Patents

Literature

31results about How to "Increase the number of stalls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

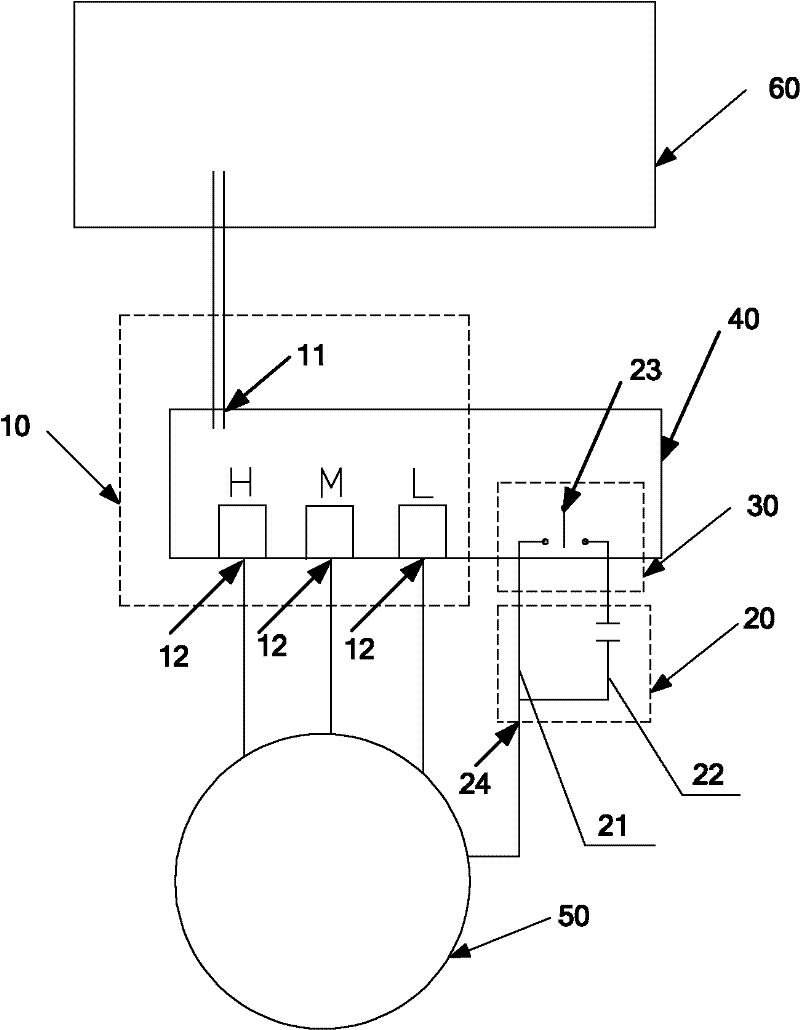

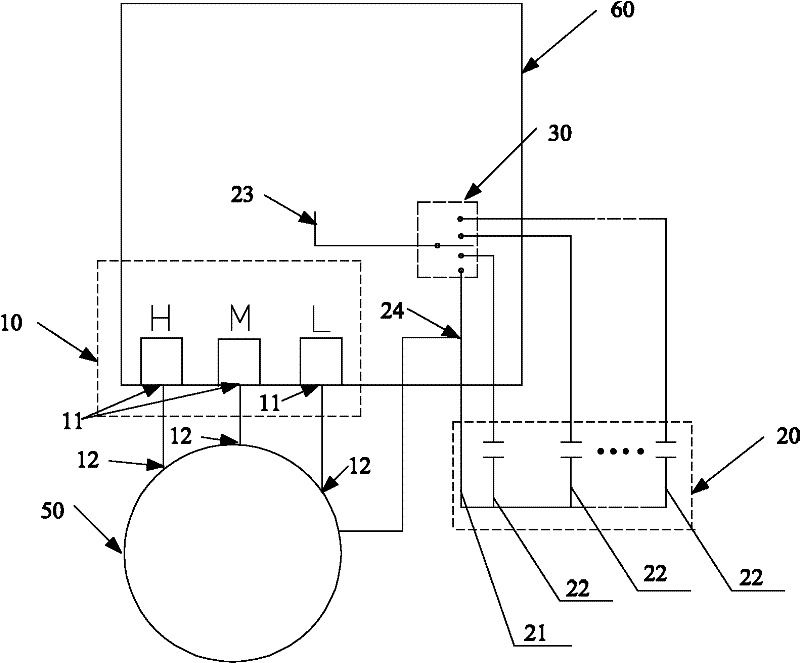

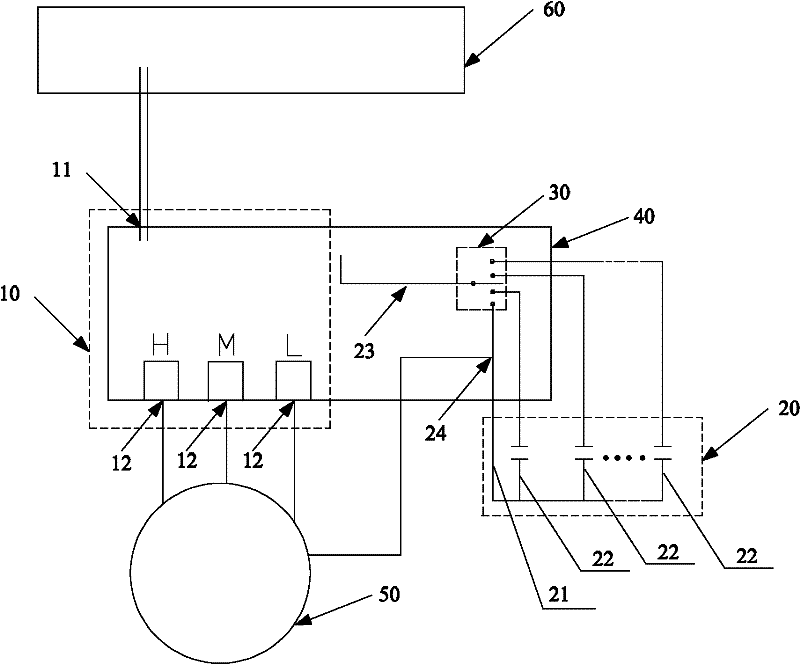

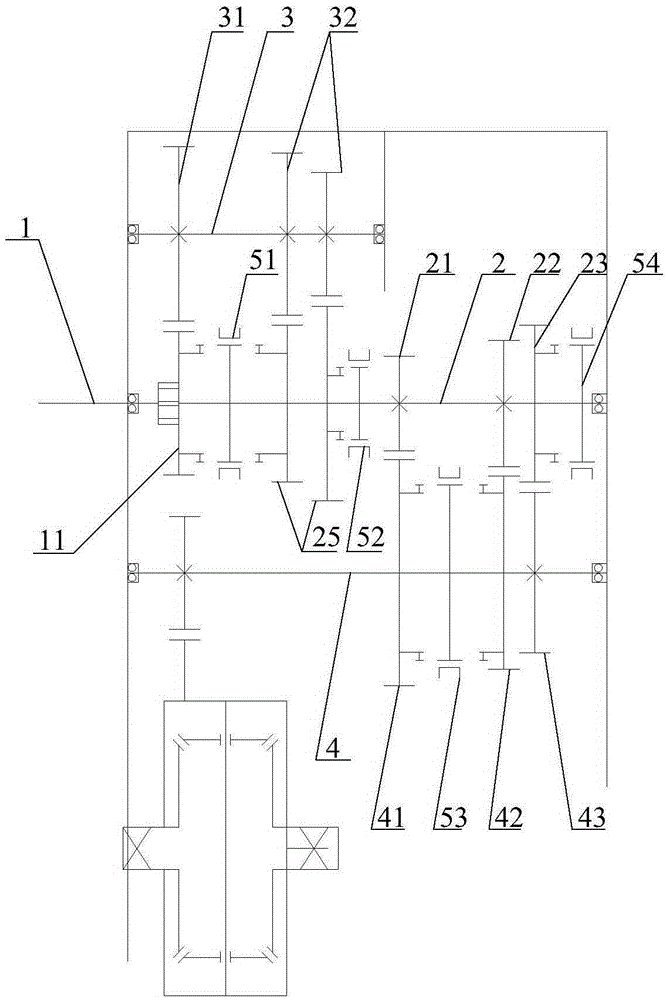

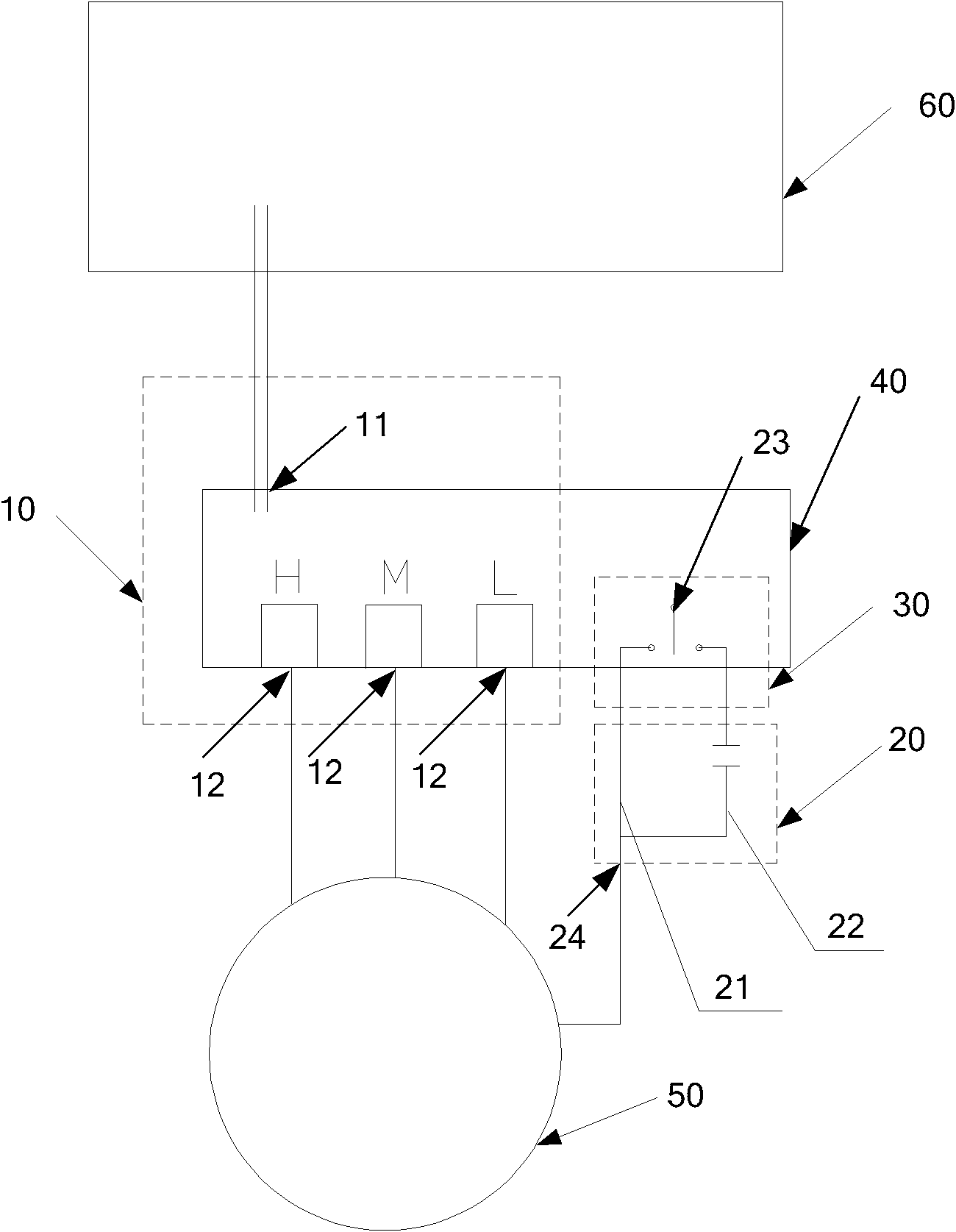

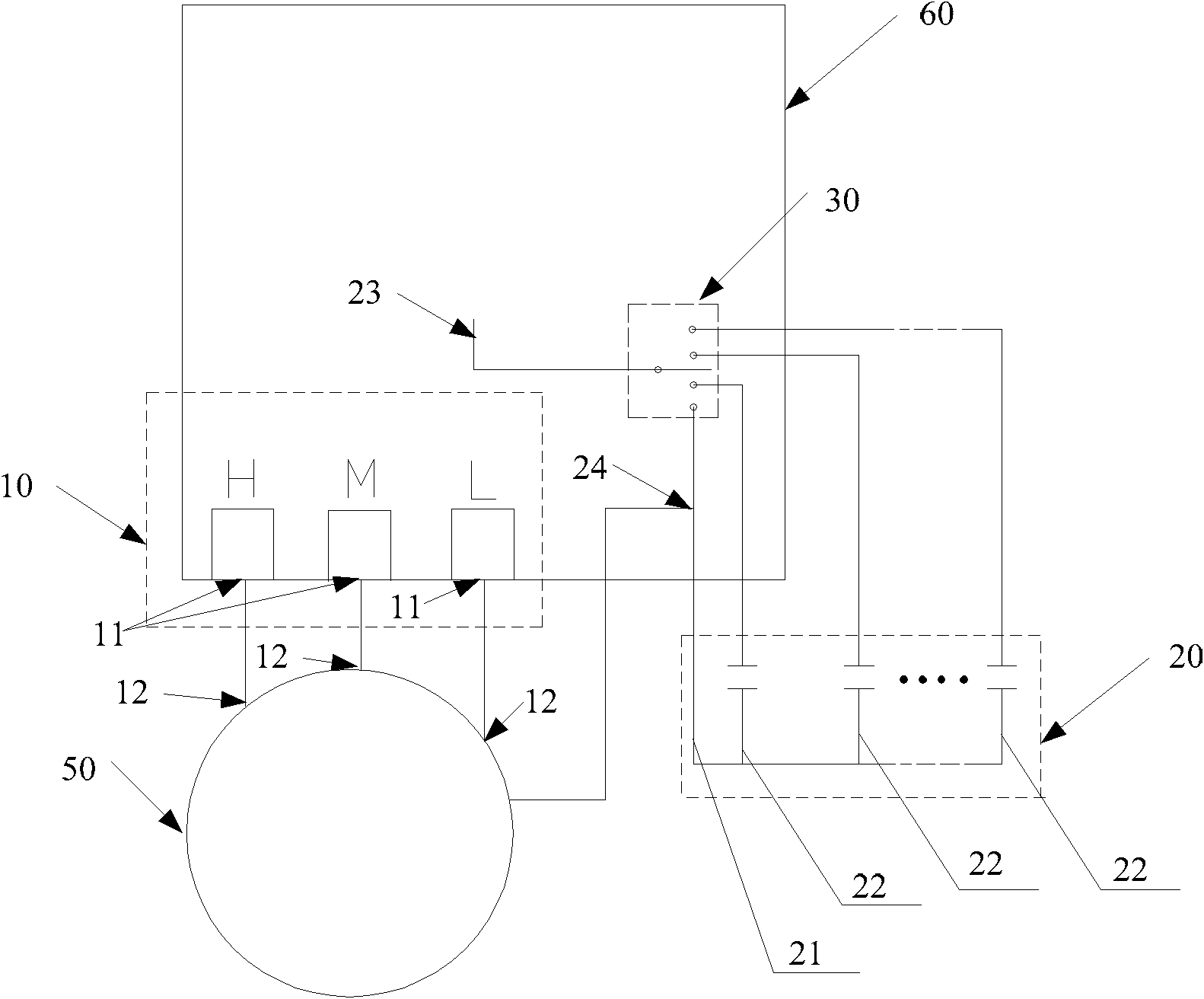

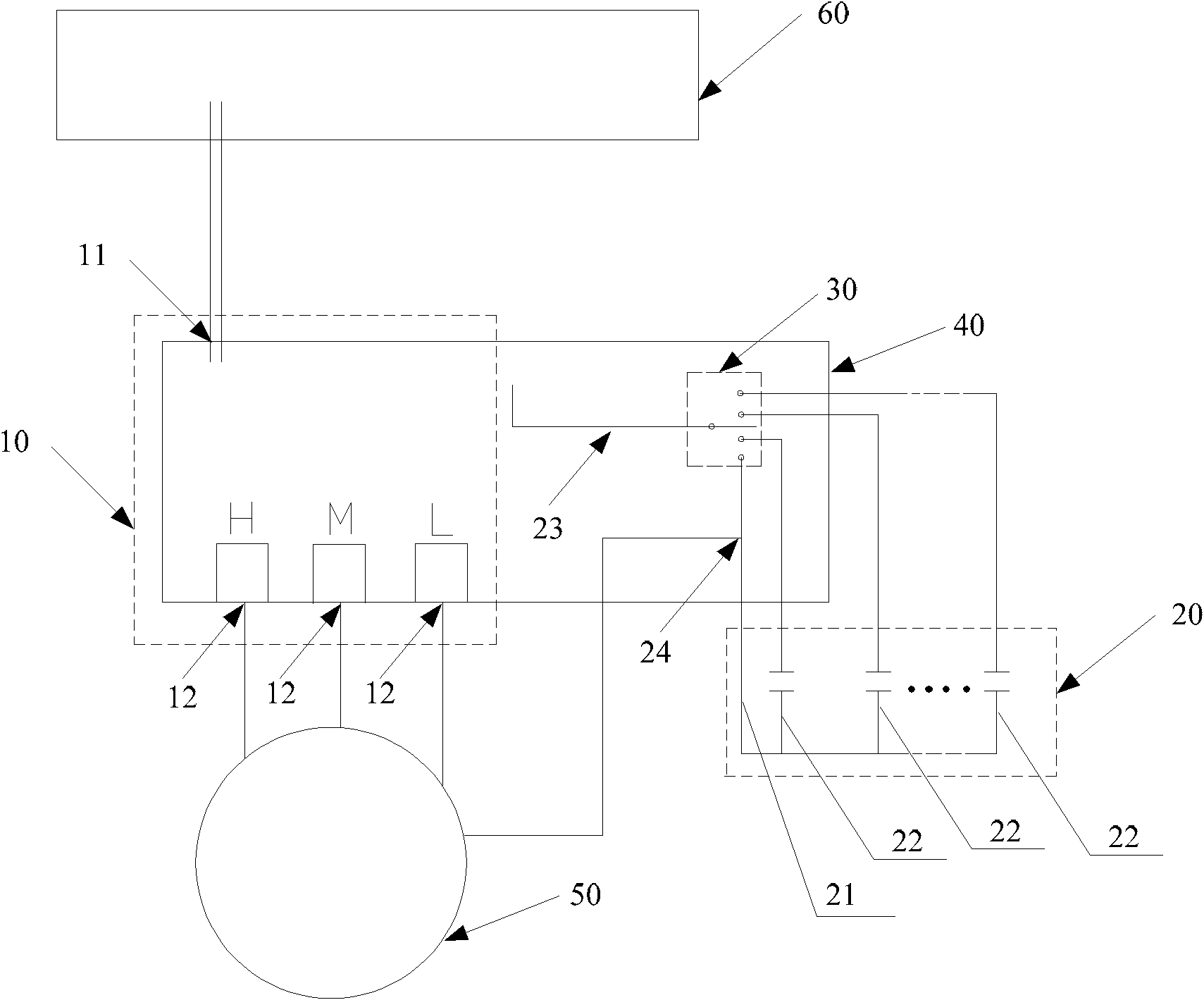

Air conditioner, alternating current motor and speed adjusting device thereof

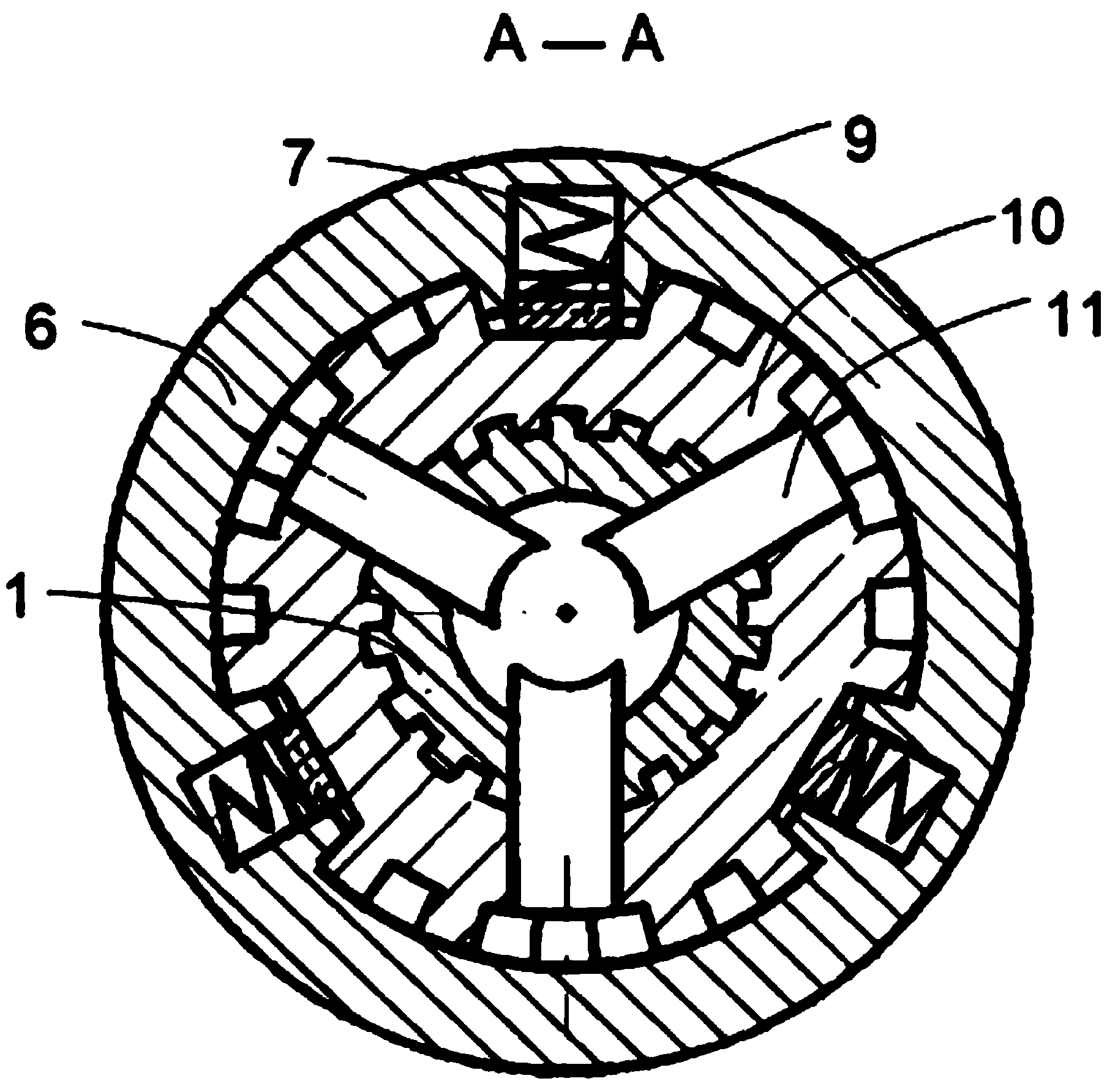

ActiveCN102480263AIncrease the number of stallsSolve electromagnetic noiseAC motor controlMotor speedCapacitance

The invention provides an air conditioner, an alternating current motor and a speed adjusting device thereof. The alternating current motor speed adjusting device comprises that: a main speed regulation unit, wherein, an input terminal forms a main speed regulation input terminal which is connected with a controller, and an output terminal forms a main speed regulation output terminal which is connected with a plurality of live wire terminals of the alternating current motor; an auxiliary speed regulation unit which comprises a first branch and at least a second branch, wherein, the first branch and the second branch have a respective input terminal and a common output terminal, and the common output terminal forms an auxiliary speed regulation output terminal which is connected with a zero line of the alternating current motor; a shift selector, wherein, an input terminal of the shift selector forms an auxiliary speed regulation input terminal which is connected with the controller, and an output terminal is selectively connected with one of the respective input terminal of the first branch and the second branch, wherein, the first branch is a direct connecting branch and the second branch is a capacitive branch. According to the air conditioner, the alternating current motor and the speed adjusting device of the invention, a problem of electromagnetic noise when utilizing a chopper speed regulation principle to carry out speed regulation on a present alternating motor in the prior art is solved.

Owner:GREE ELECTRIC APPLIANCES INC

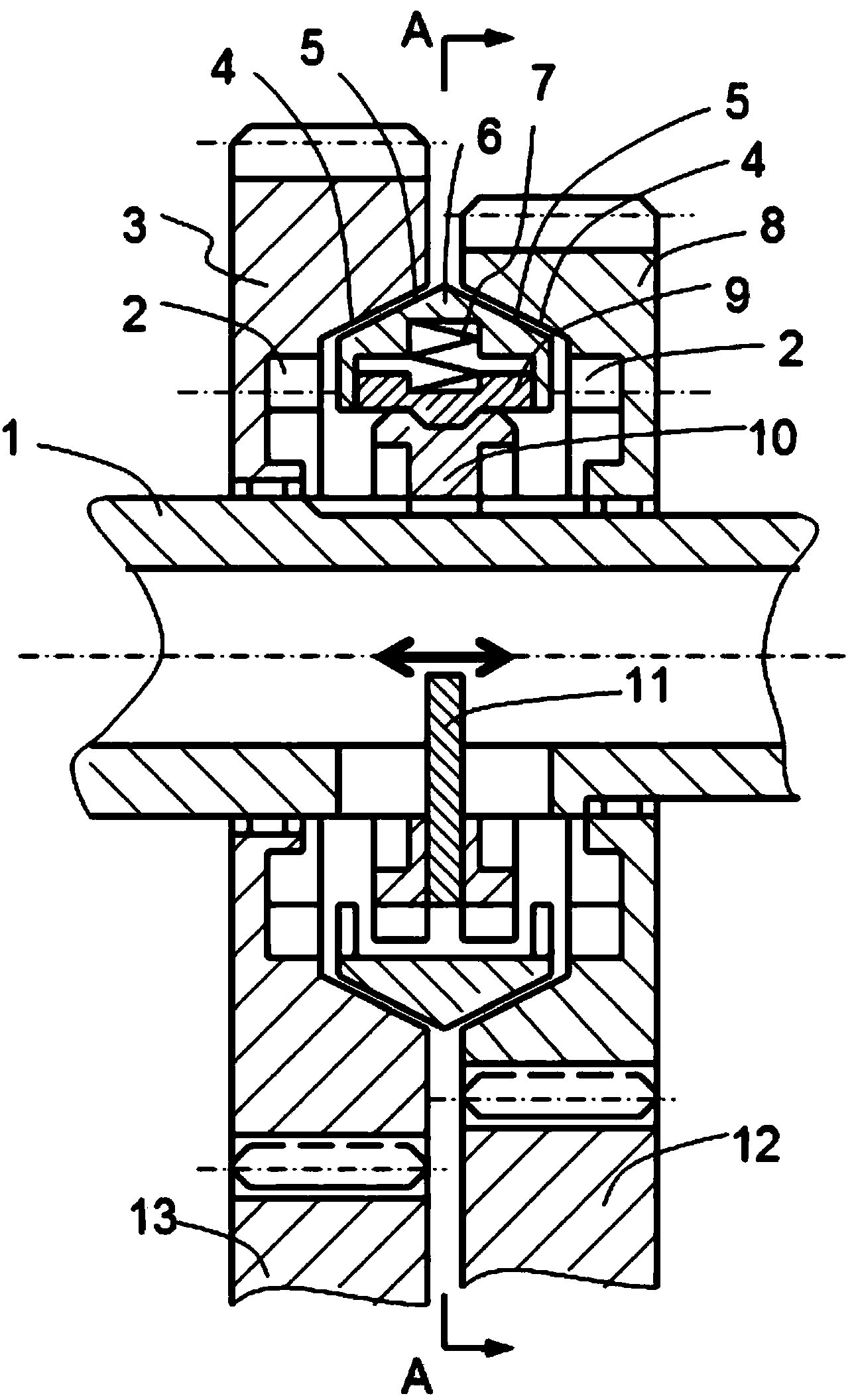

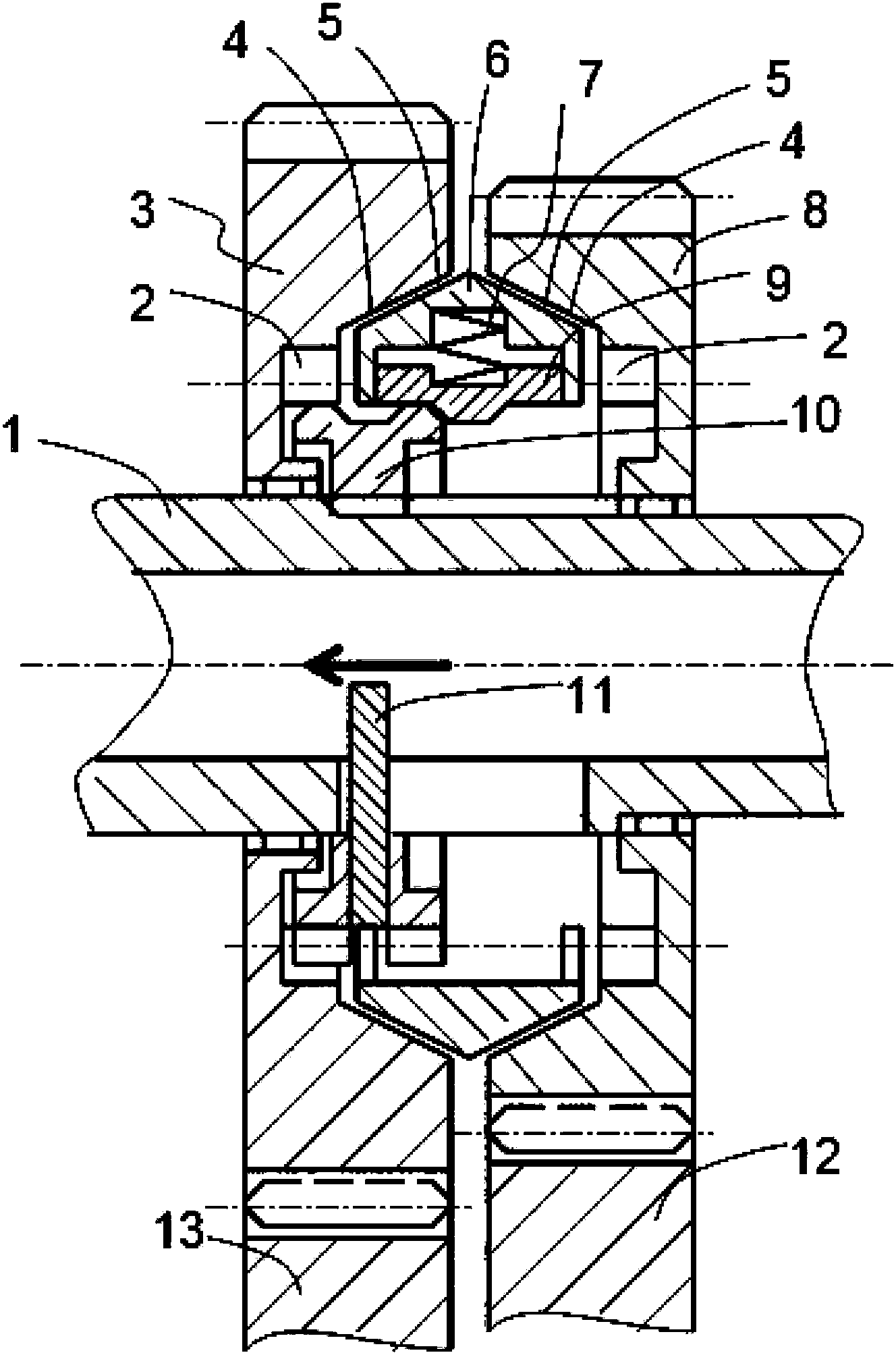

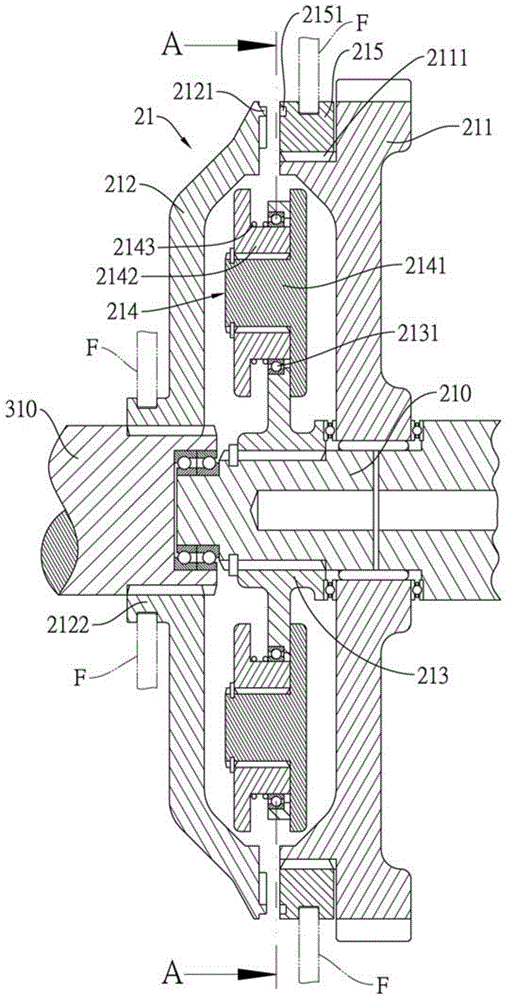

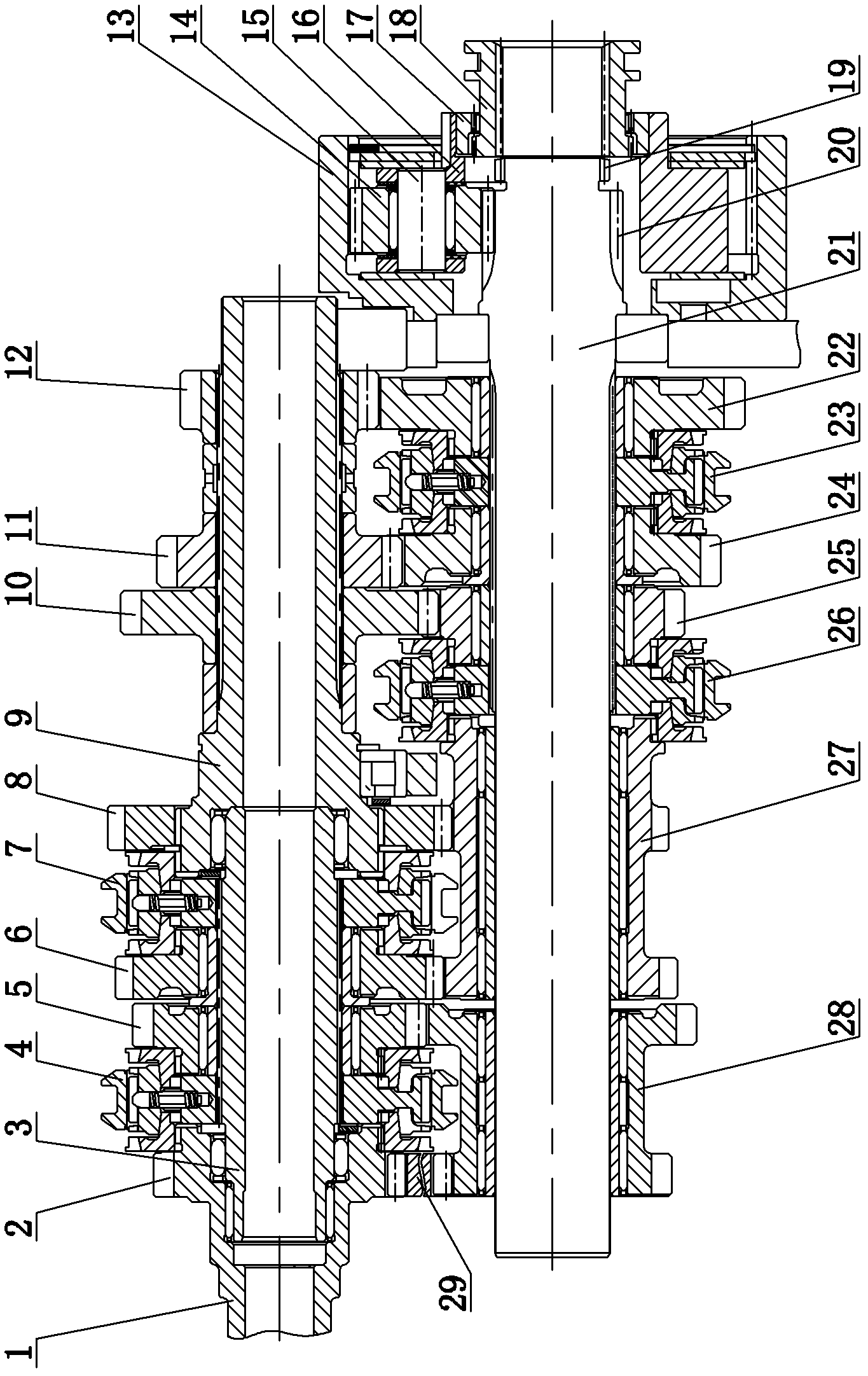

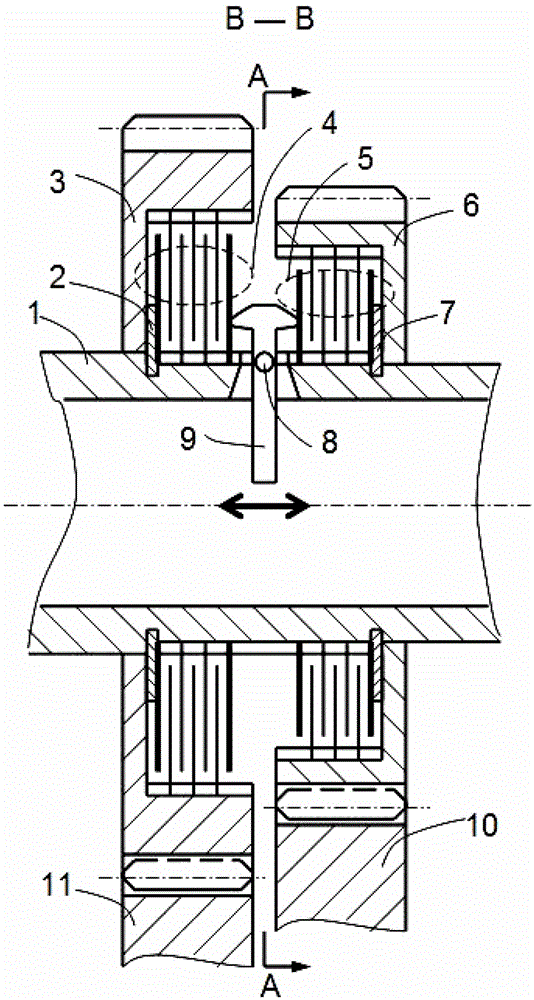

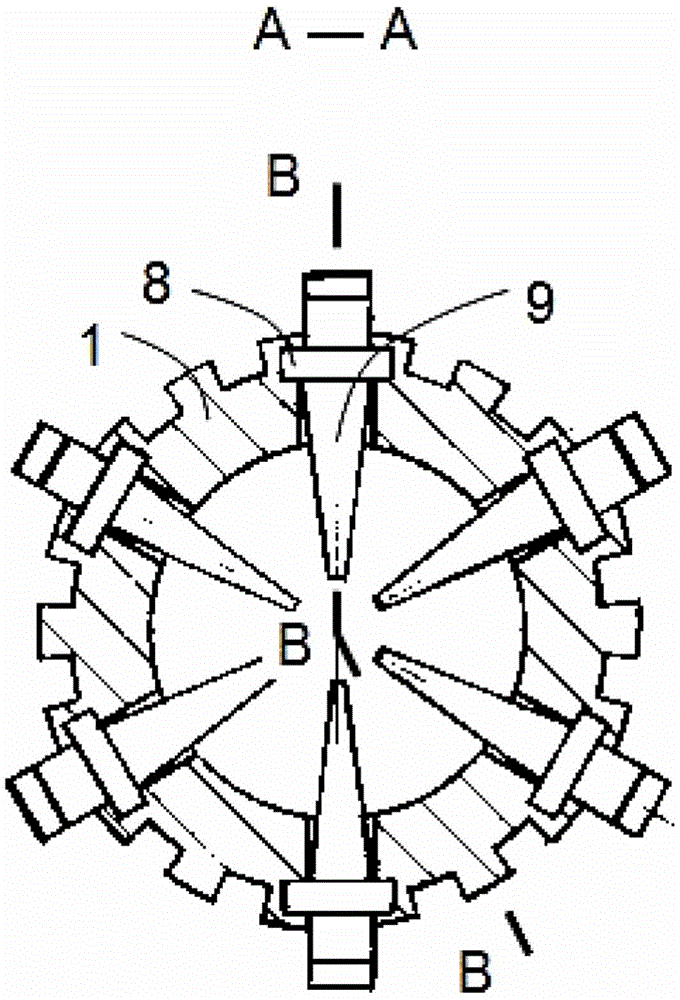

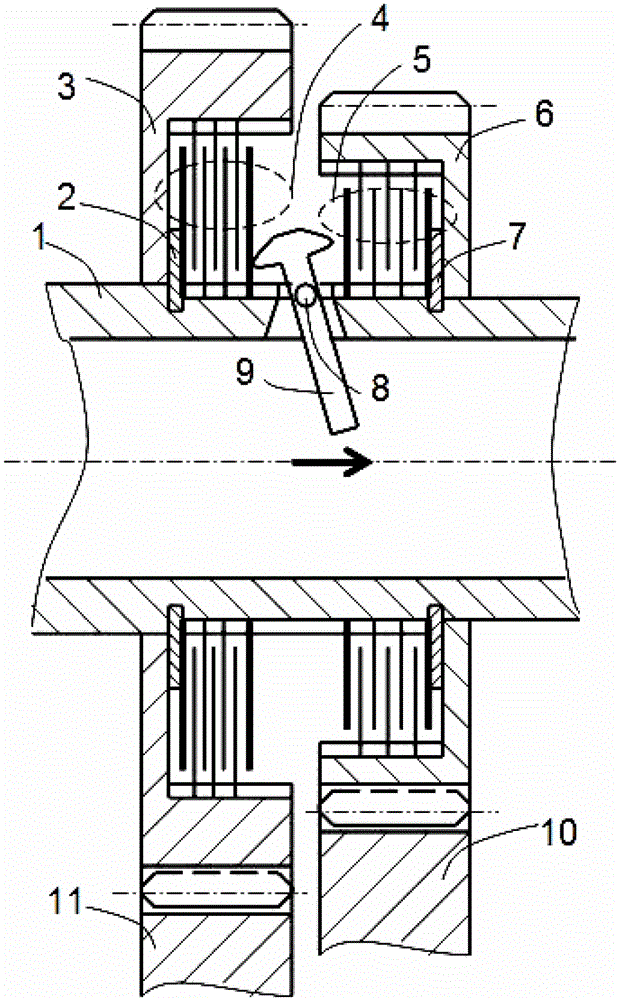

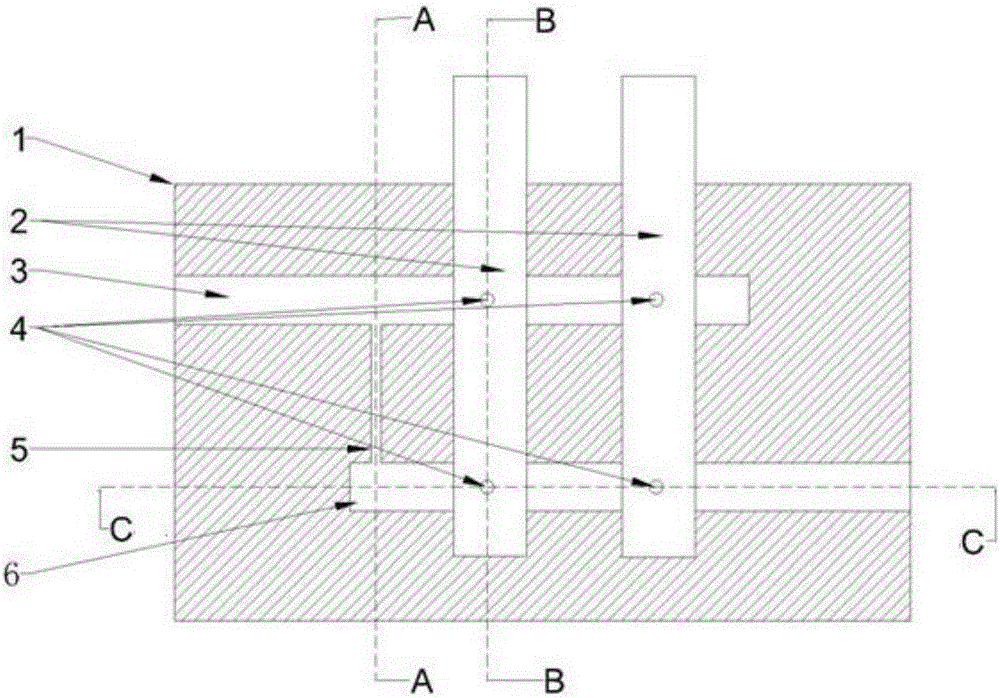

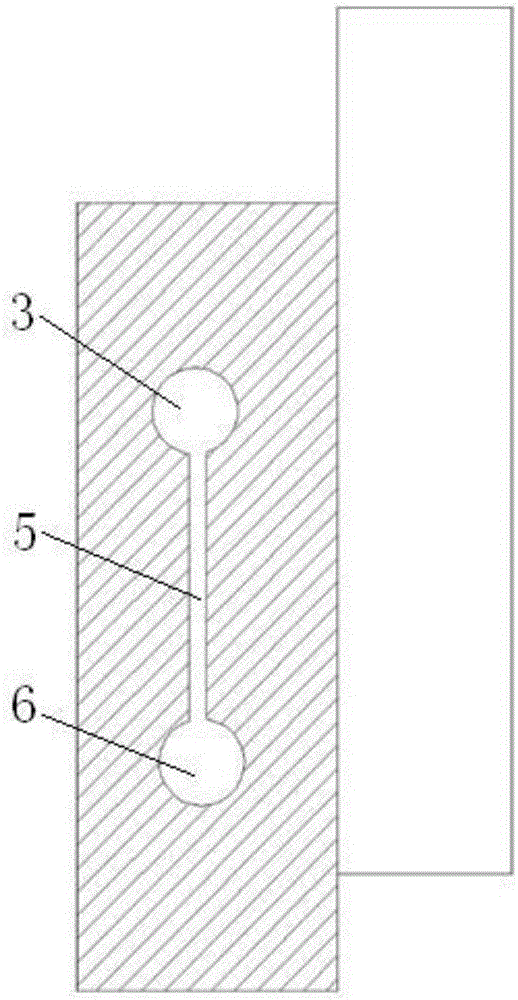

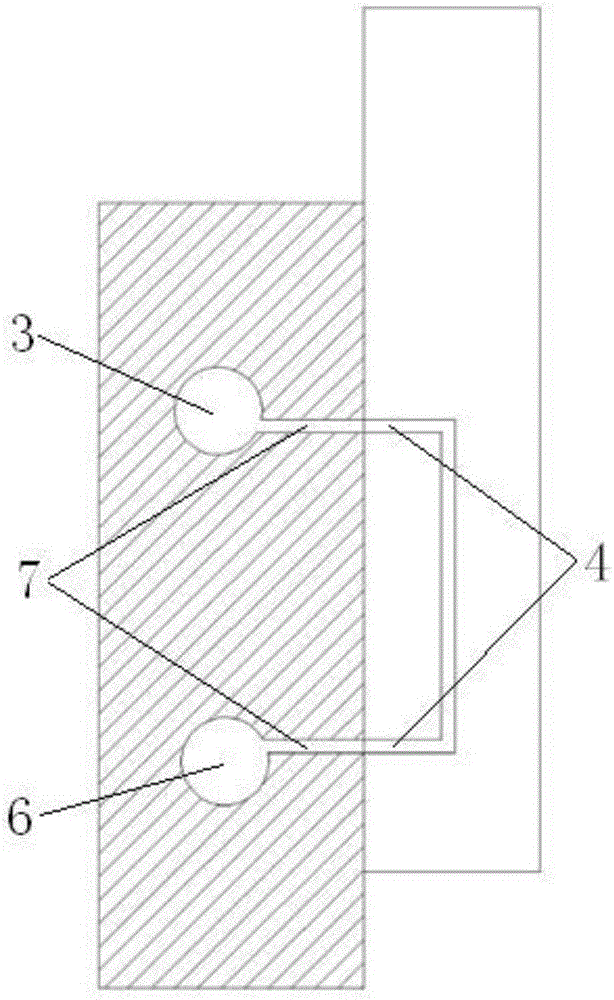

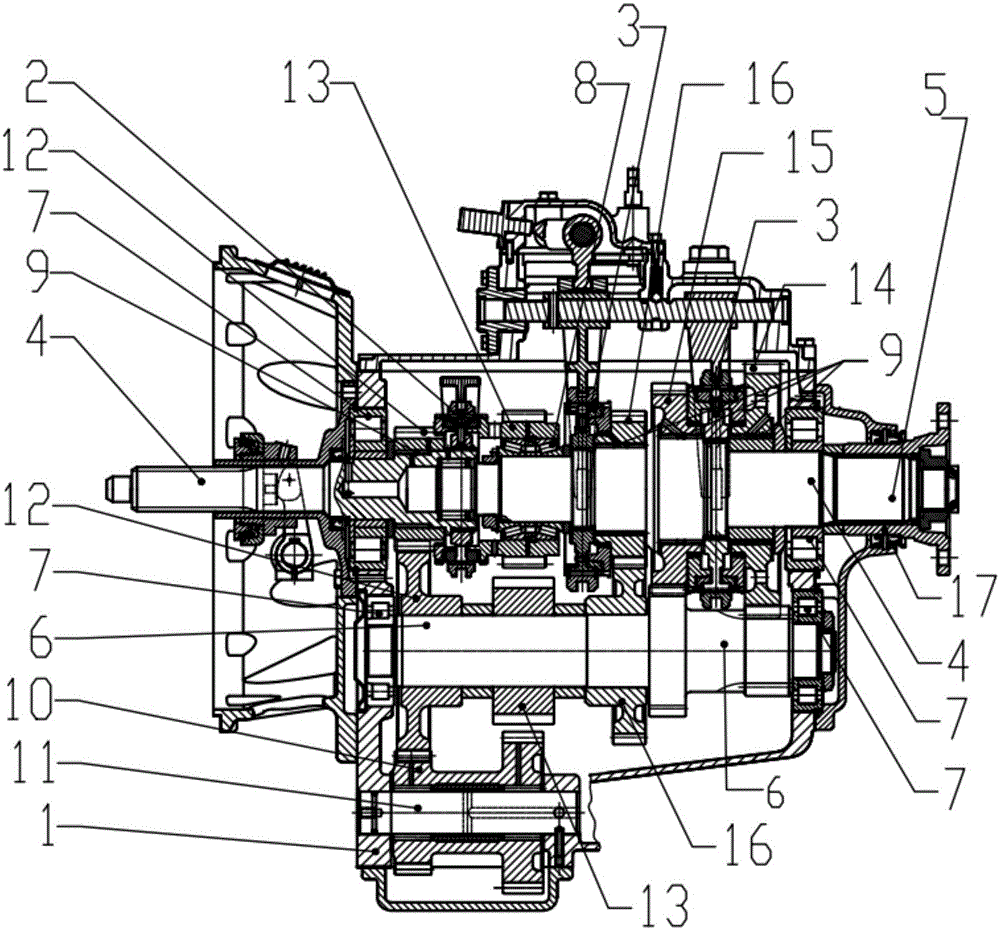

Built-in clutch and gear shifting control mechanism thereof

InactiveCN103758887ACompact layoutReduce axial sizeMechanical actuated clutchesGearing controlEngineeringGear transmission

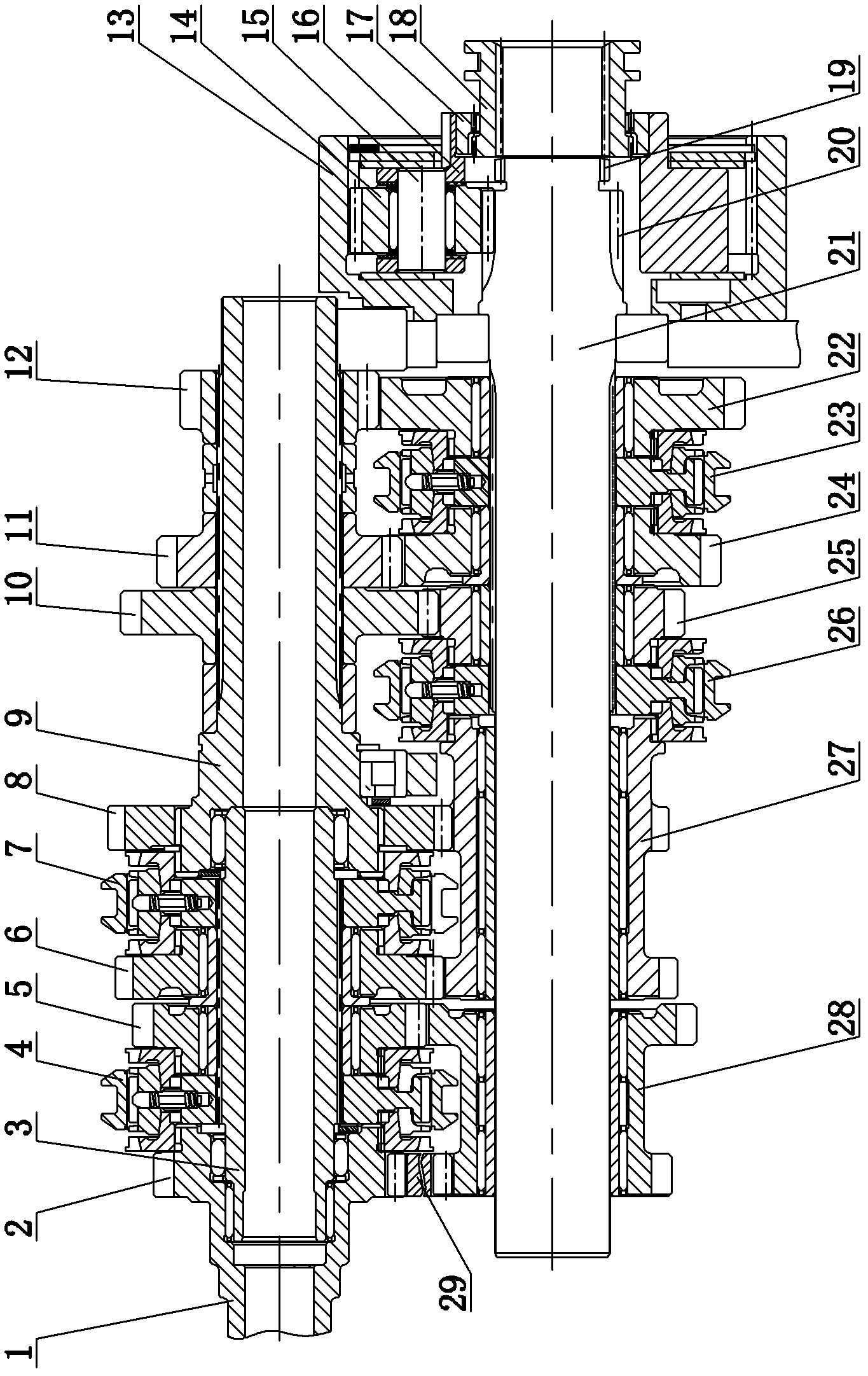

The invention discloses a built-in clutch which comprises a mounting shaft, gears, a splined hub, lifting levers and a bidirectional synchronization ring. The gears are sleeved on the mounting shaft, the splined hub is connected with the mounting shaft, cavities are arranged on the gears, inner joint gear rings are arranged on the side walls of the cavities, a hollow shaft sleeve is arranged in the mounting shaft, a slot is formed in the shaft sleeve, one end of each lifting lever is inlaid in the splined hub, the other end of each lifting lever penetrates the shot of the shaft sleeve and is inserted into an inner cavity of the shaft sleeve, an outer gear ring of the splined hub is matched with the inner joint gear rings of the gears, and the bidirectional synchronization ring is arranged among the splined hub and the side walls of the inner cavities of the gears. The built-in clutch has the advantages that the built-in clutch and a gear shifting control mechanism of the built-in clutch are based on an existing parallel shaft type gear transmission, so that gears of the transmission can be closely arranged, the axial size of the transmission can be reduced, the volume of the transmission can be decreased, the transmission can be lightened, and the manufacturing cost can be lowered.

Owner:赵良红

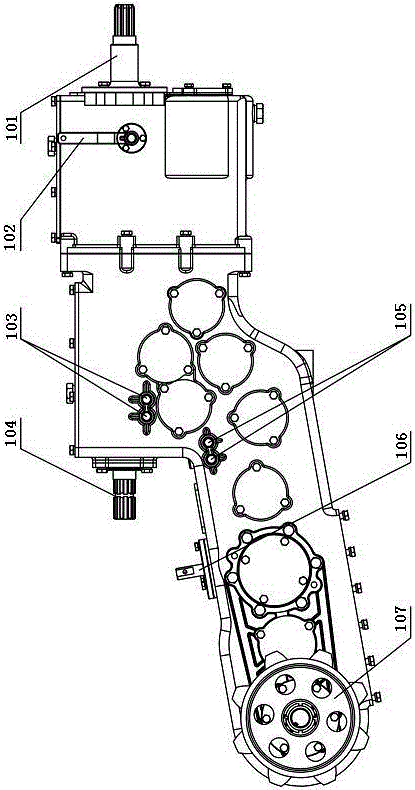

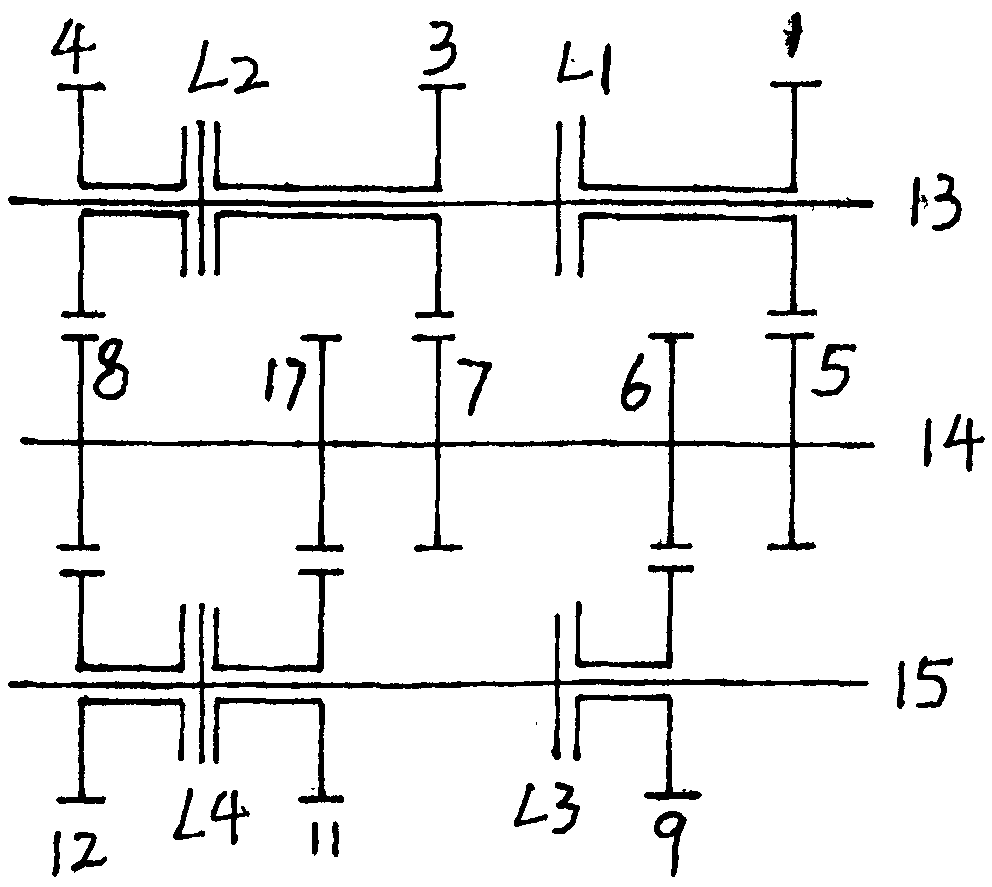

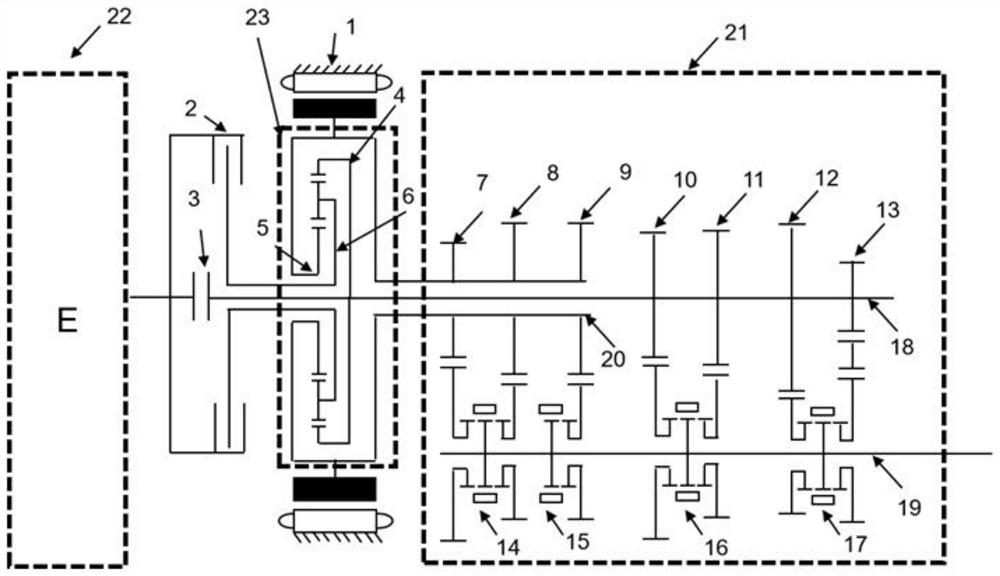

Track tractor twelve-gear transmission assembly

InactiveCN106224457AAdjustable walking speedIncrease the number of stallsToothed gearingsGearing controlLow speedDrive wheel

The invention discloses a track tractor twelve-gear transmission assembly. Power is respectively transferred to a rotary cultivation power output shaft part 104 and a walking power driving part 107 through a power input shaft part 101; the clutching and rotating speed adjustment of the rotary cultivation power output shaft part 104 is controlled through a rotary cultivation gear shifting part 102; a driving wheel controls a high-speed gear, a low-speed gear and a reverse gear through a walking high, low and reverse gear shifting part 103; four speed gears are controlled through a walking four-gear shifting part 105; and a walking steering part 106 respectively controls left-right output of the power to realize the steering function. The track tractor twelve-gear transmission assembly has the following advantages: (1) the track tractor twelve-gear transmission assembly can be connected with multiple machine tools on the market, has twelve gears, adopts low walking output, and can arrange various driving track patterns; (2) the rotary cultivation output and the walking are relatively independent; and (3) after the lower power output is applied to a medium-small track tractor, a small load wheel can be adopted.

Owner:湖南润田农机装备科技股份有限公司

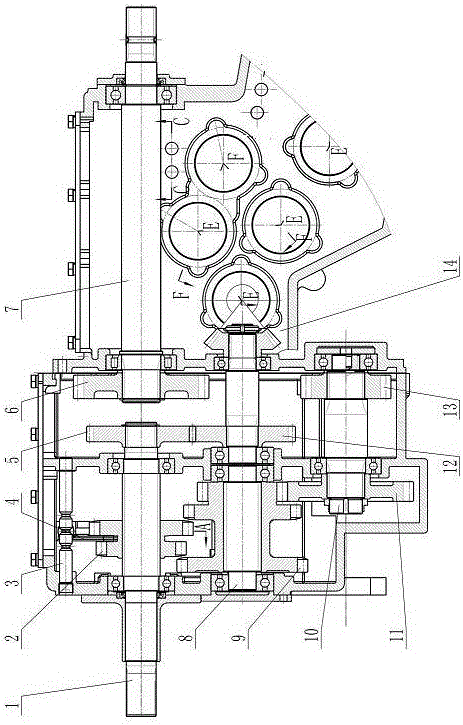

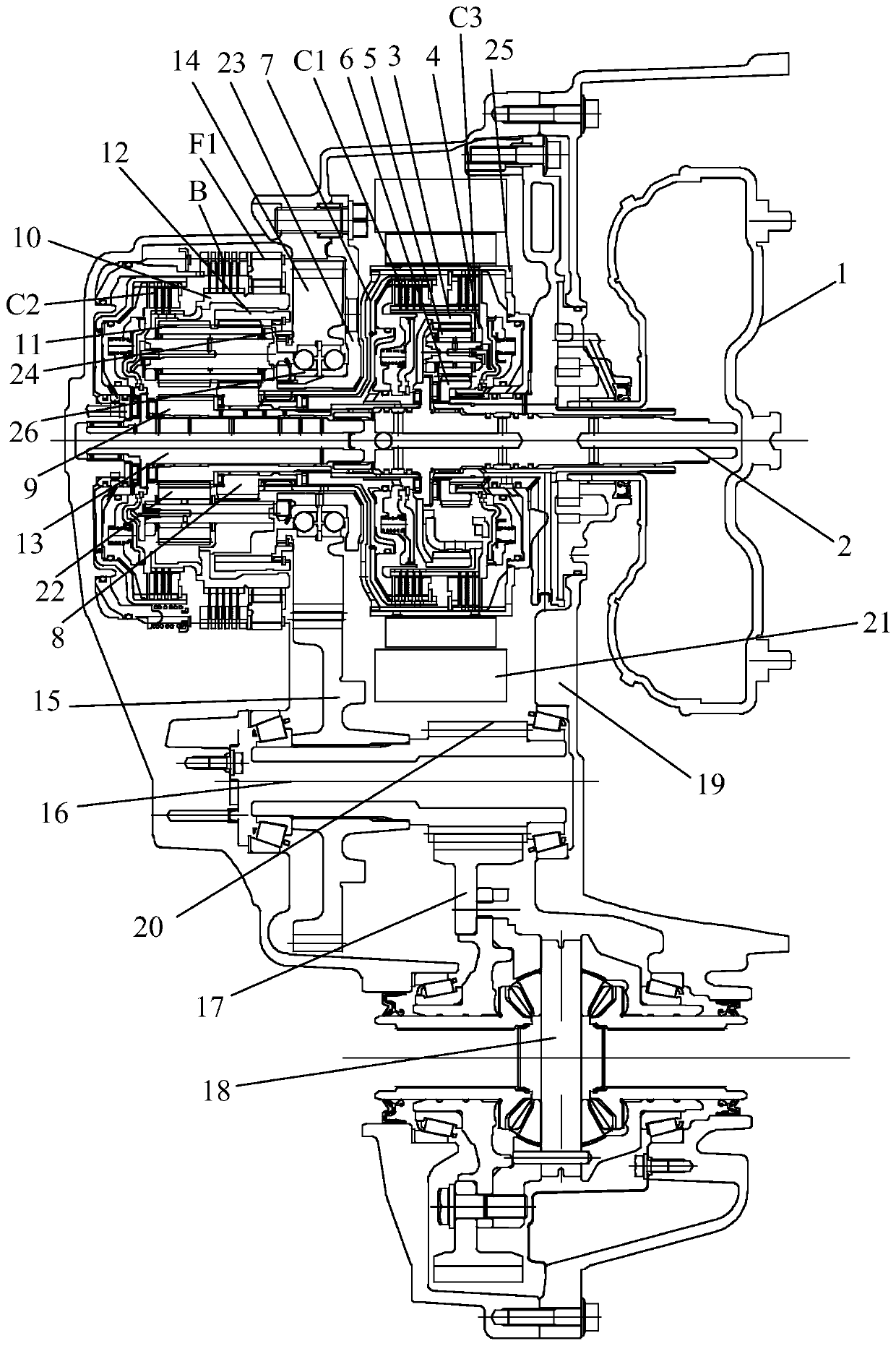

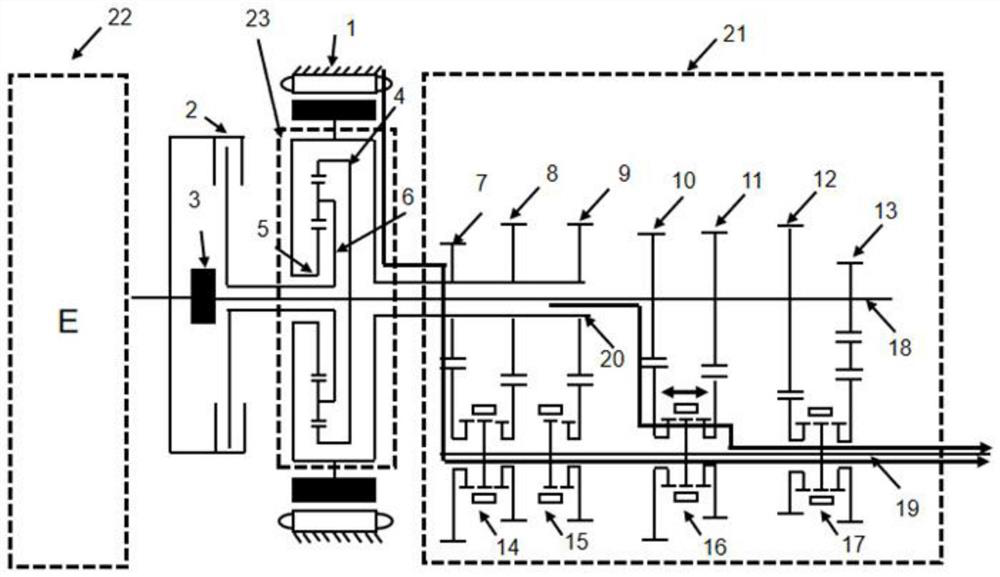

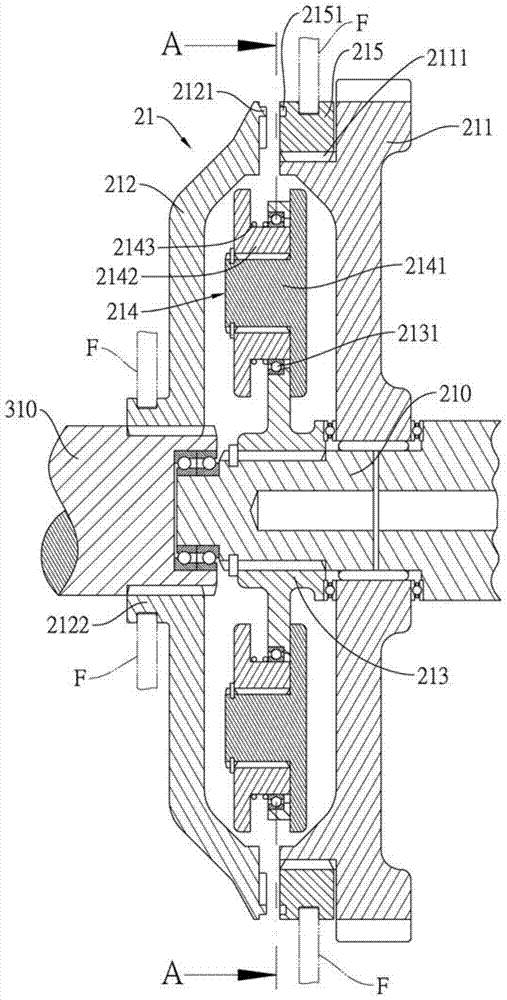

Hybrid power gearbox

PendingCN110529569ACompact structureIncrease the number of stallsToothed gearingsTransmission elementsEngineeringDrive motor

The invention discloses a hybrid power gearbox which comprises an input shaft, an intermediate shaft connected with the input shaft, an output shaft, an output driven gear arranged on the output shaft, a differential mechanism driven gear meshed with a differential mechanism driving gear and connected with a differential mechanism assembly, a hydraulic torque converter and a front-row planetary gear mechanism which are connected with the input shaft; a central support mechanism, a first clutch connected with the front-row planetary gear mechanism and a Ravigneaux planetary gear mechanism, a second clutch connected with the Ravigneaux type planetary gear mechanism and the intermediate shaft, a third clutch connected with the front row planetary gear mechanism and a driving disc, a one-way clutch connected with the Ravigneaux type planetary gear mechanism and a transmission shell, and a driving motor connected with the front row planetary gear mechanism through the third clutch. The hybrid power gearbox is compact in structure, many in function modes, small in space and remarkable in cost advantage, the number of gears is increased, and the fuel economic performance is improved.

Owner:吉孚汽车技术(苏州)有限公司

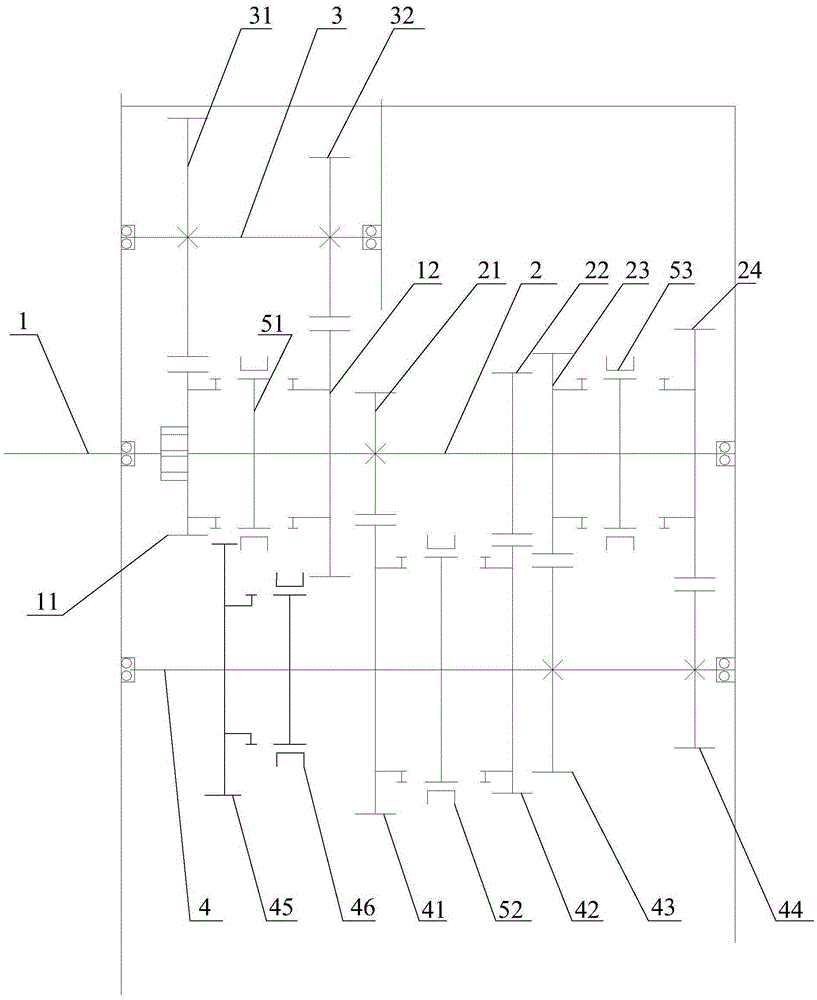

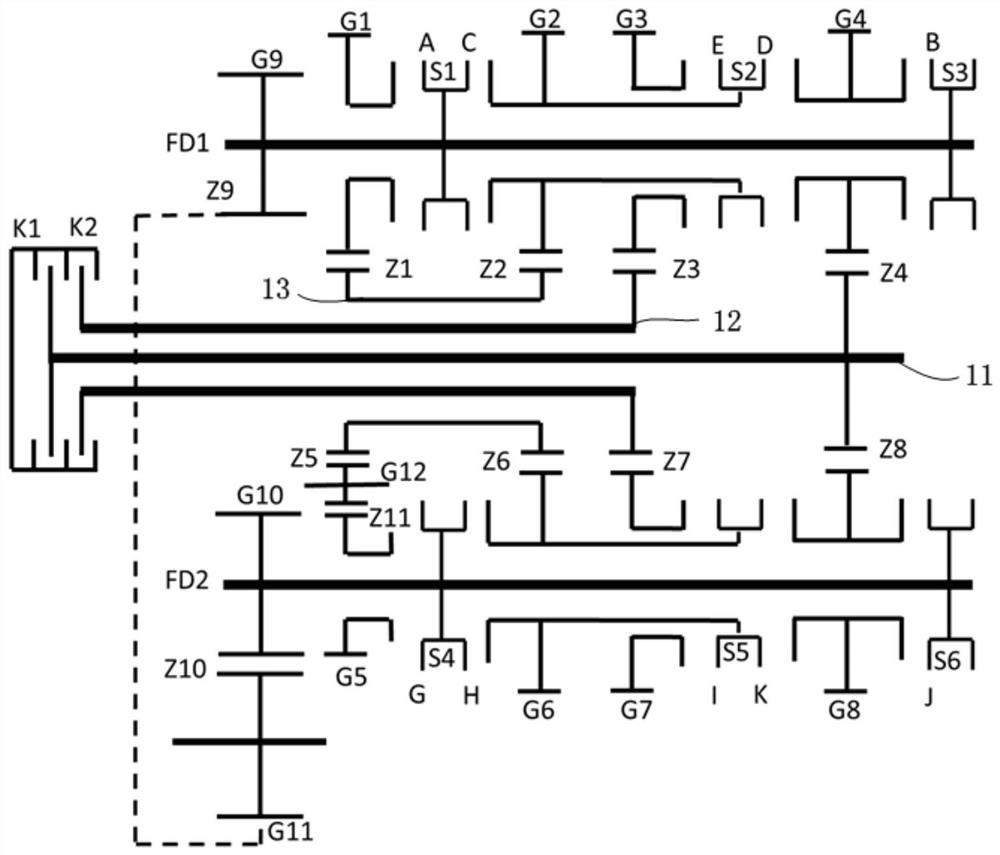

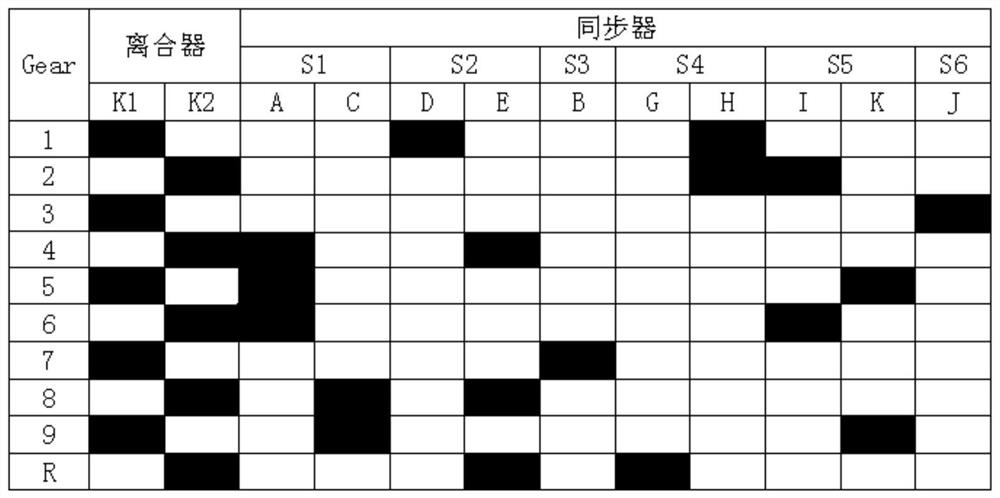

Multi-clutch type variable transmission device

The invention relates to a multi-clutch type variable transmission device and relates to a double-clutch variator. The multi-clutch type variable transmission device comprises an input shaft, a first auxiliary shaft, a second auxiliary shaft, an output shaft, double clutches, a synchronizer and gears. According to the multi-clutch type variable transmission device provided by the invention, by virtue of the combination of the two double clutches, the synchronizer and the gears, the gear is automatically and smoothly changed; by virtue of the structure of sharing the gears and adding one double clutch, the gear number is greatly increased, and the amount of gear shifting gear is reduced; and as each pair of gears adopt a small velocity ratio and a short transmission shaft structure, the rigidity of a variator is strengthened, the radial and axial sizes of the variator are reduced, and the structure of the variator is compact.

Owner:郭质刚

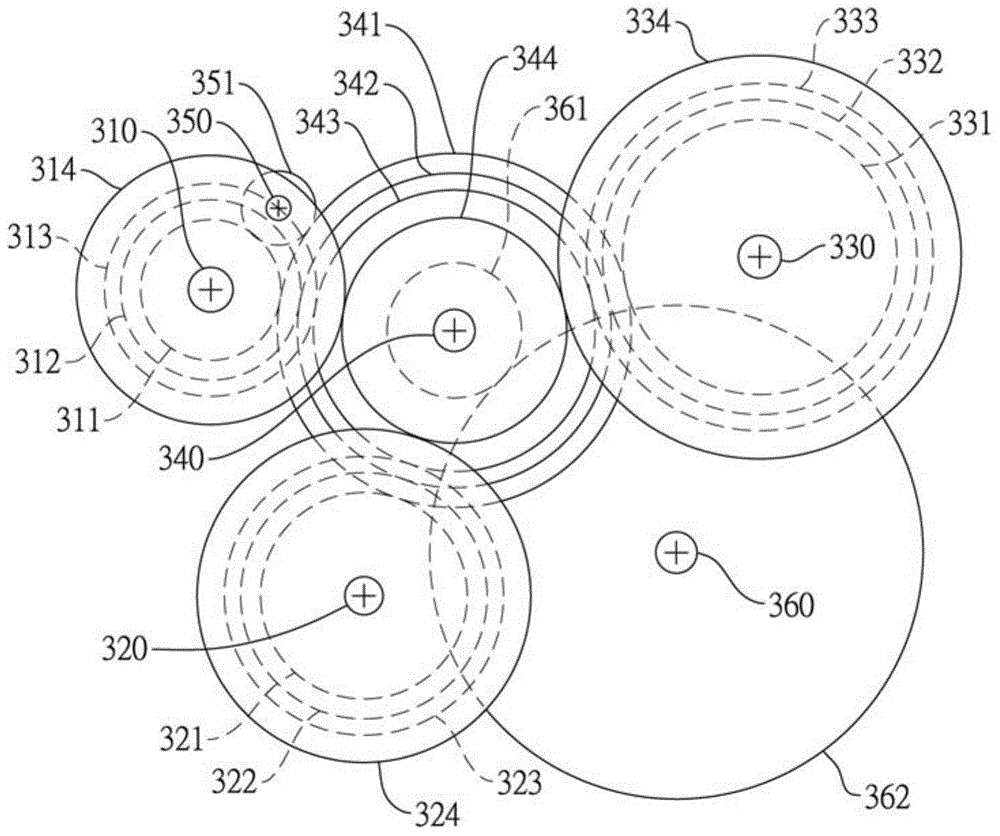

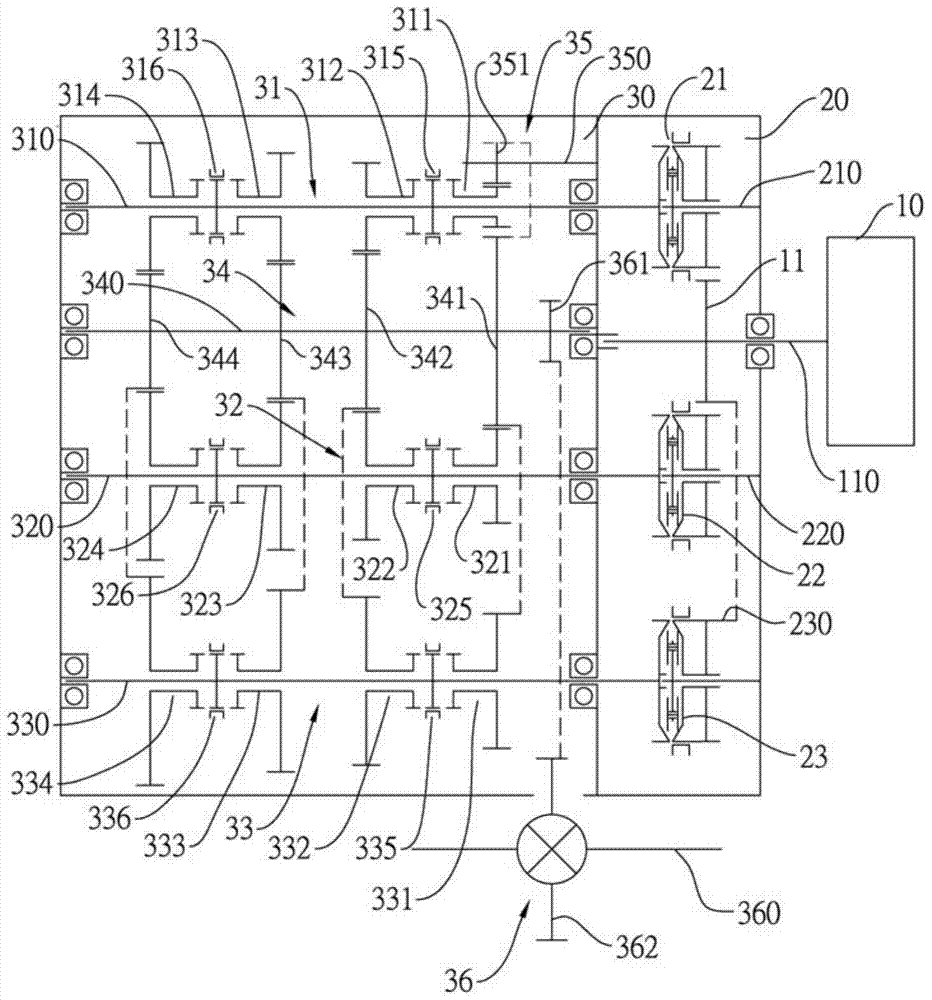

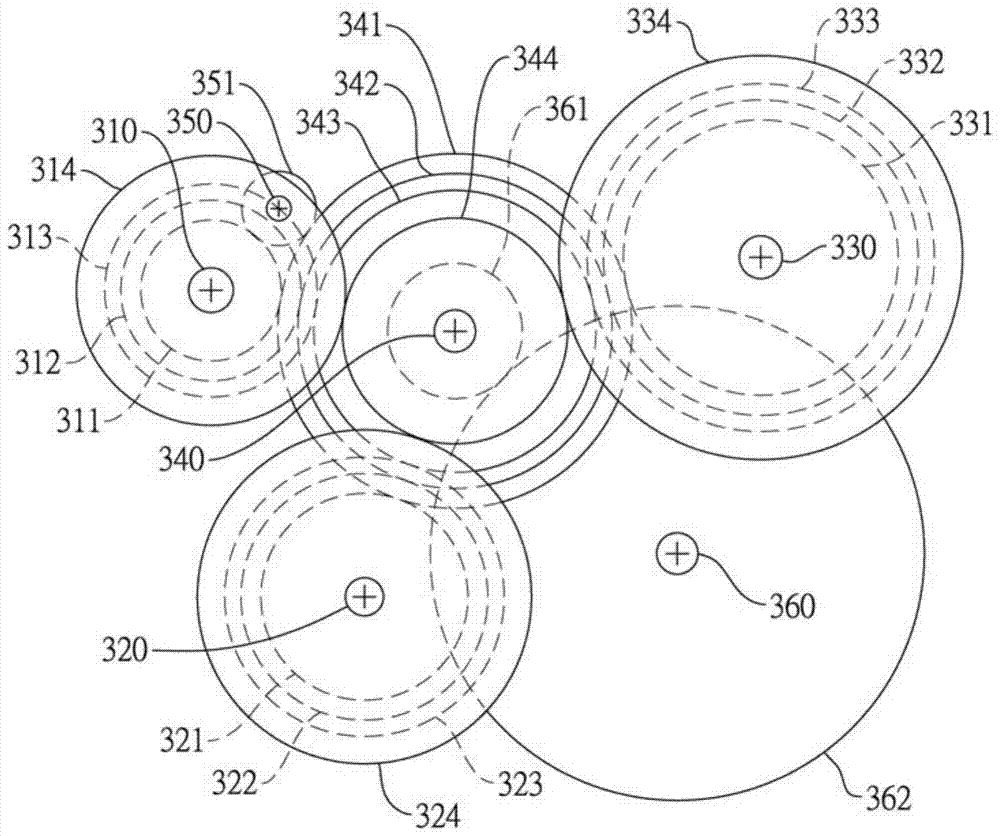

Traction driving isochronism speed governor and multiple-driving-shaft transmission adopting same

InactiveCN105221683AIncrease the number of stallsAvoid wear and tearToothed gearingsDrive shaftEngineering

The invention relates to a traction driving isochronism speed governor and a multiple-driving-shaft transmission adopting the same. The multiple-driving-shaft transmission comprises a speed governor chamber and a variable-speed gear chamber. According to the invention, the power of an engine is transmitted to an output set of the transmission in a traction driving manner by the isochronism speed governor in the speed governor chamber, a plurality of roller sets are arranged between an input part and an output part of the speed governor in a planetary manner and the output part pushes against the roller sets to move axially so as to be in contact with the input part, therefore, the effect of transmission of power is realized; and meanwhile, the shaft of all driving sets in the variable-speed gear chamber are arranged in parallel at unequal shaft intervals around the shaft of the output set and by taking the shaft of the output set as a center, so that number of gears of the transmission can be increased in limited space. Through adopting the traction driving isochronism speed governor and implementing the technical means of arranging shafts of all driving sets, the problems of low transmission efficiency of a transmission, clutch abrasion and larger occupied area during speed change gear increase in the prior art are improved.

Owner:孙振台

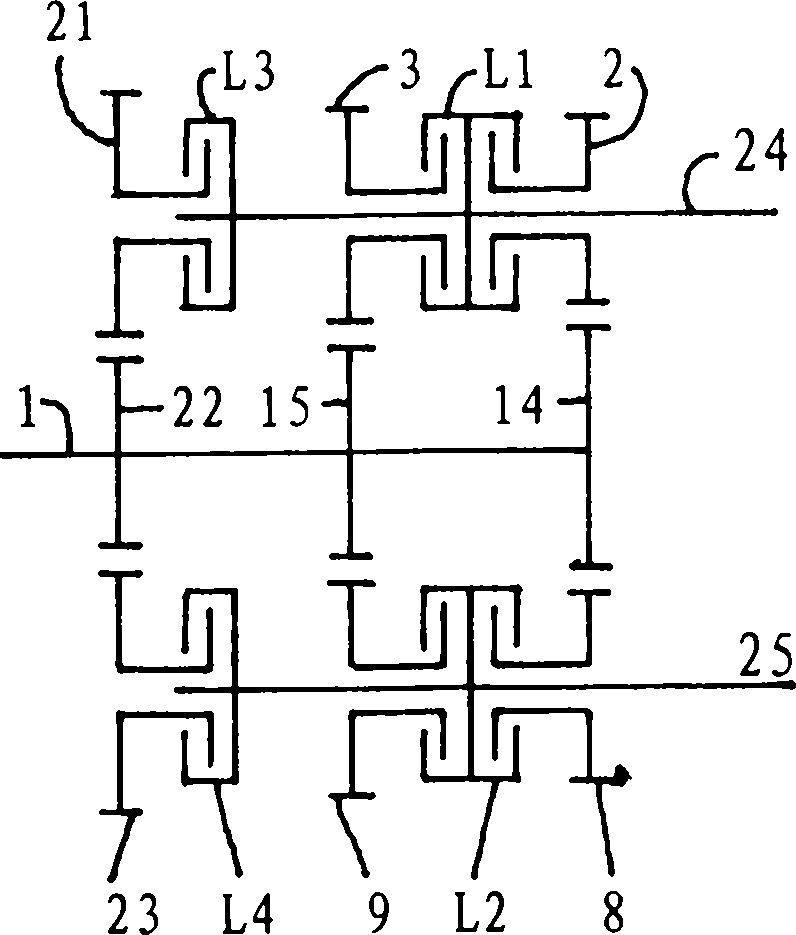

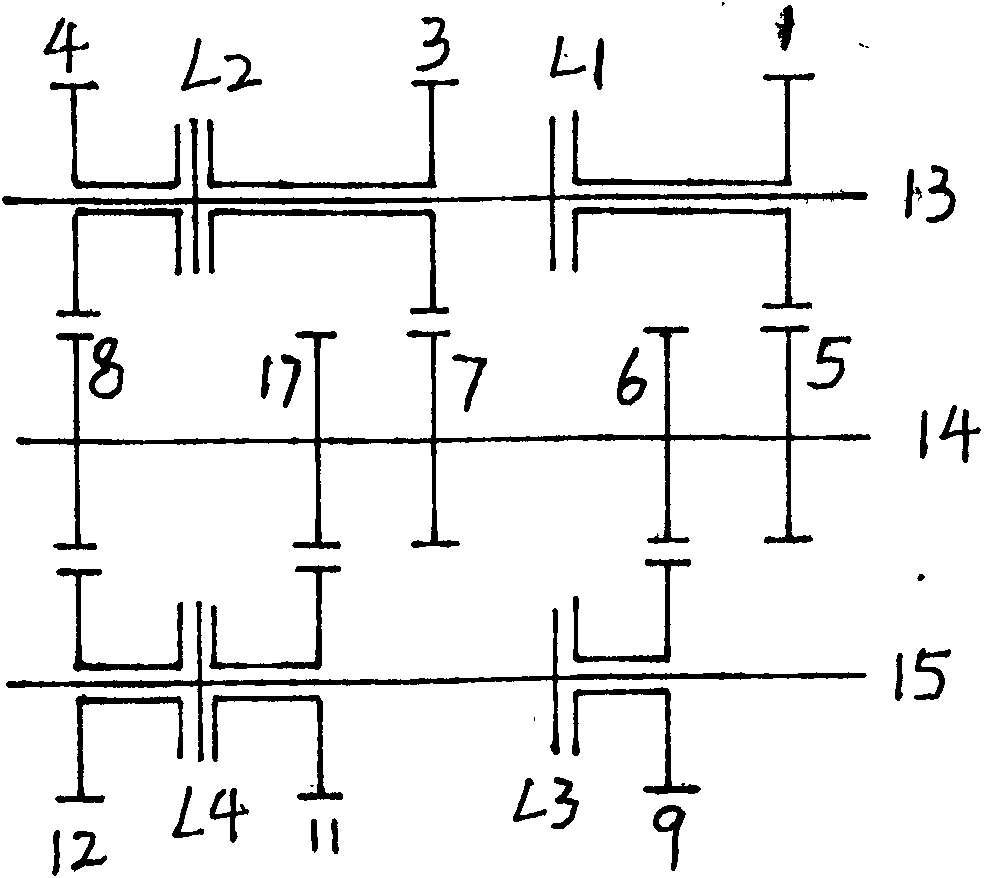

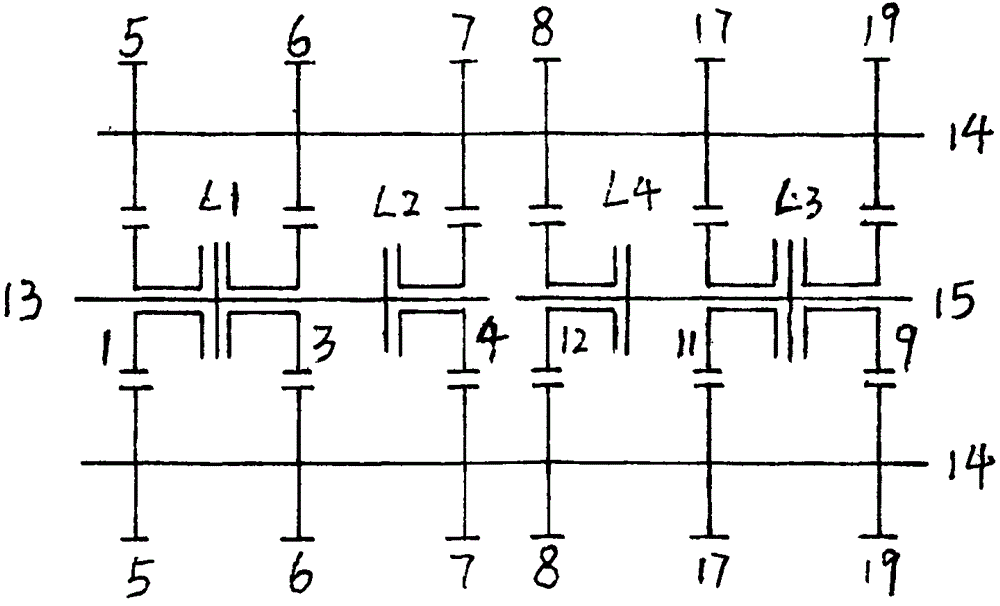

Automobile and mixed-connected double-intermediate-shaft transmission thereof

InactiveCN105402332AGear change implementationReduce wasteGearboxesToothed gearingsGear wheelTransmitted power

The invention discloses an automobile and a mixed-connected double-intermediate-shaft transmission thereof. The mixed-connected double-intermediate-shaft transmission comprises an input shaft, a first intermediate shaft, a second intermediate shaft, an output shaft, gears installed and distributed on all the shafts, a gear shifting mechanism, a shell, bearing oil seals and other components. In the power transmission process, the second intermediate shaft can be connected to the first intermediate shaft to transmit power and can be directly connected with the input shaft without being connected with the first intermediate shaft to transmit power, and therefore the transmission efficiency of the transmission is improved. The gear number of the mixed-connected double-intermediate-shaft transmission is equal to the product of the number of gears on the first intermediate shaft and the number of gears on the output shaft, however, the gear number of an existing transmission is usually equal to the sum of all the gear meshing pairs of the transmission. By the adoption of the mixed-connected double-intermediate-shaft transmission of the automobile, on the premise that the size and the weight of a traditional 6-gear transmission are not changed, the transmission with 8 gears or 9 gears can be achieved. The power performance, the fuel economical efficiency and the driving and riding comfort of the whole automobile can be remarkably improved, and the transmission is particularly suitable for being used as an AMT.

Owner:力帆科技(集团)股份有限公司

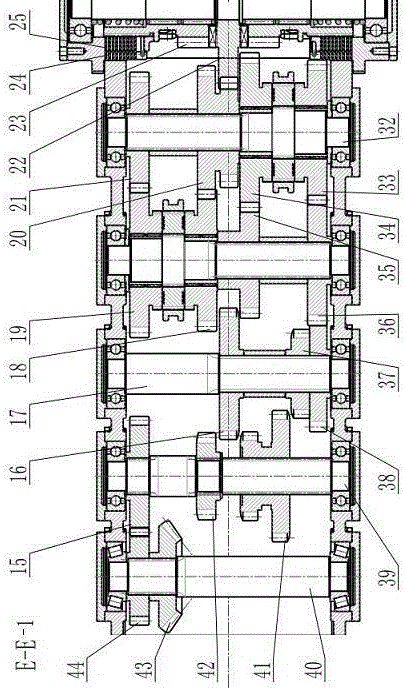

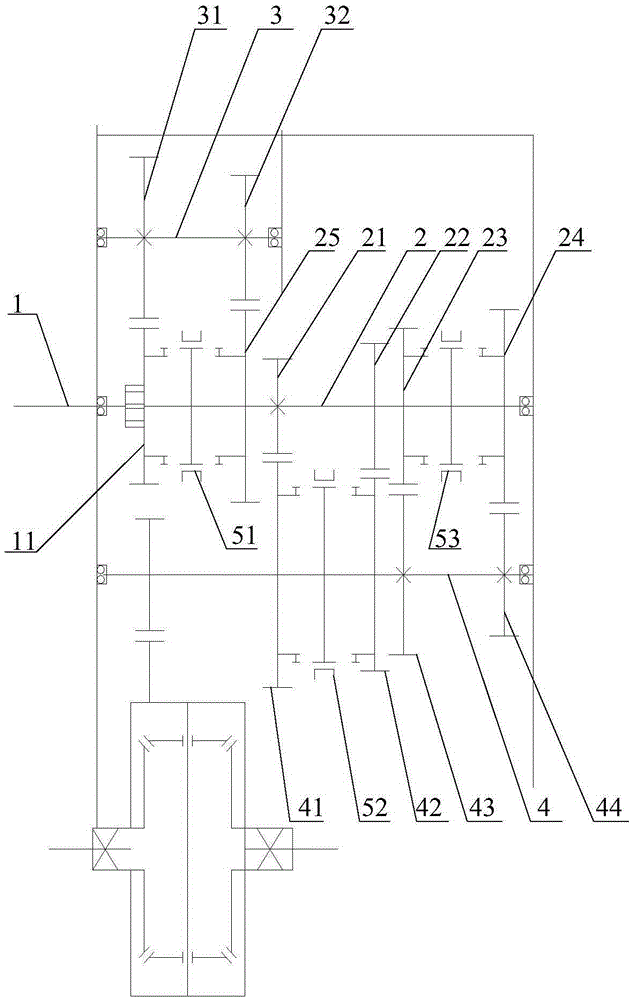

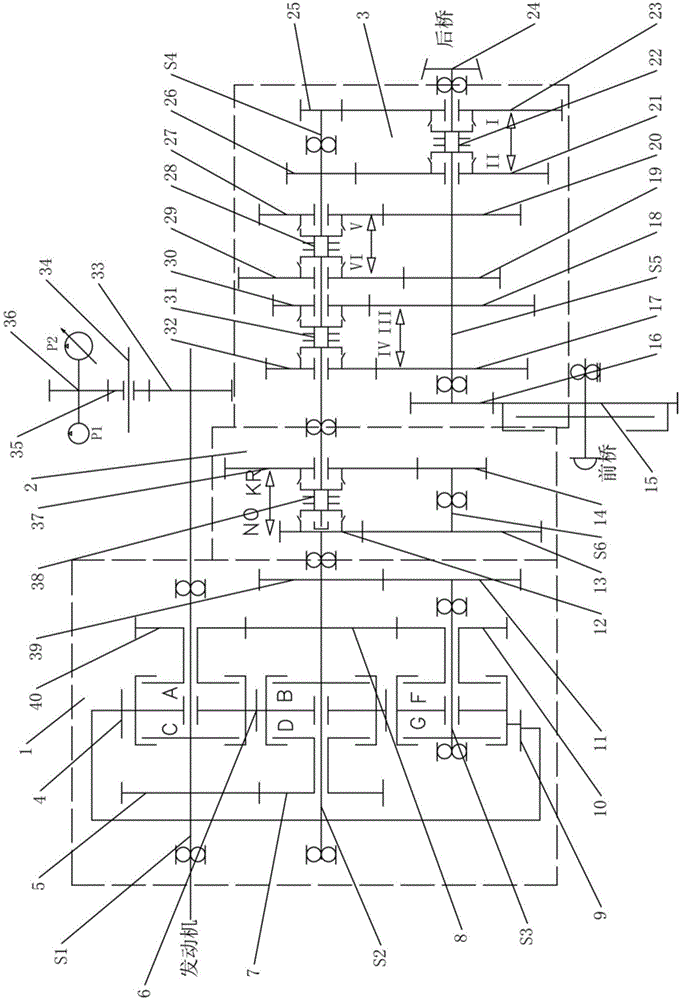

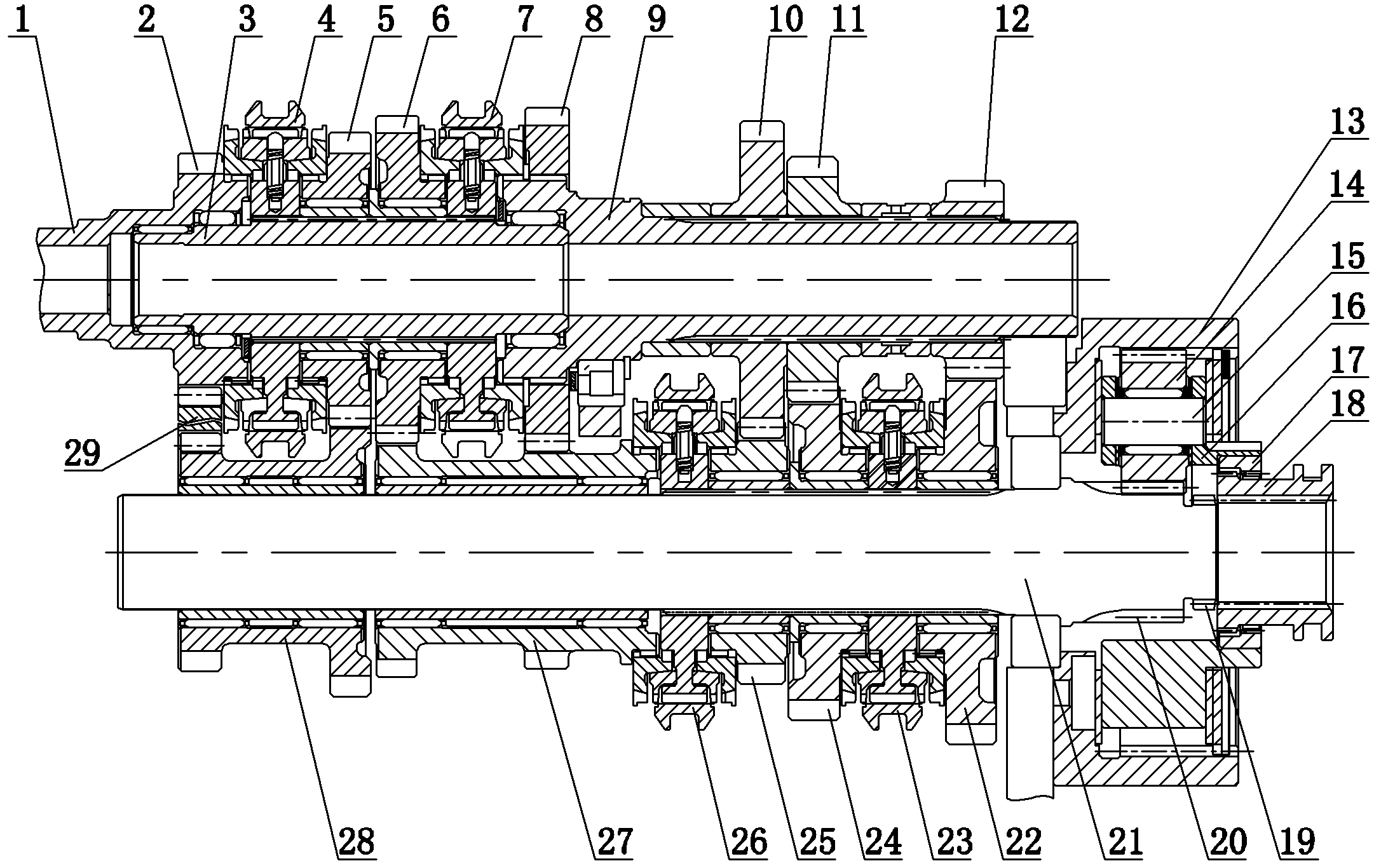

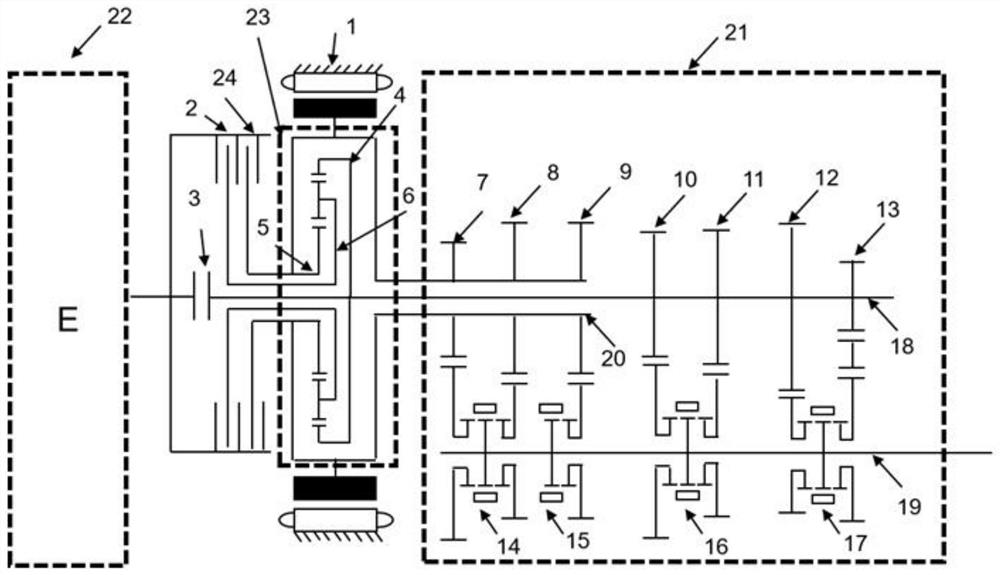

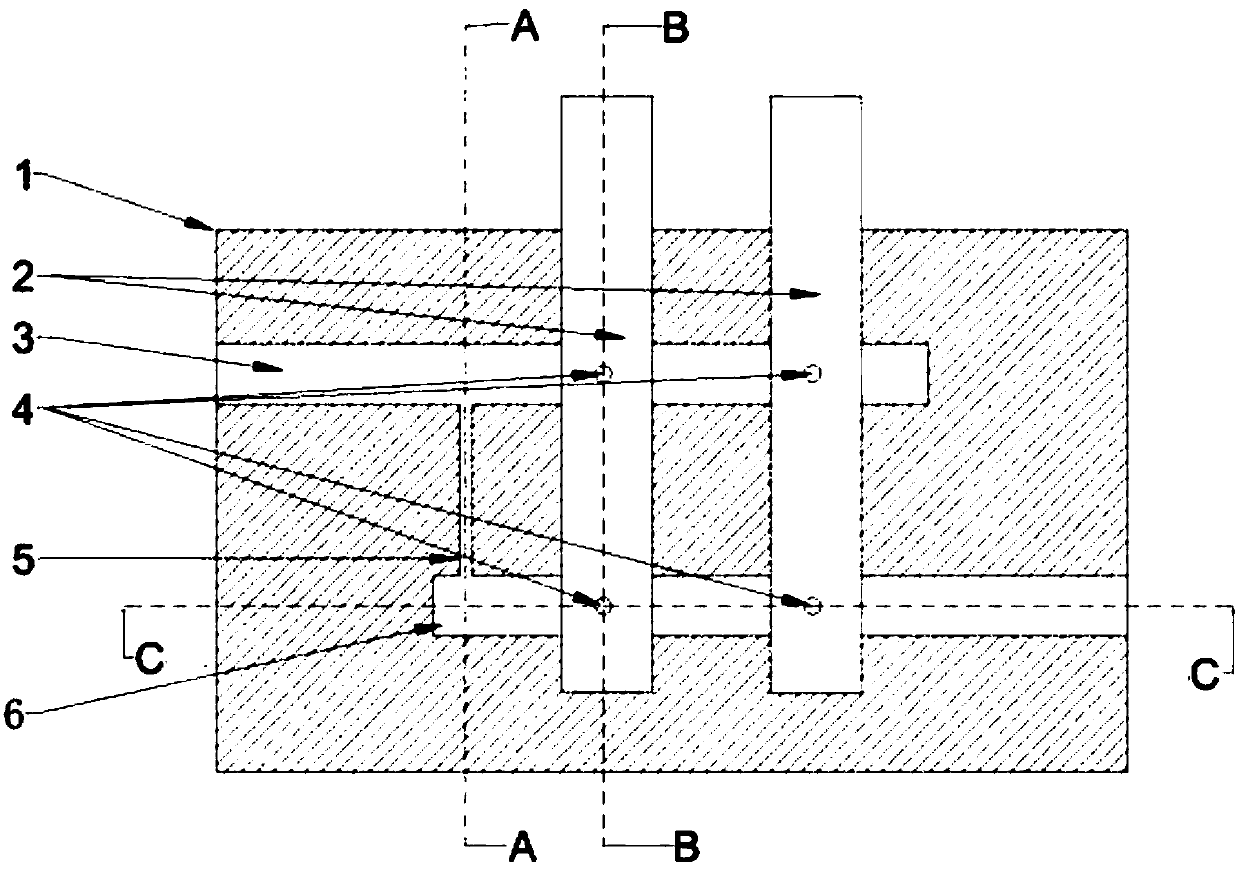

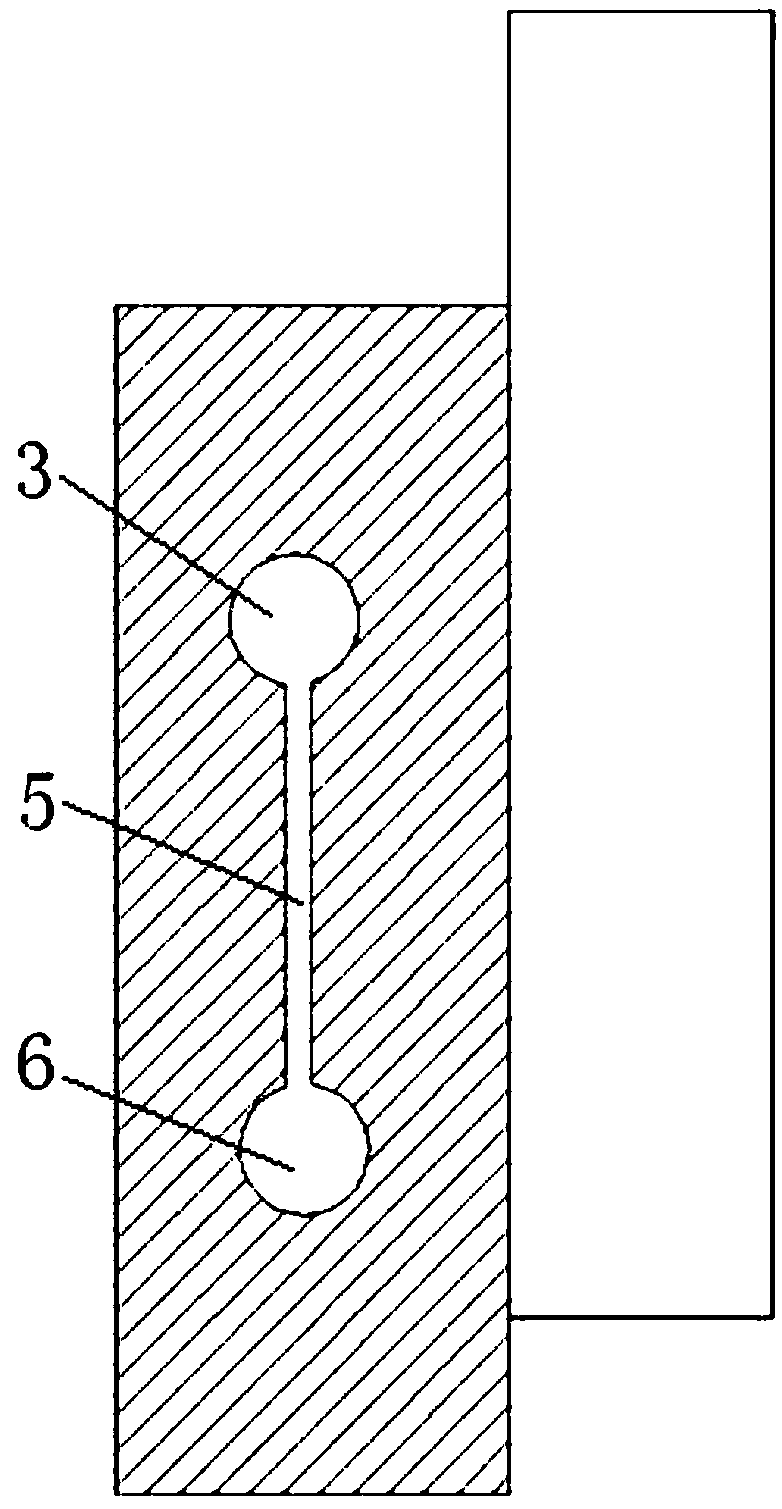

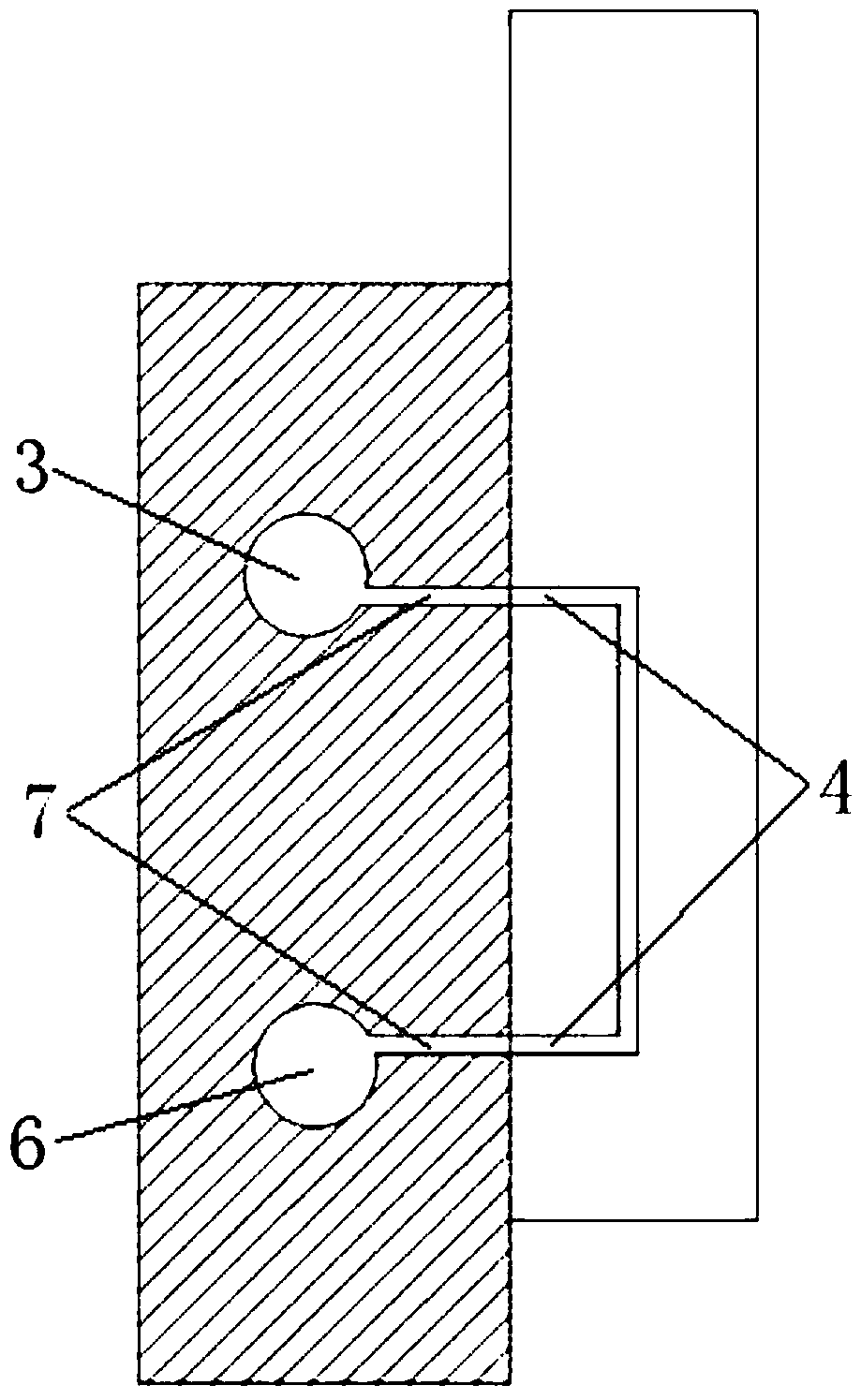

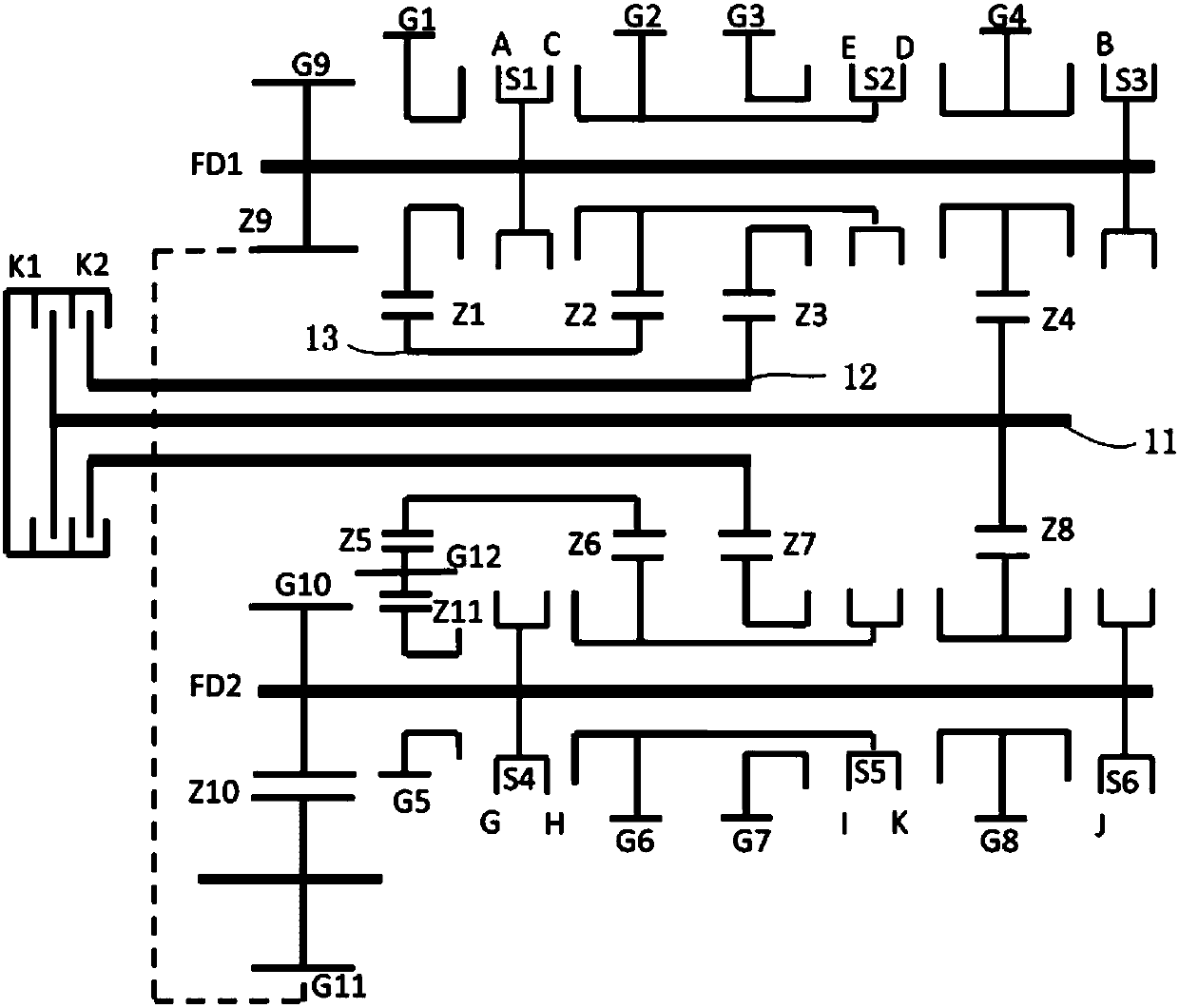

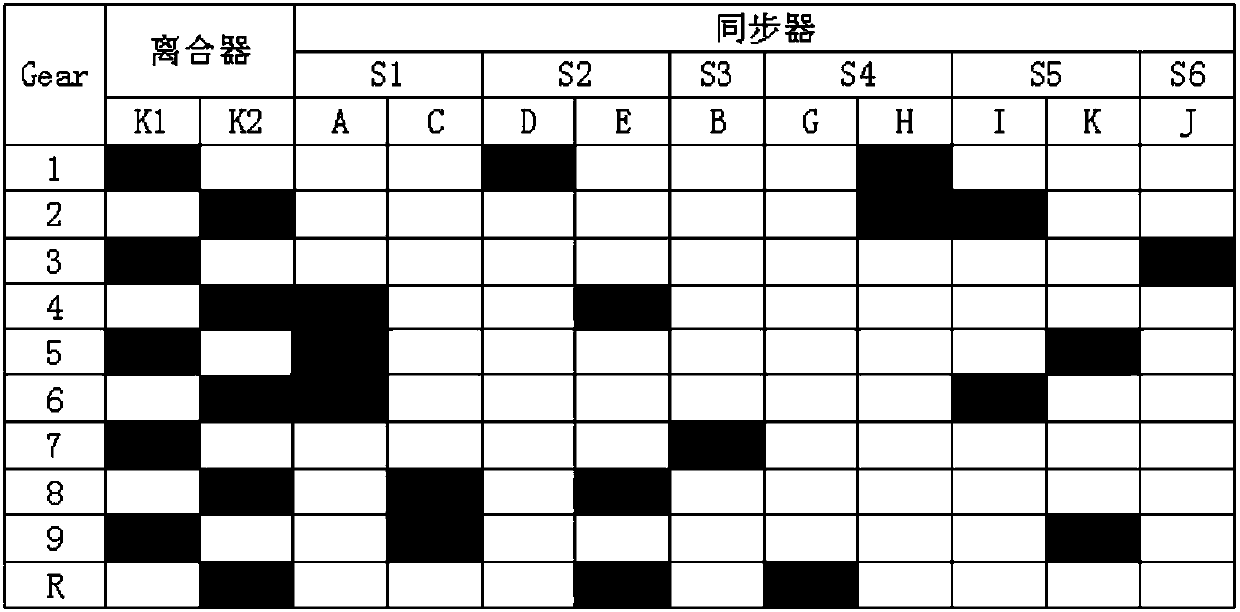

Partial power shifting transmission device for tractor

InactiveCN104653720AIncrease the number of stallsHigh transmission efficiencyGearboxesToothed gearingsEngineeringTractor

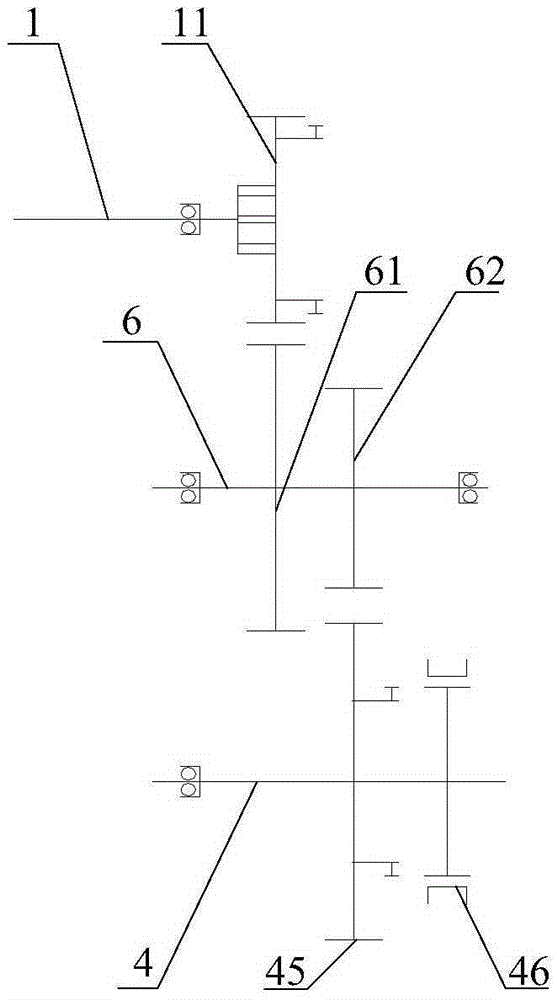

The invention relates to the field of a tractor and discloses a partial power shifting transmission device for the tractor. The partial power shifting transmission device for the tractor comprises a power shifting part (1), an ordinary creeper gear shifting part (2) and a synchronizer shifting part (3), wherein a shaft I (S1), a shaft II (S2) and a reverse gear shaft (S3) are mounted inside the power shifting part (1); a shaft IV (S4) and a shaft V (S5) are mounted inside the synchronizer shifting part (3); one end of the shaft I (S1) is connected with an engine, and the other end of the shaft I (S1) is connected with a hydraulic control mechanism (36); one end of the shaft V (S5) is connected with a rear axle, and the other end of the shaft V (S5) optionally outputs power to a front axle; the shaft IV (S4) and the shaft II (S2) are coaxially arranged, and are connected with each other through the ordinary creeper gear shifting part (2). With the adoption of the partial power shifting transmission device for the tractor, the gear number is increased while partial power shifting is realized, so that the transmission efficiency of the entire transmission device is improved, and the manufacture cost is reduced.

Owner:HENAN LISHEN MACHINERY

Gear combined type variable-speed transmission device

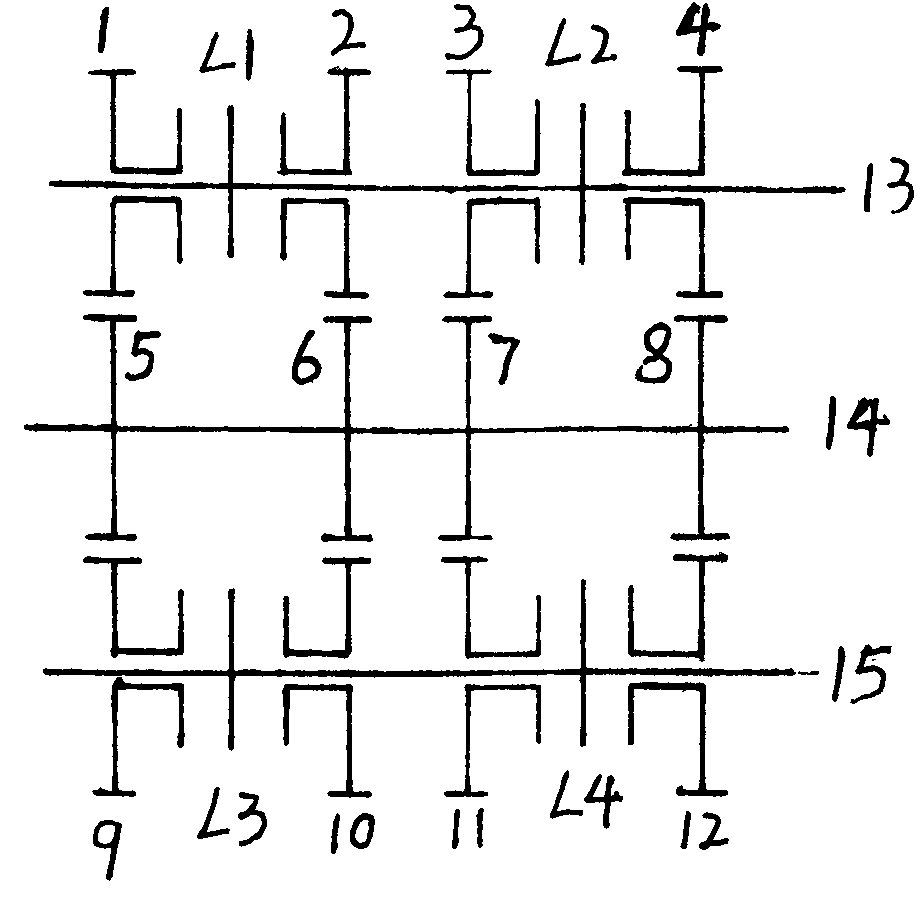

The invention relates to a gear combined type variable-speed transmission device. The gear combined type variable-speed transmission device consists of an input shaft, an output shaft, an intermediate shaft, clutches (or synchronizers) and gears. More than 6 clutches or one clutch and more than 6 synchronizers and more than 9 gears are combined in serial-parallel connection modes, the gear number is remarkably increased, and the number of shifting gears is decreased. Due to the fact that each pair of gears has small speed ratio and adopts a short transmission shaft structure, the rigidity of a transmission is improved, the radial and axial sizes are reduced, and the transmission is compact in structure and high in mechanical efficiency. The invention further provides a reverse gear device used on a mechanical variable-speed transmission mechanism.

Owner:郭质刚

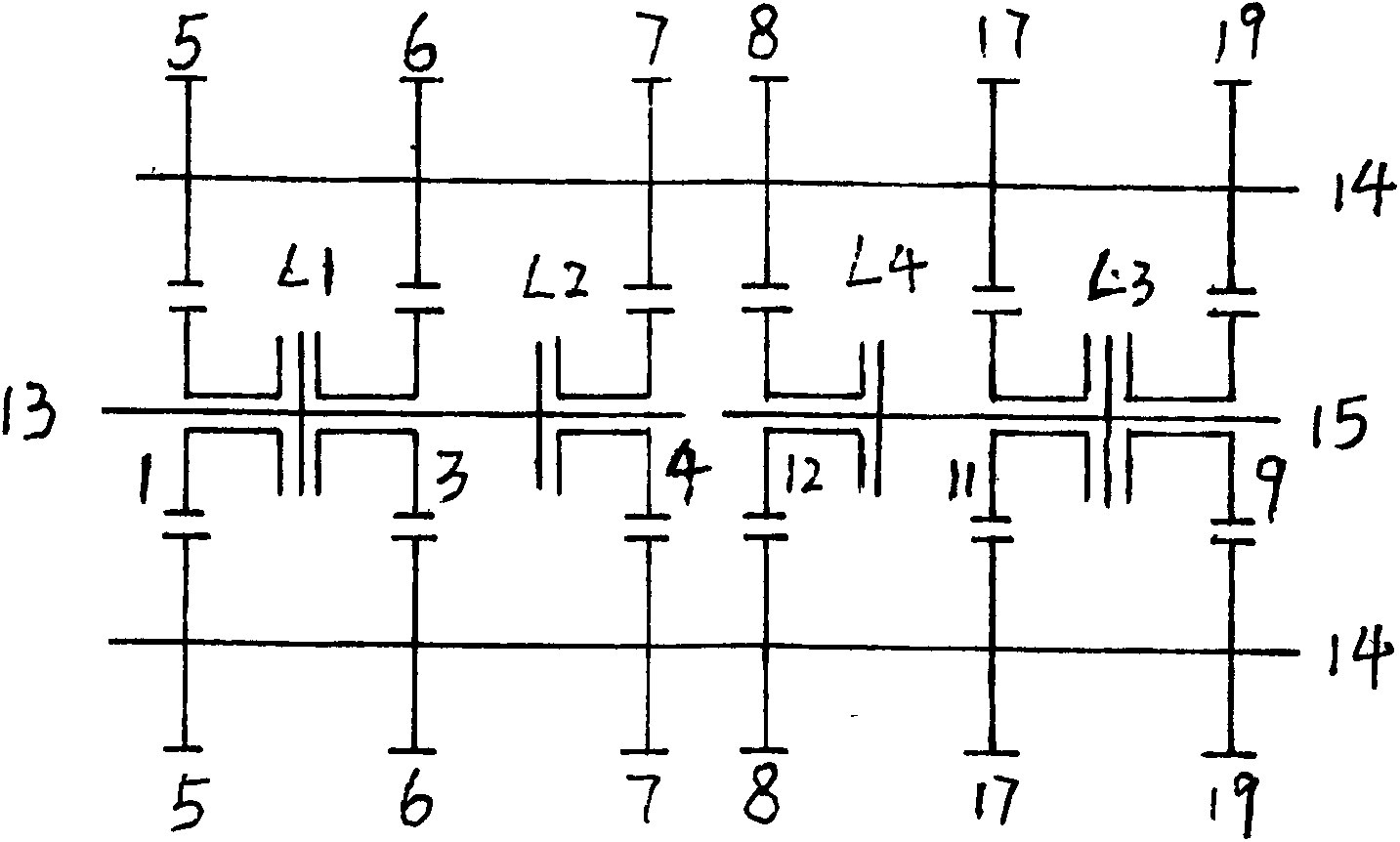

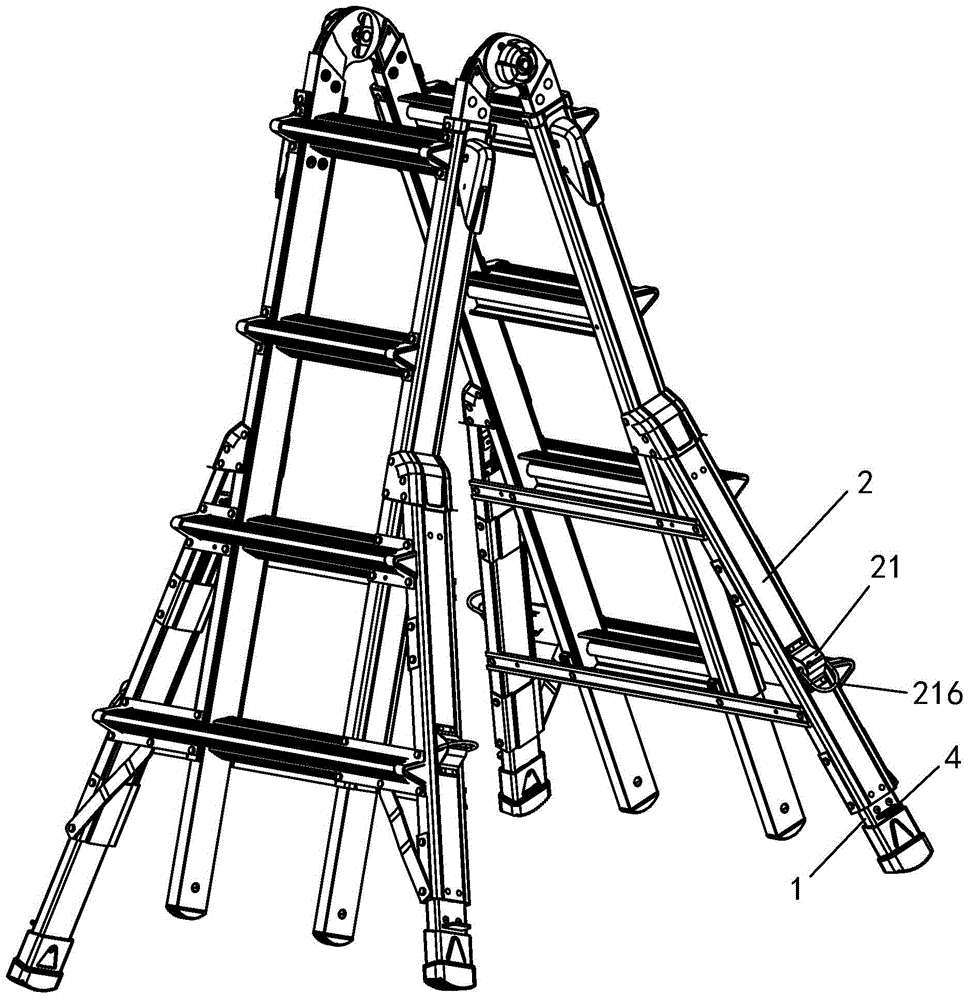

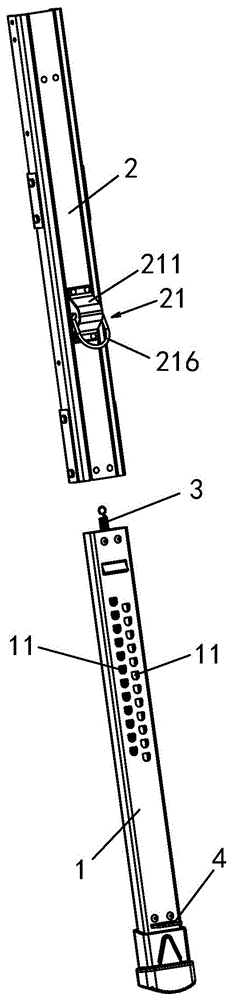

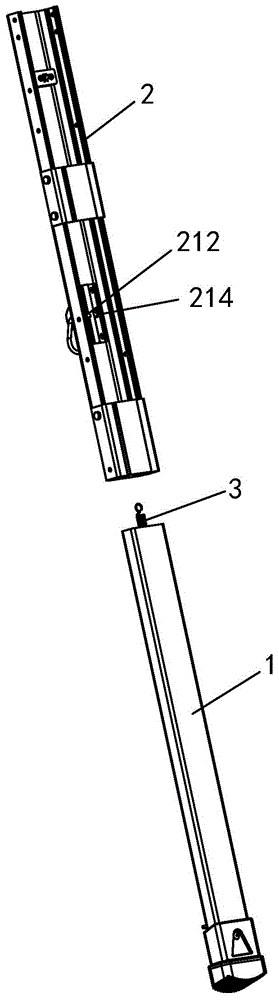

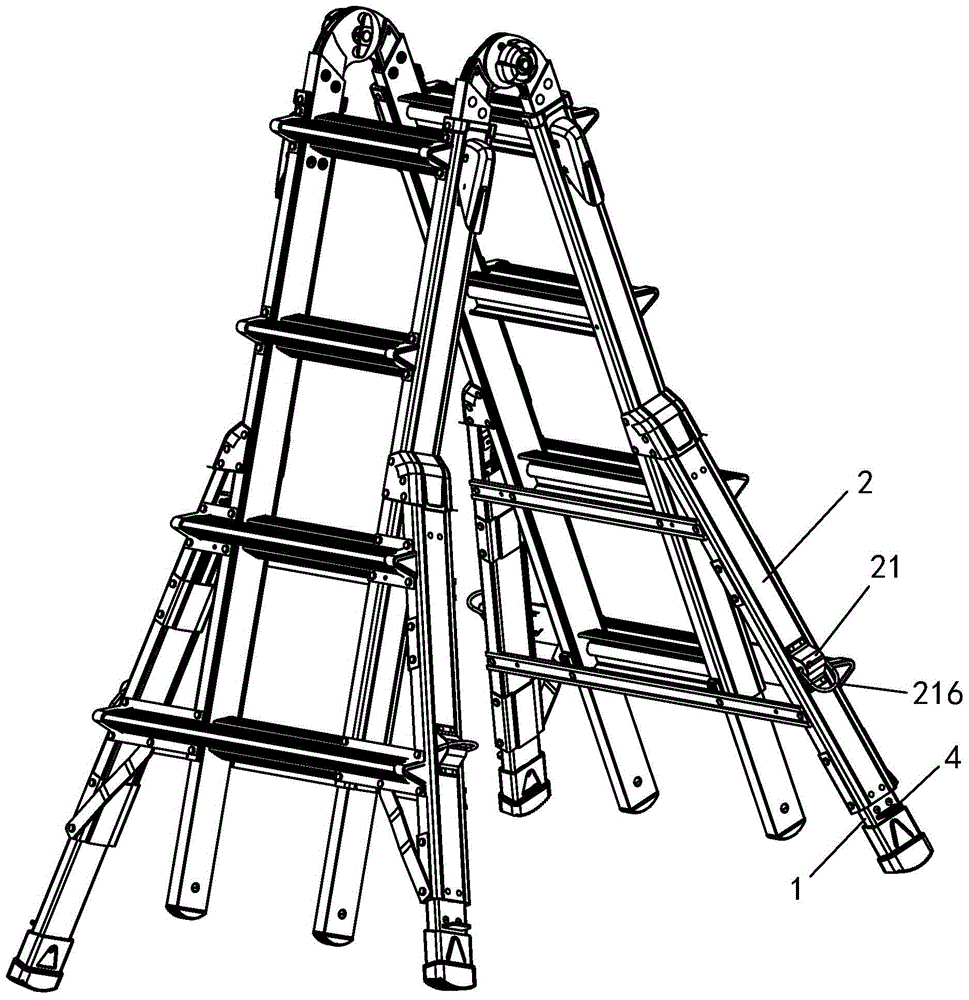

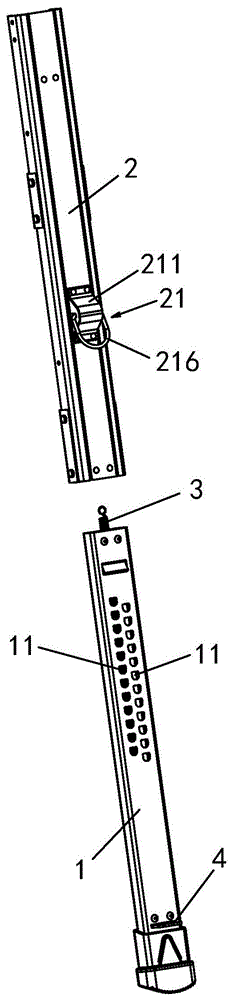

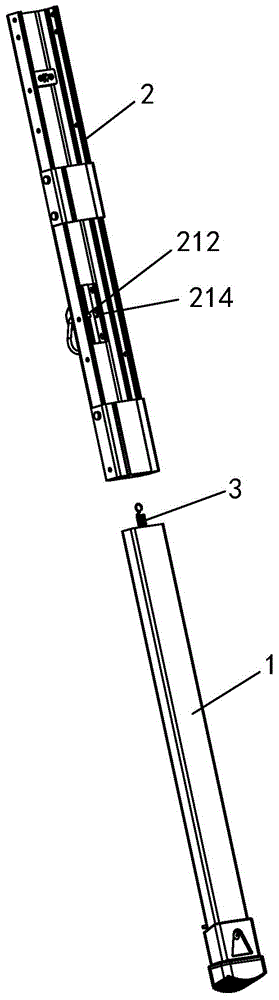

Stretching foot lock catch adjusting mechanism

ActiveCN105041196AIncrease the number of stallsImprove ease of useScaffold accessoriesLaddersMechanical engineeringEngineering

Owner:小巨人公司

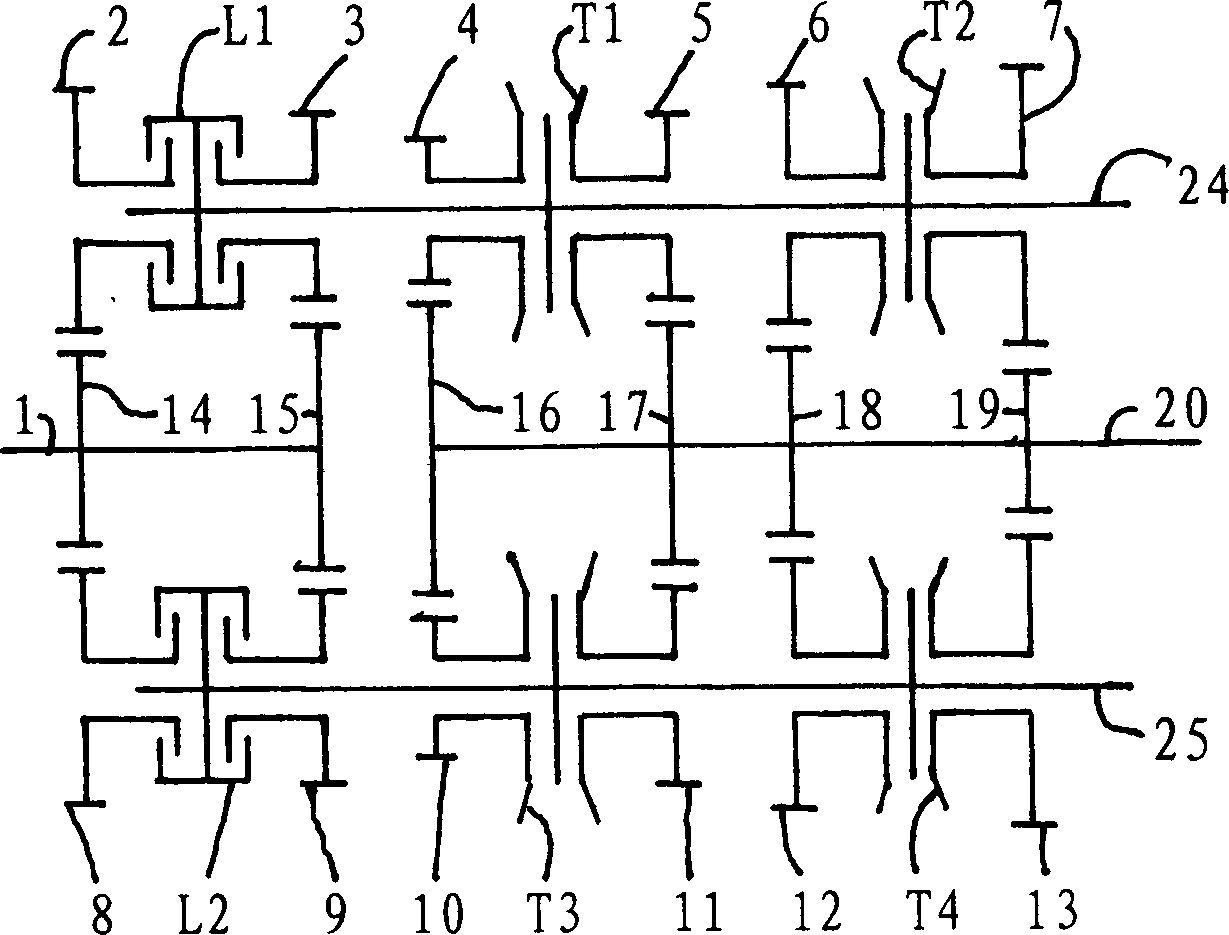

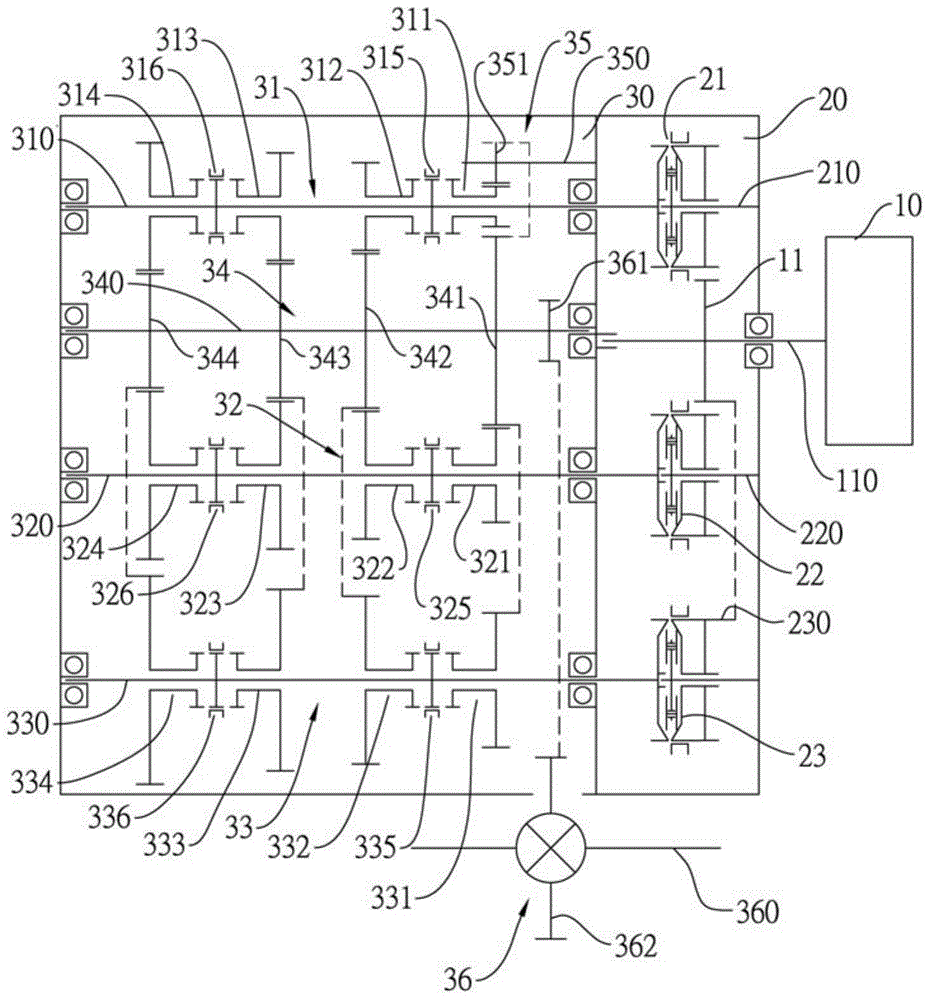

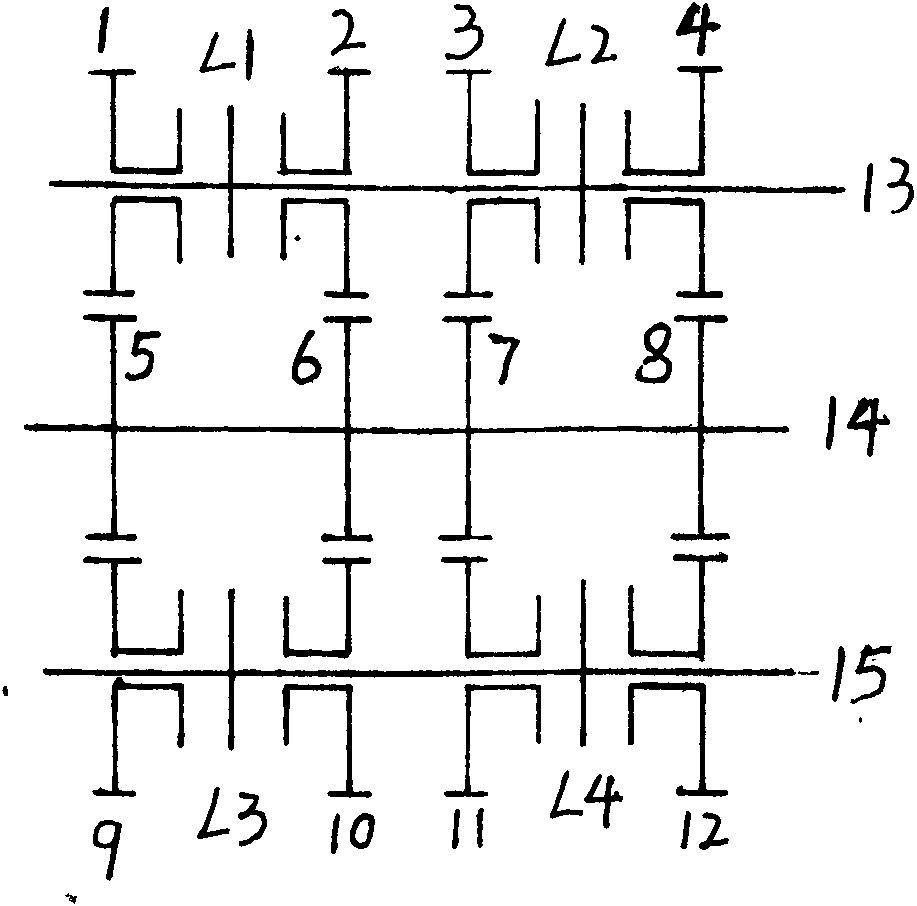

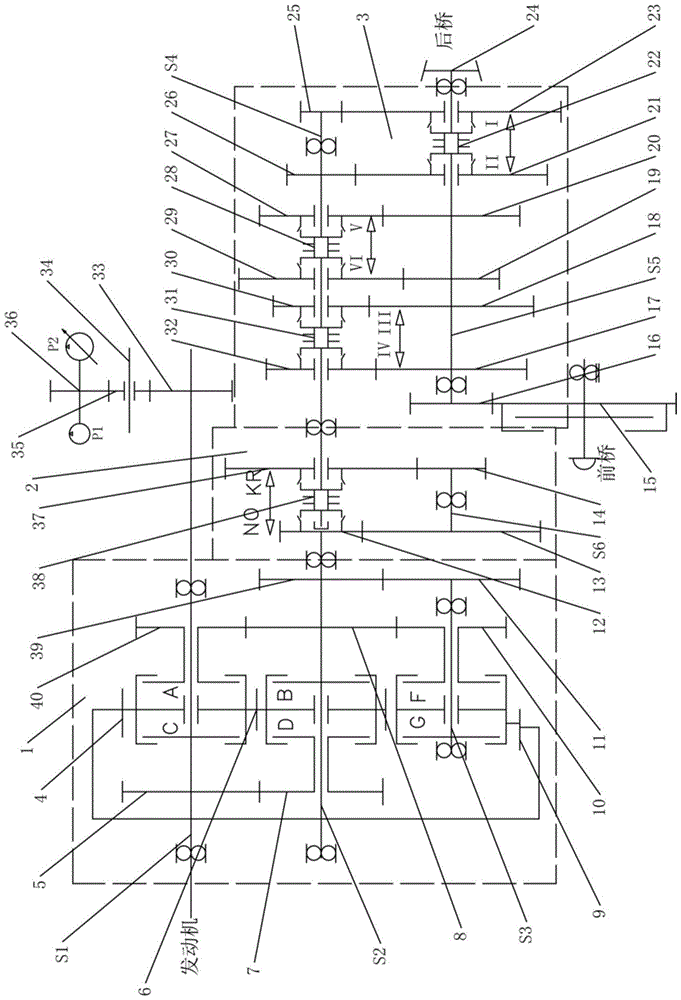

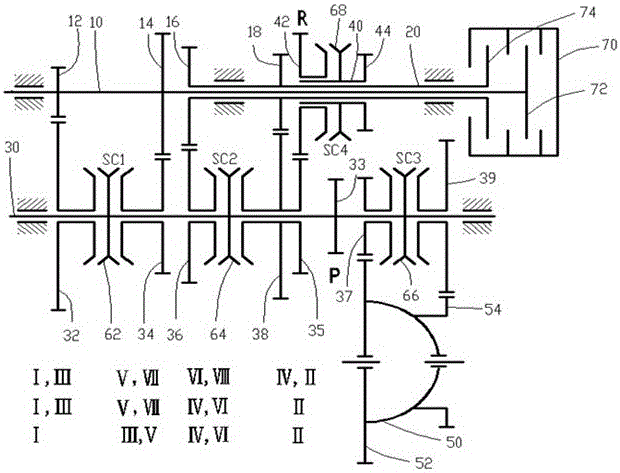

Tractor speed change device with 16+16 gears

ActiveCN102537288AAchieve conversionIncrease the number of stallsGearboxesToothed gearingsControl engineeringTractor

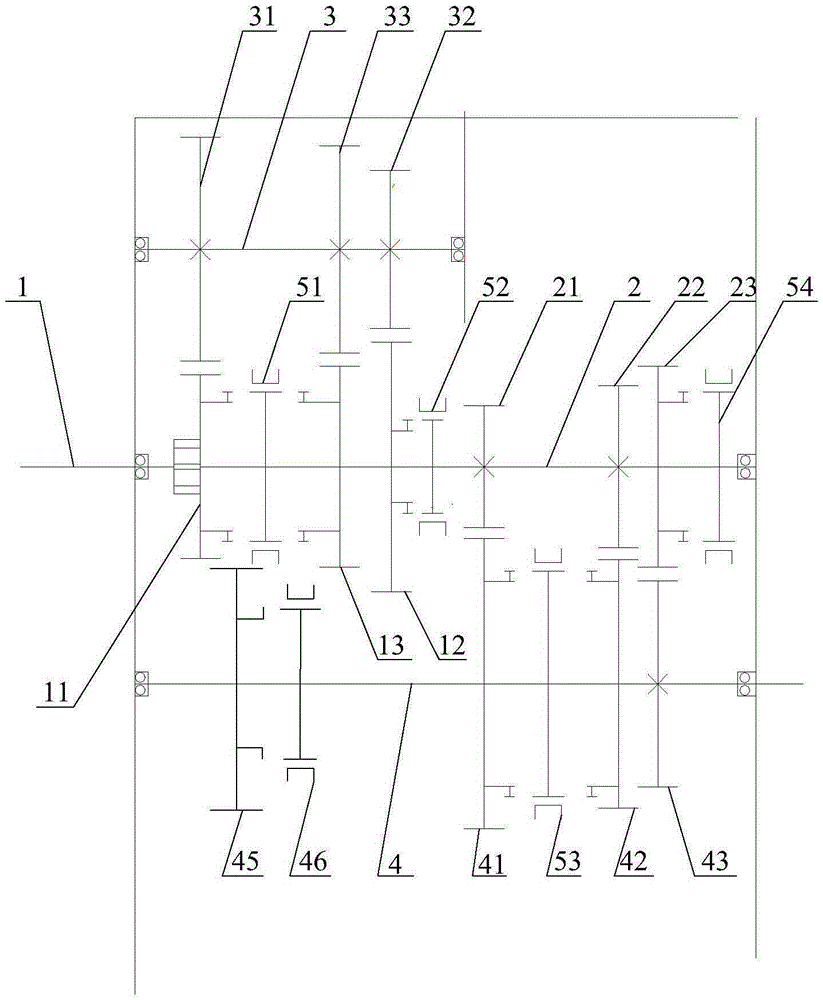

The invention discloses a tractor speed change device with 16+16 gears, which comprises a gear shifting unit, a primary auxiliary speed change unit, a main speed change unit and a secondary auxiliary speed change unit, wherein the gear shifting unit, the primary auxiliary speed change unit, the main speed change unit and the secondary auxiliary speed change unit are all arranged in a transmission box, the gear shifting unit is used for realizing advancing or backing of a tractor, the primary auxiliary speed change unit is used for realizing switching between the high gear to the low gear, the main speed change unit is used for realizing switching among four gears, and the secondary auxiliary speed change unit is used for switching between the high gear and the low gear, an output end of the gear shifting unit is connected with an input end of the primary auxiliary speed change unit, an output end of the primary auxiliary speed change unit is connected with an input end of the main speed change unit, an output end of the main speed change unit is connected with an input end of the secondary auxiliary speed change unit. The speed change device is capable of providing 16 advancing gears and 16 backing gears for the tractor and capable of meeting requirements of tractors for various special locality and special operations, and guarantees normal operation of the tractor.

Owner:LOVOL HEAVY IND CO LTD

Tractor part power shift transmission

InactiveCN104653720BImprove transmission efficiencyIncrease the number of stallsGearboxesToothed gearingsManufacturing cost reductionTractor

The invention relates to the field of a tractor and discloses a partial power shifting transmission device for the tractor. The partial power shifting transmission device for the tractor comprises a power shifting part (1), an ordinary creeper gear shifting part (2) and a synchronizer shifting part (3), wherein a shaft I (S1), a shaft II (S2) and a reverse gear shaft (S3) are mounted inside the power shifting part (1); a shaft IV (S4) and a shaft V (S5) are mounted inside the synchronizer shifting part (3); one end of the shaft I (S1) is connected with an engine, and the other end of the shaft I (S1) is connected with a hydraulic control mechanism (36); one end of the shaft V (S5) is connected with a rear axle, and the other end of the shaft V (S5) optionally outputs power to a front axle; the shaft IV (S4) and the shaft II (S2) are coaxially arranged, and are connected with each other through the ordinary creeper gear shifting part (2). With the adoption of the partial power shifting transmission device for the tractor, the gear number is increased while partial power shifting is realized, so that the transmission efficiency of the entire transmission device is improved, and the manufacture cost is reduced.

Owner:HENAN LISHEN MACHINERY

Automobile and mixed connection type double-middle-shaft transmission thereof

InactiveCN105370855AReduce wasteReduce energy lossGearboxesGearing detailsConnection typeAutomatic transmission

The invention discloses an automobile and a mixed connection type double-middle-shaft transmission thereof. The mixed connection type double-middle shaft transmission comprises an input shaft, a first middle shaft, a second middle shaft, an output shaft, a reverse-gear gear shaft, gears distributed on the shafts, a gear shifting mechanism, a shell, a bearing oil seal and other parts. The number of gears is equal to the product of the number of gears on the first middle shaft and the number of gears on the second middle shaft. The number of gears of an existing transmission is equal to the sum of the number of all gear meshing pairs of the existing transmission. Due to the adoption of the transmission, on the premise that the size and the weight of a traditional six-gear transmission are unchanged, the traditional six-gear transmission can be changed into an eight-gear or nine-gear transmission, the dynamic performance, fuel economical efficiency and driving comfort of the whole automobile are obviously improved, and the transmission is suitable for serving as an AMT automatic transmission. A reverse-gear gear is arranged to be a bevel gear, gear shifting is smoother than a spur gear, and meshing noise is obviously lowered.

Owner:力帆科技(集团)股份有限公司

Tractor speed change device with 16+16 gears

ActiveCN102537288BAchieve conversionIncrease the number of stallsGearboxesToothed gearingsControl engineeringTractor

The invention discloses a tractor speed change device with 16+16 gears, which comprises a gear shifting unit, a primary auxiliary speed change unit, a main speed change unit and a secondary auxiliary speed change unit, wherein the gear shifting unit, the primary auxiliary speed change unit, the main speed change unit and the secondary auxiliary speed change unit are all arranged in a transmission box, the gear shifting unit is used for realizing advancing or backing of a tractor, the primary auxiliary speed change unit is used for realizing switching between the high gear to the low gear, the main speed change unit is used for realizing switching among four gears, and the secondary auxiliary speed change unit is used for switching between the high gear and the low gear, an output end of the gear shifting unit is connected with an input end of the primary auxiliary speed change unit, an output end of the primary auxiliary speed change unit is connected with an input end of the main speed change unit, an output end of the main speed change unit is connected with an input end of the secondary auxiliary speed change unit. The speed change device is capable of providing 16 advancing gears and 16 backing gears for the tractor and capable of meeting requirements of tractors for various special locality and special operations, and guarantees normal operation of the tractor.

Owner:LOVOL HEAVY IND CO LTD

Gear combined variable speed transmission

The invention relates to a gear combined type variable-speed transmission device. The gear combined type variable-speed transmission device consists of an input shaft, an output shaft, an intermediate shaft, clutches (or synchronizers) and gears. More than 6 clutches or one clutch and more than 6 synchronizers and more than 9 gears are combined in serial-parallel connection modes, the gear number is remarkably increased, and the number of shifting gears is decreased. Due to the fact that each pair of gears has small speed ratio and adopts a short transmission shaft structure, the rigidity of a transmission is improved, the radial and axial sizes are reduced, and the transmission is compact in structure and high in mechanical efficiency. The invention further provides a reverse gear device used on a mechanical variable-speed transmission mechanism.

Owner:郭质刚

Air conditioner, alternating current motor and speed adjusting device thereof

ActiveCN102480263BIncrease the number of stallsSolve electromagnetic noiseAC motor controlCapacitanceMotor speed

The invention provides an air conditioner, an alternating current motor and a speed adjusting device thereof. The alternating current motor speed adjusting device comprises that: a main speed regulation unit, wherein, an input terminal forms a main speed regulation input terminal which is connected with a controller, and an output terminal forms a main speed regulation output terminal which is connected with a plurality of live wire terminals of the alternating current motor; an auxiliary speed regulation unit which comprises a first branch and at least a second branch, wherein, the first branch and the second branch have a respective input terminal and a common output terminal, and the common output terminal forms an auxiliary speed regulation output terminal which is connected with a zero line of the alternating current motor; a shift selector, wherein, an input terminal of the shift selector forms an auxiliary speed regulation input terminal which is connected with the controller, and an output terminal is selectively connected with one of the respective input terminal of the first branch and the second branch, wherein, the first branch is a direct connecting branch and the second branch is a capacitive branch. According to the air conditioner, the alternating current motor and the speed adjusting device of the invention, a problem of electromagnetic noise when utilizing a chopper speed regulation principle to carry out speed regulation on a present alternating motor in the prior art is solved.

Owner:GREE ELECTRIC APPLIANCES INC

Transmission, driving system and vehicle

PendingCN112356651AAvoid development difficultiesGuaranteed shift qualityHybrid vehiclesGas pressure propulsion mountingGear trainControl theory

The invention relates to the technical field of transmission, and in particular relates to a transmission, a driving system and a vehicle. The transmission comprises a planetary gear train, a first clutch, a second clutch and a gear box; the gear box comprises a first input shaft and a second input shaft; the first clutch is in transmission connection with the first input shaft; the planetary geartrain is in transmission connection with the second clutch and the second input shaft. Through the planetary gear train, simultaneous input of the two input shafts can be achieved, and through cooperation of the first clutch, the second clutch and the planetary gear train, the number of gears is increased; a first power source matches the planetary gear train through the first clutch, the enginestarting function can be achieved through the planetary gear train, and the development difficulty of starting the first clutch is avoided; in the gear shifting process of the first power source, a second power source can be used for driving torque compensation through the second input shaft, and the gear shifting quality of the driving system is fully guaranteed while the gear increasing and starting functions are achieved.

Owner:BEIJING NEW ENERGY VEHICLE TECH INNOVATION CENT CO LTD

A multi-channel flow regulating valve

ActiveCN106151631BIncrease the number of stallsQuick adjustmentFluid-delivery valvesValve housingsSolenoid valveStreamflow

The invention discloses a multi-channel flow control valve. The multi-channel flow control valve comprises a valve body and a plurality of electromagnetic valves mounted on the valve body, wherein a main input channel and a main output channel which are parallel to each other are arranged in the valve body; one end of the main input channel penetrates through the valve body and is served as a fluid inlet, and the other end does not penetrate through the valve body; one end of the main output channel penetrates through the valve body and is served as a fluid outlet, and the other end does not penetrate through the valve body; the fluid inlet and the fluid outlet are respectively positioned at the two opposite ends of the valve body; a normal-open channel is arranged at the end, which does not penetrate through the valve body, of the main output channel and communicates with the main input channel; a plurality of by-pass flow holes communicating with the main input channel and the main output channel are formed in the axial directions of the main input channel and the main output channel respectively; the by-pass flow holes in the main input channel and the main output channel are distributed in a one-to-one correspondence manner; an electromagnetic valve is mounted corresponding to each pair of the by-pass flow holes; two flow holes corresponding to such pair of the by-pass flow holes respectively are formed in the electromagnetic valve; and the two flow holes in the electromagnetic valve communicate with each other.

Owner:山东美迪宇能医疗科技有限公司

Gearbox

InactiveCN102797805AReduce fuel consumptionIncrease the number of stallsToothed gearingsDrive shaftEngineering

Owner:候福新

Built-in clutch and its shifting mechanism

InactiveCN103759000BCompact layoutReduce axial sizeMechanical actuated clutchesGearing controlEngineeringGear transmission

Owner:赵良红

Multi-channel flow control valve

ActiveCN106151631AIncrease the number of stallsQuick adjustmentFluid-delivery valvesValve housingsSolenoid valveEngineering

The invention discloses a multi-channel flow control valve. The multi-channel flow control valve comprises a valve body and a plurality of electromagnetic valves mounted on the valve body, wherein a main input channel and a main output channel which are parallel to each other are arranged in the valve body; one end of the main input channel penetrates through the valve body and is served as a fluid inlet, and the other end does not penetrate through the valve body; one end of the main output channel penetrates through the valve body and is served as a fluid outlet, and the other end does not penetrate through the valve body; the fluid inlet and the fluid outlet are respectively positioned at the two opposite ends of the valve body; a normal-open channel is arranged at the end, which does not penetrate through the valve body, of the main output channel and communicates with the main input channel; a plurality of by-pass flow holes communicating with the main input channel and the main output channel are formed in the axial directions of the main input channel and the main output channel respectively; the by-pass flow holes in the main input channel and the main output channel are distributed in a one-to-one correspondence manner; an electromagnetic valve is mounted corresponding to each pair of the by-pass flow holes; two flow holes corresponding to such pair of the by-pass flow holes respectively are formed in the electromagnetic valve; and the two flow holes in the electromagnetic valve communicate with each other.

Owner:山东美迪宇能医疗科技有限公司

A dual-clutch automatic transmission device

ActiveCN103671760BShift quicklySmooth shiftingToothed gearingsTransmission elementsAutomatic transmissionGear wheel

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

A telescopic foot lock adjustment mechanism

ActiveCN105041196BIncrease the number of stallsImprove ease of useScaffold accessoriesLaddersEngineeringMechanical engineering

Owner:小巨人公司

A road roller transmission

InactiveCN103615505BLow costEasy to operateToothed gearingsTransmission elementsNeedle roller bearingEngineering

The invention provides a transmission of a road roller. The transmission comprises a reversing synchronizer arranged, a speed variable synchronizer, an input shaft, an output shaft, an intermediate shaft, a short cylindrical bearing, a tapered roller bearing, a needle roller bearing, a reverse idler gear, a reverse idler gear shaft, a reversing gear set, a speed variable gear set composed of paired gears with different transmission ratios, and an output flange, wherein the speed variable synchronizer, the input shaft, the output shaft, the intermediate shaft, the short cylindrical bearing, the tapered roller bearing, the needle roller bearing, the reverse idler gear, the reverse idler gear shaft, the reversing gear set, the speed variable gear set composed of the paired gears with the different transmission ratios, and the output flange are arranged in a shell. According to the transmission of the road roller, the manipulation of the change of the forward gear position and the reverse gear position is easy, operation is clear, and gear shifting is easy and convenient; the number of the gears of the transmission of the road roller is increased compared with a transmission of a traditional structure, three forward gears are provided, and three reverse gears are provided; gears can be increased and extended conveniently, the structure is more compact, the number of the parts is less than that of parts of the transmission of the traditional structure, and the cost is further lowered; interchangeability is good, the size and the installing method of the transmission of the road roller are completely the same as those of the transmission of the traditional structure, and upgrading and updating of the transmission with the low cost are facilitated.

Owner:WUHAN ZHONGJUN AUTO PARTS

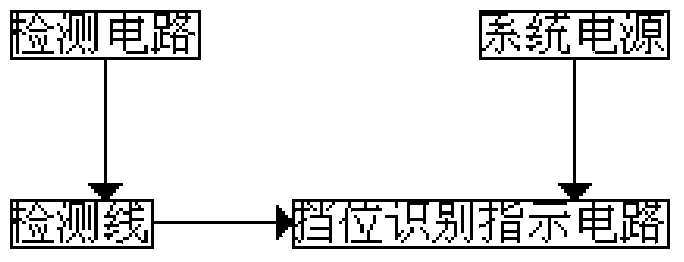

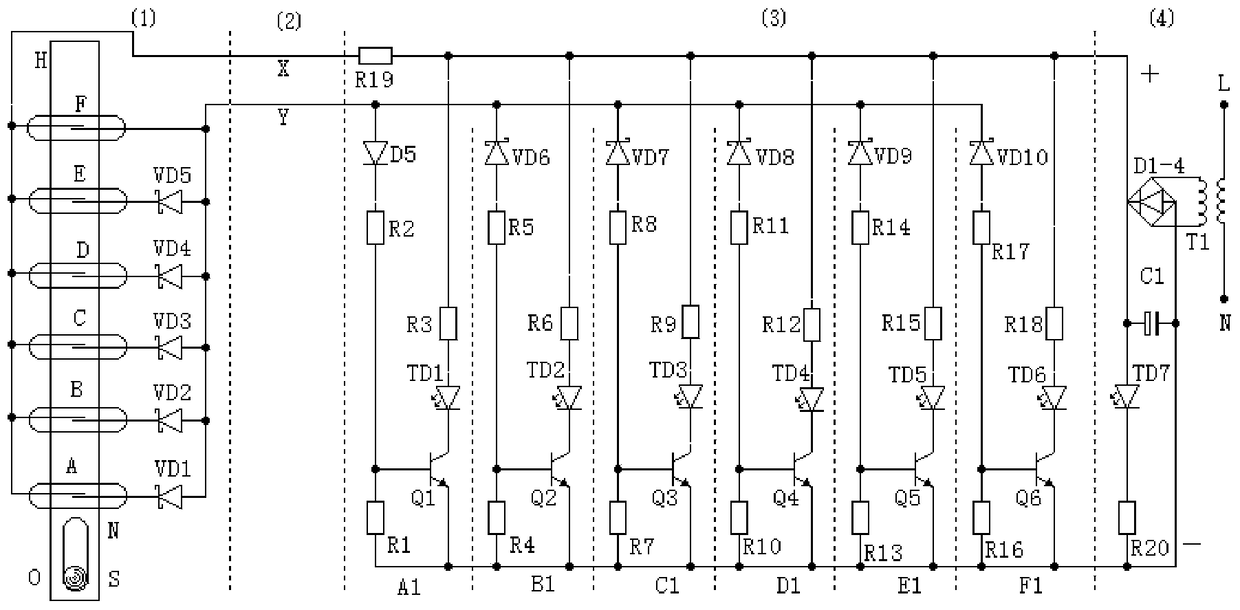

Multi-gear identification circuit detected by two detection lines

ActiveCN105115408BIncrease the number of stallsEasy to identifyElectrical testingUsing electrical meansMagnetPower supply voltage

The invention discloses a multi-gear identification circuit detected by two detection lines, and the circuit is characterized by comprising a system power supply, a detection circuit, detection lines, and a gear identification indicating circuit. A magnet is moved, magnetic control probe breakover is performed, voltage difference is formed by the stabilized voltage characteristic of a stabilivolt, detection and recognition are performed, and an indication is identified at a glance; just two detection lines are needed between a gear identification indicating circuit and a probe circuit, and positions where multi-gears locate can be detected; the system power supply voltage is increased, meanwhile the number of gears of a detection circuit and the number of corresponding identification circuit gears, namely the number of detection gears is increased; wire length is controlled, so as to greatly save wire rods, the wiring is simple, the maintenance is convenient, and the circuit is stable and reliable.

Owner:卡维亚(南通)洁净材料有限公司

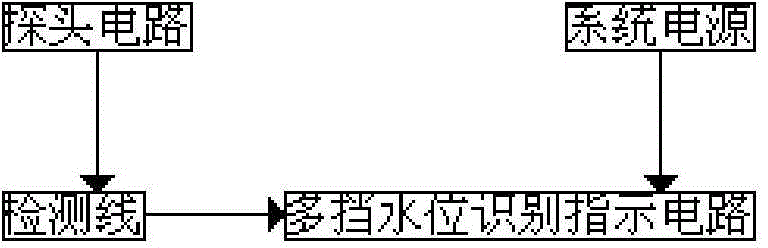

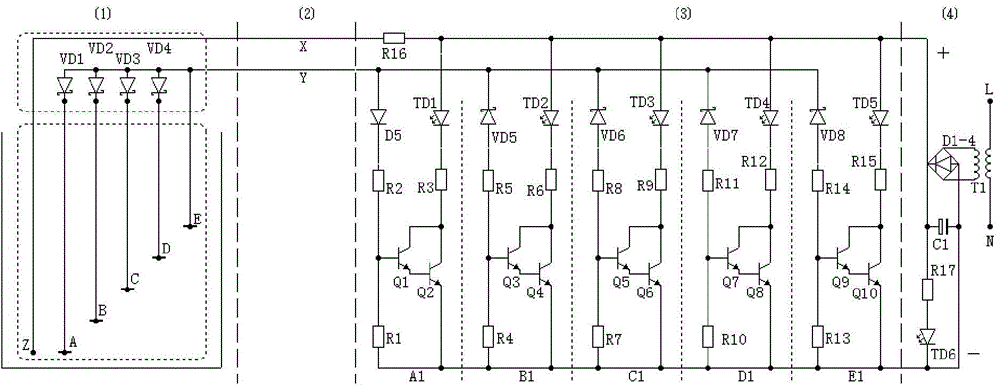

Multi-level water level identification circuit with two detection lines for detection

A multi-level water level identification circuit with two detection lines for detection is formed by a system power supply, a probe circuit, detection lines, and a multi-level water level identification indicating circuit. By virtue of the conductivity of water, voltage differences are formed due to voltage stabilization characteristics of voltage-regulator tubes and used for detection and identification. Identification indication is clear at a glance. Only two detection lines are needed between the indicating circuit and the probe circuit for detecting and identifying the level of the water level. When the voltage of the system power supply is increased, and the number of levels of a detecting circuit and the number of the levels of a corresponding identifying circuit are increased, the number of detection levels is increased. The line length is controlled, so that line material can be substantially saved. The wiring is simple, the maintenance is convenient, and the circuit is stable and reliable.

Owner:兰如根

Nine-speed double-clutch automatic transmission and vehicle

ActiveCN110230667APromote localizationSimple design processToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The invention relates to a nine-speed double-clutch automatic transmission and a vehicle. The nine-speed double-clutch automatic transmission comprises input shafts and output shafts, wherein the input shafts comprises the first input shaft, the second input shaft and the input gear shaft; and the output shafts comprises a first intermediate shaft and a second intermediate shaft. The first intermediate shaft is provided with a first output gear, a first bilateral synchronizer, a first output gear shaft, a fourth output gear and a first unilateral synchronizer, wherein the first output gear shaft is provided with a third output gear and a second bilateral synchronizer; and the second intermediate shaft is provided with a fifth output gear, a third bilateral synchronizer, a second output gear shaft, an eighth output gear and a second unilateral synchronizer, wherein the second output gear shaft is provided with a seventh output gear and a fourth bilateral synchronizer. The nine-speed double-clutch automatic transmission is improved on the basis of an existing seven-speed double-clutch transmission, when nine-speed gear shifting is completed, the numbers of inner core output gears andthe synchronizers can be optimized to the maximum extent, the structure is compact, and the occupied space is small.

Owner:SAIC MOTOR

Traction drive synchronous governor and multi-shaft gearbox having the governor

InactiveCN105221683BIncrease the number of stallsAvoid wear and tearToothed gearingsDrive shaftControl engineering

The present invention relates to a traction drive synchronous speed governor and a multi-drive shaft gearbox with the speed governor. The multi-drive shaft gearbox has a speed governor chamber and a speed change gear chamber. The present invention uses the speed governor The traction drive synchronous governor in the room transmits the power of the engine to the output group of the gearbox in the form of traction drive. The governor adopts a plurality of planetary roller sets between its input part and output part, and the output part pushes The roller group moves axially to contact the input member, so as to achieve the effect of power transmission. At the same time, the shafts of each driving group in the transmission gear chamber are unequal around the shaft of the output group around the shaft of the output group. The parallel arrangement of pitches can increase the number of gears of the gearbox in a limited space. Through the implementation of the technical means of the traction drive synchronous speed governor and the shaft arrangement of each driving group in the present invention, the problems of low transmission efficiency of the gearbox, wear of the clutch and large space occupied when increasing the shifting gear in the prior art are improved.

Owner:孙振台

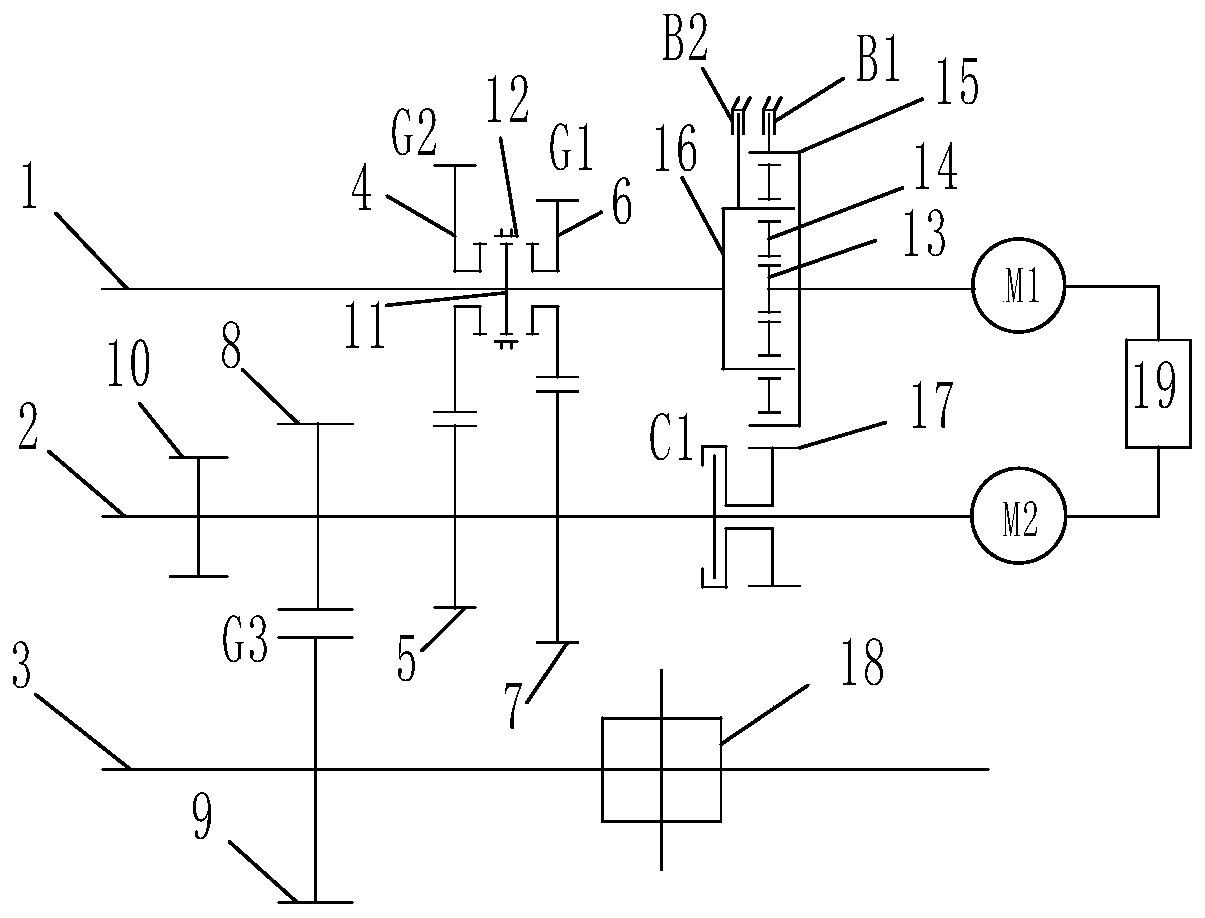

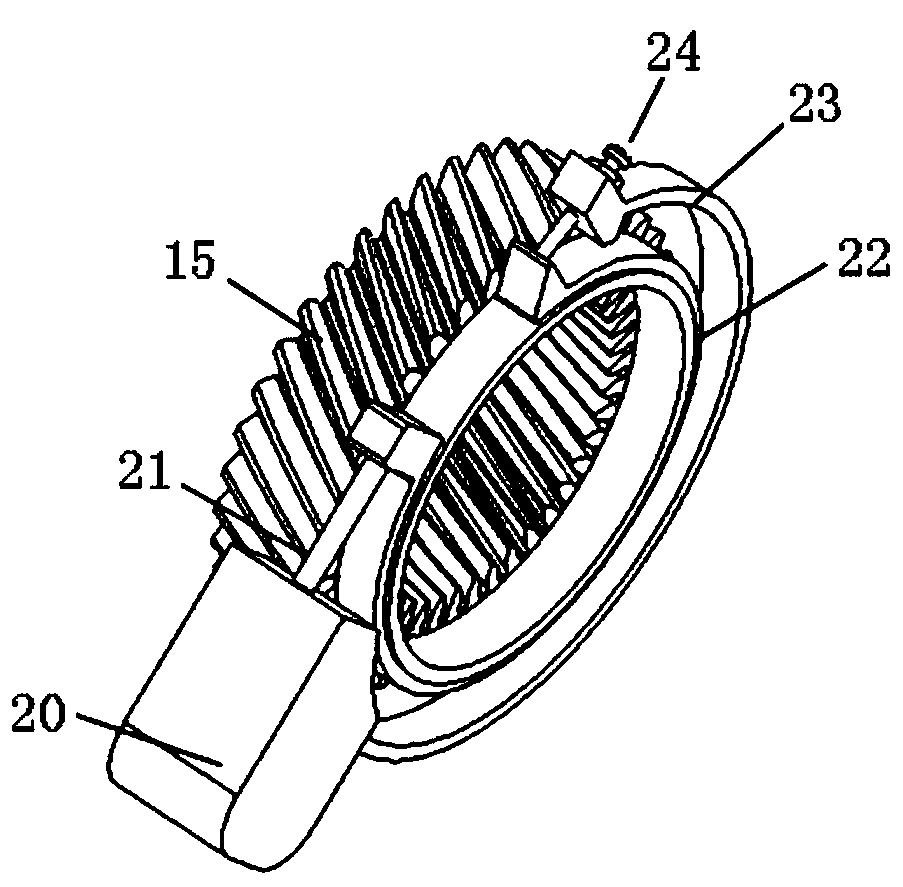

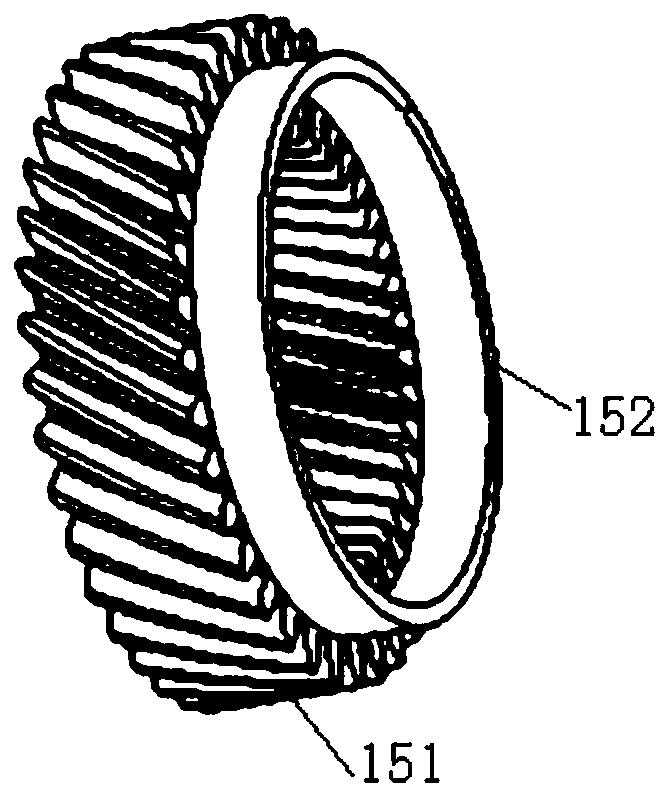

Three-speed planetary gear automatic transmission and pure electric vehicle

ActiveCN109667893BPowerfulReduce energy consumptionToothed gearingsGearing controlAutomatic transmissionGear drive

The invention provides a third gear planetary gear automatic transmission and a pure electric vehicle, and belongs to the technical field of vehicle transmission systems. The third gear planetary gearautomatic transmission includes a first gear meshing pair G1, a second gear meshing pair G2, a shifting mechanism, a planetary gear train, a third gear driven gear, a main retarder gear meshing pairG3, a parking ratchet, an axle and left and right axles, wherein the shifting mechanism is arranged between the first gear meshing pair G1 and the second gear gearing pair G2; a planetary ring gear isbraked by a brake B1; a planetary carrier is braked by a brake B2; the third gear driven gear is sleeved on an output shaft and meshed with the planetary ring gear; the third gear driven gear is clutched by a clutch C1 mounted on the output shaft; the parking ratchet is braked by the parking mechanism, so that the deceleration parking is achieved; the axle and the left and right axles achieves power transmission through the first gear meshing pair G1, the second gear meshing pair G2, and the main retarder gear meshing pair G3. The third gear planetary gear automatic transmission has the advantages of simple and compact structure, stable transmission and wide transmission ratio range.

Owner:HEBEI UNIV OF TECH

A nine-speed dual-clutch automatic transmission and vehicle

ActiveCN110230667BPromote localizationSimple design processToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The invention relates to a nine-speed dual-clutch automatic transmission and a vehicle, wherein the nine-speed dual-clutch automatic transmission comprises: an input shaft including a first input shaft, a second input shaft and an input gear shaft; an output shaft including a first intermediate shaft and the second intermediate shaft. The first intermediate shaft is provided with a first output gear, a first double-sided synchronizer, a first output gear shaft, a fourth output gear and a first single-sided synchronizer, and the first output gear shaft is provided with a third output gear and a second double-sided synchronizer. Synchronizer; the second intermediate shaft is provided with the fifth output gear, the third bilateral synchronizer, the second output gear shaft, the eighth output gear and the second single-sided synchronizer, and the second output gear shaft is provided with the seventh output gear and Fourth bilateral synchronizer. The nine-speed dual-clutch automatic transmission is improved on the basis of the existing seven-speed dual-clutch transmission. While completing nine-speed shifting, it can maximize the number of core output gears and synchronizers, and is compact in structure and takes up space. smaller.

Owner:SAIC MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com