Crane wheel

A technology for lifting vehicles and cranes, applied in the directions of traveling mechanisms, mechanical equipment, gear transmission devices, etc., can solve problems such as large volume, achieve reliable torque transmission, reduce assembly parts, and reduce volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

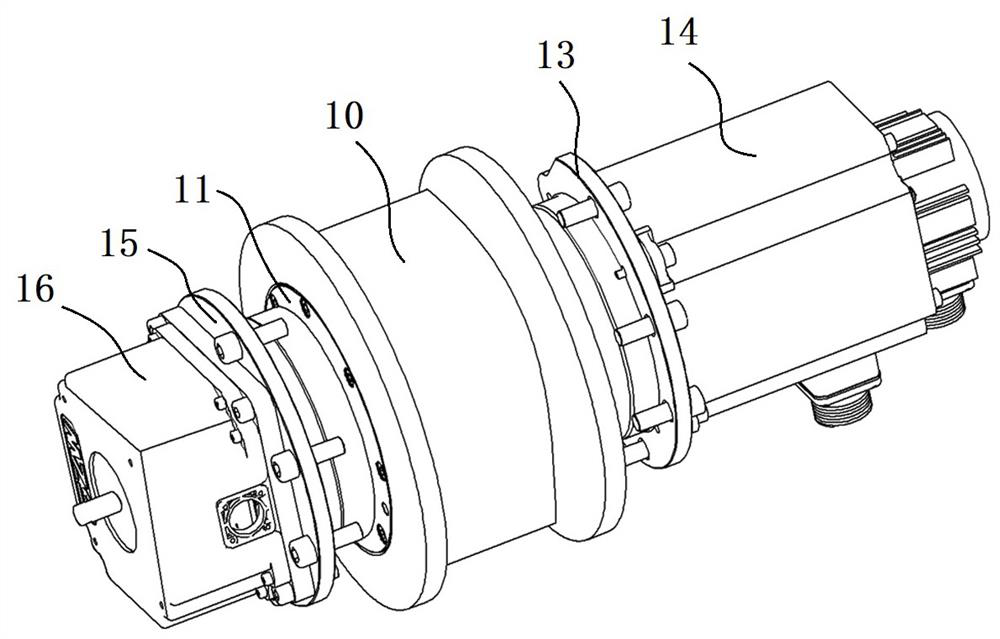

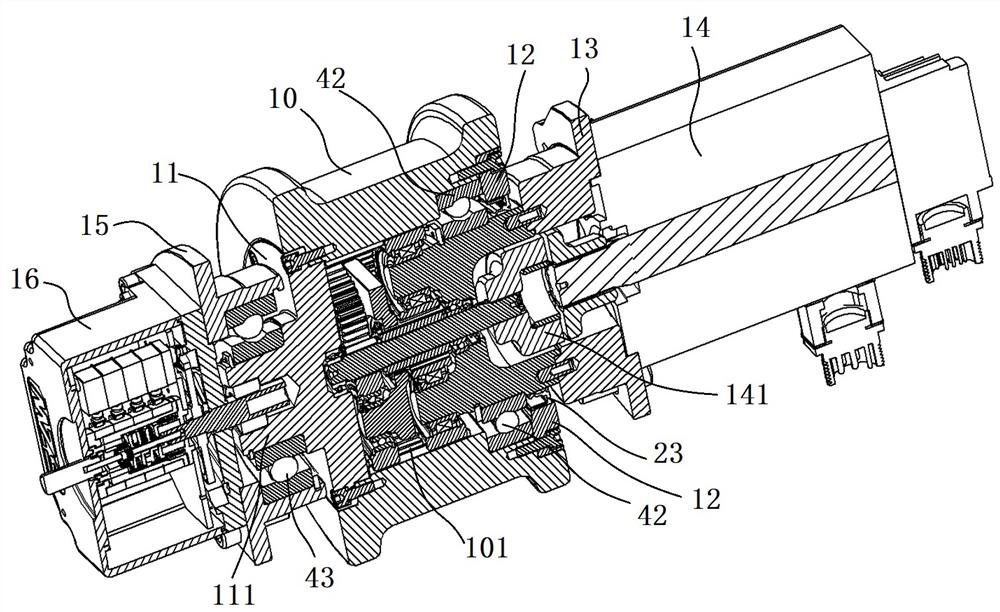

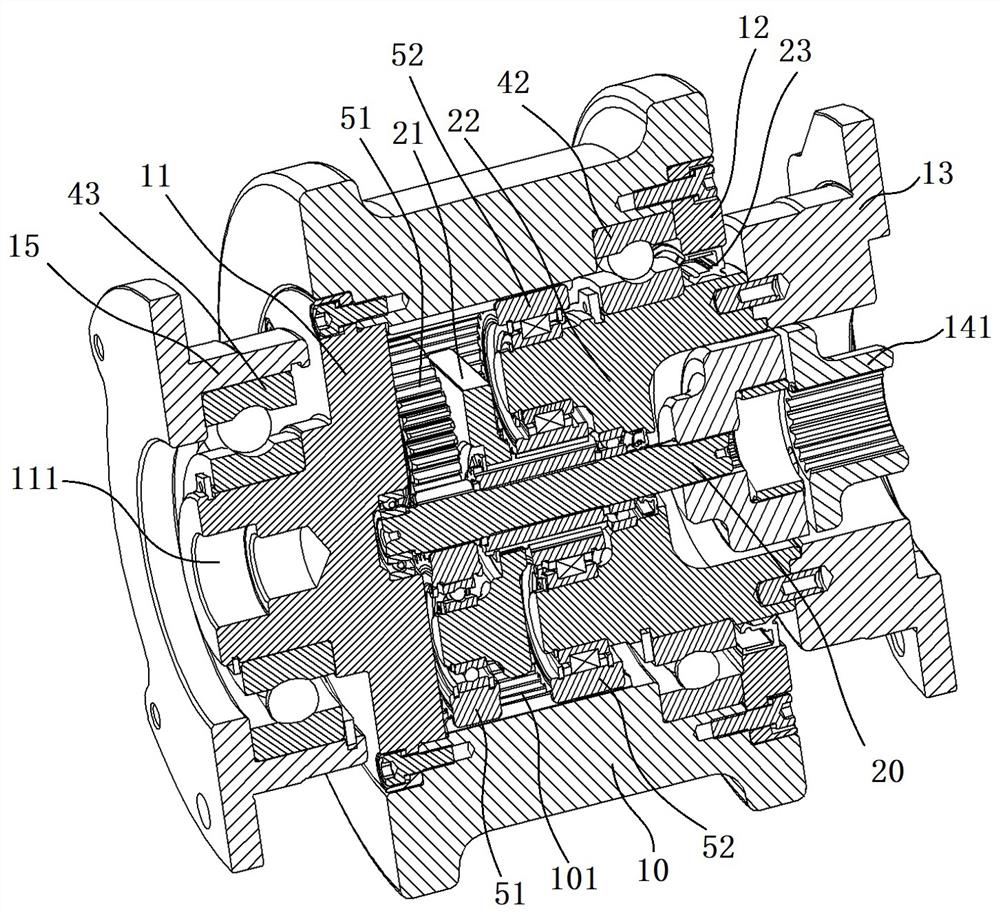

[0028] like Figure 1 to Figure 6 In one embodiment of the crane wheel of the present invention shown, the crane wheel of this embodiment includes a cylindrical hub 10, one side of the hub 10 is fixed with a circular shaft seal end cover 11, and the other side of the hub 10 is fixed. An annular shaft seal retaining ring 12 is fixed on the side, an inner gear ring 101 is provided on the inner surface of the hub 10, and a planetary deceleration module is installed in the hub 10. The planetary deceleration module includes a central rotating shaft 20, a first-level planet carrier 21, The secondary planetary carrier 22, the primary sun gear 31 and the secondary sun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com