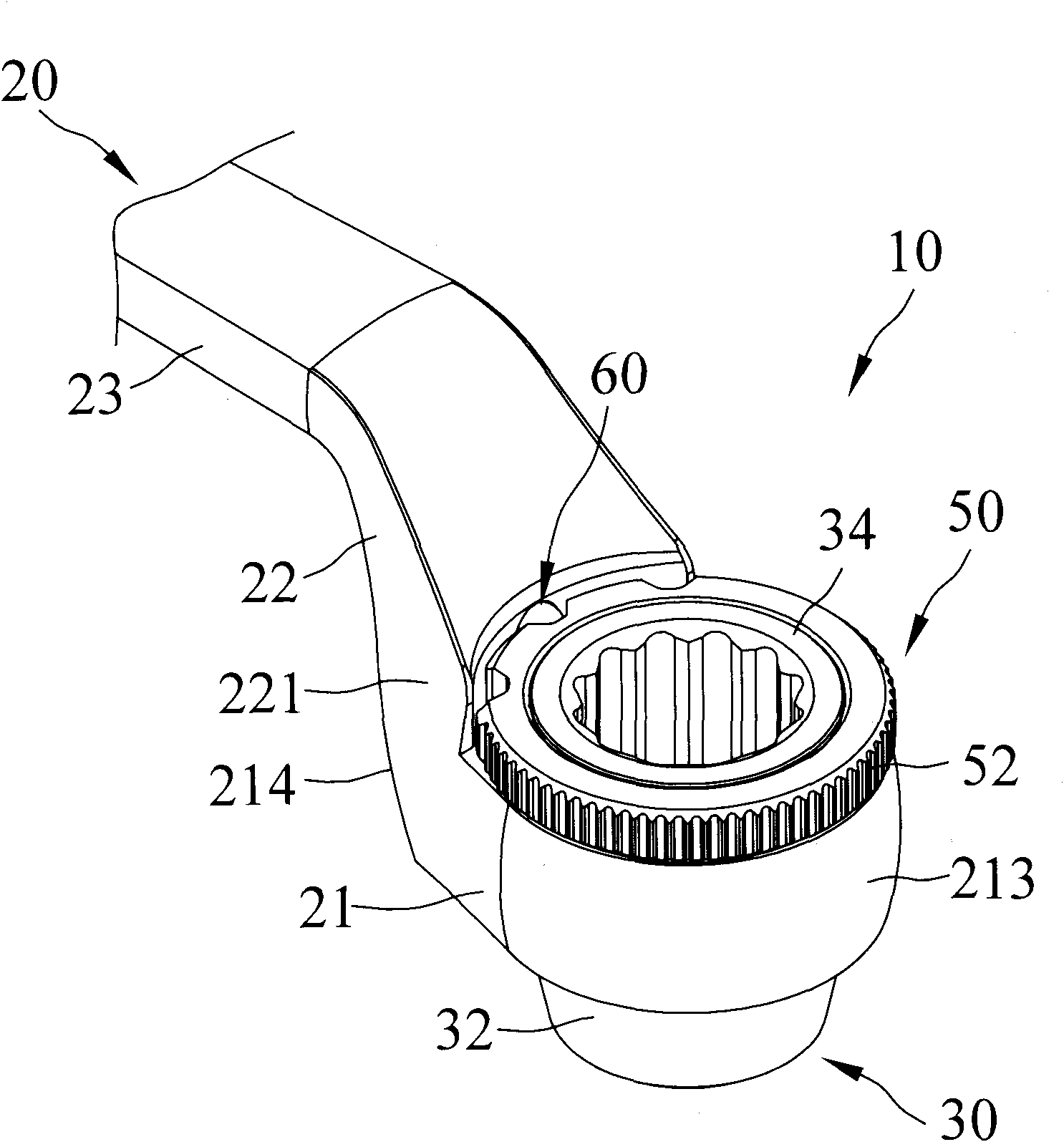

A rotor for an electric motor or generator

ActiveCN104767304AEfficient use ofSave radial spaceSpeed controllerMagnetic circuit rotating partsV formationRare earth

An external rotor for an electrical motor or generator (e.g. a wheel motor) has poles, each comprising a pair of rare earth permanent magnets 30 inclined towards each other in V formation. Soft ferromagnetic elements 32, 33 are arranged to retain the magnets, element 32 being mounted by its outer surface 35 to the inner rim of the rotor by means of adhesive or mechanical connectors, magnet surfaces 36 of each of the magnet pairs being adhesive mounted in V formation on the inclined inner surface of the element 32. Wedge shaped elements 33 are secured to the opposite face 37 of the magnets 30, and are arranged with respect to adjacent elements with an air gap 34 between respective end potions of the elements 33. Surface 38 of the element 33 forms the pole surface. The method of assembly may comprise magnetically holding the elements 33 to a former, securing the magnets 30 thereto, attaching the element 32 to the other faces of the magnets and subsequently mounting the circumferential potion of the rotor over element 32. The gap 34 may comprise a low reluctance material and the V assembly may be replaced by a single C shaped magnet.

Owner:PROTEAN ELECTRIC LIMITED

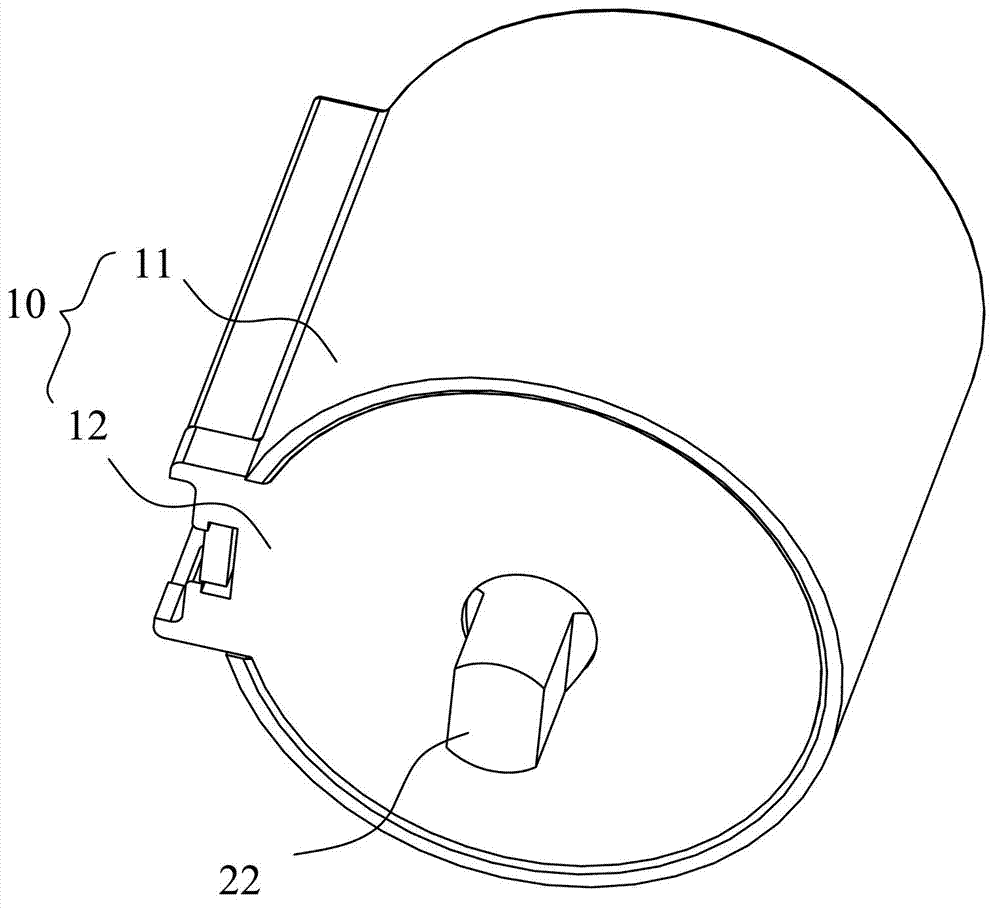

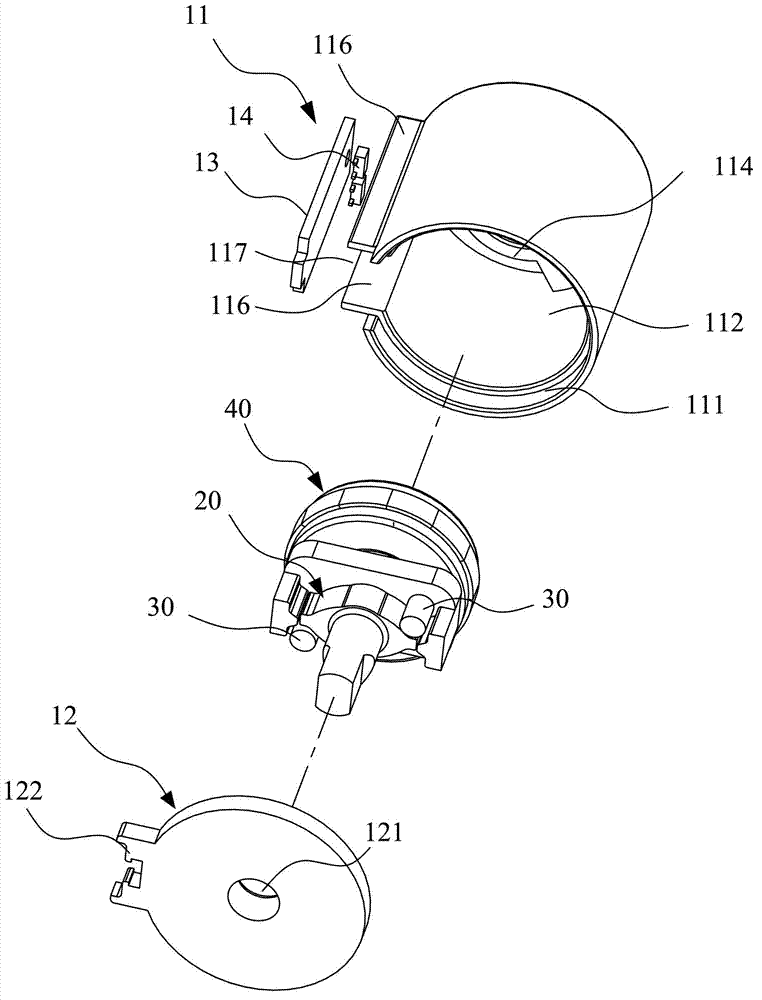

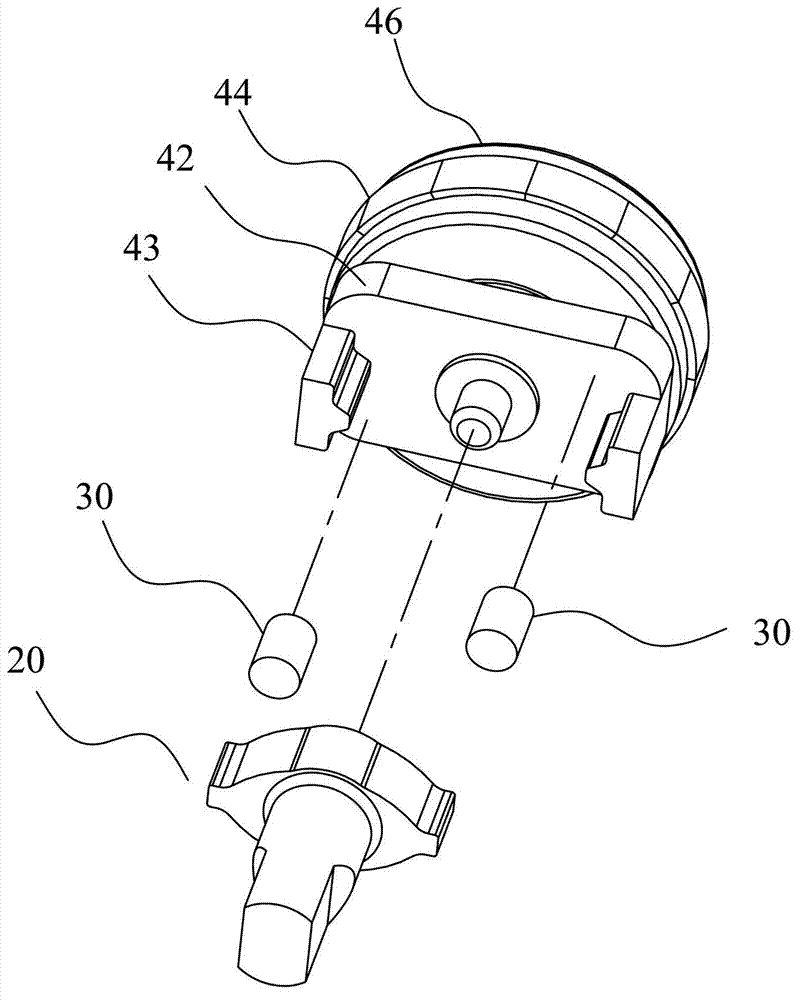

Built-in clutch and combined motor with same

ActiveCN103206468ARealize clutchGuaranteed running stabilityMagnetically actuated clutchesMechanical energy handlingEngineeringCam

The invention discloses a built-in clutch and a combined motor with the same. The clutch comprises a fixed shell and a clutch component in the shell. The shell comprises a shell body and a cover. The clutch component comprises a magnetic drive member, a non-magnetic driven member and a magnetic slider. The drive member and the driven member are connected concentrically. The drive member is a cam structure with first clamping parts on the outer side. The first clamping parts can drive the slider to rotate and guarantee that the slider does not move radially. The driven member is provided with at least one drive block relative to the outer side of the cam. The inner side of the drive block is provided with second clamping parts. The shell adjacent to the drive member is provided with a magnetic inner annular face. The end face of the slider always attaches to the inner annular face of the shell. The side of the slider always attaches to on the inner side wall between the first clamping parts. When the clutch is closed, the slider is located between the first clamping parts and the second clamping parts, and the drive member can drive the driven member to rotate simultaneously.

Owner:湖州荣辉进出口有限公司

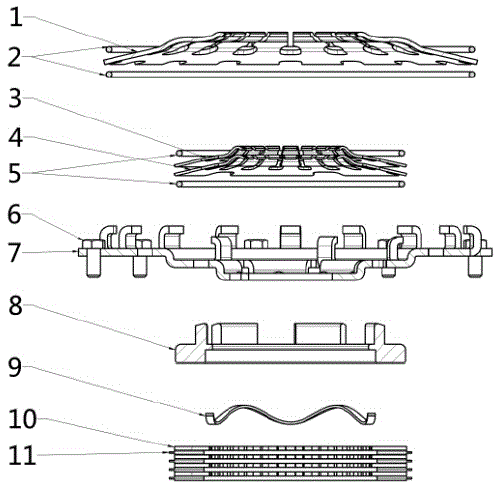

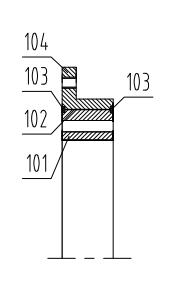

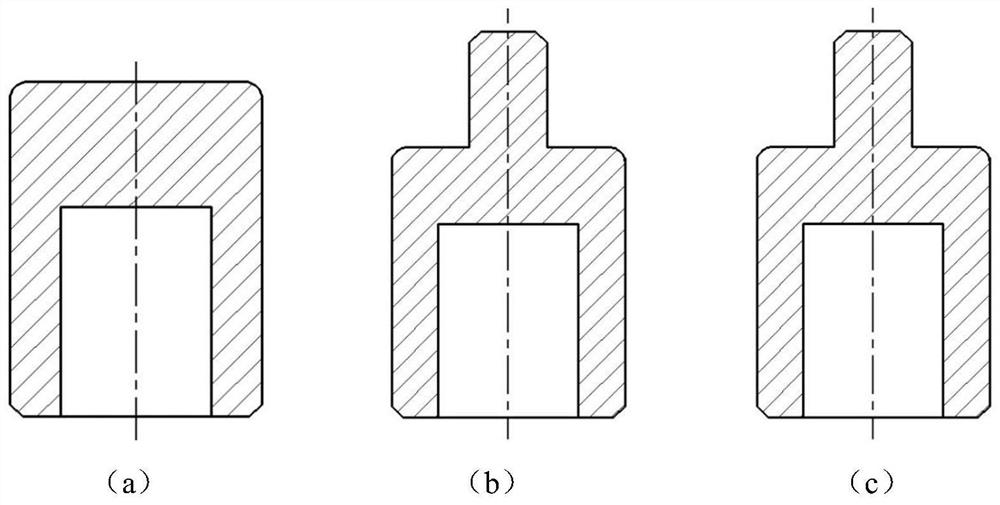

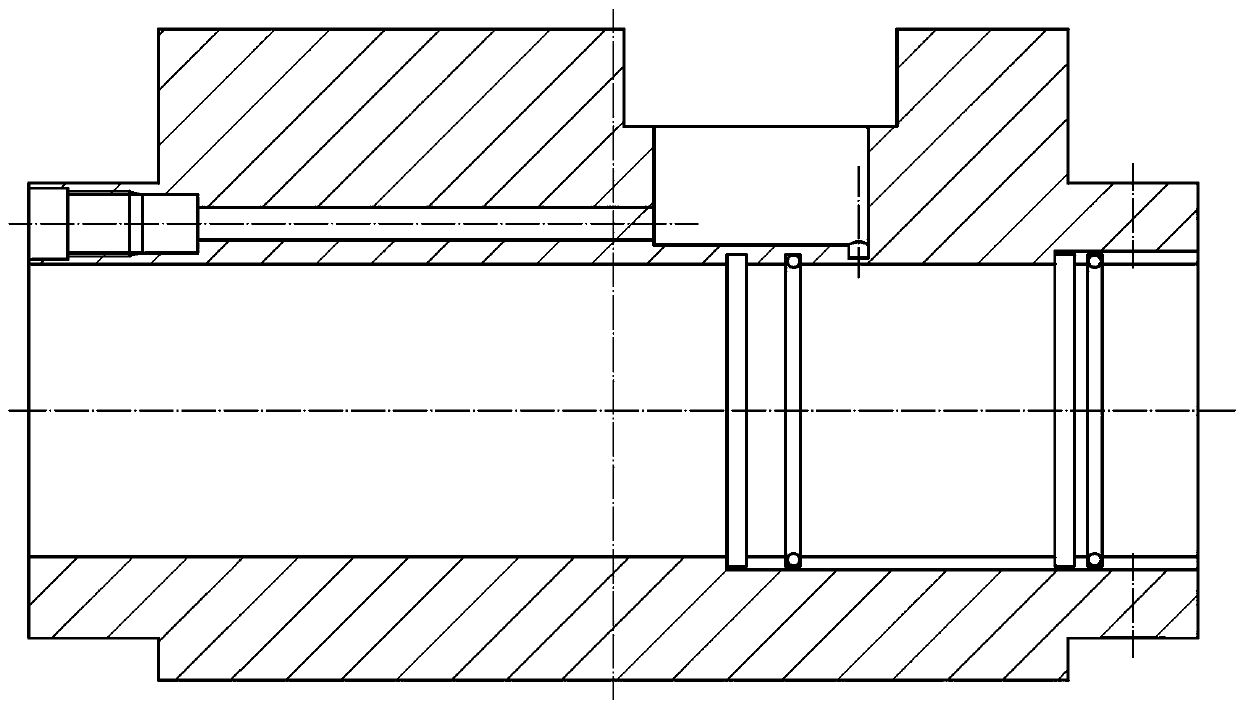

Assembly structure of insulating rolling bearing

InactiveCN102497071AProtection against galvanic corrosionSave radial spaceManufacturing dynamo-electric machinesFastenerCorrosion

The invention provides an assembly structure of an insulating rolling bearing. An insulating bearing sleeve of the assembly structure consists of a bearing sleeve and a sleeve ring, wherein an insulating washer is arranged between radial matching surfaces of the bearing sleeve and the sleeve ring, a polyimide film layer is padded between axial matching surfaces of the bearing sleeve and the sleeve ring, an annular groove is formed at a joint seam of the other radial end faces of the bearing sleeve and the sleeve ring, and epoxy resin strips are filled in the groove; and the insulating bearing sleeve is combined with the an end cover through a belleville spring and hex bolts, an insulating washer is arranged between the radial matching surfaces of the insulating bearing sleeve and the end cover, an insulating pipe is sleeved at an axial matched part of the hex bolts and the end cover, and an insulating washer is arranged between the radial matching surfaces of the belleville spring and the end cover. By adoption of the insulating bearing sleeve, and insulating devices are arranged between the insulating bearing sleeve and a radial abutted surface of the end cover, and between a fastening piece of the insulating bearing sleeve and the end cover and an abutted surface of the end cover, the assembly structure disclosed by the invention can reliably block a shaft current path between a bearing assembly and the end cover, and then protect the bearing from electro-corrosion. The assembly structure disclosed by the invention saves the radial space, and is particularly suitable for occasions on which the radial space for bearing assembly is limited.

Owner:SEC ELECTRIC MACHINERY

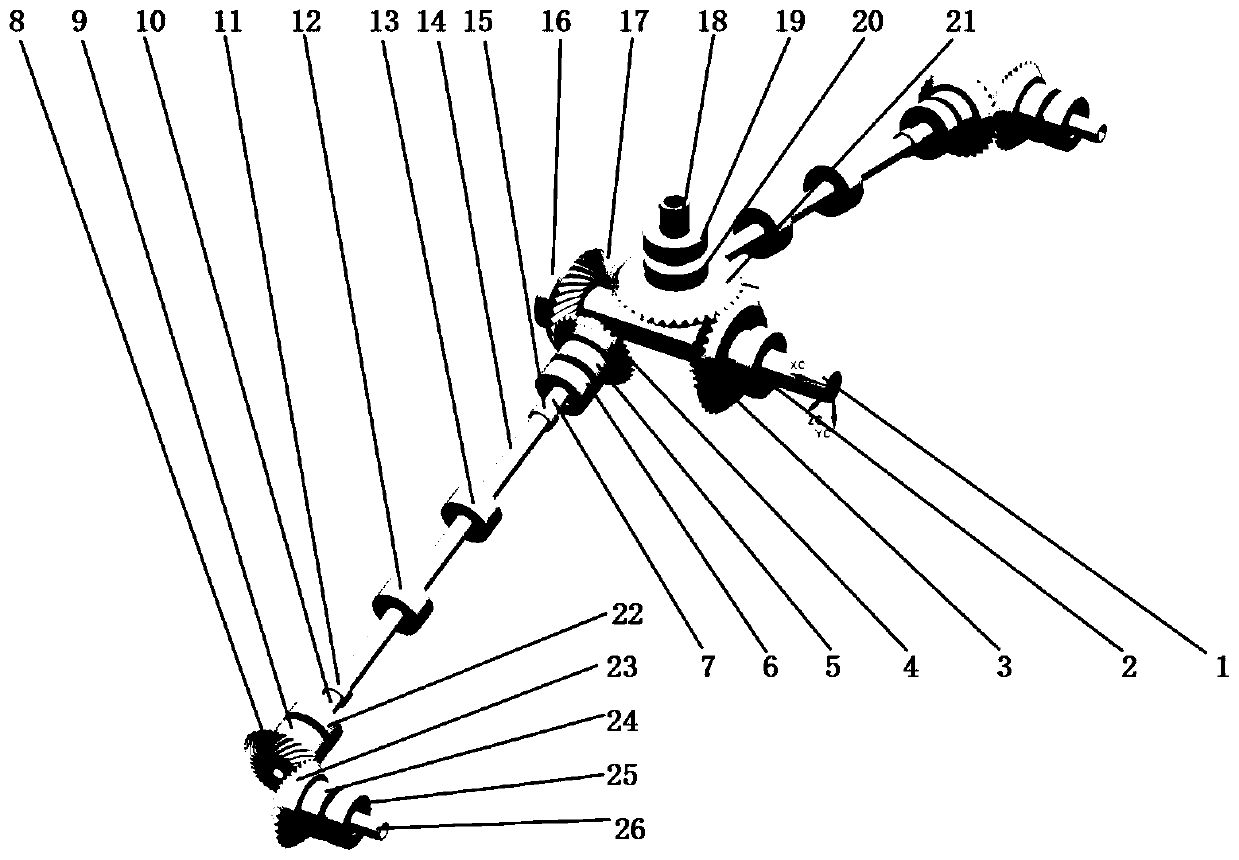

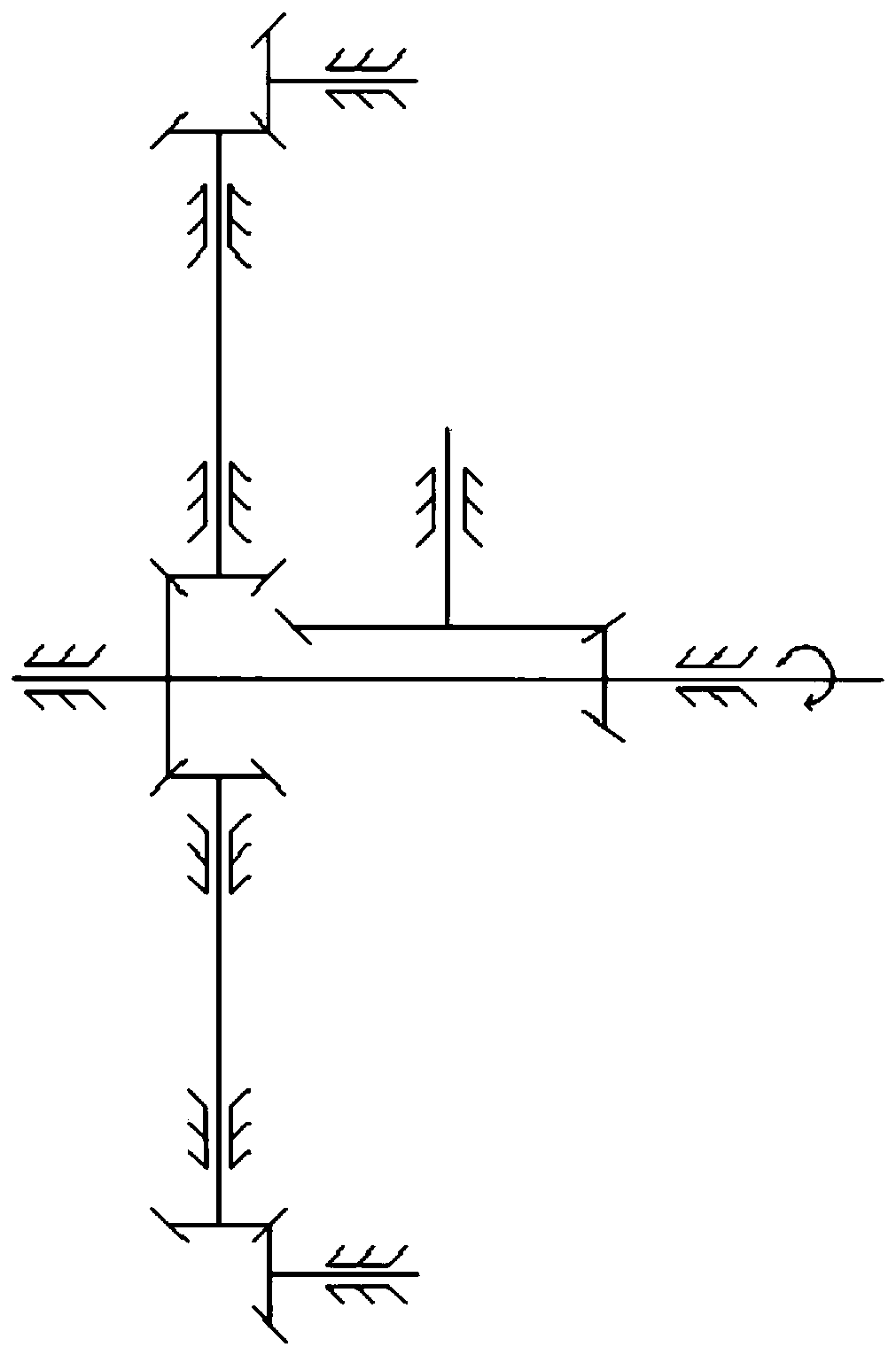

High-speed helicopter transmission system

InactiveCN110920912AEliminate axial forceImprove stabilityAircraft power transmissionAviationPropeller

The invention relates to a high-speed helicopter transmission system, which belongs to the field of space flight and aviation, comprises a main rotor transmission subsystem and a propeller transmission subsystem, adopts a pure bevel gear train in structure, and consists of a propeller horizontal reversing bevel gear pair, a main rotor vertical reversing bevel gear pair and a two-wing horizontal reversing bevel gear pair. Power is input through a helicopter main reduction shaft. Power is transmitted through two paths to drive the main rotor and the two-wing propellers respectively, wherein onepath is transmitted from the main reduction shaft to the propeller horizontal reversing bevel gear pair and the two-wing propeller bevel gear pair and then horizontally reverses through the two-wing propeller bevel gear pair to drive the propeller, and the other path is transmitted from the main reduction shaft to the main rotor vertical reversing bevel gear pair and then drives the main rotor torealize power output. While two functions of driving the main rotor wing by vertical reversing of power and driving the propeller by horizontal reversing are realized, the structure is compact, the weight is light, the transmission efficiency is high, the stability is good, the stable driving capability is realized, and the medium-high speed transmission is realized.

Owner:CHONGQING UNIV

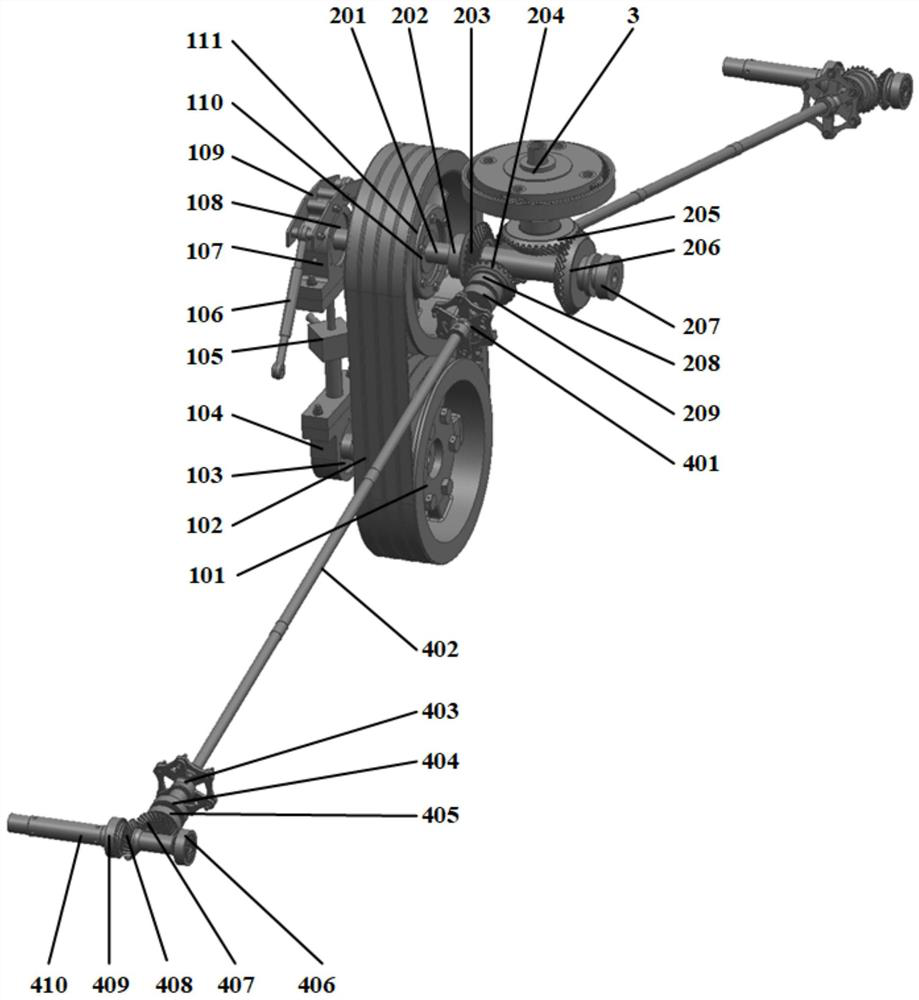

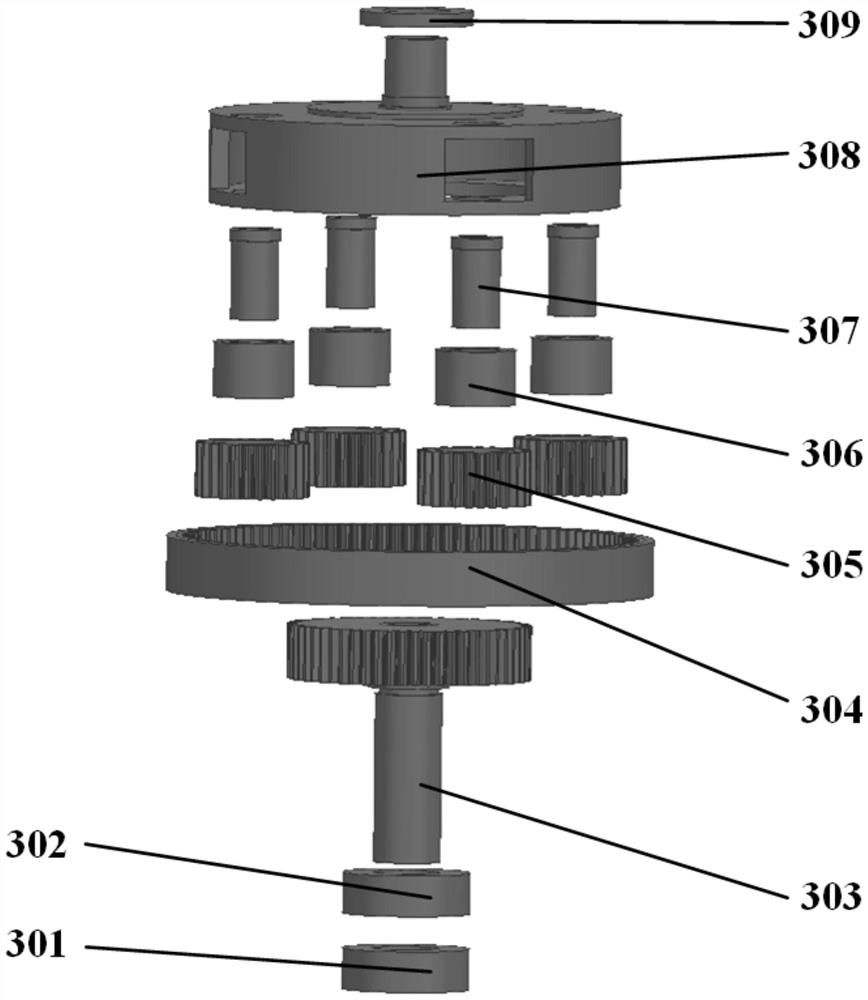

Wheel edge planetary gear speed reducer for electric formula racing car

The invention relates to a wheel edge planetary gear speed reducer for an electric formula racing car. The wheel edge planetary gear speed reducer for the electric formula racing car comprises a planetary gear mechanism, a double-web planet carrier mechanism and a gear box mechanism. According to the wheel edge planetary gear speed reducer for the electric formula racing car, the form of planetarygear sets arranged in series is used to replace the form of a single planetary row or a plurality of planetary rows in the prior art, so that the structure of the speed reducer is simplified, and therequirement on a large speed ratio of the speed reducer in a limited wheel edge installation space of the electric formula racing car is realized.

Owner:BEIHANG UNIV

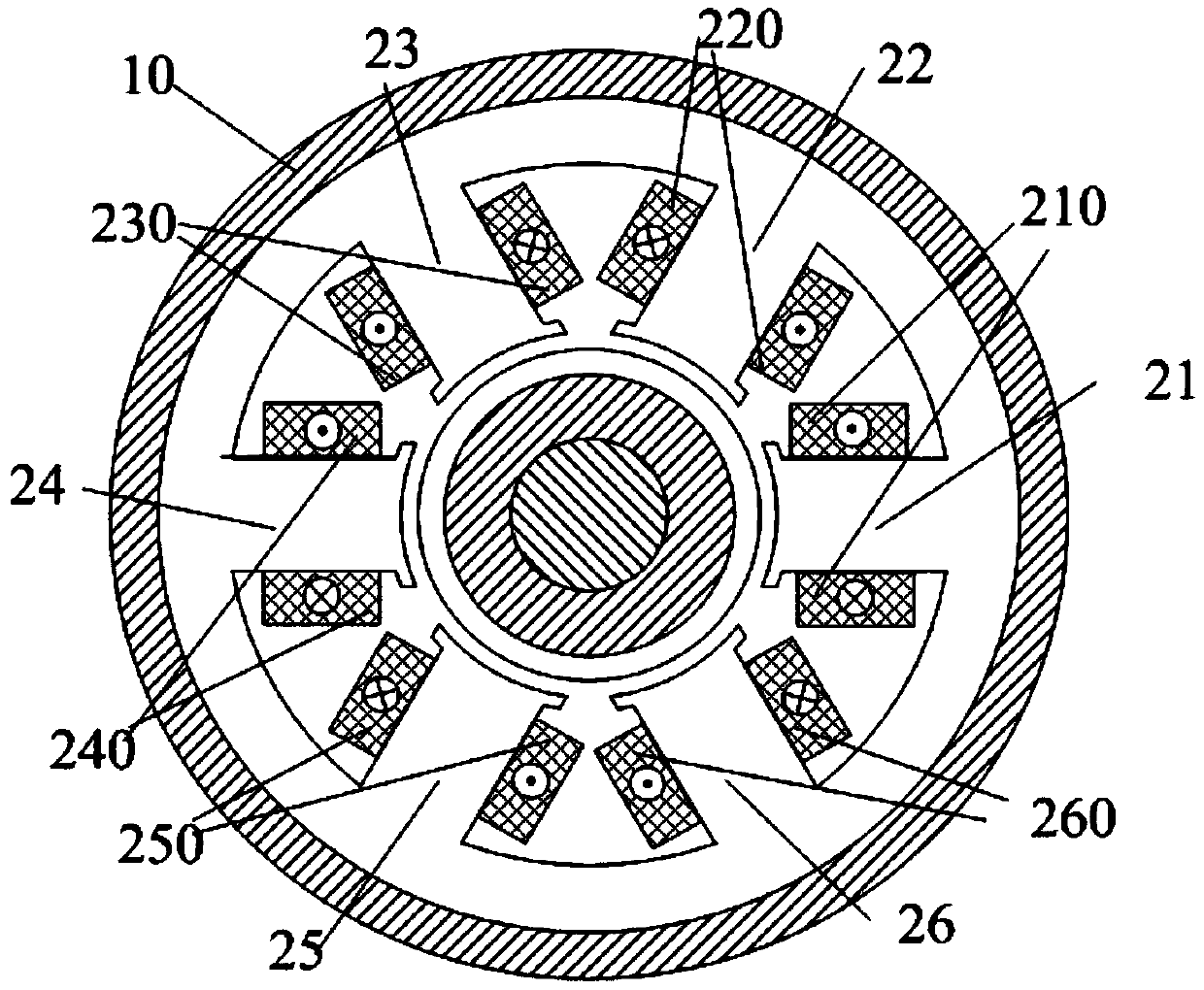

Compact-structure type magnetic coupling driving motor

ActiveCN106487201AAxial space savingSave radial spacePermanent-magnet clutches/brakesStructural associationControl theoryStructure type

The invention provides a compact-structure type magnetic coupling driving motor. The magnetic coupling driving motor comprises a motor shell, and an inner stator, an inner rotor and an inner rotary shaft positioned in the motor shell, wherein the inner rotor adopts a cylindric shape; the two ends of the inner rotor are connected with an inner rotor front end bearing and an inner rotor back end bearing respectively; inner rotor inner magnets and inner rotor outer magnets are uniformly distributed on the inner and outer side walls of the inner rotor; the inner rotary shaft is arranged in the inner rotor in a sleeving manner; the inner rotary shaft coincides with the axle wire of the inner rotor; the two ends of the inner rotary shaft are connected with an inner rotary shaft front end bearing and an inner rotary shaft back end bearing respectively; inner rotary shaft permanent magnets corresponding to the inner rotor inner magnets of the inner rotor are also fixed on the inner rotary shaft; and the inner rotor and the inner rotary shaft are subjected to physical isolation. The compact-structure type magnetic coupling driving motor has the beneficial effects of capability of satisfying flexible connection requirement, skillful layout, compact structure, high magnetic field efficiency of the permanent magnets, high sealing property, and capability of saving the axial space of the motor.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

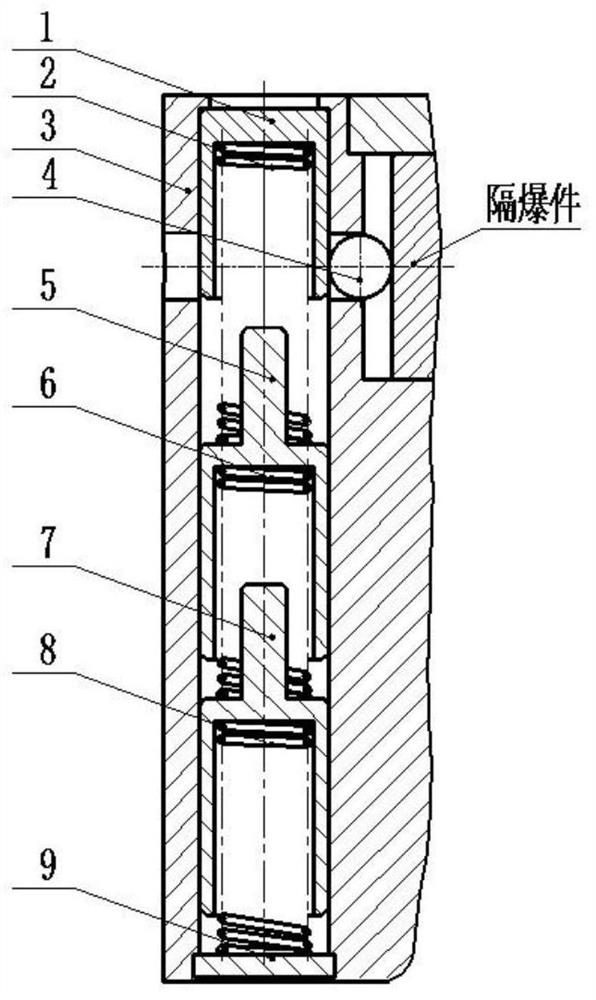

Fuse three-degree-of-freedom recoil safety mechanism

PendingCN113804070AReliable identification of emission overloadsReliably distinguish between environmentsAmmunition fuzesStructural engineeringControl theory

The invention discloses a fuse three-degree-of-freedom recoil safety mechanism. The fuse three-degree-of-freedom recoil safety mechanism comprises an upper inertia cylinder, an upper inertia spring, a body, a secured piece, a middle inertia cylinder, a middle inertia spring, a lower inertia cylinder, a lower inertia spring and a bottom cover, two channels which vertically communicate with each other are arranged in the body, the secured piece is arranged in the channel which is vertical to the axis of the body, the upper inertia cylinder, the upper inertia spring, the middle inertia cylinder, the middle inertia spring, the lower inertia cylinder and the lower inertia spring are sequentially connected in series in the channel parallel to the axis of the body, the two ends of an inertia mechanism are limited by the body and the bottom cover, and the bottom cover is fixedly connected with the body. The fuse three-degree-of-freedom recoil safety mechanism is simple in structure, small in occupied radial space, low in cost, high in applicability, capable of recognizing launching overload of 30 g or even lower and capable of guaranteeing safety when a fuse falls to a hard target and a soft target in any posture.

Owner:NANJING UNIV OF SCI & TECH

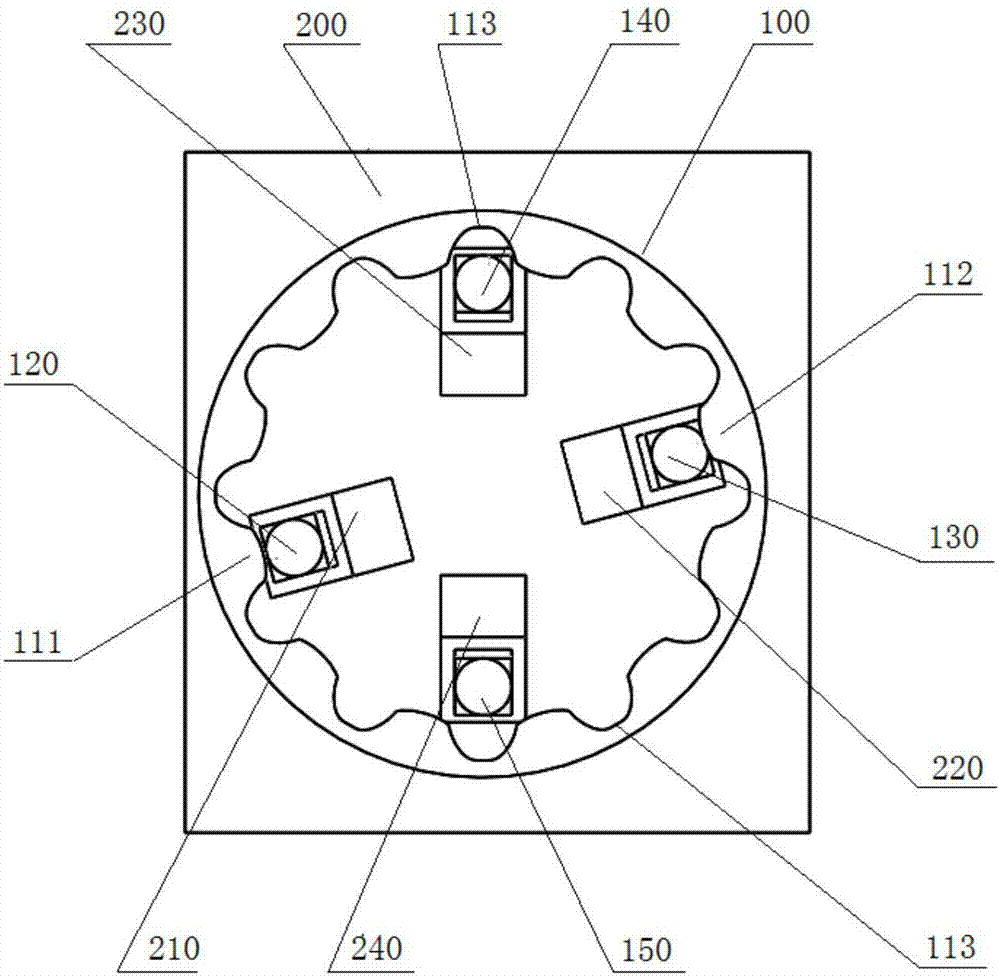

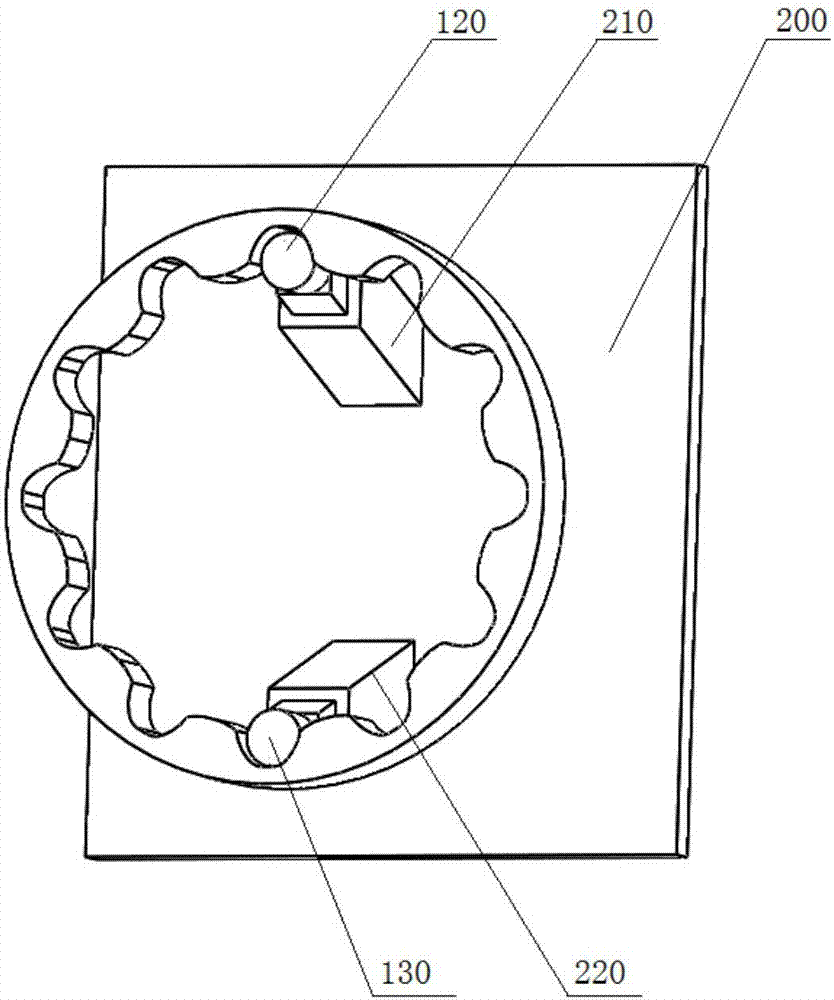

Automatic parking brake used for transmission and control method thereof

ActiveCN108006222ASave radial spaceSimple structureGearing controlWind energy generationAutomatic transmissionEngineering

The invention discloses an automatic parking brake used for a transmission. The automatic parking brake used for the transmission comprises an interconnected ratchet; the interconnected ratchet is inan annular disk shape and a plurality of ratchet teeth are arranged at an inner ring of the interconnected ratchet along the circumferential direction; a first group of electromagnetic execution mechanisms comprise two electromagnetic execution mechanisms arranged opposite to each other along the radial direction of the interconnected ratchet and the electromagnetic execution mechanisms are mounted on a transmission shell body; the ends, which are close to the interconnected ratchet, of the electromagnetic execution mechanisms are fixedly connected with parking pawls; the structure of a secondgroup of electromagnetic execution mechanisms is the same with the first group of electromagnetic execution mechanisms; wherein, the parking pawls of the first group of electromagnetic execution mechanisms and the second group of electromagnetic execution mechanisms are capable of getting into or getting out from the interconnected ratchet; when the two parking pawls of the first group of electromagnetic execution mechanisms correspond to the positions of the ratchet teeth, the two parking pawls of the second group of electromagnetic execution mechanism correspond to the positions of the bottoms of the ratchet teeth. The automatic parking brake used for the transmission provided by the invention is simple in structure, smaller in occupied space and capable of improving parking success rate.

Owner:JILIN UNIV

Novel friction clutch and separating and combining device thereof

InactiveCN102278384BImprove transmission efficiencyStable clutch functionFriction clutchesDrive shaftControl system

The invention provides a novel friction clutch. The friction clutch provided by the invention mainly comprises an outer driving disk cover, an inner driving disk sleeve, a release bearing, internal friction pieces, an external friction piece, a driving shaft and a driven shaft, wherein the outer driving disk cover is connected with the driving shaft; the release bearing bell is sleeved on the outside of a sliding sleeve, the sliding sleeve is sleeved outside a lining, the sliding sleeve and the lining are sleeved on the driving shaft or the driven shaft; the external friction piece is connected with the outer driving disk cover and positioned between two internal friction pieces, and a thick washer is arranged between the two adjacent internal friction pieces. The friction clutch is characterized in that the release bearing is connected with a separating and combining device which mainly comprises a combining mechanism, a separating mechanism, and a permanent connecting mechanism, wherein the combining mechanism and the separating mechanism are respectively connected with the permanent connecting mechanism. The clutch provided by the invention has the advantages of stable on-off function, large transmission torque, small abrasion, high transmission efficiency, good heat dispersion, low failure rate and small radial space; when the clutch is used on a motorcycle, the existing manual control system or pedal operating system can be utilized, thereby completing the functions of combination and separation.

Owner:姜成立

Gear combined type variable-speed transmission device

The invention relates to a gear combined type variable-speed transmission device. The gear combined type variable-speed transmission device consists of an input shaft, an output shaft, an intermediate shaft, clutches (or synchronizers) and gears. More than 6 clutches or one clutch and more than 6 synchronizers and more than 9 gears are combined in serial-parallel connection modes, the gear number is remarkably increased, and the number of shifting gears is decreased. Due to the fact that each pair of gears has small speed ratio and adopts a short transmission shaft structure, the rigidity of a transmission is improved, the radial and axial sizes are reduced, and the transmission is compact in structure and high in mechanical efficiency. The invention further provides a reverse gear device used on a mechanical variable-speed transmission mechanism.

Owner:郭质刚

Crane wheel

ActiveCN114538276AReduce volumeCompact structureToothed gearingsGearing detailsDrive wheelElectric machinery

The invention relates to a crane wheel which comprises a cylindrical hub, a circular shaft seal end cover is fixed to one side of the hub, an annular shaft seal baffle ring is fixed to the other side of the hub, an inner gear ring is arranged on the inner surface of the hub, and a planetary speed reduction module is arranged in the hub. The planetary speed reduction module comprises a central rotating shaft, a first-stage planet carrier, a second-stage planet carrier, a first-stage sun gear and a second-stage sun gear, and planet gears on the first-stage planet carrier and the second-stage planet carrier are meshed with an inner gear ring of the hub; the inner gear ring is arranged on the inner surface of the hub, the planet wheels on the first-stage planet carrier and the second-stage planet carrier are both engaged with the inner gear ring of the hub, so that the output shaft of the driving motor drives the hub to rotate through two-stage planet speed reduction, and the structure of the wheel is compact through the mode that the planet speed reduction module is integrated in the hub; the size of a crane traveling mechanism can be effectively reduced, so that the crane wheel is compact in structure.

Owner:HENAN DONGQI MACHINERY

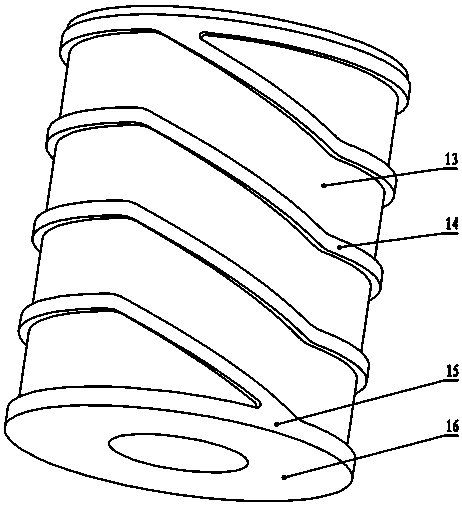

Recirculation structure for turbo chargers

InactiveCN100395432CEasy to moveImprove efficiencyPump componentsBlade accessoriesFree edgeWaste management

Recirculation structure for turbocompressors, having a ring chamber which is arranged in the area of the free blade ends of a blade ring largely upstream of the latter and adjoins the main flow duct. A plurality of guiding elements are arranged in the ring chamber distributed over its circumference and are arranged and shaped in a fluidically advantageous manner with respect to the recirculation flow, with recesses provided in the leading and / or trailing area of the ring chamber. The side of the ring chamber which adjoins the contour of the main flow duct is open along its axial length as well as along its entire circumference, the free edges of the guiding elements being situated on the or close to the contour of the main flow duct.

Owner:MTU AERO ENGINES GMBH

A low-speed high-torque single-stage reducer electric wheel

ActiveCN107599824BSave radial spaceAvoid interferenceBraking element arrangementsMotor depositionTime rangeLow speed

The invention discloses a low-speed large-torque single reduction gear electric wheel, and belongs to the technical field of off-road vehicle chassis. The low-speed large-torque single reduction gearelectric wheel includes a hub device; a drive device arranged in the hub device; a supporting device connected to the drive device, wherein the hub device is movably arranged on the supporting device;a transmission device, wherein a first end of the transmission device is connected to an output end of the drive device, and the transmission device is arranged in the supporting device; a reducer arranged in the hub device, wherein the reducer is connected to a second end of the transmission device; a travel brake device arranged on the drive device, wherein the travel brake device is connectedto the hub device; a parking brake device connected to the drive device, wherein the parking brake device is arranged on an output end of the drive device. The low-speed large-torque single reductiongear electric wheel can achieve electric wheel driving, travel braking, parking braking, and heat dissipation in a designated time range.

Owner:SPECIAL VEHICLE TECH CENT OF HUBEI AEROSPACE TECH RES INST

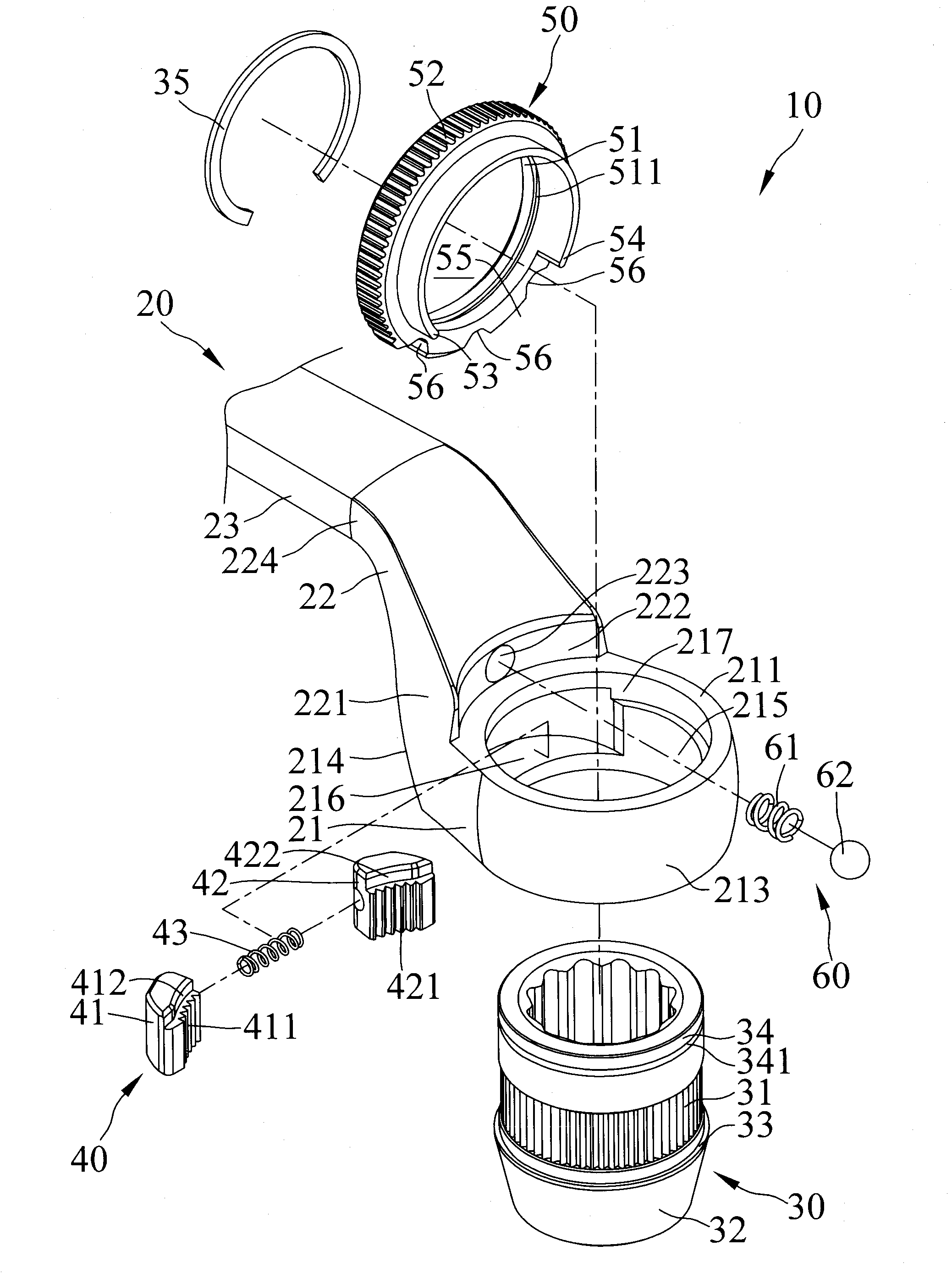

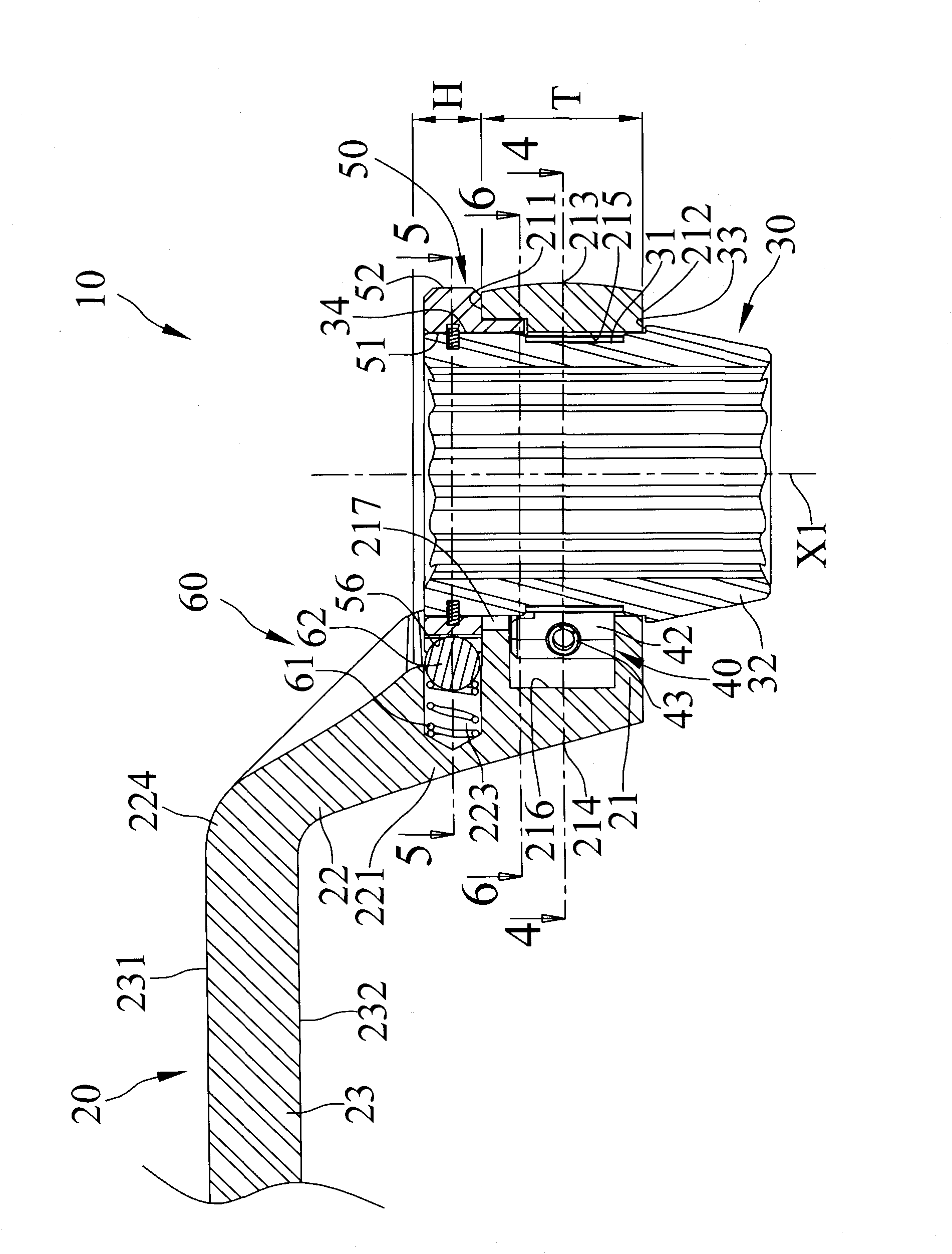

Ratchet wrench with head capable of being shrunk

The invention relates to a ratchet wrench with a head capable of being shrunk. The ratchet wrench comprises a body, a driving piece, a ratchet device and a reversing switch, wherein the body comprises the head, a connecting segment connected with one surface of the head, and a handle body arranged at the connecting segment oppositely to one end of the head, and a longitudinal connecting part connected with one surface of the head is formed at one end of the connecting segment; the driving piece is rotatably arranged at the head of the body; the ratchet device can be selectively meshed with the driving piece; and the reversing switch is pivoted with the driving piece and can control the ratchet device, a stirring ring of the reversing switch is tied and exposed outside the first surface of the head of the body and corresponds to the outer surface of the head of the body, and therefore, a user can stir the stirring ring of the reversing switch by the outer surface of the head of the body, thereby effectively reducing the radial distance of the head and achieving the effect of shrinking the head of the body.

Owner:胡厚飞

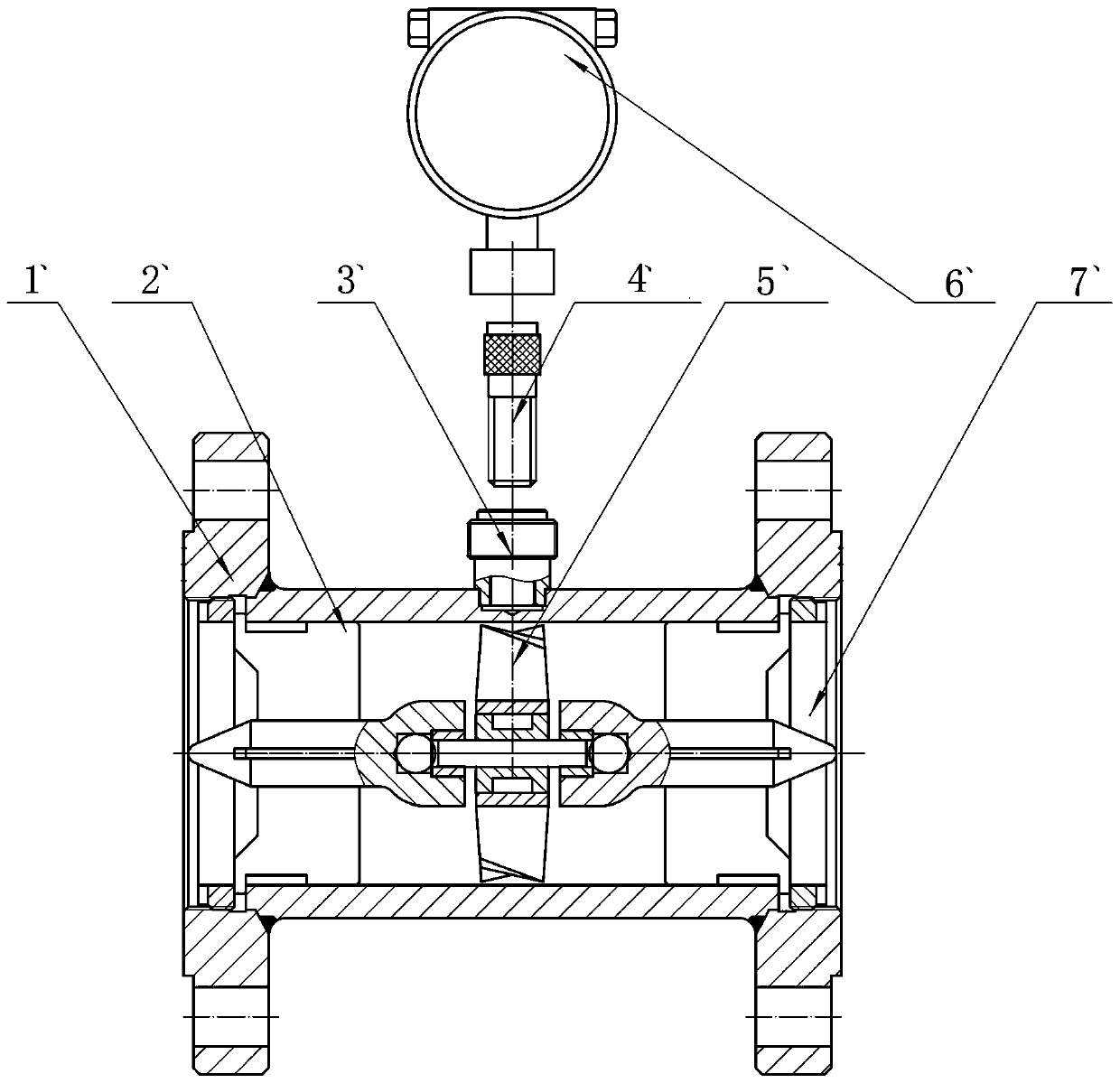

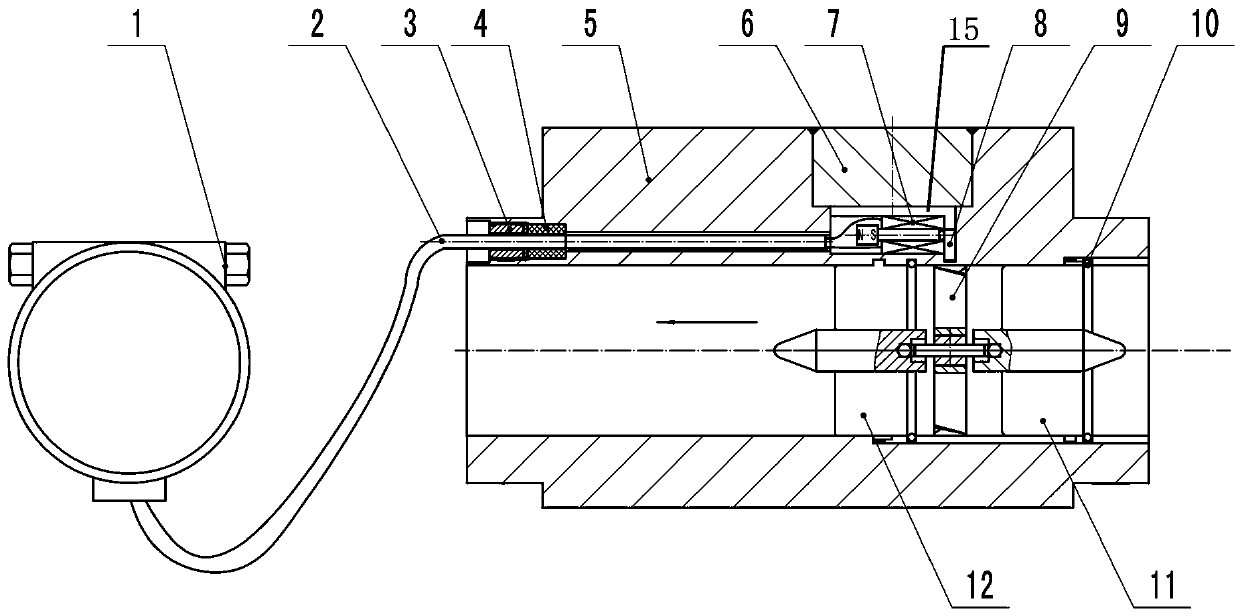

Parallel turbine flow sensor

PendingCN110044425ASave radial spaceSatisfy the use environmentVolume/mass flow by electric/magnetic effectsVolume/mass flow by dynamic fluid flow effectImpellerAudio power amplifier

The present invention discloses a parallel turbine flow sensor, including a casing, an impeller assembly, and front and rear flow guiding members. The front guiding member, a front guiding member pressing member, the impeller assembly, and the rear guiding member, and the rear guide member pressing member are sequentially installed from one end of the housing. A detection groove is disposed on anouter side wall of the casing, and a signal detector in which an iron core is parallel to a rotating shaft of the impeller assembly is disposed in the detection groove. A signal output end of the signal detector is connected to a wire, and the wire is connected to a signal input end of a signal amplifier. A sealing block is mounted in the detection groove outside the signal detector. An expanded core perpendicular to the iron core of the signal detector is disposed between the other end of the signal detector relative to the other end of an outlet and an inner wall of the detection groove. Theexpanded core corresponds to the position of the impeller assembly, and the upper end of the expanded core and the right end of the iron core of the signal detector are fitted. A fastening seal assembly is disposed at the outer end of the through hole through which the wire passes.

Owner:KAIFENG INSTR

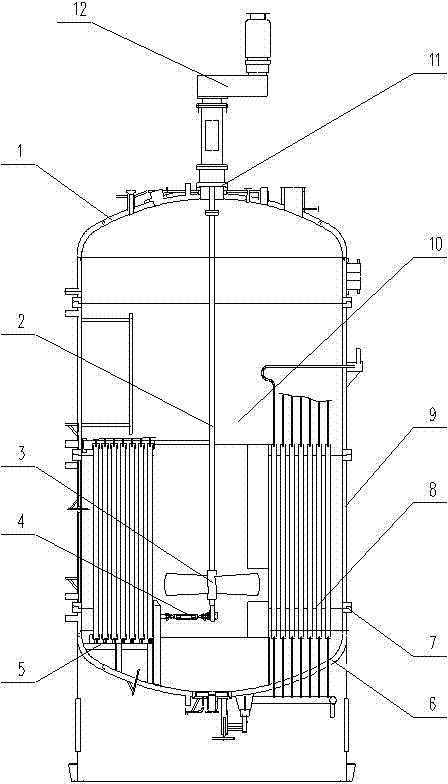

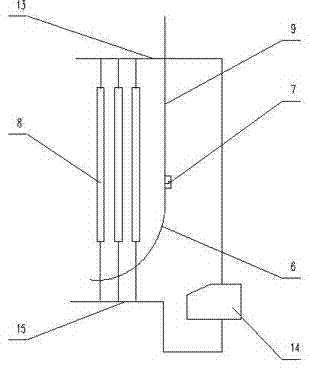

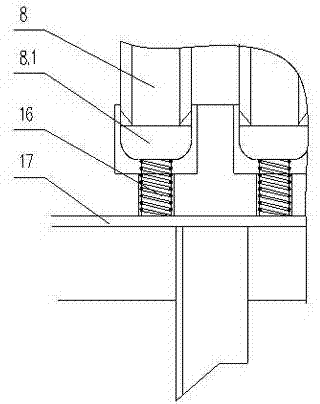

Esterification reactor

ActiveCN103170298BEasy to install on siteEasy to disassembleOrganic compound preparationCarboxylic acid esters preparationEngineeringFlange

The invention relates to an esterification reactor, comprising a reactor barrel, and a heating device and a top stirrer which are arranged in the reactor barrel, wherein the top stirrer is provided with a main spindle, a stirrer driving device is connected to the upper end of the main spindle, the reactor barrel is formed by an upper end enclosure, a middle barrel body and a lower end enclosure which are connected with one another in sequence by flanges with slot structures, all the slot structures are processed by a large vertical lathe, the heating device comprises a plurality of vertical heating barrels which are connected with an evaporator by corresponding inlet and outlet guide pipes, and the heating barrels, the guide pipes and the evaporator form a vacuum system with unpowered circulation of heating mediums. The esterification reactor is suitable for a current large equipment processing technology, the coaxiality of the internal parts is high, and the esterification reactor has a simple and reasonable structure and is convenient to transport, install and maintain, so that an ultra-large esterification reactor becomes possible.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com