Gear combined type variable-speed transmission device

A variable speed transmission and combined technology, which is applied in the field of synchronizers, gear combined variable speed transmissions, and clutches, can solve the problems of complex structure and control system, difficult parts processing and manufacturing, and achieve simplified control methods and control links, saving axial space and radial space, simple control and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

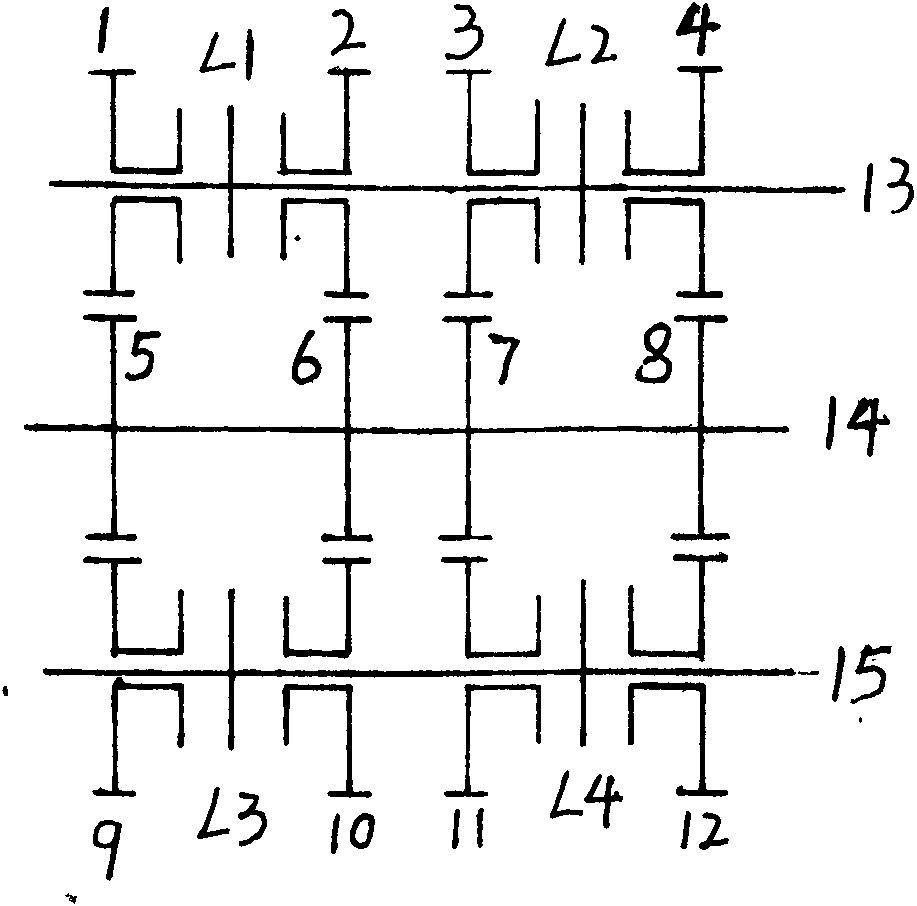

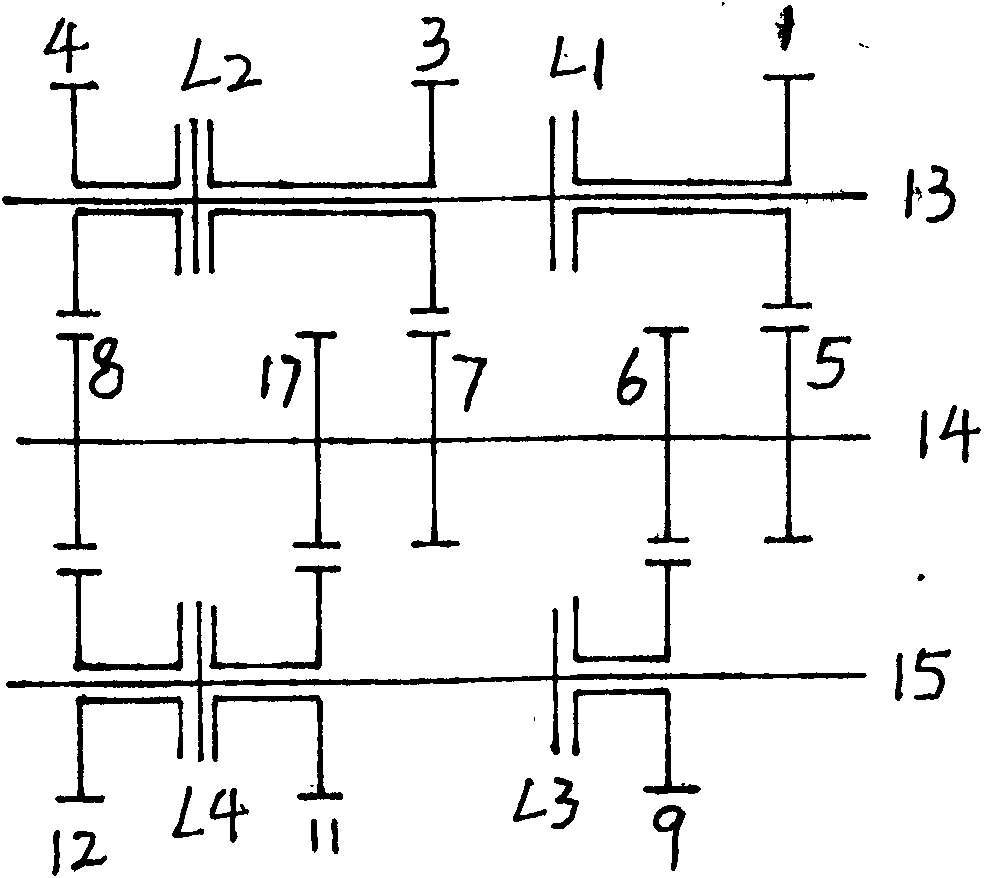

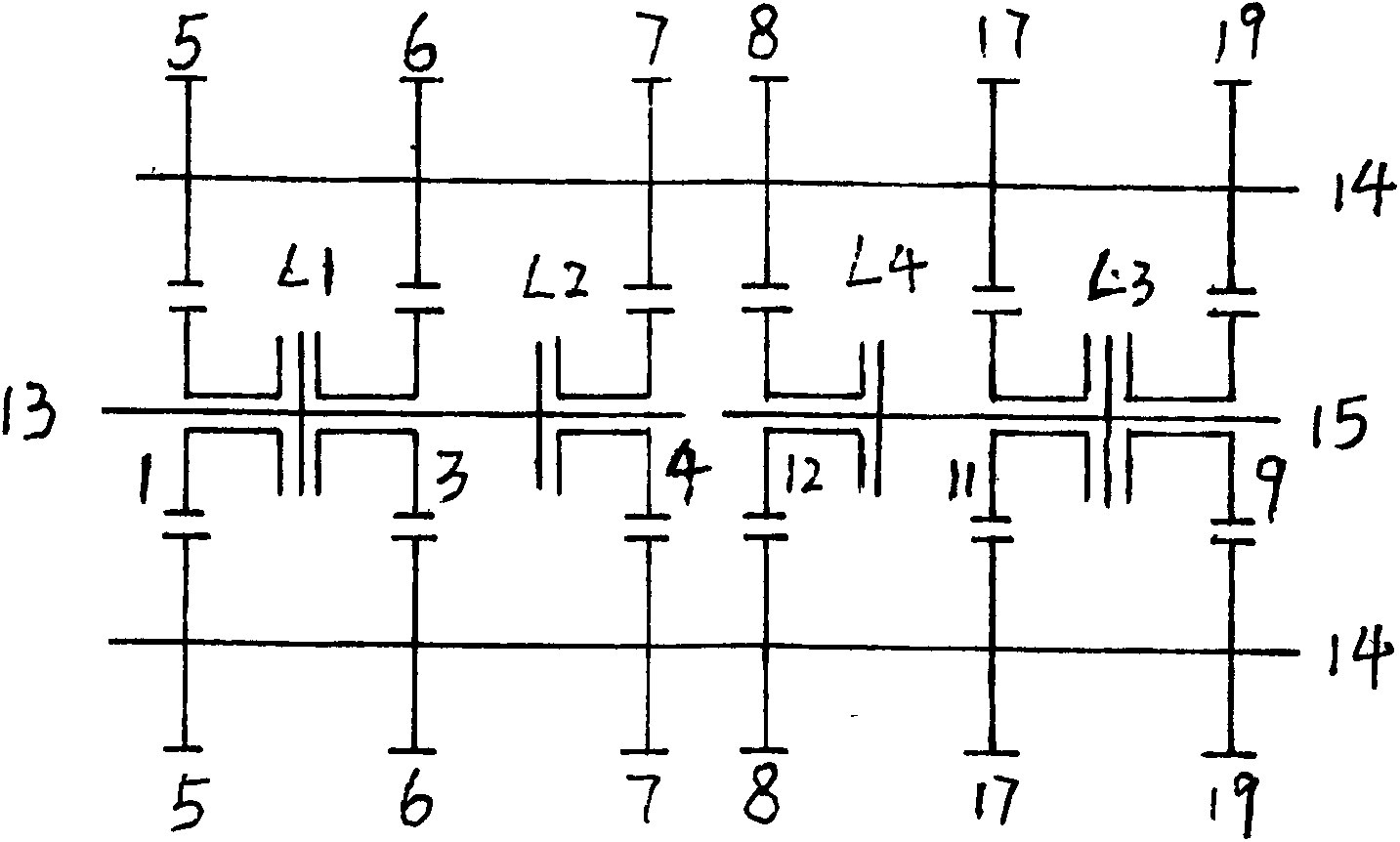

[0022] Such as figure 2Shown, the input shaft (13), output shaft (15) and intermediate shaft (14) and reverse gear shaft (not shown in the figure) arranged in parallel, are rigidly connected with gear (5) (6) on the intermediate shaft (14). )(7)(8)(17), three gears (1)(3)(4) that can rotate freely around its axis are arranged on the input shaft (13), and there are three gears (1)(3)(4) that can freely rotate around its axis on the output shaft (15). The three gears (9) (11) (12) that rotate, the gears (4) (12) mesh with the gear (8) on the intermediate shaft (14) respectively, and the gear (3) meshes with the upper gear (7) on the intermediate shaft (14). ), the gear (1) meshes with the gear (5) on the countershaft (14), the gear (11) meshes with the gear (17) on the countershaft (14), and the gear (9) meshes with the gear (14) on the countershaft (14) 6) meshing, there is a double clutch (L2) between the upper gear (3) (4) of the input shaft (13), the upper gear (1) of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com