Patents

Literature

50results about How to "Simple speed regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

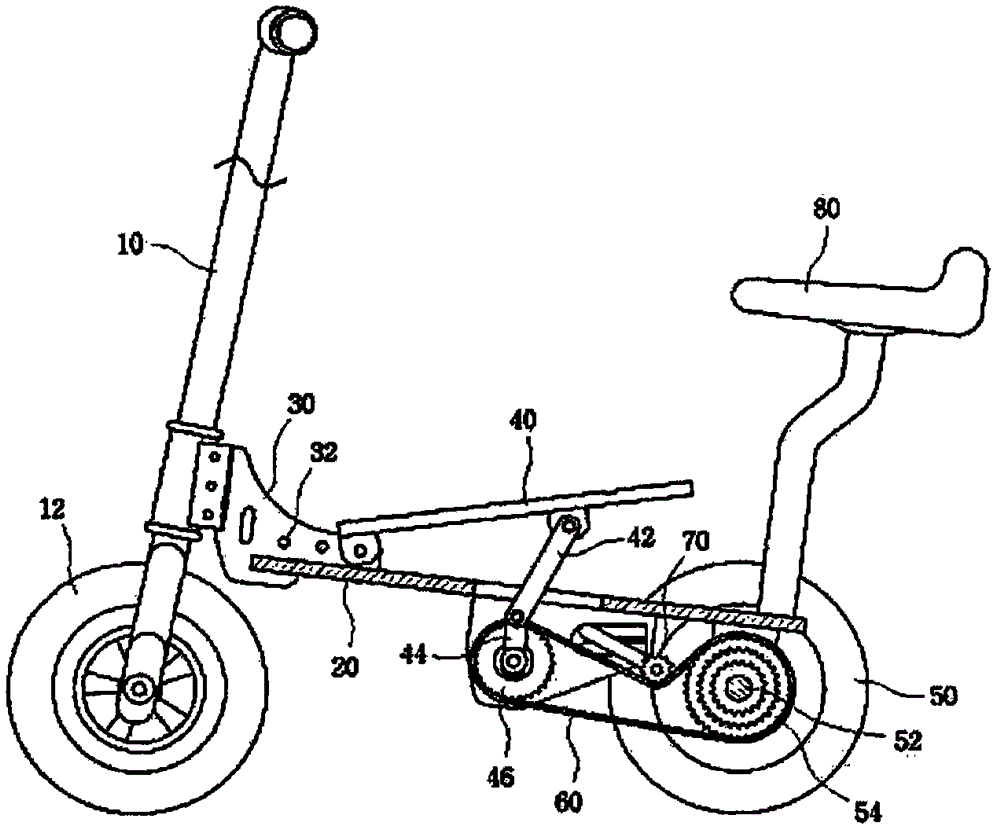

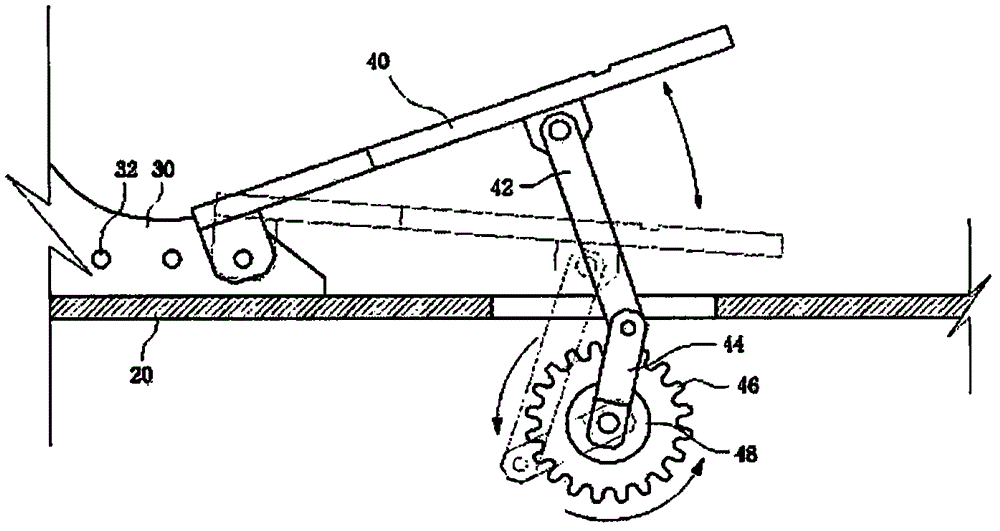

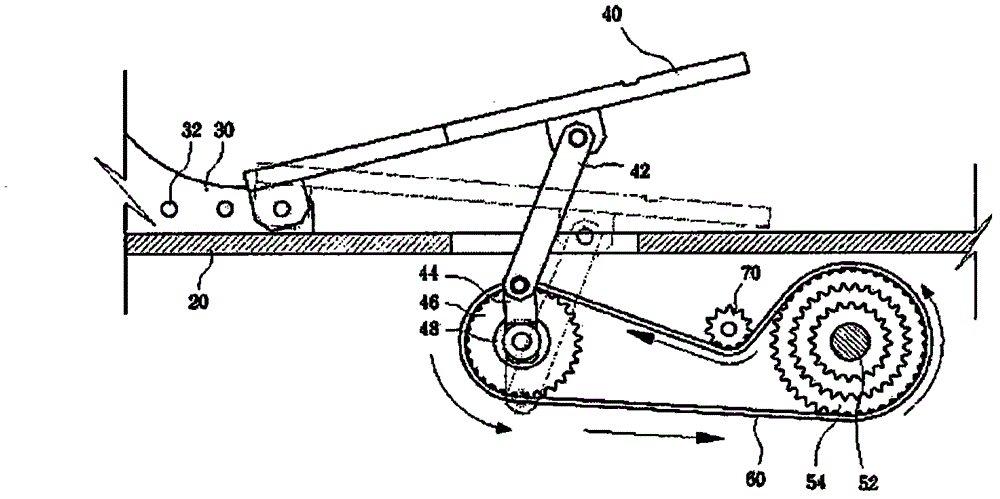

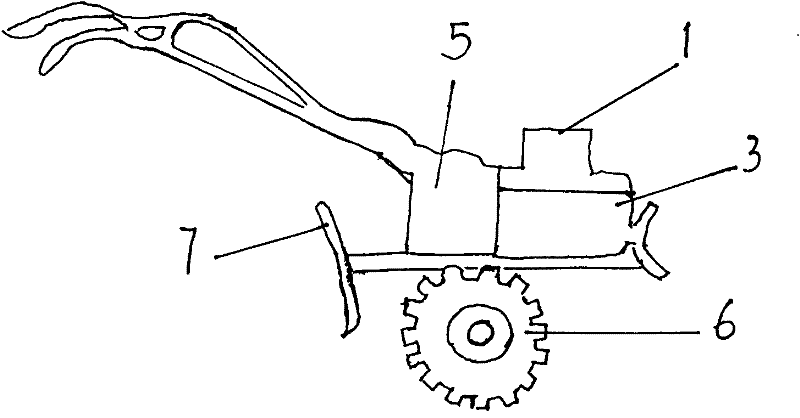

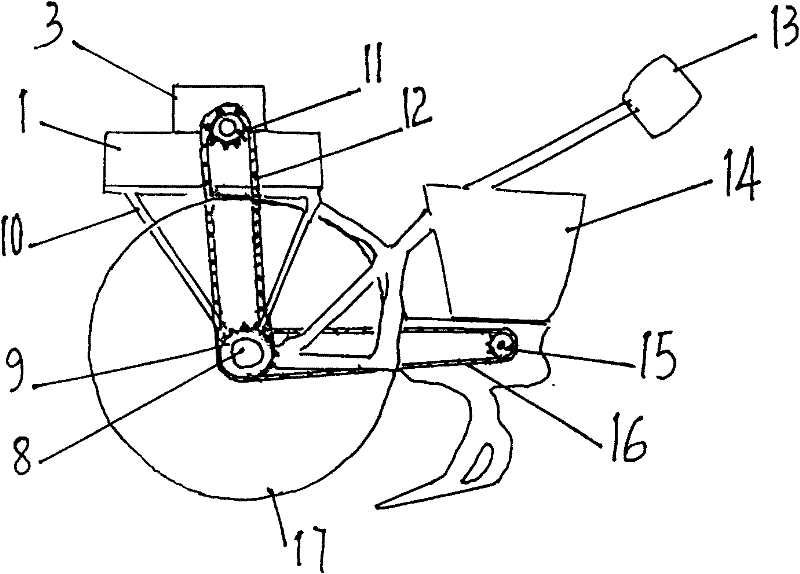

Kickboard-type bicycle

InactiveCN102753427AUniform body developmentAdjustable positionVehicle cranksChain/belt transmissionEngineeringSprocket

The present disclosure relates a bicycle, and more particularly, to a kickboard-type bicycle capable of being used as a kickboard or a bicycle according to the user's choice, can be shifted between different speeds for easy speed control, requires the use of both legs (unlike conventional kickboards) so as to promote the balanced growth of youngsters who are in their growing years, and has pedals that can be adjusted to positions suitable for the user.; To this end, the kickboard-type bicycle according to the present invention, with respect to a bicycle having a front wheel steered by a handle and a rear wheel driven by pedals, has a handle connected and fixed to the front of the body through a connecting frame, has one end of a link coupled via a hinge to one end of a pedal and the other end of the link coupled via a shaft with a crankshaft, has a drive sprocket installed on one end of the crankshaft, has a rotation shaft formed on the rear bottom side of the body with the rear wheel installed at the end thereof, has a multistage sprocket for shifting speed installed on an end of the rotation shaft, and has the drive sprocket installed on the crankshaft connected via a chain to the multistage sprocket installed on the rotation shaft.

Owner:HAPPYLIFE

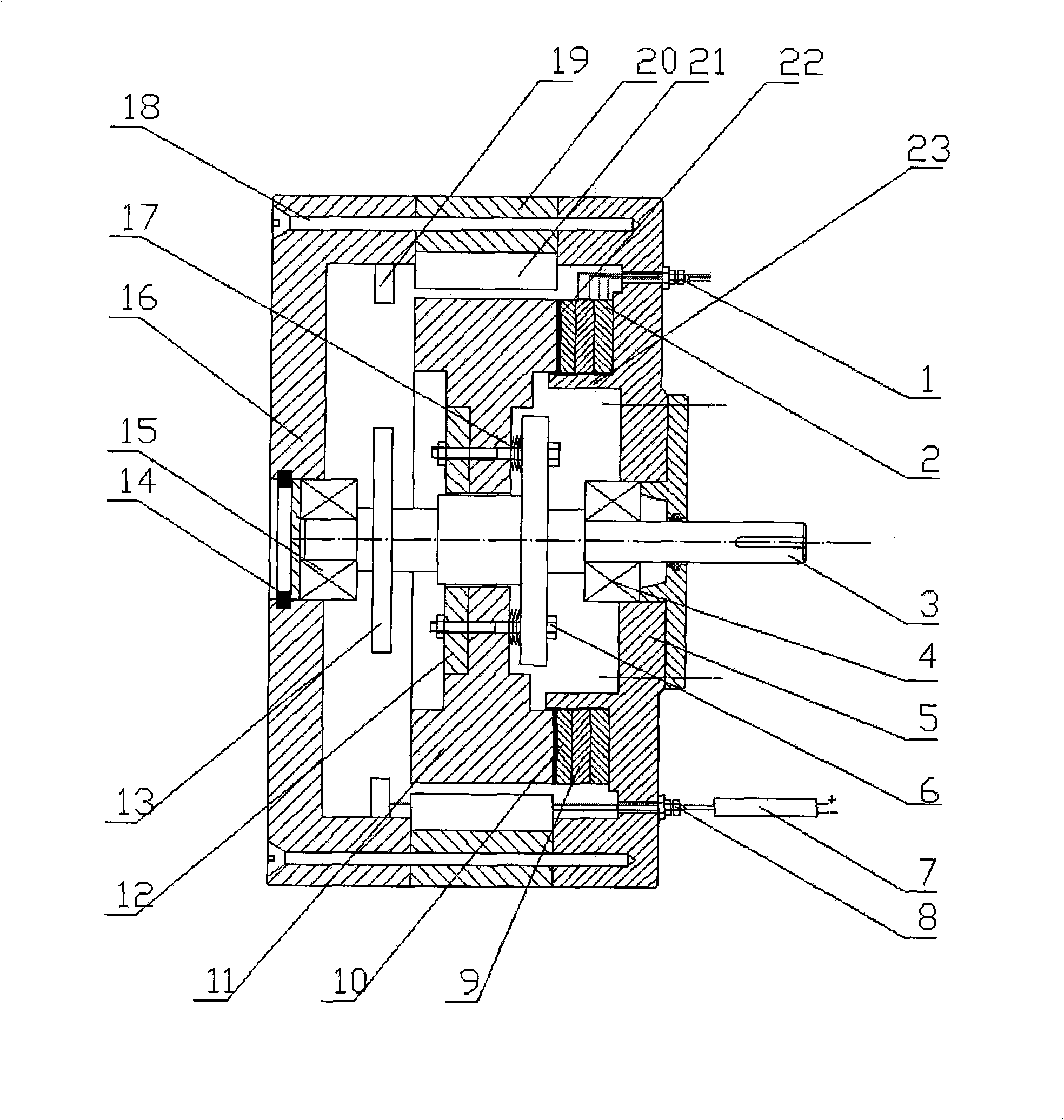

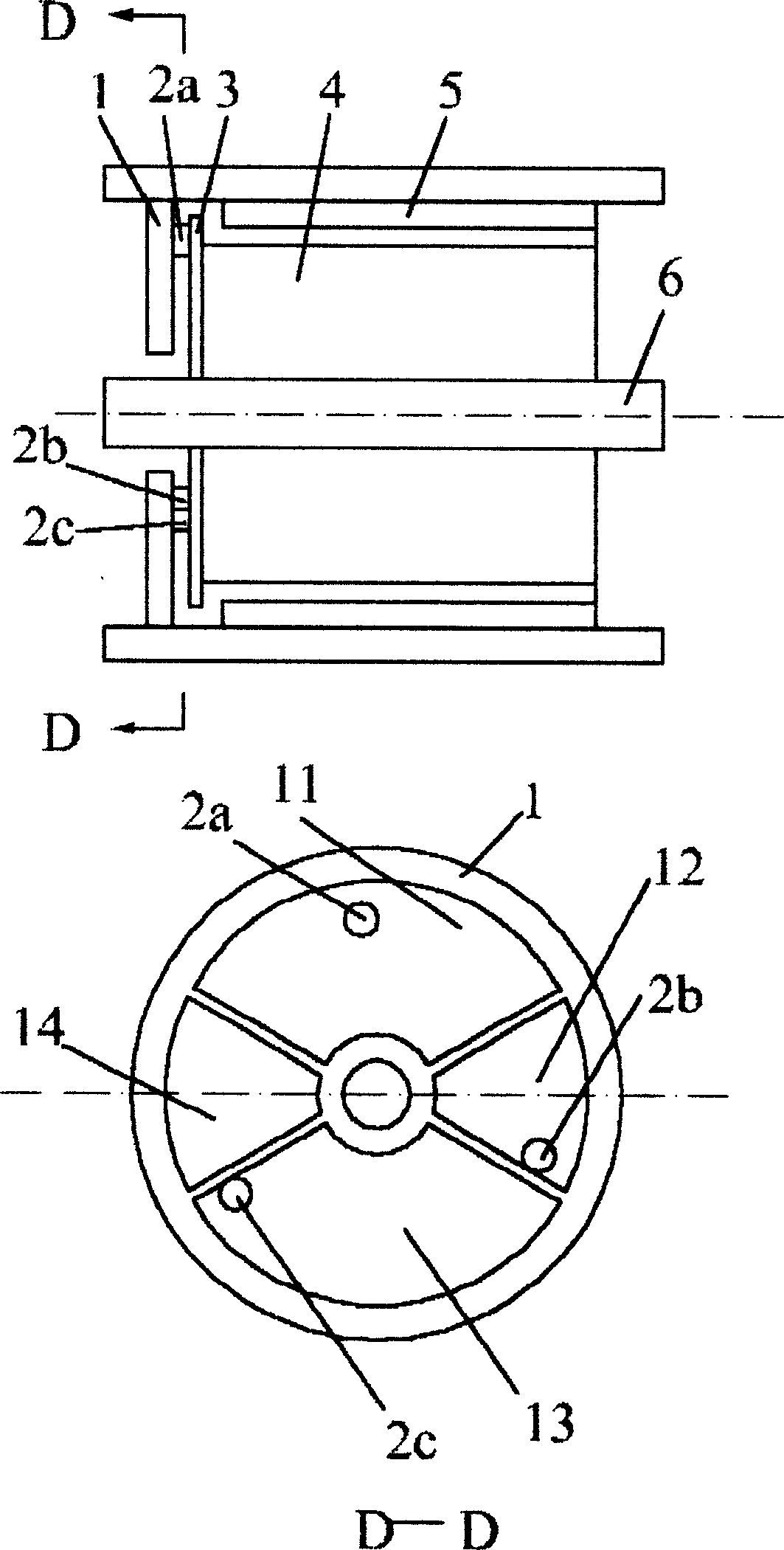

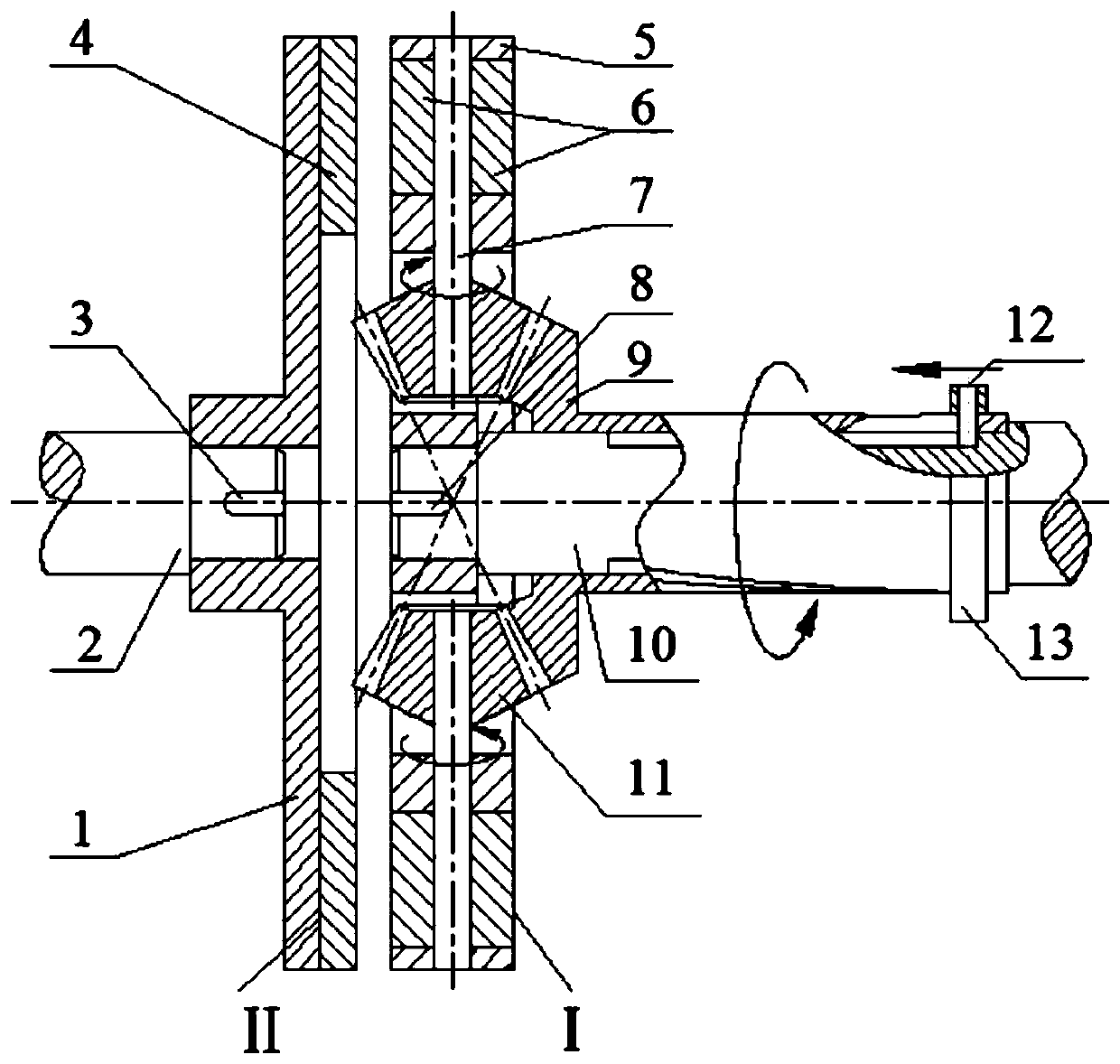

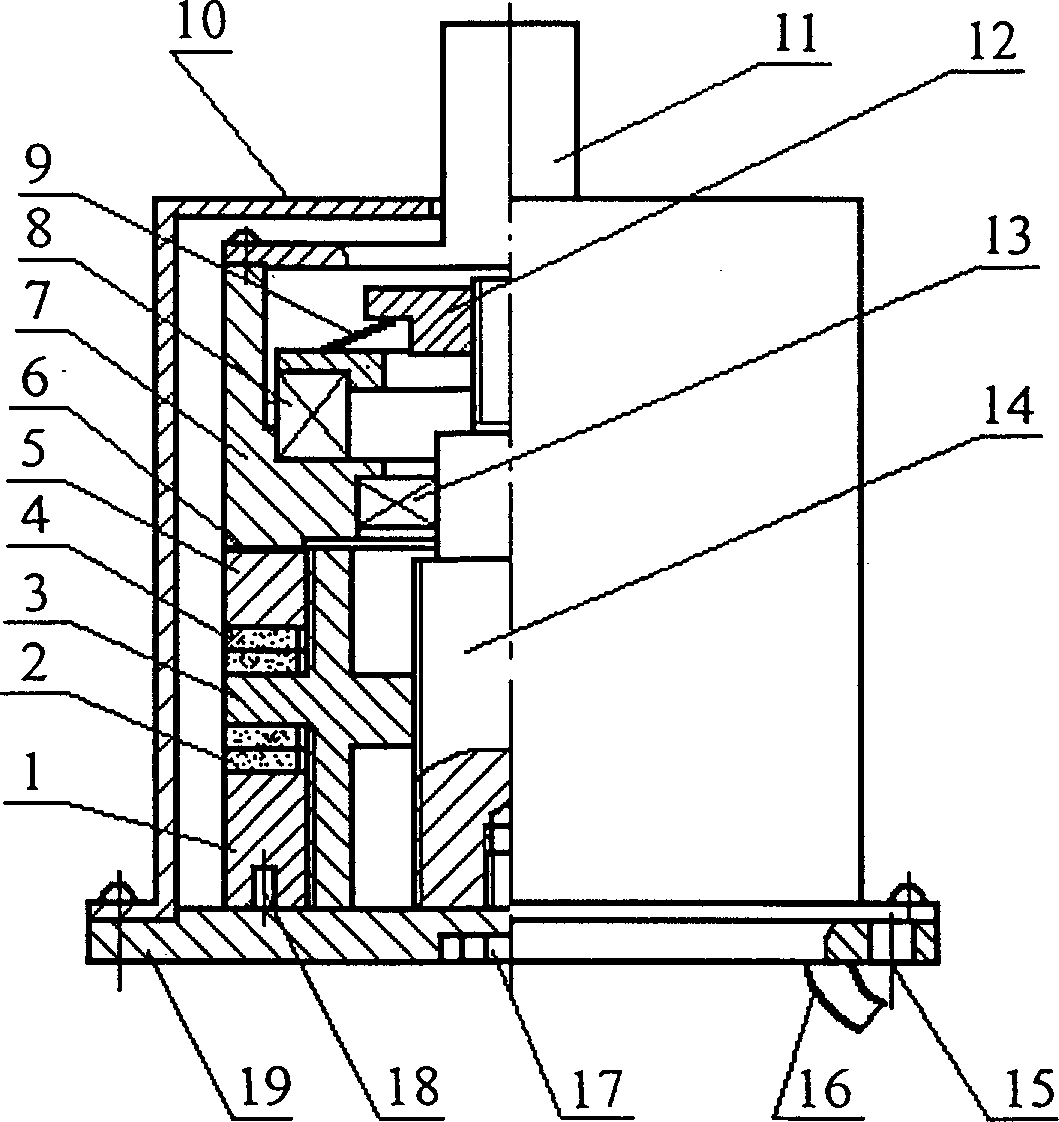

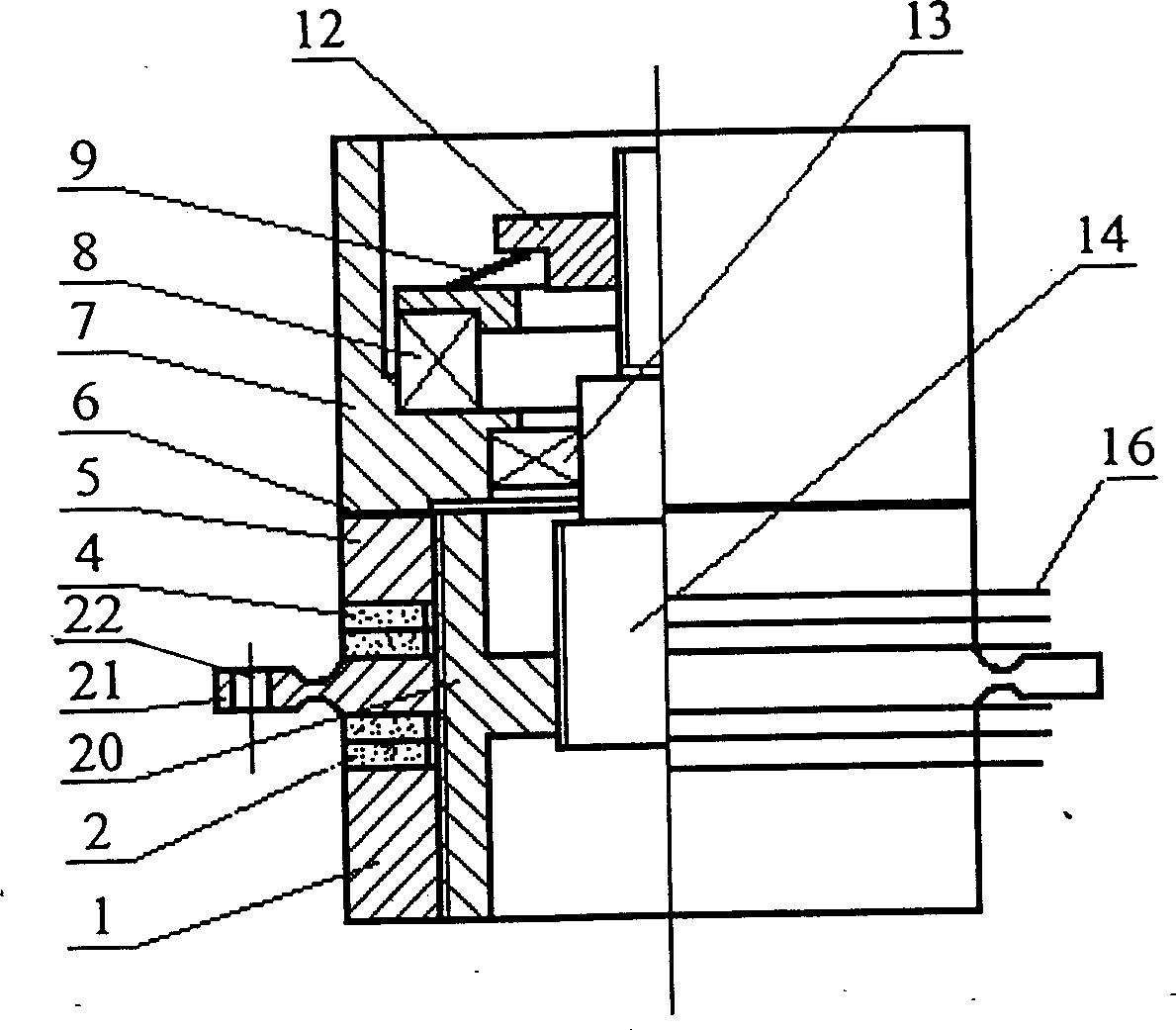

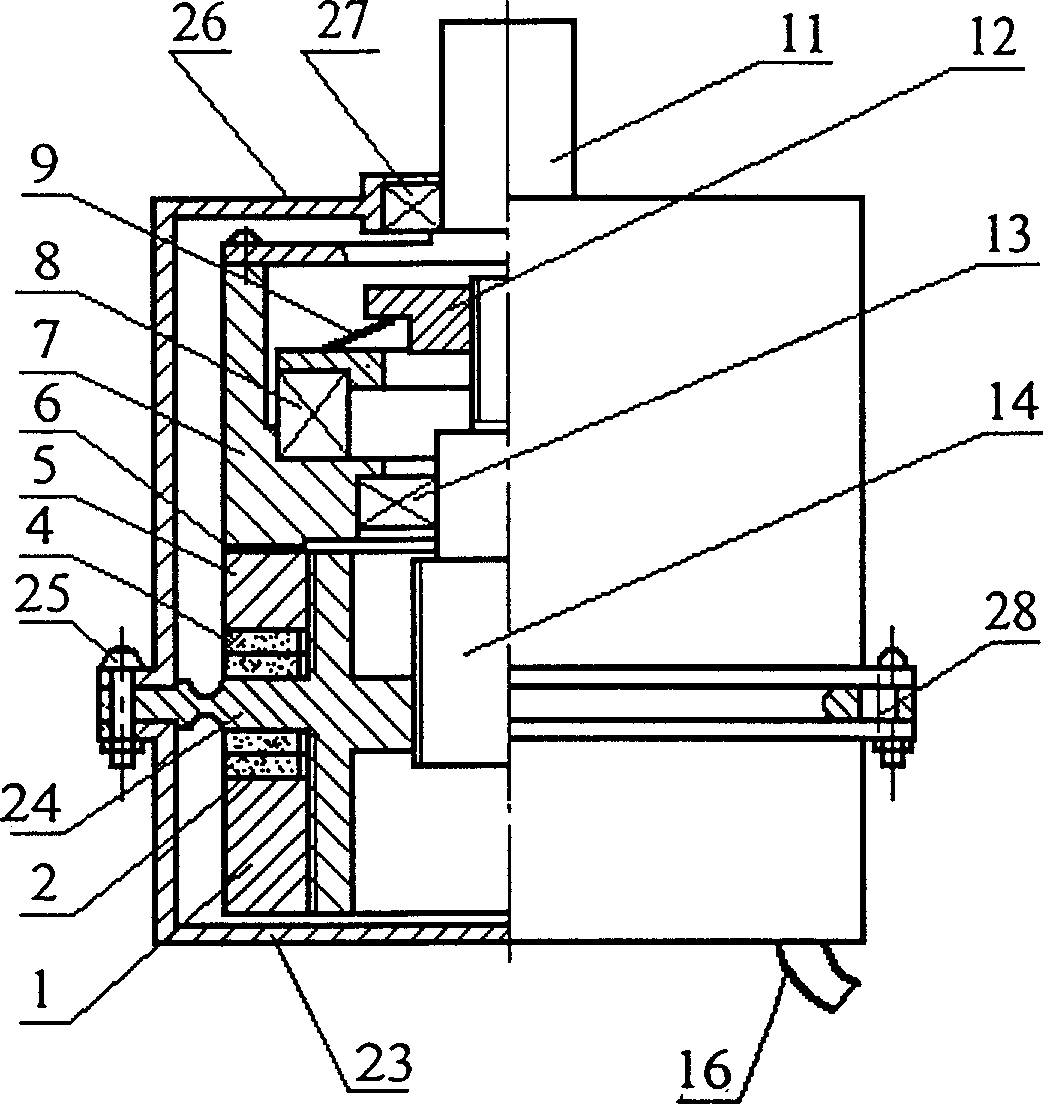

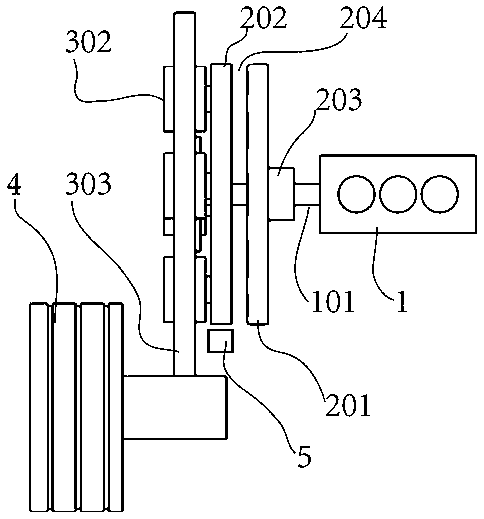

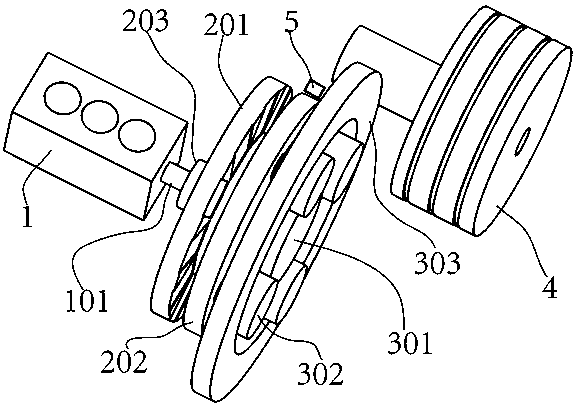

Piezo-electricity ultrasound and electromagnet integration driven electric motor

InactiveCN101404442AElectrical time constant is smallFast dynamic responsePiezoelectric/electrostriction/magnetostriction machinesDynamo-electric machinesStatorSelf locking

The invention discloses an integrated piezoelectric ultrasound and electromagnetic combination drive motor, mainly comprising a torsional vibration piezoelectric chip, a longitudinal vibration piezoelectric chip, a piezoelectric drive stator, a sleeve, an electromagnetic drive stator, a multiplex rotor, a pre-tightening spring, a fastening bolt, abrasion-proof material and an output shaft. The longitudinal vibration piezoelectric chip, the torsional vibration piezoelectric chip and the piezoelectric drive stator are sequentially installed on a circular thin-wall sleeve and connected by the abrasion-proof material and the multiplex rotor which is installed on the output shaft and offers pre-tightening force to compress the abrasion-proof material as well as the piezoelectric drive stator by the fastening bolt and the pre-tightening spring. The motor, on the structural basis of the traditional brushless dc torque motor, is embedded with a longitudinal and torsional combined piezoelectric drive, integrates the advantages of two drives almost without expanding the volume, and is characterized by both the high thrust, high reliability and long service life of electromagnetic drive and the high dynamic response (millisecond level), high control precision and passive self-locking of piezoelectric ultrasound drive.

Owner:ZHEJIANG UNIV

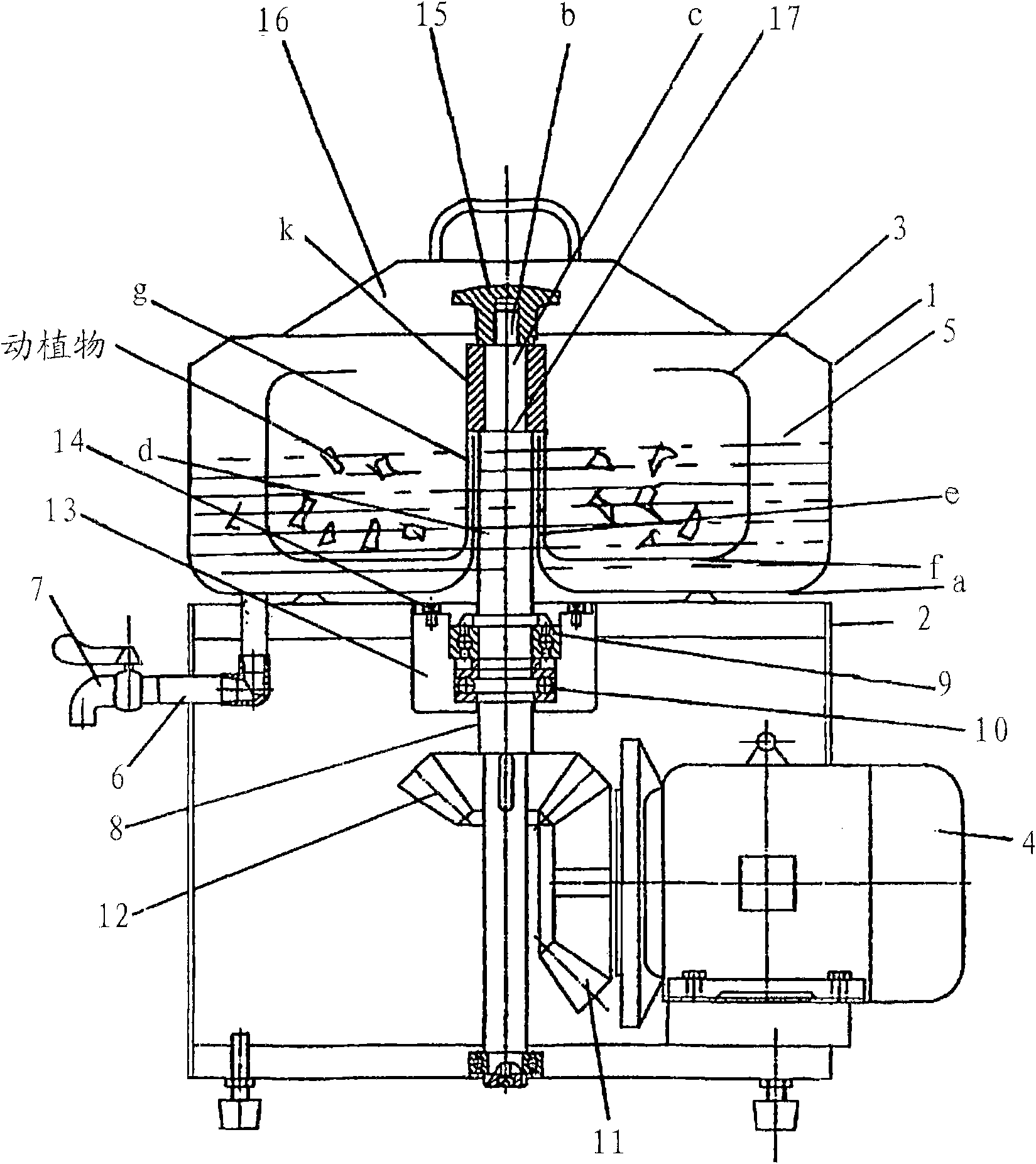

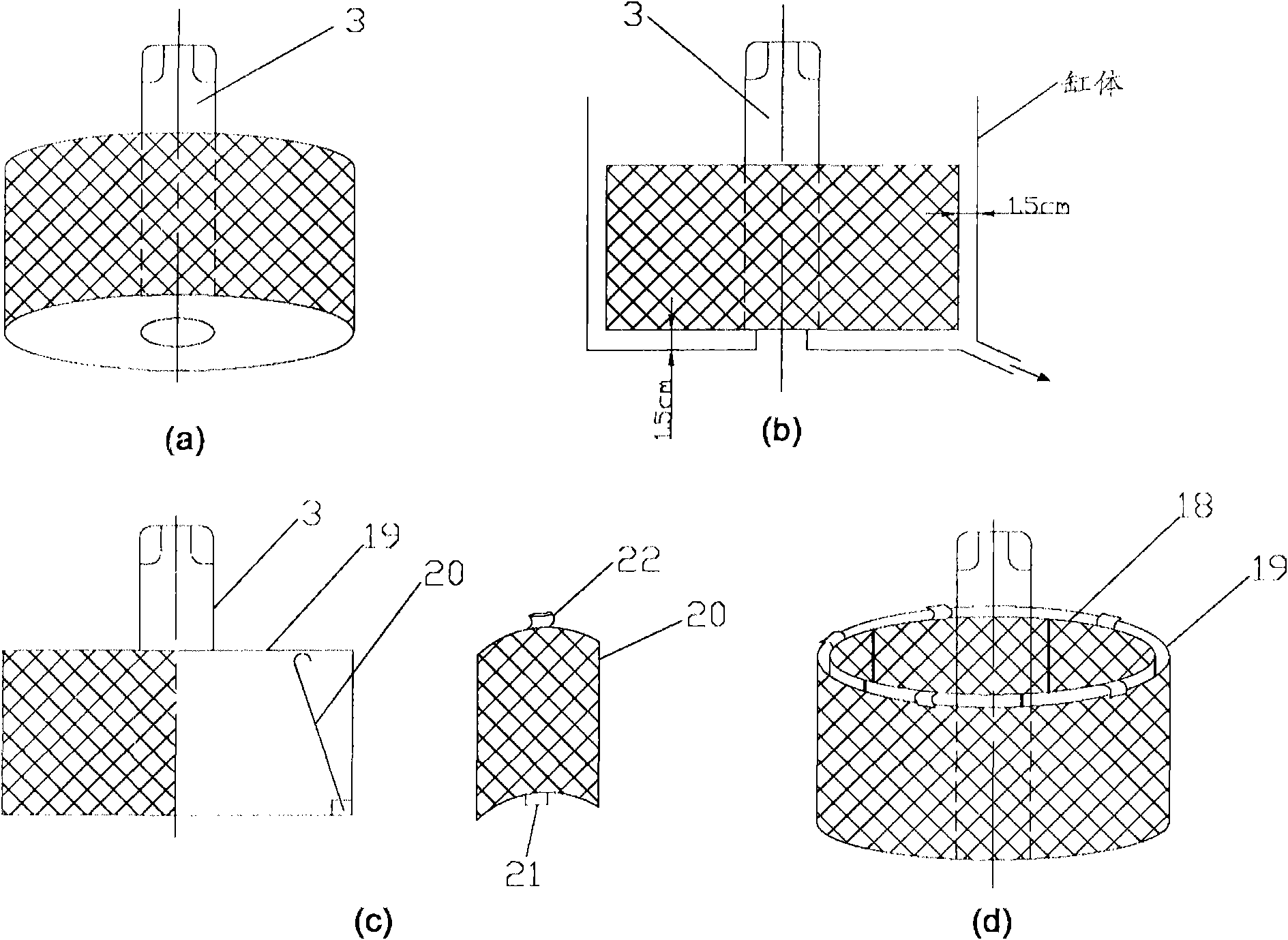

Centrifugal device for extracting drug ingredients and method thereof

InactiveCN101637666AEasy to separateFacilitated DiffusionSolid solvent extractionAdditive ingredientDrive shaft

The invention provides a centrifugal device for extracting drug ingredients and a method thereof. The centrifugal device for extracting the drug ingredients comprises a cylinder body, a base, a centrifugal extraction basket, a rotary driving device and a control part, wherein the cylinder body is used for containing drug extraction solvent and is fixed on the base; the centrifugal extraction basket is supported and arranged in the cylinder body by a transmission shaft connected with the centrifugal extraction basket, and is connected with the rotary driving device by the transmission shaft and other transmission mechanisms; by applying rotary driving force to the centrifugal extraction basket, the rotary driving device enables the centrifugal extraction basket to rotate by the transmission shaft and other transmission mechanisms, animals and plants can be arranged in the centrifugal extraction basket, and the drug extraction solvent in the cylinder body flows into the periphery wall of the extraction basket through a plurality of through holes arranged on the periphery wall of the centrifugal extraction basket; according to an externally inputted running instruction, the control part controls the soak time and the rotational speed and the rotation time of an electromotor so that the centrifugal device for extracting the drug ingredients can sequentially carry out the working procedures of soaking, centrifugal extraction and centrifugal liquid removal; and by enabling the centrifugal extraction basket to rotate at a high speed, the working procedure of centrifugal liquid removal enables the centrifugal extraction basket to generate the centrifugal force on the animals and the plants so that liquid removal can be carried out on the animals and the plants.

Owner:BEIJING COLLAB PHARMA +1

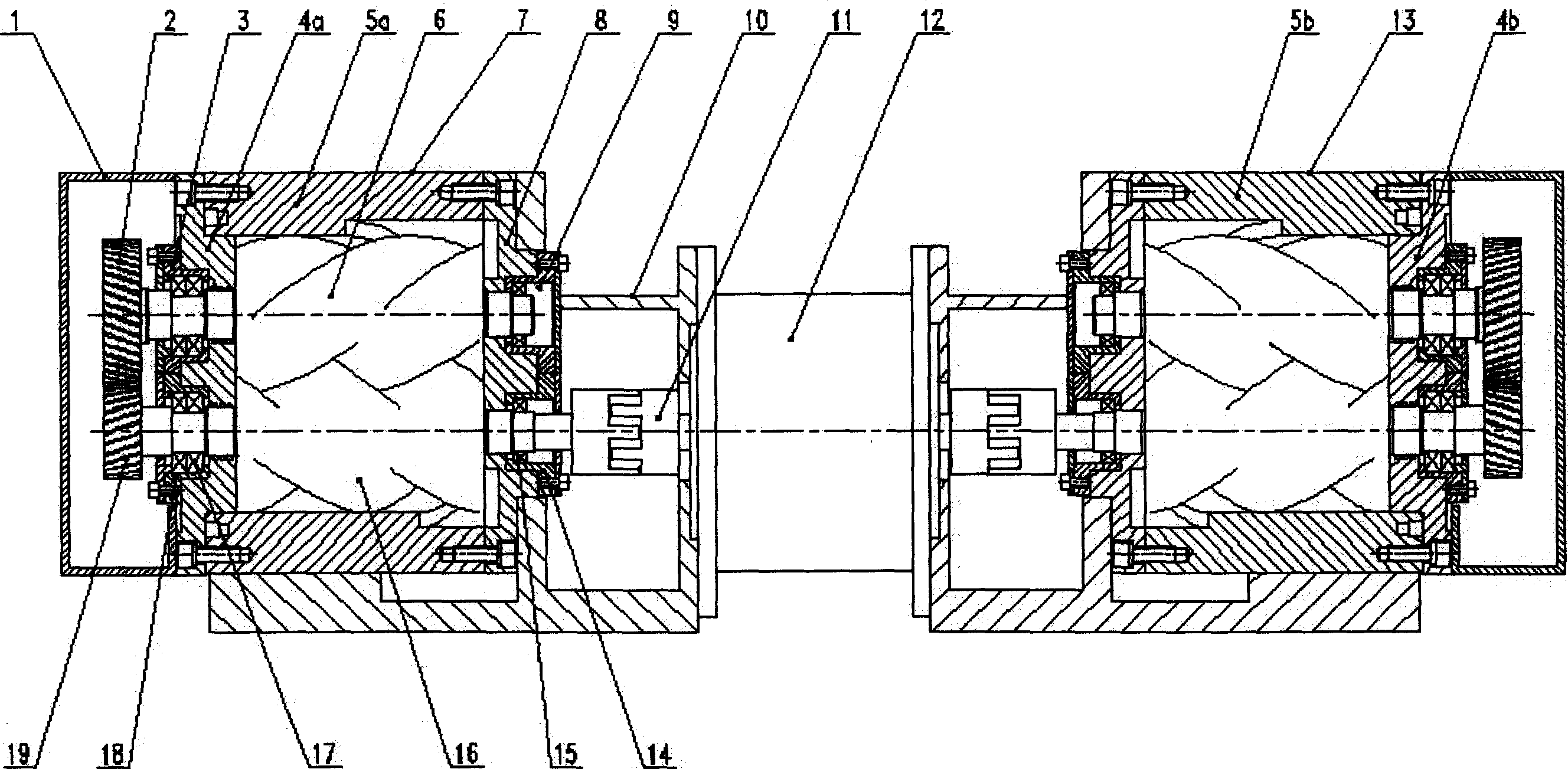

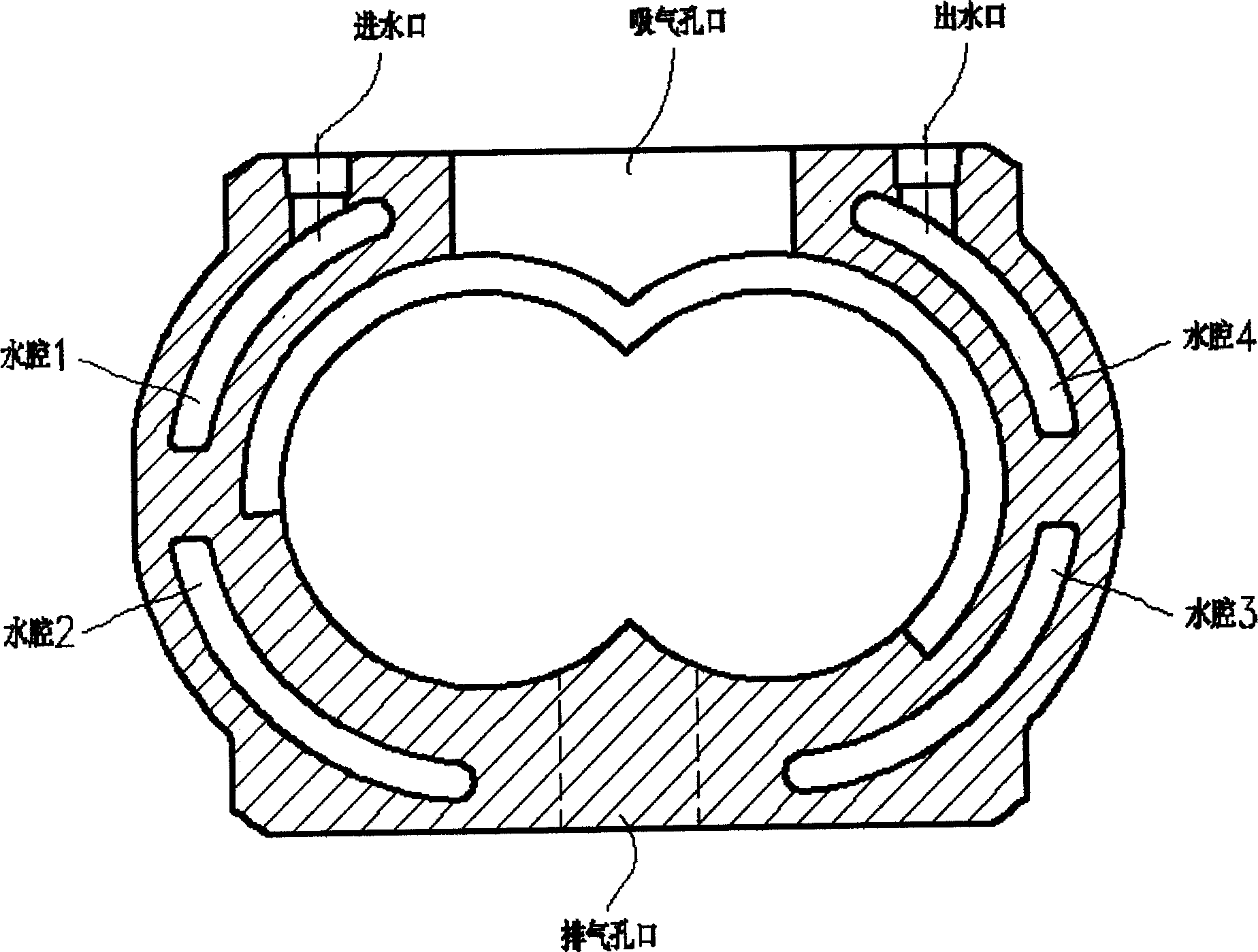

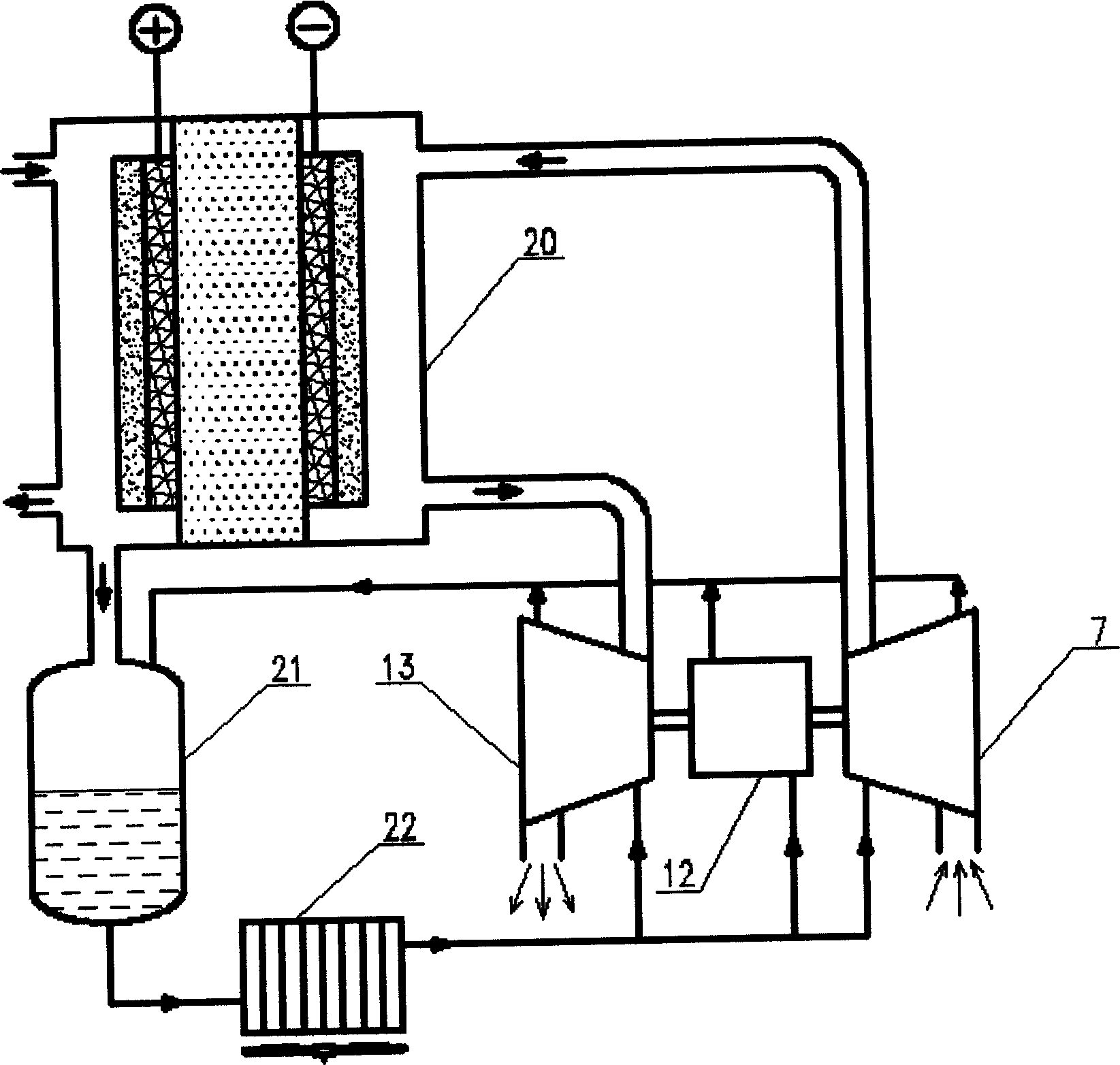

Screw rod compression-expansion unit for fuel battery automobile

InactiveCN1702899AEasy to installEasy to disassembleFuel cellsElectric propulsionMachine partsFuel cells

This invention discloses one fuel battery automobile screw lever contracting expansion set, wherein, the contracting machine, direct current water flow high speed motor and expansion machine are connected through axis fixing to ensure the matching structure through two sockets of both ends; the contracting machine and expansion machine comprise one pair of rotors, drawing terminals, exhaust terminal, gas cylinders with water chambers. Socket element and one pair of synchronization gear; the expansion machine and contracting machine parts are highly united and exchangeable and the cooling water is the water generated by the fuel battery.

Owner:XI AN JIAOTONG UNIV

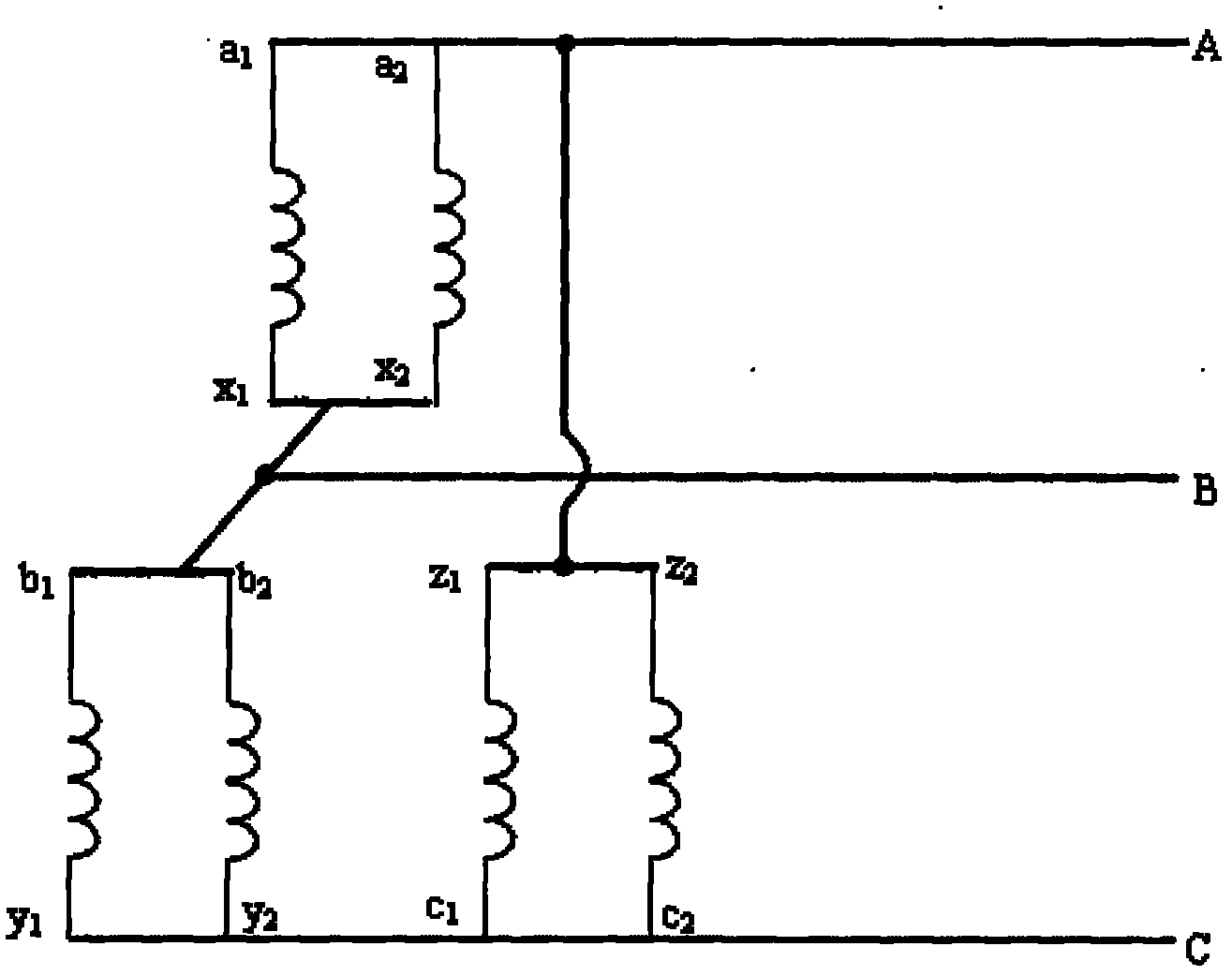

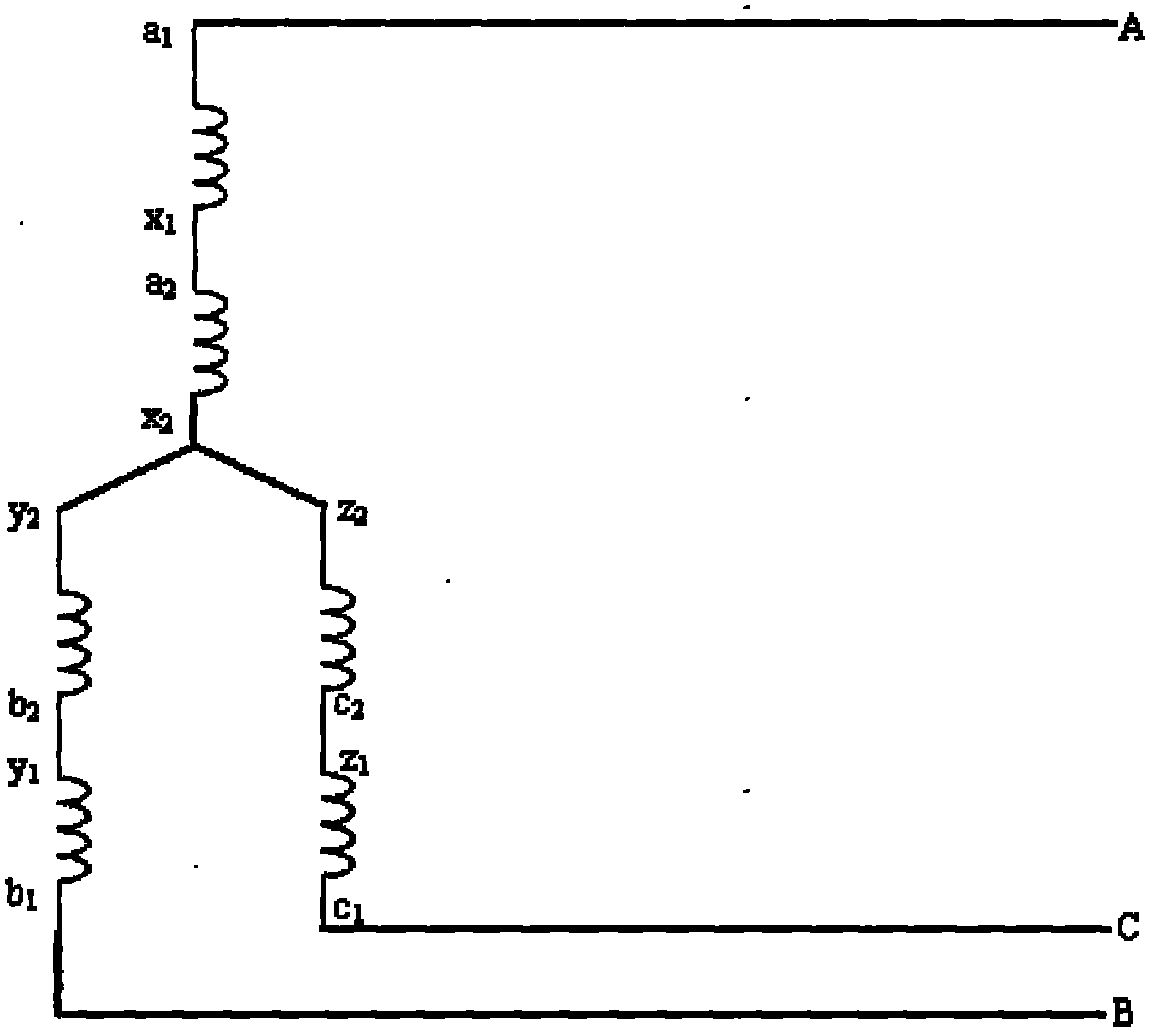

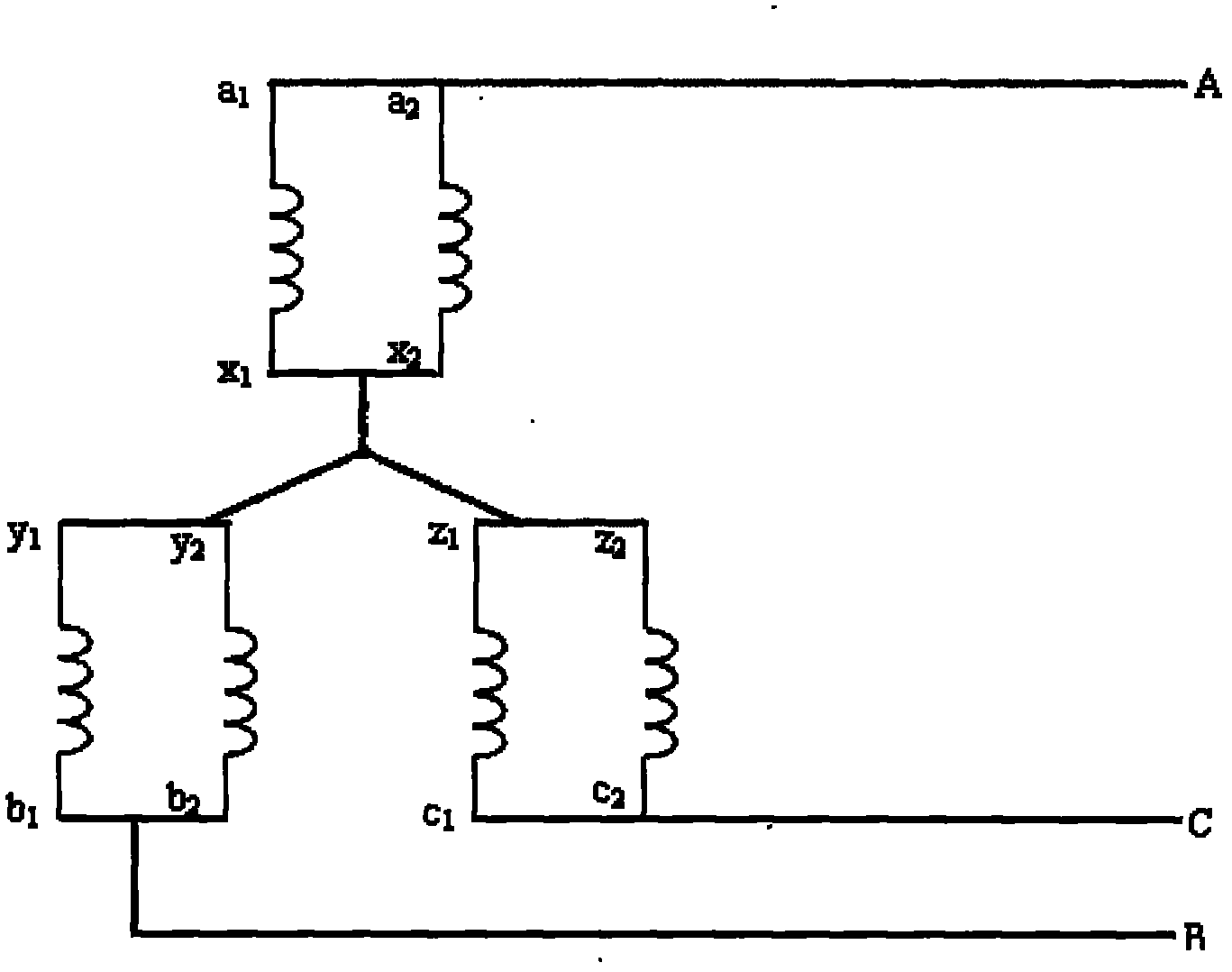

Variable-speed three-phase asynchronous motor

InactiveCN102013776AEnables multi-speed operationIncrease or decrease internal electromagnetic state changesAsynchronous induction motorsWindings conductor shape/form/constructionHarmonicThree phase asynchronous motor

The invention provides a variable-speed three-phase asynchronous motor which is characterized in that under the condition of no auxiliary device, multispeed running in a broad range is realized, and the shortages of high running cost caused by using a variable frequency speed control asynchronous motor and serious pollution of power grid harmonic wave are solved since the connection of three-phase stator winding and the connection of phase winding and split winding as well as a three-phase asynchronous motor winding structure are changed. The invention has the advantages that the speed control is simple, the cost is low, the multispeed running condition on the three-phase asynchronous motor is satisfied, and the variable frequency speed control motor can be replaced in mechanical equipment capable of realizing multispeed-running in a large scale.

Owner:TAIYUAN UNIV OF TECH

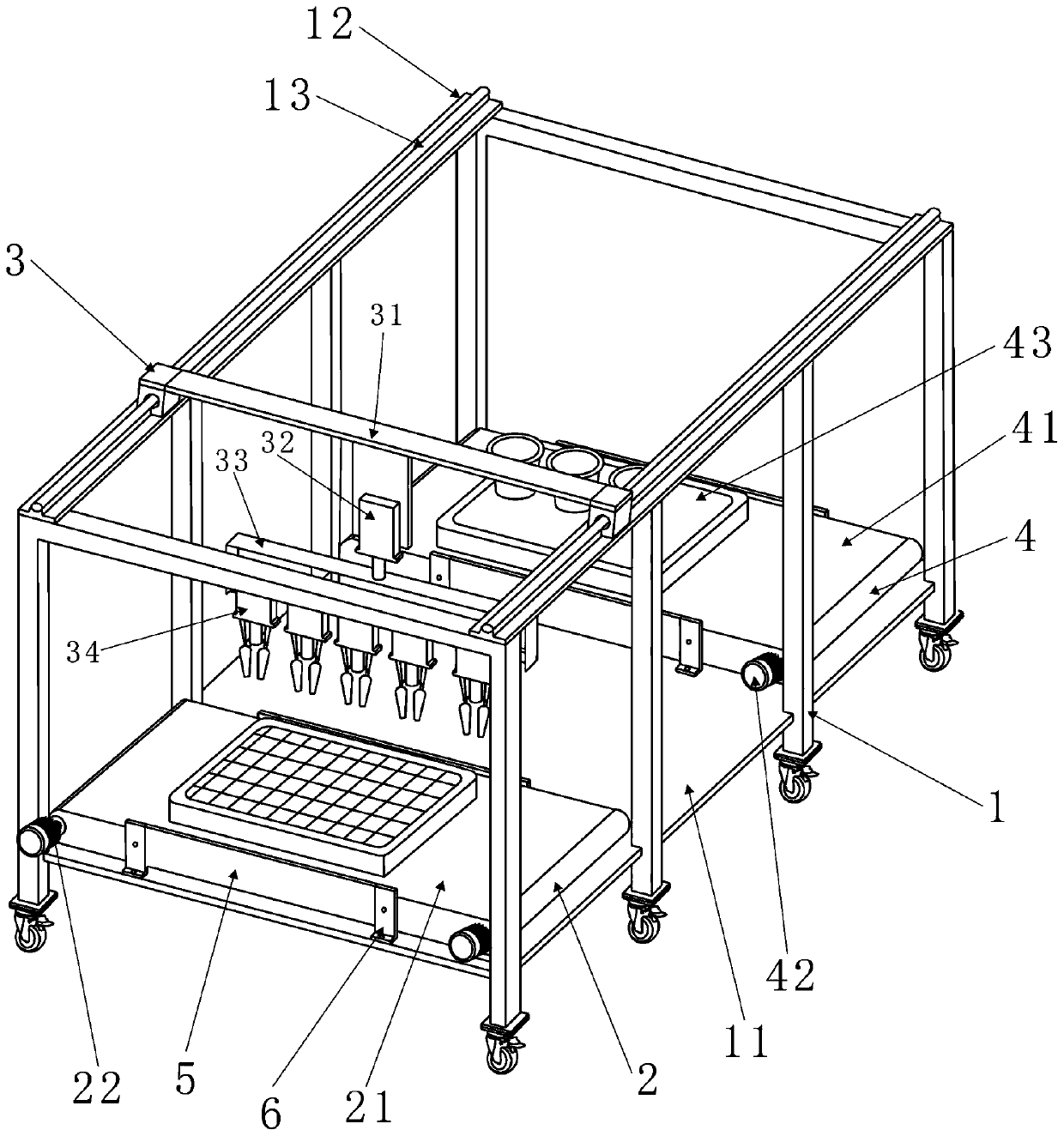

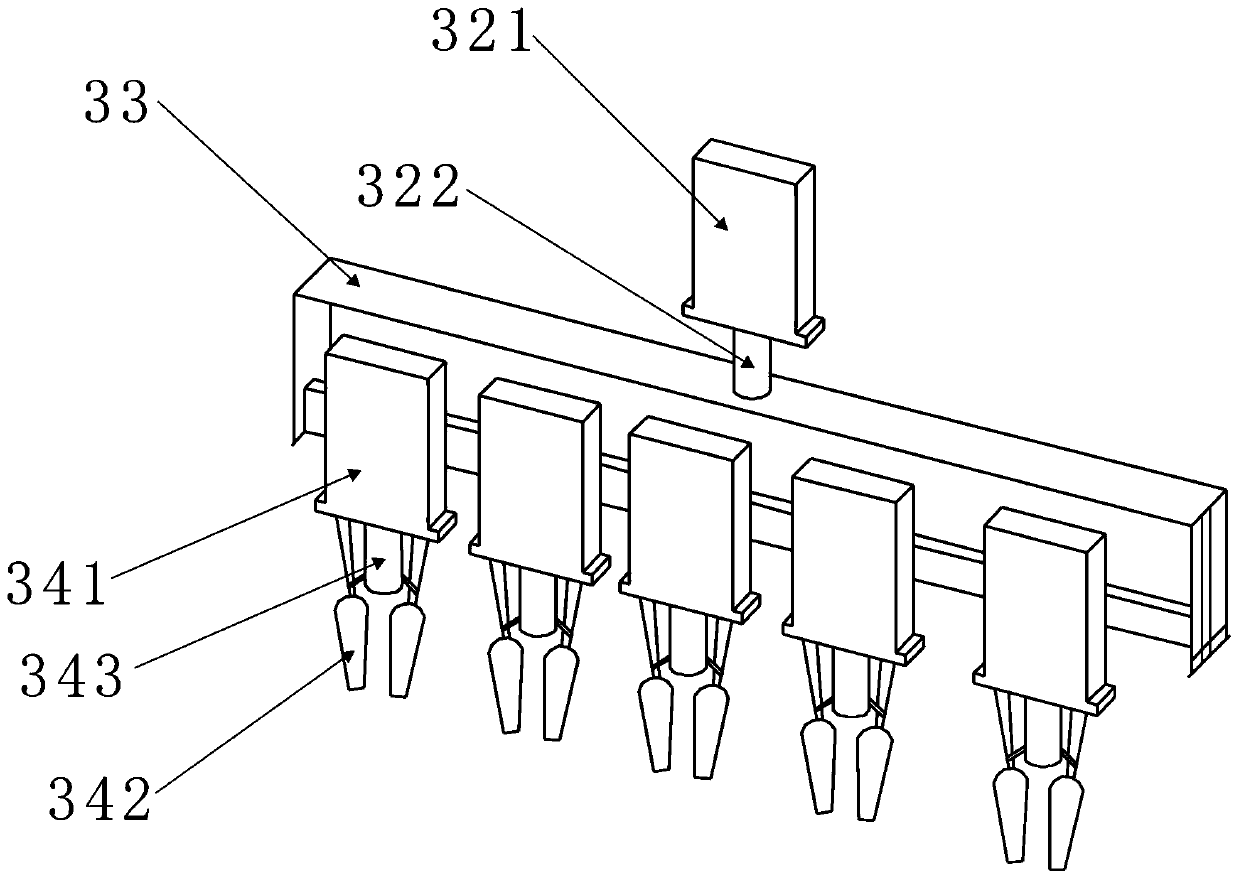

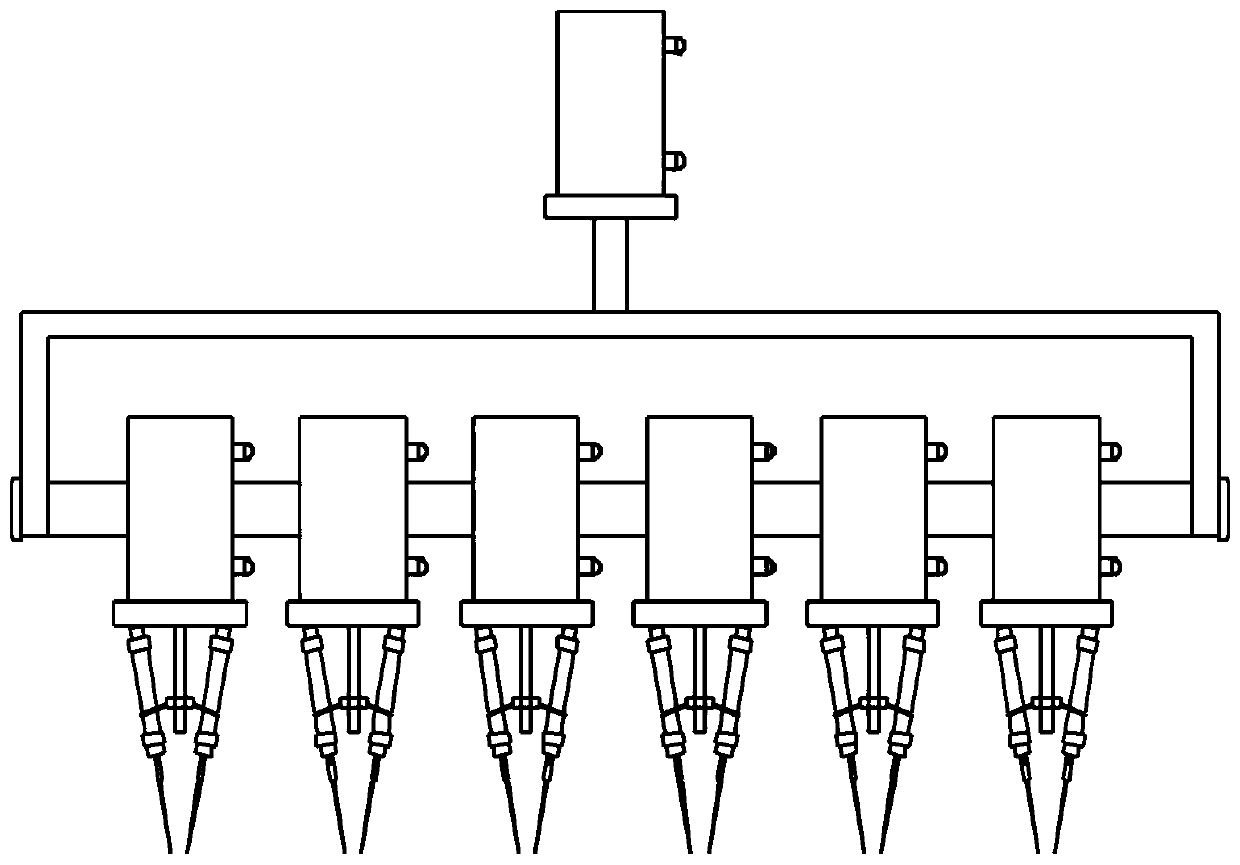

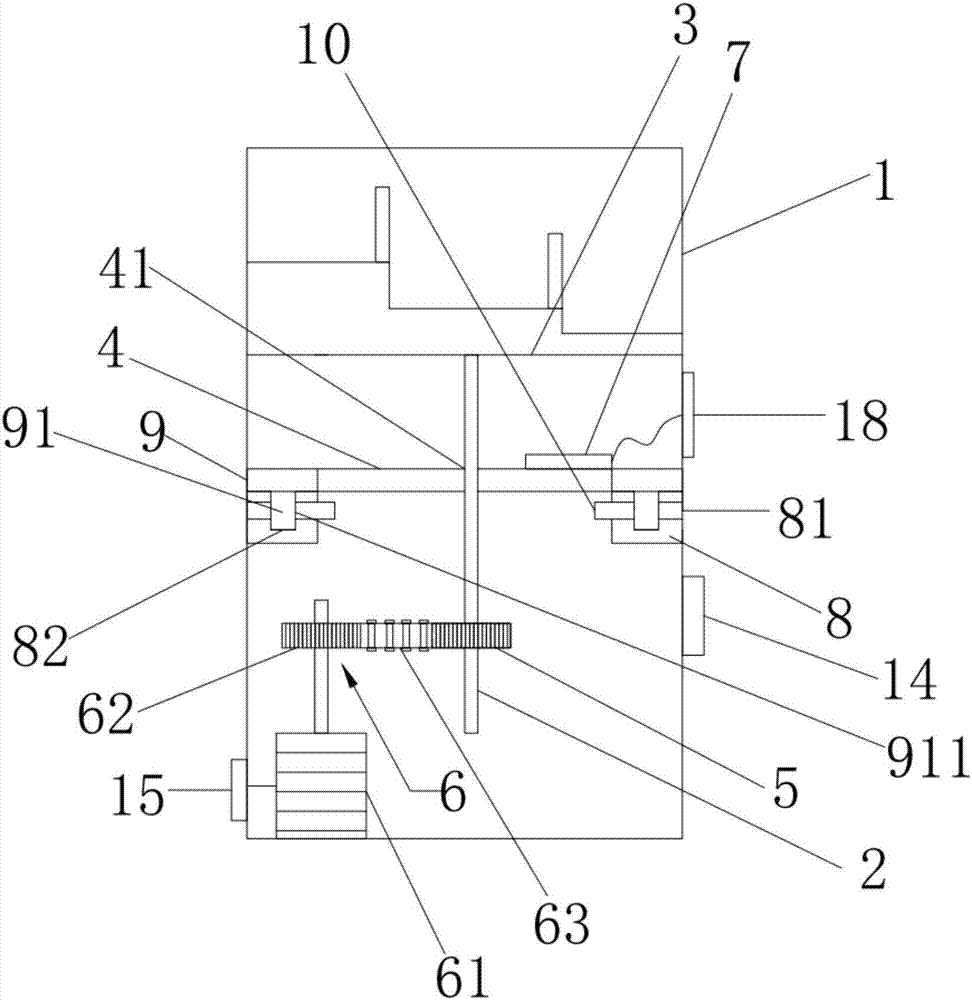

Automatic plug-tray seedling transplanting device

ActiveCN110521361AAutomatic and accurate seedling extractionAutomatic and Precise OperabilityTransplantingDrive shaftControl system

The invention discloses an automatic plug-tray seedling transplanting device. The device comprises a rack, a plug tray conveying system, a transplanting manipulator system, a flowerpot conveying system and a control system; the plug tray conveying system and the flowerpot conveying system are located at the two sides of a bottom plate of the rack respectively, and the transplanting manipulator system is arranged in the middle above the rack and is slidably connected with the rack; the plug tray conveying system comprises a first belt, two transmission shafts, a speed reducer and a first motor;the flowerpot conveying system comprises a second belt, a belt driving shaft, a belt driven shaft and a second motor; the transplanting manipulator system comprises a manipulator bracket, a pneumatictelescopic device, a seedling taking claw bracket, a seedling taking claw and a position detection device. The automatic plug-tray seedling transplanting device can achieve automatic and precise seedling taking and seedling placing operation on plug-tray seedlings, avoid the damage to the seedlings in the manual transplanting process, achieve the automation of the transplanting and production process of the plug-tray seedlings, reduce the labor intensity of the plug-tray seedling transplanting operation, and improve the plug-tray seedling transplanting quality.

Owner:YANGZHOU POLYTECHNIC COLLEGE

Air conditioner, alternating current motor and speed adjusting device thereof

ActiveCN102480263AIncrease the number of stallsSolve electromagnetic noiseAC motor controlMotor speedCapacitance

The invention provides an air conditioner, an alternating current motor and a speed adjusting device thereof. The alternating current motor speed adjusting device comprises that: a main speed regulation unit, wherein, an input terminal forms a main speed regulation input terminal which is connected with a controller, and an output terminal forms a main speed regulation output terminal which is connected with a plurality of live wire terminals of the alternating current motor; an auxiliary speed regulation unit which comprises a first branch and at least a second branch, wherein, the first branch and the second branch have a respective input terminal and a common output terminal, and the common output terminal forms an auxiliary speed regulation output terminal which is connected with a zero line of the alternating current motor; a shift selector, wherein, an input terminal of the shift selector forms an auxiliary speed regulation input terminal which is connected with the controller, and an output terminal is selectively connected with one of the respective input terminal of the first branch and the second branch, wherein, the first branch is a direct connecting branch and the second branch is a capacitive branch. According to the air conditioner, the alternating current motor and the speed adjusting device of the invention, a problem of electromagnetic noise when utilizing a chopper speed regulation principle to carry out speed regulation on a present alternating motor in the prior art is solved.

Owner:GREE ELECTRIC APPLIANCES INC

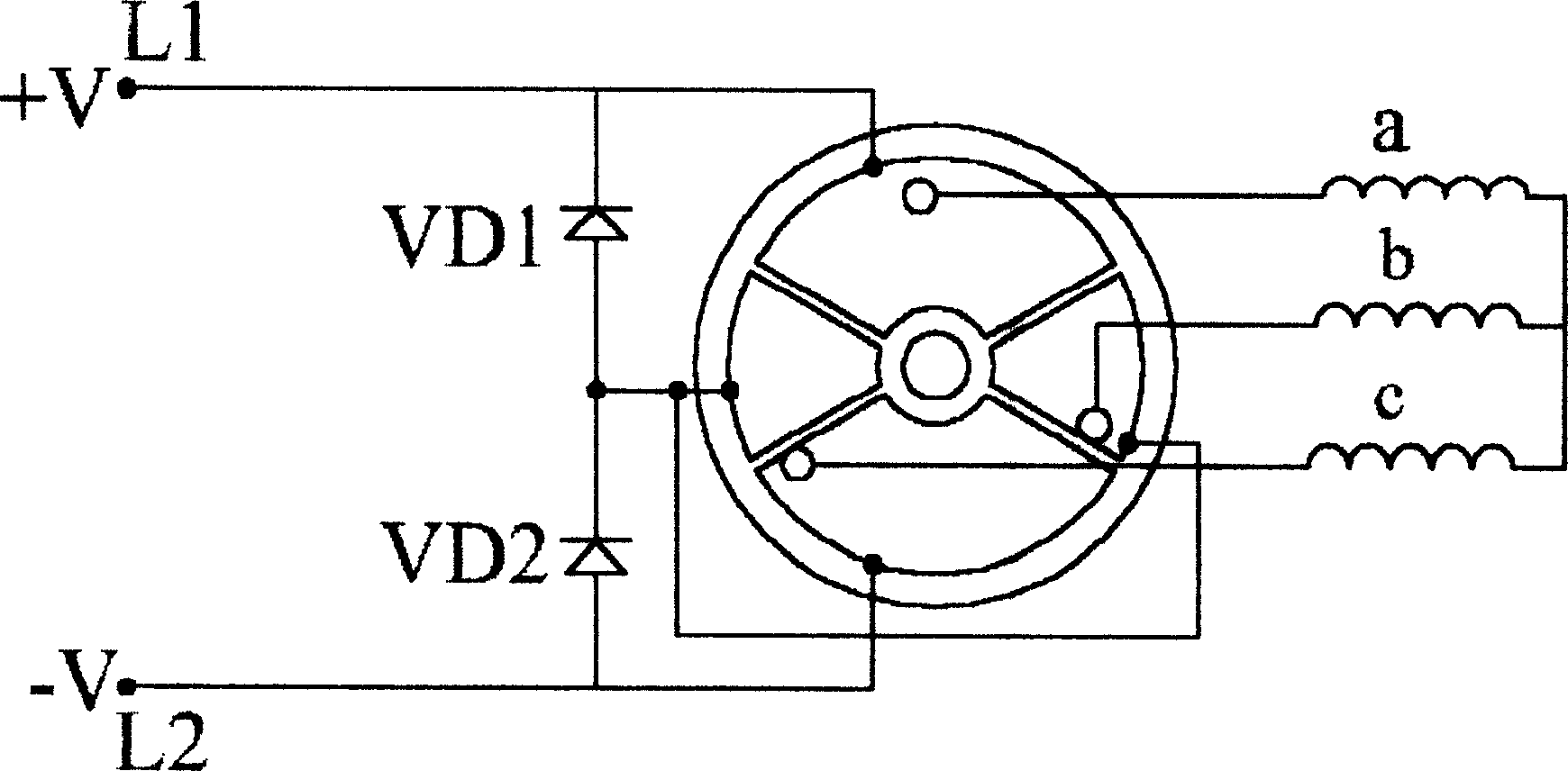

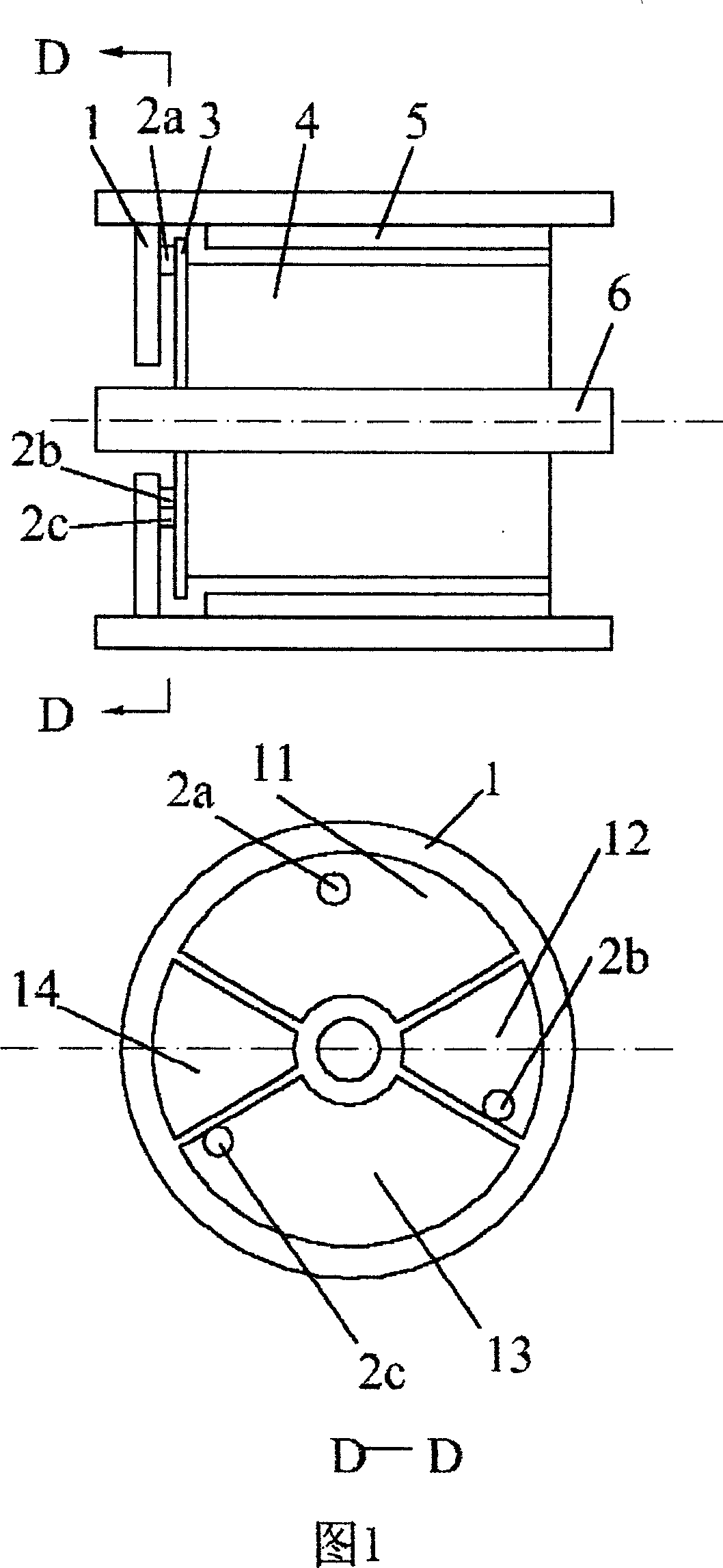

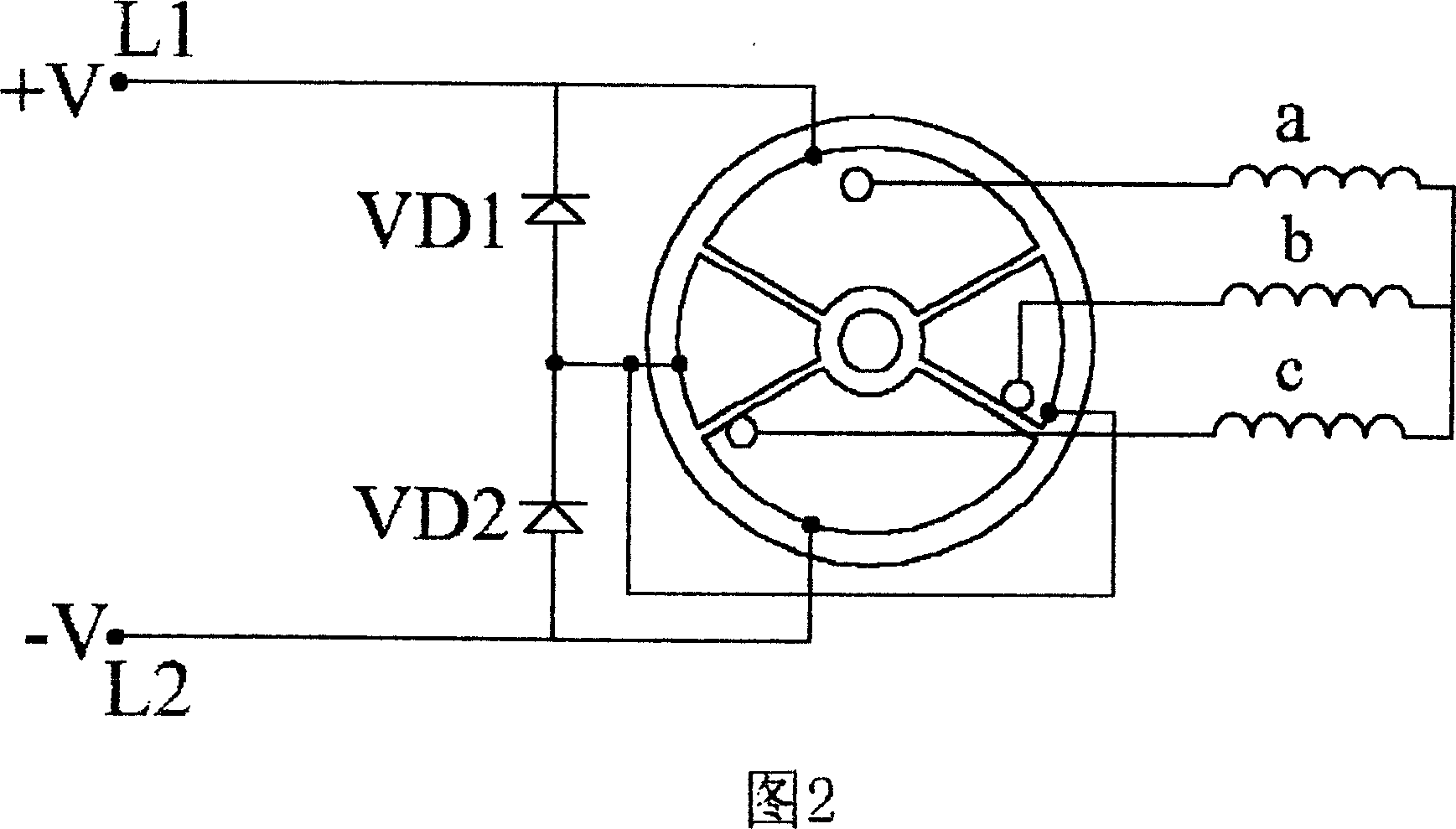

DC motor with commutator and its driven washing machine

ActiveCN1649242AMeet the freewheeling time requirementsProtection against overvoltageControl devices for washing apparatusDynamo-electric machinesCross overStator

This invention relates to a DC motor with a commutator and a washing machine driven by it. Its brush at the rotor is connected with the phase windings of the pivot phase by phase, the commutator is set at the stator, the positive and negative commutator bars are isolated by continuous commutator bars distributed alternately along the rotary face relating to the shaft. The two bars are connected with the first pole of the power supply device, two semiconductor diodes or valves with the opposite conduction direction to the supply cross over the second pole of the supply after serial connection, its serial points are connected to the continuous commutator bars.

Owner:JINLING ELECTRICAL CO LTD

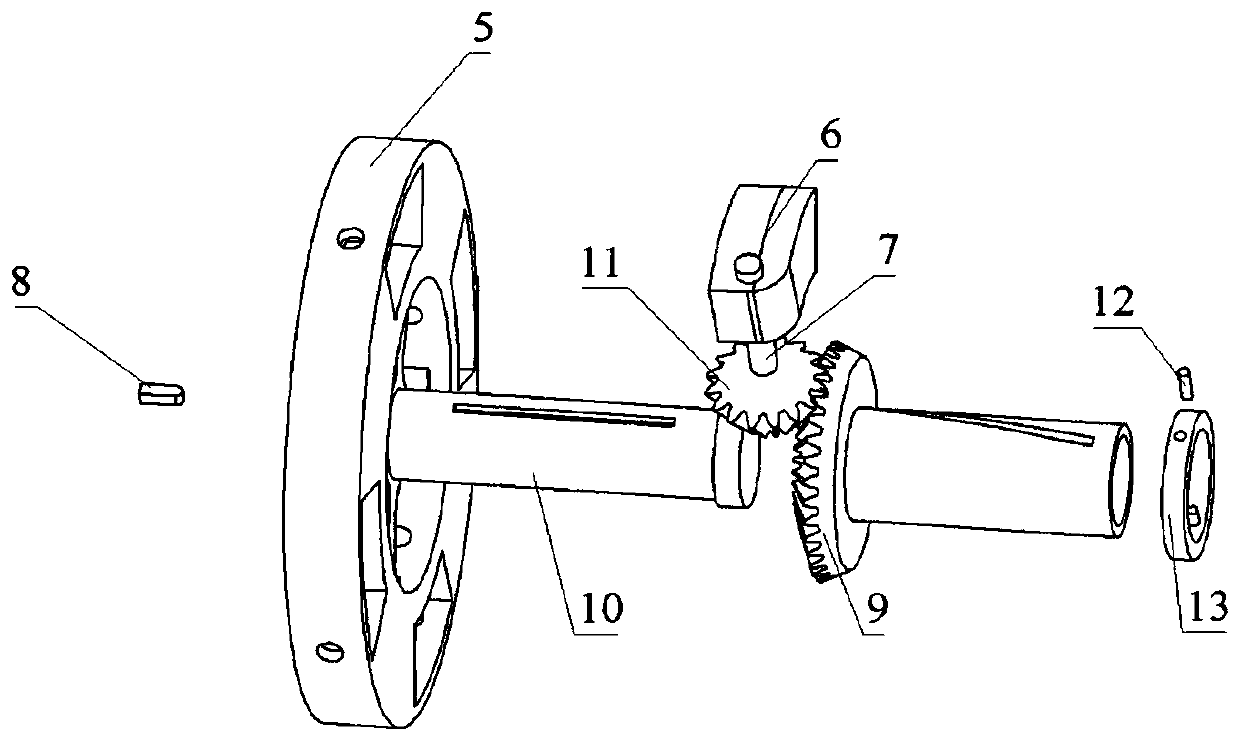

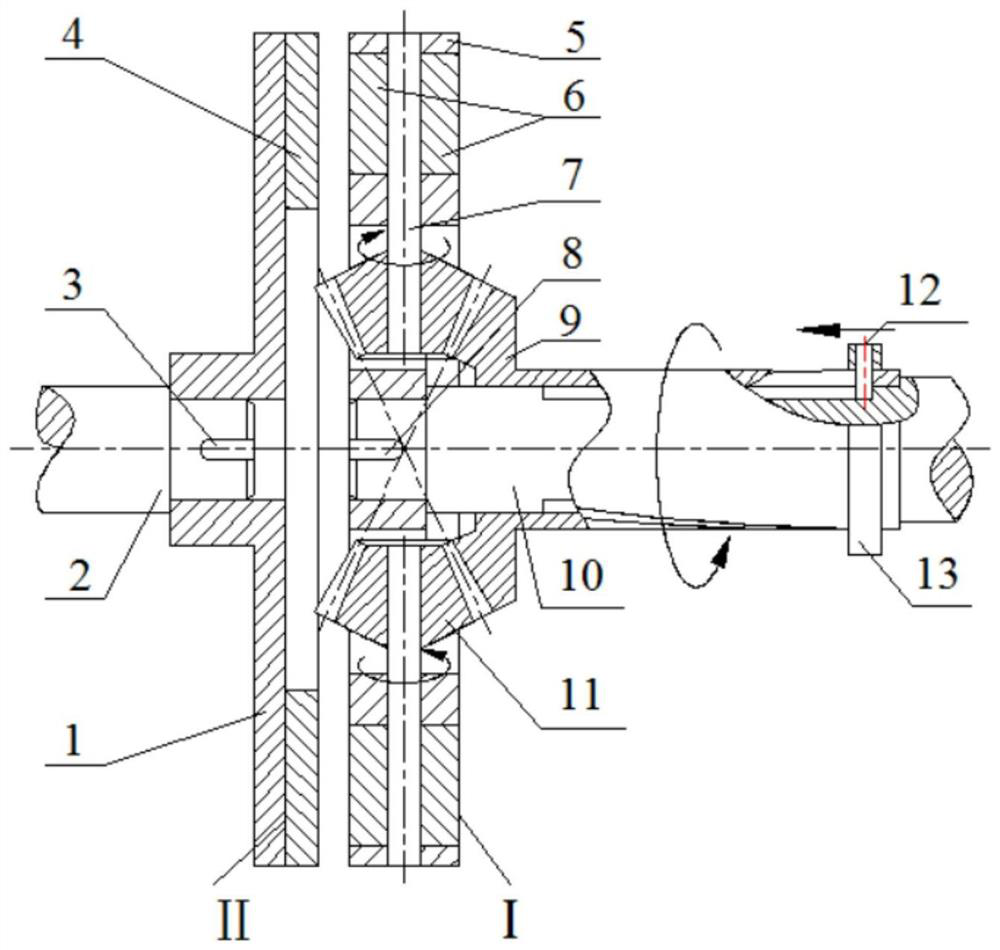

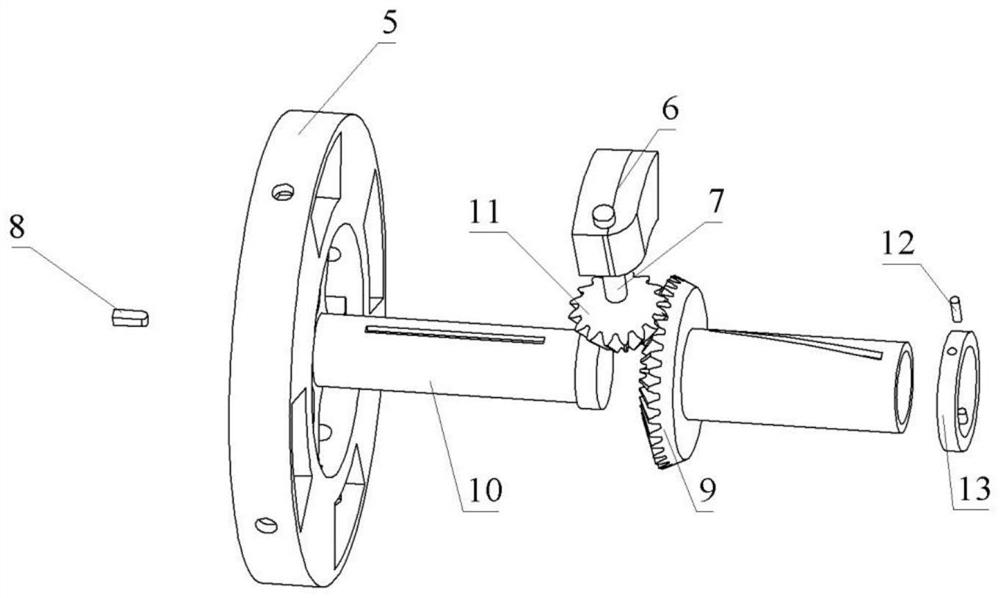

Monopole magnet rotating speed adjustable cage type magnetic coupling

ActiveCN110504816AAchieving a soft startAchieve protectionPermanent-magnet clutches/brakesMechanical energy handlingInterference fitElectrical conductor

The invention relates to the field of mechanical transmission, and is a monopole magnet rotating speed adjustable cage type magnetic coupling. In the invention, the copper disc uses a cage type copperdisc, all the fan-shaped grooves generate fan-shaped ring current around, the generated eddy current loss is small and the transmission efficiency is high, the fan-shaped grooves of the cage type copper disc and the small bumps on the surface of the yoke are in interference fit, and the small bumps of the yoke modulate the magnetic field, thereby further increasing the electromagnetic torque of the coupler. The coupler provides three speed adjustment methods that the first is to adjust the air gap between the copper disc and the permanent magnet disc through an axial moving device, the secondis to change the rotation angle of the rotating permanent magnet by fixing the air gap to further adjust the head-on area between a conductor disc and the permanent magnet disc, and the third is to use the composite speed adjustment of the air gap between the two disks in axial movement and the rotating permanent magnet, so that the coupler can meet different degrees of speed adjustment requirements.

Owner:JIANGSU UNIV

Composite supersonic motor with great moment and longitudinal torque

InactiveCN1384594ACompact structureReduce weightPiezoelectric/electrostriction/magnetostriction machinesLow speedMoment of inertia

The composite supersonic motor includes stator comprising lower metal ring, twisting piezoelectric ceramic vibrator, middle metal body, longitudinal piezoelectric ceramic vibrator and upper metal ring; rotor and spindle, via which the stator and the rotor are connected and pressed. By applying AC signals of the same frequency, the same as resonant frequency of the stator, and different phase to the twisting vibrator and longitudinal vibrator, the stator is made to produce longitudinal and twisting vibration acted intermittently to the rotor with friction material adhered to the outer surface of the bottom. High frequency and rotation inertia of the rotor makes the rotor move in homogeneous and low speed and great moment.

Owner:ZHEJIANG UNIV

Novel pen container

The invention provides a novel pen container, and relates to the field of stationery. The novel pen container comprises a pen container body and a screw; the pen container body is of a tubular structure; a notch is formed in the side wall of the pen container body; external threads are arranged on the screw; a chassis, a fixing disc and a gear are sequentially arranged in the pen container body from top to bottom; the fixing disc is disc-shaped; a screw hole is formed in the center of the fixing disc; internal threads are arranged on the inner side wall of the screw hole; one end of the screw is connected to the gear; the other end of the screw penetrates through the screw hole to be connected to the center of the chassis; a driving device is arranged in the pen container body and comprises a motor, a master gear and a chain; the motor is arranged at the bottom surface in the pen container body; the master gear is arranged on an output shaft of the motor; the gear is connected to the master gear through the chain; a pressure sensor is arranged on the top surface of the fixing disc; and a pressure displayer is arranged on the outer side wall of the pen container body and is electrically connected to the pressure displayer. The novel pen container has the advantages that a user can rapidly and conveniently fetch required shorter pens, and disassembly and assembly are convenient.

Owner:合肥展游软件开发有限公司

Selecting method of primary positioning reference of engine connecting rod

The invention discloses a selecting method of a primary positioning reference of an engine connecting rod. The method comprises the following steps of firstly, selecting the upper end surfaces and the lower end surfaces of head holes as first positioning references, and respectively selecting a small head hole and the outer side as a second positioning reference and a third positioning reference; roughly grinding the upper end surfaces and the lower end surfaces, adopting a mutual reference method to process, and meanwhile during drilling and rough boring of the small head hole, selecting the end surfaces of the small head hole and the contour of a small head as reference surfaces; during finishing operation, adopting a uniform reference method to process, processing the small head hole by taking the end surfaces of a large head hole and the small head hole and the outer side surface of a large head as the uniform precise references, and grinding the upper end surface and the lower surface of the small head hole by taking the upper end surface and the lower surface of the small head hole as the precise references; and selecting the size, direction and action points of clamping force, wherein the direction of the clamping force faces the main positioning surface and the end surfaces of the large head and the small head. The method has the beneficial effects that the stability and easy speed adjusting in the linear movement are realized, the running precision of a machine is favorably improved, and the service life of the machine is prolonged; and meanwhile, the convenient and flexible arrangement is favorably realized according to requirements, the operation controllability is improved, and the labor strength is reduced.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

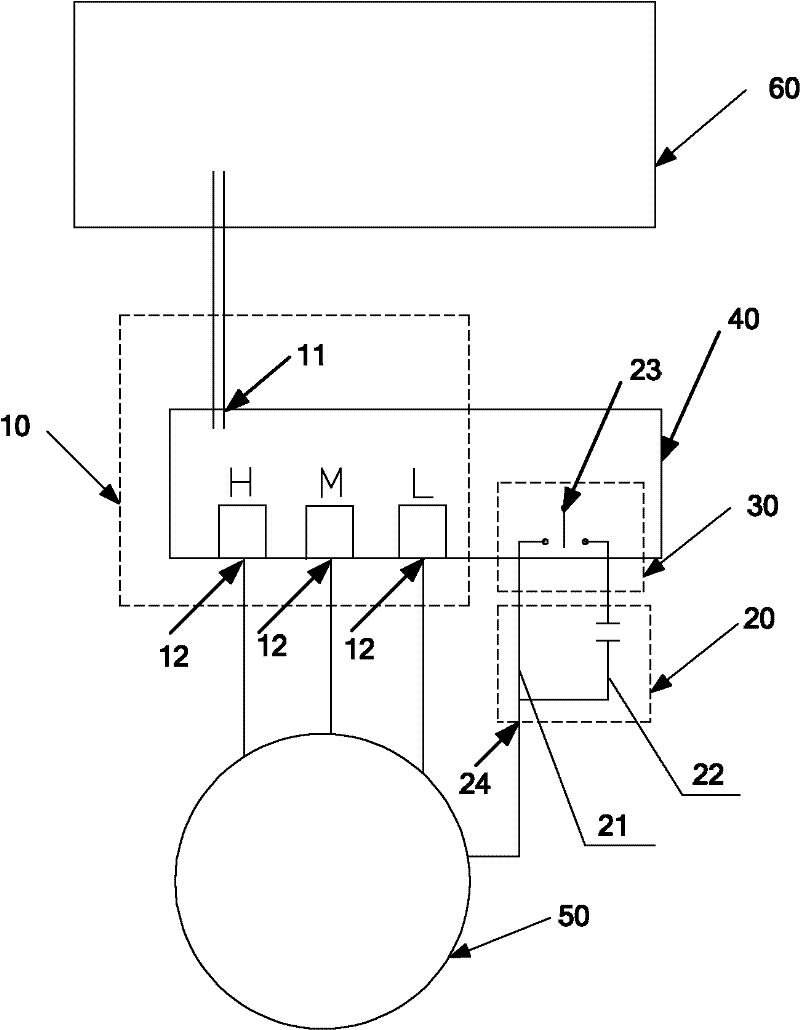

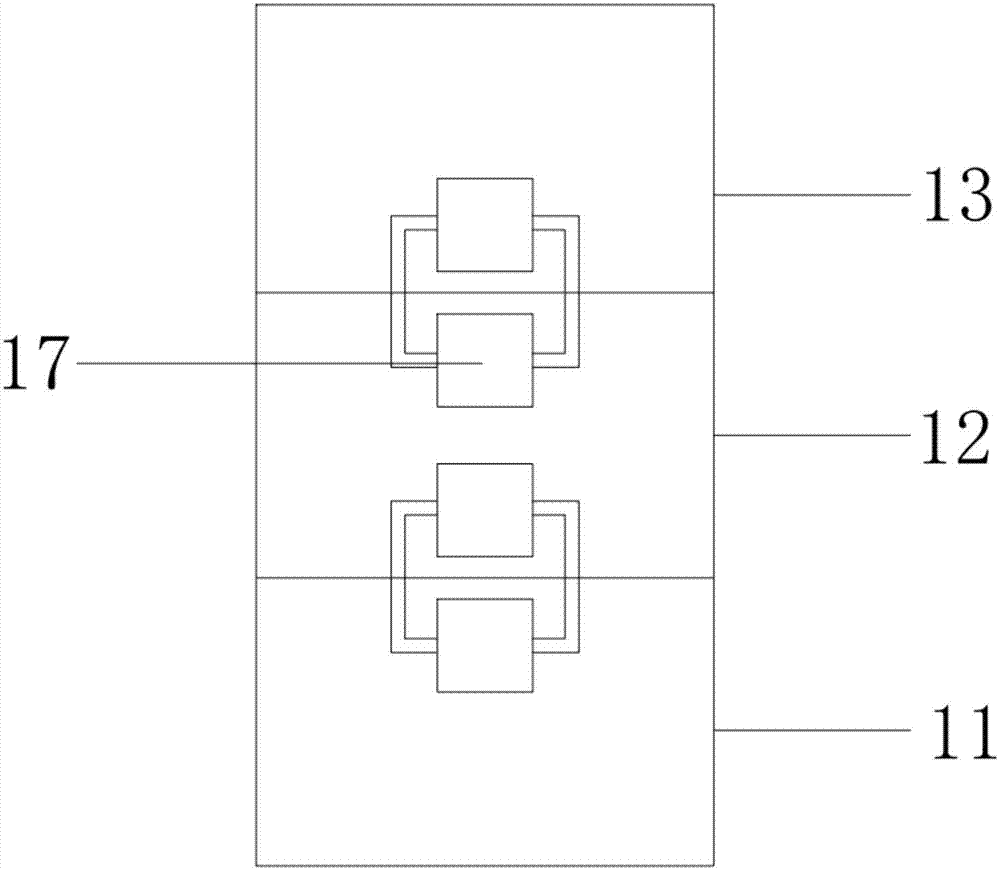

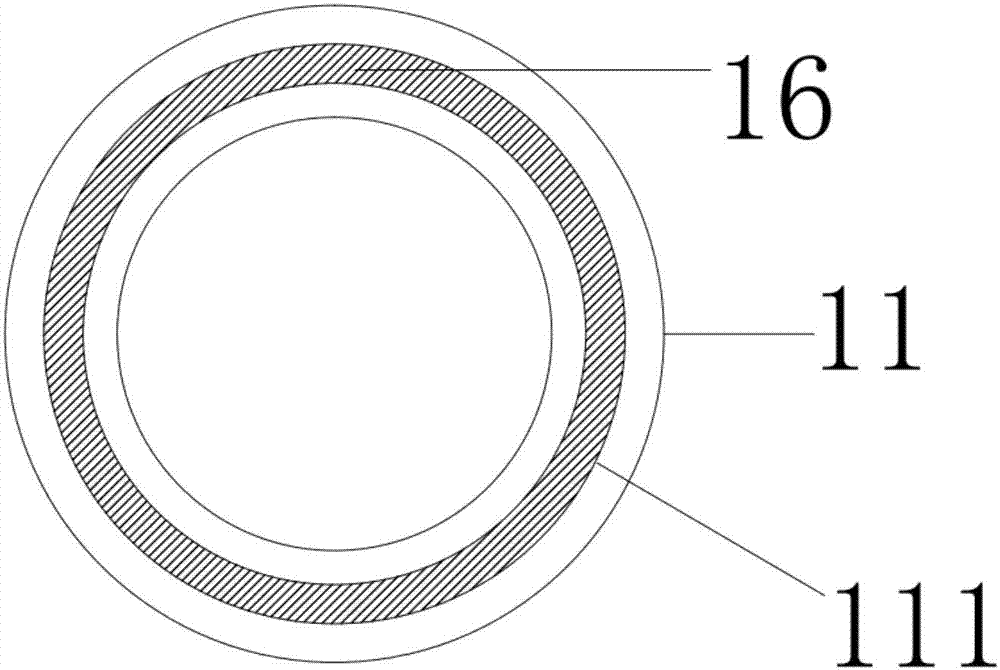

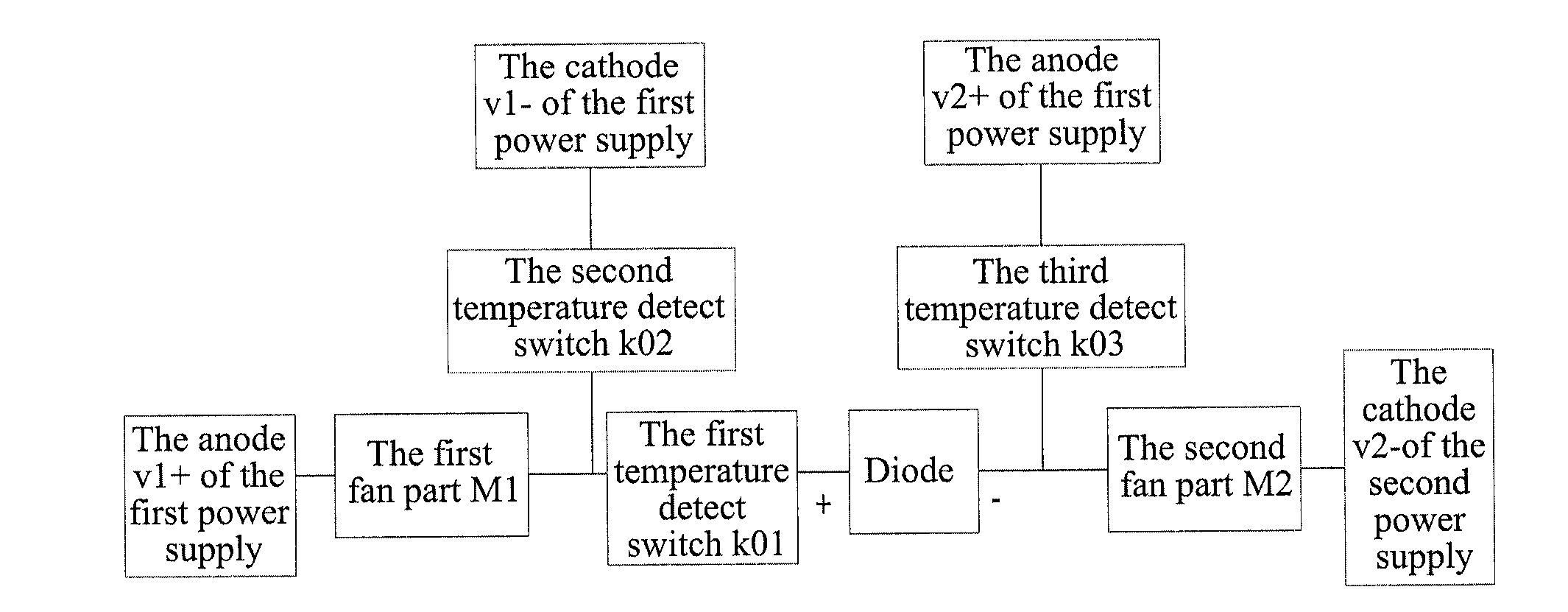

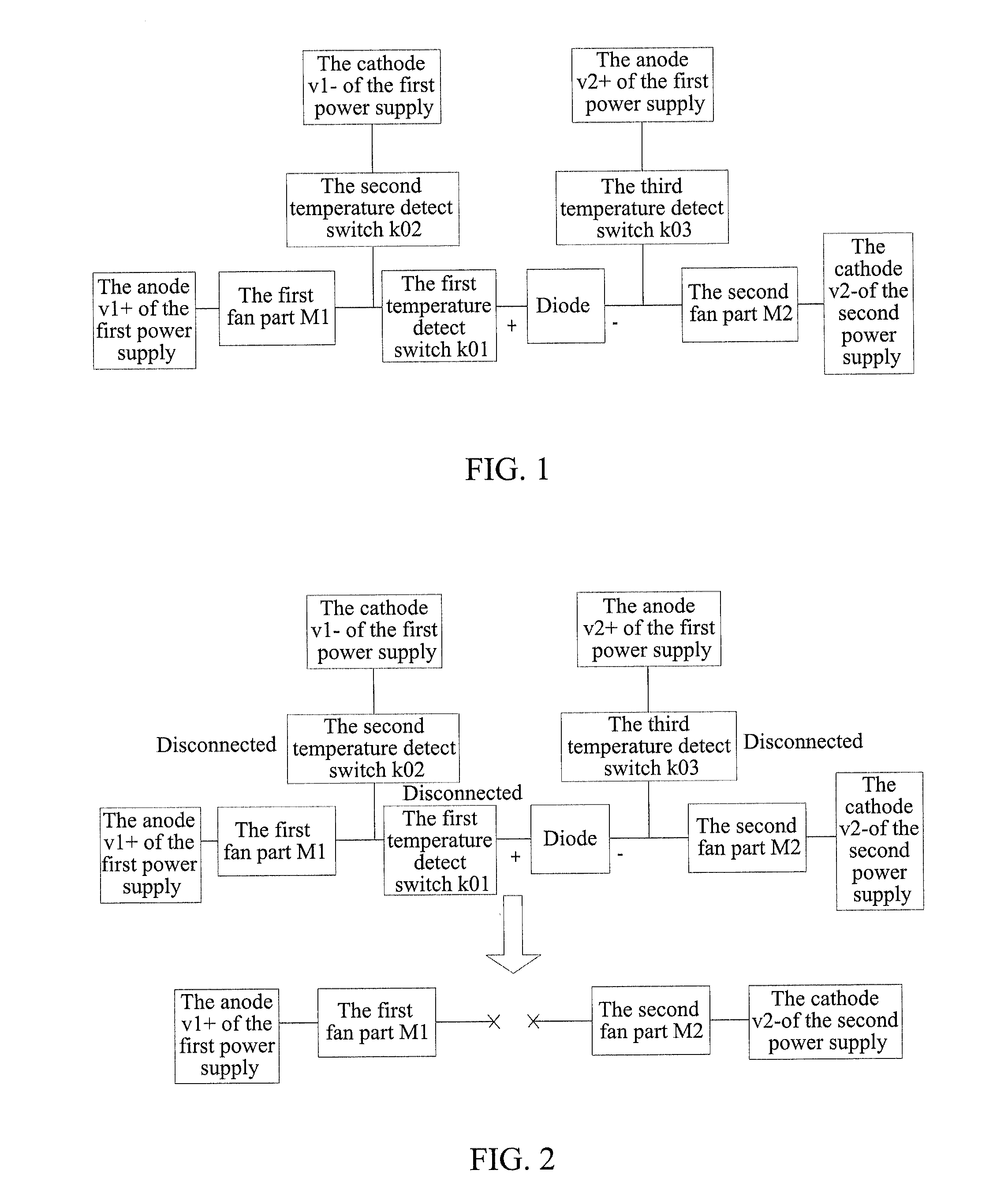

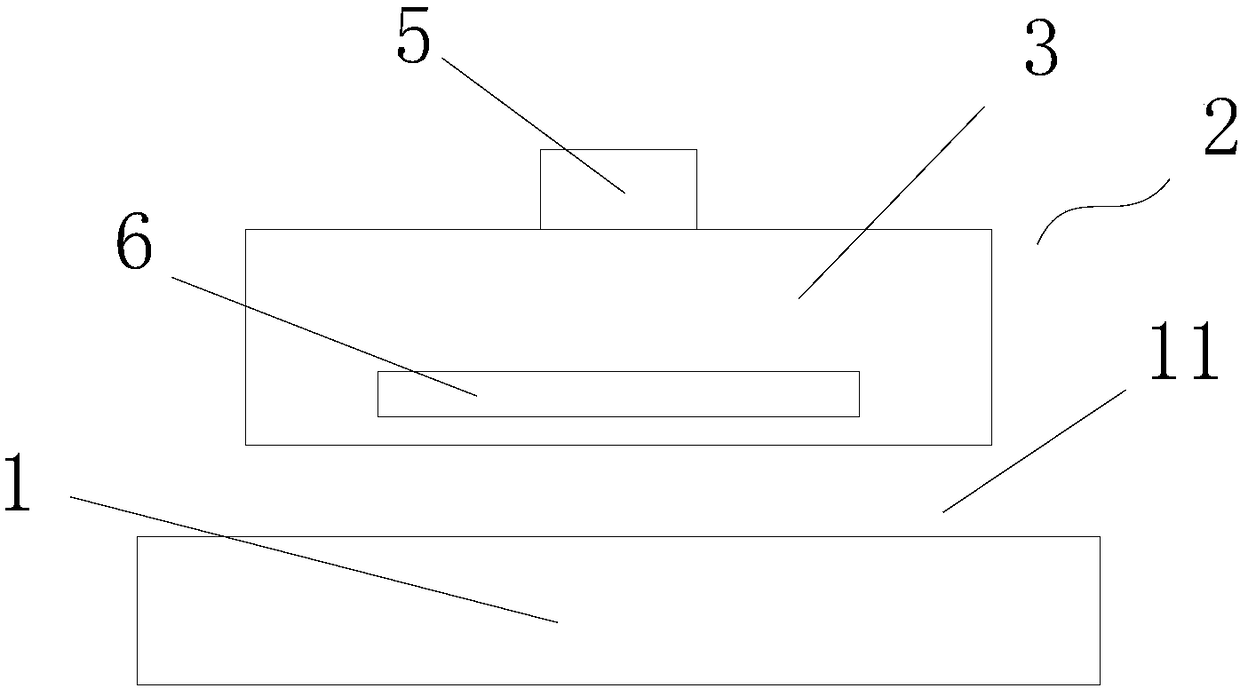

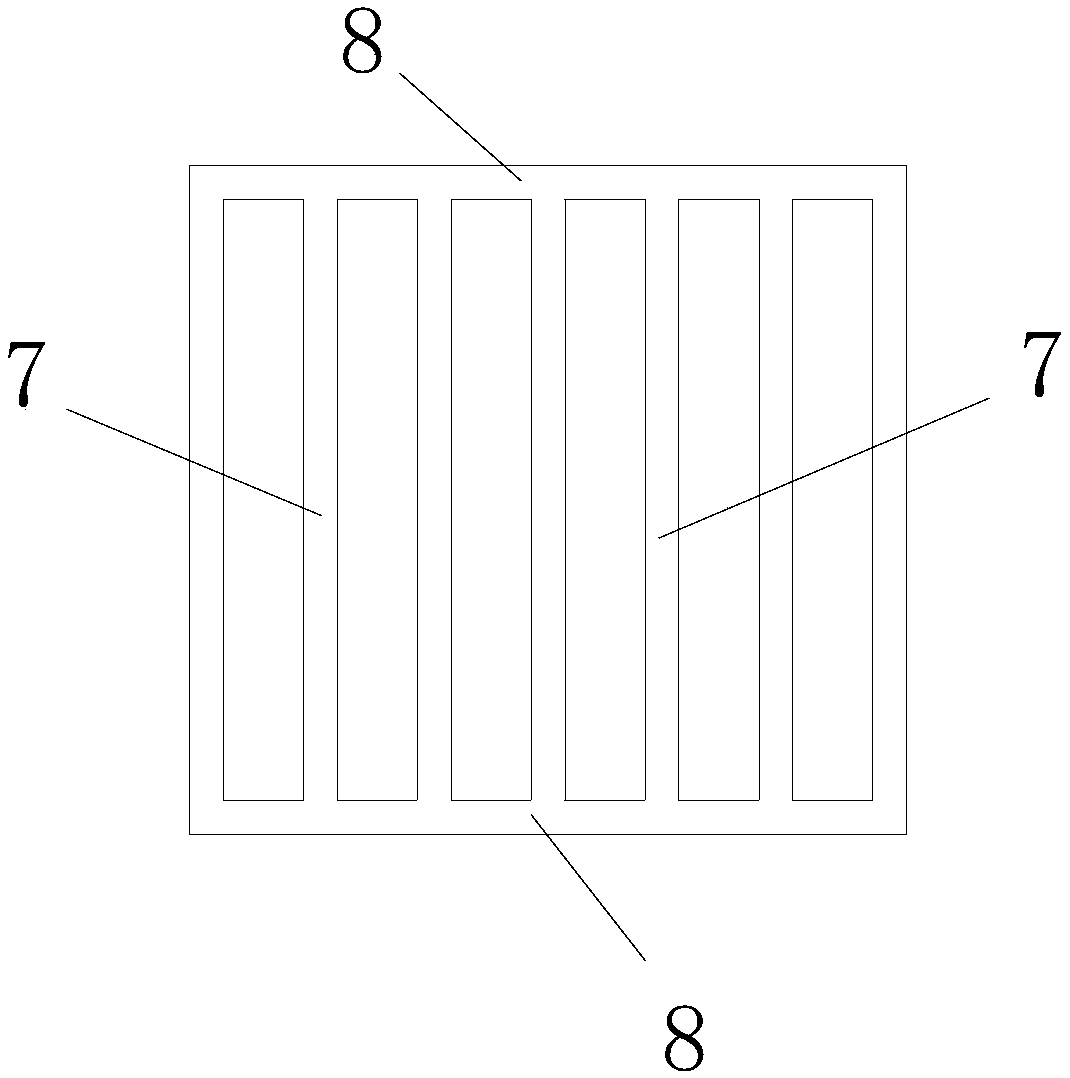

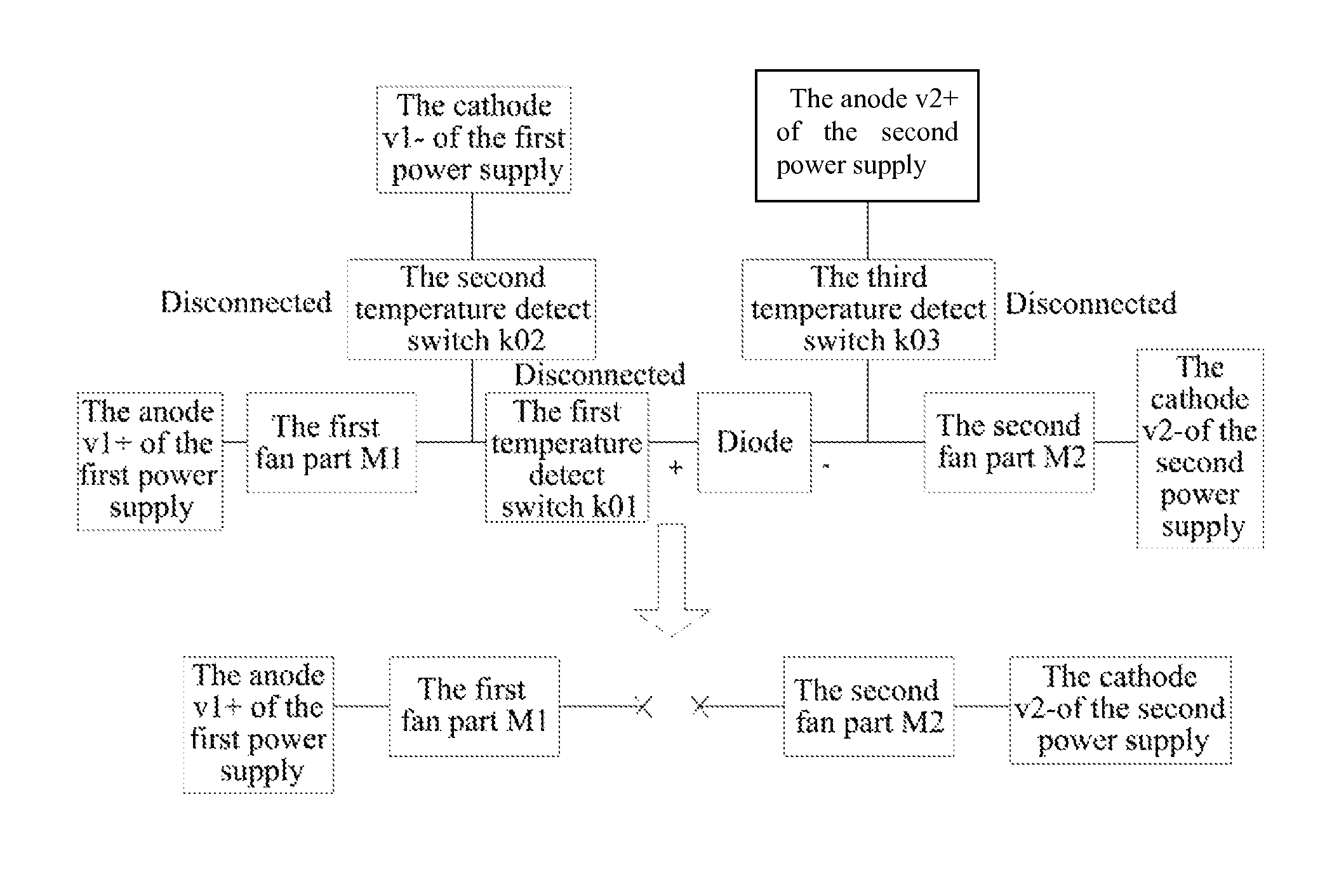

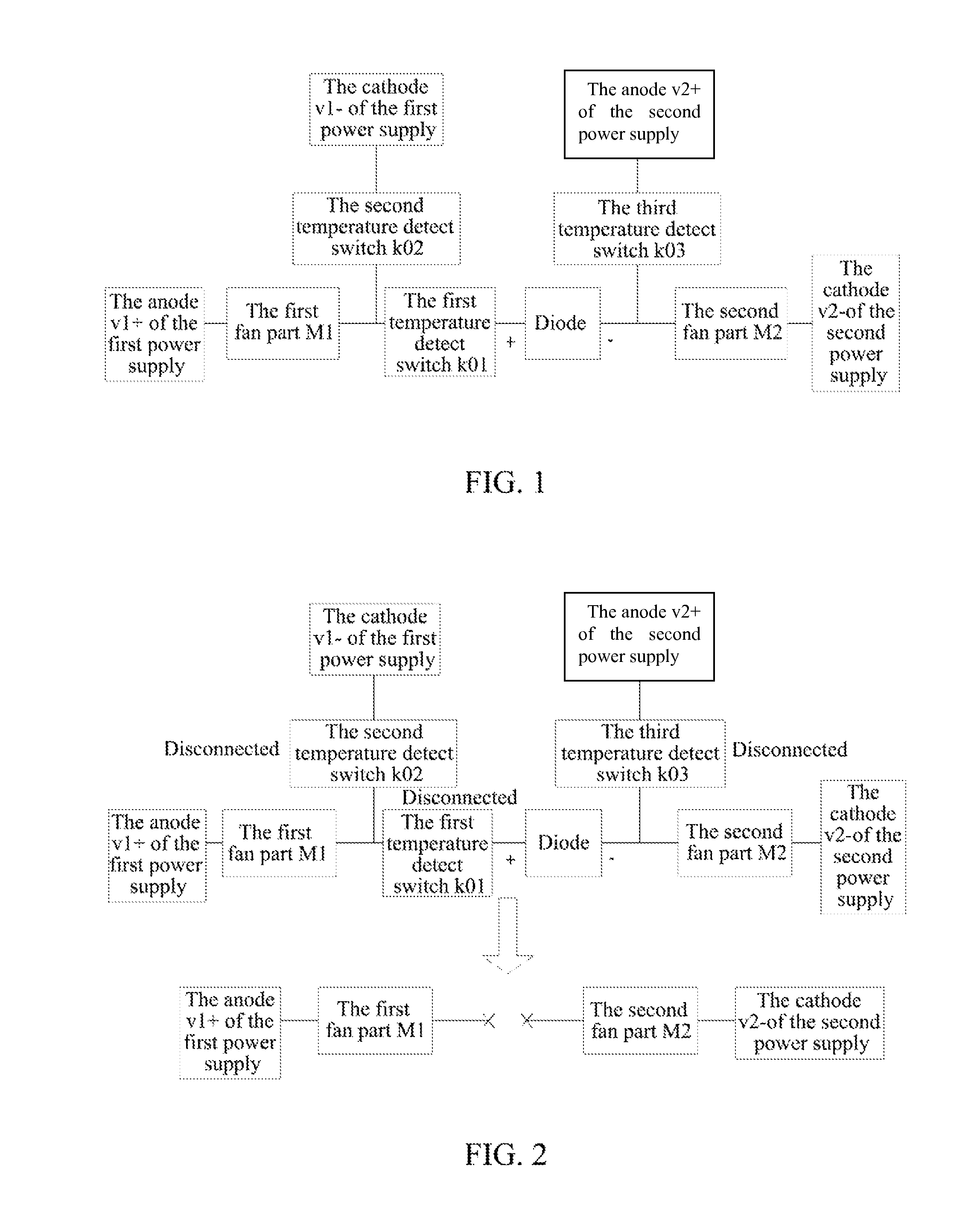

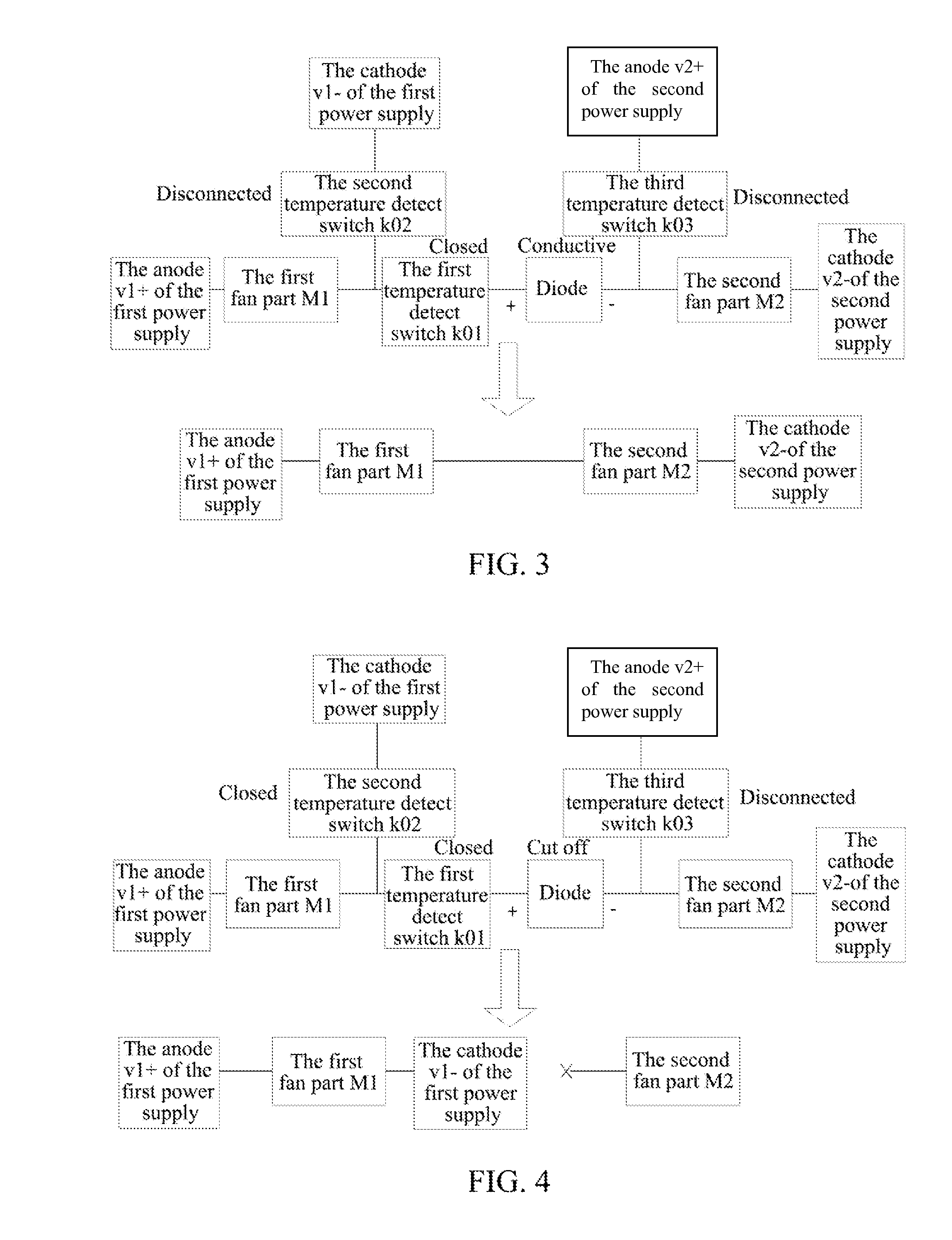

Fan type temperature control method and device

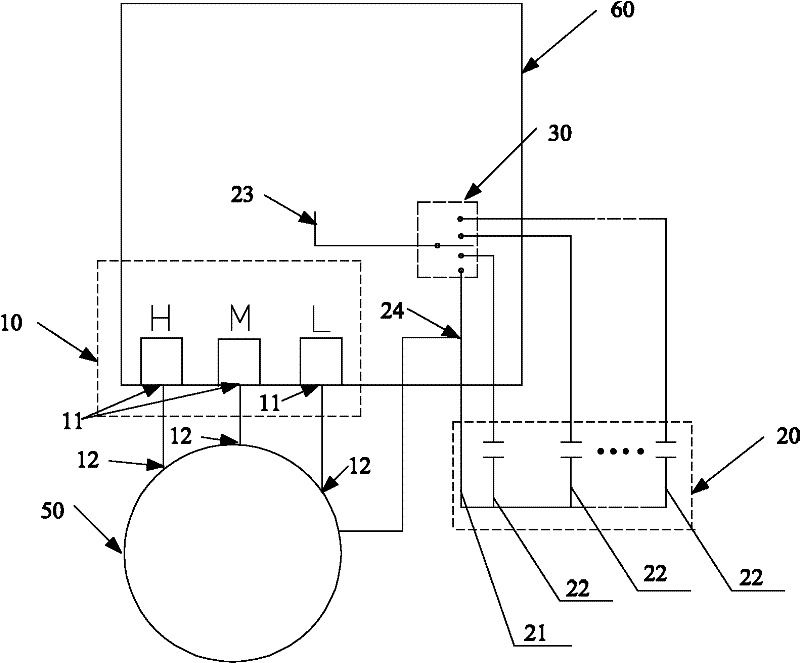

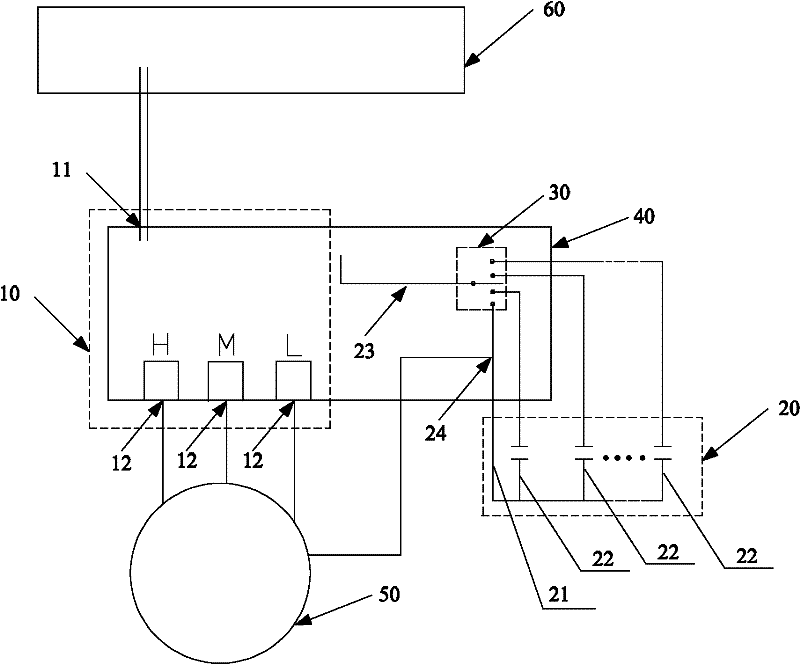

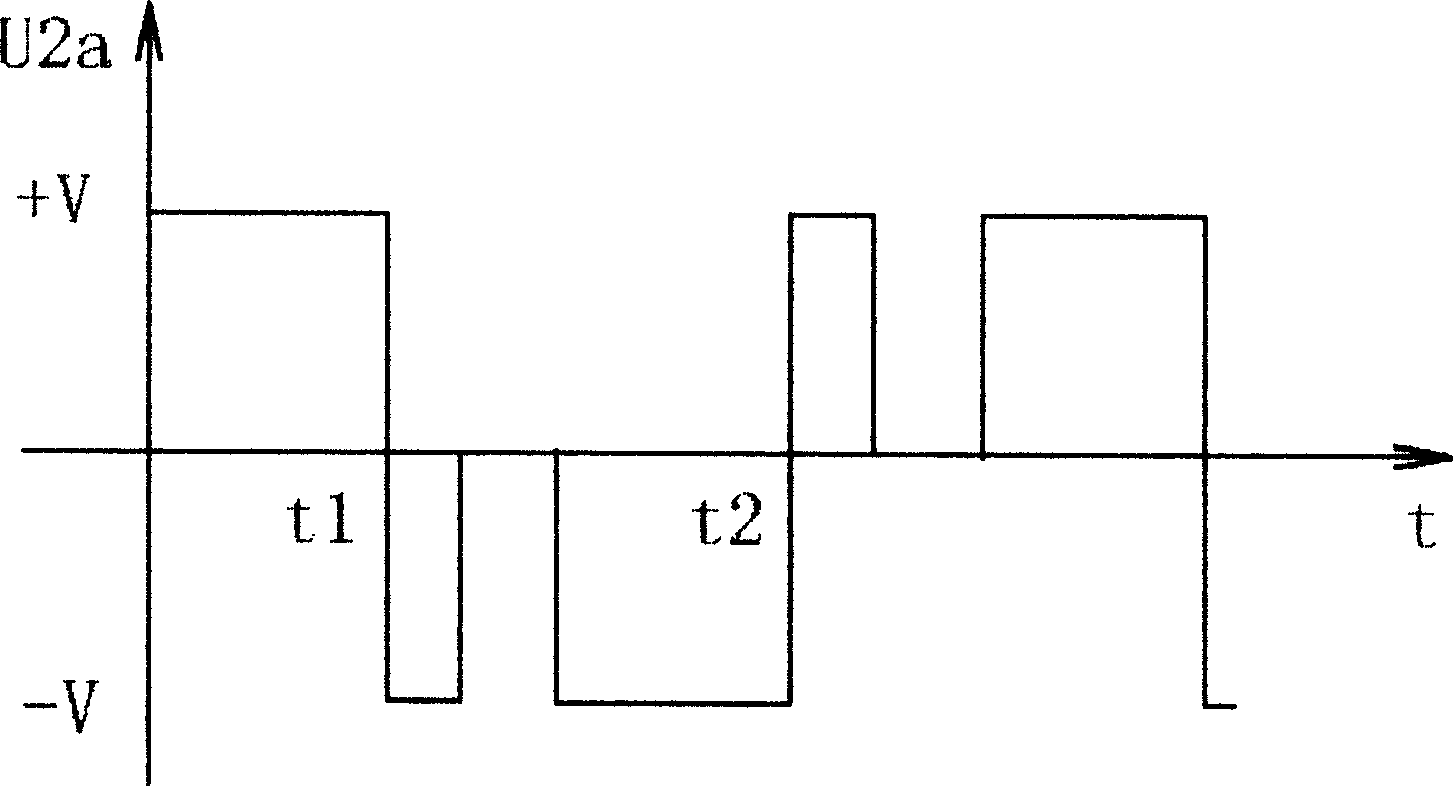

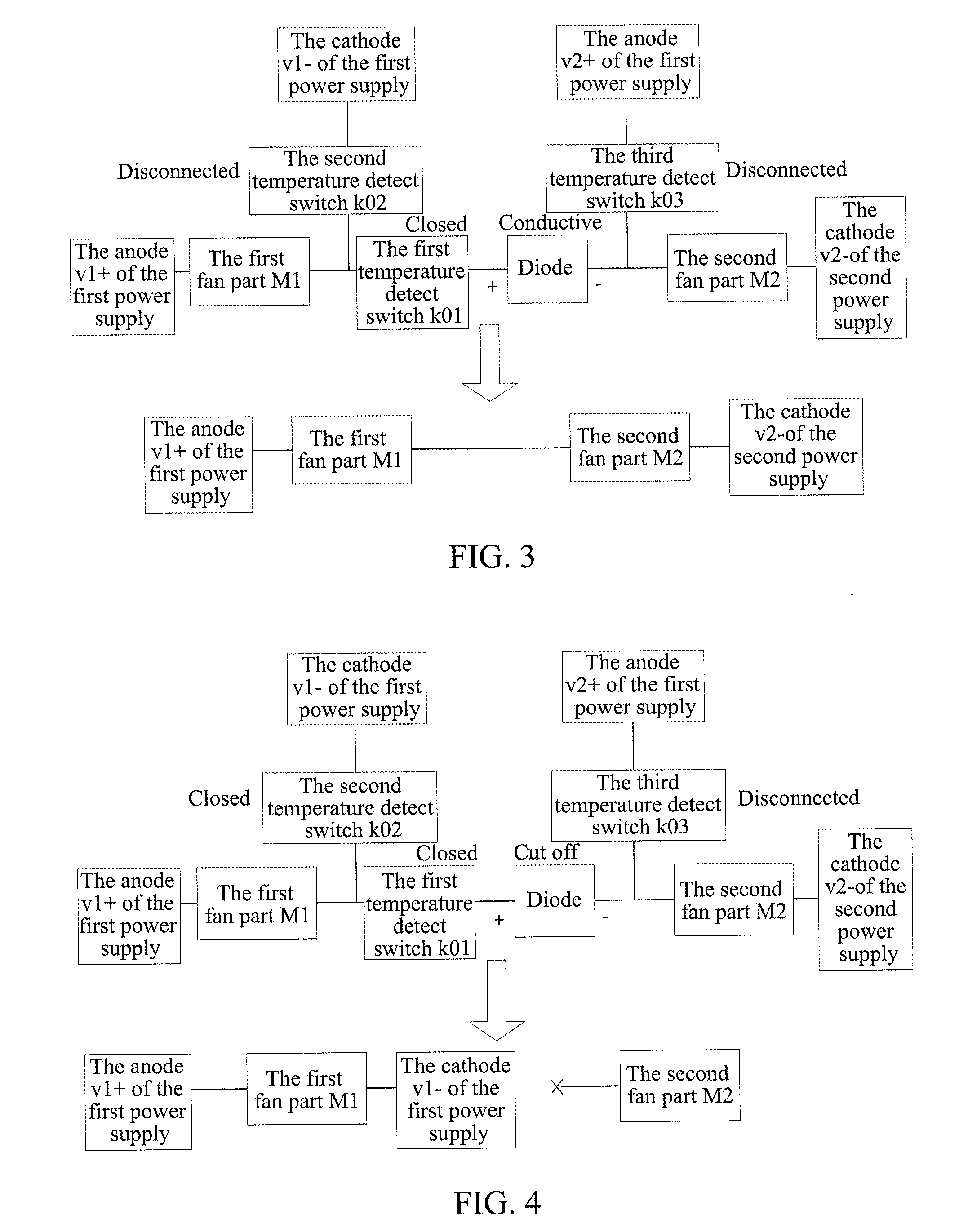

ActiveUS20120184199A1Simple and effective typeSimple speed regulationTemperature control using analogue comparing deviceDucting arrangementsTemperature controlEngineering

A fan type temperature control method and device are provided. The device includes a fan unit including a plurality of fans and cooling an apparatus to be cooled, power supplies (v1,v2) supplying power for the fans in the fan unit, and a fan control unit which controls the fans as follows: when temperature t of the apparatus is lower than critical temperature t1 of a first temperature detect switch (k01), all fans stop; when t is higher than t1 and lower than critical temperature t2 of a second temperature detect switch (k02), all fans rotate at half speed; when t is higher than t2 while lower than critical temperature t3 of a third temperature detect switch (k03), a first fan part (M1) rotates at full speed and a second fan part (M2) stops; when t is higher than t3, all fans rotate at full speed.

Owner:ZTE CORP

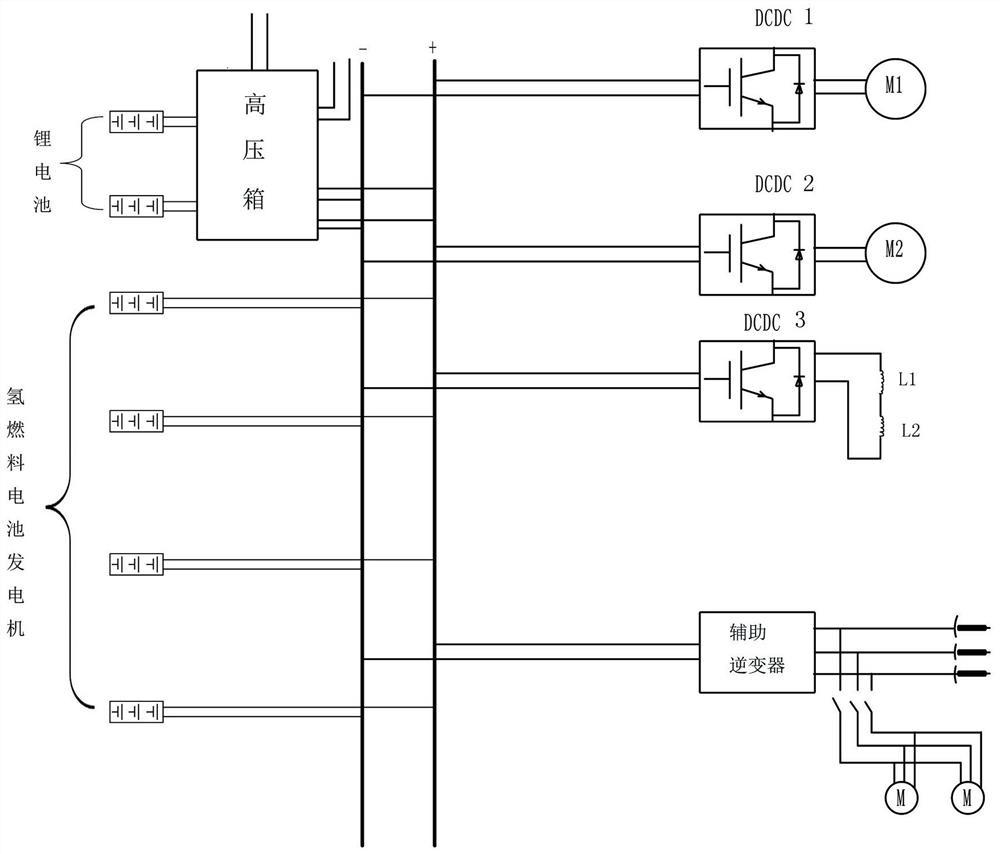

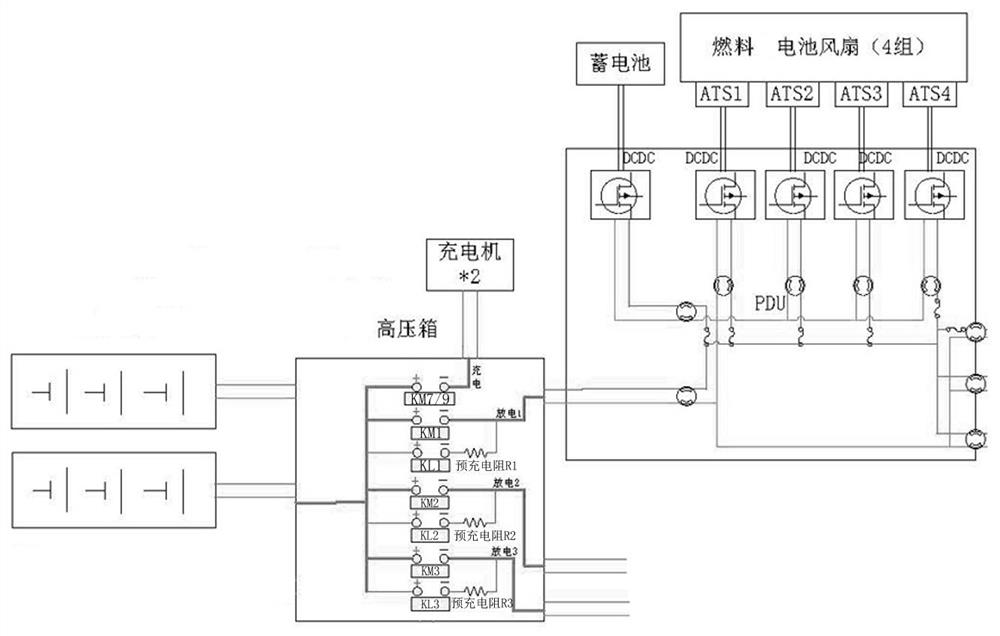

Power control system of new energy electric wheel mining dump truck

PendingCN111775677AImprove performanceReduce vibration and noiseElectrodynamic brake systemsElectric propulsion mountingTruckGenerating unit

The invention relates to an electric wheel mining dump truck, in particular to a power control system of a new energy electric wheel mining dump truck. The defects and problems existing in an electricwheel mining dump truck which adopts a diesel generator set to provide power are solved. The power control system of the new energy electric wheel mining dump truck comprises a lithium battery, a hydrogen fuel cell engine, a direct-current bus, a first DC / DC triple chopper, a second DC / DC triple chopper and a third DC / DC triple chopper, wherein the lithium battery and the hydrogen fuel cell engine are respectively connected in parallel with the direct-current bus; the first DC / DC triple chopper takes power from the direct-current bus and supplies power to an armature winding of the first DC motor; the second DC / DC triple chopper takes power from the direct-current bus and supplies power to the armature winding of the second DC motor, and the third DC / DC triple chopper takes power from thedirect-current bus and supplies power to the excitation windings of the first DC motor and the second DC motor. The power control system adopts a hydrogen fuel engine and lithium battery hybrid energy system to replace the diesel generator set to provide power.

Owner:CRRC YONGJI ELECTRIC CO LTD

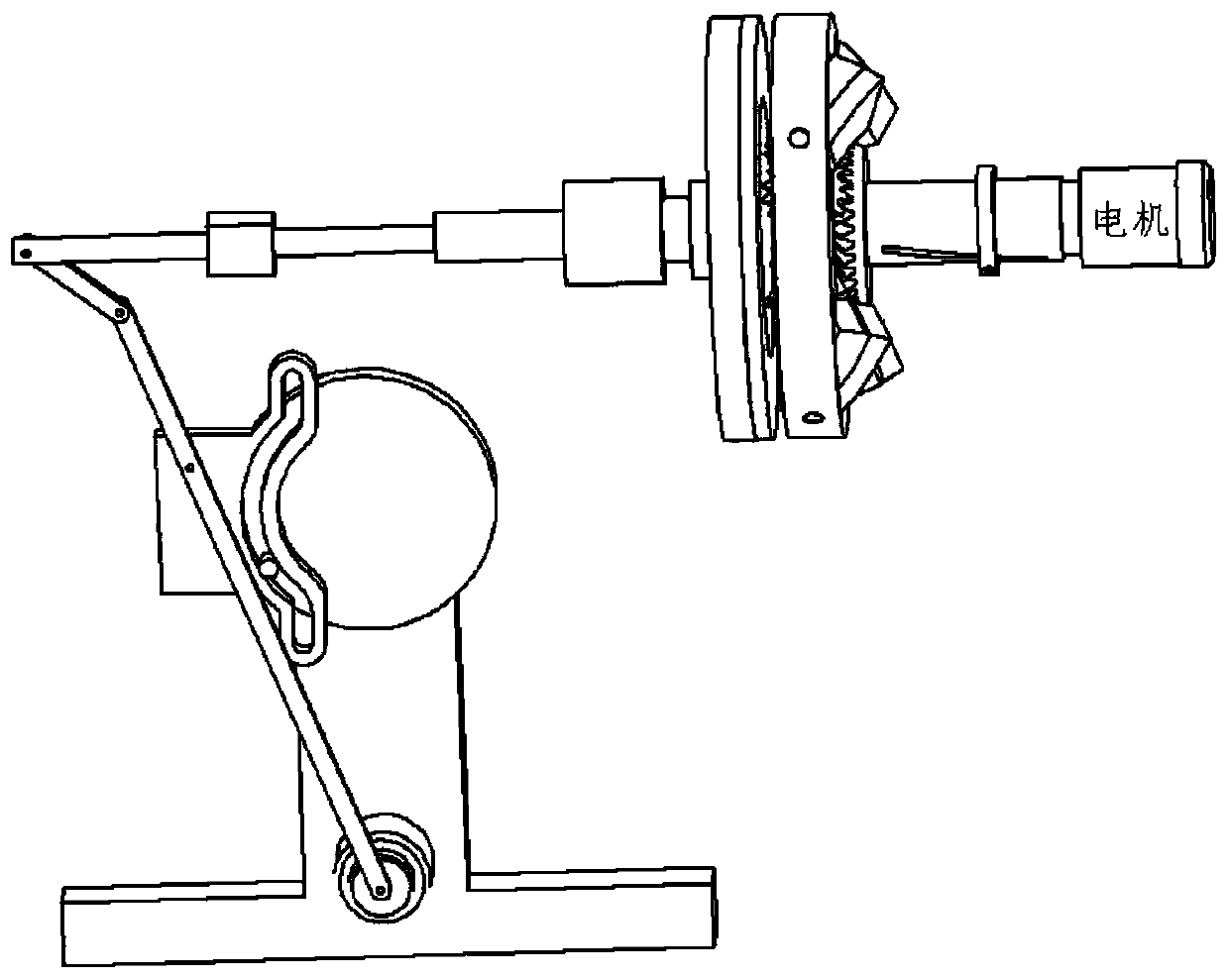

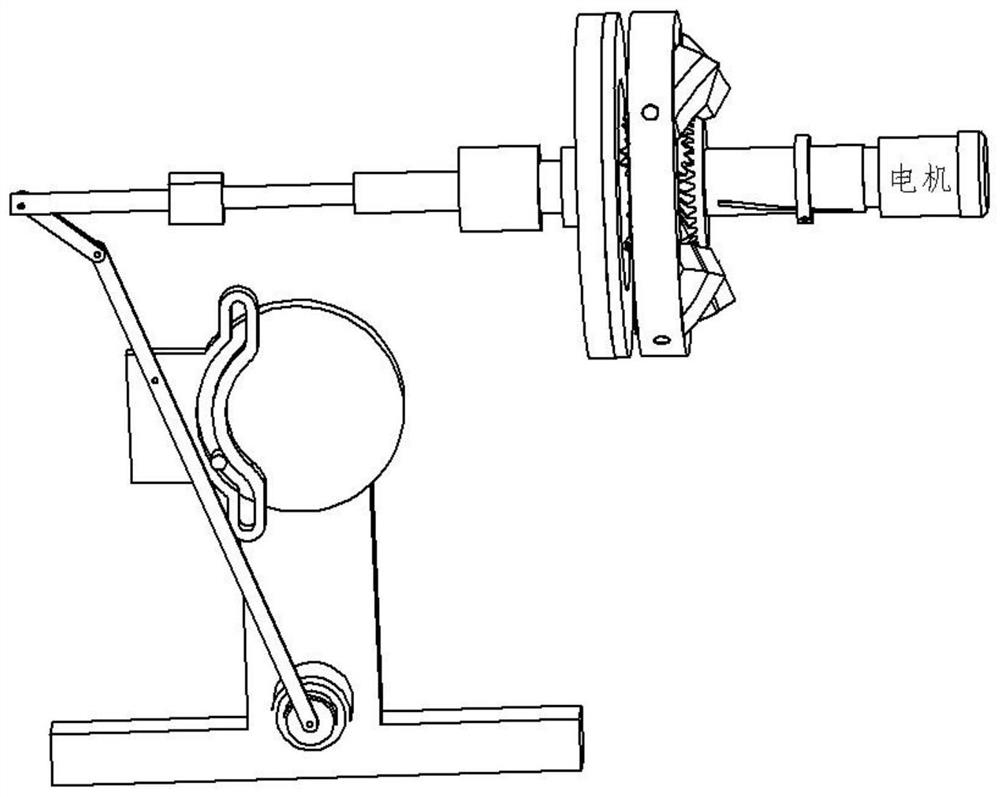

Agricultural machine driven by direct-current motor

InactiveCN102388691ASimple speed regulationSimple structureAgricultural machinesAgricultural engineeringBattery charger

The invention discloses an agricultural machine driven by a direct-current motor, and the agricultural machine comprises a power mechanism, a transmission mechanism and a control mechanism. The agricultural machine is characterized in that a power mechanism is formed by connecting a charger, storage cell and a direct-current motor by virtue of power lines; the transmission mechanism is rotatably connected with a rotary shaft for driving the agricultural machine to work via the direct-current motor; and the control mechanism is composed of a belt regulator for controlling the revolving speed of the motor. The direct-current motor has the characteristics of low revolving speed, large moment of force and simple speed regulation; the agricultural machine (tool) can be matched with the storage cell and the direct-current motor according to power required by the agricultural machine (tool); the agricultural machine is suitable for farming and working various types of paddy fields and dry lands, vibration is small, energy is saved, and consumption is saved; and fire hazards brought by adding oil and storing oil can be avoided to guarantee the safety. The complex gear case speed regulation system of gasoline and diesel, which is used by the original agricultural machine, is not used, and the agricultural machine has a simple structure and is convenient to operate and maintain.

Owner:曲靖宏程工贸有限公司

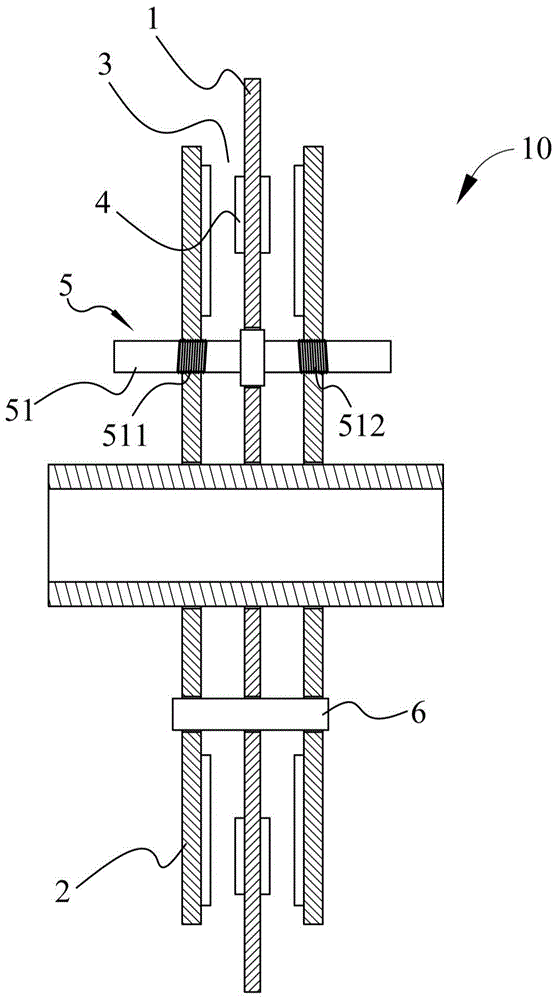

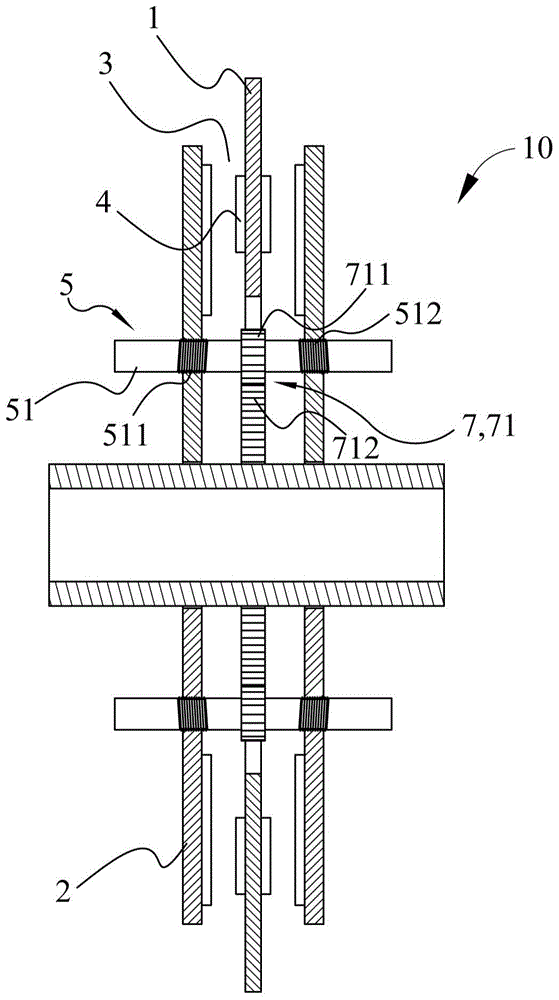

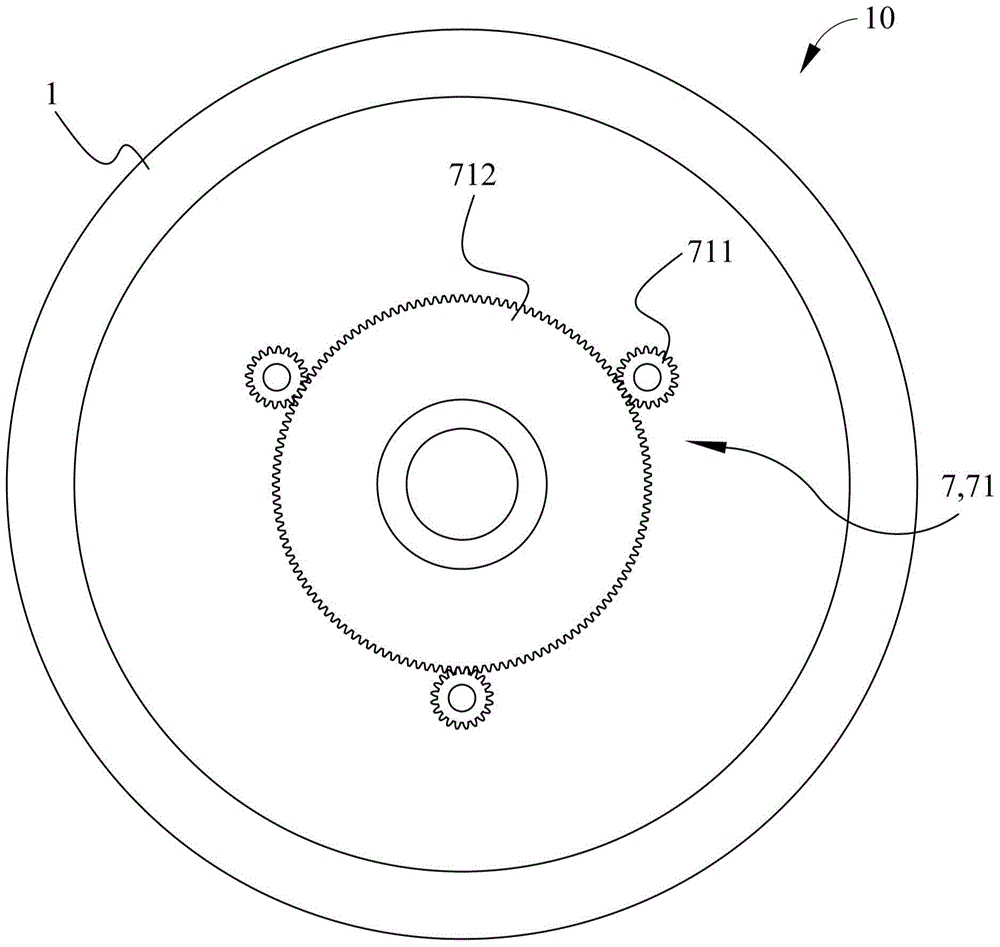

Automatic stepless planetary gear continuous transmission system adopting electromagnetic transmission

InactiveCN109099121ARealize energy savingEmission reductionToothed gearingsPermanent-magnet clutches/brakesEngineeringGear train

The invention provides an automatic stepless planetary gear continuous transmission system adopting electromagnetic transmission. The automatic stepless planetary gear continuous transmission system comprises an input end, a planetary gear train, an output end and a permanent magnet speed adjusting device. The permanent magnet speed adjusting device is also divided into an input end and an outputend according to the power direction, wherein the input end and the output end are named as the end A and the end B correspondingly to be distinguished from the input end and the output end of the system. The end A of the permanent magnet speed adjusting device is the power input end of the device, and the end B of the permanent magnet speed adjusting device is the power output end of the device.The input end, the end B of the permanent magnet speed adjusting device and the output end are connected to three sets of gears of the planetary gear train correspondingly.

Owner:赵山山

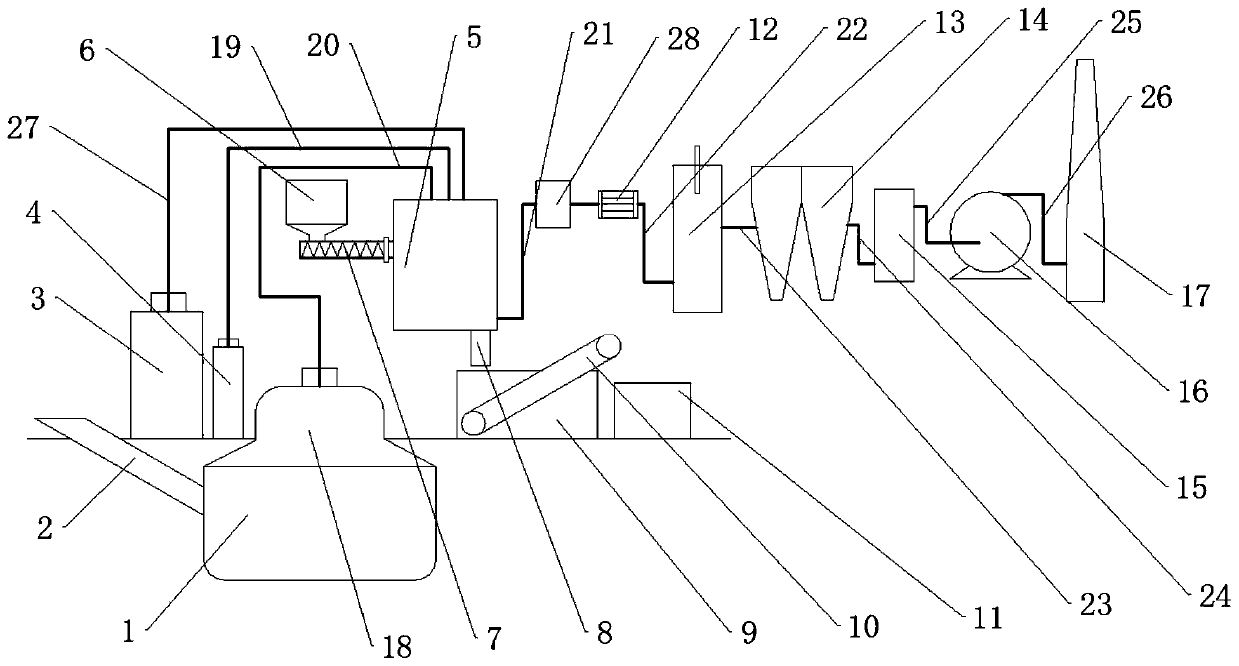

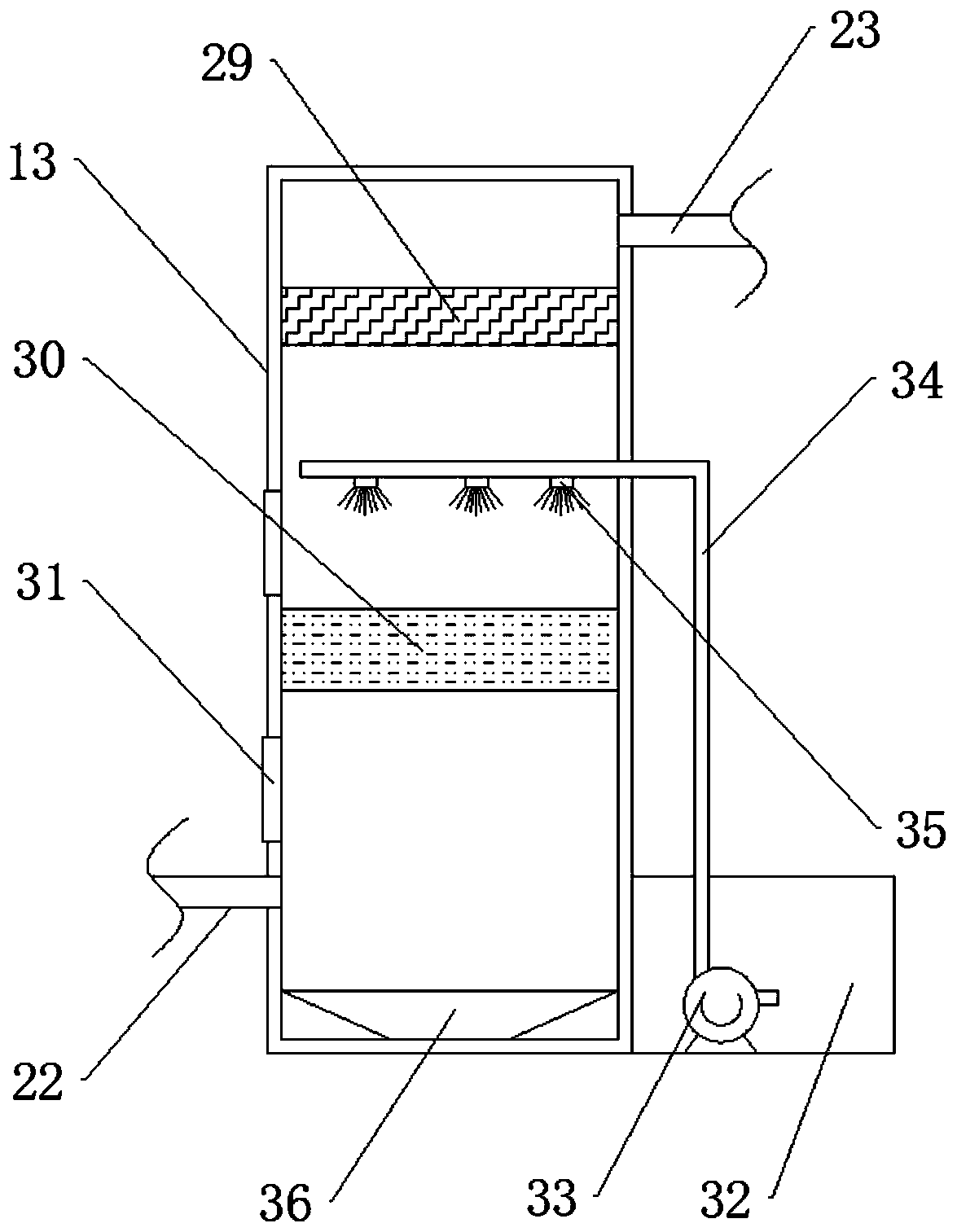

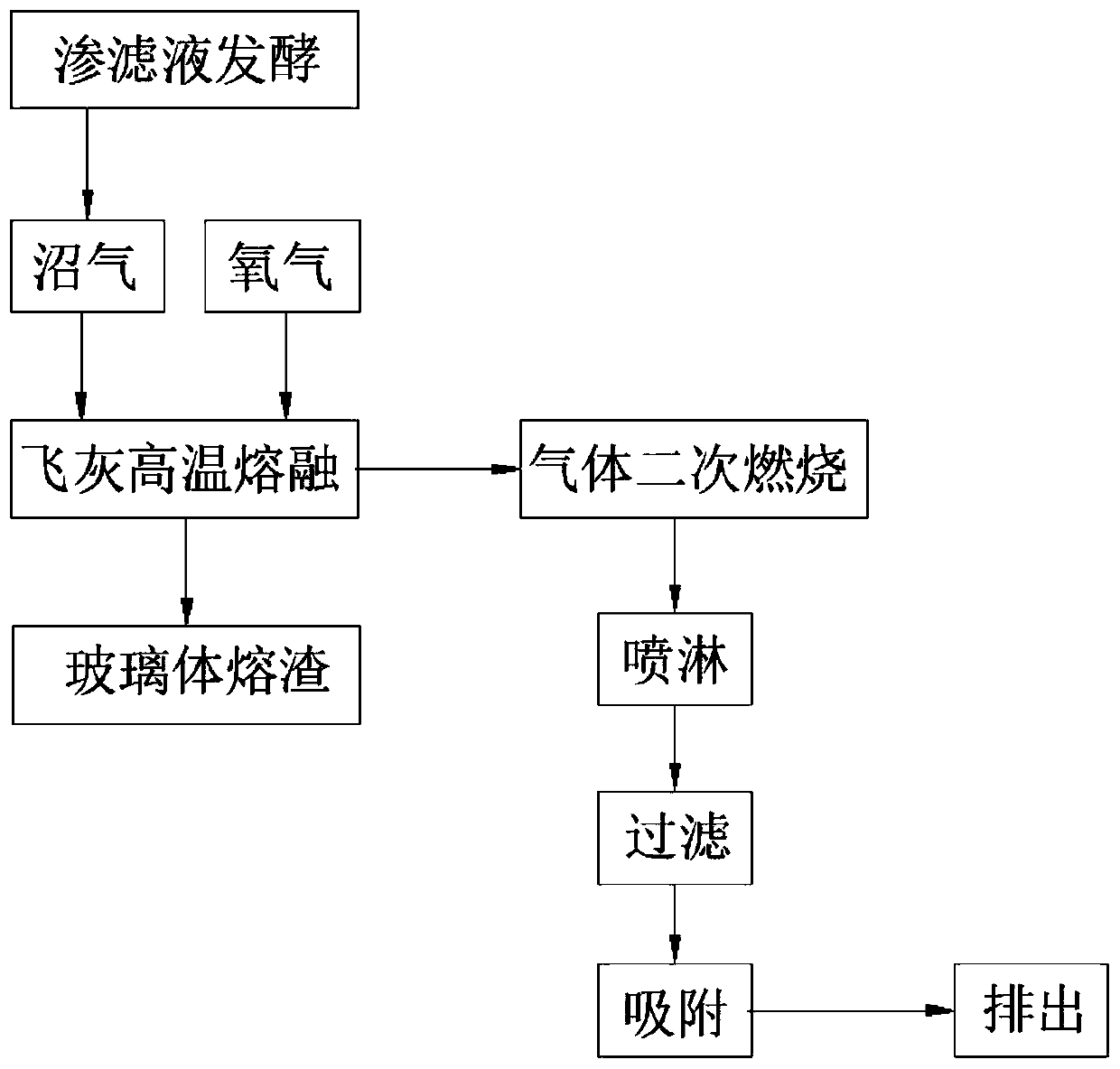

Fly ash melting system based on pure oxygen combustion and used for waste incineration plant

InactiveCN110594755AAchieve reuseReduce secondary pollutionSolid waste disposalIncinerator apparatusPollutionMaterials science

The invention discloses a fly ash melting system based on pure oxygen combustion and used for a waste incineration plant, and belongs to the technical field of fly ash melting systems. The fly ash melting system based on pure oxygen combustion and used for the waste incineration plant comprises a biogas pool, a liquid oxygen tank, a fly ash melting furnace, a heat exchanger, an alkali liquid spraytower, a dust remover, an adsorption tower, a fan and a chimney, wherein a feeding port is connected to the biogas pool; a gas storage tank is connected to the upper end of the biogas pool, and the biogas pool communicates with the gas storage tank; a gas transmission pipe I is connected between the liquid oxygen tank and the fly ash melting furnace; a gas transmission pipe B is connected betweenthe gas storage tank and the fly ash melting furnace; and a charging port is formed in one side of the fly ash melting furnace. The biogas generated by a leachate in the waste incineration plant canbe taken as a fuel; pure oxygen is used for combustion supporting for the fly ash melting furnace, so that the biogas generated by the leachate in the waste incineration plant is consumed, synchronousresourceful disposal is realized, and the treatment cost is greatly reduced; and moreover, adequate treatment for waste gas is achieved, and the secondary pollution of waste gas is greatly reduced.

Owner:徐晓

Linear induction synchronous motor

InactiveCN108462360ASimple structureReduce manufacturing costPropulsion systemsSuperconductor elements usageSynchronous motorThermal insulation

The invention provides a linear induction synchronous motor, which at least comprises a stator and a rotor, wherein the rotor comprises a thermal insulation device and a mouse cage, and the mouse cageis arranged in the thermal insulation device. The beneficial effects of the invention are as follows: the structure is simple, and the production and maintenance costs are low; because a high-temperature superconducting material is applied, the size of the motor is small, loss is little, and the efficiency is high; in the process of starting, the motor operates in an asynchronous mode, the characteristic of the motor is the same as the characteristic of a linear induction motor, and therefore, compared with a linear synchronous motor, the motor has the advantage of simple starting operation,and does not require the positioning of the stator; after starting, during normal operation, the motor operates in a synchronous mode, the characteristic is the same as the characteristic of the linear synchronous motor, therefore the motor has the advantages of flexible control and simple speed regulation, moreover, the efficiency is high during high-speed operation, and the motor is highly suitable for high-speed, long-time operation; quench protection is not needed, and the motor can automatically operate in the asynchronous mode even if conducting bars are quenched, and can still normallyoperate when the characteristic of the motor is degraded to the characteristic of the ordinary linear induction motor.

Owner:SHANGHAI JIAO TONG UNIV

Fan type temperature control method and device

ActiveUS8900042B2Simple and effective typeSimple speed regulationDucting arrangementsDC motor speed/torque controlTemperature controlEngineering

A fan type temperature control method and device are provided. The device includes a fan unit including a plurality of fans and cooling an apparatus to be cooled, power supplies (v1,v2) supplying power for the fans in the fan unit, and a fan control unit which controls the fans as follows: when temperature t of the apparatus is lower than critical temperature t1 of a first temperature detect switch (k01), all fans stop; when t is higher than t1 and lower than critical temperature t2 of a second temperature detect switch (k02), all fans rotate at half speed; when t is higher than t2 while lower than critical temperature t3 of a third temperature detect switch (k03), a first fan part (M1) rotates at full speed and a second fan part (M2) stops; when t is higher than t3, all fans rotate at full speed.

Owner:ZTE CORP

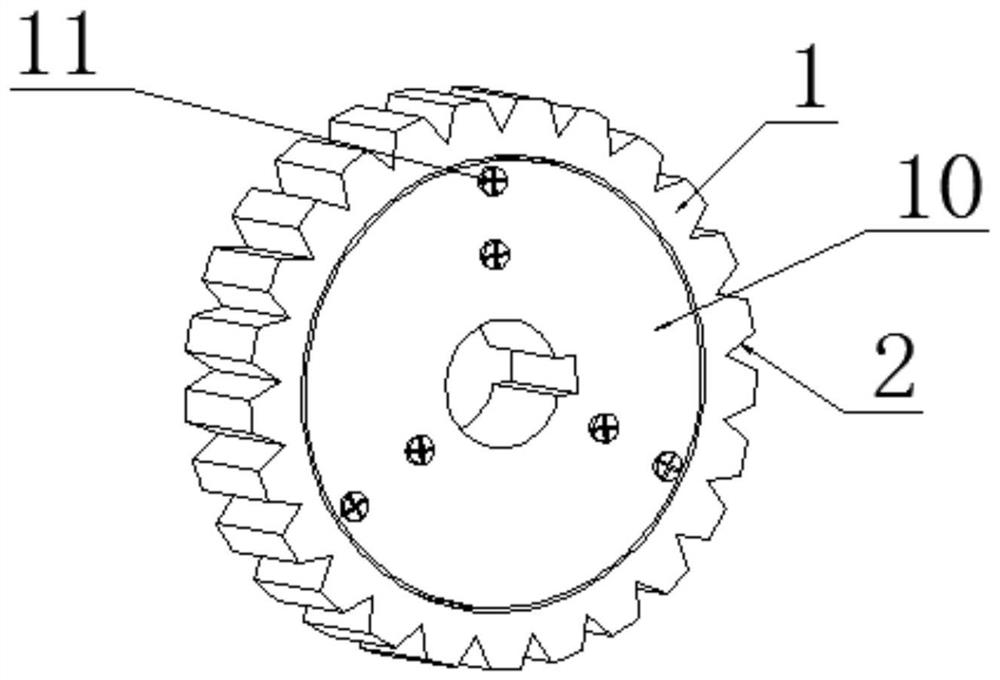

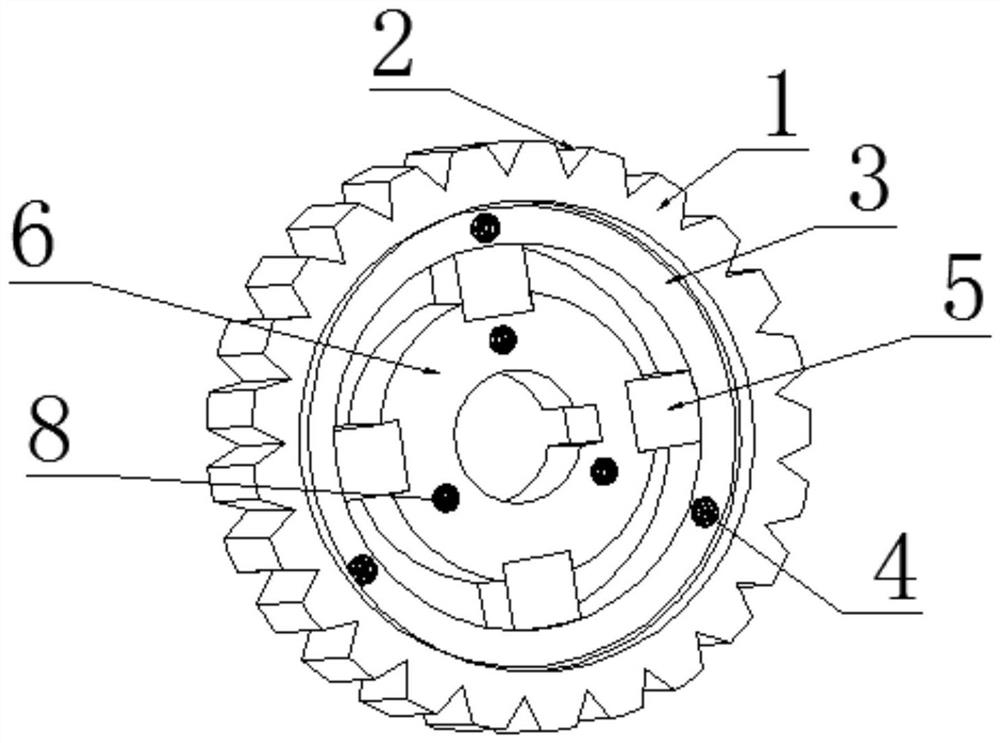

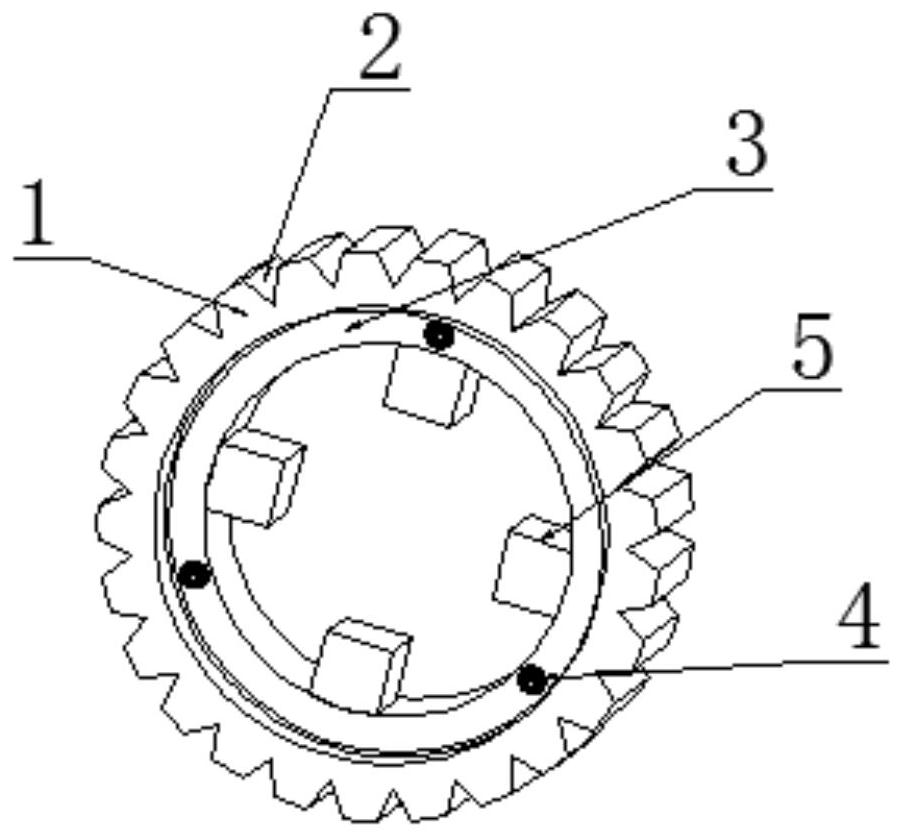

Annular gear with speed regulating function

InactiveCN111664240AWith speed control functionSimple speed regulationEngine sealsPortable liftingGear wheelEngineering

Owner:黄华

Method for setting manipulator rotating mechanism of hydraulic system

InactiveCN102966621AHigh movement precisionEasy to processServomotor componentsServomotorsFuel tankHydraulic circuit

The invention discloses a method for setting a manipulator rotating mechanism of a hydraulic system. The method comprises the following steps that firstly, a section of valve control circuit is additionally arranged between a variable pump and a hydraulic cylinder, a hydraulic control reversing valve is arranged in the valve control circuit, and a swinging motor is arranged in a manipulator rotating hydraulic system; then, a one-way valve and an overflow valve are additionally arranged in a hydraulic circuit connected with the periphery of the motor, and when an electromagnetic valve returns to the middle position, because the pressures at both ends of the cycloidal motor are unbalanced, if the pressure at the left end of the cycloidal motor is larger, the hydraulic fluid flows to a hydraulic tank through the one-way valve and the overflow valve; a three-position and four-way one-way valve is adopted as the one-way valve, and the locking of the hydraulic motor and the buffering of the hydraulic fluid are realized by the additional one-way valve and the overflow valve. The method has the beneficial effects that the stability and the easy speed adjustment in the linear movement are realized, the running precision of the machine is favorably improved, and the service life of the machine is prolonged; and meanwhile, the convenient and flexible arrangement is favorably realized according to requirements, the operation controllability is improved, and the labor strength is reduced.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Speed-adjustable coupling machine structure

The invention relates to a speed-adjustable coupling machine structure. A simple mechanical transmission structure is used for changing magnetic coupling distance of a permanent-magnet coupling machine so as to achieve a function of speed regulation. The speed-adjustable coupling machine structure comprises a magnetic rotary disc, wherein magnetic conduction rotary discs are coaxially arranged at two sides of the magnetic rotary disc, and air gaps are reserved between the magnetic rotary disc and the two magnetic conduction rotary discs; magnetic units are arranged on end surfaces of the two sides of the magnetic rotary disc so that the magnetic rotary disc and the two magnetic conduction rotary discs are in magnetic connection and simultaneously rotate; a protective cover is arranged outside each magnetic unit and is used for preventing the magnetic unit from falling off and being collided; air gap adjustment units are arranged between the two magnetic conduction rotary discs, so that the two magnetic conduction rotary discs get close to or deviate from the magnetic rotary disc to change air gap distances and the relative rotational speed between the magnetic rotary disc and the two magnetic conduction rotary discs are further changed; each air gap adjustment unit comprises a screw rod, the two magnetic conduction rotary discs are arranged at two ends of the screw rod in a penetrating way by threads with opposite rotation directions; and when the screw rod rotates, the two magnetic conduction rotary discs are synchronously driven to get close to or deviate from the magnetic rotary disc by the two threads, and thus, the air gap distances of two sides of the magnetic rotary disc are maintained consistent.

Owner:中兴杰达电能科技股份有限公司

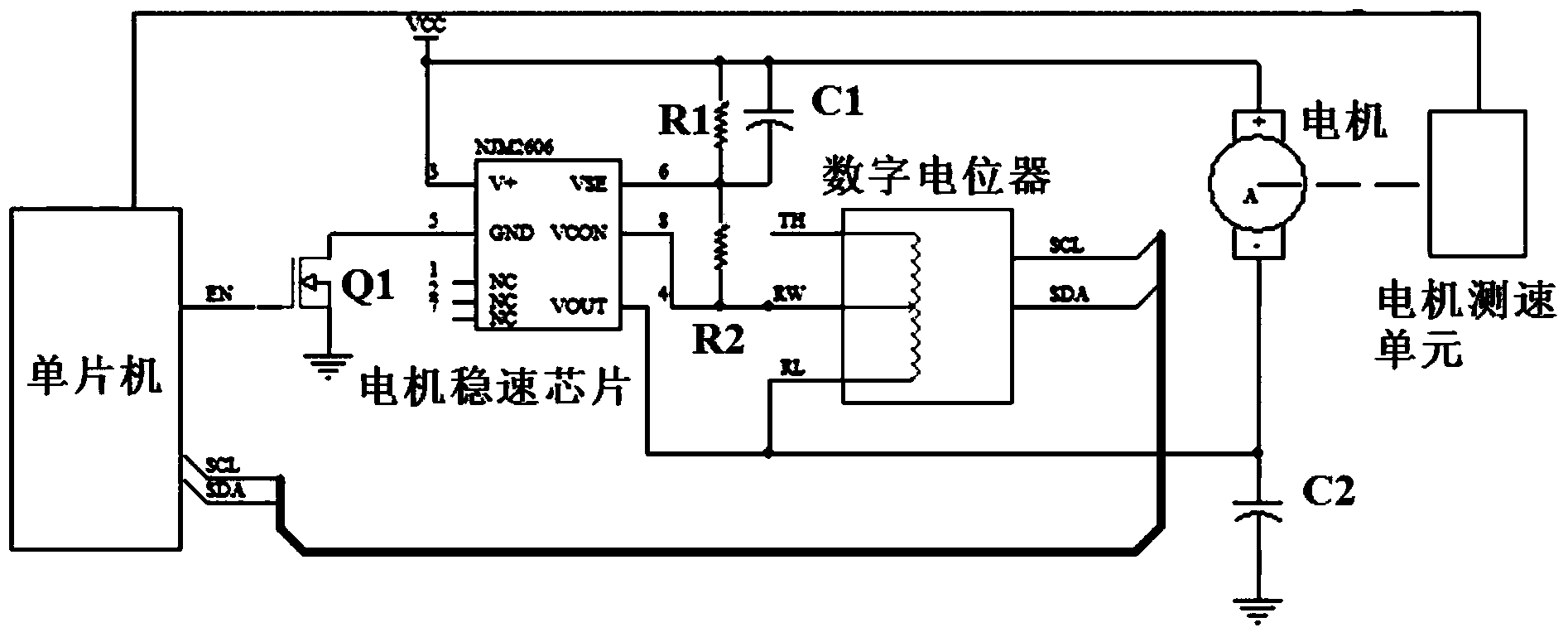

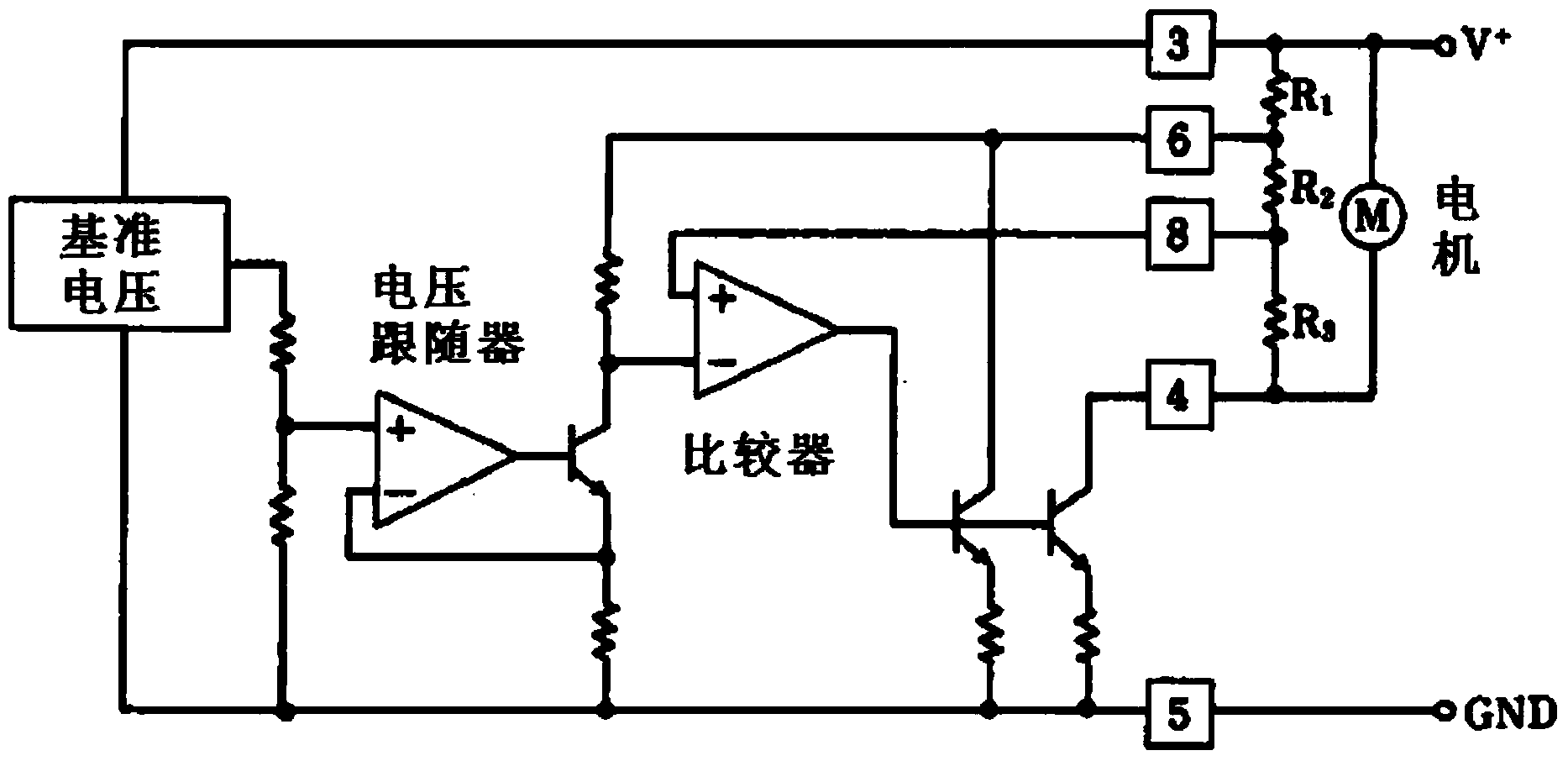

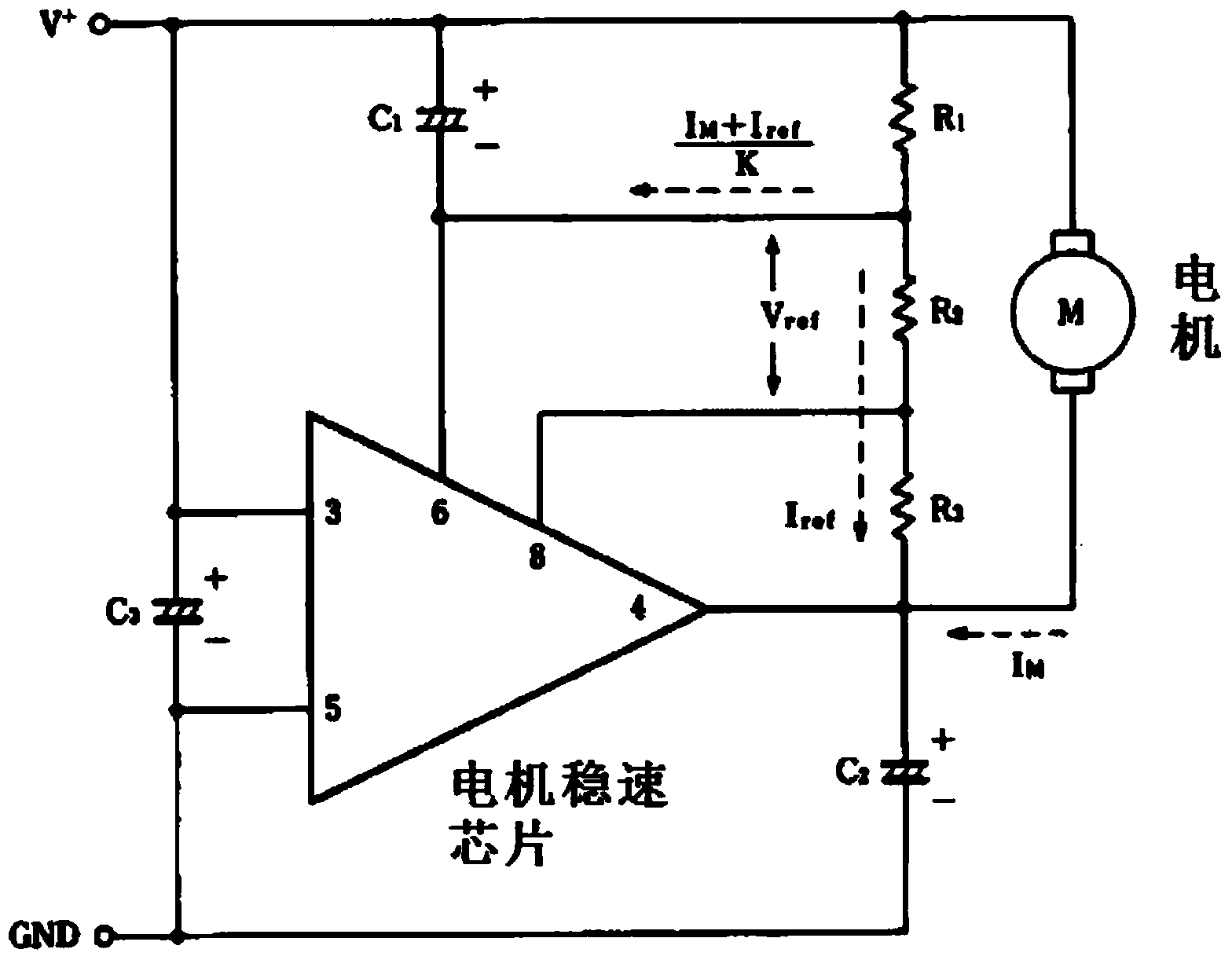

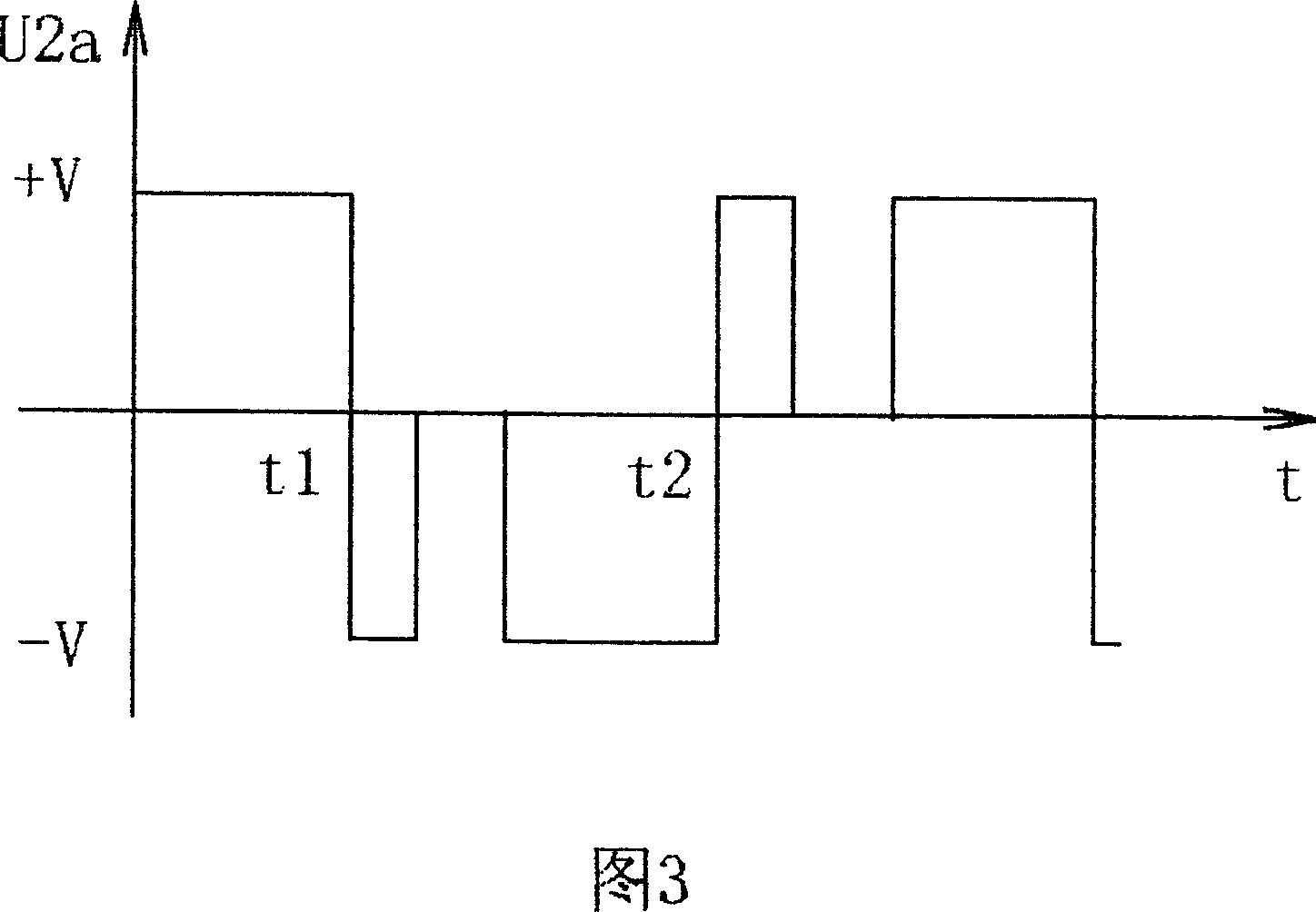

Motor control circuit for laser swinger

InactiveCN104242751AShort stabilization timeSmall overshootField or armature current controlMotor speedMicrocomputer

The invention provides a motor control circuit for a laser swinger. The motor control circuit is connected to the two ends of a motor and comprises a motor speed regulation module and a motor speed stabilization module. The motor speed stabilization module comprises a single-chip microcomputer and a motor speed stabilization chip. The single-chip microcomputer controls the work state of the motor speed stabilization chip. The motor speed stabilization chip is connected to the two ends of the motor. The motor speed regulation module comprises a resistance value adjustable device. The resistance value adjustable device is connected with the motor speed stabilization chip so as to serve as a load of the motor speed stabilization chip. The rotating speed of the motor can be adjusted by changing the resistance value of the resistance value adjustable device. By the adoption of the technical scheme, adjustment time and stabilization time of the rotating speed of the motor are shorter, occupation of resources of the single-chip microcomputer is greatly reduced, and the use efficiency of the single-chip microcomputer is improved.

Owner:CHANGZHOU HUADA KEJIE OPTO ELECTRO INSTR

DC motor with commutator and its driven washing machine

ActiveCN1306688CMeet the continuous flow requirementsThe overall structure is simple and reliableControl devices for washing apparatusDynamo-electric machinesElectrical polarityElectromagnetic interference

Owner:JINLING ELECTRICAL CO LTD

A Unipolar Magnet Rotary Adjustable Speed Cage Magnetic Coupler

ActiveCN110504816BAchieving a soft startAchieve protectionPermanent-magnet clutches/brakesMechanical energy handlingMagnetic tension forceInterference fit

The invention relates to the field of mechanical transmission, and relates to a unipolar magnet rotary adjustable speed cage magnetic coupler. In the present invention, the copper disk adopts a cage-shaped copper disk, and fan-shaped annular currents are generated around all the fan-shaped grooves, and the eddy current loss generated by it is small, and the transmission efficiency is high. The bump is an interference fit, and the small bump of the yoke plays a role in modulating the magnetic field, further improving the electromagnetic torque of the coupler. The coupler provides three speed regulation methods, the first is to adjust the size of the air gap between the copper disk and the permanent disk through the axial movement device, the second is to fix the size of the air gap to change the rotation angle of the rotating permanent magnet to adjust the conductor The facing area between the disk and the permanent magnet disk, the third is to use the composite speed regulation of the air gap size between the two disks moving axially and the rotating permanent magnet, so the coupler can meet the speed regulation requirements of different degrees.

Owner:JIANGSU UNIV

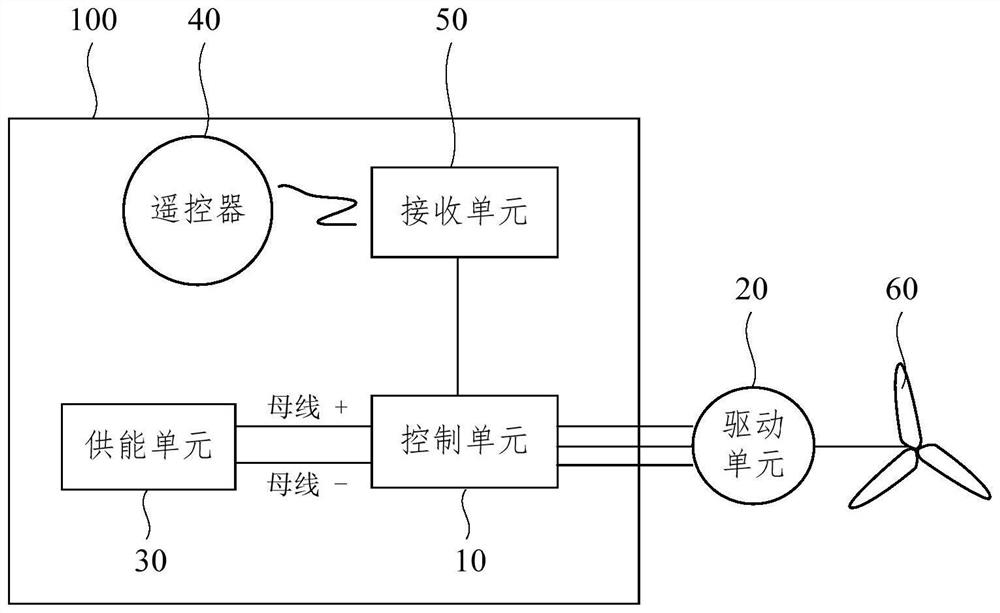

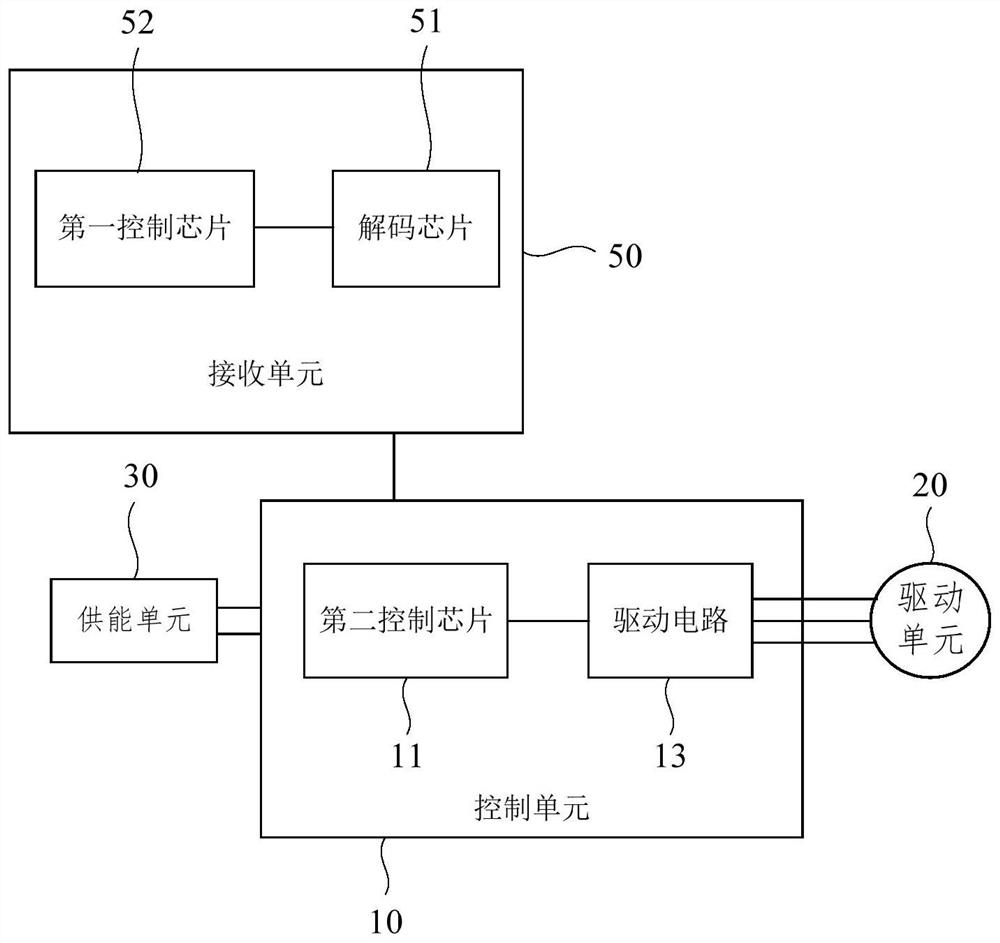

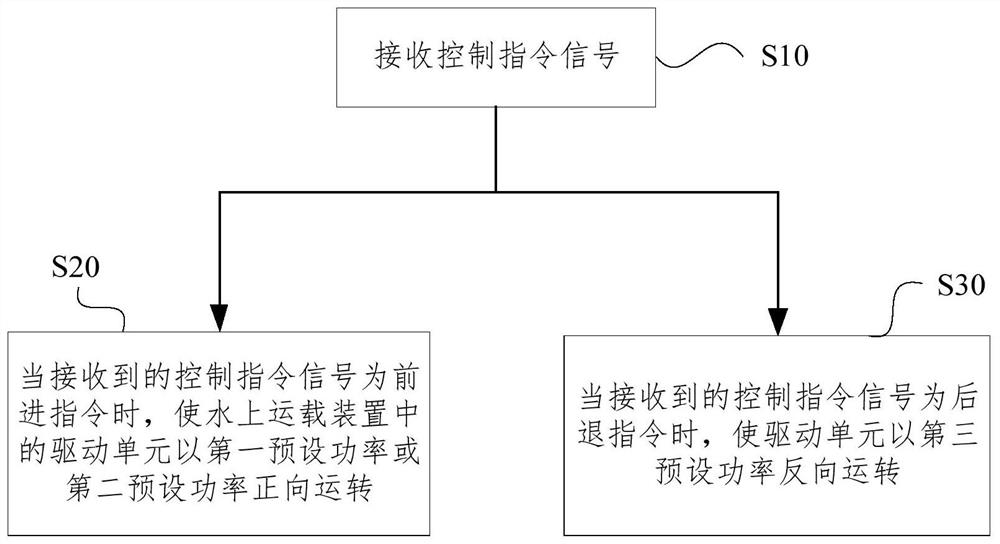

Control device and control method of water carrying device and water carrying device

PendingCN114285346AIncrease the difficultySimple controlWater sport boardsPropulsion power plantsProcess engineeringElectrical and Electronics engineering

The invention relates to a control device and a control method of a water carrying device and the water carrying device. The control device of the water carrying device comprises a control unit and a driving unit. The control unit is electrically connected with the driving unit; the control unit is used for controlling the driving unit to operate in the forward direction at a first preset power or a second preset power when the received control instruction signal is a forward instruction; the control unit is further used for controlling the driving unit to reversely operate at third preset power when the received control instruction signal is a retreating instruction, and compared with the mode that the driving unit is controlled through sliding speed regulation in the prior art, the operation state of the driving unit is single, and control is easy.

Owner:DONGGUAN EPROPULSION INTELLIGENCE TECH LTD

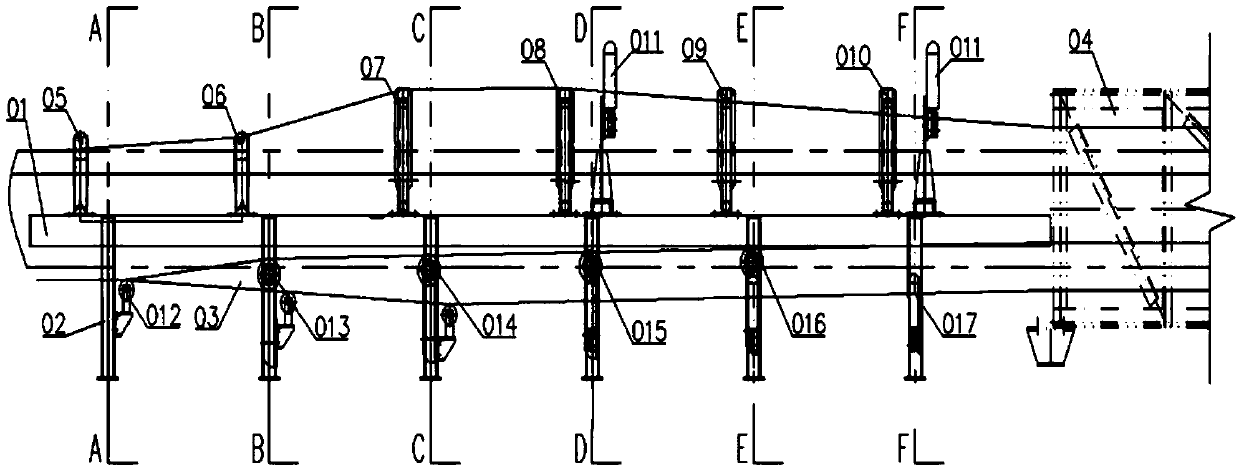

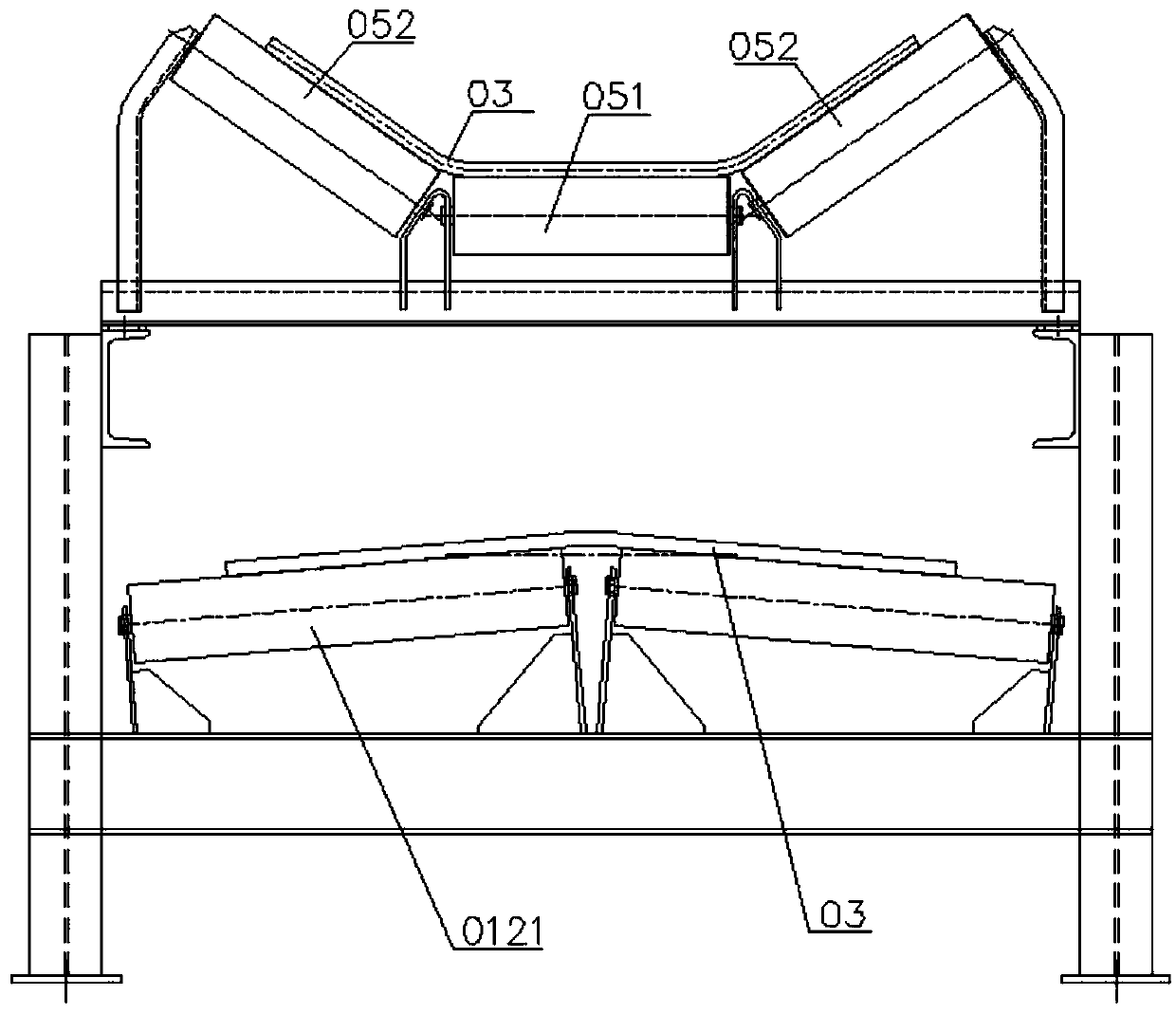

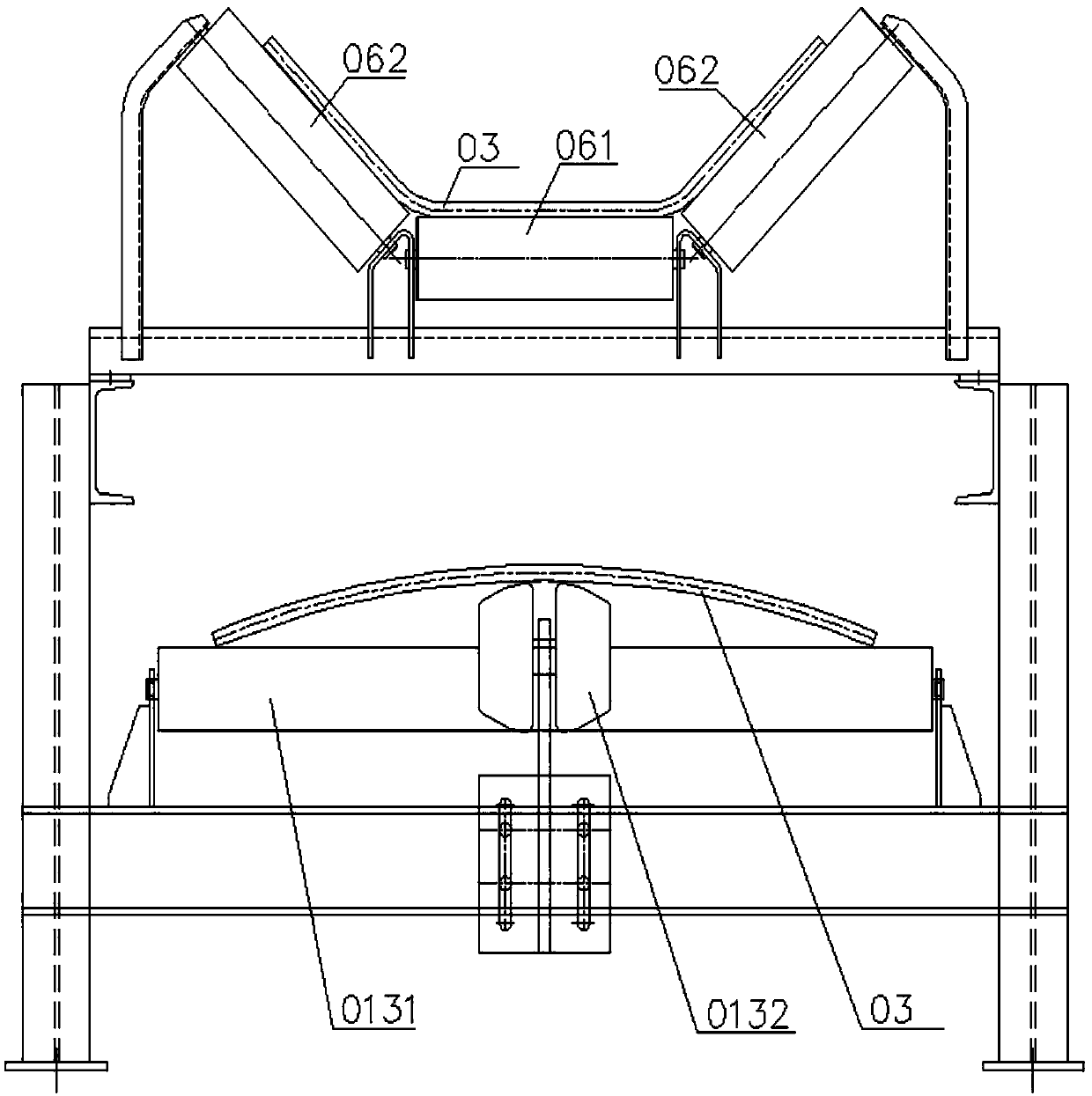

Assembly tooling for tubular belt conveyor and method for assembling conveyor using the tooling

InactiveCN106429554BMeet installation needsNo movementWebs handlingPulp and paper industryAssembly line

The invention belongs to the technical field of material transportation, and discloses a tubular belt conveyor assembly tooling and a method for assembling a conveyor by using the same. The tubular belt conveyor assembly tooling comprises an unwinding tooling and a multi-work-condition belt releasing tooling, wherein the multi-work-condition belt releasing tooling comprises a middle bracket which is arranged on the ground by virtue of multiple supporting legs; an adjusting device for gradually adjusting an adhesive tape from an unwound state into a wound state is arranged below the middle bracket; at least one transition supporting roller group and at least two adjustable supporting roller groups for gradually adjusting the adhesive tape from the unwound state into the wound state are sequentially arranged on the middle bracket; and each adjustable supporting roller group comprises a third bottom supporting roller, two adjusting plates and two fixed plates, the fixed plates and the third bottom supporting roller are arranged on the middle bracket, and the fixed plates are arranged on two sides of the third bottom supporting roller respectively.

Owner:SICHUAN DONGLIN MINE TRANSPORT MACHINERY

Setting method of hydraulic oil tank of milling equipment

InactiveCN102927068AEasy to process and manufactureHigh movement precisionPump assembliesMilling equipment detailsInjectorFuel tank

The invention discloses a setting method of a hydraulic oil tank of milling equipment. The setting method comprises the following steps: an oil sucking filter sufficient in capacity is added on the oil tank for avoiding excessive resistance; the oil filter is provided with the filtering capacity more than double the suction volume of an oil pump; an oil level indicating meter as high as the wall is arranged on the sidewall of the oil tank; an oil injector is provided with a filtering net structure; oil-resistant coatings are coated on the internal wall of the oil tank; an oil sucking pipe and an oil returning pipe are arranged at a certain interval, wherein the distance from the oil sucking pipe to the bottom of the tank is more than three times of the diameter of the pipe; the distance from the oil sucking pipe to the wall of the box is more than four times of the diameter of the pipe; the oil returning pipe is inserted below the lowest oil level; the distance from the oil returning pipe to the bottom of the box is more than three times of the diameter of the pipe; an oil discharging port faces the wall of the tank; the pipe is obliquely inclined at 45 degrees; and finally, the bottom of the oil tank is provided with proper inclination; an oil discharging plug and a hand hole are arranged at the bottom of the oil tank; and the sucked oil and the returned oil are separated by a separating plate. The setting method has the beneficial effects that the linear movement can be stable, the speed is easy to adjust, the movement precision of a machine can be improved, and the hydraulic oil tank can be conveniently and flexibly distributed as required.

Owner:无锡市京锡冶金液压机电有限公司

Intelligent speed-regulating handle of electric sprayer

InactiveCN103990565ASolve the problem of waterproof and anti-corrosionSimple speed regulationSpraying apparatusKey pressingSprayer

The invention aims to provide an intelligent speed-regulating handle of an electric sprayer. The intelligent speed-regulating handle of the electric sprayer comprises the sprayer on the tail portion, a sprayer head on the head portion and a speed-regulating handle body arranged between the sprayer and the sprayer head. The speed-regulating handle body is designed to be sealed. A touch display screen of the speed regulating handle body is an LED touch display screen, digital keys are arranged on the LED touch display screen to regulate speed, and an indicator light for displaying the working state is arranged on the LED touch display screen. The speed-regulating handle is convenient to use and more suitable for user-friendly operation and solves problems about water proofness and corrosion resistance.

Owner:SUZHOU HONGQI YEYI ELECTRONICS TECH

Precise basis type production processing flow for engine connecting rod

The invention discloses a precise reference type production processing flow for an engine connecting rod. The production processing flow comprises the following steps of firstly, carrying out the first phase of processing before cutting of a connecting rod body and a cover, respectively carrying out blank inspection, magnetic particle inspection and rough drilling of a small-end hole, and preparing for the processing of upper and lower end surfaces, the small-end hole, two planes at bolt hole ends, an outer surface of a large-end hole, and the like in the precise basis way; then, carrying out processing after cutting of the connecting rod body and the cover, roughening the large-end hole, except for precise referencebasis, and preparing for the roughening of the bolt hole and the combining surface, and the processing of a bearing counterbored groove; and carrying out processing after cutting of the connecting rod body and the cover, and sequentially carrying out the finishing of the large-end hole after the assembly of the connecting rod, the finishing of the upper and lower end surfaces, and the finishing of the large-end hole and the small-end hole. The production processing flow has the beneficial effects that the speed of the linear movement can be smoothly adjusted, the running precision of the machine is favorably improved, the service life of the machine is prolonged, the arrangement is conveniently and flexibly realized according to requirements, the operation controllability is improved, and the labor strength is reduced.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com