Esterification reactor

A reactor and esterification technology, which is applied in the chemical industry, can solve the problems of excessive reactor size and increased heat demand, achieve high heat transfer coefficient, improve thermal efficiency, and ensure alignment reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

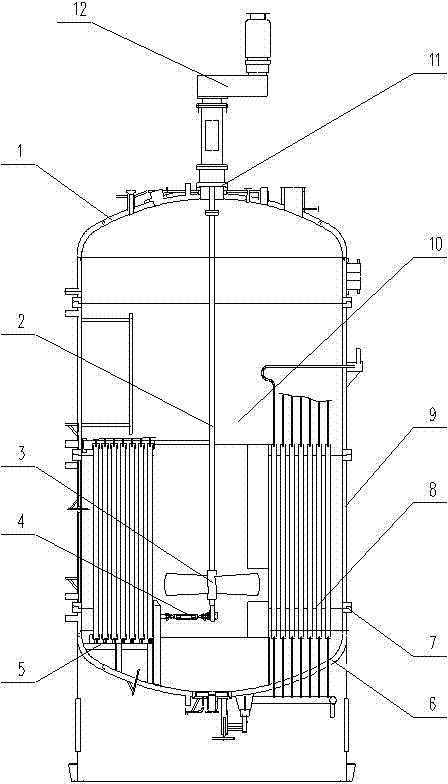

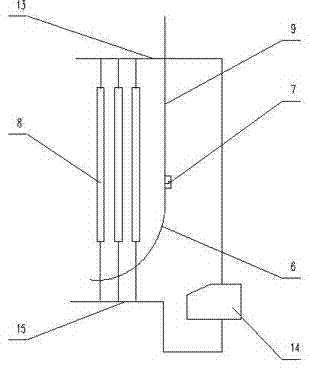

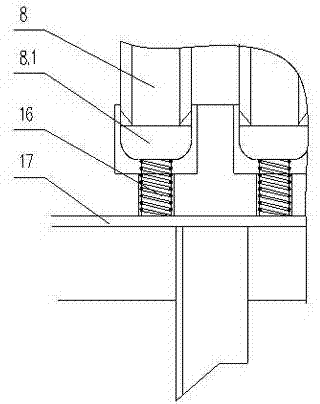

[0025] see Figure 1-5 , the object of the present invention is to provide a super large esterification reaction device suitable for polyester devices, which belongs to the internal circulation esterification reactor, including the reactor cylinder and the inner cavity 10 of the reactor cylinder. A heating device and a top-mounted agitator 3, the top-mounted agitator is provided with a main shaft 2, and the top (upper head) of the reactor cylinder is provided with an agitator flange 11, and the agitator passes through the agitator The flange of the reactor is installed on the reactor cylinder, and the upper end of the main shaft is connected with the agitator driving device 12, and realizes the rotational connection with the reactor cylinder through the corresponding main shaft bearing.

[0026] The reactor cylinder is formed by sequentially connecting the upper head 1, the middle cylinder 9 and the lower head 6, and the upper head, the middle cylinder and the lower head are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com