Compact-structure type magnetic coupling driving motor

A compact, magnetic coupling technology, applied in structural connections, permanent magnetic clutches/brakes, electrical components, etc., can solve problems such as low efficiency of magnetic field utilization, increasing the axial size of the pump, and limiting the installation space of the magnetic coupling pump. Achieve the effect of compact structure, shortened axial dimension, and meet the needs of flexible connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

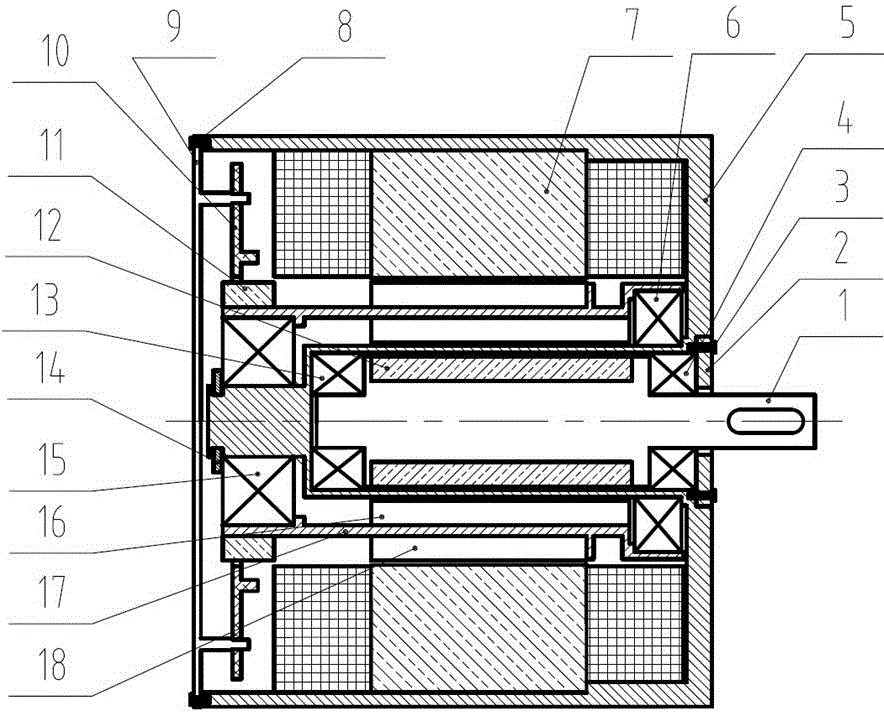

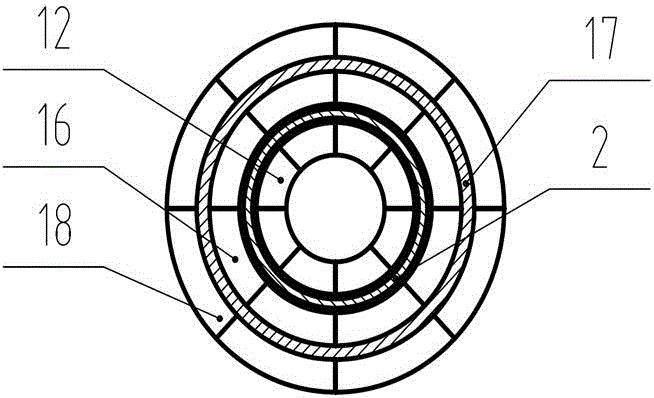

[0029] figure 1 It is a structural schematic diagram of a compact magnetic coupling drive motor of the present invention, figure 2 for figure 1 A schematic diagram of the local structure. figure 2 A schematic diagram of the axial structure of the permanent magnet 12 of the inner shaft, the inner magnet 16 of the inner rotor, and the outer magnet 18 of the inner rotor is shown. exist figure 1 , figure 2 Among them, the compact magnetic coupling motor of the present invention includes a motor housing 5, an inner shaft front end bearing 4, an inner rotor front end bearing 6, a rear end cover 9, an inner shaft rear end bearing 13, a rear end bearing 15 and a The inner stator 7 and the inner rotor 17 in the casing 5, the inner rotor 17 is cylindrical. The connection relationship is that the two ends of the inner rotor 17 are respectively connected to the inner rotor front end bearing 6 and the inner rotor rear end bearing 15, and several inner rotor inner magnets 16 are eve...

Embodiment 2

[0046] The structure of this embodiment is the same as that of Embodiment 1. The difference is that the permanent magnet poles of the inner shaft permanent magnet, the inner rotor inner magnet, and the inner rotor outer magnet are all equal even-numbered poles. In this embodiment, the even-numbered poles are twelve. indivual.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com