Recirculation structure for turbo chargers

A technology of turbo compressor and circulation structure, which is applied to the components, mechanical equipment, engine components, etc. of the pumping device for elastic fluid, which can solve the problems of increasing the surge limit and reducing the efficiency of the compressor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

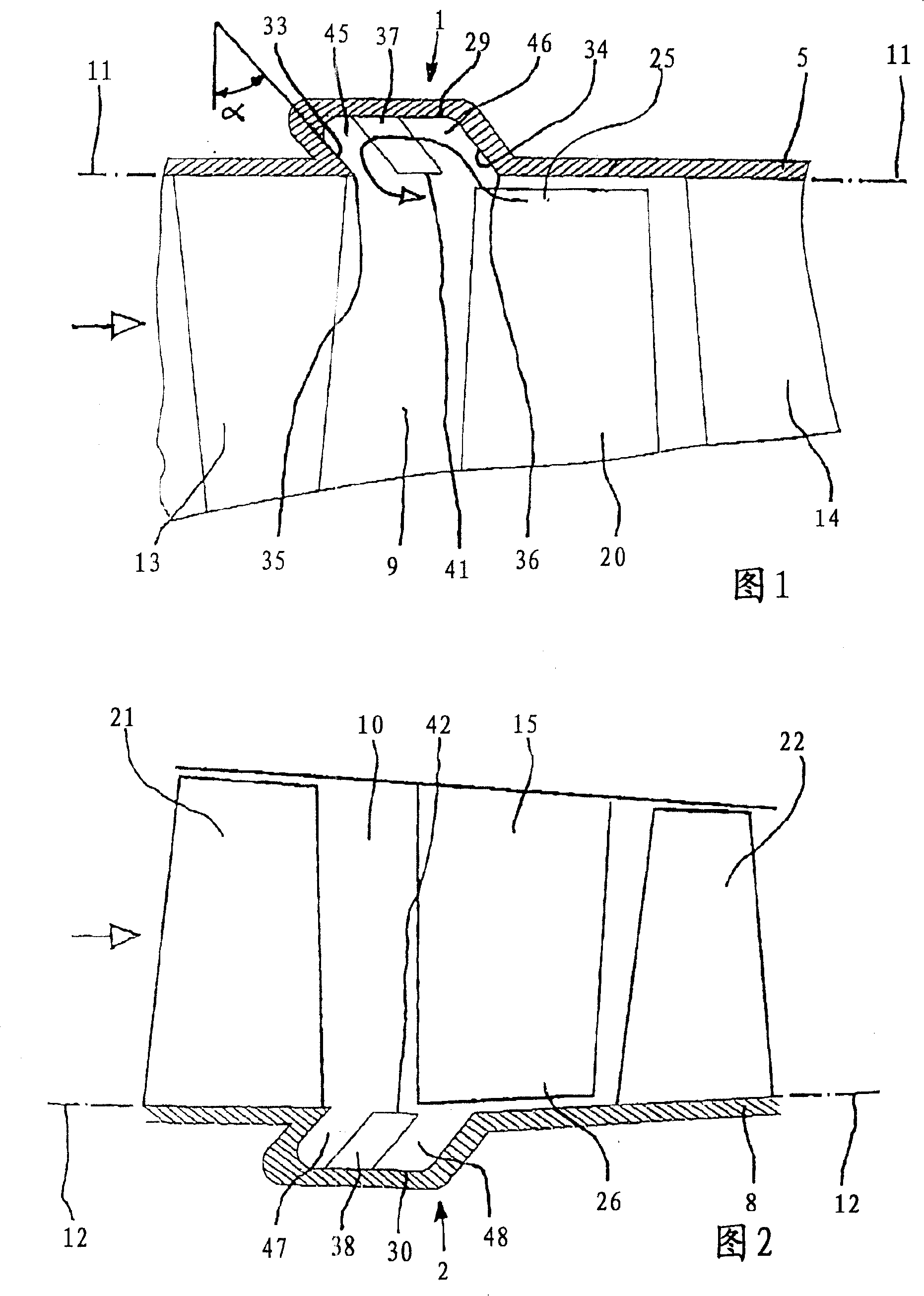

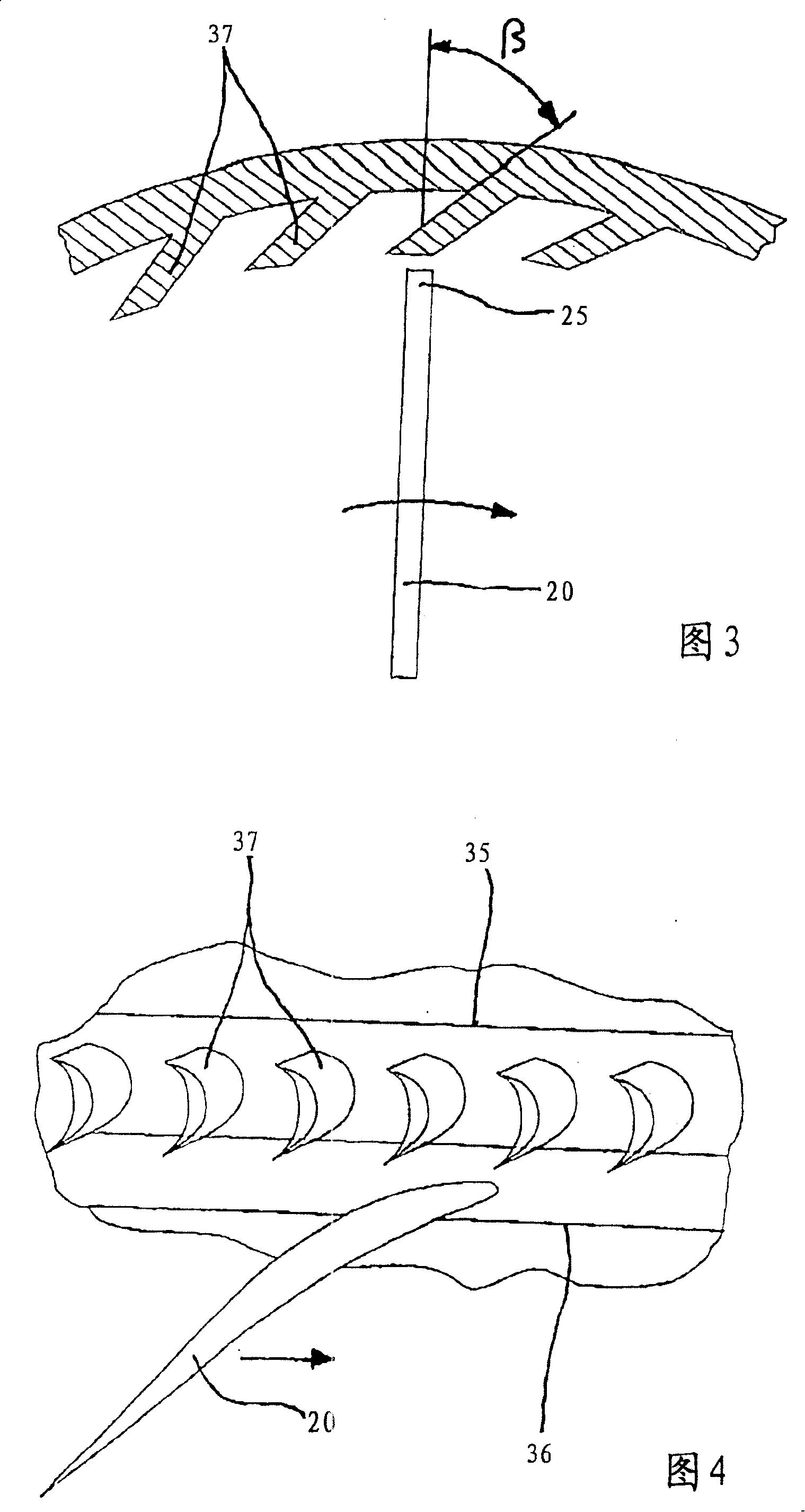

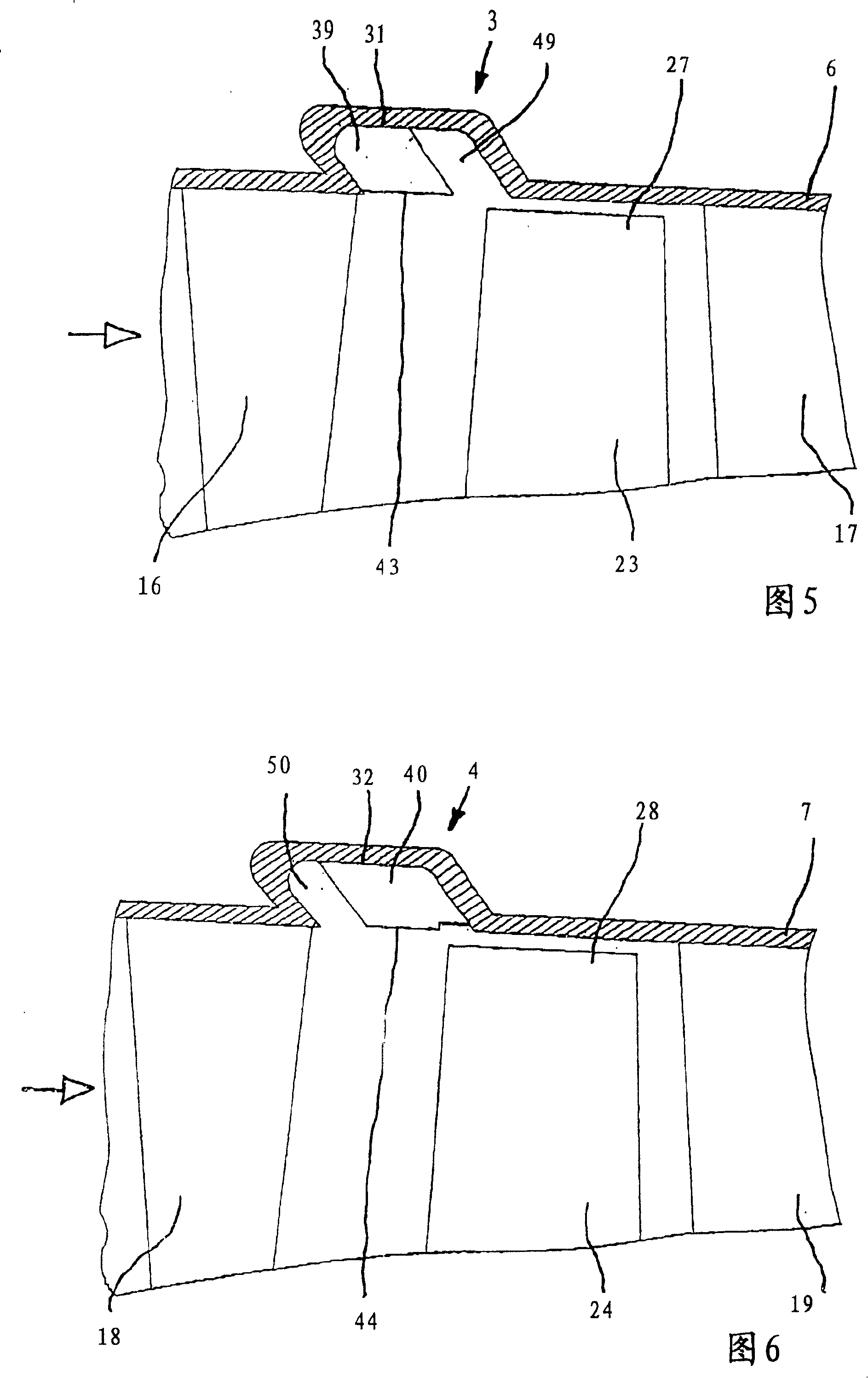

[0017] The circuit arrangement 1 shown in FIG. 1 is installed in the casing 5 of a turbocompressor and can therefore be referred to as a "casing treatment". The direction of flow in the vaned main flow duct 9 is indicated on the left by an arrow, ie it flows from left to right. In the region shown, the flow impinges first on a guide vane ring 13 , then on a rotor vane ring 20 and finally on a guide vane ring 14 again. The radial outer contour 11 of the main flow duct 9 conforms to the inner shape of the casing 5 and, in order to show this clearly, is extended by a dotted line to the left and right of the actual figure. The static circulation structure 1 interacts with the rotor blade ring 20 and is mostly located axially in front of the rotor blade ring, that is to say upstream of the rotor blade ring. The annular chamber 29 forming the circulation structure 1 together with the guide element 37 is located radially outside and adjoins the main flow duct 9 and opens into the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com