Automobile hybrid power assembly

A hybrid power and assembly technology, applied in the field of hybrid electric vehicle components, can solve problems such as power interruption, improve comfort, shorten axial space, and solve the effects of AMT shift power interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

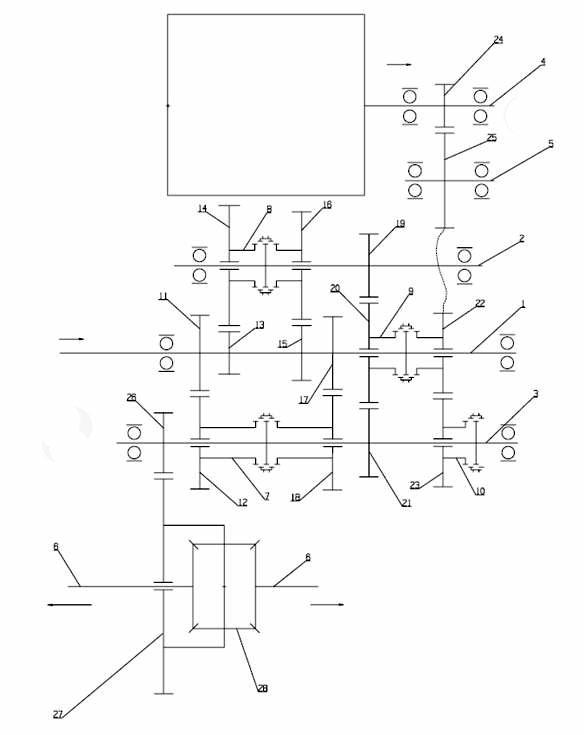

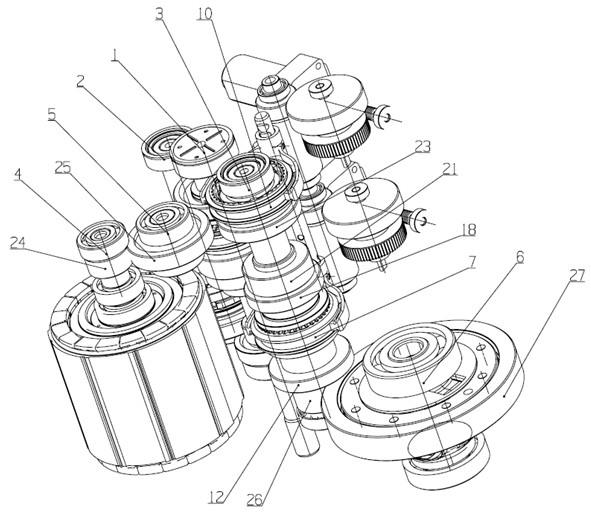

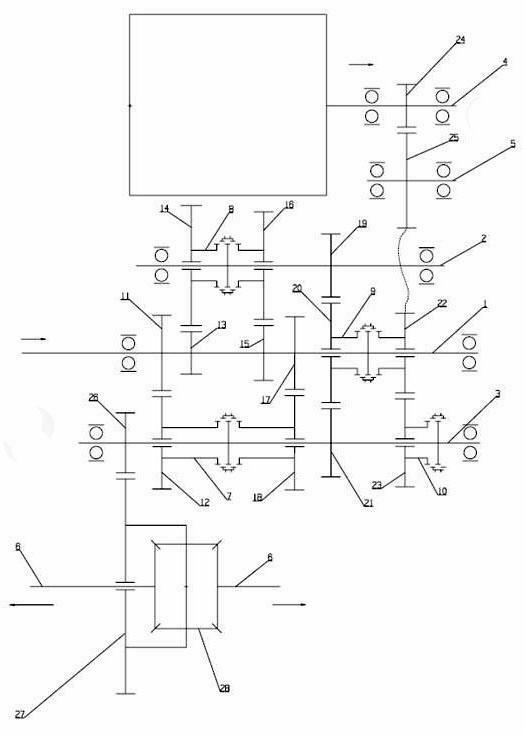

[0020] see figure 1 with figure 2 A vehicle hybrid powertrain shown includes an ISG motor and an AMT transmission, and the AMT transmission includes an input shaft 1, a first intermediate shaft 2, a second intermediate shaft 3, and a motor shaft 4 that are positioned and fitted on the casing , motor idler shaft 5 and output shaft 6, the six shafts are arranged horizontally in space;

[0021] Described input shaft 1 is connected with engine by clutch, is provided with three gears driving gear 11, first gear driving gear 13, second gear driving gear 15, fourth gear driving gear 17, fifth gear driving gear 20, Fifth gear motor synchronizer 9 and sixth gear driving gear 22.

[0022] The first gear driven gear 14, the first and second gear synchronizers 8, the second gear driven gear 16 and the fifth gear input gear 19 are successively arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com