Parallel turbine flow sensor

A turbine flow and sensor technology, applied in the field of sensors, can solve the problems of measurement, axial positioning and radial anti-rotation difficulties, and the impossibility of processing and assembly, and achieve the effect of reducing radial space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

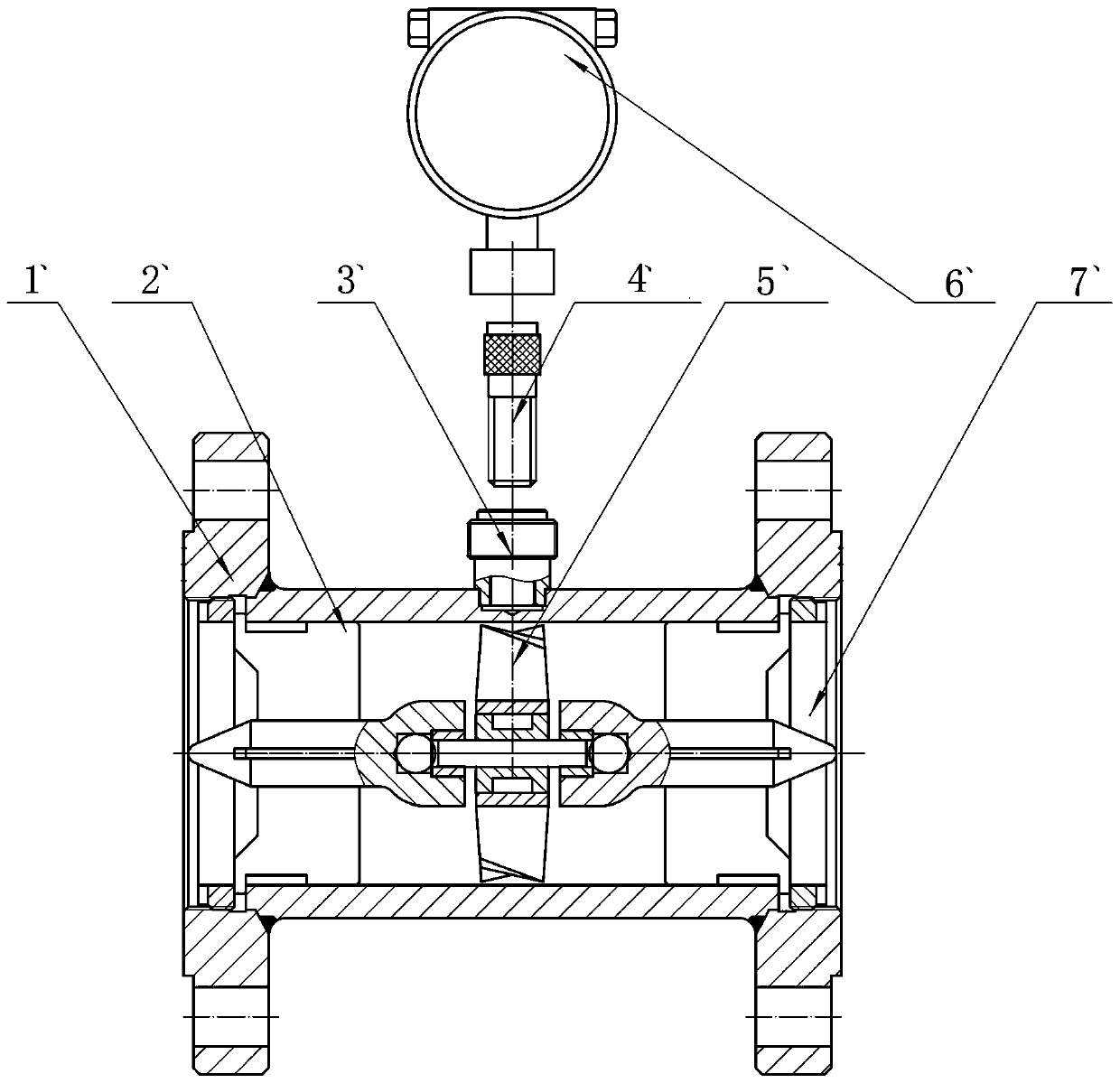

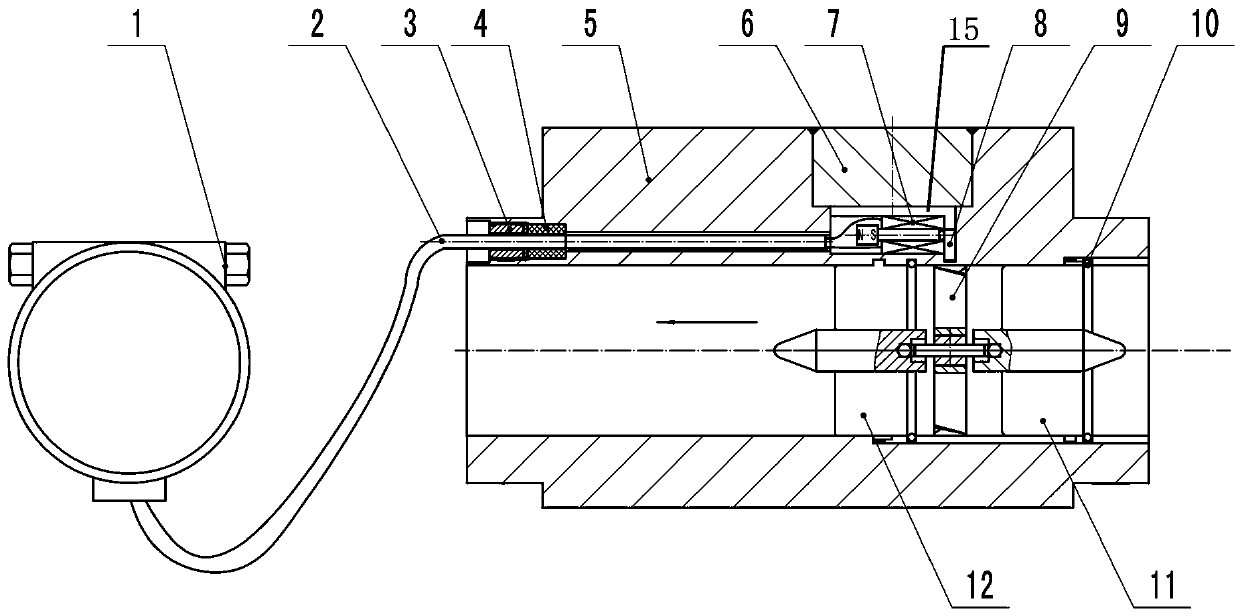

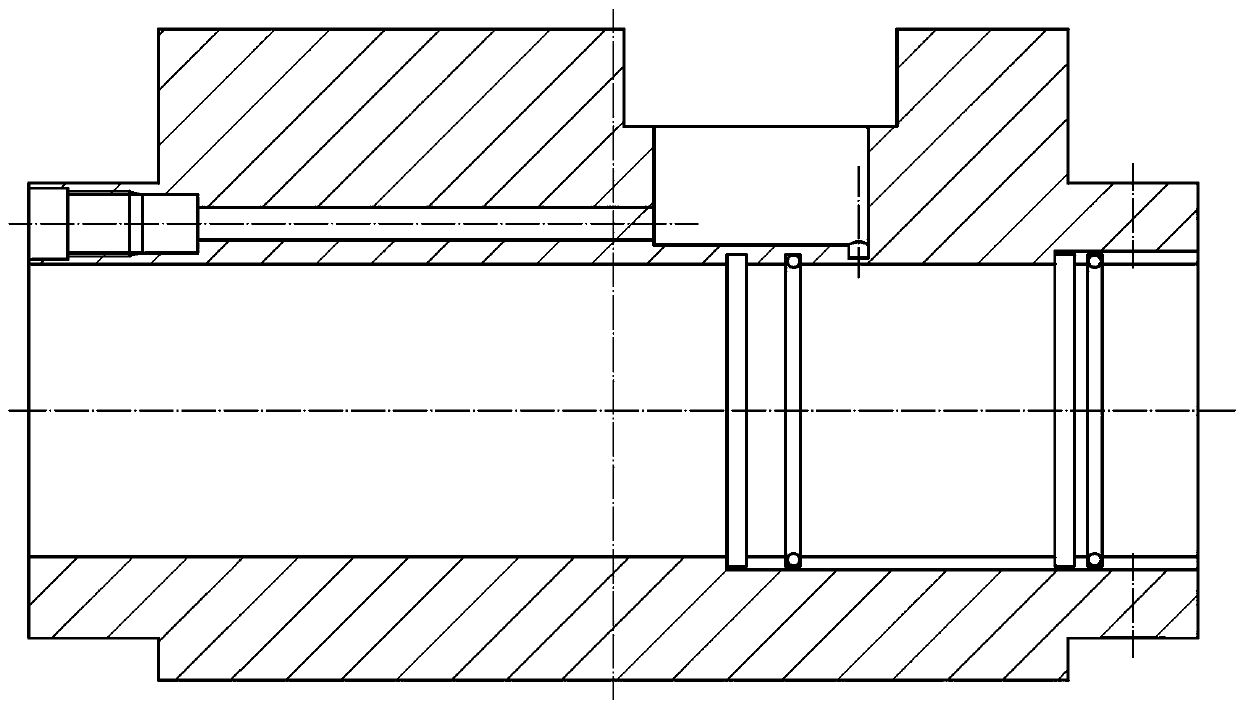

[0025] Such as Figure 2-8 As shown, the parallel turbine flow sensor of the present invention includes a housing 5, an impeller assembly 9 axially installed in the medium flow chamber of the housing, and front and rear flow guides 12, respectively installed at both ends of the impeller assembly 9. 11. Two front card slots 13 and rear card slots 14 are axially processed on the inner wall of the medium flow chamber at one end of the housing, each pair of front card slots and rear card slots do not overlap, and each pair of front card slots Both between and between the rear slots are symmetrical with respect to the axis of the housing; the outer edges of the two vanes on the same plane in the front deflector 12 are all processed with protrusions for being snapped into the front slots 13 ; The outer edges of the two blades on the same plane in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com